Analysis of the Structural, Chemical, and Mechanical Characteristics of Polyurethane Foam Infused with Waste from Thermal Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of the Polyurethane Foam Composites

2.2. Evaluation and Analysis of the Foam Samples

2.3. Evaluation of Aging Behavior

3. Results

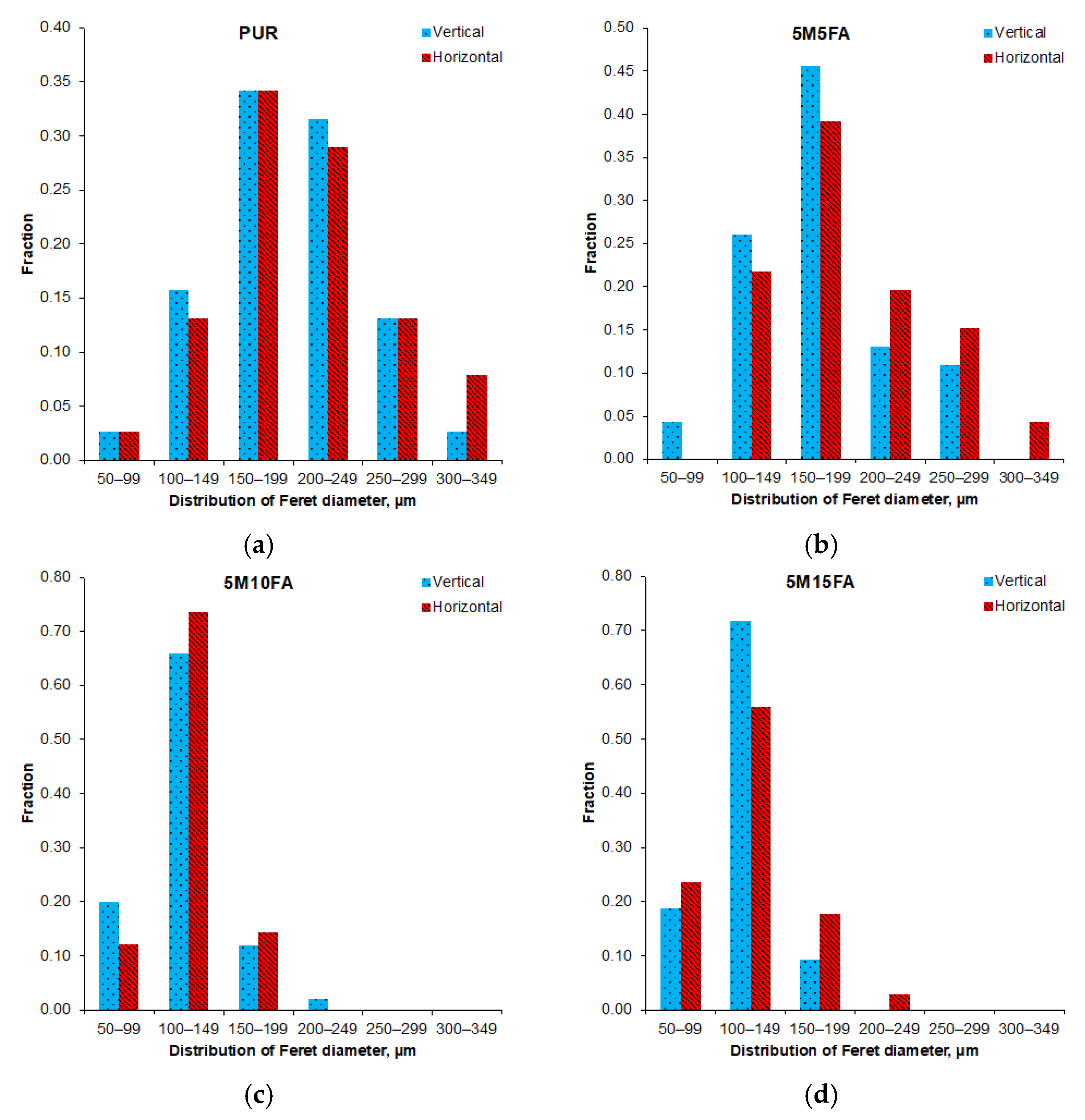

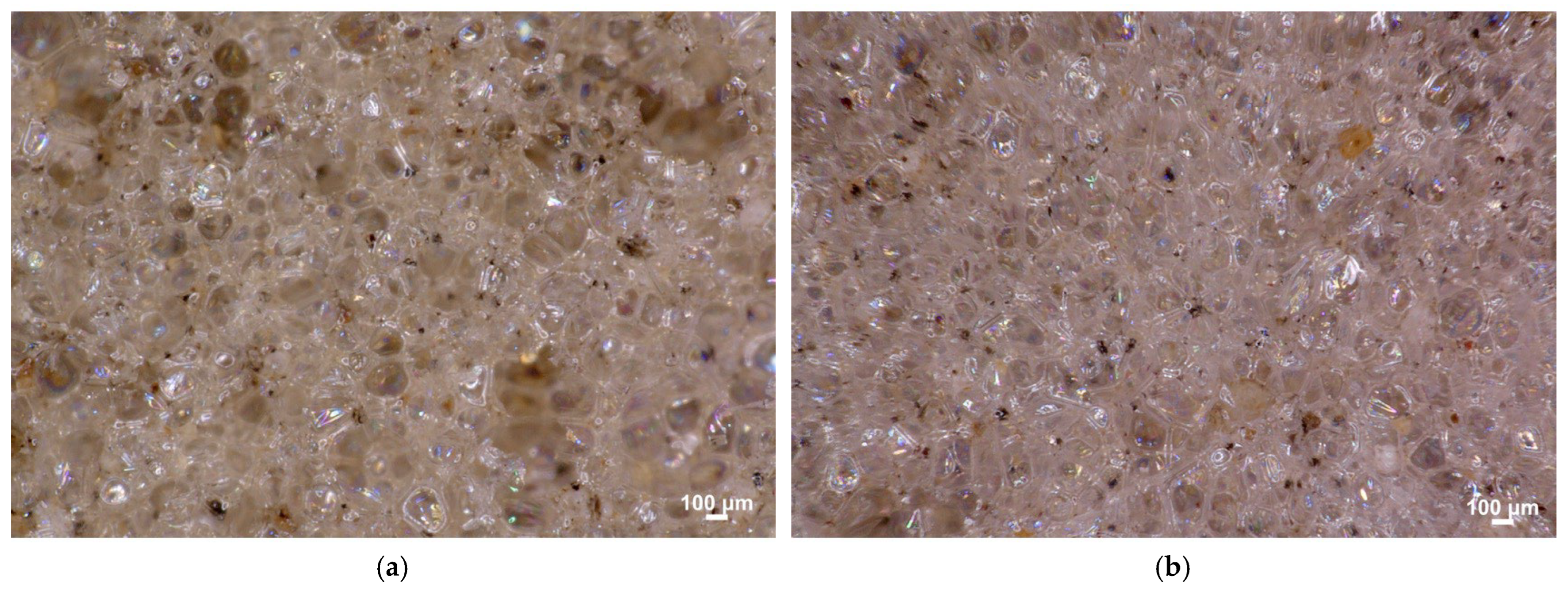

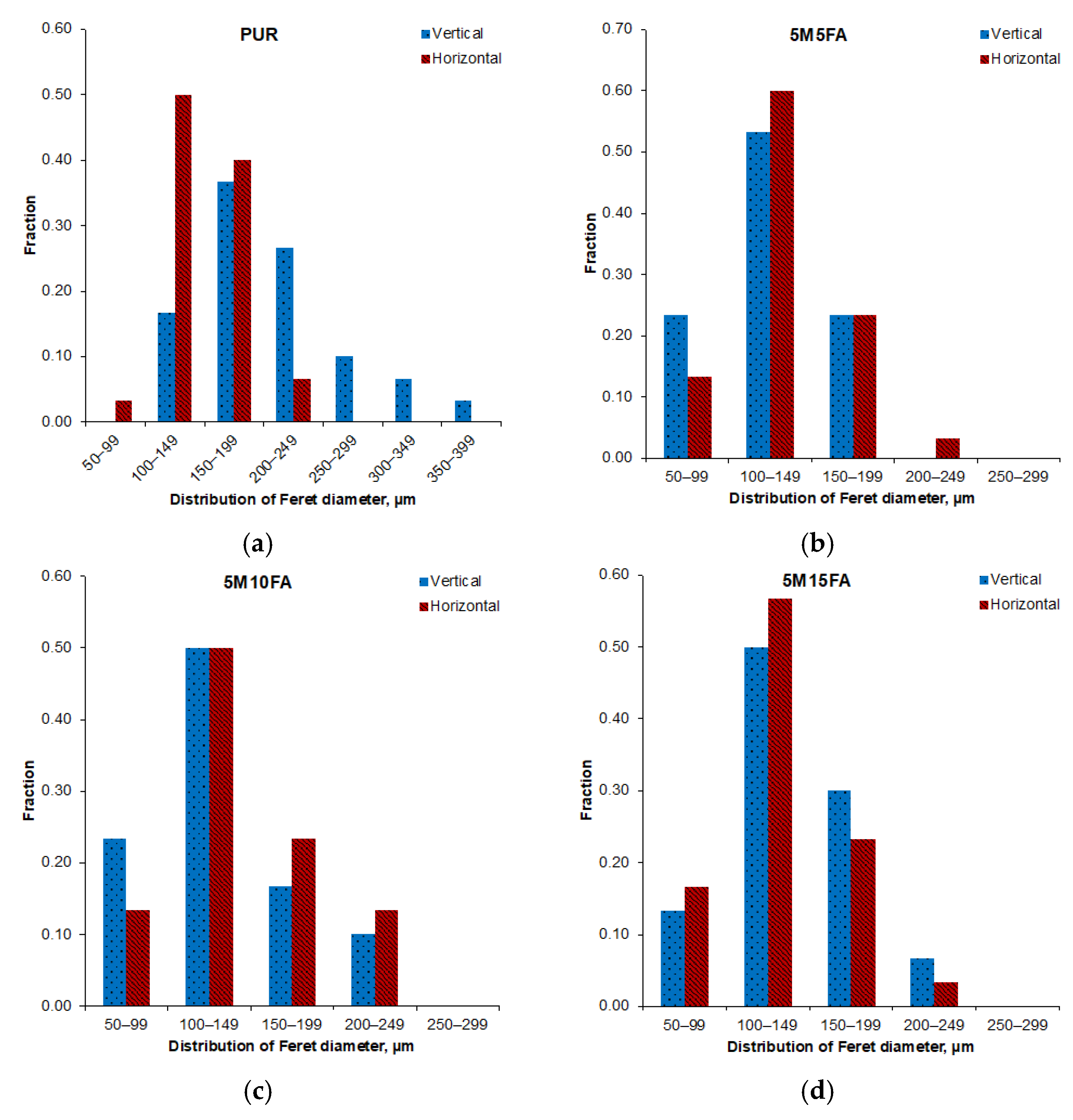

3.1. Cellular Structure and Microstructure

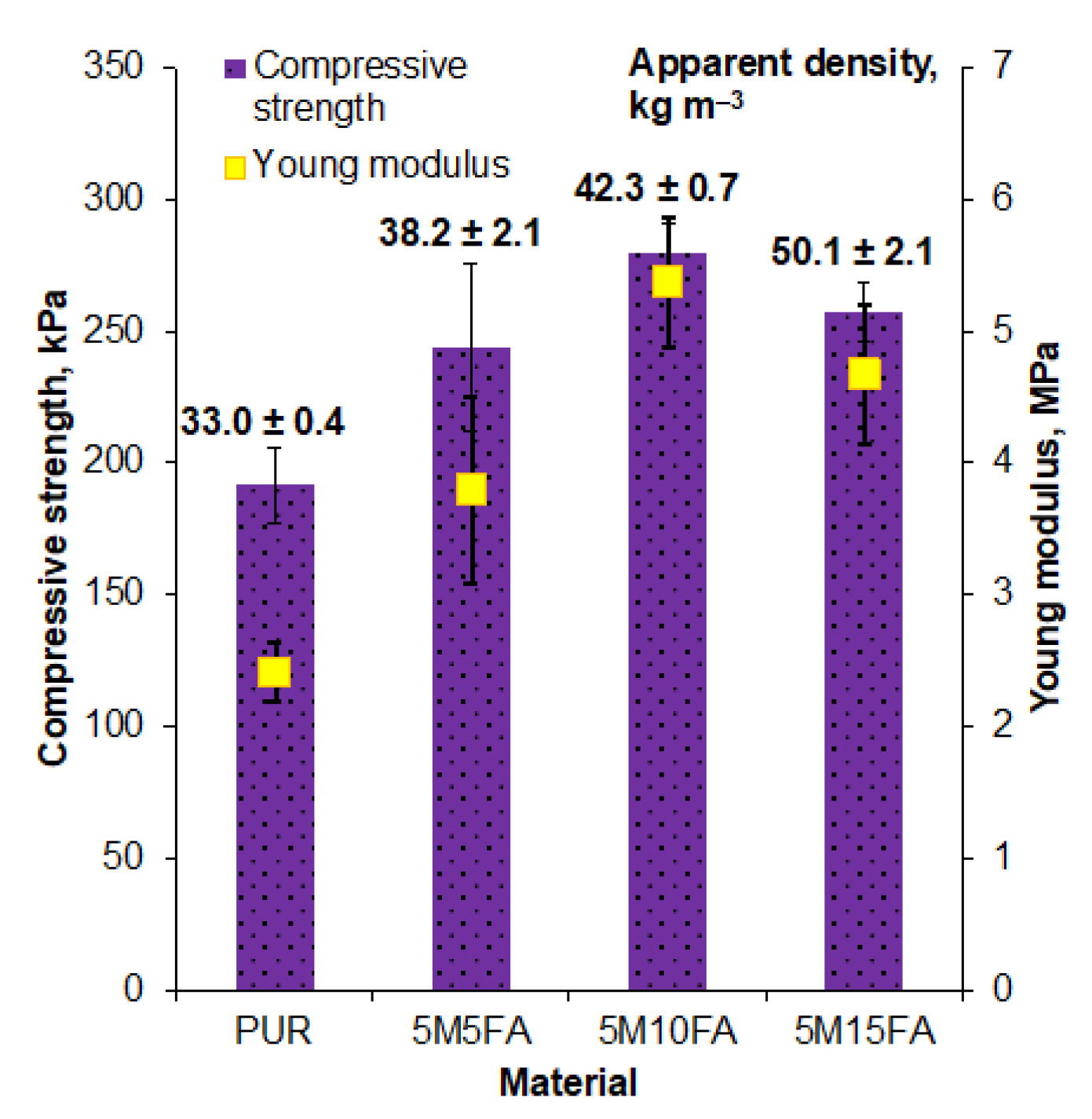

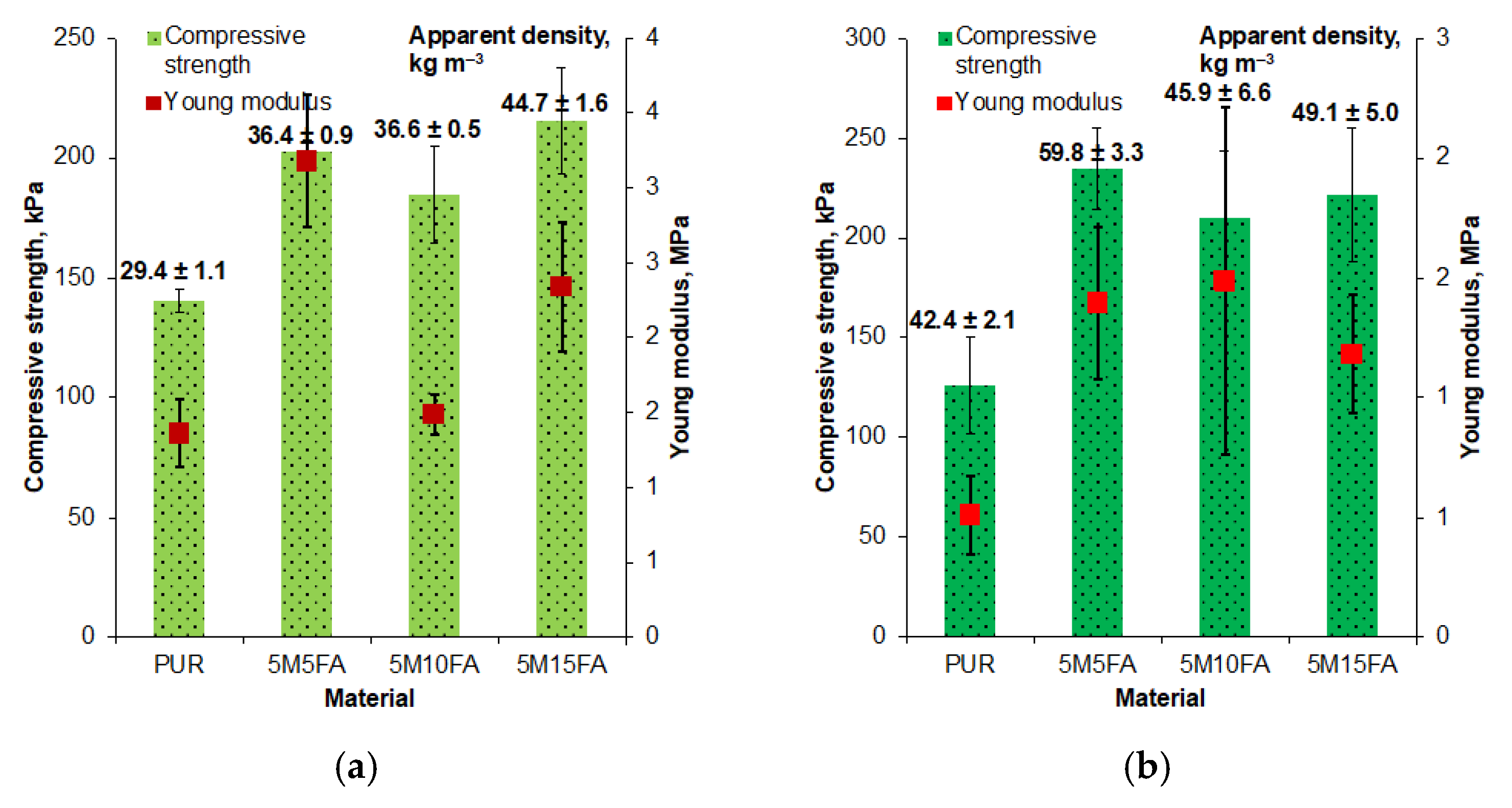

3.2. Characterization of Chemical Composition and Mechanical Behavior

3.3. Durability Assessments

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| RPUF | Rigid polyurethane foam |

