Abstract

High-efficiency, lead-free dielectrics are sought for pulsed-power capacitors, yet pristine Bi0.5Na0.5TiO3 (BNT) suffers from large remanence, high coercivity, and limited breakdown strength. Here, we report (1 − x)Bi0.5Na0.5Ti0.97Nb0.03O3-xSr0.85Ba0.15Ta0.5+0.02xAl0.5−0.02xO3 (BNTNb–SBTA, x = 0–0.15) ceramics synthesized via solid-state reaction, achieving enhanced relaxor ferroelectric behavior through multi-cation substitution at A- and B-sites. X-ray diffraction confirms a pure perovskite solid solution, while scanning electron microscopy reveals grain refinement, suppressing oxygen vacancies and boosting the breakdown strength. Raman and dielectric analyses evidence strengthened relaxor behavior, accompanied by loop slimming and a systematic rise in breakdown strength. The composition x = 0.10 achieves the best trade-off, delivering Wrec = 3.357 J cm−3 and η = 90.5% at Eb = 240 kV cm−1. Robust operational stability is demonstrated with small variations of Wrec/η over 0.1–200 Hz, 25–175 °C, and 106 cycles. Pulsed tests show fast discharge (∼26 ns) with Wd = 0.826 J cm−3 at ∼90% efficiency under moderate fields. These results indicate that synergistic A/B-site disorder (Sr/Ba on A-site; Ta/Al with Nb on B-site), combined with microstructural densification, effectively minimizes Pr while elevating Eb, enabling high-efficiency energy storage under practical operating conditions.

1. Introduction

In recent years, escalating global energy consumption and environmental concerns have intensified the demand for sustainable and efficient energy storage technologies []. Dielectric capacitors stand out among various energy storage devices, such as batteries and electrochemical capacitors, due to their ultrahigh charge–discharge rates (on the order of nanoseconds), exceptional power density (up to 108 W kg−1), superior fatigue endurance (>106 cycles), and excellent thermal stability, making them indispensable for pulsed power systems in applications like electric vehicles, aerospace, medical devices, and military equipment [,]. However, traditional lead-based ceramics, such as Pb(Zr,Ti)O3 (PZT) and its derivatives, dominate the market owing to their superior energy storage properties, but their toxicity poses significant environmental and health risks, prompting urgent calls for lead-free alternatives [,,].

Among lead-free candidates, Bi0.5Na0.5TiO3 (BNT)-based ceramics have emerged as particularly promising due to their high intrinsic saturation polarization (Ps ~ 40–43 μC cm−2) stemming from the Bi3+ lone electron pair, coupled with a high Curie temperature (Tc ~ 320 °C), offering environmental compatibility and suitability for high-temperature operations [,]. However, pure BNT exhibits limitations including high remnant polarization (Pr ~ 38 μC cm−2) [], large coercive field (Ec ~ 70–73 kV cm−1) [], and defects from Bi/Na volatility during sintering, which compromise breakdown strength (Eb ~ 60–100 kV cm−1) and energy storage efficiency (η ~ 50%) []. To address these challenges, extensive strategies—such as A or/and B-site doping [,,,,,], binary/ternary solid solutions [,,,,], and microstructural engineering [,,]—have been employed to induce relaxor ferroelectric (RFE) or relaxor antiferroelectric (RAFE) behavior [], characterized by slim polarization-electric field (P-E) hysteresis loops, reduced Pr, and enhanced Eb, thereby achieving recoverable energy densities (Wrec) up to 7–12 J cm−3 in bulk ceramics with η > 85–95% []. Additionally, multilayer ceramic capacitor (MLCC) architectures offer enhanced breakdown strength and energy density through interface engineering and optimized layer design []. Despite progress in BNT-based energy storage ceramics, existing approaches face key limitations. Systems relying solely on A-site modifications often achieve loop slimming but struggle with leakage and limited breakdown strength at moderate fields. Conversely, single B-site substitution strategies (using Ta or Al independently) either excel at high-field robustness but sacrifice polarization difference, or enhance loop characteristics but introduce charge compensation challenges. Furthermore, most high-performance systems reported to date require impractically high operating fields (600–800 kV cm−1), limiting their applicability in real-world pulsed power devices.

A/B-site co-modification represents a synergistic strategy in BNT ceramics [,,], coupling A-site disorder (e.g., Ba2+/Sr2+/K2+/La3+ replacing Bi3+/Na+) with B-site octahedral tuning to push the lattice toward an ergodic/non-ergodic relaxor or RAFE state, maximizing ΔP = Pmax − Pr while minimizing losses and boosting Eb through refined microstructure and defect reduction [,]. On the A-site, tolerance-factor adjustment and random fields suppress long-range R3c order and lower Pr/Ec []; the B-site then sets the loop shape and leakage via substitutions such as Sn4+, Zr4+, Nb5+, Ta5+, Mg2+, Cu2+, Ni2+, or complex ions like [Nb0.5Al0.5]4+ [,]. In particular, Al3+ substitution (direct Al→Ti or via BiAlO3/BaAl0.5Nb0.5O3) introduces strong compositional disorder that slims P-E loops and promotes relaxor/AFE-like behavior [,]. Because Al3+ is acceptor-type, it should be paired with donor co-dopants (e.g., Nb5+ [,,]) or oxygen-vacancy control to avoid leakage []. By contrast, Ta5+ (donor) on the Ti site and Ta-bearing complex perovskites reduces oxygen vacancies (VO) [], raises electrical homogeneity and Eb [], and stabilizes double/relaxor loops with lower Pr, which often translates to higher Wrec and efficiency at large fields, exemplified by (1 − x)[0.90NaNbO3 − 0.10Bi(Mg0.5Ta0.5)O3] − x(Bi0.5Na0.5)0.7Sr0.3TiO3 (x = 0.25) yielding Wrec = 8 J cm−3 and η = 90.4% at Eb = 800 kV cm−1, highlighting thermal stability (20 to 200 °C) and fast discharge (∼32 ns) []. It is speculated that, A-site (Sr/Ba) + B-site (Al + Nb or Ta) pairs are high-yield recipes. Al-centered routes excel at loop slimming and large ΔP, while Ta-centered routes excel at leakage suppression and high-field robustness—both benefiting further from microstructural densification, sub-micron grains, and core–shell/blocking-layer architectures, positioning co-modified BNT as promising for lead-free pulsed power applications in electric vehicles, aerospace, and renewable energy storage.

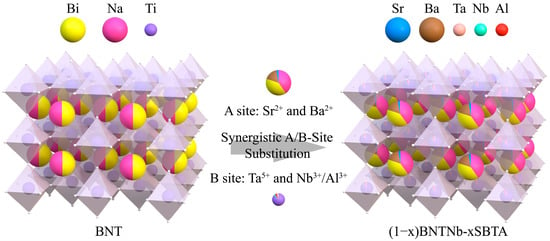

In this work, we address these challenges through a novel quaternary lead-free relaxor ferroelectric system as shown in Scheme 1: (1 − x)Bi0.5Na0.5Ti0.97Nb0.03O3-xSr0.85Ba0.15Ta0.5+0.02xAl0.5−0.02xO3 (abbreviated as (1 − x)BNTNb-xSBTA, x = 0, 0.05, 0.1, 0.15, 0.2). In this notation, BNTNb denotes Nb-modified Bi0.5Na0.5TiO3 (Bi0.5Na0.5Ti0.97Nb0.03O3), and SBTA denotes the complex perovskite Sr0.85Ba0.15Ta0.5+0.02xAl0.5−0.02xO3, which introduces Sr2+/Ba2+ on the A-site and Ta5+/Al3+ on the B-site. The novelty of this composition lies in three synergistic design strategies. First, we employ Nb-modified BNT as the base matrix to establish initial relaxor characteristics and donor-type doping for oxygen vacancy suppression. Second, we introduce a complex perovskite end-member (SBTA) featuring dual A-site cations (Sr2+/Ba2+) that adjust the tolerance factor and create random local fields to promote ergodic relaxor behavior, combined with a variable-stoichiometry B-site pair (Ta5+/Al3+) that simultaneously induces strong compositional disorder for loop slimming while maintaining donor-acceptor charge balance to prevent leakage. Third, this multi-cation substitution strategy naturally drives grain refinement through solute drag mechanisms, increasing grain boundary density to enhance breakdown strength without requiring additional processing steps. This integrated approach combines the complementary advantages of Al-centered routes (excellent loop slimming and large polarization difference) with Ta-centered strategies (superior leakage suppression and high-field robustness) in a single system, which has not been systematically explored in BNT-based ceramics. The Nb concentration of 3 mol% in the BNT matrix was selected to provide optimal donor doping within established solubility limits [], reducing oxygen vacancy concentration while enhancing breakdown strength. The SBTA end-member employs an Sr:Ba ratio of 0.85:0.15 to balance relaxor behavior and phase stability, combined with a coupled Ta:Al variation (Ta0.5+0.02xAl0.5−0.02x) that synergistically integrates donor doping effects with relaxor-promoting disorder []. Through comprehensive structural, dielectric, and ferroelectric characterization, we demonstrate that the optimized composition achieves high energy storage density (Wrec = 3.357 J cm−3) with exceptional efficiency (η = 90.5%) at moderate and practically accessible fields (240 kV cm−1), alongside robust thermal stability (25–175 °C), frequency independence (0.1–200 Hz), fatigue resistance (106 cycles), and ultrafast discharge capability (approximately 26 ns). These results establish a viable pathway for high-performance lead-free dielectric capacitors in practical pulsed power applications.

