Assessment of a Clothing Ensemble with an Active Heating Function Based on Thermal Manikin Tests

Abstract

1. Introduction

1.1. Existing Electrically Heated Garment Solutions

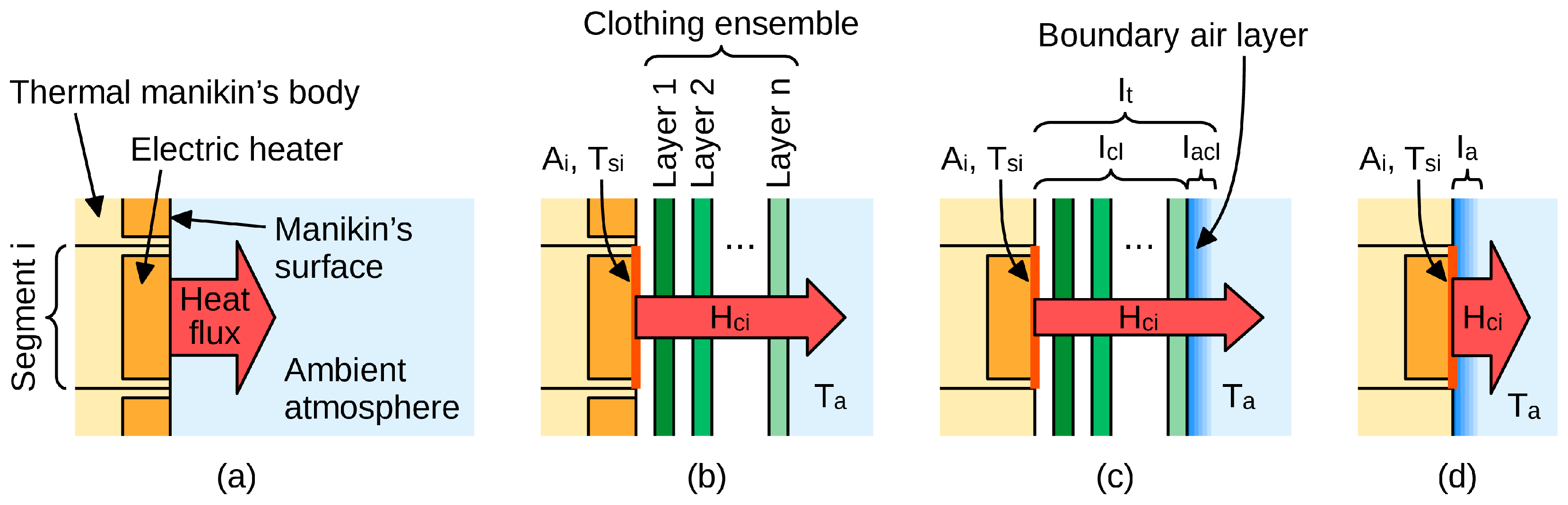

1.2. Thermal Insulation of Clothing

1.3. Motivation and Scope of This Work

2. Materials and Methods

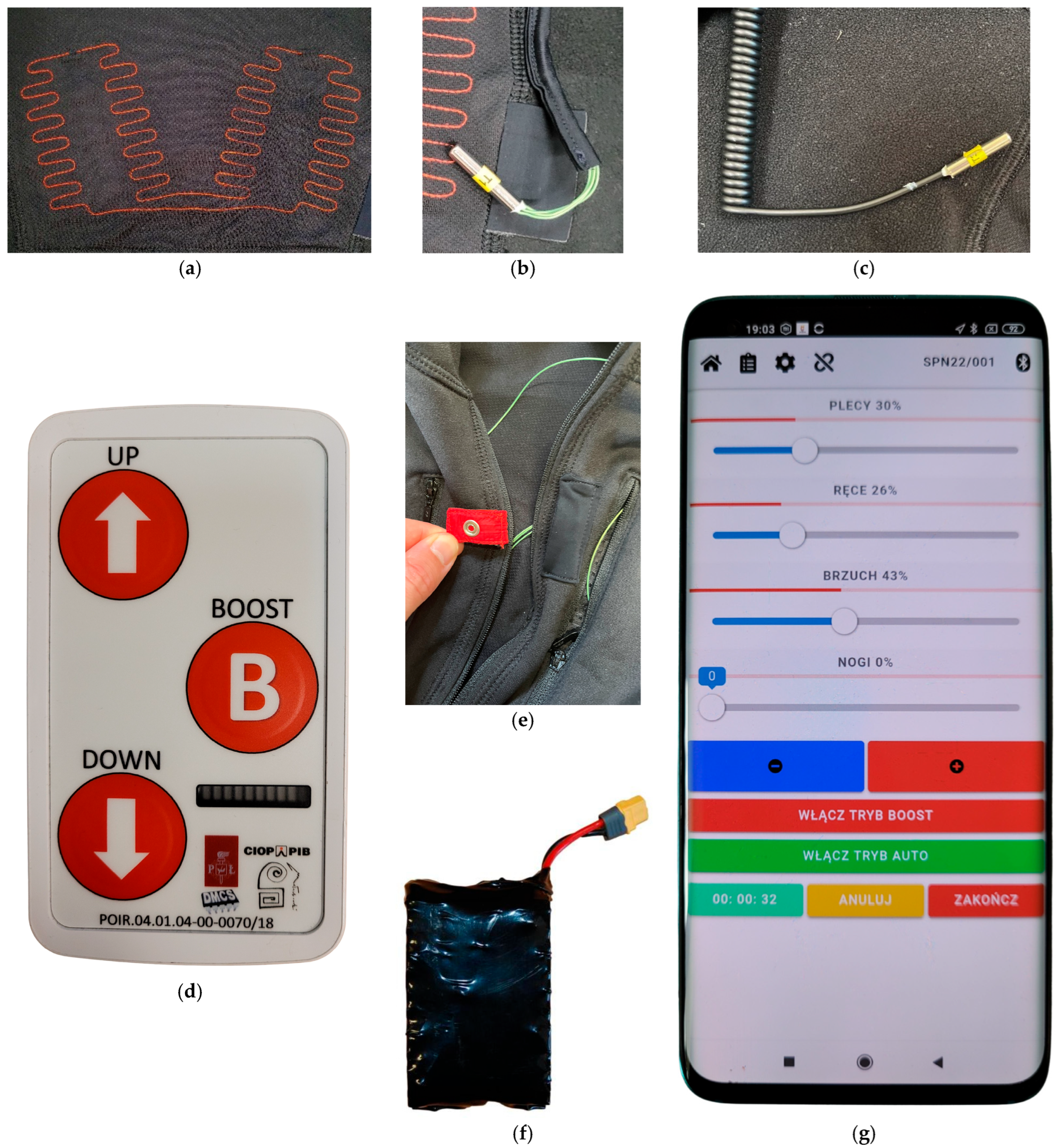

2.1. Tested Object

- an electrically heated suit (inner layer),

- a down jacket (middle layer, optional),

- an outer suit made of waterproof laminate (outer layer).

- twelve flexible heating parts (pads) grouped into four independently controlled heating zones: arms, legs, abdomen, and back, with a total surface area of 840 cm2 (a),

- two undergarment microclimate temperature sensors (b, c) and one ambient temperature sensor (d),

- a controller with buttons, onboard accelerometer, gyroscope, and pressure sensor, as well as an attached undergarment temperature and humidity sensor (e),

- a metal snap (f) and

- a battery pack (g).