| PCC | Pulverized coal combustion |

| FBC | Fluidized bed combustion |

| SEM | Scanning electron microscopy |

| FTIR | Fourier-transform infrared spectroscopy |

References

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańka, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and egg shells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Bo, G.; Xu, X.; Tian, X.; Wu, J.; He, X.; Xu, L.; Yan, Y. Enhancing the flame retardancy for castor oil-based rigid polyurethane foams via silica aerogel. J. Non-Cryst. Solids 2021, 562, 120783. [Google Scholar] [CrossRef]

- Khatoon, H.; Ahmad, S. Polyurethane: A versatile scaffold for biomedical applications. Significances Bioeng. Biosci. 2018, 2, 000536. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Andersons, J.; Kirpluks, M.; Cabulis, P.; Kalnins, K.; Cabulis, U. Bio-based rigid high-density polyurethane foams as a structural thermal break material. Constr. Build. Mater. 2020, 260, 120471. [Google Scholar] [CrossRef]

- Zhang, J.; Hori, N.; Takemura, A. Reinforcement of agricultural wastes liquefied polyols based polyurethane foams by agricultural wastes particles. J. Appl. Polym. Sci. 2021, 138, 50583. [Google Scholar] [CrossRef]

- Husainie, S.M.; Deng, X.; Ghalia, M.A.; Robinson, J.; Naguib, H.E. Natural fillers as reinforcement for closed-molded polyurethane foam plaques: Mechanical, morphological, and thermal properties. Mater. Today Commun. 2021, 27, 102187. [Google Scholar] [CrossRef]