Scheme 1.

Schematic representation of the crystal structures illustrating synergistic A-site and B-site substitution in the (1 − x)BNTNb-xSBTA solid solution system.

2. Materials and Methods

2.1. Sample Preparation

(1 − x)Bi0.5Na0.5Ti0.97Nb0.03O3-xSr0.85Ba0.15Ta0.5+0.02xAl0.5−0.02xO3 (x = 0, 0.05, 0.1, 0.15, 0.2) ceramics were synthesized using the conventional solid-state reaction method. High-purity starting materials, including Bi2O3 (99%), Na2CO3 (99.8%), TiO2 (99%), Nb2O5 (99.5%), SrCO3 (99%), BaCO3 (99.8%), Ta2O5 (99.5%), and Al2O3 (99%) (Aladdin Biochemistry and Technology Co., Ltd., Shanghai, China), were dried at 80 °C for 12 h prior to use. The reagents were weighed in stoichiometric proportions, mixed thoroughly, and subjected to primary ball milling (Nanjing Nanda Instrument Co., Ltd., Nanjing, China) in nylon jars at 400 rpm for 12 h, followed by drying at 80 °C for 4 h. The resulting powders were then calcined in a muffle furnace (KSL-1400X, Hefei Kejing, Hefei, China) at 800 °C for 4 h. Subsequently, the calcined powders underwent secondary ball milling at 400 rpm for 12 h and were dried again at 80 °C for 4 h. For pellet formation, 0.2 g of dried powder was weighed and uniaxially pressed manually in a 10 mm diameter die to obtain green compacts. These compacts were encased in rubber sleeves, evacuated, and densified via cold isostatic pressing at 250 MPa for 10 min. Finally, the green bodies corresponding to x = 0, 0.05, 0.1, and 0.15 were sintered at 1070 °C for 3 h in air. This sintering temperature was selected based on optimization trials and guidance for BNT-based ceramics with A-site substitutions, which demonstrated that temperatures in the 1050–1100 °C range effectively balance densification with minimized Bi/Na volatilization and controlled grain growth [,]. For x = 0.2, the samples exhibited poor densification and were excluded from subsequent characterizations. The sintered pellets were polished to a thickness of 0.1–0.2 mm, and silver electrodes were applied on both polished surfaces for electrical measurements.

2.2. Characterization Methods

The crystal structures of the ceramic samples were characterized using an X-ray diffractometer (XRD; D8 Advance, Bruker, Berlin, Germany). The microstructures were investigated via field-emission scanning electron microscopy (FE-SEM; Apero HiVac, Thermo Fisher Scientific, Waltham, MA, USA). The bulk densities of the sintered ceramics were measured using the Archimedes method in distilled water at room temperature. Laser confocal micro-Raman spectroscopy (Renishaw inVia, Wotton-under-Edge, UK) was employed to gain deeper insights into the vibrational modes and local structural evolution of the materials. Ferroelectric properties, including P-E hysteresis loops measured at 1 Hz, as well as temperature, frequency, and fatigue stability, were evaluated using a ferroelectric analyzer (TF Analyzer 3000, aixACCT, Aachen, Germany). Dielectric properties, including the frequency- and temperature-dependent dielectric constants, were determined with a dielectric temperature spectrometer (CH400-100-P8, Beijing Sinocera Functional Material Co., Ltd., Beijing, China). Charge–discharge performance was analyzed using a dielectric charge–discharge system (CFD-300, Beijing Sinocera Functional Material Co., Ltd., Beijing, China).

2.3. Energy Storage Parameter Calculations

2.3.1. Total Energy Storage Density (Wtot)

The total electrostatic energy density stored during charging is calculated as

where E(P) is the electric field as a function of polarization during the charging branch of the unipolar loop, and Pmax is the maximum polarization reached under the applied field.

2.3.2. Recoverable Energy Storage Density (Wrec)

The recoverable (dischargeable) portion of the stored energy is obtained from the unloading branch of the same unipolar loop and is given by

where Pr is the remanent polarization after the external field is removed. Physically, Wrec corresponds to the area under the discharge curve between Pmax and Pr.

2.3.3. Energy Storage Efficiency (η)

The energy storage efficiency, which reflects dielectric loss and hysteresis loss, is defined as

2.3.4. Breakdown Electric Field (Eb)

For each composition, the breakdown electric field was defined as the highest field that could be applied without electrical failure (catastrophic increase in leakage current or dielectric puncture).

2.3.5. Pulsed Charge–Discharge Analysis

For the pulsed discharge tests, the discharged energy density Wd and the power-related quantities were extracted from the transient voltage–current waveforms. The discharged energy density is obtained from

where V(t) and I(t) are the instantaneous voltage and current during discharge, Vsamp is the sample volume, and t0 − tf spans the main discharge pulse. The peak power density (PD) is estimated from

The reported charge density (CD) corresponds to the maximum current per electrode area, and the quoted discharge time corresponds to the interval required to deliver the majority of Wd.

3. Results

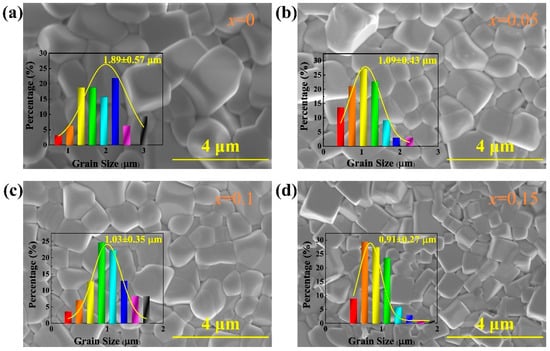

Figure 1 shows the scanning electron microscopy (SEM) images of (1 − x)BNTNb- xSBTA ceramics sintered at 1070 °C for x = 0, 0.05, 0.10, and 0.15, respectively. All samples exhibit dense microstructures with well-defined grain boundaries, minimal porosity, and no secondary phases. Statistical analysis (inset bar charts) reveals that average grain size decreases systematically with increasing SBTA content: 1.89 μm (x = 0), 1.09 μm (x = 0.05), 1.03 μm (x = 0.10), and 0.91 μm (x = 0.15). This grain refinement provides indirect evidence for oxygen vacancy suppression [] and enhances breakdown strength by increasing grain boundary density, which acts as a scattering center for charge carriers and improves insulation resistance [].

Figure 1.

SEM images of the (1 − x)BNTNb-xSBTA ceramics with (a) x = 0, (b) x = 0.05, (c) x = 0.1, (d) x = 0.15, insets show the average grain size and the grain size distribution.

To quantitatively assess the densification, bulk density measurements were conducted using the Archimedes method. Table 1 summarizes the bulk density, average grain size, and breakdown strength for all compositions. The bulk density increases systematically from 5.68 g cm−3 (x = 0) to 5.86 g cm−3 (x = 0.15), demonstrating progressive densification with increasing SBTA content. This trend correlates directly with the observed grain refinement and enhancement in breakdown strength. The systematic increase in bulk density with SBTA doping demonstrates that the addition of SBTA not only refines the grain size but also promotes better densification of the ceramic matrix. With increasing SBTA doping content, the synergistic combination of enhanced bulk density and reduced grain size creates a microstructure with higher grain boundary density. These grain boundaries serve as effective scattering centers for charge carriers, thereby suppressing oxygen vacancy formation, reducing leakage current pathways, and increasing the breakdown strength. This microstructural optimization through SBTA incorporation improves the overall insulation resistance and energy storage performance of the ceramics, consistent with mechanisms observed in other BNT-based systems with refined and densified microstructures [].

Table 1.

The effect of composition (x) on the bulk density, average grain size, and breakdown strength.

