Effect of Temperature on Deformation and Fatigue Behaviour of A356–T7 Cast Aluminium Alloys Used in High Specific Power IC Engine Cylinder Heads

Abstract

1. Introduction

2. Materials and Methods

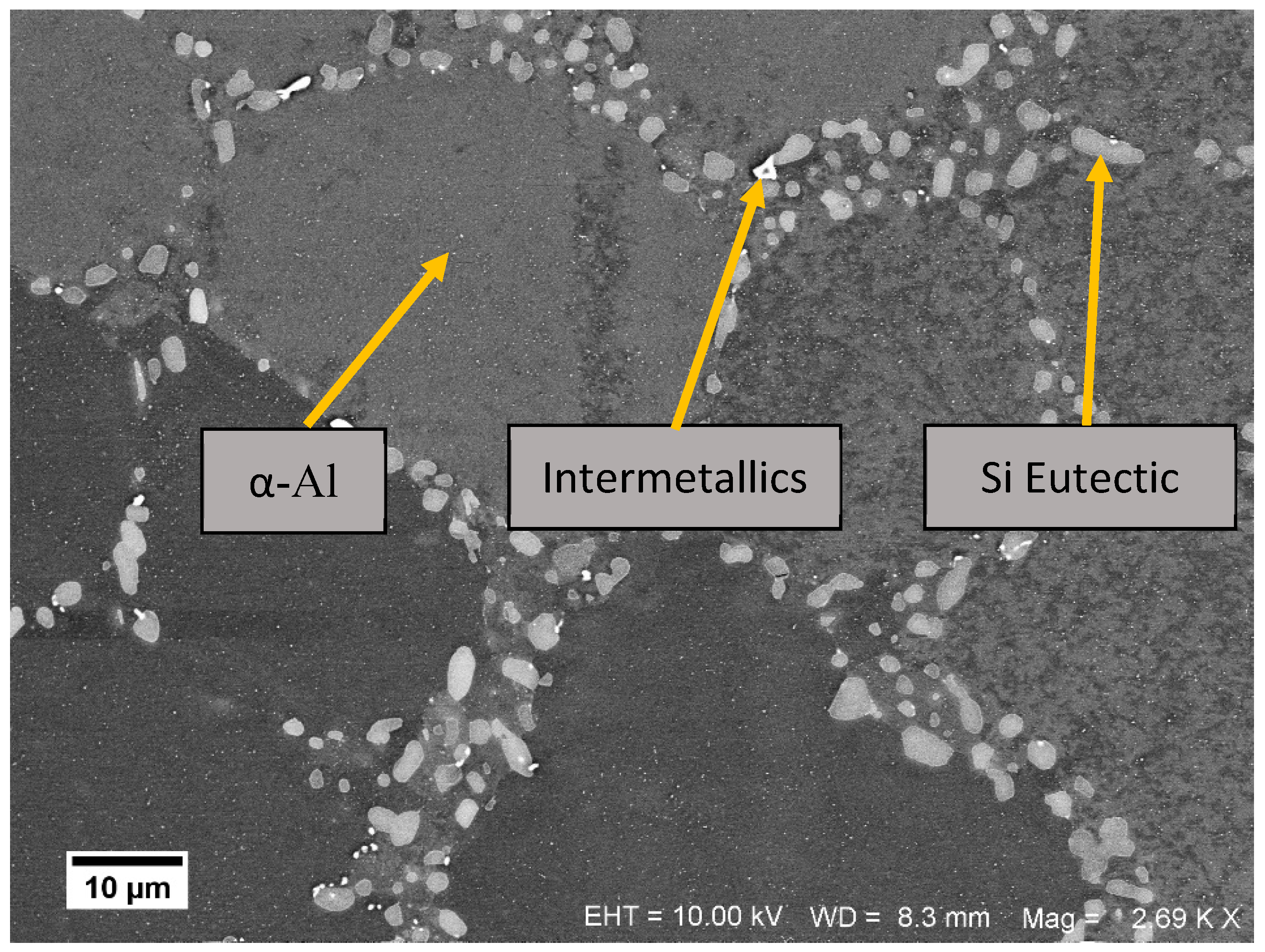

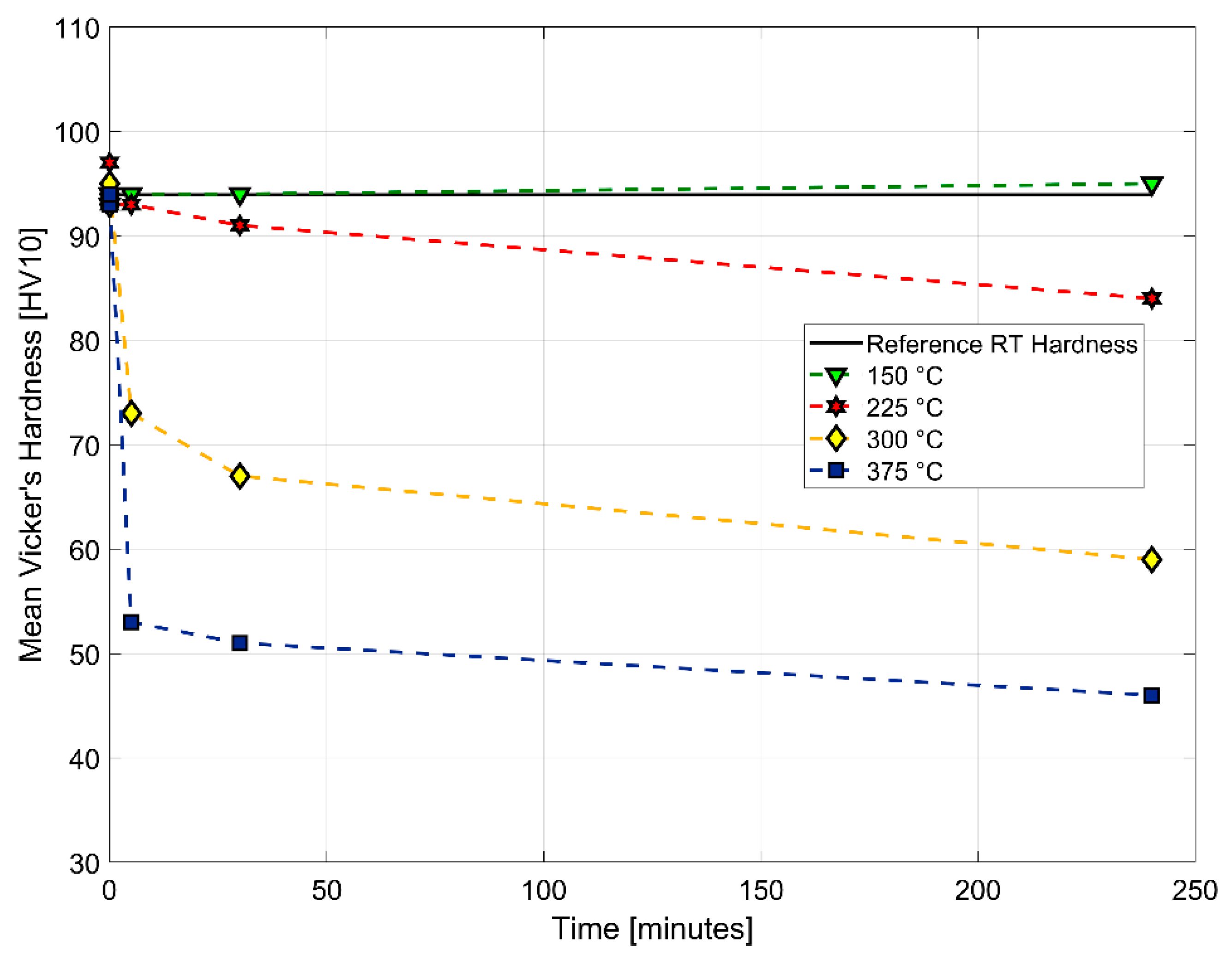

2.1. Material

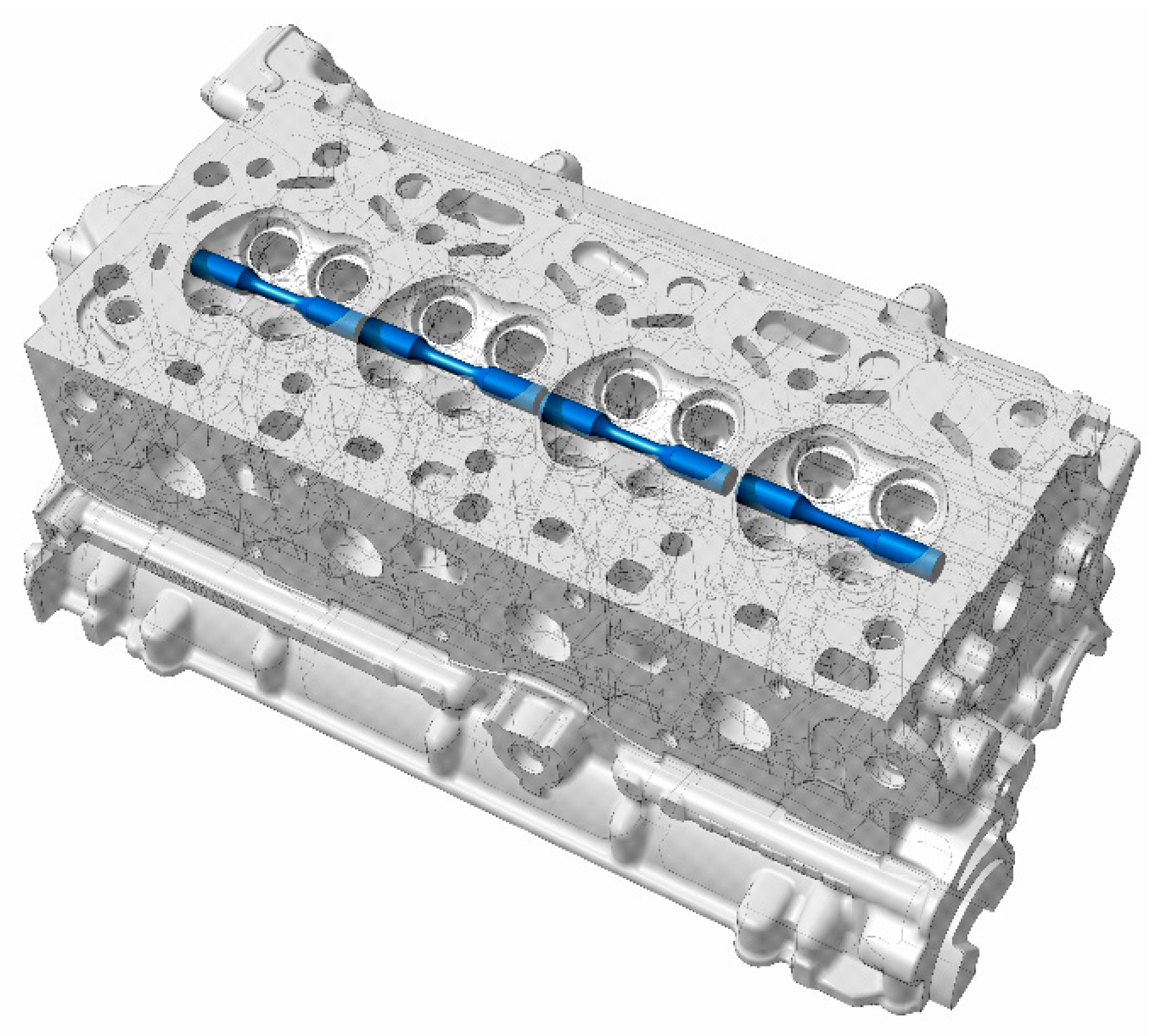

2.2. Sample Extraction

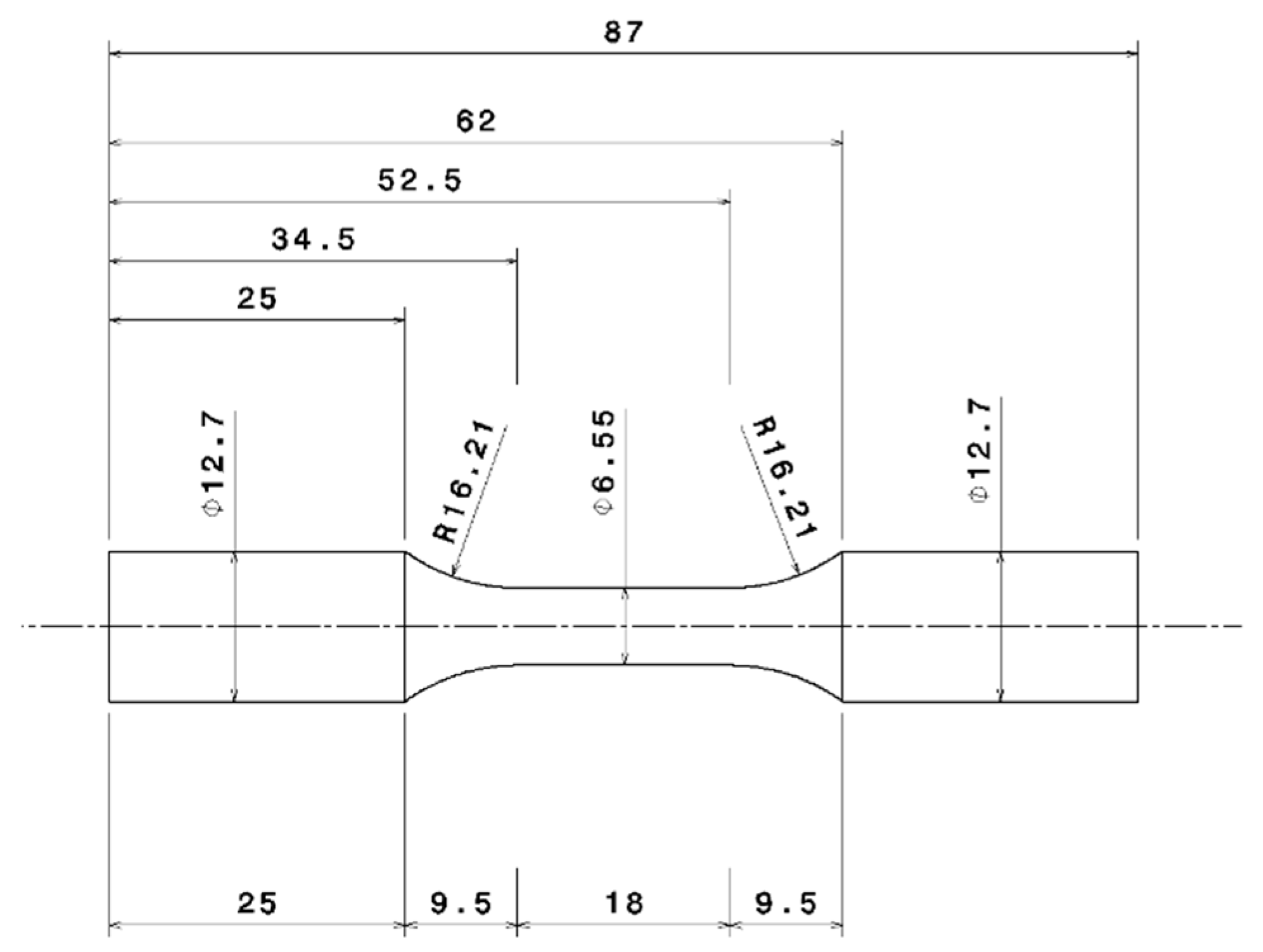

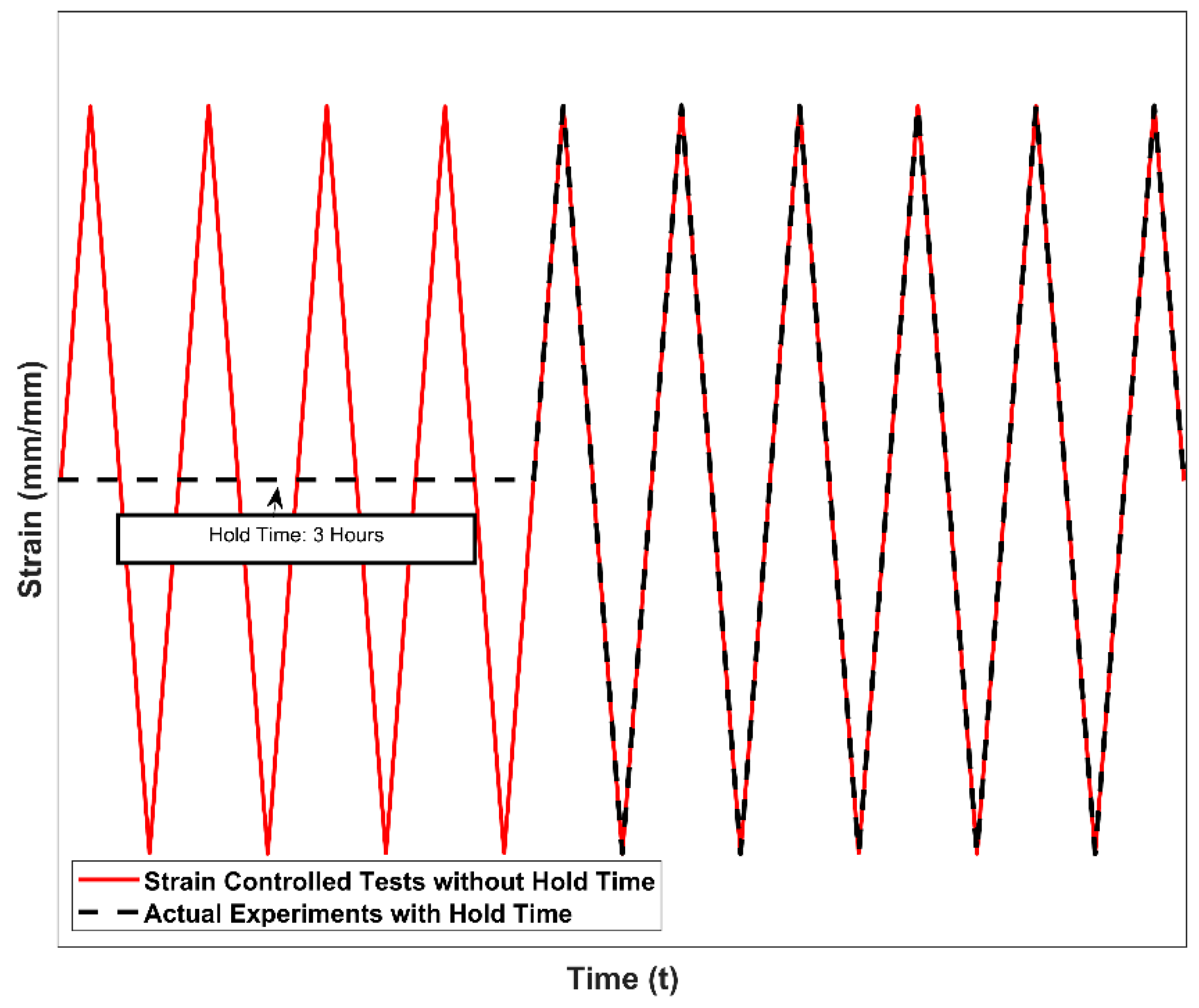

2.3. Testing

2.3.1. Test Equipment