- Beverte, I.; Cabulis, U.; Andersons, J.; Kirpluks, M.; Skruls, V.; Cabulis, P. Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources. Polymers 2023, 15, 2582. [Google Scholar] [CrossRef]

- Xing, Y.; Guo, F.; Xu, M.; Gui, X.; Li, H.; Li, G.; Xia, Y.; Han, H. Separation of unburned carbon from coal fly ash: A review. Powder Technol. 2019, 353, 372–384. [Google Scholar] [CrossRef]

- Strigac, J.; Stevulova, N.; Mikusinec, J.; Sobolev, K. The fungistatic properties and potential application of by-product fly ash from fluidized bed combustion. Constr. Build. Mater. 2018, 159, 351–360. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Jaturapitakkul, C. Utilization of fly ash blends from pulverized coal and fluidized bed combustions in geopolymeric materials. Cem. Concr. Compos. 2011, 33, 55–60. [Google Scholar] [CrossRef]

- Catauro, M.; Tranquillo, E.; Barrino, F.; Dal Poggetto, G.; Blanco, I.; Cicala, G.; Ognibene, G.; Recca, G. Mechanical and thermal properties of fly ash-filled geopolymers. J. Therm. Anal. Calorim. 2019, 138, 3267–3276. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Dąbrowski, M. The influence of fluidized bed combustion fly ash on the phase composition and microstructure of cement paste. Materials 2019, 12, 2838. [Google Scholar] [CrossRef] [PubMed]

- Ohenoja, K.; Pesonen, J.; Yliniemi, J.; Illikainen, M. Utilization of fly ashes from fluidized bed combustion: A review. Sustainability 2020, 12, 2988. [Google Scholar] [CrossRef]