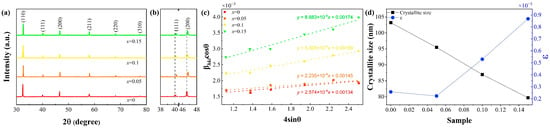

From the X-ray diffraction (XRD) patterns (Figure 2a) of (1 − x)BNTNb-xSBTA ceramics recorded at room temperature in the 2θ range of 30–80°, all diffraction peaks can be indexed to a pure perovskite structure, with no detectable secondary phases across the investigated compositions (x = 0–0.15). This confirms the complete solid solubility of the SBTA component within the BNTNb lattice, forming a homogeneous solid solution without phase segregation, consistent with the formation of perovskite-based relaxor ferroelectrics in BNT systems []. A magnified view of the (111) and (200) diffraction peaks in the 2θ range of 38–48° is presented in Figure 2b. With increasing SBTA doping content, the evolution of these characteristic peaks reflects competing effects from simultaneous A-site and B-site substitutions. At the A-site, Bi3+ (1.03 Å, CN = 8) and Na+ (1.18 Å, CN = 8) are partially replaced by Sr2+ (1.26 Å, CN = 8) and Ba2+ (1.42 Å, CN = 8), both possessing larger ionic radii, which tends to expand the lattice and shift diffraction peaks toward lower 2θ angles. Conversely, at the B-site, the average ionic radius of [Ti0.97Nb0.03]4+ (approximately 0.606 Å) in the BNTNb matrix is replaced by the smaller [Ta0.5+0.02xAl0.5−0.02x]4+ (approximately 0.588 Å), driven by the incorporation of Ta5+ (0.64 Å, CN = 6) and Al3+ (0.535 Å, CN = 6), which contracts the lattice and shifts peaks toward higher 2θ angles. The non-monotonic lattice parameter evolution observed in the diffraction patterns results from the delicate balance between these two counteracting mechanisms, with the B-site contraction effect dominating at low SBTA concentrations and the A-site expansion effect becoming more pronounced at higher concentrations. Such lattice shrinkage disrupts long-range ferroelectric order, promoting the formation of polar nanoregions (PNRs) and potentially enhancing the Eb by improving insulation and reducing domain wall mobility [,,,,,]. Williamson-Hall analysis was conducted to quantitatively evaluate microstructural changes using the equation βcosθ = kλ/D + 4εsinθ. where β represents the corrected full width at half maximum, θ is the Bragg angle (in radians), k is the Scherrer constant (0.9), λ is the X-ray wavelength (1.5406 Å), D is the volume-weighted crystallite size, and ε denotes the lattice microstrain. As illustrated in Figure 2c,d, crystallite size decreases systematically from 103 nm at x = 0 to 80 nm at x = 0.15, while lattice microstrain increases from 0.2574 × 10−3 to 0.8683 × 10−3. The grain refinement results from solute drag and Zener pinning effects induced by SBTA incorporation, which inhibit grain growth during sintering. The substantial microstrain enhancement originates from ionic radius mismatch at both A-sites (Sr2+/Ba2+ versus Bi3+/Na+) and B-sites (Ta5+/Al3+ versus Ti4+/Nb5+), along with coherency strain at phase interfaces. These microstructural modifications contribute synergistically to enhanced breakdown strength and relaxor ferroelectric characteristics favorable for energy storage performance. Furthermore, energy-dispersive X-ray spectroscopy (EDS) mapping (Figure S1) reveals a homogeneous distribution of all constituent elements in the x = 0.1 ceramic samples. This uniformity indicates that Sr2+, Ba2+, Ta5+, Al3+ and Nb5+ ions have been successfully incorporated into the crystal lattice, substituting for host cations at the A- and B-sites, which is consistent with the phase purity and structural integrity confirmed by XRD analysis.

Figure 2.

(a) XRD patterns of (1 − x)BNTNb-xSBTA ceramics with different compositions, (b) Magnified views of the (111) and (200) characteristic peaks, (c) Williamson-Hall plots of βcosθ versus 4sinθ for (1 − x)BNTNb-xSBTA ceramics with varying SBTA content (x = 0, 0.05, 0.1, 0.15), (d) Compositional dependence of crystallite size (black squares, left axis) and lattice microstrain (blue circles, right axis) extracted from Williamson-Hall analysis for (1 − x)BNTNb-xSBTA ceramics.

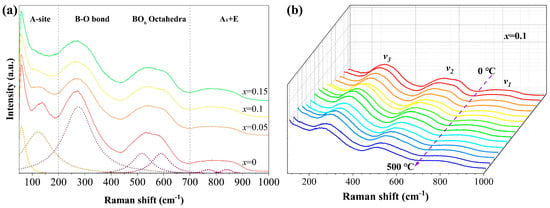

To gain a deeper understanding of the vibrational modes and local structural evolution of (1 − x)BNTNb-xSBTA ceramics, Raman spectra of ceramics with different components were acquired at room temperature over the wavenumber range of 50–1000 cm−1. The low-wavenumber region (<200 cm−1) corresponds to vibrational modes involving A-site cations (Bi3+, Na+, Sr2+, and Ba2+), while the intermediate range (200–450 cm−1) is dominated by B–O bending modes. The high-wavenumber region (450–700 cm−1) arises from stretching vibrations of the BO6 octahedra, and peaks above 700 cm−1 reflect overlapping A1 + E longitudinal optical (LO) modes []. With increasing SBTA doping content (x = 0–0.15), the peak intensity near 135 cm−1 gradually disappears, attributable to restricted displacements of Bi3+ and Na+ ions at the A-site due to the incorporation of larger Sr2+ and Ba2+ cations []. Similarly, the peak at ~270 cm−1, associated with B-O bending, exhibits smoothing, indicative of enhanced cation disorder where Bi3+, Na+, Sr2+, and Ba2+ randomly occupy A-sites, while Ti4+, Nb5+, Ta5+, and Al3+ substitute at B-sites []. The broadening and flattening of the ~570 cm−1 peak, linked to BO6 octahedral stretching, further signify local distortions induced by SBTA doping. These spectral evolutions underscore the development of dielectric relaxation, characterized by disordered local structures and PNRs, which influence the ferroelectric and dielectric properties of the ceramics. Figure 3b illustrates the temperature-dependent Raman spectra for the x = 0.1 composition (0.9BNTN–0.1SBTA) from 0 to 500 °C, revealing minimal shifts or intensity changes across the measured range. The temperature insensitivity of the spectra indicates the absence of macroscopic phase transitions, a hallmark of relaxor ferroelectrics. This behavior is primarily governed by the persistence of dynamic PNRs,—thermally fluctuating nanoscale polar clusters that reorient reversibly without coalescing into macroscopic domains even at elevated temperatures beyond the dielectric maximum temperature (Tm). Such nanoscale heterogeneity contributes to the observed enhanced dielectric stability in the x = 0.1 composition, suppressing long-range ferroelectric ordering and promoting slim P-E hysteresis loops essential for high energy storage efficiency.

Figure 3.

(a) Raman spectra of (1 − x)BNTNb-xSBTA ceramics with different compositions, (b) Temperature-dependent evolution of Raman peaks for the x = 0.1 composition in the range of 0 to 500 °C.

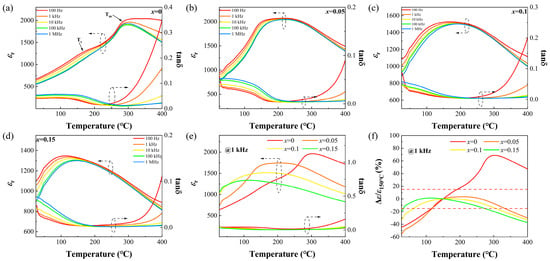

To investigate the dielectric behavior and its evolution with SBTA doping, the temperature-dependent dielectric permittivity (εr) and dielectric loss tangent (tan δ) for (1 − x)BNTNb-xSBTA ceramics with different compositions were measured over a frequency range of 0.1 kHz to 1 MHz from 25 to 400 °C (Figure 4a–d). Each composition displays two characteristic dielectric anomalies: a shoulder peak at Ts (associated with the onset of thermal evolution of PNRs, where nanoscale polar clusters begin to grow and interact more strongly due to cooling-induced correlations) and a maximum peak at Tm (reflecting the diffuse phase transition). These anomalies are consistent with the thermal dynamics of PNRs in rhombohedral R3c and tetragonal P4bm structures typical of BNT-based relaxor ferroelectrics [,]. Moreover, both Ts and Tm exhibit pronounced frequency dispersion, with peaks shifting to higher temperatures and broadening as frequency increases, confirming the relaxor ferroelectric nature of the ceramics.

Figure 4.

(a–d) Temperature-dependent dielectric spectra of (1 − x)BNTNb-xSBTA ceramics with different compositions, (e) Dielectric spectra of (1 − x)BNTNb-xSBTA ceramics with different compositions measured at 1 kHz, (f) Thermal stability of the dielectric constant (εr) of (1 − x)BNTNb-xSBTA ceramics.

