Properties of a New Insulation Material Glass Bubble in Geopolymer Concrete

Abstract

1. Introduction

- α = thermal diffusivity,

- k = thermal conductivity,

- ρ = density and

- C = specific heat capacity

2. Experimental Details

2.1. Materials

2.2. Methods

2.2.1. Workability Test

2.2.2. Density Test

2.2.3. Compressive Strength Test

- Fm = Compressive strength (MPa)

- P = Total load (N)

- A = Area of loaded surface (mm2)

2.2.4. Water Absorption

- Ws = saturated weight (g)

- Wd = dry weight (g)

2.2.5. Thermal Insulation

3. Results and Discussions

3.1. Investigation of the Novel Geopolymer Concrete Performance of the Effects of Replacement of Glass Bubble

3.1.1. Workability

3.1.2. Density

3.1.3. Compressive Strength

3.1.4. Water Absorption

3.2. Thermal Insulation Performance of the Novel Geopolymer Concrete with Glass Bubble

3.2.1. Thermal Conductivity

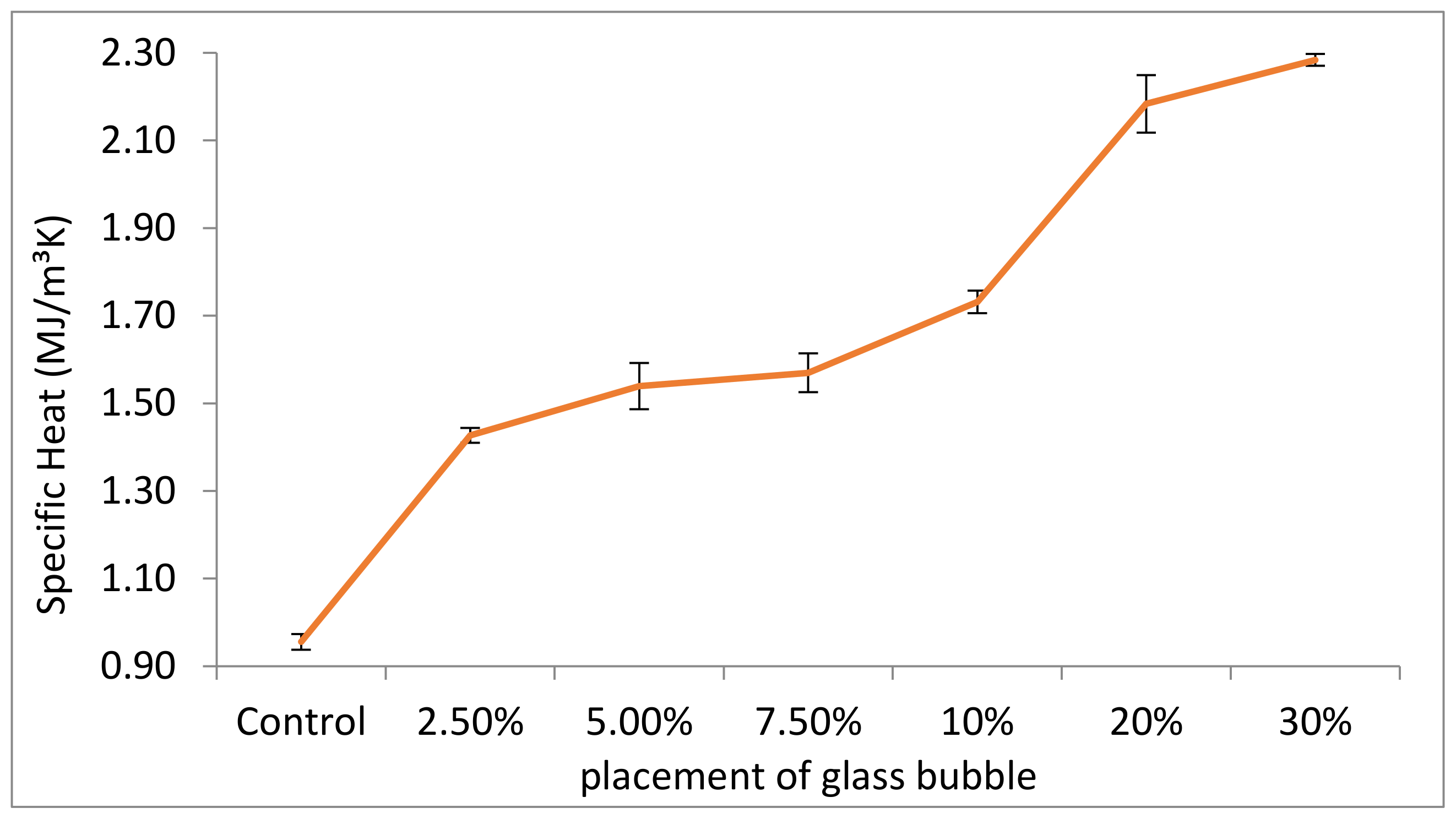

3.2.2. Specific Heat

3.2.3. Thermal Diffusivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cornaro, C.; Buratti, C. Energy efficiency in buildings and innovative materials for building construction. Appl. Sci. 2020, 10, 2866. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Butler, L.J.; West, J.S.; Tighe, S.L. Towards the classification of recycled concrete aggregates: Influence of fundamental aggregate properties on recycled concrete performance. J. Sustain. Cem. 2014, 3, 140–163. [Google Scholar] [CrossRef]

- Yu, C.R.; Sen Guo, H.; Wang, Q.C.; Chang, R.D. Revealing the impacts of passive cooling techniques on building energy performance: A residential case in Hong Kong. Appl. Sci. 2020, 10, 4188. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A. Phase change materials for energy efficiency in buildings and their use in mortars. Materials 2019, 12, 1260. [Google Scholar] [CrossRef]