- Zahedi, M.; Rajabipour, F. Fluidized bed combustion (FBC) fly ash and its performance in concrete. ACI Mater. J. 2019, 116, 163–172. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.; Tang, J.; Ge, L.; Xia, M.; Xi, Y. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Prabhu, R.; Jeevananda, T.; Reddy, K.R.; Raghu, A.V. Polyaniline-fly ash nanocomposites synthesized via emulsion polymerization: Physicochemical, thermal and dielectric properties. Mater. Sci. Energy Technol. 2021, 4, 107–112. [Google Scholar] [CrossRef]

- Loganayagan, S.; Bhagavath, B.A.; Kalaiyarasan, U.; Arasan, E. Experimental investigation on characteristics of fly-ash based geo-polymer mixed concrete. Mater. Today Proc. 2021, 45, 1559–1562. [Google Scholar] [CrossRef]

- Van der Merwe, E.M.; Mathebula, C.L.; Prinsloo, L.C. Characterization of the surface and physical properties of South African coal fly ash modified by sodium lauryl sulphate (SLS) for applications in PVC composites. Powder Technol. 2014, 266, 70–78. [Google Scholar] [CrossRef]

- Kumar, P.N.; Nagappan, V.; Karthikeyan, C. Effects of fly ash, calcium carbonate fillers on mechanical, moisture absorption properties in poly vinyl chloride resin. Mater. Today Proc. 2019, 16, 1219–1225. [Google Scholar] [CrossRef]

- Raju, G.M.; Madhu, G.; Khan, M.A.; Reddy, P.D.S. Characterizing and modeling of mechanical properties of epoxy polymer composites reinforced with fly ash. Mater. Today Proc. 2018, 5, 27998–28007. [Google Scholar] [CrossRef]

- Pattanaik, A.; Mukherjee, M.; Mishra, S. Influence of curing condition on thermo-mechanical properties of fly ash reinforced epoxy composite. Compos. Part B Eng. 2019, 176, 107301. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Pielichowska, K.; Ziąbka, M.; Benko, A.; Szatkowski, P.; Jerzak, W. Fluidized bed combustion fly ash as filler in composite polyurethane materials. Waste Manag. 2019, 92, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Sun, Q.; Wang, B.; Wang, P.; Zou, J. Morphology and composition of microspheres in fly ash from the Luohuang Power Plant, Chongqing, Southwestern China. Minerals 2016, 6, 30. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Jerzak, W.; Ziąbka, M.; Lach, R. Study on chemical composition of fly ash ram fluidized-bed and conventional coal combustion. Przem. Chem. 2017, 96, 1699–1703. [Google Scholar]

- Vassilev, S.V.; Menendez, R.; Borrego, A.G.; Diaz-Somoano, M.; Martinez-Tarazona, M.R. Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 3. Characterization of magnetic and char concentrates. Fuel 2004, 83, 1563–1583. [Google Scholar] [CrossRef]

- Ngu, L.N.; Wu, H.; Zhang, D.K. Characterization of ash cenospheres in fly ash from Australian power stations. Energy Fuels 2007, 21, 3437–3445. [Google Scholar] [CrossRef]

- Hejna, A.; Kopczyńska, M.; Kozłowska, U.; Klein, M.; Kosmela, P.; Piszczyk, Ł. Foamed polyurethane composites with different types of ash–morphological, mechanical and thermal behavior assessments. Cell. Polym. 2016, 35, 287–308. [Google Scholar] [CrossRef]

- Porabka, A.; Jurkowski, K.; Laska, J. Fly ash used as a reinforcing and flame-retardant filler in low-density polyethylene. Polimery 2015, 60, 251–257. [Google Scholar] [CrossRef]

- Tarakcilar, A.R. The effects of intumescent flame retardant including ammonium polyphosphate/pentaerythritol and fly ash fillers on the physicomechanical properties of rigid polyurethane foams. J. Appl. Polym. Sci. 2010, 120, 2095–2102. [Google Scholar] [CrossRef]

- Usta, N. Investigation of fire behavior of rigid polyurethane foams containing fly ash and intumescent flame retardant by using a cone calorimeter. J. Appl. Polym. Sci. 2012, 124, 3372–3382. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Yi, L.; Sun, J. Heat transfer mechanism of concurrent flame spread over rigid polyurethane foam: Effect of ambient pressure and inclined angle. Int. J. Therm. Sci. 2020, 155, 106403. [Google Scholar] [CrossRef]