As shown in Figure 4e, increasing SBTA doping content leads to a substantial reduction in εr and a shift in the dielectric peaks toward lower temperatures. At 1 kHz, the maximum εr decreases from ~1962 for the undoped BNTNb (x = 0) to ~1516 for the x = 0.1 composition, reflecting suppressed long-range ferroelectric order and enhanced local disorder from multi-cation substitution at A- and B-sites. Concurrently, tan δ decreases monotonically with higher x, indicating reduced electrical conductivity and hysteresis losses, which favors improved energy storage efficiency (η). To evaluate thermal stability, the temperature coefficient of capacitance (TCC) was calculated relative to 150 °C using the formula [,,]:

where and are the dielectric constants at a certain temperature and benchmark temperature, respectively. Figure 4f demonstrates progressive improvement in TCC stability with increasing SBTA content. Notably, the x = 0.1 composition maintains a dielectric permittivity variation of Δεr/ε150°C ≤ ±15% over the broad range of 63–307 °C, underscoring the role of SBTA-induced PNRs in promoting diffuse phase transitions and enhancing temperature-insensitive dielectric response.

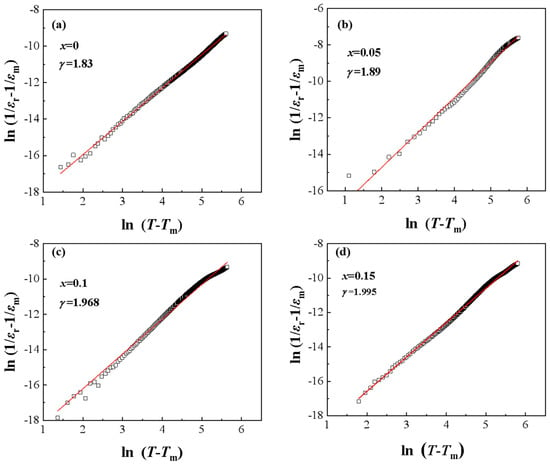

The degree of diffuseness in the phase transition of the ceramics was quantified using the modified Curie–Weiss law []:

where ε represents the dielectric constant at temperature T, εm is the maximum permittivity at the temperature Tm of the dielectric peak, C is the Curie constant, and γ is the diffuseness parameter ranging from 1 (normal ferroelectric behavior) to 2 (ideal relaxor ferroelectric with complete diffuseness). Values of γ closer to 2 indicate stronger relaxor characteristics, associated with the dynamic evolution of PNRs (where these polar clusters fluctuate and grow in size or correlation length as temperature decreases, suppressing long-range ferroelectric order) and suppressed long-range ferroelectric order. Figure 5a–d displays the modified Curie–Weiss plots for (1 − x)BNTNb-xSBTA ceramics (x = 0, 0.05, 0.10, 0.15), fitted to extract the γ values. The diffuseness coefficients increase progressively with SBTA doping, from 1.83 (x = 0) to 1.89 (x = 0.05), 1.968 (x = 0.10), and 1.995 (x = 0.15). This enhancement of γ reflects the increasing degree of structural disorder induced by multi-cation substitution at A- and B-sites, promoting nanoscale heterogeneity and PNR formation. Notably, the x = 0.10 composition exhibits a γ of 1.968, signifying pronounced relaxor behavior that contributes to slim P-E hysteresis loops, reduced remnant polarization, and improved energy storage efficiency by minimizing hysteresis losses.

Figure 5.

(a–d) Linear fitting curves of ln(1/εr − 1/εm) versus ln(T − Tₘ) for (1 − x)BNTNb-xSBTA ceramics with different compositions.

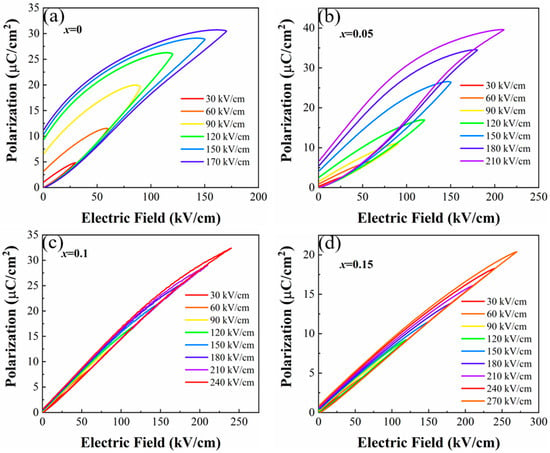

To assess the ferroelectric response and energy storage capabilities under varying SBTA doping, unipolar P-E hysteresis loops for (1 − x)BNTNb-xSBTA ceramics were measured at room temperature and 1 Hz as a function of the applied electric field up to breakdown (Figure 6a–d). With increasing SBTA doping content, the loops progressively narrow, indicative of reduced hysteresis and enhanced relaxor ferroelectric characteristics. This slimming arises from the disruption of long-range ferroelectric domains into dynamic PNRs (nanoscale polar entities that fluctuate thermally and align reversibly under electric fields), facilitated by B-site cation migration under the electric field. The substitution of Ti4+ and Nb5+ by Ta5+ and Al3+ generates random local fields due to charge imbalances and ionic radius mismatches, further promoting nanoscale heterogeneity and PNR formation. These PNRs enable reversible transitions to long-range order under applied fields, yielding larger maximum polarization with minimal remnant polarization and energy loss. The systematic enhancement of breakdown strength with SBTA doping (Table 2) can be ascribed to two synergistic effects: suppression of oxygen vacancy formation, which mitigates defect-induced conductivity and improves insulation resistance, and progressive grain refinement, leading to a higher density of grain boundaries that scatter charge carriers and impede leakage currents. To evaluate the insulation properties and charge transport behavior of (1 − x)BNTNb-xSBTA ceramics, DC leakage current density measurements were conducted at room temperature across electric fields ranging from 0 to 100 kV/cm. As shown in Figure S1 (Supplementary Materials), the leakage current density reduces from approximately 1.7 × 10−7 A cm−2 for the undoped composition (x = 0) to approximately 5.2 × 10−8 A cm−2 for the optimized composition (x = 0.1), representing nearly an order of magnitude suppression. This progressive reduction provides direct experimental evidence for the effectiveness of our multi-cation substitution strategy in suppressing oxygen vacancy formation and improving insulation resistance.

Figure 6.

(a–d) Unipolar P-E loops of (1 − x)BNTNb-xSBTA ceramics at 1 Hz under varying electric fields.

Table 2.

Summary of energy storage performance parameters for (1 − x)BNTNb-xSBTA ceramics at breakdown electric field.

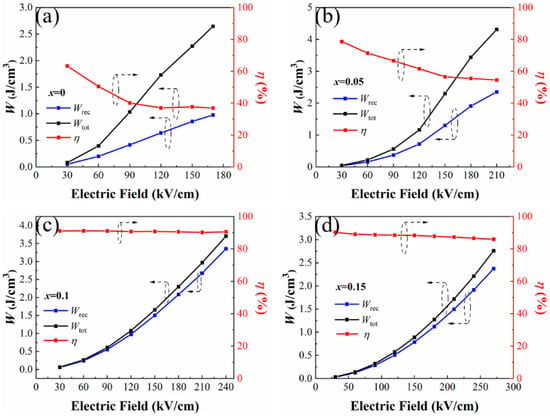

To evaluate the energy storage performance and its evolution with SBTA doping across applied fields, Figure 7 depicts the electric field dependence of recoverable energy storage density (Wrec), total energy storage density (Wtot), and energy storage efficiency (η) for (1 − x)BNTNb-xSBTA ceramics at room temperature. With increasing SBTA doping content, both Wrec and Wtot exhibit monotonic enhancement across the applied field range, attributed to the progressively larger polarization difference and elevated breakdown strength enabled by refined grains and suppressed defects. Notably, η shows enhanced field stability in higher SBTA compositions, declining for x = 0 and 0.05 due to hysteresis from long-range order, but plateauing above 80% for x = 0.10 and 0.15 via dynamic PNRs that reduce dissipation through minimized domain motion and stronger relaxor traits. This evolution underscores the role of SBTA-induced nanoscale heterogeneity in optimizing the overall energy storage performance, facilitating slim P-E loops and low-loss behavior essential for practical dielectric capacitor applications.

Figure 7.

(a–d) Variations in recoverable energy density (Wrec), total energy density (Wtot), and energy efficiency (η) with electric field strength for (1 − x)BNTNb-xSBTA ceramics at room temperature.