- Ramírez-Villegas, R.; Eriksson, O.; Olofsson, T. Life cycle assessment of building renovation measures–trade-off between building materials and energy. Energies 2019, 12, 344. [Google Scholar] [CrossRef]

- Ruuska, A.; Häkkinen, T. Material efficiency of building construction. Buildings 2014, 4, 266–294. [Google Scholar] [CrossRef]

- La Gennusa, M.; Llorach-Massana, P.; Montero, J.I.; Peña, F.J.; Rieradevall, J.; Ferrante, P.; Scaccianoce, G.; Sorrentino, G. Composite building materials: Thermal and mechanical performances of samples realised with hay and natural resins. Sustainability 2017, 9, 373. [Google Scholar] [CrossRef]

- Shahedan, N.F.; Abdullah, M.M.A.B.; Mahmed, N.; Kusbiantoro, A.; Binhussain, M.; Zailan, S.N. Review on thermal insulation performance in various type of concrete. AIP Conf. Proc. 2017, 1835, 020046. [Google Scholar]

- Hu, J.; Wang, K.; Ge, Z. Study of concrete thermal properties for sustainable pavement design. J. Sustain. Cem. Based 2012, 1, 126–137. [Google Scholar] [CrossRef]

- Qiang Li Wang, H.; Zuhua, Z.; Reid, A. Numerical simulation of porosity on thermal properties and fire resistance of foamed concrete. J. Sustain. Cem. Based 2013, 2, 13–19. [Google Scholar]

- Biswas, K.; Shrestha, S.S.; Bhandari, M.S.; Desjarlais, A.O. Insulation materials for commercial buildings in North America: An assessment of lifetime energy and environmental impacts. Energy Build. 2016, 112, 256–269. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Liu MY, J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Yun, T.S.; Jeong, Y.J.; Han, T.-S.; Youm, K.-S. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013, 61, 125–132. [Google Scholar] [CrossRef]