- Hazrol, M.D.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M.; Abdul Wahab, N.I. Corn Starch (Zea mays) Biopolymer Plastic Reaction in Combination with Sorbitol and Glycerol. Polymers 2021, 13, 242. [Google Scholar] [CrossRef]

- Kairytė, A.; Kremensas, A.; Vaitkus, S.; Członka, S.; Strąkowska, A. Fire Suppression and Thermal Behavior of Biobased Rigid Polyurethane Foam Filled with Biomass Incineration Waste Ash. Polymers 2020, 12, 683. [Google Scholar] [CrossRef]

- Cabrera, F.C. Eco-friendly polymer composites: A review of suitable methods for waste management. Polym. Compos. 2021, 42, 2653–2677. [Google Scholar] [CrossRef]

- PCC Group. EKOPRODUR PM4032 Characteristics Sheet ASTM D1622-03 Standard Test Method for Apparent Density of Rigid Cellular Plastics. Available online: https://www.products.pcc.eu/wp-content/uploads/import/product/broszura/2b322bd8-5c34-4786-bd88-fffce8e829d9/ekoprodur-pm4032_broszura_en.pdf (accessed on 28 February 2025).

- Magiera, A.; Kuźnia, M.; Jerzak, W.; Ziąbka, M.; Lach, R.; Handke, B. Microspheres as potential fillers in composite polymeric materials. E3S Web Conf. 2019, 108, 02009. [Google Scholar] [CrossRef]

- ASTM D1622-03; Standard Test Method for Apparent Density of Rigid Cellular Plastics. ASTM International Online Library: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/d1622-03.html (accessed on 3 June 2024).

- Sousa, J.M.; Correia, J.R.; Cabral-Fonseca, S. Some permanent effects of hygrothermal and outdoor ageing on a structural polyurethane adhesive used in civil engineering applications. Int. J. Adhes. Adhes. 2018, 84, 406–419. [Google Scholar] [CrossRef]

- Ospina, A.C.; Orozco, V.H.; Giraldo, L.F.; Fuensanta, M.; Martin-Martinez, J.M.; Mateo-Oliveras, N. Study of waterborne polyurethane materials under aging treatments. Effect of the soft segment length. Prog. Org. Coat. 2020, 138, 105357. [Google Scholar] [CrossRef]

- Liszkowska, J.; Moraczewski, K.; Borowicz, M.; Paciorek-Sadowska, J.; Czupryński, B.; Isbrandt, M. The effect of accelerated aging conditions on the properties of rigid polyurethane-polyisocyanurate foams modified by cinnamon extract. Appl. Sci. 2019, 9, 2663. [Google Scholar] [CrossRef]

- Gujral, P.; Varshney, S.; Dhawan, S. Designing of multiphase fly ash/MWCNT/PU composite sheet against electromagnetic environmental pollution. J. Electron. Mater. 2016, 45, 3142–3148. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P.; Mikicka, M.; Danowska, M.; Piszczyk, Ł. Modification of microporous polyurethane elastomers with different types of ash—Morphological, mechanical, and thermal studies. Polym. Compos. 2016, 37, 881–889. [Google Scholar] [CrossRef]

- Fauzi, A.; Nuruddin, M.F.; Malkawi, A.B.; Abdullah, M.M.A.B. Study of fly ash characterization as a cementitious material. Procedia Eng. 2016, 148, 487–493. [Google Scholar] [CrossRef]

- Mozgawa, W.; Król, M.; Dyczek, J.; Deja, J. Investigation of the coal fly ashes using IR spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 132, 889–894. [Google Scholar] [CrossRef]

- Baek, S.H.; Kim, J.H. Polyurethane composite foams including silicone-acrylic particles for enhanced sound absorption via increased damping and frictions of sound waves. Compos. Sci. Technol. 2020, 198, 108325. [Google Scholar] [CrossRef]

- Bartczak, P.; Siwińska-Ciesielczyk, K.; Haak, N.; Parus, A.; Piasecki, A.; Jesionowski, T.; Borysiak, S. Closed-cell polyurethane spray foam obtained with novel TiO2–ZnO hybrid fillers–mechanical, insulating properties and microbial purity. J. Build. Eng. 2023, 65, 105760. [Google Scholar] [CrossRef]

- Uram, K.; Leszczyńska, M.; Prociak, A.; Czajka, A.; Gloc, M.; Leszczyński, M.K.; Michałowski, S.; Ryszkowska, J. Polyurethane composite foams synthesized using bio-polyols and cellulose filler. Materials 2021, 14, 3474. [Google Scholar] [CrossRef]