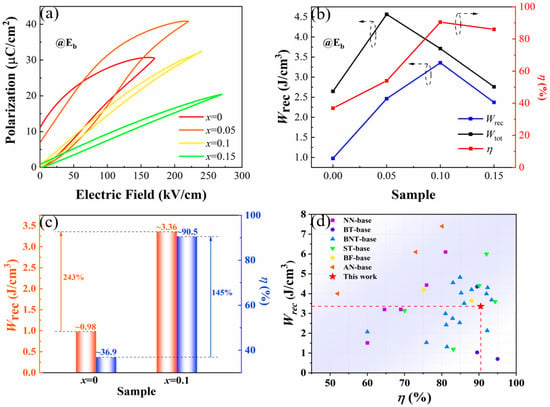

To quantify the compositional optimization of energy storage performance under maximum applied fields, Figure 8a–d summarizes the unipolar P-E hysteresis loops and key metrics for (1 − x)BNTNb-xSBTA ceramics evaluated at their respective breakdown strengths, with detailed numerical results presented in Table 2. As shown in Figure 8a, the loops narrow progressively with increasing SBTA content, reflecting diminished hysteresis due to the transition from long-range ferroelectric domains to dynamic PNRs, which suppress remnant polarization and enhance the polarization difference. The composition-dependent trends (Figure 8b and Table 2) reveal that energy storage performance initially rises with x before peaking at x = 0.10, where the balanced local disorder, grain refinement, and defect suppression minimize energy loss while maximizing recoverable energy density and efficiency. Figure 8c highlights the substantial enhancements relative to the undoped sample, with the x = 0.10 composition exhibiting a 243% increase in Wrec and 145% improvement in η, underscoring the efficacy of SBTA doping in promoting relaxor behavior and insulation. For contextual benchmarking, Figure 8d compares the performance of this work with reported lead-free ceramics across BNT-, ST-, NN-, and AN-based systems, demonstrating that the x = 0.10 composition outperforms the majority of prior studies, particularly in achieving high efficiency under moderate fields, attributable to the synergistic nanoscale heterogeneity and microstructural tailoring that yield slim P-E loops and robust breakdown strength. Specifically, the superior performance relative to other BNT-based ceramics can be attributed to its refined grain structure and the effective suppression of deleterious defects. The pronounced grain refinement achieved in this composition yields a higher density of grain boundaries, which act as insulating barriers that scatter charge carriers and inhibit domain wall motion. This microstructural feature elevates the overall insulation resistance and helps maintain slim hysteresis loops by limiting extrinsic energy losses. Concurrently, the aliovalent co-doping with Ta5+ and Al3+ minimizes oxygen vacancy formation through internal charge compensation, thereby reducing defect-induced leakage currents. The lower concentration of oxygen vacancies bolsters the breakdown strength and ensures that high efficiency is retained under moderate electric fields. Together, these structural (grain boundary engineering) and electrical (defect mitigation) mechanisms synergistically explain why the x = 0.10 composition outperforms conventional BNT-based systems in energy storage efficiency and reliability.

Figure 8.

(a) Unipolar P-E loops of (1 − x)BNTNb-xSBTA ceramics at the breakdown electric field (Eb) as a function of x content. (b) Composition-dependent recoverable energy density (Wrec), total energy density (Wtot), and energy efficiency (η) at Eb. (c) Comparison of energy storage performance between x = 0 and x = 0.1 ceramics. (d) Performance comparison between the ceramics in this work and previously reported lead-free ceramics.

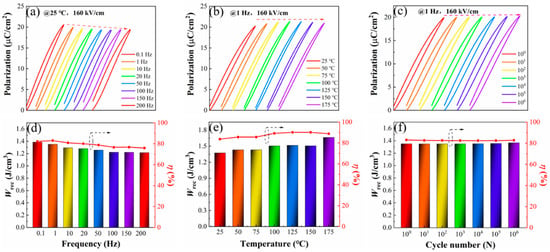

In practical applications, operational stability under varying frequency, temperature, and cycling conditions is paramount for dielectric capacitors []. To assess these attributes, the 0.9BNTNb-0.1SBTA ceramics were evaluated under a fixed electric field of 160 kV cm−1, with unipolar P-E hysteresis loops and derived energy storage metrics (Wrec, Wtot, and η) presented in Figure 9a–f. Figure 9a,d reveal the frequency dependence from 0.1 to 200 Hz at 25 °C; the loops remain slender with minimal broadening, yielding Wrec = 1.30 ± 0.09 J cm−3 and η = 79 ± 3%. This frequency insensitivity stems from the relaxor nature of the material, where the dynamic PNRs (induced by SBTA multi-cation substitution) respond rapidly and reversibly to alternating fields, suppressing frequency-induced domain pinning and associated energy dissipation that would otherwise arise from sluggish domain wall motion in conventional ferroelectrics. Temperature dependence from 25 to 175 °C at 1 Hz, shown in Figure 9b,e, demonstrates robust loop integrity, with Wrec = 1.37 ± 0.15 J cm−3 and η = 87 ± 3%, attributed to the thermal persistence of nanoscale heterogeneity; specifically, the PNRs maintain short-range polar order without coalescing into long-range ferroelectric domains even at elevated temperatures, thereby inhibiting sharp phase transitions and ensuring a diffuse, temperature-stable dielectric response. Fatigue resistance over 106 cycles at 1 Hz and 25 °C is depicted in Figure 9c,f, where the P-E loops exhibit negligible degradation, maintaining Wrec = 1.36 ± 0.10 J cm−3 and η = 83 ± 0.01%; this endurance reflects the fatigue-resistant characteristics of the PNRs, which facilitate reversible polarization switching with minimal structural degradation or charge trapping, as opposed to the irreversible domain reorientation and defect accumulation typical in non-relaxor systems. Overall, the variations in Wrec and η across these conditions remain within ±10–15%, highlighting the superior thermal, frequency, and cycling stability of the 0.9BNTNb-0.1SBTA composition, which arises from SBTA-induced structural disorder and enhanced insulation, positioning it as a promising candidate for reliable high-temperature capacitor applications.

Figure 9.

Energy storage stability of 0.9BNTNb-0.1SBTA ceramics under various conditions. (a–c) Evolution of P-E loops with (a) frequency, (b) temperature, and (c) cycling number, respectively. (d–f) Corresponding variations in recoverable energy density (Wrec) and energy efficiency (η) with (d) frequency, (e) temperature, and (f) cycling number, respectively.

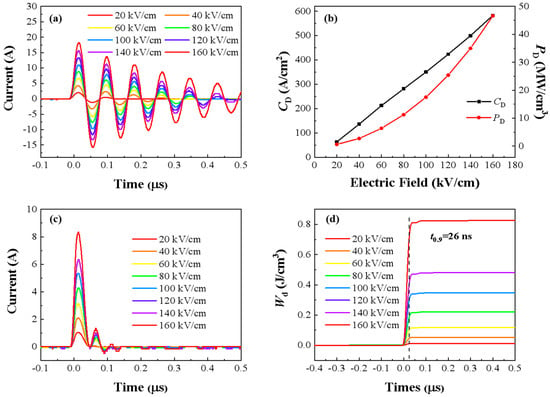

To evaluate the practical charge–discharge capabilities of the 0.9BNTNb-0.1SBTA ceramics, pulsed discharge tests were conducted under both underdamped and overdamped conditions across electric fields from 20 to 160 kV cm−1, as detailed in Figure 10. In the underdamped regime (Figure 10a), the discharge waveforms maintain stable oscillatory profiles with no distortion, and the peak current (Imax) increases from 4.23 to 18.3 A as the field rises, corresponding to a charge density (CD) enhancement from 63.7 A cm−2 to 582 A cm−2 and a power density (PD) rise from 0.6 to 46.6 MW cm−3 (Figure 10b). This field-dependent scaling reflects the efficient polarization reversal facilitated by dynamic PNRs, which enable rapid energy release with minimal losses in relaxor ferroelectrics. For the overdamped configuration (Figure 10c), the waveforms exhibit consistent pulse shapes, with Imax similarly increasing with field strength, and the discharged energy density (Wd) progressing from 0.013 to 0.826 J cm−3 (Figure 10d). Notably, the maximum Wd of 0.826 J cm−3 is released at 90% efficiency within ~26 ns, underscoring the ultrafast discharge kinetics driven by low hysteresis and high insulation resistance. These results demonstrate the potential of 0.9BNTNb-0.1SBTA ceramics for high-power pulsed applications, where sub-microsecond response times and power densities align with requirements for advanced electronic systems [].

Figure 10.

Energy storage and discharge behavior of 0.9BNTNb-0.1SBTA ceramics under electric fields ranging from 20 to 160 kV cm−1. (a) Underdamped pulsed charge–discharge current curves. (b) Charge density (CD) and power density (PD) values. (c) Overdamped pulsed charge–discharge waveforms. (d) Variation in discharged energy density (Wd) with time.