2.3.2. Heat up and Temperature Stabilization

2.3.3. Sample Preparation and Testing

3. Results

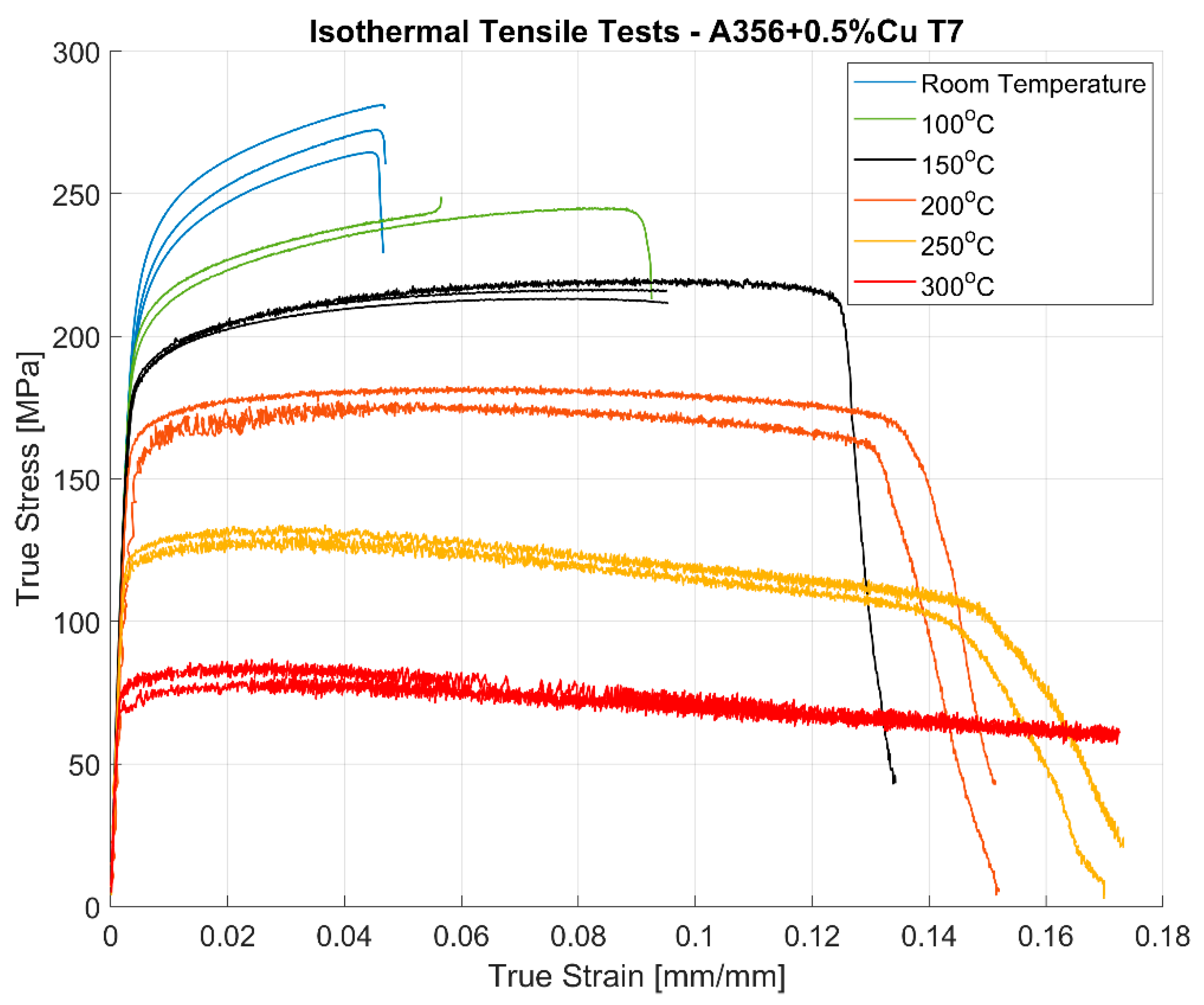

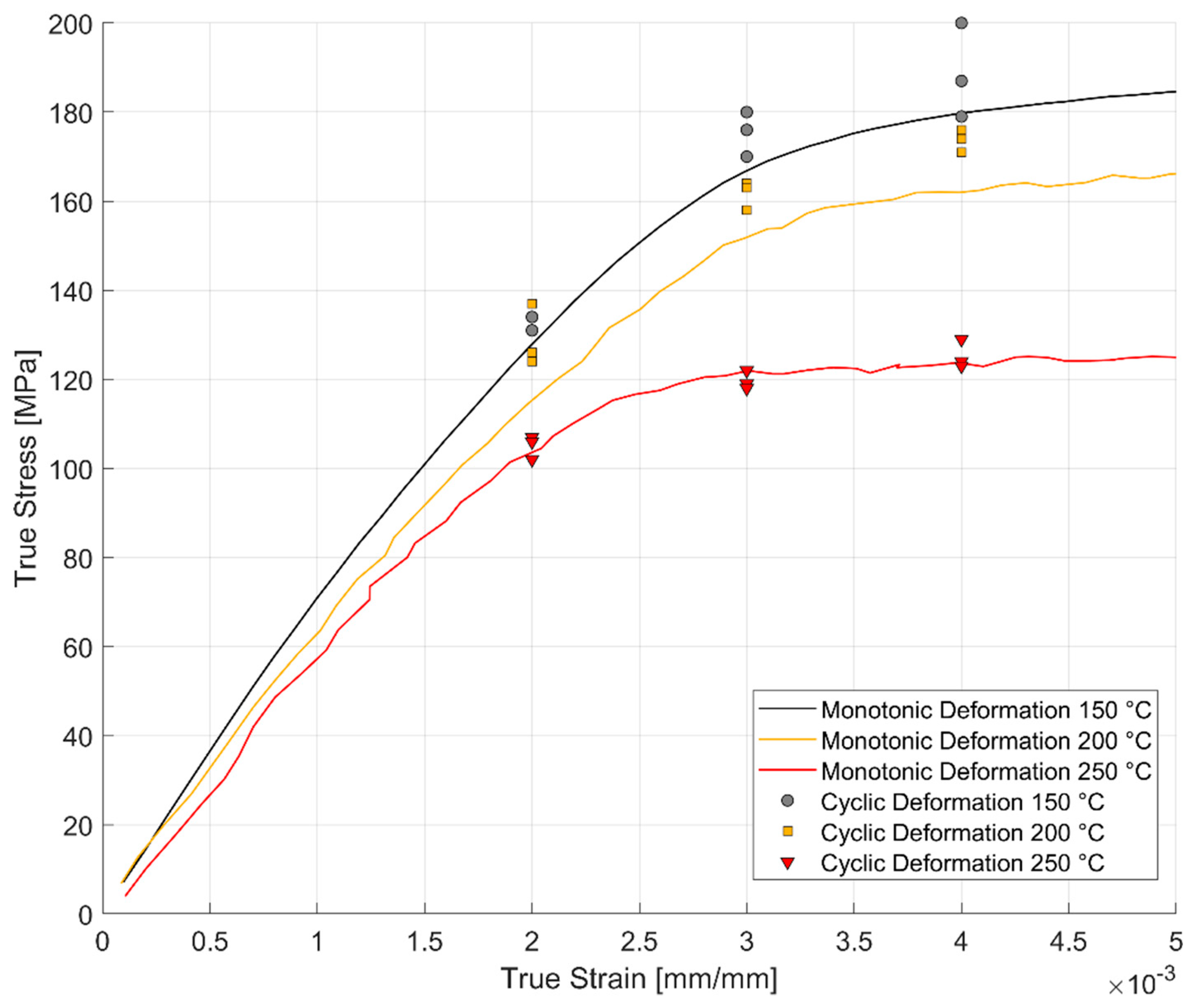

3.1. Monotonic Deformation

3.2. Strain Controlled Fatigue Tests

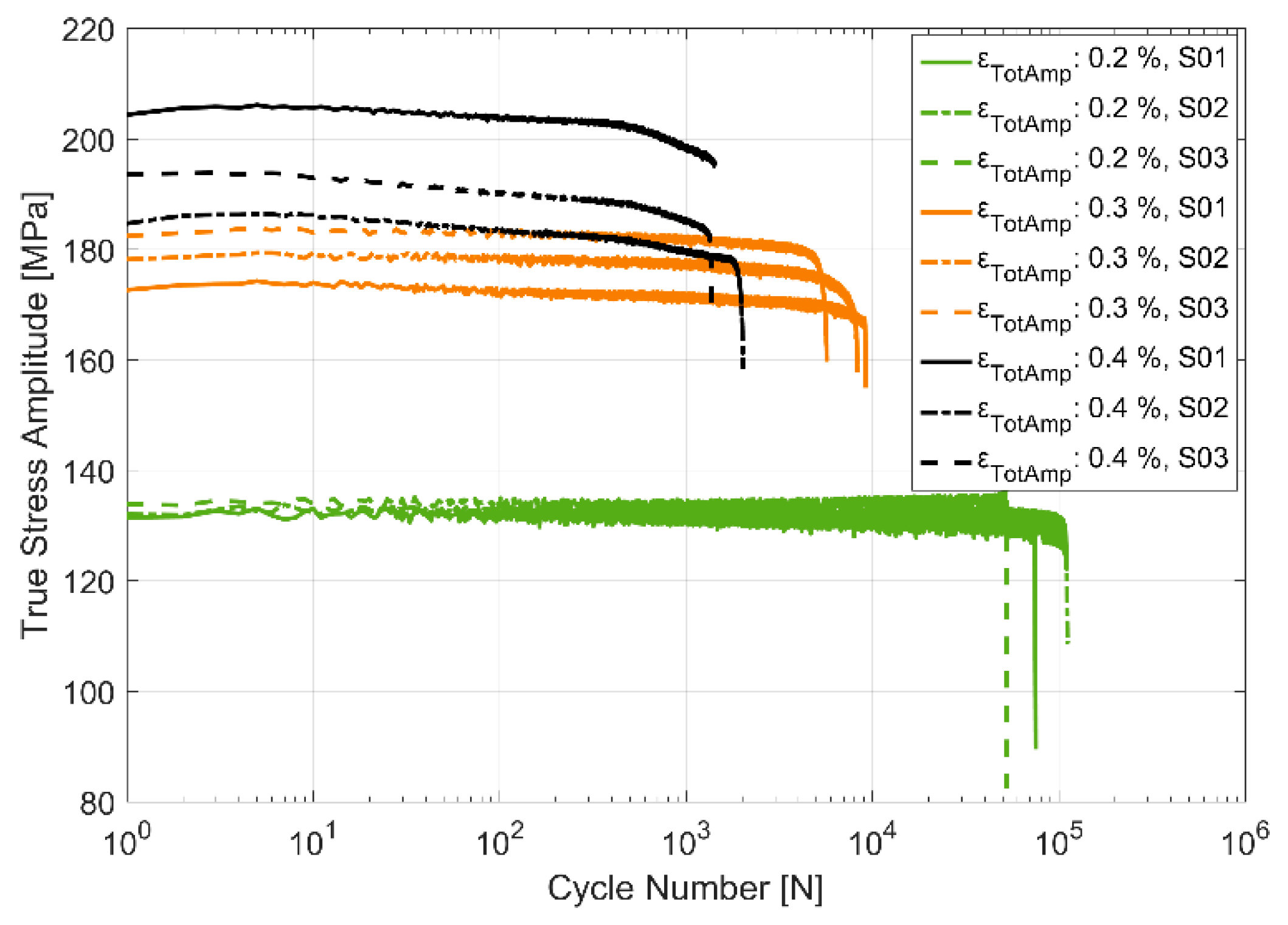

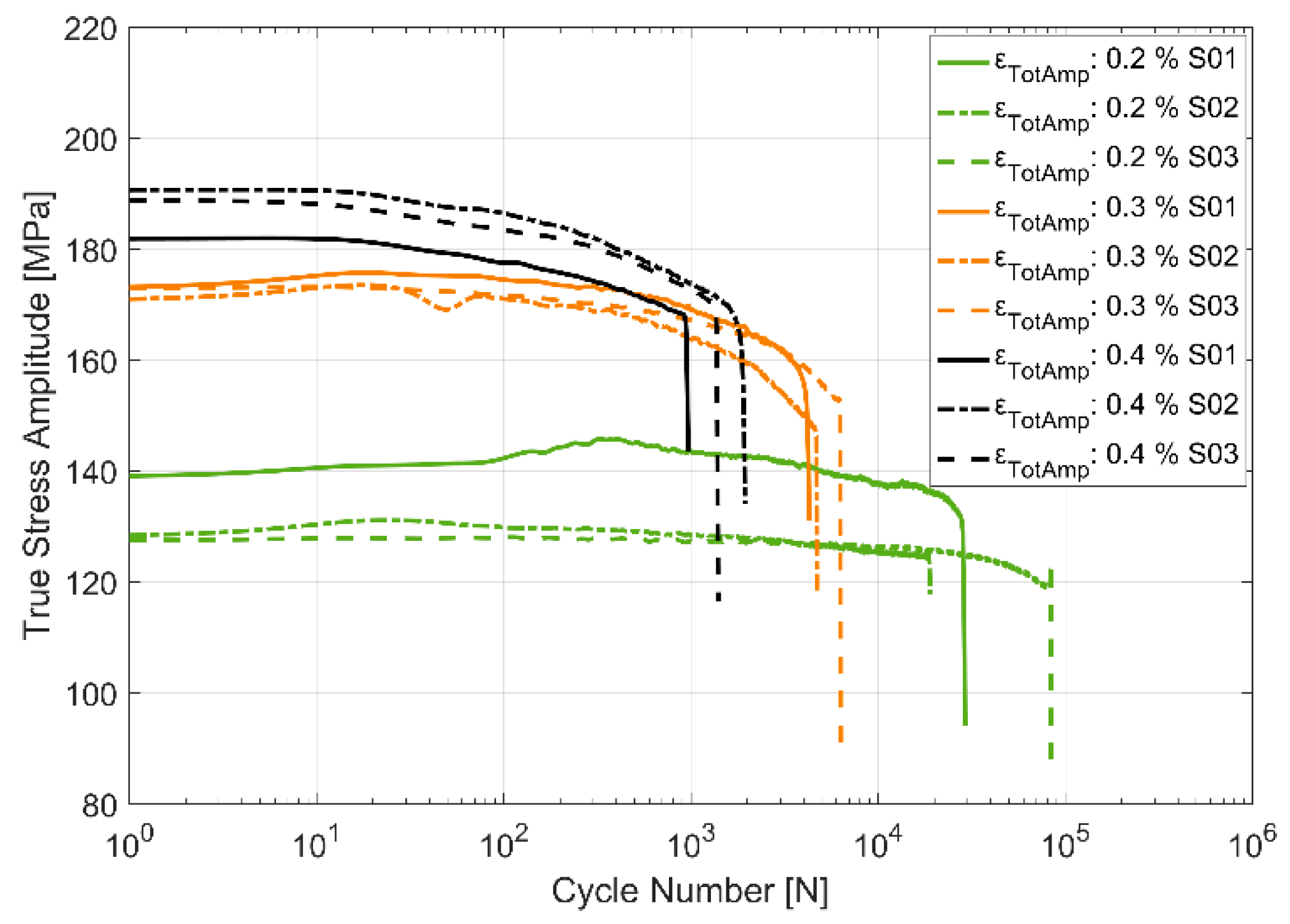

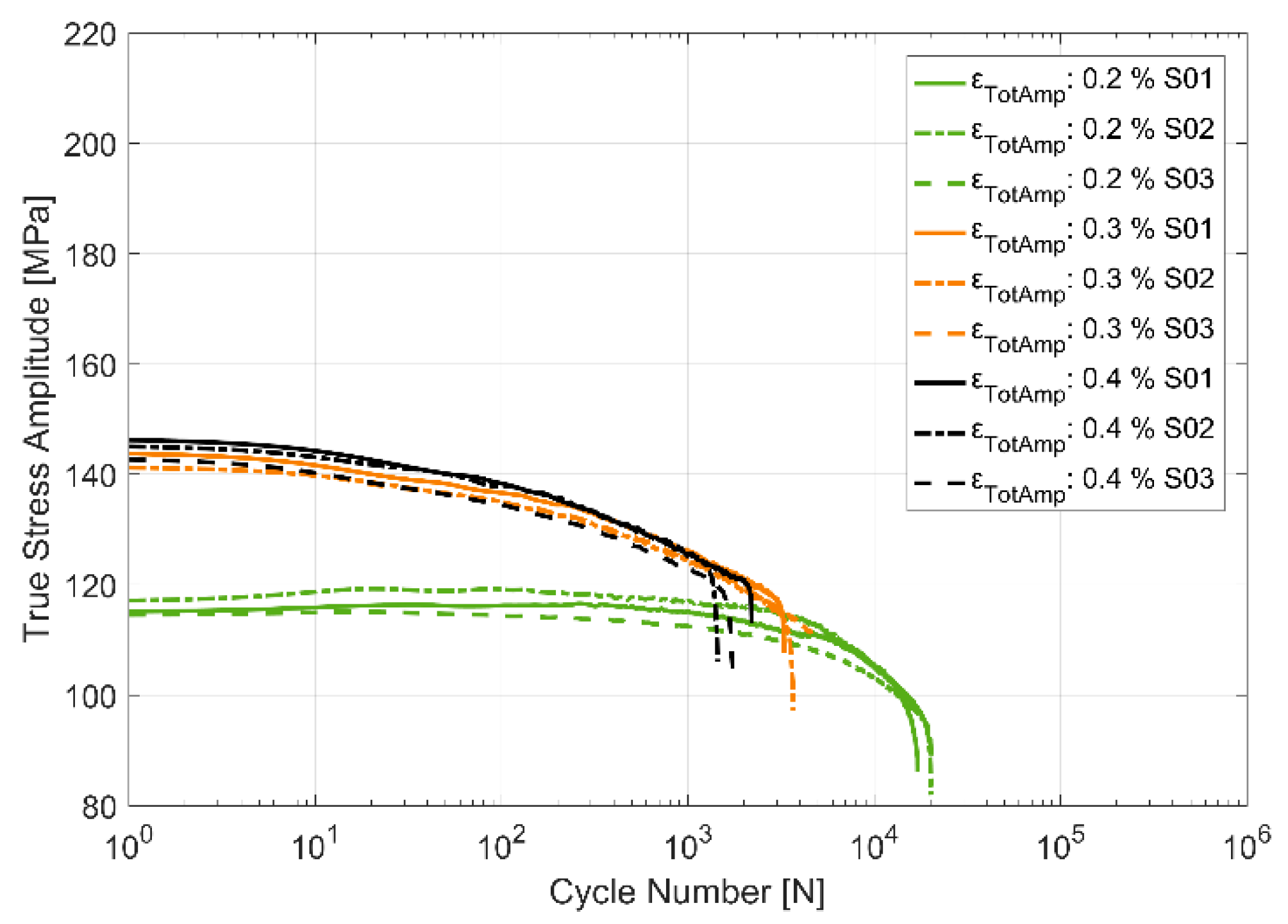

3.2.1. Stress Evolution

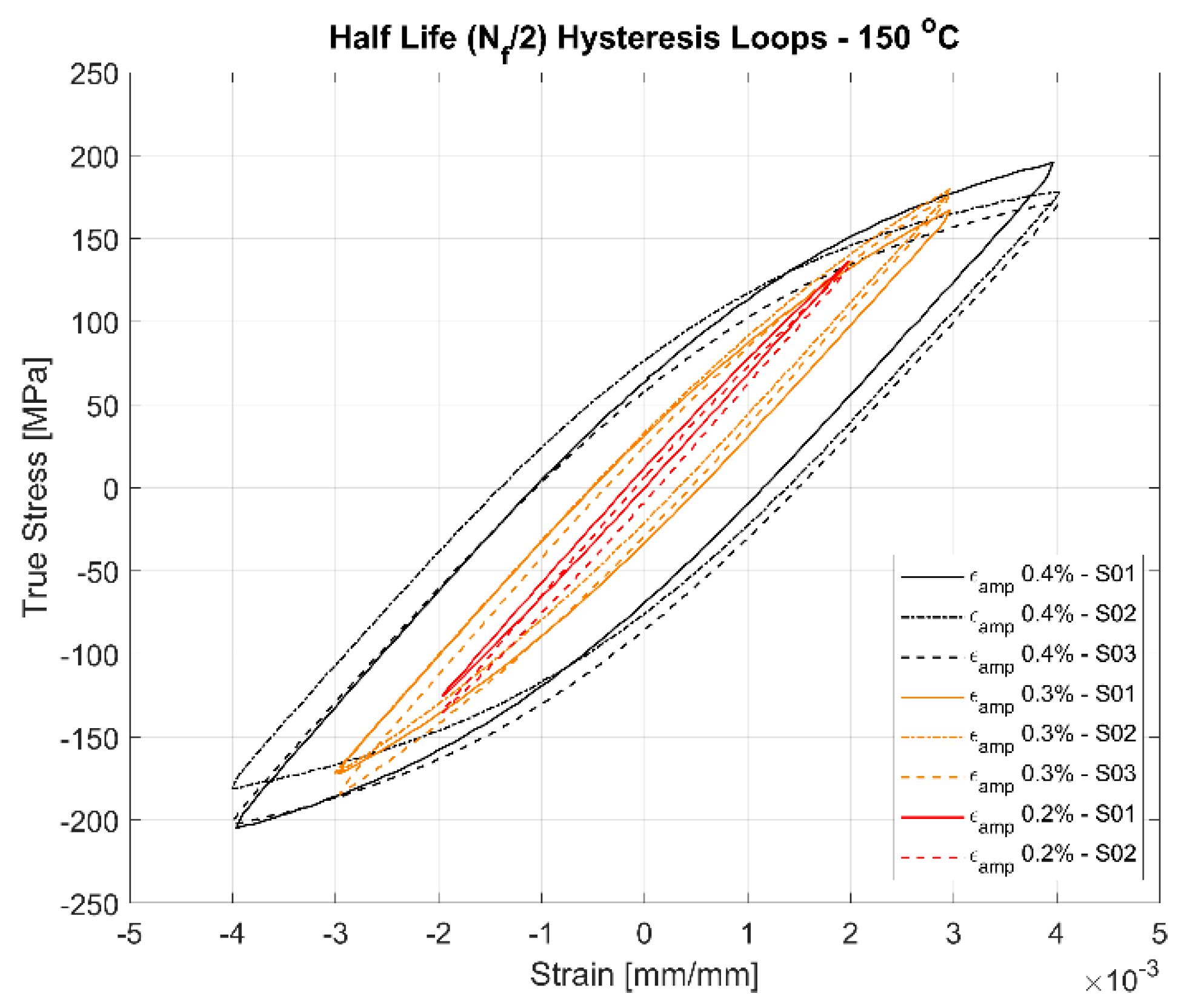

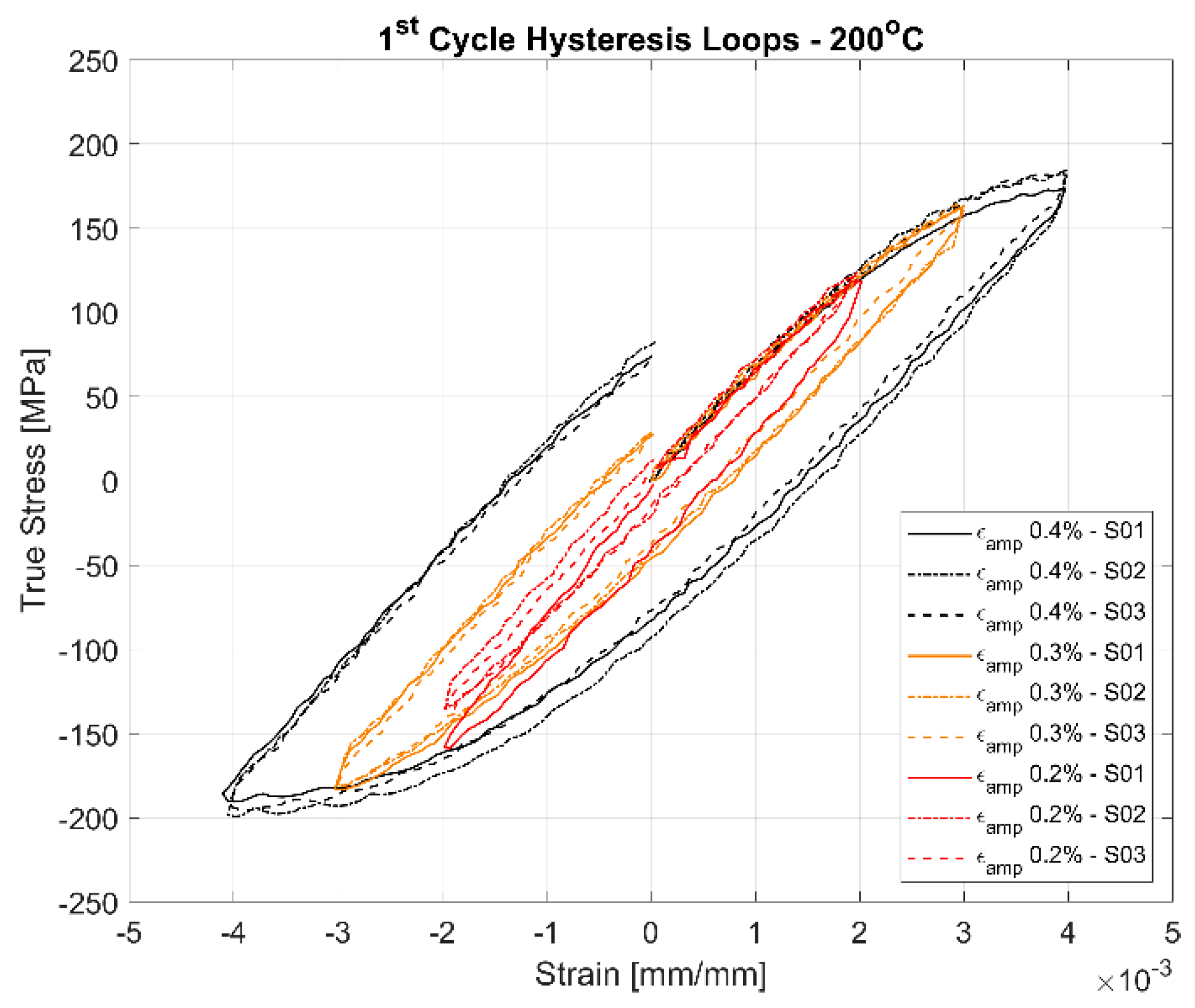

