Multi-Objective Optimization of Injection Molding Process Parameters for Junction Boxes Based on BP Neural Network and NSGA-II Algorithm

Abstract

1. Introduction

2. Establishment of Finite Element Model and Process Analysis

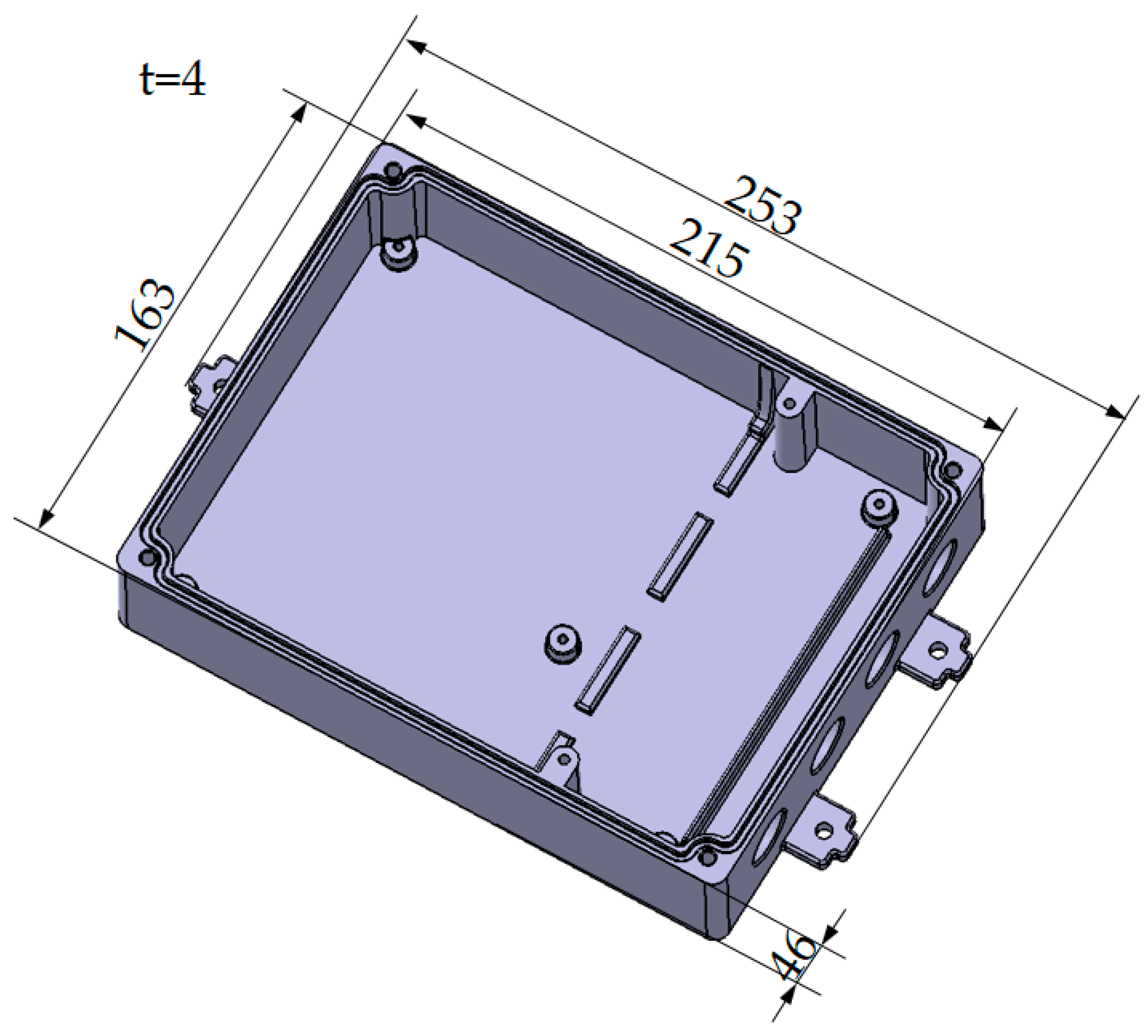

2.1. Structural Analysis of Junction Box

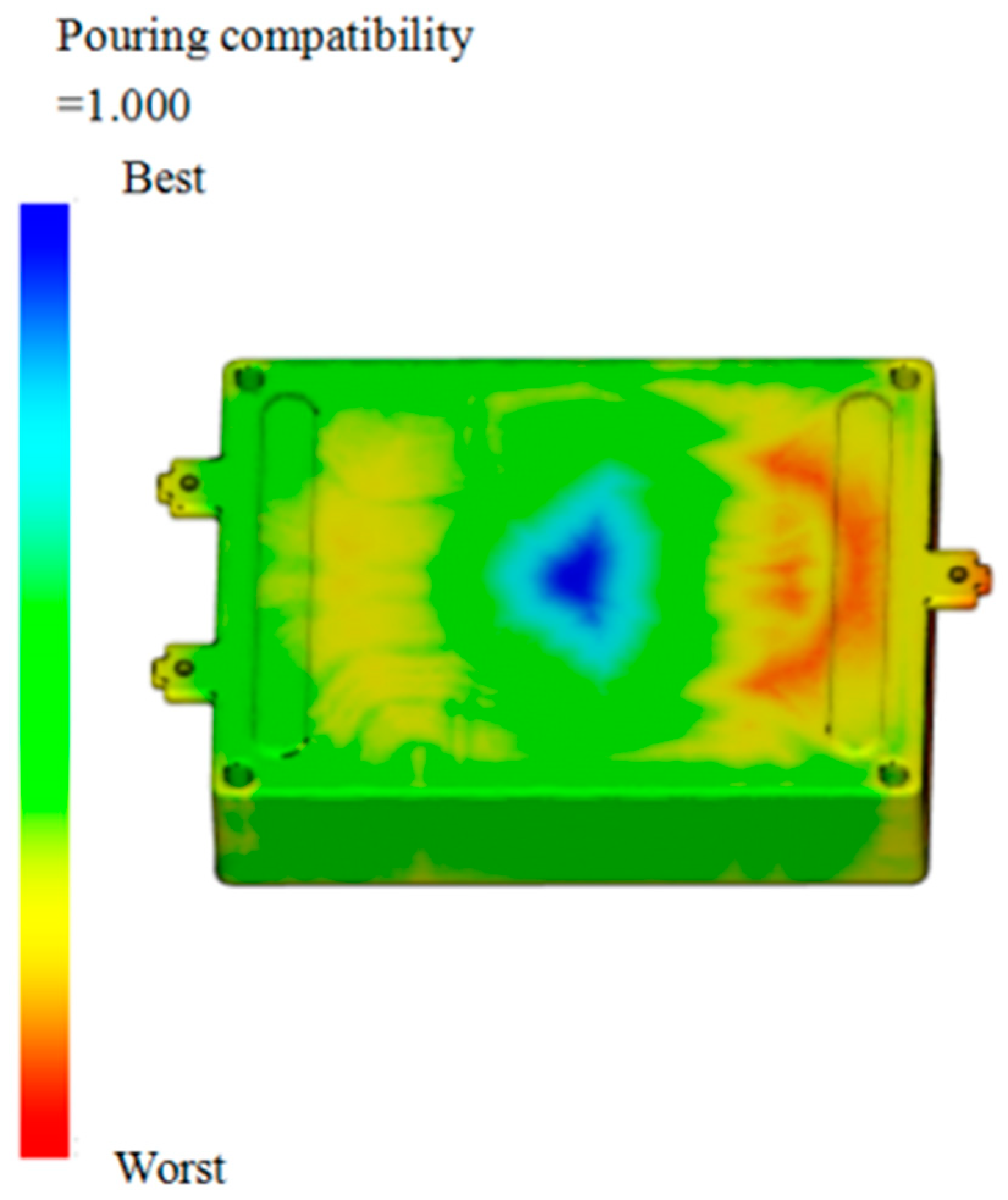

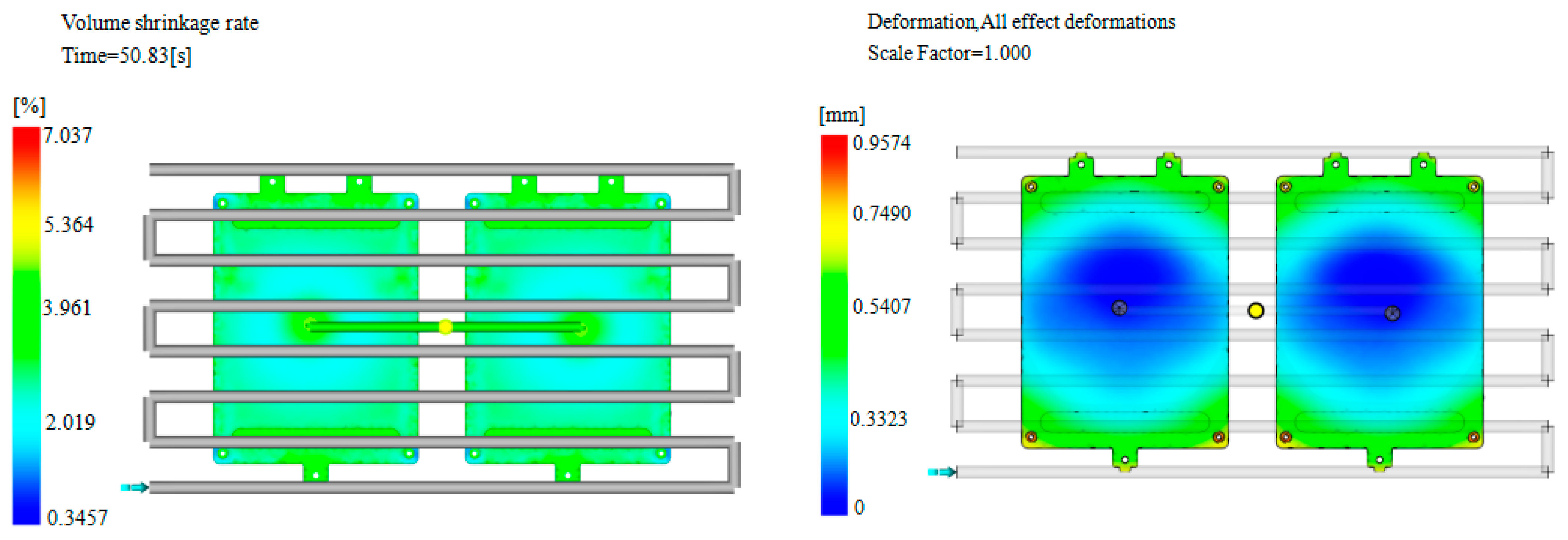

2.2. Analysis of Mold Flow Under Initial Process Parameter Conditions

3. Orthogonal Experiments

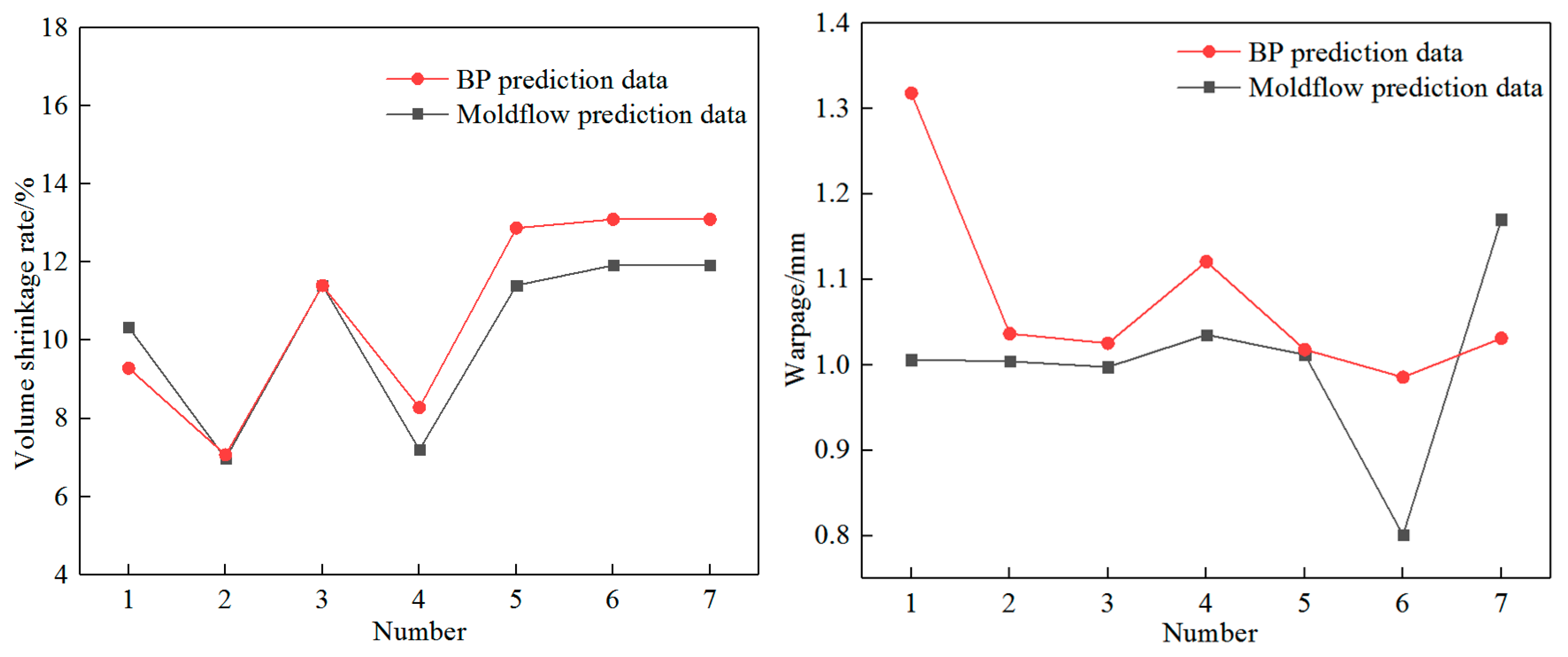

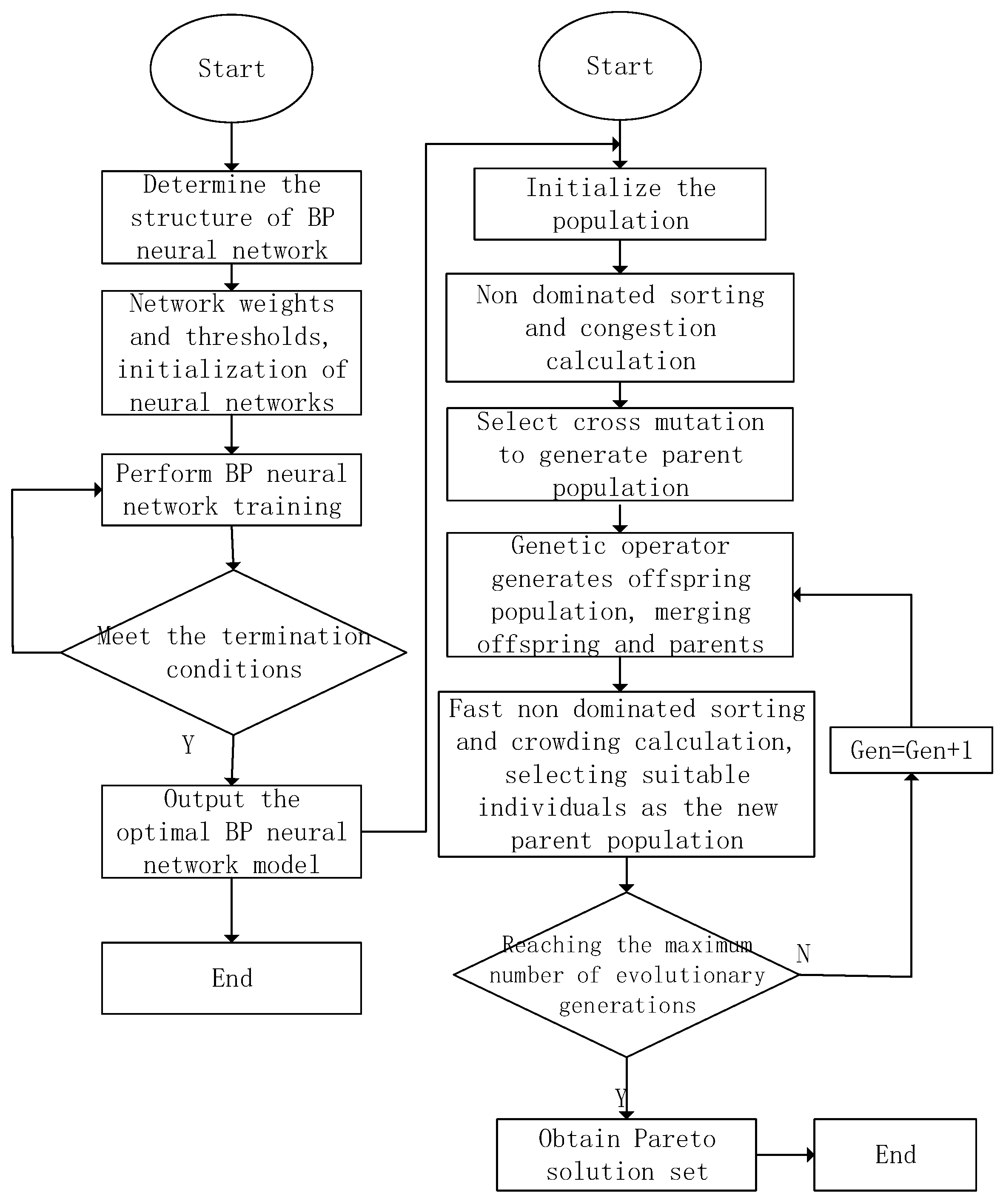

4. BP Neural Network

5. Process Parameter Optimization Based on NSGA-II Algorithm

5.1. NSGA-II Algorithm

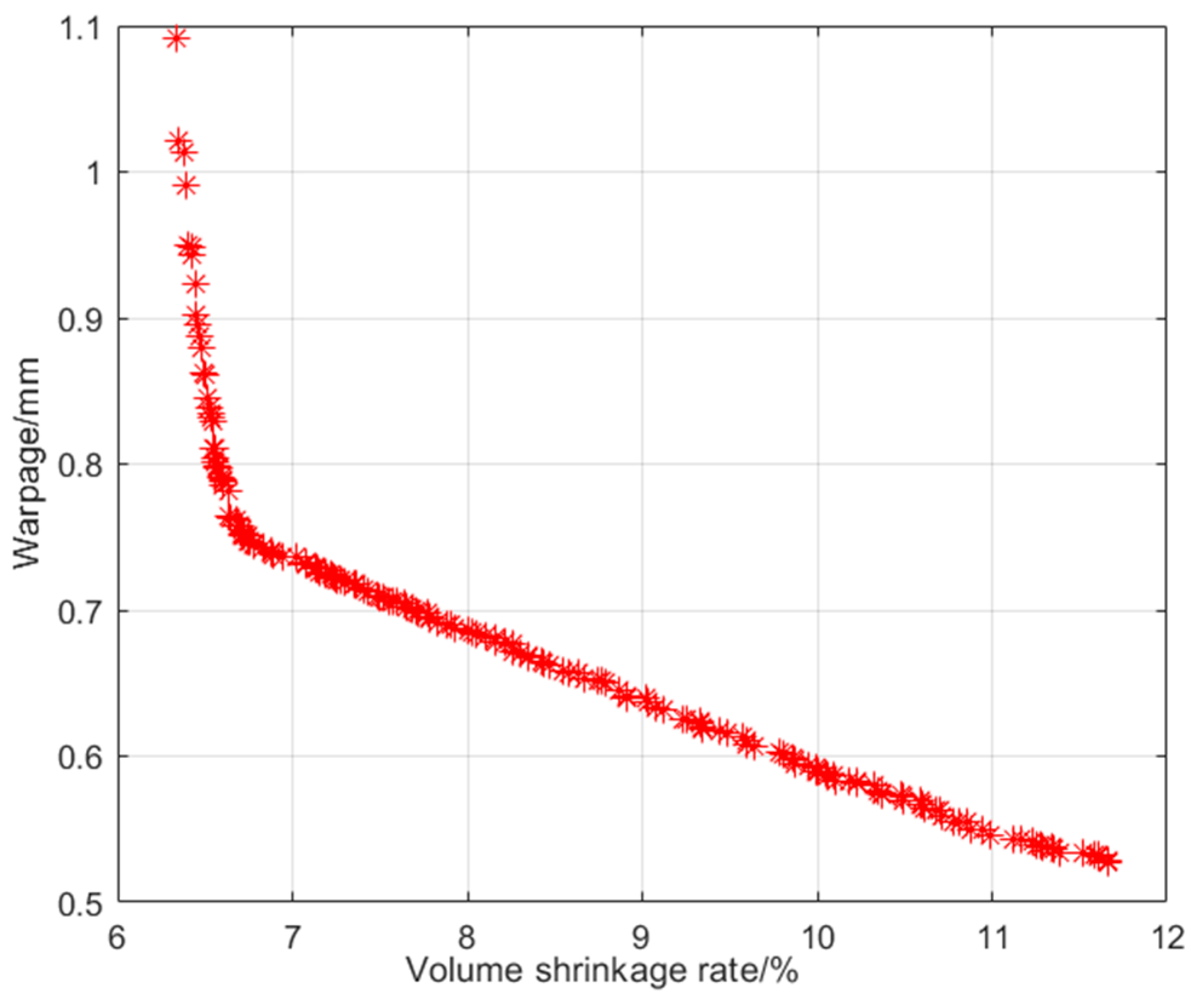

5.2. Process Parameter Optimization

- (1)

- Determine the indicator data matrix. There are a total of 50 samples to be evaluated, and the evaluation matrices for two evaluation indicators are as follows:Equation (4), yij represents the value of the jth evaluation index in the i-th experiment.