4. Conclusions

This work establishes a novel compositional design pathway for high-performance lead-free energy storage ceramics through synergistic A/B-site substitution in (1 − x)Bi0.5Na0.5Ti0.97Nb0.03O3-xSr0.85Ba0.15Ta0.5+0.02xAl0.5−0.02xO3. The fundamental innovation lies in the strategic integration of three complementary modification mechanisms within a single quaternary system, an approach not previously explored in BNT-based materials. Specifically, the composition combines Nb-modified BNT as a base matrix with a complex perovskite end-member featuring dual A-site cations (Sr2+/Ba2+) and a variable-stoichiometry B-site pair (Ta5+/Al3+). This design synergistically merges the loop-slimming and high-polarization advantages characteristic of Al-centered modification routes with the leakage-suppression and high-field robustness typically achieved through Ta-centered strategies, while simultaneously employing multi-cation substitution to naturally drive microstructural refinement through solute drag mechanisms without requiring additional processing steps.

Structural characterization confirmed the formation of a homogeneous perovskite solid solution with progressive lattice contraction and enhanced microstrain, reflecting the successful incorporation of multi-scale ionic disorder at both A- and B-sites. This compositional disorder disrupts long-range ferroelectric ordering, promoting the formation of dynamic polar nanoregions that yield slim P-E hysteresis loops with minimized remnant polarization and reduced energy losses. The synergistic substitution strategy also suppresses oxygen vacancy formation through internal charge compensation between donor (Nb5+, Ta5+) and acceptor (Al3+) dopants while refining grain size to enhance breakdown strength via increased grain boundary scattering of charge carriers. These structural and electrical modifications work in concert to maximize the polarization difference while elevating the breakdown field, establishing optimal conditions for high-efficiency energy storage.

The optimized composition at x = 0.10 achieved a recoverable energy density of 3.357 J cm−3 with 90.5% efficiency at a moderate and practically accessible breakdown field of 240 kV cm−1, representing a 243% increase in Wrec and 145% improvement in η relative to the undoped sample. Critically, these metrics were obtained at electric fields substantially lower than the 600–800 kV cm−1 typically required in reported high-performance systems, demonstrating a key practical advantage stemming directly from the synergistic A/B-site modification approach. The material exhibited robust operational stability with minimal performance variation across frequency (0.1–200 Hz), temperature (25–175 °C), and cycling (106 cycles) tests, attributed to the thermal persistence of polar nanoregions that maintain diffuse dielectric response without macroscopic phase transitions. Charge–discharge evaluations further validated practical viability, delivering 0.826 J cm−3 discharged energy density at 90% efficiency within approximately 26 nanoseconds alongside charge and power densities of 582 A cm−2 and 46.6 MW cm−3, respectively.

These results establish that synergistic A/B-site co-modification, combining tolerance-factor engineering, compositional disorder induction, and internal defect compensation within a single system, provides a superior design framework for lead-free dielectric capacitors. The demonstrated balance of high energy storage density, exceptional efficiency under moderate operating fields, and robust stability positions this material platform as a promising candidate for practical pulsed power applications in electric vehicles, aerospace systems, and renewable energy storage technologies.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ma18235259/s1, Figure S1. Enlarged SEM morphology and EDS mapping images of (1 − x)BNTNb-xSBTA (x = 0.1) ceramics. Figure S2. Leakage current density as a function of electric field for (1 − x)BNTNb-xSBTA ceramics with different compositions (x = 0, 0.05, 0.1, 0.15) measured at room temperature.

Author Contributions

Conceptualization, T.D. and C.L.; methodology, T.D. and C.L.; validation, W.Z., T.D. and C.L.; investigation, W.Z.; resources, W.Z.; data curation, W.Z., T.D. and C.L.; writing—original draft preparation, W.Z.; writing—review and editing, T.D. and C.L.; visualization, W.Z.; supervision, T.D. and C.L.; project administration, T.D. and C.L.; funding acquisition, T.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Basic Research Program of Shaanxi (Program No. 2024JC-YBMS-334); Fundamental Research Funds for the Central Universities (QTZX25116); Science Fund of Shandong Laboratory of Advanced Materials and Green Manufacturing at Yantai (AMGM2021A01).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for High-Energy Density Capacitors: Current Status and Future Perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef]

- Li, D.; Zeng, X.; Li, Z.; Shen, Z.-Y.; Hao, H.; Luo, W.; Wang, X.; Song, F.; Wang, Z.; Li, Y. Progress and perspectives in dielectric energy storage ceramics. J. Adv. Ceram. 2021, 10, 675–703. [Google Scholar] [CrossRef]

- Jayakrishnan, A.R.; Silva, J.P.B.; Kamakshi, K.; Dastan, D.; Annapureddy, V.; Pereira, M.; Sekhar, K.C. Are lead-free relaxor ferroelectric materials the most promising candidates for energy storage capacitors? Prog. Mater. Sci. 2023, 132, 101046. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, T.; Zhang, Q.; Ma, W.; Fan, P.; Salamon, D.; Zhang, S.-T.; Nan, B.; Tan, H.; Ye, Z.-G. A review on the development of lead-free ferroelectric energy-storage ceramics and multilayer capacitors. J. Mater. Chem. C 2020, 8, 16648–16667. [Google Scholar] [CrossRef]

- Zhao, P.; Cai, Z.; Wu, L.; Zhu, C.; Li, L.; Wang, X. Perspectives and challenges for lead-free energy-storage multilayer ceramic capacitors. J. Adv. Ceram. 2021, 10, 1153–1193. [Google Scholar] [CrossRef]

- Zhou, X.; Xue, G.; Luo, H.; Bowen, C.R.; Zhang, D. Phase structure and properties of sodium bismuth titanate lead-free piezoelectric ceramics. Prog. Mater. Sci. 2021, 122, 100836. [Google Scholar] [CrossRef]

- Pattipaka, S.; Lim, Y.; Son, Y.H.; Bae, Y.M.; Peddigari, M.; Hwang, G.-T. Ceramic-Based Dielectric Materials for Energy Storage Capacitor Applications. Materials 2024, 17, 2277. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Shen, Z.-Y.; Li, Z.; Luo, W.; Wang, X.; Wang, Z.; Song, F.; Li, Y. P-E hysteresis loop going slim in Ba0.3Sr0.7TiO3-modified Bi0.5Na0.5TiO3 ceramics for energy storage applications. J. Adv. Ceram. 2020, 9, 183–192. [Google Scholar] [CrossRef]

- Yan, F.; Huang, K.; Jiang, T.; Zhou, X.; Shi, Y.; Ge, G.; Shen, B.; Zhai, J. Significantly enhanced energy storage density and efficiency of BNT-based perovskite ceramics via A-site defect engineering. Energy Storage Mater. 2020, 30, 392–400. [Google Scholar] [CrossRef]

- Deng, T.; Liu, Z.; Hu, T.; Dai, K.; Hu, Z.; Wang, G. Excellent energy-storage performance in Bi0.5Na0.5TiO3-based lead-free composite ceramics via introducing pyrochlore phase Sm2Ti2O7. Chem. Eng. J. 2023, 465, 142992. [Google Scholar] [CrossRef]

- Zhang, A.; Jing, R.; Zhuang, M.; Hou, H.; Zhang, L.; Zhang, J.; Lu, X.; Yan, Y.; Du, H.; Jin, L. Nonstoichiometric effect of A-site complex ions on structural, dielectric, ferroelectric, and electrostrain properties of bismuth sodium titanate ceramics. Ceram. Int. 2021, 47, 32747–32755. [Google Scholar] [CrossRef]

- Han, F.; Deng, J.; Liu, X.; Yan, T.; Ren, S.; Ma, X.; Liu, S.; Peng, B.; Liu, L. High-temperature dielectric and relaxation behavior of Yb-doped Bi0.5Na0.5TiO3 ceramics. Ceram. Int. 2017, 43, 5564–5573. [Google Scholar] [CrossRef]

- Zhou, C.R.; Liu, X.Y. Effect of B-site substitution by (Ni1/3Nb2/3)4+ for Ti4+ on microstructure and piezoelectric properties in (Bi1/2Na1/2)TiO3 piezoelectric ceramics. J. Alloys Compd. 2008, 466, 563–567. [Google Scholar] [CrossRef]

- Qiao, Y.; Li, W.; Zhang, Y.; Jing, L.; Yang, X.; Gao, C.; Cao, W.; Fei, W. Ba and Mg co-doping to suppress high-temperature dielectric loss in lead-free Na0.5Bi0.5TiO3-based systems. J. Eur. Ceram. Soc. 2020, 40, 720–727. [Google Scholar] [CrossRef]

- Yan, F.; Zhou, X.; He, X.; Bai, H.; Wu, S.; Shen, B.; Zhai, J. Superior energy storage properties and excellent stability achieved in environment-friendly ferroelectrics via composition design strategy. Nano Energy 2020, 75, 105012. [Google Scholar] [CrossRef]

- Fan, X.; Wang, J.; Yuan, H.; Zheng, Z.; Zhang, J.; Zhu, K. Multi-scale synergic optimization strategy for dielectric energy storage ceramics. J. Adv. Ceram. 2023, 12, 649–680. [Google Scholar] [CrossRef]