- Liang, J.Z.; Li, F.H. Measurement of thermal conductivity of hollow glass-bead-filled polypropylene composites. Polym. Test. 2006, 25, 527–531. [Google Scholar] [CrossRef]

- Oreshkin, D.; Semenov, V.; Rozovskaya, T. Properties of light-weight extruded concrete with hollow glass microspheres. Procedia Eng. 2016, 153, 638–643. [Google Scholar] [CrossRef]

- Ren, S.; Liu, J.; Guo, A.; Zang, W.; Geng, H.; Tao, X.; Du, H. Mechanical properties and thermal conductivity of a temperature resistance hollow glass microspheres/borosilicate glass buoyance material. Mater. Sci. Eng. A 2016, 674, 604–614. [Google Scholar] [CrossRef]

- Shahidan, S.; Aminuddin, E.; Noor, K.M.; Izzati, N.; Hannan, R.R.; Amira, N.; Bahari, S. Potential of Hollow Glass Microsphere as Cement Replacement for Lightweight Foam Concrete on Thermal Insulation Performance. MATEC Web Conf. 2017, 103, 1–9. [Google Scholar] [CrossRef]

- Swetha, C.; Kumar, R. Quasi-static uni-axial compression behaviour of hollow glass microspheres/epoxy based syntactic foams. Mater. Des. 2011, 32, 4152–4163. [Google Scholar] [CrossRef]

- Ueki Peres, C.Y.; Munhoz, A.H.; Miranda, L.F.; Neto, A.C.; Zandonadi, A.R.; Peres, R.M.; Diaz, F.R.V. Concrete with Addition of Hollow Glass Microspheres. Mater. Sci. Forum 2015, 820, 509–514. [Google Scholar] [CrossRef]

- Yung, K.C.; Zhu, B.L.; Yue, T.M.; Xie, C.S. Preparation and properties of hollow glass microsphere-filled epoxy-matrix composites. Compos. Sci. Technol. 2009, 69, 260–264. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Qin, Q.H. Modelling and characterisation of effective thermal conductivity of single hollow glass microsphere and its powder. Materials 2018, 11, 133. [Google Scholar] [CrossRef]

- Wang, H.; Hou, F.; Zhao, X. Simulation of Thermal Behavior in Hollow-glass-microsphere-filled. Cem. Compos. 2015, 4, 1–11. [Google Scholar]

- Hanif, A.; Diao, S.; Lu, Z.; Fan, T.; Li, Z. Green lightweight cementitious composite incorporating aerogels and fly ash cenospheres—Mechanical and thermal insulating properties. Constr. Build. Mater. 2016, 116, 422–430. [Google Scholar] [CrossRef]

- Nazarimofrad, E.; Shaikh, F.U.A.; Nili, M. Effects of steel fibre and silica fume on impact behaviour of recycled aggregate concrete. J. Sustain. Cem. Based Mater. 2017, 6, 54–68. [Google Scholar] [CrossRef]

- Zaman, A.U. Measuring waste management performance using the “Zero Waste Index”: The case of Adelaide, Australia. J. Clean. Prod. 2014, 66, 407–419. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Van Dao, D.; Ly, H.B.; Trinh, S.H.; Le, T.T.; Pham, B.T. Artificial intelligence approaches for prediction of compressive strength of geopolymer concrete. Materials 2019, 12, 983. [Google Scholar]

- Nergis, D.D.B.; Abdullah, M.M.A.B.; Sandu, A.V.; Vizureanu, P. XRD and TG-DTA study of new alkali activated materials based on fly ash with sand and glass powder. Materials 2020, 13, 343. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Tarallo, O.; Ferone, C.; Colangelo, F.; Roviello, V.; Cioffi, R. Innovative fly ash geopolymer-epoxy composites: Preparation, microstructure and mechanical properties. Materials 2016, 9, 461. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, J.; Wang, J.; Wang, C.; Huang, P.; Fang, C. Sulfate resistance of recycled aggregate concrete with GGBS and fly ash-based geopolymer. Materials 2019, 12, 1247. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part. B 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Sasui, S.; Kim, G.; Nam, J.; Koyama, T.; Chansomsak, S. Strength and microstructure of class-C fly ash and GGBS blend geopolymer activated in NaOH & NaOH + Na2SiO3. Materials 2020, 13, 59. [Google Scholar]