- Strąkowska, A.; Członka, S.; Kairyte, A. Rigid polyurethane foams reinforced with POSS-impregnated sugar beet pulp filler. Materials 2020, 13, 5493. [Google Scholar] [CrossRef]

- Kairyte, A.; Członka, S.; Seputyte-Jucike, J.; Vejelis, S. Impact of sunflower press cake and its modification with liquid glass on polyurethane foam composites: Thermal stability, ignitability, and fire resistance. Polymers 2022, 14, 4543. [Google Scholar] [CrossRef]

- Hou, L.; Li, H.; Liu, Y.; Niu, K.; Shi, Z.; Liang, L.; Yao, Z.; Liu, C.; Tian, D. Synergistic effect of silica aerogels and hollow glass microspheres on microstructure and thermal properties of rigid polyurethane foam. J. Non-Cryst. Solids 2022, 592, 121753. [Google Scholar] [CrossRef]

- Li, T.T.; Liu, P.; Wang, H.; Dai, W.; Wang, J.; Wang, Z.; Shiu, B.C.; Lou, C.W.; Lin, J.H. Preparation and characteristics of flexible polyurethane foam filled with expanded vermiculite powder and concave-convex structural panel. J. Mater. Res. Technol. 2021, 12, 1288–1302. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Czupryński, B.; Borowicz, M.; Liszkowska, J. Rigid polyurethane–polyisocyanurate foams modified with grain fraction of fly ashes. J. Cell. Plast. 2020, 56, 53–72. [Google Scholar] [CrossRef]

| Sample Name | Vertical Feret Diameter, μm | Horizontal Feret Diameter, μm | Strut Thickness, μm |

|---|---|---|---|

| PUR | 193.4 ± 15.3 | 207.4 ± 15.7 | 19.8 ± 1.2 |

| 5M5FA | 175.2 ± 12.7 | 192.5 ± 13.1 | 18.7 ± 0.6 |

| 5M10FA | 124.5 ± 6.7 | 125.5 ± 6.0 | 17.0 ± 0.5 |

| 5M15FA | 120.6 ± 7.4 | 129.9 ± 10.5 | 18.0 ± 0.5 |

| Sample Name | Vertical Feret Diameter, μm | Horizontal Feret Diameter, μm | Strut Thickness, μm |

|---|---|---|---|

| PUR | 248.7 ± 0.9 | 198.0 ± 0.8 | 18.4 ± 0.7 |

| 5M5FA | 134.6 ± 0.7 | 146.1 ± 0.7 | 20.0 ± 0.7 |

| 5M10FA | 118.7 ± 0.6 | 130.0 ± 0.7 | 17.7 ± 0.6 |

| 5M15FA | 119.8 ± 0.6 | 128.3 ± 0.7 | 17.6 ± 0.4 |

| Sample Name | Vertical Feret Diameter, μm | Horizontal Feret Diameter, μm | Strut Thickness, μm |

|---|---|---|---|

| PUR | 208.1 ± 0.8 | 150.7 ± 0.7 | 21.0 ± 1.0 |

| 5M5FA | 129.0 ± 0.7 | 132.8 ± 0.7 | 20.3 ± 1.0 |

| 5M10FA | 134.4 ± 0.7 | 142.4 ± 0.7 | 19.2 ± 1.1 |

| 5M15FA | 141.1 ± 0.7 | 132.8 ± 0.7 | 21.2 ± 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magiera, A.; Kuźnia, M.; Jerzak, W. Analysis of the Structural, Chemical, and Mechanical Characteristics of Polyurethane Foam Infused with Waste from Thermal Processing. Materials 2025, 18, 1327. https://doi.org/10.3390/ma18061327

Magiera A, Kuźnia M, Jerzak W. Analysis of the Structural, Chemical, and Mechanical Characteristics of Polyurethane Foam Infused with Waste from Thermal Processing. Materials. 2025; 18(6):1327. https://doi.org/10.3390/ma18061327

Chicago/Turabian StyleMagiera, Anna, Monika Kuźnia, and Wojciech Jerzak. 2025. "Analysis of the Structural, Chemical, and Mechanical Characteristics of Polyurethane Foam Infused with Waste from Thermal Processing" Materials 18, no. 6: 1327. https://doi.org/10.3390/ma18061327

APA StyleMagiera, A., Kuźnia, M., & Jerzak, W. (2025). Analysis of the Structural, Chemical, and Mechanical Characteristics of Polyurethane Foam Infused with Waste from Thermal Processing. Materials, 18(6), 1327. https://doi.org/10.3390/ma18061327