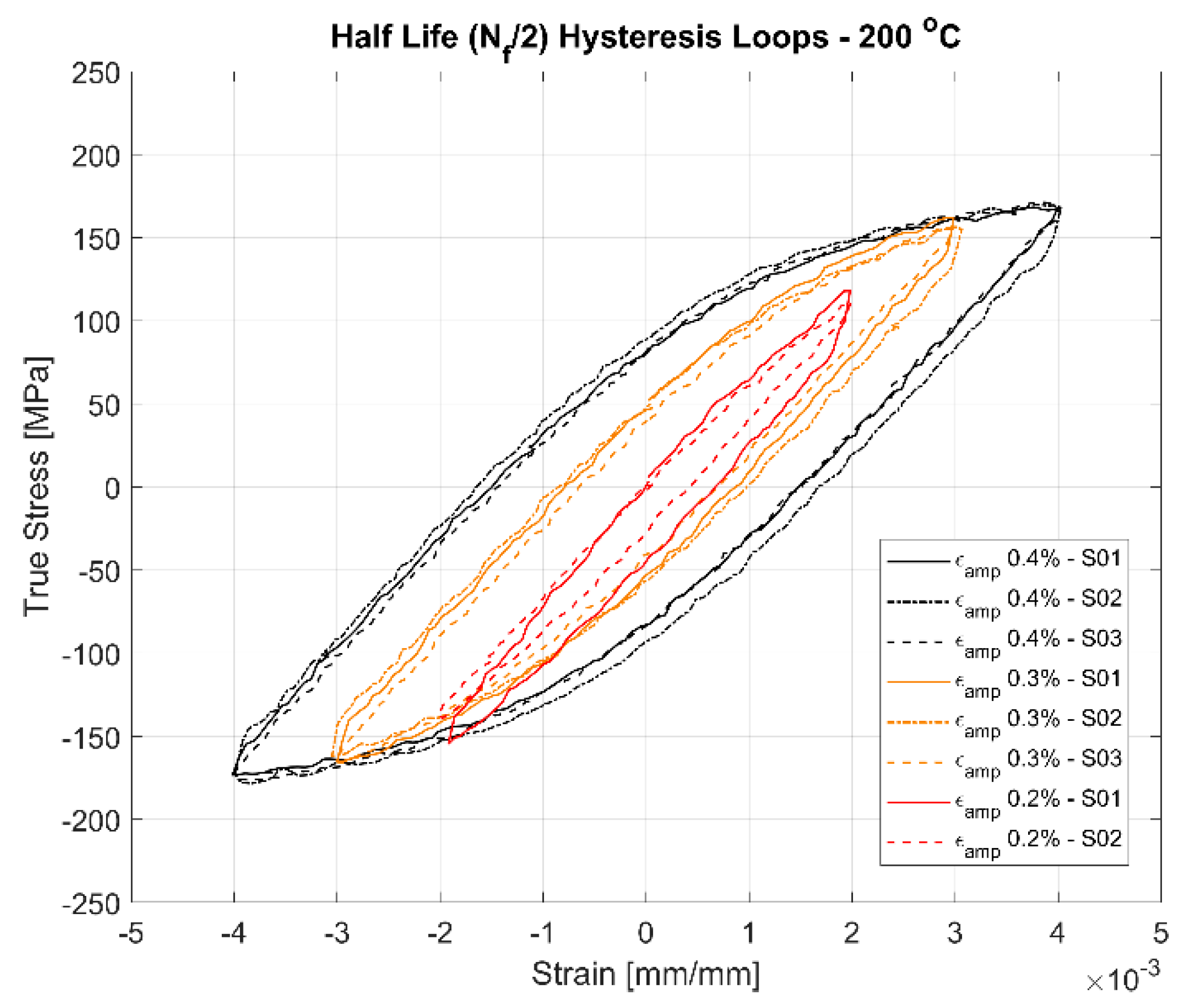

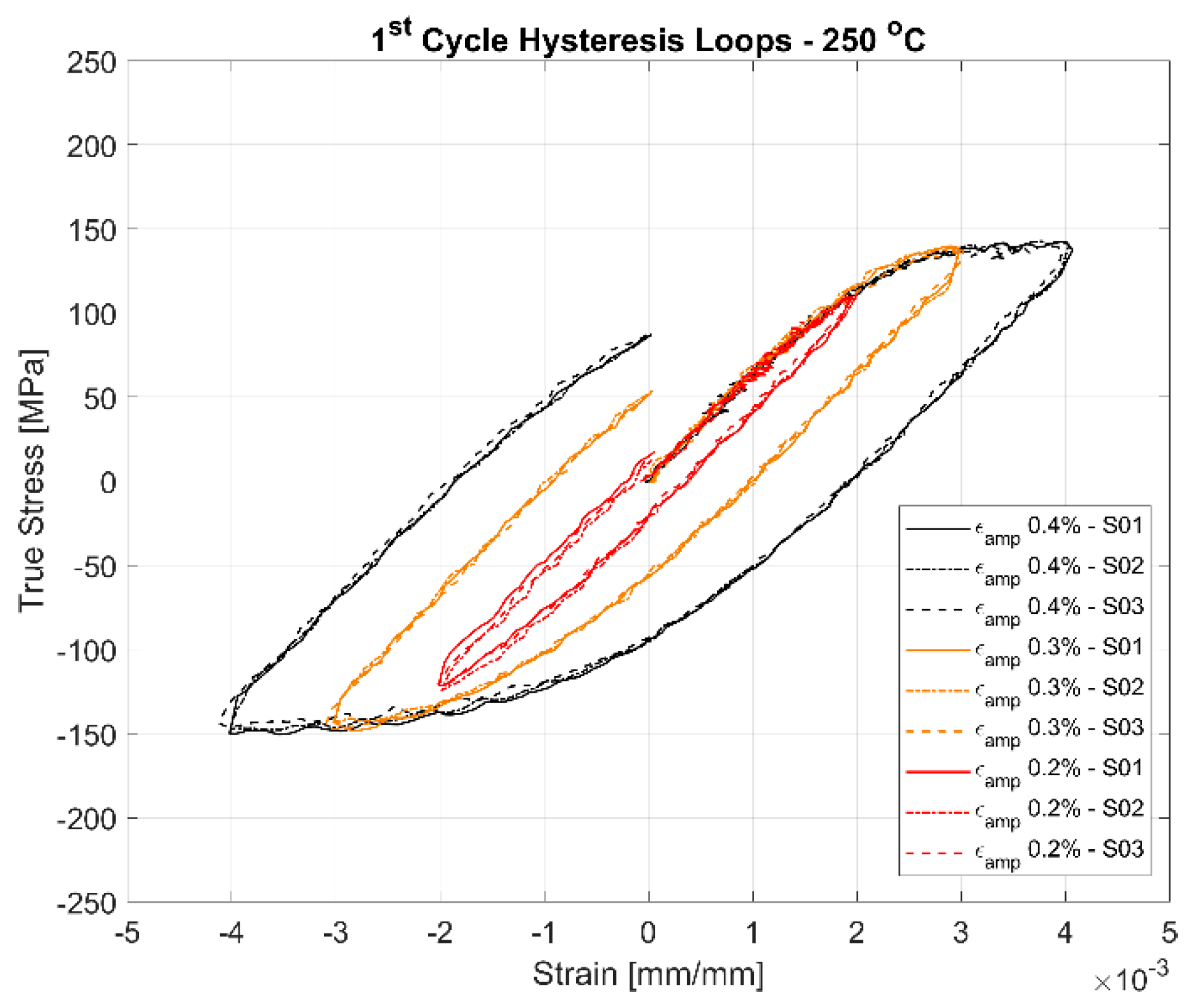

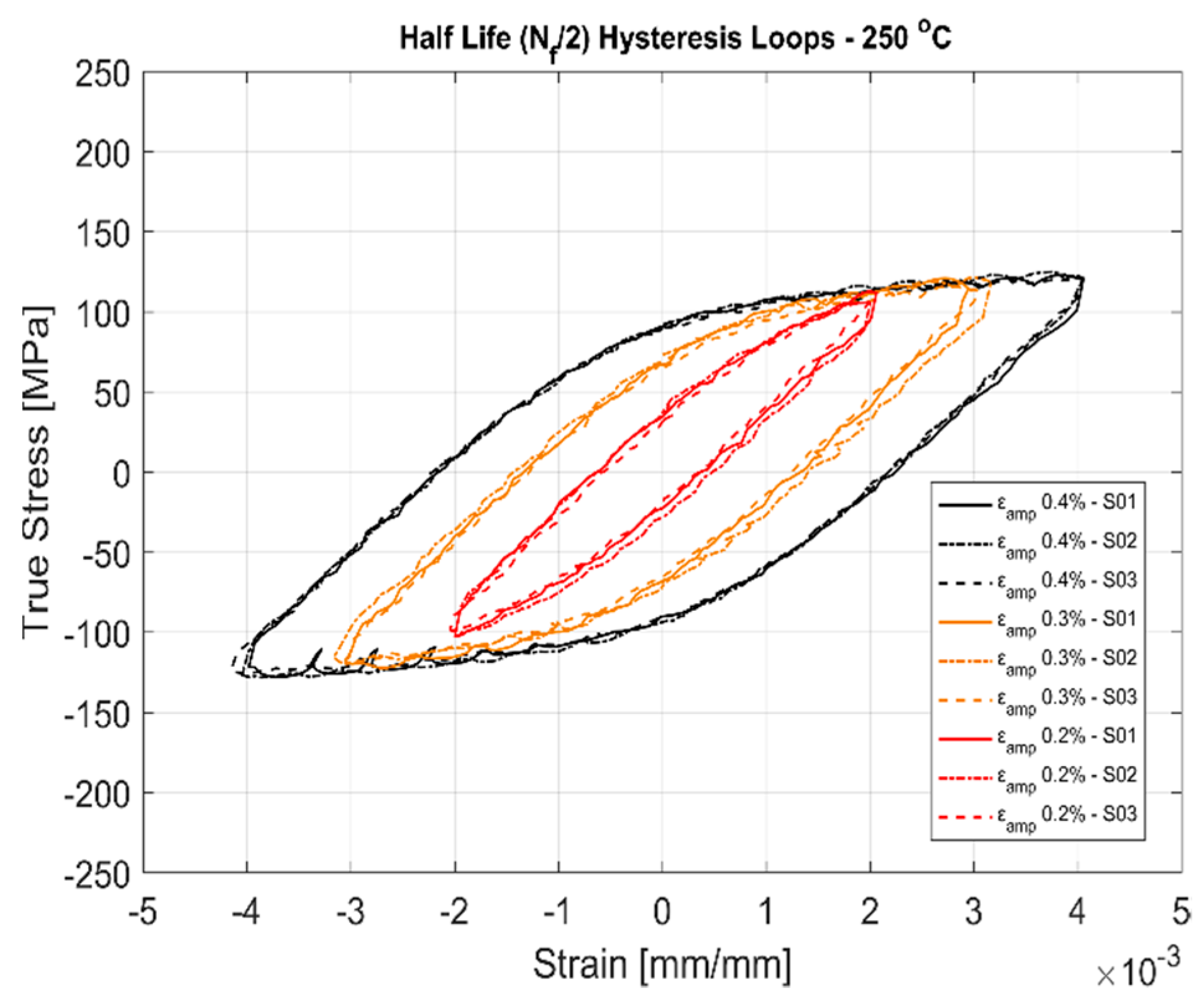

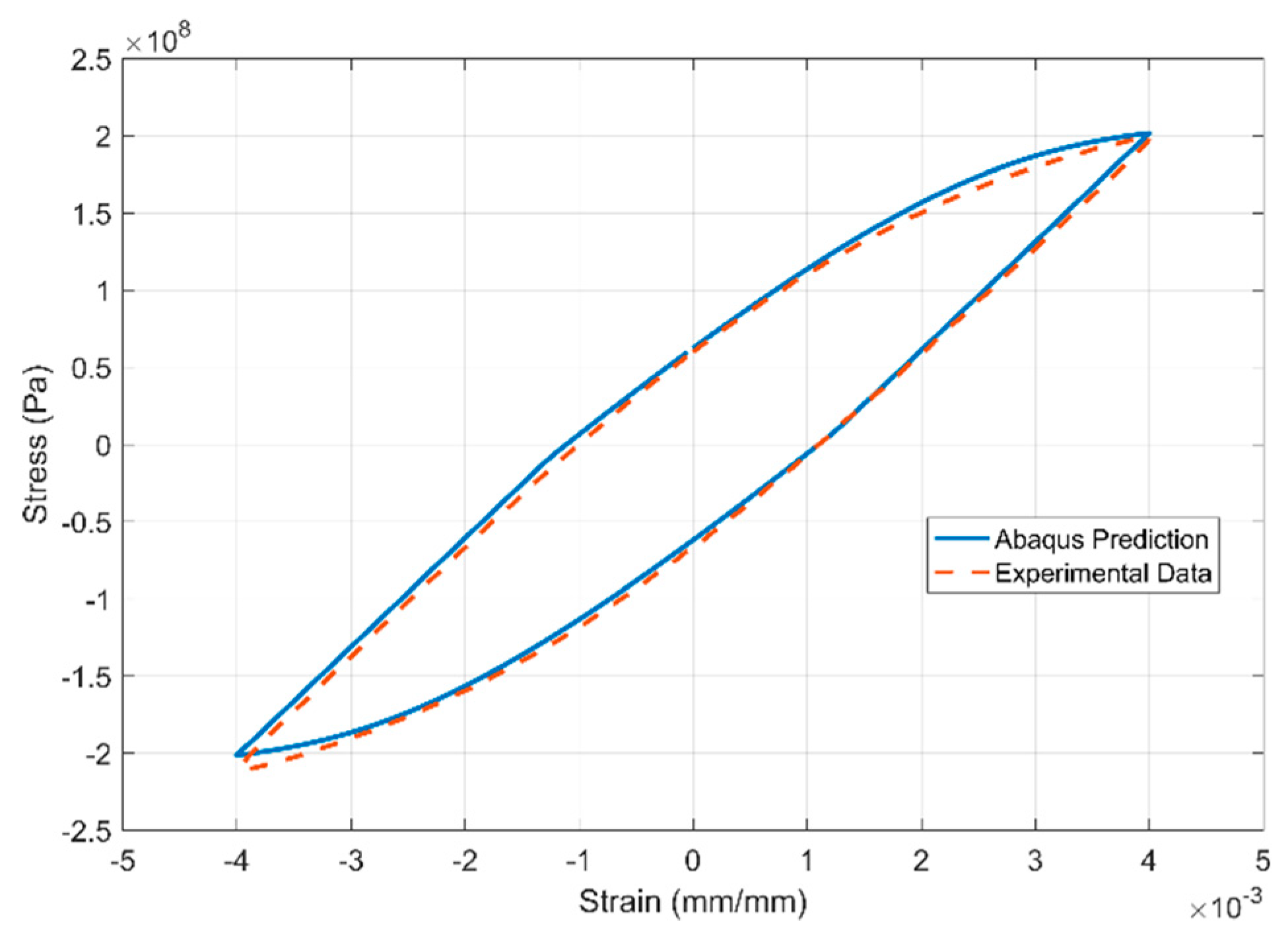

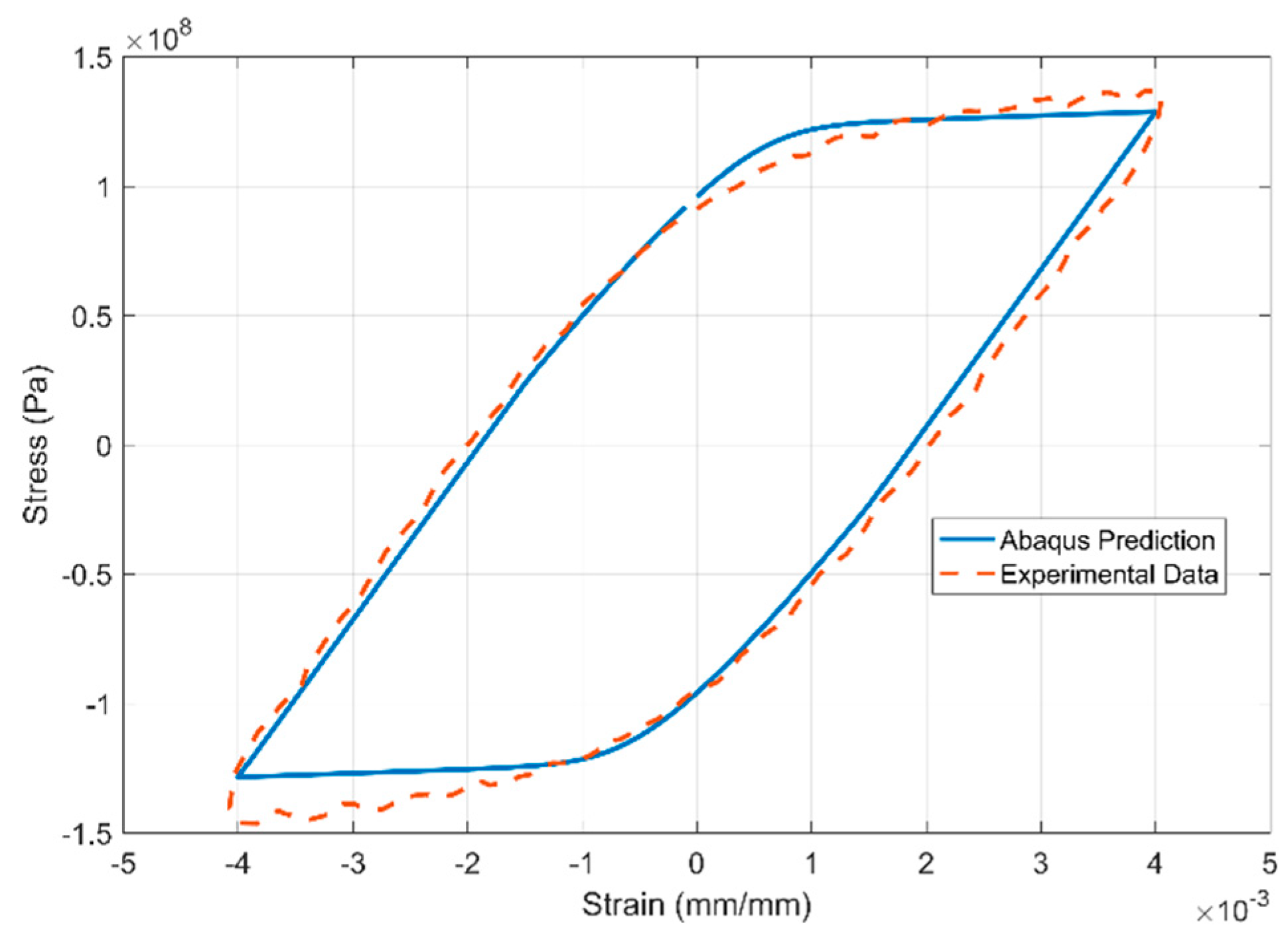

3.2.2. Hysteresis Loops

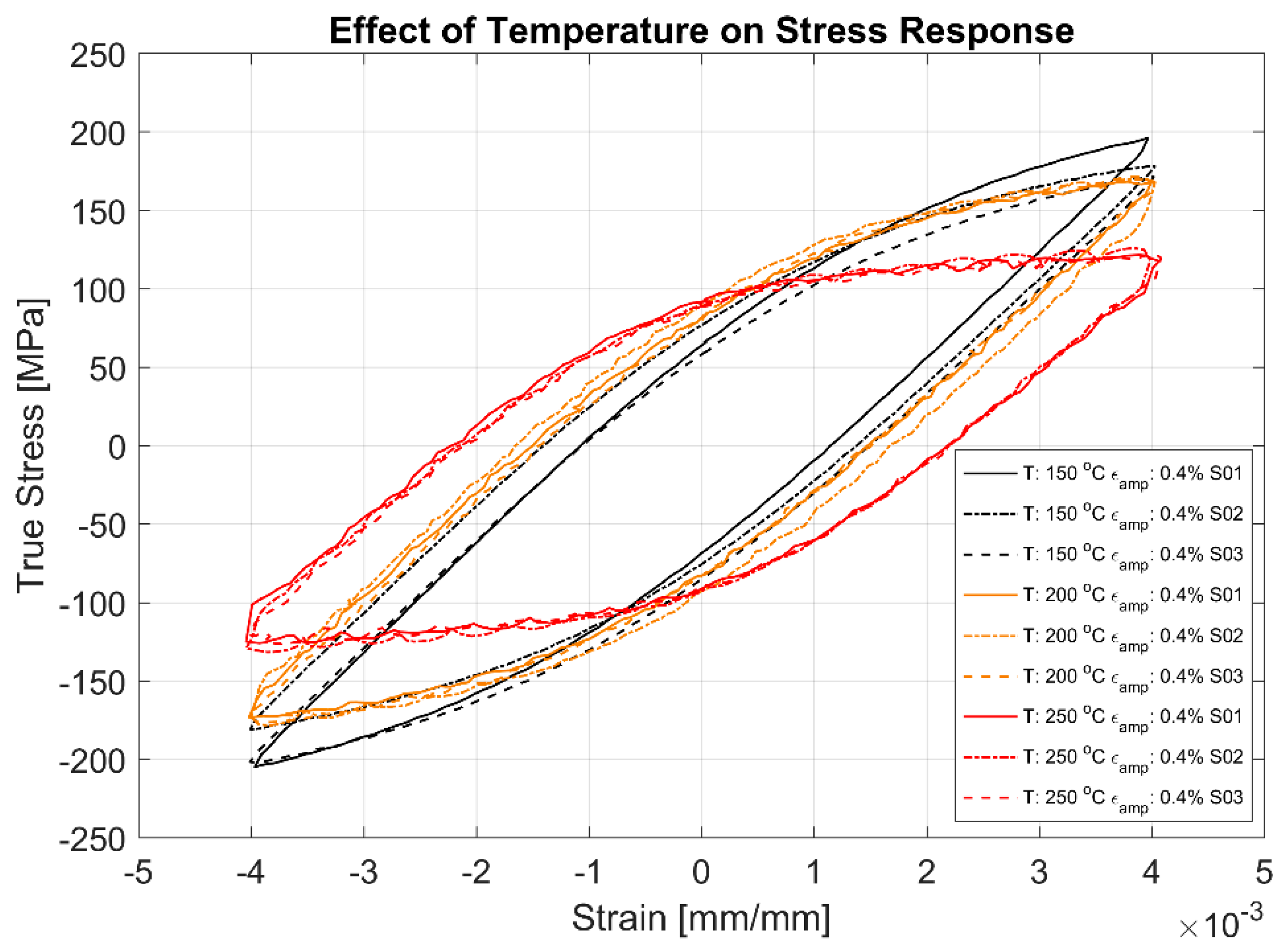

3.2.3. Effect of Temperature on the Hysteresis Loops

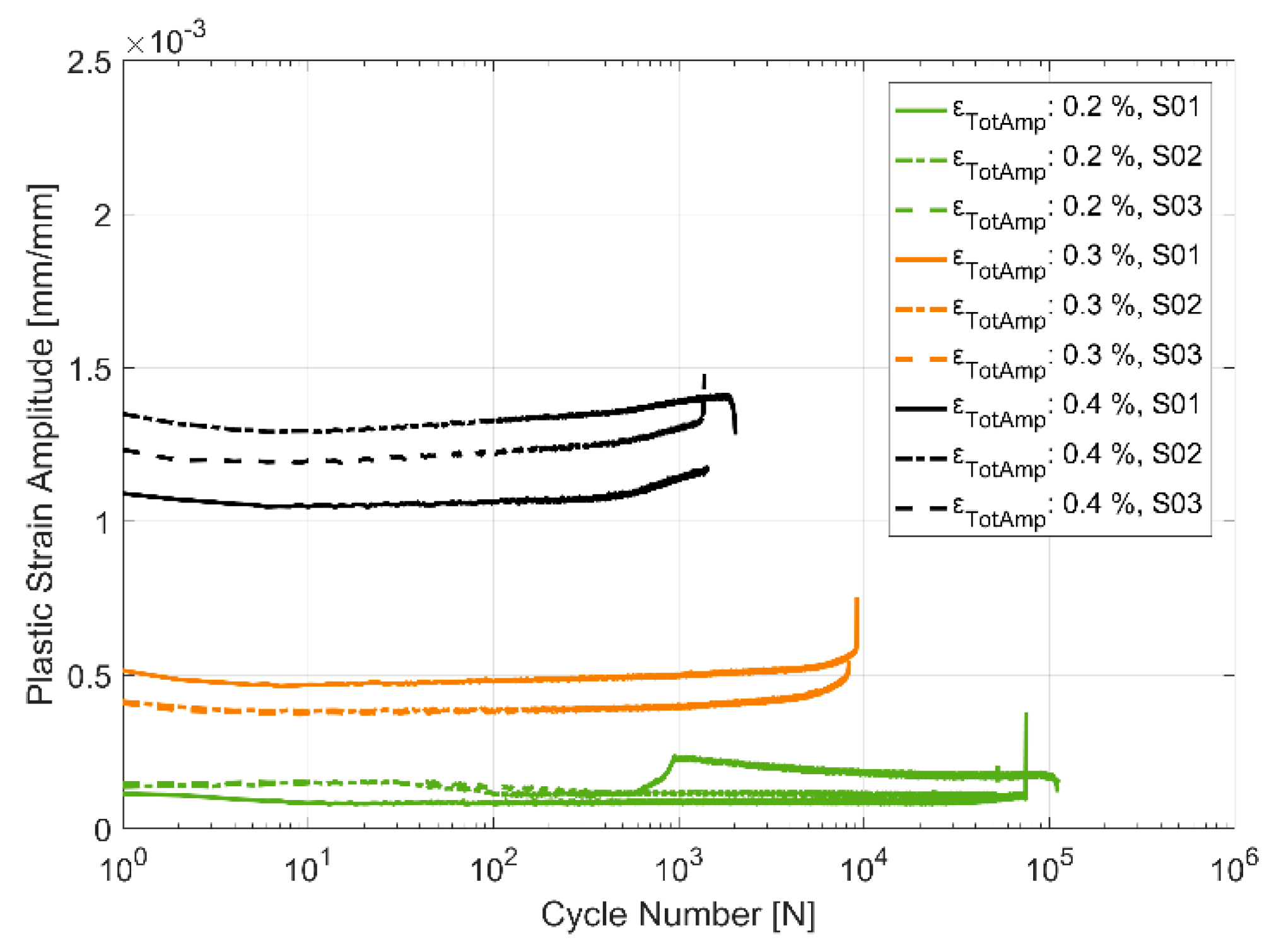

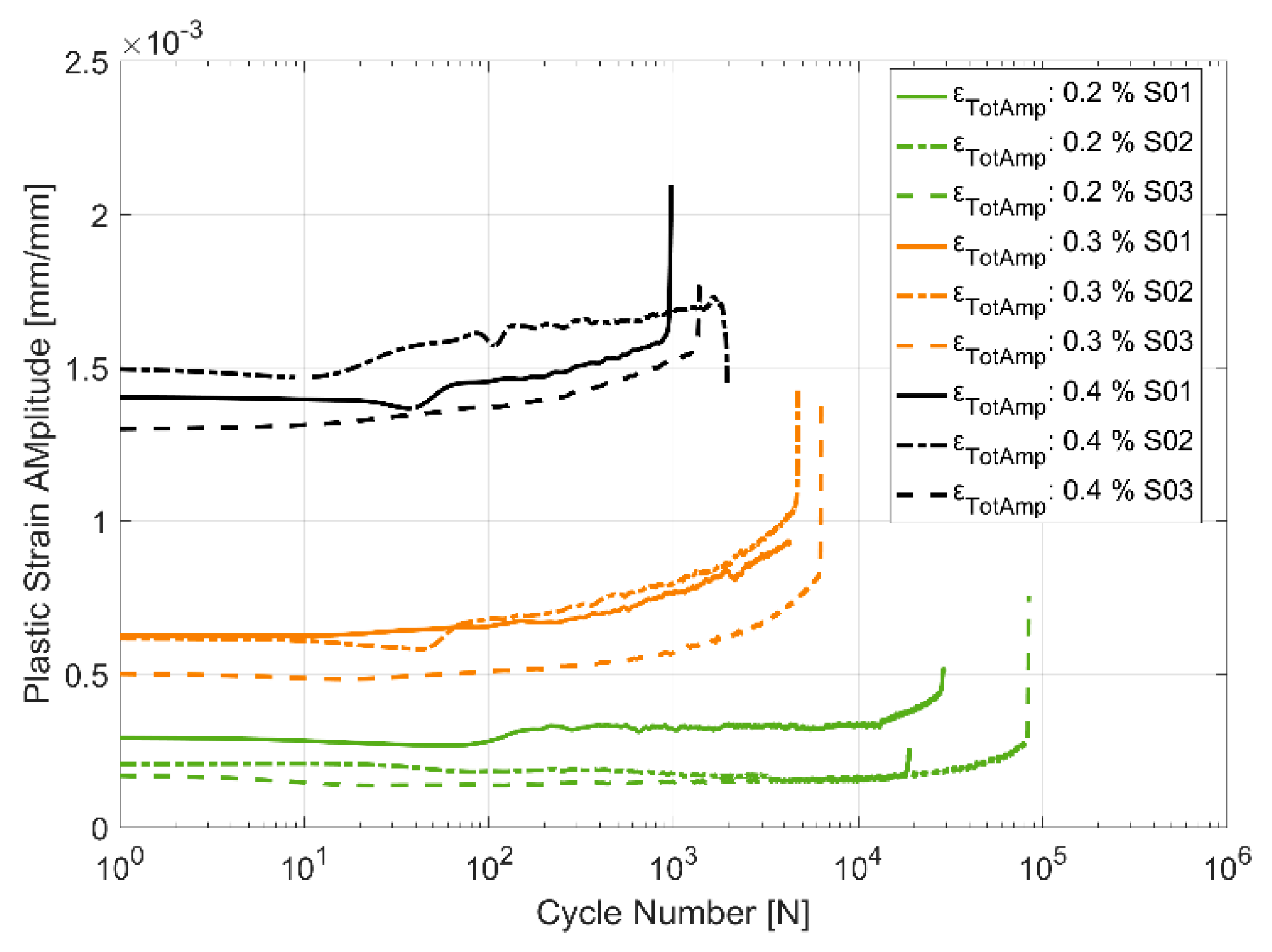

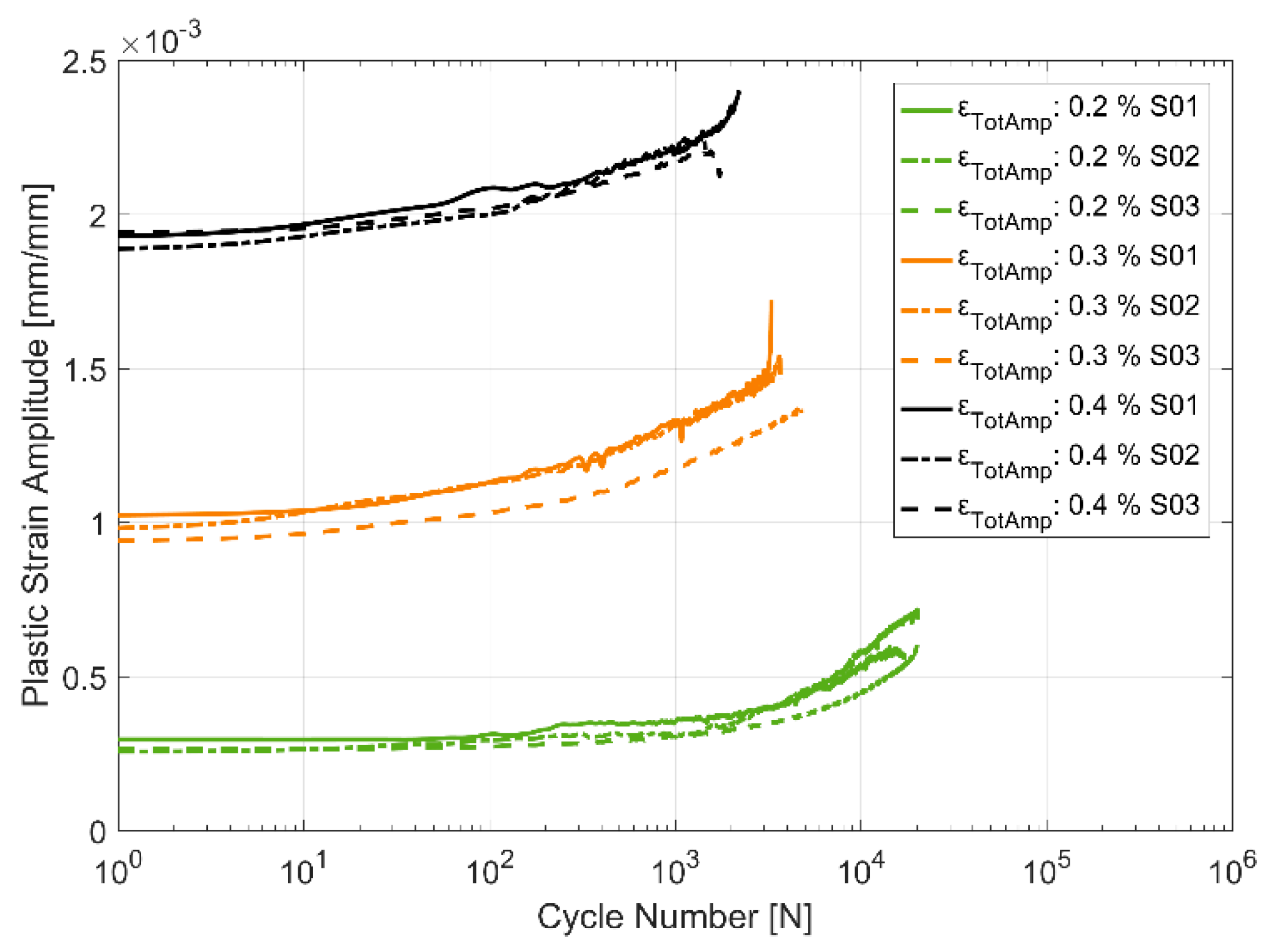

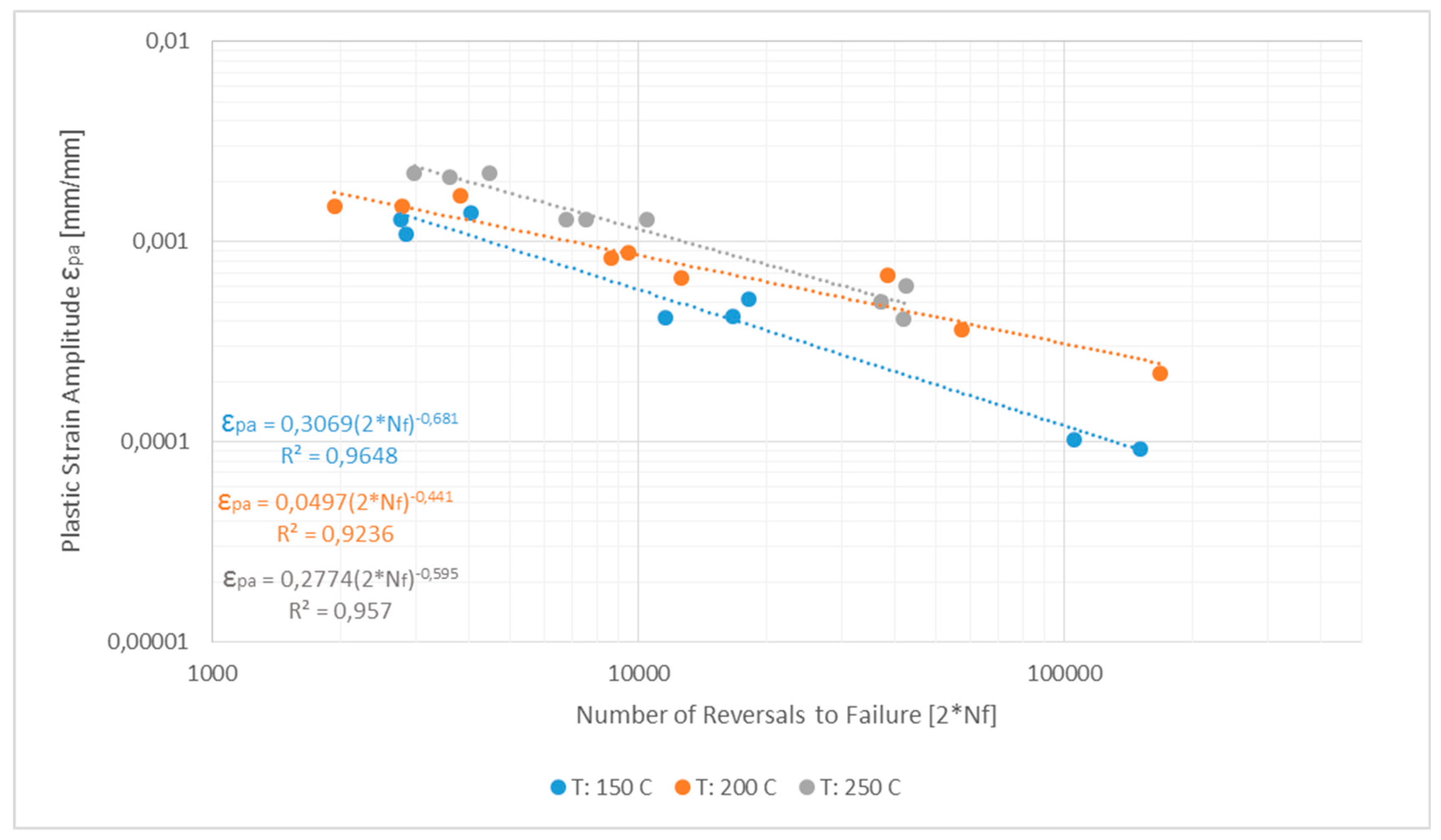