- Kuo, W.-T.; Liu, M.Y.; Juang, C.U. Bonding behavior of repair material using fly-ash/ground granulated blast furnace slag-based geopolymer. Materials 2019, 12, 1697. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, U.S.; Wanjari, S.P.; Naresh, D.N. Characteristic study of geopolymer fly ash sand as a replacement to natural river sand. Constr. Build. Mater. 2017, 150, 681–688. [Google Scholar] [CrossRef]

- Prochon, P.; Zhao, Z.; Courard, L.; Piotrowski, T.; Michel, F.; Garbacz, A. Influence of Activators on Mechanical Properties of Modified Fly Ash Based Geopolymer Mortars. Materials 2020, 13, 1033. [Google Scholar] [CrossRef]

- Biondi, L.; Perry, M.; Vlachakis, C.; Wu, Z.; Hamilton, A.; McAlorum, J. Ambient cured fly ash geopolymer coatings for concrete. Materials 2019, 16, 923. [Google Scholar] [CrossRef] [PubMed]

- Bentz, D.; Peltz, M.; Durán-Herrera, A.; Valdez, P.; Juárez, C. Thermal properties of high-volume fly ash mortars and concretes. J. Build. Phys. 2011, 34, 263–275. [Google Scholar] [CrossRef]

- ASTM C168-97. Standard Terminology Relating to Thermal Insulating Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 1997.

- Do Yun, H.; Ahn, K.L.; Jang, S.J.; Khil, B.S.; Park, W.S.; Kim, S.W. Thermal and Mechanical Behaviors of Concrete with Incorporation of Strontium-Based Phase Change Material (PCM). Int. J. Concr. Struct. Mater. 2019, 13, 18. [Google Scholar] [CrossRef]

- De Schutter, G.; Taerwe, L. Specific heat and thermal diffusivity of hardening concrete. Mag. Concr. Res. 1995, 47, 203–208. [Google Scholar] [CrossRef]

- Cavanaugh, K.; Speck, J.F. Guide to Thermal Properties of Concrete and Masonry Systems; ACI Committee 122; American Concrete Institute: Farmington Hills, MN, USA, 2002. [Google Scholar]

- Gustafsson, S.E. Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Rev. Sci. Instrum. 1991, 62, 797–804. [Google Scholar] [CrossRef]

- Al-Ajlan, S.A. Measurements of thermal properties of insulation materials by using transient plane source technique. Appl. Therm. Eng. 2006, 26, 2184–2191. [Google Scholar] [CrossRef]

- Choktaweekarn, P.; Saengsoy, W.; Tangtermsirikul, S. A model for predicting the specific heat capacity of fly-ash concrete. ScienceAsia 2009, 35, 178–182. [Google Scholar] [CrossRef]

- Al Faruq, S.A.; Alamin, M.; Hasan, M.R.; Haque, M.T.; Alam, S. Measuring specific heat of normal strength concrete and the comparison of the specific heat with different types of concrete. Int. J. Adv. Struct. Geotech. Eng. 2013, 2, 4–11. [Google Scholar]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Tunner R., H. Steady Heat Condition. Heat Mass Transfer a Practical Approach, 3rd ed.; McGraw-Hill: Boston, MA, USA, 2006. [Google Scholar]

- Amos, S.E.; Yalcin, B. Hollow Glass Microspheres for Plastics, Elastomers, and Adhesives Compounds; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- ASTM C618. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2001.