- (2)

- Dimensionless processing.To remove effects of different dimensions on the assessment, it is necessary to make the volume shrinkage rate and warpage deformation dimensionless. The smaller the indicators to be optimized, the better. Therefore, when standardizing, negative indicators are used for the calculation.Equation (5): represents the standardized value, and ymax and ymin are the upper and lower limits of indicator j.

- (3)

- Calculate indicator variability σjIn the CRITIC method, the standard deviation is used to represent the fluctuation of values within each indicator. The larger the standard deviation, the greater the numerical difference of the indicator and the stronger the evaluation strength of the indicator itself. Therefore, more weight should be assigned to the indicator.In Equations (6) and (7), n is the total number of experimental groups, and σj represents the standard deviation of the jth indicator.

- (4)

- Calculate indicator conflict RjIn Equation (8), rij represents the correlation coefficient between evaluation indicators i and j. The correlation coefficient is used to represent the correlation between indicators. The stronger the correlation with other indicators, the less conflicting the indicator is with other indicators, reflecting more similar information. The evaluation content that can be reflected is more repetitive, which weakens the evaluation strength of the indicator to a certain extent. Therefore, the weight assigned to the indicator should be reduced.

- (5)

- Calculate the amount of information CjThe larger the Cj, the greater the role of the jth evaluation indicator in the entire evaluation indicator system, and it should be distributed with more weight.

- (6)

- Calculate objective weight WjAccording to Equations (5)–(10) above, gradually calculate the objective weight values of the two indicators. As shown in Table 6, the objective weight of the volume shrinkage rate in the two molding masses is 0.4878, and the objective weight of warpage