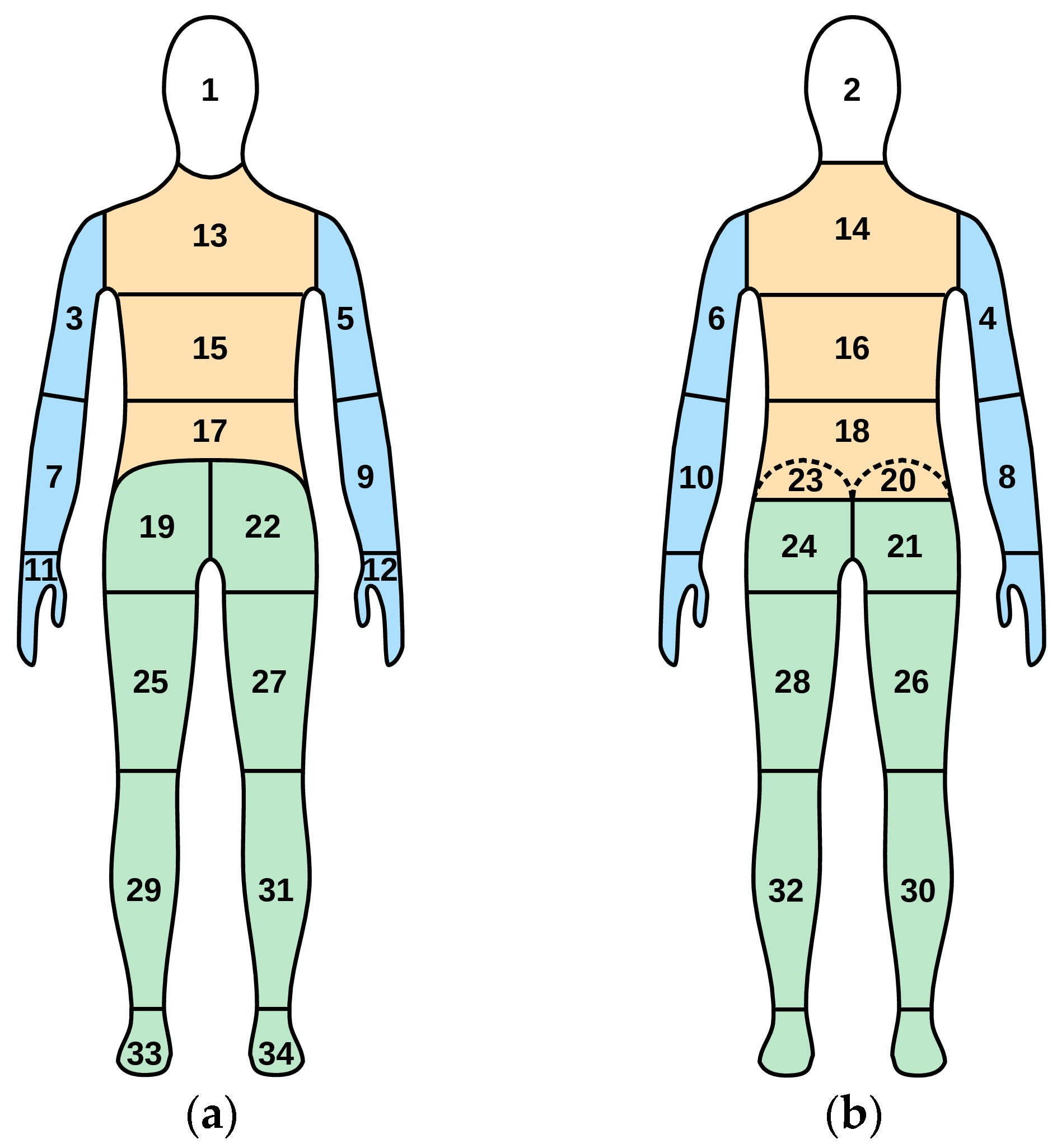

2.2. Testing Methodology

3. Results

3.1. Thermal Insulation

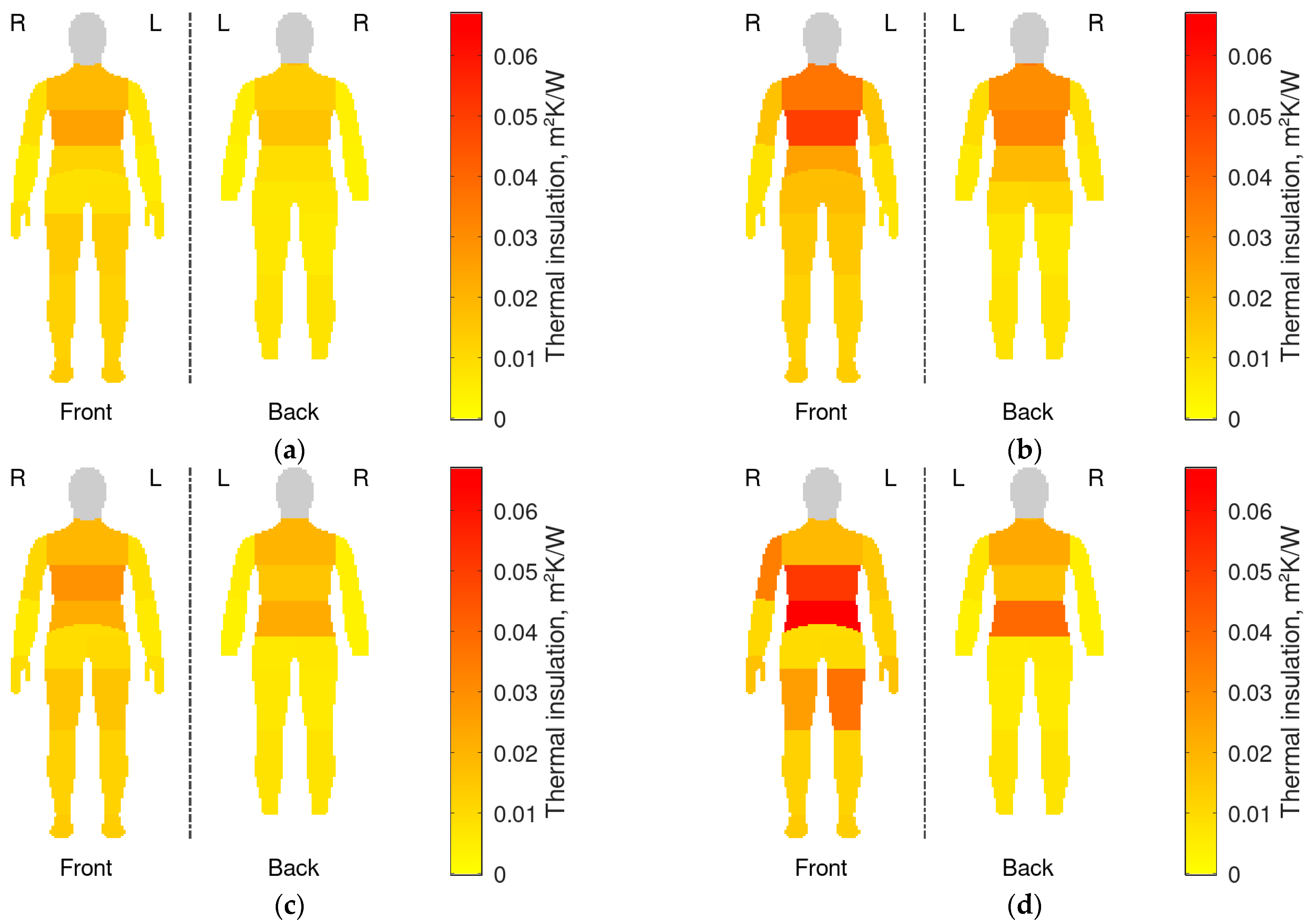

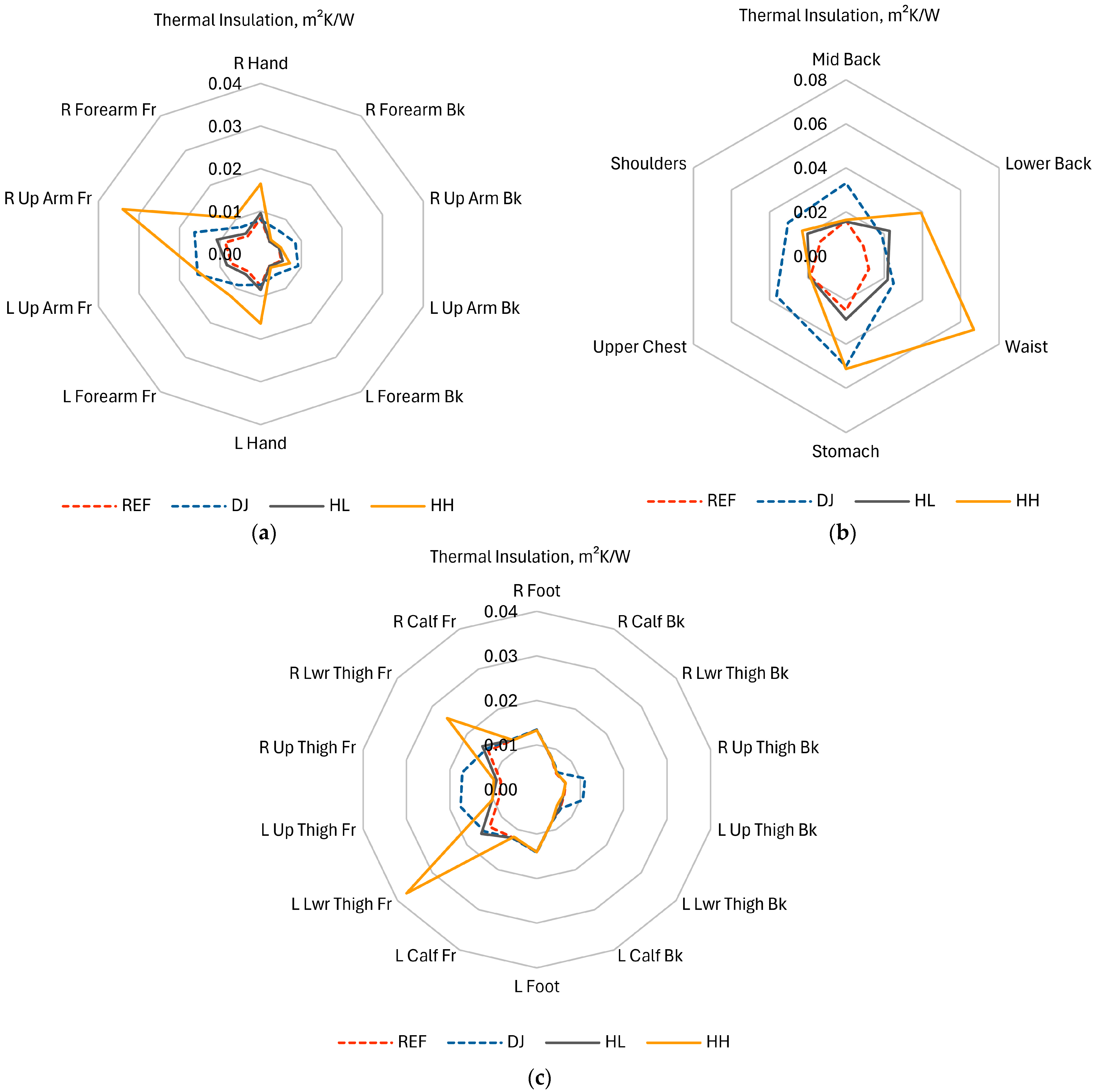

3.2. Local Thermal Insulation

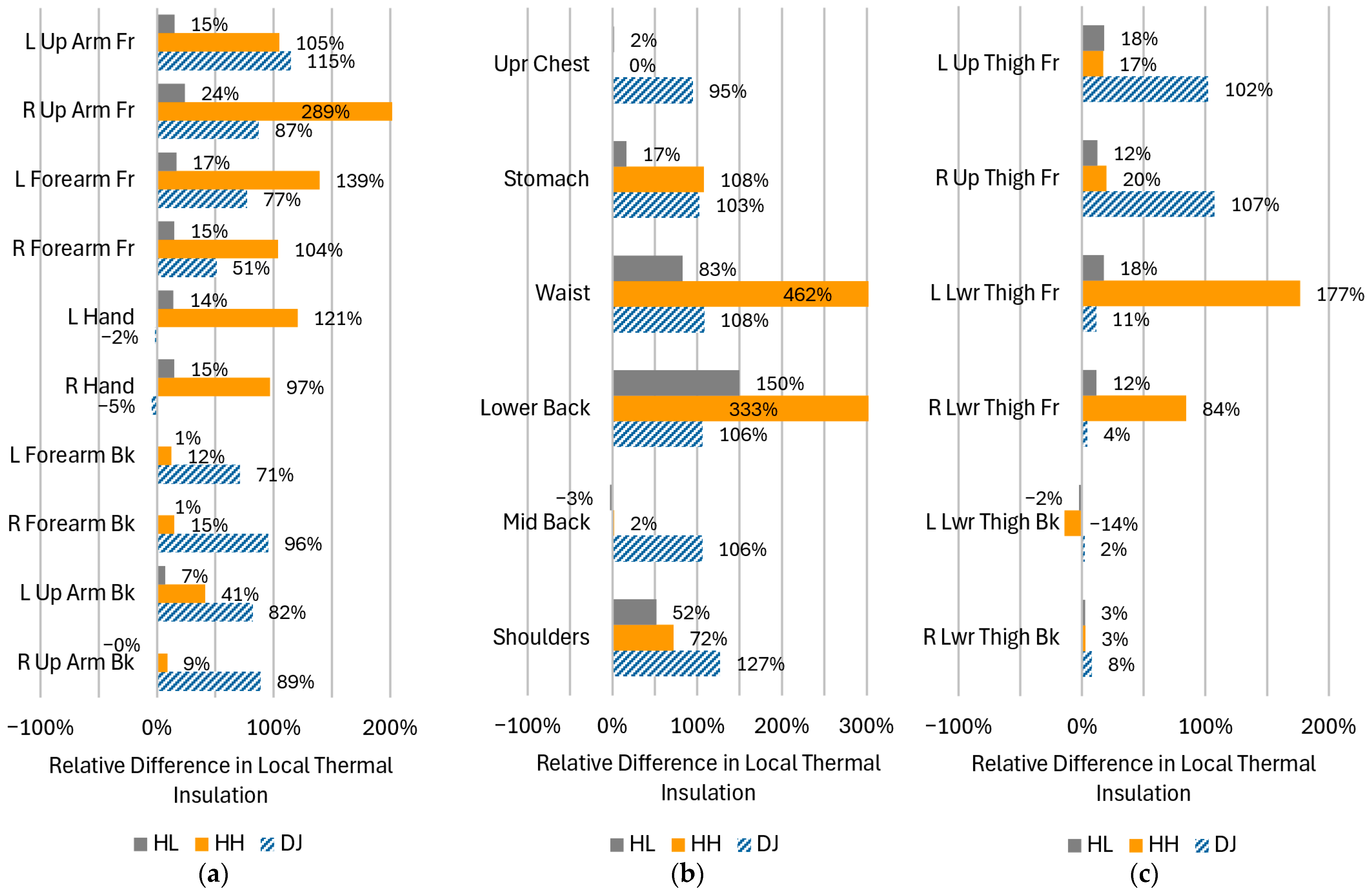

- The effect of heating (HL and HH) was greatest in segments where heating pads were located (compare Figure 7c,d against Figure 2 and Figure 7a). This is particularly apparent on the waist (Figure 8b), as well as on the front of the right arm (Figure 8a, R Up Arm Fr) and lower thighs (Figure 8c, R/L Lwr Thigh Fr).

- The effect of the down jacket (DJ) was more uniform than that of heating (HL and HH) not only in terms of different segments but also front vs. back side (as seen in Figure 7b in comparison with Figure 7d as well as in Figure 9). Still, Figure 7a,b and Figure 8 reveal some bias towards the front of the body in terms of absolute values for both configurations with the heating off (DJ and REF).

- When operated at the higher power (HH), the heating system tended to outperform the down jacket (DJ) on the front, while the opposite was true on the back.

- Low heating power (HL) had a small (still observable) impact even at the front, with increase in local thermal insulation ranging from 10% to 20% in most segments.

- Upper limbs