- Ma, C.; Tan, X. In situ Transmission Electron Microscopy Study on the Phase Transitionsin Lead-Free (1 − x)(Bi1/2Na1/2)TiO3 − xBaTiO3 Ceramics. J. Am. Ceram. Soc. 2011, 94, 4040–4044. [Google Scholar] [CrossRef]

- Kang, R.; Wang, Z.; Yang, W.; Zhu, X.; He, L.; Gao, Y.; Zhao, J.; Shi, P.; Zhao, Y.; Mao, P.; et al. Enhanced energy storage performance in Sr0.7La0.2Zr0.15Ti0.85O3-modified Bi0.5Na0.5TiO3 ceramics via constructing local phase coexistence. Chem. Eng. J. 2022, 446, 137105. [Google Scholar] [CrossRef]

- Li, Z.; Li, D.-X.; Shen, Z.-Y.; Zeng, X.; Song, F.; Luo, W.; Wang, X.; Wang, Z.; Li, Y. Remarkably enhanced dielectric stability and energy storage properties in BNT—BST relaxor ceramics by A-site defect engineering for pulsed power applications. J. Adv. Ceram. 2022, 11, 283–294. [Google Scholar] [CrossRef]

- Yang, F.; Li, Q.; Zhang, A.; Jia, Y.; Sun, Y.; Wang, W.; Fan, H. High energy storage density and temperature stable dielectric properties of (1 − x)Bi0.5(Na0.82K0.18)0.5Ti0.99(Y0.5Nb0.5)0.01O3–xNaNbO3 ceramics. J. Alloys Compd. 2022, 925, 166782. [Google Scholar] [CrossRef]

- Wang, F.; Xu, M.; Tang, Y.; Wang, T.; Shi, W.; Leung, C.M. Large Strain Response in the Ternary Bi0.5Na0.5TiO3–BaTiO3–SrTiO3 Solid Solutions. J. Am. Ceram. Soc. 2012, 95, 1955–1959. [Google Scholar] [CrossRef]

- Yan, Y.; Geng, L.D.; Zhu, L.-F.; Leng, H.; Li, X.; Liu, H.; Lin, D.; Wang, K.; Wang, Y.U.; Priya, S. Ultrahigh Piezoelectric Performance through Synergistic Compositional and Microstructural Engineering. Adv. Sci. 2022, 9, 2105715. [Google Scholar] [CrossRef]

- Xi, J.; Lin, L.; Bai, W.; Wu, S.; Zheng, P.; Li, P.; Zhai, J. Compromise boosted high capacitive energy storage in lead-free (Bi0.5Na0.5)TiO3-based relaxor ferroelectrics by phase structure modulation and defect engineering. Chem. Eng. J. 2024, 502, 157986. [Google Scholar] [CrossRef]

- Xu, K.; Yang, L.; Wang, J.; Huang, H. Design of high energy storage ferroelectric materials by phase-field simulations. J. Mater. Inform. 2025, 5, 24. [Google Scholar] [CrossRef]

- Dai, S.; Li, M.; Wu, X.; Wu, Y.; Li, X.; Hao, Y.; Luo, B. Combinatorial optimization of perovskite-based ferroelectric ceramics for energy storage applications. J. Adv. Ceram. 2024, 13, 877–910. [Google Scholar] [CrossRef]

- Zhu, W.; Shen, Z.-Y.; Deng, W.; Li, K.; Luo, W.; Song, F.; Zeng, X.; Wang, Z.; Li, Y. A review: (Bi,Na)TiO3 (BNT)-based energy storage ceramics. J. Mater. 2024, 10, 86–123. [Google Scholar] [CrossRef]

- Feng, M.; Feng, Y.; Zhang, T.; Li, J.; Chen, Q.; Chi, Q.; Lei, Q. Recent Advances in Multilayer-Structure Dielectrics for Energy Storage Application. Adv. Sci. 2021, 8, 2102221. [Google Scholar] [CrossRef] [PubMed]

- Zubairi, H.; Lu, Z.; Zhu, Y.; Reaney, I.M.; Wang, G. Current development, optimisation strategies and future perspectives for lead-free dielectric ceramics in high field and high energy density capacitors. Chem. Soc. Rev. 2024, 53, 10761–10790. [Google Scholar] [CrossRef]

- Yan, F.; Qian, J.; Wang, S.; Zhai, J. Progress and outlook on lead-free ceramics for energy storage applications. Nano Energy 2024, 123, 109394. [Google Scholar] [CrossRef]

- Veerapandiyan, V.; Benes, F.; Gindel, T.; Deluca, M. Strategies to Improve the Energy Storage Properties of Perovskite Lead-Free Relaxor Ferroelectrics: A Review. Materials 2020, 13, 5742. [Google Scholar] [CrossRef]

- Luo, C.; Feng, Q.; Luo, N.; Yuan, C.; Zhou, C.; Wei, Y.; Fujita, T.; Xu, J.; Chen, G. Effect of Ca2+/Hf4+ modification at A/B sites on energy-storage density of Bi0.47Na0.47Ba0.06TiO3 ceramics. Chem. Eng. J. 2021, 420, 129861. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, F.; Miao, W.; Su, Z.; Zhao, J.; Tang, L.; Shen, Y.; Hu, D.; Chen, Y.; Li, P.; et al. Effective improved energy storage performances of Na0.5Bi0.5TiO3-based relaxor ferroelectrics ceramics by A/B-sites co-doping. J. Alloys Compd. 2021, 883, 160837. [Google Scholar] [CrossRef]

- Xiong, W.; Zhang, H.; Cao, S.; Gao, F.; Svec, P.; Dusza, J.; Reece, M.J.; Yan, H. Low-loss high entropy relaxor-like ferroelectrics with A-site disorder. J. Eur. Ceram. Soc. 2021, 41, 2979–2985. [Google Scholar] [CrossRef]

- Li, M.; Li, L.; Zang, J.; Sinclair, D.C. Donor-doping and reduced leakage current in Nb-doped Na0.5Bi0.5TiO3. Appl. Phys. Lett. 2015, 106, 102904. [Google Scholar] [CrossRef]

- Cen, Z.; Zhou, C.; Cheng, J.; Zhou, X.; Li, W.; Yan, C.; Feng, S.; Liu, Y.; Lao, D. Effect of Zr4+ substitution on thermal stability and electrical properties of high temperature BiFe0.99Al0.01O3–BaTi1−xZrxO3 ceramics. J. Alloys Compd. 2013, 567, 110–114. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.-M.; Zhao, X.-M.; Liang, X.-X.; Zhou, J.-P.; Liu, P. Effects of BiAlO3-doping on dielectric and ferroelectric properties of 0.93Na0.5Bi0.5TiO3–0.07BaTiO3 lead-free ceramics. Mater. Res. Bull. 2015, 67, 94–101. [Google Scholar] [CrossRef]

- Yan, F.; Yang, H.; Lin, Y.; Wang, T. Dielectric and Ferroelectric Properties of SrTiO3–Bi0.5Na0.5TiO3–BaAl0.5Nb0.5O3 Lead-Free Ceramics for High-Energy-Storage Applications. Inorg. Chem. 2017, 56, 13510–13516. [Google Scholar] [CrossRef]

- Jin, C.C.; Wang, F.F.; Wei, L.L.; Tang, J.; Li, Y.; Yao, Q.R.; Tian, C.Y.; Shi, W.Z. Influence of B-site complex-ion substitution on the structure and electrical properties in Bi0.5Na0.5TiO3-based lead-free solid solutions. J. Alloys Compd. 2014, 585, 185–191. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, J.; Zhou, C.; Yuan, C.; Li, Q.; Chen, G.; Wang, H.; Yang, L. High energy storage properties and dielectric behavior of (Bi0.5Na0.5)0.94Ba0.06Ti1−x(Al0.5Nb0.5)xO3 lead-free ferroelectric ceramics. Ceram. Int. 2016, 42, 2221–2226. [Google Scholar] [CrossRef]

- Groszewicz, P.B.; Koch, L.; Steiner, S.; Ayrikyan, A.; Webber, K.G.; Frömling, T.; Albe, K.; Buntkowsky, G. The fate of aluminium in (Na,Bi)TiO3-based ionic conductors. J. Mater. Chem. A 2020, 8, 18188–18197. [Google Scholar] [CrossRef]

- Jiang, Z.; Yang, H.; Cao, L.; Yang, Z.; Yuan, Y.; Li, E. Enhanced breakdown strength and energy storage density of lead-free Bi0.5Na0.5TiO3-based ceramic by reducing the oxygen vacancy concentration. Chem. Eng. J. 2021, 414, 128921. [Google Scholar] [CrossRef]