deformation in the two molding masses is 0.5122. Based on the obtained weight values, calculate the comprehensive evaluation value of the molding quality for each group of schemes according to Equation (1). Among them, the comprehensive evaluation value of the injection molding process scheme corresponding to a volume shrinkage rate of 6.905% and a warpage deformation of 0.991 mm reached 3.876, which is the minimum value among the 50 schemes. At this time, the optimal process parameter combination is the melt temperature of 230.03 °C, mold temperature of 51.27 °C, injection pressure of 49.13 MPa, holding pressure of 69.01 MPa, holding time of 15.48 s, and cooling time of 34.91 s.

6. Conclusions

- (1)

- Based on a six-factor five-level orthogonal experiment, the influence of the melt temperature, mold temperature, injection pressure, holding pressure, holding time, and cooling time on the volume shrinkage rate and warpage deformation of junction boxes was studied using Moldflow simulation software. By analyzing the range of the signal-to-noise ratio, the primary and secondary order of the influence of injection molding process parameters on the volume shrinkage rate and warpage deformation of junction boxes is obtained as follows: melt temperature > holding time > holding pressure > cooling time > injection pressure > mold temperature.

- (2)

- Based on a fitted BP neural network model and combined with the NSGA-II algorithm, multi-target optimization was carried out within a specified parameter range using the quality indicators to determine the optimal solution, with a melt temperature of 230.03 °C, mold temperature of 51.27 °C, injection pressure of 49.13 MPa, holding pressure of 69.01 MPa, holding time of 15.48 s, and cooling time of 34.91 s. The resulting product had a warpage deformation of 0.912 mm, which was 33.2% lower than the average volume fraction before optimization (10.34884%). The optimal results were significant, and the injection molding quality of the junction box was improved.