- With the heating on, whatever the power, the highest relative increase in local thermal insulation was recorded in the right arm front segment (R Up Arm Fr): by 289% with the HH configuration and 24% with the HL one. In both cases, the heating effect was much smaller in the corresponding segment of the left limb (L Up Arm Fr), which suggests that this was due to a worse adhesion of the left pad to the manikin.

- The effect of the heating system was stronger on the front, where local thermal insulation increased by more or nearly 100% in all segments at high power (HH). This was more than with the down jacket (DJ, 77% to 115%), except on the problematic left upper arm. On the other hand, the much weaker effect of the down jacket on the right forearm (R Forearm Fr, 51%) can be due to how the jacket was arranged on the manikin.

- On the back, the impact of the heating system was close to none at low power (HL) and still low at high power (HH, 9% to 41%). Conversely, the effect of the down jacket (DJ) was similarly strong on the back as on the front (between 71% and 96%). On the other hand, the down jacket had no impact on hands, where the application of heating increased the local thermal insulation like in the front segments of the arms (97% and 121%).

- The torso

- It is only in this region that the effect of the heating system was strong even at low power (HL). It reached 83% on the waist and 150% on the lower back, the latter result exceeding that of the down jacket (DJ, 108%). It was also in these segments that the strongest effect over the entire body was observed at high power (HH): an increase in thermal insulation of 462% (up to 0.067 m2K/W) in the waist area and of 333% (up to 0.039 m2K/W) in the lower back one. This was where heating pads were located, but a substantial increase (108%) occurred also on the abdomen (Stomach).

- When operated at high power (HH), the heating system outperformed the down jacket (DJ) in the lower part of the torso, was on par with it on the abdomen and only worse on the shoulders. On the other hand, the heating had no effect on the mid back and upper chest; in these segments, the uniformity of the jacket’s effect (improvements in local thermal insulation between 95% and 127% over the torso) proved crucial.

- Lower limbs

- The positive impact of the heating system was only noted on the front, consistently with the positioning of the leg pads (compare Figure 7d with Figure 2). This impact was only significant on lower thighs and at the higher power (L/R Lwr Thigh Fr; HH), with an increase in local thermal insulation of 177% (left) and 84% (right). In these segments, the down jacket (DJ) performed worse (11% and 4% increase) than low-power heating (HL; 18% and 12%, respectively); this was because the jacket did not extend to these areas.

- Conversely, the jacket improved local thermal insulation of the upper thighs (L/R Up Thigh Fr) which it covered, like elsewhere (by 102% and 107%). The heating system performed poorly in that area (17% and 20% improvement at high power), because pads were located lower. Still, heat transfer from neighboring pads is seen. It must be noted that the leg pads operated at full power in the HH configuration (Table 3).

- None of the tested clothing configurations were able to increase local thermal insulation on the back of lower thighs where pads were missing and the jacket did not reach.

4. Discussion

4.1. Overall Thermal Insulation

- 1.

- 2.

- 3.

- Sewn-on steel thread was used as the heating element instead of carbon wire [29], graphene sheets [26] or carbon polymer fabric [27]. It is remarkable that all these less efficient solutions use carbon-based materials. It can also be noted that the best of them, i.e., the one described in [29], has the heating element in the form of a wire applied on a polyester substrate. As these characteristics are shared with our EHG, it is probable that they also played a role. This may also be the cause of thermal insulation being greater in [29] than in [26] despite the pads being closer to the body in the latter solution.