- De Gracia, A.; Barreneche, C.; Farid, M.M.; Cabeza, L.F. New equipment for testing steady and transient thermal performance of multilayered building envelopes with PCM. Energy Build. 2011, 43, 3704–3709. [Google Scholar] [CrossRef]

- Prakash, D. Transient analysis and improvement of indoor thermal comfort for an air-conditioned room with thermal insulations. Ain Shams Eng. J. 2015, 6, 947–956. [Google Scholar] [CrossRef]

- Bouguerra, A.; Laurent, J.P.; Goual, M.S.; Queneudec, M. The measurement of the thermal conductivity of solid aggregates using the transient plane source technique. J. Phys. D Appl. Phys. 1999, 30, 2900–2904. [Google Scholar] [CrossRef]

- ASTM C143. Standard Test Method for Slump of Hydraulic-Cement Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM C39. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ASTM C1585-04. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- Bouguerra, A.; Aït-Mokhtar, A.; Amiri, O.; Diop, M.B. Measurement of thermal conductivity, thermal diffusivity and heat capacity of highly porous building materials using transient plane source technique. Int. Commun. Heat Mass Transf. 2001, 28, 1065–1078. [Google Scholar] [CrossRef]

- Yüksel, N. The Review of Some Commonly Used Methods and Techniques to Measure the Thermal Conductivity of Insulation Materials; Insulation Materials in Context of Sustainability; IntechOpen: London, UK, 2016. [Google Scholar]

- Tye, R.P.; Kubičár, L.; Lockmuller, N. The development of a standard for contact transient methods of measurement of thermophysical properties. Int. J. Thermophys. 2005, 26, 1917–1938. [Google Scholar] [CrossRef]

- Vartanyan, M.A.; Gerasimov, R.I.; Pyren’kin, O.V.; Dolbilova, I.B.; Oistrakh, A.V.; Somov, A.A. Study of heat insulation material thermal conductivity by a hot-wire method. Refract. Ind. Ceram. 2016, 57, 332–333. [Google Scholar] [CrossRef]

- Ranjbar, N.; Behnia, A.; Alsubari, B.; Moradi Birgani, P.; Jumaat, M.Z. Durability and mechanical properties of self-compacting concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016, 112, 723–730. [Google Scholar] [CrossRef]

- Boga, J.A.; Gomes, M.G.; Gomes, A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 2013, 53, 962–972. [Google Scholar] [CrossRef]

- Budaiwi, I.; Abdou, A.; Al-Homoud, M. Variations of thermal conductivity of insulation materials under different operating temperatures: Impact on envelope-induced cooling load. J. Archit. Eng. 2002, 8, 125–132. [Google Scholar] [CrossRef]

- Berata, W.; Wijanarko, W.; Sidharta, I. Effect of volume fraction epoxy-hollow glass microspheres and curing temperature variation on compressive properties. ARPN J. Eng. Appl. Sci. 2016, 11, 2729–2733. [Google Scholar]

- Abdou, A.A.; Budaiwi, I.M. Comparison of thermal conductivity measurements of building insulation materials under various operating temperatures. J. Build. Phys. 2005, 29, 171–184. [Google Scholar] [CrossRef]

- Kontoleon, K.J.; Theodosiou, T.G.; Tsikaloudaki, K.G. The influence of concrete density and conductivity on walls’ thermal inertia parameters under a variety of masonry and insulation placements. Appl. Energy 2013, 112, 325–337. [Google Scholar] [CrossRef]

- Li, B.; Yuan, J.; An, Z.; Zhang, J. Effect of microstructure and physical parameters of hollow glass microsphere on insulation performance. Mater. Lett. 2011, 65, 1992–1994. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Ng, S.-C.; Low, K.-S. Thermal conductivity of newspaper sandwiched aerated lightweight concrete panel. Energy Build. 2010, 42, 2452–2456. [Google Scholar] [CrossRef]

- Liu, Z.; Ding, Y.; Wang, F.; Deng, Z. Thermal insulation material based on SiO2 aerogel. Constr. Build. Mater. 2016, 122, 548–555. [Google Scholar] [CrossRef]