- (3)

- The errors between the volume shrinkage rate and warpage deformation predicted using BP-NSGA-II and the simulated values using Moldflow software are 1.9% and 3.4%, respectively, indicating that the optimization method of the BP neural network and NSGA-II algorithm is reliable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Y.; Feng, Y.; Peng, S.; Mao, Z.; Chen, B. Generative machine learning-based multi-objective process parameter optimization towards energy and quality of injection molding. Environ. Sci. Pollut. Res. 2023, 30, 51518–51530. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Zeng, D.; Tibbenham, P.; Su, X.; Kang, H.-T. A new characterizing method for warpage measurement of injection-molded thermoplastics. Polym. Test. 2019, 76, 320–325. [Google Scholar] [CrossRef]

- Shen, C.; Wang, L.; Li, Q. Optimization of injection molding process parameters using combination of artificial neural network and genetic algorithm method. J. Mech. Work. Technol. 2007, 183, 412–418. [Google Scholar] [CrossRef]

- Mohan, M.; Ansari, M.; Shanks, R.A. Review on the Effects of Process Parameters on Strength, Shrinkage, and Warpage of Injection Molding Plastic Component. Polym. Technol. Eng. 2017, 56, 1–12. [Google Scholar] [CrossRef]

- Agrawal, A.R.; Pandelidis, I.O.; Pecht, M. Injection-molding process control—A review. Polym. Eng. Sci. 2010, 27, 1345–1357. [Google Scholar] [CrossRef]

- Li, X.; Liu, F.; Zhang, C.; Gao, R.; Xu, X.; Fu, J.; Zhao, P. The influence of mold design and process parameters on dimensional shrinkage of perfluoroalkoxy alkane injection molding parts. J. Appl. Polym. Sci. 2024, 141, e55757. [Google Scholar] [CrossRef]

- Guo, F.; Han, D.; Kim, N. Multi-Objectives Optimization of Plastic Injection Molding Process Parameters Based on Numerical DNN-GA-MCS Strategy. Polymers 2024, 16, 2247. [Google Scholar] [CrossRef]

- Mukras, S.M.S.; Omar, H.M.; Al-Mufadi, F.A. Experimental-Based Multi-objective Optimization of Injection Molding Process Parameters. Arab. J. Sci. Eng. 2019, 44, 7653–7665. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, S.; Wang, Z. Multi-objective optimization of process parameters in plastic injection molding using a differential sensitivity fusion method. Int. J. Adv. Manuf. Technol. 2021, 114, 423–449. [Google Scholar] [CrossRef]

- Ding, W.; Fan, X.; Guo, Y.; Lu, X.; Wang, D.; Wang, C.; Zhang, X. Quality monitoring of injection molding based on TSO-SVM and MOSSA. J. Polym. Eng. 2024, 44, 64–72. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Nguyen, M.Q. A Numerical Simulation and Multi-objective Optimization for the Plastic Injection Molding of a Centrifugal Pump Casing. IOP Conf. Ser. Earth Environ. Sci. 2023, 1278, 012026. [Google Scholar] [CrossRef]

- Cao, Y.; Fan, X.; Guo, Y.; Ding, W.; Liu, X.; Li, C. Multi-objective optimization of injection molding process parameters based on BO-RFR and NSGAII methods. Int. Polym. Process. 2023, 38, 8–18. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Sun, Z.; Bo, C.; Gao, F. Multiobjective optimization of injection molding parameters based on the GEK-MPDE method. J. Polym. Eng. 2023, 43, 820–831. [Google Scholar] [CrossRef]

- Wu, W.; He, X.; Li, B.; Shan, Z. An Effective Shrinkage Control Method for Tooth Profile Accuracy Improvement of Micro-Injection-Molded Small-Module Plastic Gears. Polymers 2022, 14, 3114. [Google Scholar] [CrossRef]

- Tan, M.; Peng, S.; Huo, Y.; Li, M. Multi-Objective Optimization of Injection Molding Parameters for Manufacturing Thin-Walled Composite Connector Terminals. Materials 2024, 17, 3949. [Google Scholar] [CrossRef]

- Zeng, W.; Yi, G.; Zhang, S.; Wang, Z. Multi-objective optimization method of injection molding process parameters based on hierarchical sampling and comprehensive entropy weights. Int. J. Adv. Manuf. Technol. 2024, 133, 1481–1499. [Google Scholar] [CrossRef]

- Hentati, F.; Masmoudi, N. The impact of injection molding process parameters on mechanical properties and microstructure of PC/ABS blends using Taguchi approach. Polym. Bull. 2024, 81, 10659–10679. [Google Scholar] [CrossRef]

- Guo, W.; Lu, T.; Zeng, F.; Zhou, X.; Li, W.; Yuan, H.; Meng, Z. Multi-objective optimization of microcellular injection molding process parameters to reduce energy consumption and improve product quality. Int. J. Adv. Manuf. Technol. 2024, 134, 5159–5173. [Google Scholar] [CrossRef]

- Liu, F.; Pang, J.; Xu, Z. Multi-Objective Optimization of Injection Molding Process Parameters for Moderately Thick Plane Lens Based on PSO-BPNN, OMOPSO, and TOPSIS. Processes 2023, 12, 36. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Kim, J. A Study on the Architecture of Artificial Neural Network Considering Injection-Molding Process Steps. Polymers 2023, 15, 4578. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, G.; Sun, Y.; Lu, S. Non-Dominant Genetic Algorithm for Multi-Objective Optimization Design of Unmanned Aerial Vehicle Shell Process. Polymers 2022, 14, 2896. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, K.; Zhao, D.; Wang, M.; Li, Q.; Hou, J. Multi-Objective Optimizations for Microinjection Molding Process Parameters of Biodegradable Polymer Stent. Materials 2018, 11, 2322. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Tang, L.; Wu, P. Research on Optimization of Injection Molding Process Parameters of Automobile Plastic Front-End Frame. Adv. Mater. Sci. Eng. 2022, 2022, 5955725. [Google Scholar] [CrossRef]