4.2. Local Thermal Insulaton

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AgNW | Silver nanowire |

| CHG | Chemically heated garment |

| CNT | Carbon nanotube |

| EHG | Electrically heated garment |

| GPS | Global Positioning System |

| NA | Not applicable |

| PA | Polyamide |

| PES | Polyester |

| PU | Polyurethane |

References

- Lee, H.; Baek, K. Developing a smart multifunctional outdoor jacket with wearable sensing technology for user health and safety. Multimed. Tools Appl. 2021, 80, 32273–32310. [Google Scholar] [CrossRef]

- Kim, K.; Kim, S.; Lim, D.; Ha, J.; Jeong, W. Analysis of design elements and heating system of domestic and foreign commercial electrical heated clothing. Fash. Text. Res. J. 2021, 23, 273–289. [Google Scholar] [CrossRef]

- Lee, B.; Lee, J. Development of design for band type heating vests. J. Fash. Bus. 2015, 19, 93–109. [Google Scholar] [CrossRef]

- Fang, S.; Wang, R.; Ni, H.; Liu, H.; Liu, L. A Review of flexible electric heating element and electric heating garments. J. Ind. Text. 2020, 51, 101S–136S. [Google Scholar] [CrossRef]

- Lee, J.; Lee, B. Development of design for heating vest with detachable heating device. J. Fash. Bus. 2014, 18, 82–98. [Google Scholar] [CrossRef]

- Lee, J. A Study of the analysis on the risk of ignition and low-temperature burns caused by the use of electrically heated clothes. J. Soc. Disaster Inf. 2018, 14, 122–129. [Google Scholar] [CrossRef]

- Repon, M.R.; Mikučionienė, D. Progress in flexible electronic textile for heating application: A critical review. Materials 2021, 14, 6540. [Google Scholar] [CrossRef]

- Xu, P.; Wang, F.; Zhao, M. Electrically heated clothing (ehc) for protection against cold stress. In Protective Clothing; Wang, F., Gao, C., Eds.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2014; pp. 281–295. ISBN 978-1-78242-032-3. [Google Scholar]

- Choi, H.N.; Jee, S.H.; Ko, J.; Kim, D.J.; Kim, S.H. Properties of surface heating textile for functional warm clothing based on a composite heating element with a positive temperature coefficient. Nanomaterials 2021, 11, 904. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, H.; Lu, H.; Li, S.; Zhang, Y. Electronic fibers and textiles: Recent progress and perspective. iScience 2021, 24, 102716. [Google Scholar] [CrossRef]

- Wang, F.; Gao, C.; Kuklane, K.; Holmér, I. A Review of technology of personal heating garments. Int. J. Occup. Saf. Ergon. 2010, 16, 387–404. [Google Scholar] [CrossRef]

- Kayacan, O.; Yazgan Bulgun, E. Heating behaviors of metallic textile structures. Int. J. Cloth. Sci. Technol. 2009, 21, 127–136. [Google Scholar] [CrossRef]

- Yang, H. Research on application of carbon fiber heating material in clothing. IOP Conf. Ser. Earth Environ. Sci. 2017, 81, 012042. [Google Scholar] [CrossRef]

- Hsu, P.-C.; Liu, X.; Liu, C.; Xie, X.; Lee, H.R.; Welch, A.J.; Zhao, T.; Cui, Y. Personal thermal management by metallic nanowire-coated textile. Nano Lett. 2015, 15, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Doganay, D.; Coskun, S.; Genlik, S.P.; Unalan, H.E. Silver nanowire decorated heatable textiles. Nanotechnology 2016, 27, 435201. [Google Scholar] [CrossRef]

- Cho, H.; Cho, S.W. Optimal heating location for developing the heating smart clothing based on thermal response of body. Sci. Emot. Sensib. 2015, 18, 93–106. [Google Scholar] [CrossRef]

- Castellani, J.W.; Yurkevicius, B.R.; Jones, M.L.; Driscoll, T.J.; Cowell, C.M.; Smith, L.; Xu, X.; O’Brien, C. Effect of localized microclimate heating on peripheral skin temperatures and manual dexterity during cold exposure. J. Appl. Physiol. 2018, 125, 1498–1510. [Google Scholar] [CrossRef]

- Kim, S.; Park, D.; Lim, D.; Yoo, E.-S.; Lee, J.-Y.; Kong, Y.-K.; Jeong, W. Influence of the forearm or hand heating on skin temperature, thermal sensation, and manual dexterity during cold exposure (−5 °C): A pilot study. In Proceedings of the Autumn Conference of the Ergonomics Society of Korea, Busan, Republic of Korea, 16–19 October 2019; p. 209. [Google Scholar]

- Kurczewska, A.; Leśnikowski, J. Variable-thermoinsulation garments with a microprocessor temperature controller. Int. J. Occup. Saf. Ergon. 2008, 14, 77–87. [Google Scholar] [CrossRef]

- Kayacan, O.; Bulgun, E.; Sahin, O. Implementation of steel-based fabric panels in a heated garment design. Text. Res. J. 2009, 79, 1427–1437. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, H.; Li, X.; Wu, L.; Chen, X.; Zhang, M. Flexible Heating Fabric System. CN Patent CN103533683A, 22 January 2014. [Google Scholar]