3.2.4. Plastic Strain Evolution

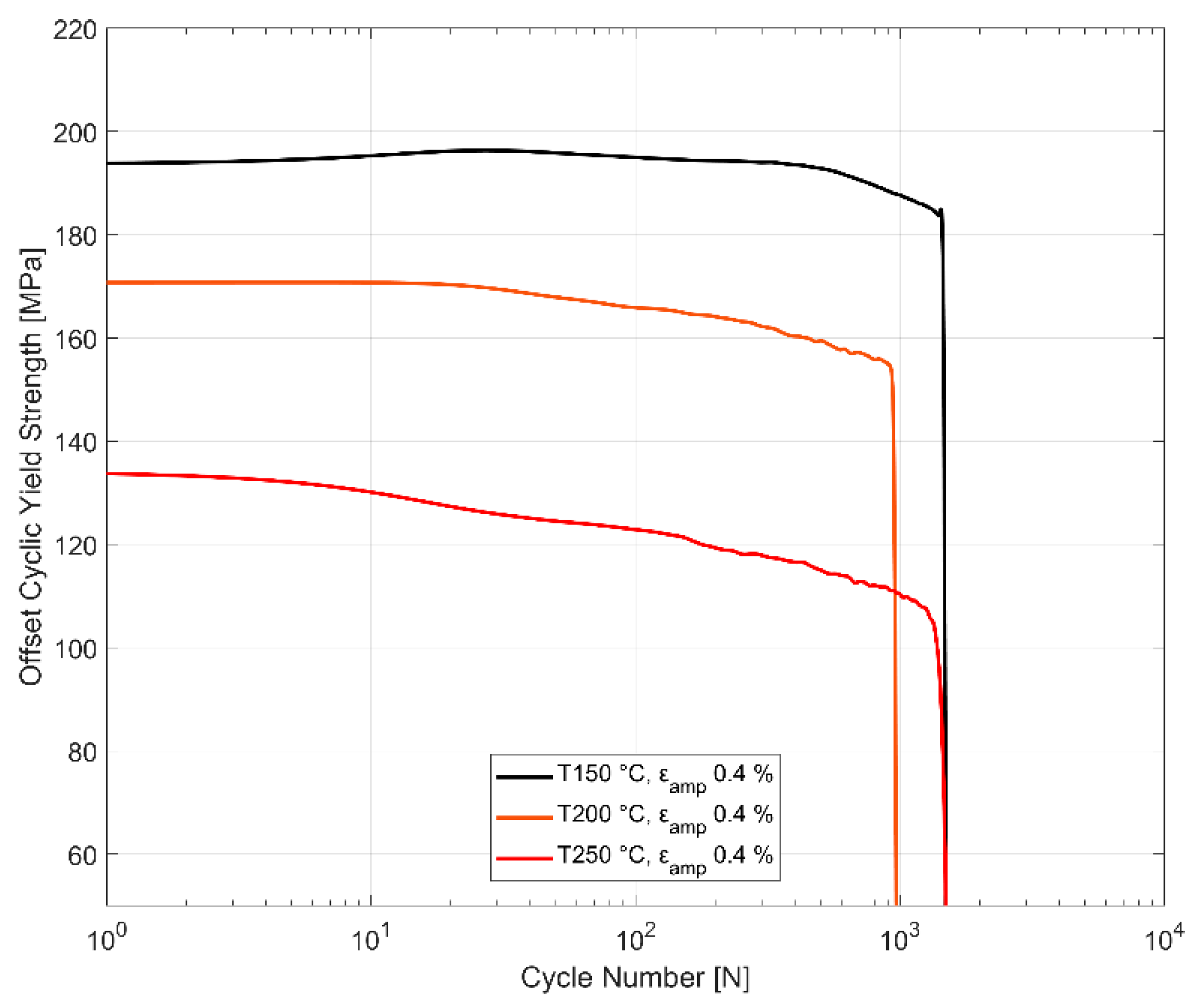

3.2.5. Cyclic Yield Evolution

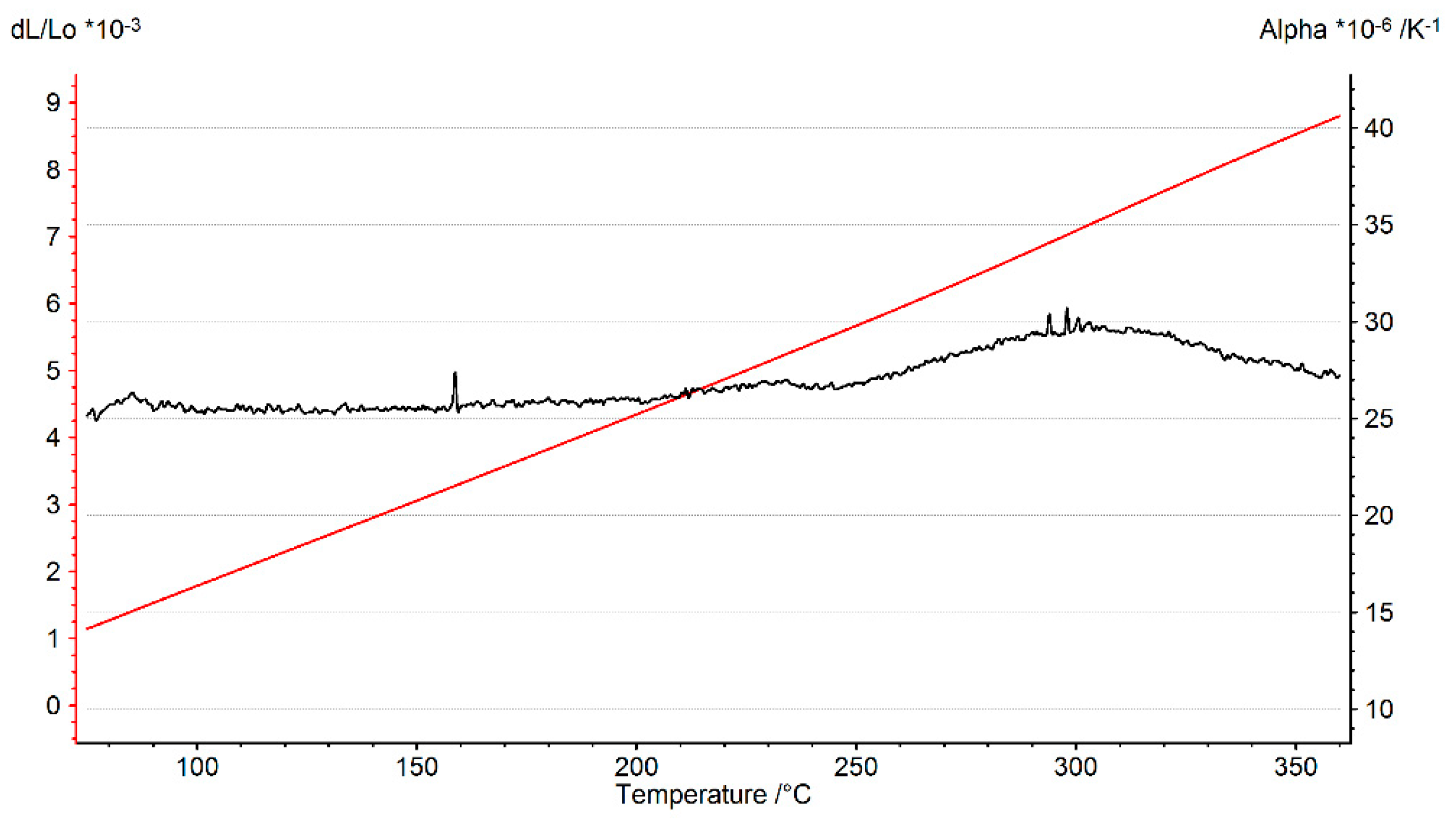

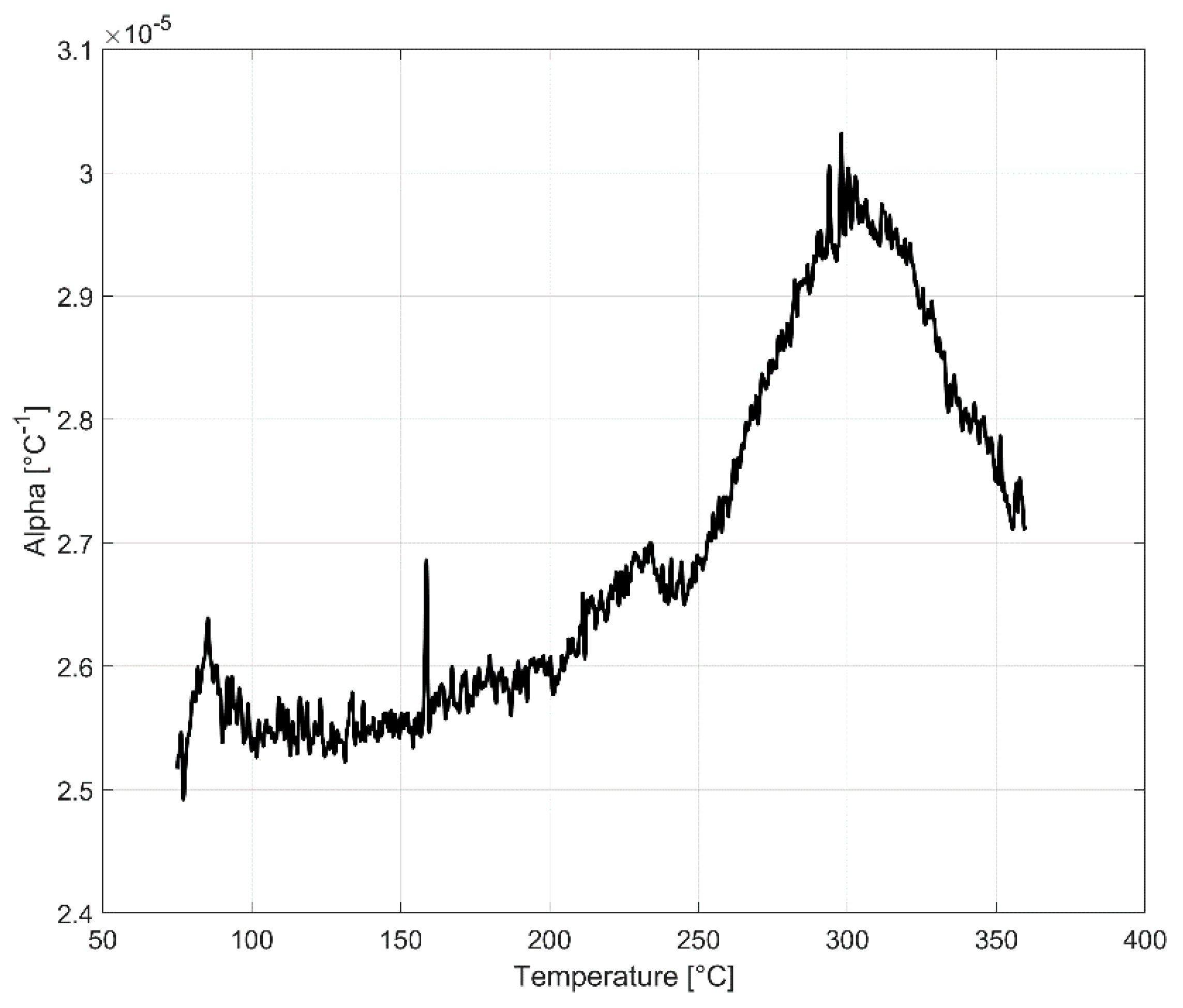

3.3. Dilatometry-Coefficient of Thermal Expansion vs. Temperature

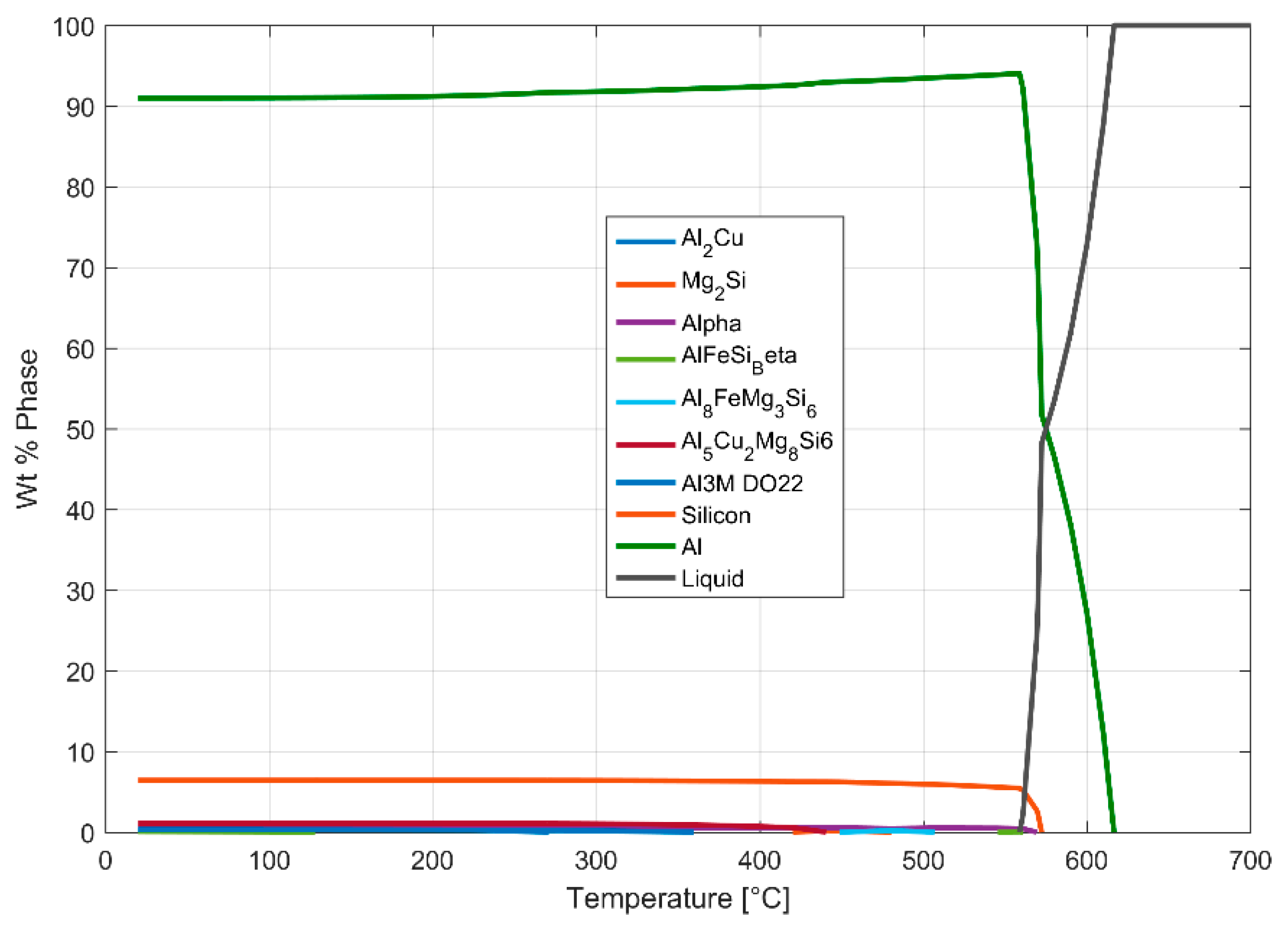

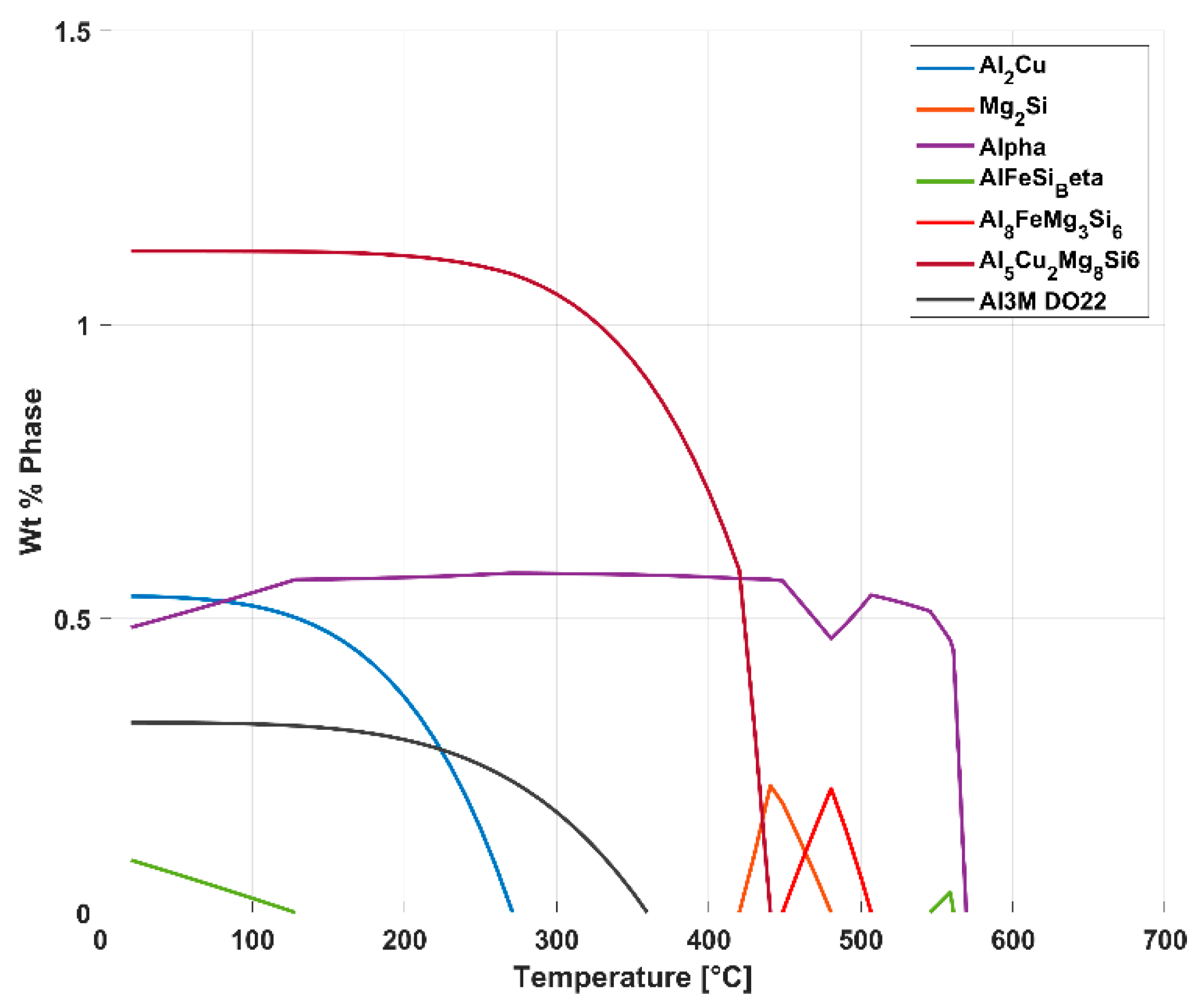

4. Discussion

4.1. General Discussion

4.2. Monotonic Deformation

4.3. Cyclic Deformation

4.3.1. Effect of Strain Amplitudes on the Hysteresis Loops