- Qiao, X.; Liao, A.; Chen, B.; Zhang, H.; Zhang, L.; Kong, T.; Chao, X.; Yang, Z. Enhanced energy storage properties of BNT-based ceramics via composition and multiscale structural engineering. Solid State Sci. 2023, 136, 107090. [Google Scholar] [CrossRef]

- Chen, H.; Shi, J.; Chen, X.; Sun, C.; Pang, F.; Dong, X.; Zhang, H.; Zhou, H. Excellent energy storage properties and stability of NaNbO3–Bi(Mg0.5Ta0.5)O3 ceramics by introducing (Bi0.5Na0.5)0.7Sr0.3TiO3. J. Mater. Chem. A 2021, 9, 4789–4799. [Google Scholar] [CrossRef]

- Petnoi, N.; Bomlai, P.; Jiansirisomboon, S.; Watcharapasorn, A. Effects of Nb-doping on the micro-structure and dielectric properties of (Bi0.5Na0.5)TiO3 ceramics. Ceram. Int. 2013, 39, S113–S117. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Q.; Zheng, S.; Chen, X.; Yang, N.; Yang, Z.; Shang, K.; Fan, H.; Wang, W. Enhancement of energy storage performance in BNT-based energy ceramics via polar nanoregions induced by doping (Al0.5Ta0.5)4+ composite particles. Ceram. Int. 2025, 51, 14501–14510. [Google Scholar] [CrossRef]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Thermal depoling process and piezoelectric properties of bismuth sodium titanate ceramics. J. Appl. Phys. 2009, 105, 084112. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Das, S.; Das, A.; Omar, S. Effect of sintering temperature on the microstructure and conductivity of Na0.54Bi0.46Ti0.99Mg0.01O3−δ. Solid State Ion. 2021, 360, 115547. [Google Scholar] [CrossRef]

- Xia, Y.; Hao, H.; Tao, C.; Cao, M.; Yao, Z.; Liu, H. Enhanced Energy Storage Performance in Mn-Doped SrBi5Ti4FeO18 Thin Films via Defect Engineering. ACS Appl. Mater. Interfaces 2025, 17, 19966–19976. [Google Scholar] [CrossRef]

- Cai, Z.; Wang, X.; Hong, W.; Luo, B.; Zhao, Q.; Li, L. Grain-size–dependent dielectric properties in nanograin ferroelectrics. J. Am. Ceram. Soc. 2018, 101, 5487–5496. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Jin, L.; Hu, Q.; Qu, S.; Yang, Z.; Yu, Y.; Wei, X.; Xu, Z. A new family of sodium niobate-based dielectrics for electrical energy storage applications. J. Eur. Ceram. Soc. 2019, 39, 2899–2907. [Google Scholar] [CrossRef]

- Cao, W.; Wu, Y.; Yang, X.; Guan, D.; Huang, X.; Li, F.; Guo, Y.; Wang, C.; Ge, B.; Hou, X.; et al. Breaking polarization-breakdown strength paradox for ultrahigh energy storage density in NBT-based ceramics. Nat. Commun. 2025, 16, 6228. [Google Scholar] [CrossRef]

- Antillon, E.; Woodward, C.; Rao, S.I.; Akdim, B. Chemical short range order strengthening in BCC complex concentrated alloys. Acta Mater. 2021, 215, 117012. [Google Scholar] [CrossRef]

- Wei, T.; Zhang, Y.; Kong, L.; Kim, Y.J.; Xu, A.; Karatchevtseva, I.; Scales, N.; Gregg, D.J. Hot isostatically pressed Y2Ti2O7 and Gd2Ti2O7 pyrochlore glass-ceramics as potential waste forms for actinide immobilization. J. Eur. Ceram. Soc. 2019, 39, 1546–1554. [Google Scholar] [CrossRef]

- Wohninsland, A.; Fetzer, A.-K.; Riaz, A.; Kleebe, H.-J.; Rödel, J.; Kodumudi Venkataraman, L. Correlation between enhanced lattice distortion and volume fraction of polar nanoregions in quenched Na1/2Bi1/2TiO3–BaTiO3 ceramics. Appl. Phys. Lett. 2021, 118, 072903. [Google Scholar] [CrossRef]

- Manley, M.E.; Lynn, J.W.; Abernathy, D.L.; Specht, E.D.; Delaire, O.; Bishop, A.R.; Sahul, R.; Budai, J.D. Phonon localization drives polar nanoregions in a relaxor ferroelectric. Nat. Commun. 2014, 5, 3683. [Google Scholar] [CrossRef]

- Wei, K.; Duan, J.; Qi, H.; Ma, L.; Du, Q.; Yu, H.; Wang, H.; Shi, X.; Li, G.; Shuai, Z.; et al. Collaborative design of polarization and antiferrodistortion configurations in high energy capacitive relaxor ferroelectrics. Nat. Commun. 2025, 16, 7833. [Google Scholar] [CrossRef]

- Yin, J.; Shi, X.; Tao, H.; Tan, Z.; Lv, X.; Ding, X.; Sun, J.; Zhang, Y.; Zhang, X.; Yao, K.; et al. Deciphering the atomic-scale structural origin for large dynamic electromechanical response in lead-free Bi0.5Na0.5TiO3-based relaxor ferroelectrics. Nat. Commun. 2022, 13, 6333. [Google Scholar] [CrossRef]

- Mendez-González, Y.; Peláiz-Barranco, A.; Curcio, A.L.; Rodrigues, A.D.; Guerra, J.D.S. Raman spectroscopy study of the La-modified (Bi0.5Na0.5)0.92Ba0.08TiO3 lead-free ceramic system. J. Raman Spectrosc. 2019, 50, 1044–1050. [Google Scholar] [CrossRef]

- Chu, B.; Hao, J.; Li, P.; Li, Y.; Li, W.; Zheng, L.; Zeng, H. High-Energy Storage Properties over a Broad Temperature Range in La-Modified BNT-Based Lead-Free Ceramics. ACS Appl. Mater. Interfaces 2022, 14, 19683–19696. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Y.; Song, S.; Chen, F.; Zeng, X.; Wang, X.; Song, C.; Liu, G.; Yan, Y. Energy storage performance of 0.55Bi0.5Na0.5TiO3-0.45SrTiO3 ceramics doped with lanthanide elements (Ln = La, Nd, Dy, Sm) using a viscous polymer processing route. Ceram. Int. 2022, 48, 10885–10894. [Google Scholar] [CrossRef]

- Liu, G.; Dong, J.; Zhang, L.; Yan, Y.; Jing, R.; Jin, L. Phase evolution in (1 − x)(Na0.5Bi0.5)TiO3-xSrTiO3 solid solutions: A study focusing on dielectric and ferroelectric characteristics. J. Mater. 2020, 6, 677–691. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, H.; Zhang, L.; Xie, J.; Hao, H.; Cao, M.; Yao, Z.; Lanagan, M.T. Structure and electrical properties of lead-free Bi0.5Na0.5TiO3-based ceramics for energy-storage applications. RSC Adv. 2016, 6, 59280–59291. [Google Scholar] [CrossRef]

- Yan, F.; Tu, Z.; Wang, W.; Zhu, Z.; Chen, Y.; Liao, J.; Zhang, S.; Liao, M.; Zhou, Y. Improving the ferroelectric and dielectric properties of barium strontium titanate thin films via local chemical design. Inorg. Chem. Front. 2025, 12, 1493–1502. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Guo, J.; Lv, X.; Lin, S.; Li, Y.; Gu, L.; Yan, F. Outstanding comprehensive energy storage performance in BNT-based lead-free ceramics via synergistic optimization strategy. Chem. Eng. J. 2025, 504, 158940. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, Z.; Luo, X.; Zhang, J.; Li, Y.; Zhou, X.; Li, M.; Zhang, D. Bi0.5Na0.5TiO3-Based Relaxor Ferroelectrics with Highly Polarizable Concentrated Nanodomains for High Capacitive Energy Storage under Moderate Electric Fields. ACS Appl. Mater. Interfaces 2025, 17, 49421–49432. [Google Scholar] [CrossRef]

- Chen, F.; Yang, L.; Feng, H.; Li, Q.; Zeng, X.; Yu, K.; Song, C.; Yan, Y.; Jin, L.; Zhang, D. An ultrahigh energy storage efficiency and recoverable density in Bi0.5Na0.5TiO3 with the modification of Sr0.85La0.1TiO3 via viscous polymer process. J. Mater. 2024, 10, 566–577. [Google Scholar] [CrossRef]

- Shi, W.; Zhang, L.; Jing, R.; Hu, Q.; Zeng, X.; Alikin, D.O.; Shur, V.Y.; Wei, X.; Gao, J.; Liu, G.; et al. Relaxor antiferroelectric-like characteristic boosting enhanced energy storage performance in eco-friendly (Bi0.5Na0.5)TiO3-based ceramics. J. Eur. Ceram. Soc. 2022, 42, 4528–4538. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).