- Trotta, G.; Cacace, S.; Semeraro, Q. Optimizing process parameters in micro injection moulding considering the part weight and probability of flash formation. J. Manuf. Process. 2022, 79, 250–258. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, H.; Shen, J.; Ni, D.; Wang, Z. Optimization of warpage deformation of thin-walled injection molded. Eng. Plast. Appl. 2024, 52, 70–75. (In Chinese) [Google Scholar]

- Li, S.; Fan, X.Y.; Guo, Y.H.; Liu, X.; Huang, H.Y.; Cao, Y.L.; Li, L.L. Optimization of Injection Molding Process of Transparent Complex Multi-Cavity Parts Based on Kriging Model and Various Optimization Techniques. Arab. J. Sci. Eng. 2021, 46, 11835–11845. [Google Scholar] [CrossRef]

- Fang, M.; Zhang, Y.; Wang, C.; Wang, R. Optimization of Injection Process Parameters for Automotive Instrument Framework Based on Particle Swarm Optimization Algorithm. China Plast. Ind. 2024, 52, 79–85+90. (In Chinese) [Google Scholar]

- Ding, Y.; Hu, S. Numerical Simulation and Process Optimization of Bottle Cap Injection Molding Based on Orthogonal Experiment. Plast. Sci. Technol. 2018, 46, 91–94. (In Chinese) [Google Scholar]

- Sun, Z.; Li, J.; Wang, Z.; Bo, C.; Zhang, Y.; Yao, K.; Gao, D. Multi-objective optimal design of key process parameters for plastic injection molding product quality. J. Chem. Eng. Chin. Univ. 2023, 37, 483–491. (In Chinese) [Google Scholar]

- Rosli, M.; Ishak, M.I.; Jamalludin, M.R.; Khor, C.; Nawi, M.; Syafiq, A.M. Simulation-Based Optimization of Plastic Injection Molding Parameter for Aircraft Part Fabrication Using Response Surface Methodology (RSM). IOP Conf. Ser. Mater. Sci. Eng. 2019, 551, 012108. [Google Scholar] [CrossRef]

- Chen, W.C.; Nguyen, M.H.; Chiu, W.H.; Chen, T.N.; Tai, P.H. Optimization of the plastic injection molding process using the Taguchi method, RSM, and hybrid GA-PSO. Int. J. Adv. Manuf. Technol. 2016, 83, 1873–1886. [Google Scholar] [CrossRef]

- Ding, F.J.; Jia, X.D.; Hong, T.J.; Xu, Y.L. Flow Stress Prediction Model of 6061 Aluminum Alloy Sheet Based on GA-BP and PSO-BP Neural Networks. Rare Met. Mater. Eng. 2020, 49, 1840–1853. [Google Scholar]

- Bensingh, R.J.; Machavaram, R.; Boopathy, S.R.; Jebaraj, C. Injection molding process optimization of a bi-aspheric lens using hybrid artificial neural networks (ANNs) and particle swarm optimization (PSO). Measurement 2019, 134, 359–374. [Google Scholar] [CrossRef]

- Feng, Q.; Liu, L.; Zhou, X. Automated multi-objective optimization for thin-walled plastic products using Taguchi, ANOVA, and hybrid ANN-MOGA. Int. J. Adv. Manuf. Technol. 2020, 106, 559–575. [Google Scholar] [CrossRef]

- Zhang, T.; Wei, Z.; Wang, L.; Xue, Z.; Wang, S.; Wang, P.; Qi, B.; Yue, Z. Multi-objective optimization of composite stiffened panels for mass and buckling load using PNN-NSGA-III algorithm and TOPSIS method. Thin-Walled Struct. 2025, 209, 112878. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining objective weights in multiple criteria problems: The critic method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

| Item | Actually | Requirement |

|---|---|---|

| Mesh-type | Triangles | — |

| Maximum aspect ratio | 16.0 | <20 |

| Average aspect ratio | 2.96 | <3 |

| Fully overlapping elements | 0 | 0 |

| Match percentage | 86% | >85% |

| Total grids | 51,388 | — |

| Factor | Melt Temperature/°C | Mold Temperature/°C | Injection Pressure/MPa | Holding Pressure/MPa | Holding Time/s | Cooling Time/s | |