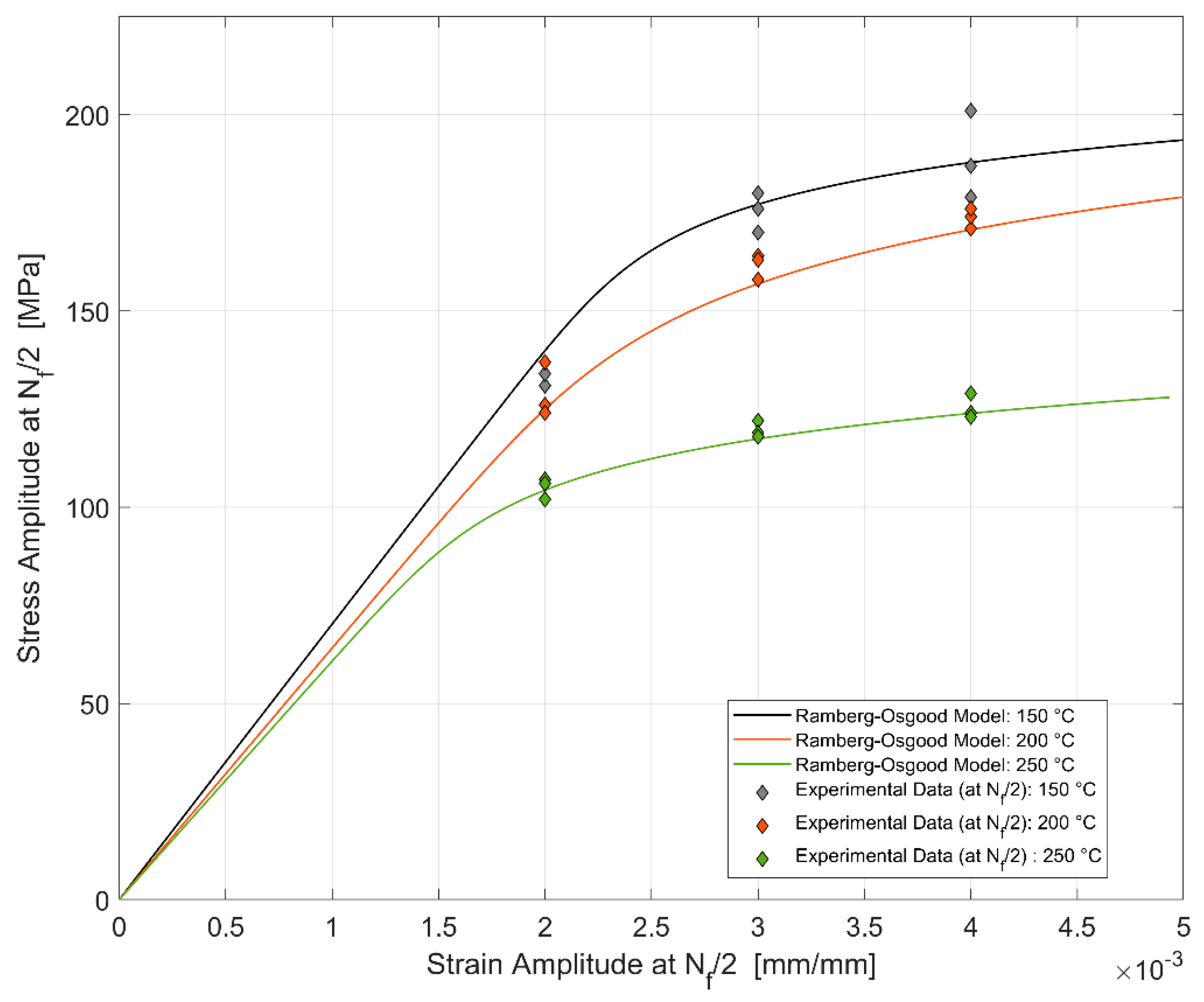

4.3.2. Constitutive Modelling of Cyclic Deformation

Cyclic Plasticity: Nonlinear Combined Isotropic–Kinematic Hardening Model

Non-Linear Kinematic Hardening Model

Non-Linear Isotropic Hardening Model

4.3.3. Fatigue Life Criterion

Coffin–Manson Relation

Coffin–Manson Relation

5. Conclusions

- The material exhibits decreasing strength and increasing ductility with increasing temperatures under monotonic loading. The material exhibits strain hardening