- Lee, E.; Roh, J.-S.; Kim, S. User-centered interface design approach for a smart heated garment. Fibers Polym. 2018, 19, 238–247. [Google Scholar] [CrossRef]

- Fan, X.; Lin, H.; Ye, C.; Guo, Y.; Huang, L. Smart heating clothes based on bluetooth. In Proceedings of the 2019 14th International Conference on Computer Science & Education (ICCSE), Toronto, ON, Canada, 19–21 August 2019; pp. 200–203. [Google Scholar] [CrossRef]

- Lee, H.; Hong, K.; Lee, Y.; Kim, S. User’s voluntary heating behavior for the programming of the efficient heating mode of smart base layer clothing. J. Korean Soc. Cloth. Text. 2017, 41, 872–882. [Google Scholar] [CrossRef]

- EN ISO 15831:2004; Clothing—Physiological Effects—Measurement of Thermal Insulation by Means of a Thermal Manikin. European Committee for Standardization: Brussels, Belgium, 2004.

- Li, S.; Deng, Y.; Cao, B. Study on the performance of personal heating in extremely cold environments using a thermal manikin. Buildings 2023, 13, 362. [Google Scholar] [CrossRef]

- Wang, F.; Lee, H. Evaluation of an electrically heated vest (EHV) using a thermal manikin in cold environments. Ann. Occup. Hyg. 2010, 54, 117–124. [Google Scholar] [CrossRef]

- EN 342:2017; Protective Clothing—Ensembles and Garments for Protection Against Cold. European Committee for Standardization: Brussels, Belgium, 2017.

- Song, W.; Lai, D.; Wang, F. Evaluating the cold protective performance (CPP) of an electrically heated garment (EHG) and a chemically heated garment (CHG) in cold environments. Fibers Polym. 2015, 16, 2689–2697. [Google Scholar] [CrossRef]

- Park, J.H. Smart Heating Clothes, System and Method for Controlling Heating Thereof; European Patent Office: Munich, Germany, 2016. [Google Scholar]

- Pękosławski, B.; Marciniak, P.; Starzak, Ł.; Stawiński, A.; Bartkowiak, G. Power supply and control unit for actively heated protective clothing with photovoltaic energy harvesting. Energies 2022, 15, 5656. [Google Scholar] [CrossRef]

- EN ISO 6330:2021; Textiles—Domestic Washing and Drying Procedures for Textile Testing. European Committee for Standardization: Brussels, Belgium, 2021.

- Młynarczyk, M.; Orysiak, J.; Jankowski, J. Effect of workwear fit on thermal insulation: Assessment using 3d scanning technology. Materials 2025, 18, 2098. [Google Scholar] [CrossRef] [PubMed]

- EN 342:2004; Protective Clothing—Garments and Clothing Combinations for Protection Against Cold. European Committee for Standardization: Brussels, Belgium, 2004.

| Clothing Layer | Garment | Structure | Composition | Surface Mass, g/m2 | Thermal Resistance, m2K/W | Water Vapor Resistance, m2Pa/W |

|---|---|---|---|---|---|---|

| 1 | Heated suit | Knitted microfleece fabric incorporating conductive thread | Fabric: 100% PES Heating thread: 100% stainless steel (diameter: 0.3 mm, resistance: ca. 30 Ω/m) | Knitted fabric: 242 ± 2 | 0.066 ± 0.000 | 5.93 ± 0.38 |

| 2 | Down jacket | Down package: fabric + filling + fabric; X-type chambers 8.5 cm wide | Fabric: 100% PA Filling: 92% goose down, 8% feathers (elasticity: 750 in3) | Woven fabric (without filling): 37 ± 1 | 0.464 ± 0.018 | 50.0 ± 1.5 |

| 3 | Outer suit | Three-layer laminate | 100% PA + 100% PU (waterproof membrane) + 100% PA | Laminate: 142 ± 2 | 0.017 ± 0.002 | 14.50 ± 0.35 |

| Symbol | Meaning | Heated Suit | Down Jacket | Outer Suit | Heating Power |

|---|---|---|---|---|---|

| REF | Reference | Yes | No | Yes | Off |

| DJ | Down jacket (unheated) | Yes | Yes | Yes | Off |

| HL | Heated, low power | Yes | No | Yes | Low |

| HH | Heated, high power | Yes | No | Yes | High |

| Configuration | Back | Arms | Abdomen | Legs | Total |

|---|---|---|---|---|---|

| REF | 0% (0.0 W) | 0% (0.0 W) | 0% (0.0 W) | 0% (0.0 W) | 0% (0.0 W) |

| DJ | 0% (0.0 W) | 0% (0.0 W) | 0% (0.0 W) | 0% (0.0 W) | 0% (0.0 W) |

| HL | 20% (3.4 W) | 20% (3.4 W) | 20% (1.7 W) | 20% (1.7 W) | 20% (10.3 W) |

| HH | 25% (4.8 W) | 75% (12.9 W) | 30% (2.6 W) | 100% (8.6 W) | 55% (28.4 W) |

| Garment | Washing | Drying | |||

|---|---|---|---|---|---|

| Procedure | Temperature | Agent | Procedure | Process | |

| Heated suit | 3N | 30 °C | Mild detergent | A | Open-air line dry |

| Down jacket | 3N | 30 °C | Mild detergent | F | Tumble dry at 60 °C |

| Outer suit | 4N | 40 °C | Reference detergent according to EN ISO 6330 [31] | A | Open-air line dry |