|---|---|---|---|---|---|---|---|

| Level | |||||||

| 1 | 230 | 50 | 40 | 50 | 10 | 15 | |

| 2 | 240 | 60 | 45 | 55 | 15 | 20 | |

| 3 | 250 | 70 | 50 | 60 | 20 | 25 | |

| 4 | 260 | 80 | 55 | 65 | 25 | 30 | |

| 5 | 270 | 90 | 60 | 70 | 30 | 35 | |

| Number | Experimental Factors | Experimental Result | ||||||

|---|---|---|---|---|---|---|---|---|

| A/℃ | B/℃ | C/MPa | D/MPa | E/s | F/s | X1/% | X2/mm | |

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 7.661 | 1.307 |

| 2 | 1 | 2 | 2 | 2 | 2 | 2 | 7.206 | 1.035 |

| 3 | 1 | 3 | 3 | 3 | 3 | 3 | 7.095 | 1.022 |

| 4 | 1 | 4 | 4 | 4 | 4 | 4 | 7.018 | 1.015 |

| 5 | 1 | 5 | 5 | 5 | 5 | 5 | 6.981 | 1.004 |

| 6 | 2 | 1 | 2 | 3 | 4 | 5 | 10.35 | 1.018 |

| 7 | 2 | 2 | 3 | 4 | 5 | 1 | 10.35 | 1.023 |

| 8 | 2 | 3 | 4 | 5 | 1 | 2 | 10.35 | 1.106 |

| 9 | 2 | 4 | 5 | 1 | 2 | 3 | 10.34 | 1.056 |

| 10 | 2 | 5 | 1 | 2 | 3 | 4 | 10.34 | 1.006 |

| 11 | 3 | 1 | 3 | 5 | 2 | 4 | 10.87 | 0.8403 |

| 12 | 3 | 2 | 4 | 1 | 3 | 5 | 10.87 | 1.008 |

| 13 | 3 | 3 | 5 | 2 | 4 | 1 | 10.87 | 1.015 |

| 14 | 3 | 4 | 1 | 3 | 5 | 2 | 10.88 | 1.016 |

| 15 | 3 | 5 | 2 | 4 | 1 | 3 | 10.88 | 1.281 |

| 16 | 4 | 1 | 4 | 2 | 5 | 3 | 11.41 | 1.013 |

| 17 | 4 | 2 | 5 | 3 | 1 | 4 | 11.42 | 1.012 |

| 18 | 4 | 3 | 1 | 4 | 2 | 5 | 11.41 | 0.9905 |

| 19 | 4 | 4 | 2 | 5 | 3 | 1 | 11.41 | 0.8618 |

| 20 | 4 | 5 | 3 | 1 | 4 | 2 | 11.41 | 0.9973 |

| 21 | 5 | 1 | 5 | 4 | 3 | 2 | 11.92 | 0.8007 |

| 22 | 5 | 2 | 1 | 5 | 4 | 3 | 11.92 | 0.8195 |

| 23 | 5 | 3 | 2 | 1 | 5 | 4 | 11.92 | 1.01 |

| 24 | 5 | 4 | 3 | 2 | 1 | 5 | 11.92 | 1.342 |

| 25 | 5 | 5 | 4 | 3 | 2 | 1 | 11.92 | 1.17 |

| Mean Signal-to-Noise Ratio | Experimental Factors | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| K1 | −17.13 | −20.28 | −20.28 | −20.27 | −20.28 | −20.28 |

| K2 | −20.30 | −20.17 | −20.17 | −20.17 | −20.17 | −20.17 |

| K3 | −20.73 | −20.14 | −20.14 | −20.15 | −20.14 | −20.14 |

| K4 | −21.15 | −20.12 | −20.12 | −20.13 | −20.12 | −20.12 |

| K5 | −21.53 | −20.11 | −20.11 | −20.11 | −20.12 | −20.11 |

| R | 4.39 | 0.16 | 0.16 | 0.16 | 0.16 | 0.16 |

| Ranking | 1 | 3 | 4 | 6 | 2 | 5 |

| Mean Signal-to-Noise Ratio | Experimental Factors | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| K1 | −0.59547 | 0.16985 | −0.14068 | −0.58619 | −1.60205 | −0.54484 |

| K3 | −0.19522 | −0.23939 | −0.28136 | −0.38984 | 0.58246 | −0.23929 |

| K4 | 0.23649 | −0.40073 | −0.50991 | −0.09286 | 0.26778 | 0.22800 |

| K5 | −0.06911 | −0.71557 | 0.23794 | 0.72449 | −0.11374 | −0.54620 |

| R | 0.83196 | 0.92755 | 0.74785 | 1.35395 | 2.18451 | 0.77419 |

| Ranking | 4 | 3 | 6 | 2 | 1 | 5 |

| Indicator | Variability | Conflict-Oriented | Information Content | Weight |

|---|---|---|---|---|

| volume shrinkage rate | 0.255 | 1.960 | 0.500 | 48.78% |

| warpage | 0.268 | 1.960 | 0.525 | 51.22% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, T.; Huang, D.; Ding, F.; Zhang, L.; Dong, F.; Chen, L. Multi-Objective Optimization of Injection Molding Process Parameters for Junction Boxes Based on BP Neural Network and NSGA-II Algorithm. Materials 2025, 18, 577. https://doi.org/10.3390/ma18030577

Hong T, Huang D, Ding F, Zhang L, Dong F, Chen L. Multi-Objective Optimization of Injection Molding Process Parameters for Junction Boxes Based on BP Neural Network and NSGA-II Algorithm. Materials. 2025; 18(3):577. https://doi.org/10.3390/ma18030577

Chicago/Turabian StyleHong, Tengjiao, Dong Huang, Fengjuan Ding, Liyong Zhang, Fulong Dong, and Lei Chen. 2025. "Multi-Objective Optimization of Injection Molding Process Parameters for Junction Boxes Based on BP Neural Network and NSGA-II Algorithm" Materials 18, no. 3: 577. https://doi.org/10.3390/ma18030577

APA StyleHong, T., Huang, D., Ding, F., Zhang, L., Dong, F., & Chen, L. (2025). Multi-Objective Optimization of Injection Molding Process Parameters for Junction Boxes Based on BP Neural Network and NSGA-II Algorithm. Materials, 18(3), 577. https://doi.org/10.3390/ma18030577