- Nagy, B.; Nehme, S.G.; Szagri, D. Thermal properties and modeling of fiber reinforced concretes. Energy Procedia 2015, 78, 2742–2747. [Google Scholar] [CrossRef]

- Mathis, N. Transient thermal conductivity measurements: Comparison of destructive and nondestructive techniques. In Proceedings of the 15th European Conference on Thermophysical Properties Proceedings, Würzburg, Germany, 5–9 September 2000; Volume 32, pp. 321–327. [Google Scholar]

- Mounir, S.; Maaloufa, Y.; Khabbazi, A. Thermal properties of the composite material clay/granular cork. Constr. Build. Mater. 2014, 70, 183–190. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Chan, J. Thermal Properties of Concrete with Different Swedish Aggregate Materials; Lund University: Lund, Sweden, 2013. [Google Scholar]

| Materials | Parameter | ||

|---|---|---|---|

| Aggregate | Coarse 60% | Aggregate | 60% |

| Fine 40% | |||

| Fly Ash | Binder | 40% | |

| Sodium Silicate | |||

| Sodium Hydroxide | |||

| Solid/Liquid | 2.0 | ||

| Na2SiO3/NaOH | 2.5 | ||

| Glass Bubble (%) | 0, 2.5, 5.0, 7.5, 10, 20, 30 | ||

| Glass Bubble (%) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Fly Ash (kg/m3) | Sodium Hydroxide (kg/m3) | Sodium Silicate (kg/m3) |

|---|---|---|---|---|---|

| 0 | 864 | 576 | 640 | 91.40 | 228.60 |

| 2.5 | 842.4 | 561 | 624 | 89.12 | 222.89 |

| 5.0 | 820.8 | 547.2 | 608 | 86.83 | 217.17 |

| 7.5 | 799.2 | 532.8 | 592 | 84.55 | 211.46 |

| 10.0 20.0 30.0 | 777.6 691.2 604.8 | 518.4 460.8 403.2 | 576 512 448 | 82.26 73.12 63.98 | 205.74 182.88 160.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahedan, N.F.; Abdullah, M.M.A.B.; Mahmed, N.; Kusbiantoro, A.; Tammas-Williams, S.; Li, L.-Y.; Aziz, I.H.; Vizureanu, P.; Wysłocki, J.J.; Błoch, K.; et al. Properties of a New Insulation Material Glass Bubble in Geopolymer Concrete. Materials 2021, 14, 809. https://doi.org/10.3390/ma14040809

Shahedan NF, Abdullah MMAB, Mahmed N, Kusbiantoro A, Tammas-Williams S, Li L-Y, Aziz IH, Vizureanu P, Wysłocki JJ, Błoch K, et al. Properties of a New Insulation Material Glass Bubble in Geopolymer Concrete. Materials. 2021; 14(4):809. https://doi.org/10.3390/ma14040809

Chicago/Turabian StyleShahedan, Noor Fifinatasha, Mohd Mustafa Al Bakri Abdullah, Norsuria Mahmed, Andri Kusbiantoro, Sam Tammas-Williams, Long-Yuan Li, Ikmal Hakem Aziz, Petrică Vizureanu, Jerzy J. Wysłocki, Katarzyna Błoch, and et al. 2021. "Properties of a New Insulation Material Glass Bubble in Geopolymer Concrete" Materials 14, no. 4: 809. https://doi.org/10.3390/ma14040809

APA StyleShahedan, N. F., Abdullah, M. M. A. B., Mahmed, N., Kusbiantoro, A., Tammas-Williams, S., Li, L.-Y., Aziz, I. H., Vizureanu, P., Wysłocki, J. J., Błoch, K., & Nabiałek, M. (2021). Properties of a New Insulation Material Glass Bubble in Geopolymer Concrete. Materials, 14(4), 809. https://doi.org/10.3390/ma14040809