| No. | Designation | Description | Body Region |

|---|---|---|---|

| 3 | R Up Arm Fr | Right arm, front | Upper Limbs |

| 4 | R Up Arm Bk | Right arm, back | |

| 5 | L Up Arm Fr | Left arm, front | |

| 6 | L Up Arm Bk | Left arm, back | |

| 7 | R Forearm Fr | Right forearm, front | |

| 8 | R Forearm Bk | Right forearm, back | |

| 9 | L Forearm Fr | Left forearm, front | |

| 10 | L Forearm Bk | Left forearm, back | |

| 11 | R Hand | Right hand | |

| 12 | L Hand | Left hand | |

| 13 | Upper Chest | Chest, upper part | Torso |

| 14 | Shoulders | Back, upper part | |

| 15 | Stomach | Torso, middle part (abdomen) | |

| 16 | Mid-Back | Back, middle part | |

| 17 | Waist | Waist | |

| 18 | Lower Back | Back, lower part | |

| 19 | R Up Thigh Fr | Right thigh, upper part, front | Lower Limbs |

| 21 | R Up Thigh Bk | Right thigh, upper part, back | |

| 22 | L Up Thigh Fr | Left thigh, upper part, front | |

| 24 | L Up Thigh Bk | Left thigh, upper part, back | |

| 25 | R Lwr Thigh Fr | Right thigh, lower part, front | |

| 26 | R Lwr Thigh Bk | Right thigh, lower part, back | |

| 27 | L Lwr Thigh Fr | Left thigh, lower part, front | |

| 28 | L Lwr Thigh Bk | Left thigh, lower part, back | |

| 29 | R Calf Fr | Right calf, front | |

| 30 | R Calf Bk | Right calf, back | |

| 31 | L Calf Fr | Left calf, front | |

| 32 | L Calf Bk | Left calf, back | |

| 33 | L Foot | Right foot | |

| 34 | R Foot | Left foot |

| Clothing Configuration | Total Thermal Insulation, It | Basic Thermal Insulation, Icl | Resultant Effective Thermal Insulation, Icler | |||

|---|---|---|---|---|---|---|

| Absolute, m2K/W | Relative Difference | Absolute, m2K/W | Relative Difference | Absolute, m2K/W | Relative Difference | |

| REF | 0.275 | - | 0.222 | - | 0.183 | - |

| DJ | 0.367 | 33% | 0.320 | 44% | 0.267 | 46% |

| HL | 0.305 | 11% | 0.254 | 15% | 0.211 | 15% |

| HH | 0.379 | 38% | 0.333 | 50% | 0.279 | 52% |

| Reference | Main Clothing Layers (Inner to Outer) | Heating Pads | Thermal Insulation with Heating | |||||

|---|---|---|---|---|---|---|---|---|

| Materials | Quantity | Locations | Total Area, cm2 | Total Power Applied, W | Absolute, m2K/W | Increase Relative to No Heating | ||

| Wang and Lee [27] | 1. Shirt 2. Vest * 3. Jacket | Carbon polymer fabric | 1 | Back (1) | 500 | 13 | ca. 0.26 (0 °C and −10 °C) | 2% |

| Song et al. [29] | 1. Underwear 2. Outerwear 3. Vest * | Carbon wire between PES fabrics | 7 | Back (3) Waist Kneecaps | 2212 | 26.5 | 0.365 (2 °C) | 11% |

| Li et al. [26] | 1. Sweater 2. Jacket * | Graphene sheet | 8 | Back Chest Abdomen Upper arms | 1400 | 25.2 | 0.250 ** (−5 °C to −15 °C; 0.5 m/s) | 7% ** |

| This work | 1. Inner suit * 2. Outer suit | Steel thread sewn onto PES fabric | 12 | Shoulders Lower back Waist Upper arms Lower arms Lower thighs | 840 | 10.3 | 0.305 0.254 ** (−7 °C) | 11% 15% ** |

| 28.4 | 0.379 0.333 ** (−7 °C) | 38% 50% ** | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Greszta, A.; Młynarczyk, M.; Dąbrowska, A.; Krzemińska, S.; Jangas, M.; Starzak, Ł.; Marciniak, P.; Małachowski, B. Assessment of a Clothing Ensemble with an Active Heating Function Based on Thermal Manikin Tests. Materials 2025, 18, 5258. https://doi.org/10.3390/ma18235258

Greszta A, Młynarczyk M, Dąbrowska A, Krzemińska S, Jangas M, Starzak Ł, Marciniak P, Małachowski B. Assessment of a Clothing Ensemble with an Active Heating Function Based on Thermal Manikin Tests. Materials. 2025; 18(23):5258. https://doi.org/10.3390/ma18235258

Chicago/Turabian StyleGreszta, Agnieszka, Magdalena Młynarczyk, Anna Dąbrowska, Sylwia Krzemińska, Monika Jangas, Łukasz Starzak, Paweł Marciniak, and Bartosz Małachowski. 2025. "Assessment of a Clothing Ensemble with an Active Heating Function Based on Thermal Manikin Tests" Materials 18, no. 23: 5258. https://doi.org/10.3390/ma18235258

APA StyleGreszta, A., Młynarczyk, M., Dąbrowska, A., Krzemińska, S., Jangas, M., Starzak, Ł., Marciniak, P., & Małachowski, B. (2025). Assessment of a Clothing Ensemble with an Active Heating Function Based on Thermal Manikin Tests. Materials, 18(23), 5258. https://doi.org/10.3390/ma18235258