at temperatures at and below 150 °C and a strain softening at temperatures above 150 °C under uniaxial tensile loading.

- The material exhibits cyclic softening with strain load cycles at all the tested temperatures of 150, 200 and 250 °C. The tests at elevated temperatures show reduced stress response and following increased plastic strains amplitudes.

- Dilatometry reveals a fairly constant coefficient of thermal expansion measured varying between (25–26) × 10−6 °C−1 in the temperature range 25–250 °C.

- The monotonic and cyclic stress–strain curves exhibiting no significant yield point can be modelled accurately with a Ramberg–Osgood type model

- The cyclic deformation behaviour can be modelled using a temperature dependent non-linear combined kinematic and isotropic model with one linear and one non-linear backstress.

- The scatter in mechanical properties measured is influenced by the test temperature with the difference between replicas decreasing with increasing temperatures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tabibian, S.; Charkaluk, E.; Constantinescu, A.; Oudin, A.; Szmytka, F. Behavior, damage and fatigue life assessment of lost foam casting aluminum alloys under thermo-mechanical fatigue conditions. Procedia Eng. 2010, 2, 1145–1154. [Google Scholar] [CrossRef][Green Version]

- Zhu, M.; Jian, Z.; Yang, G.; Zhou, Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Svensson, I.L.; Taylor, J.A. Strength-ductility behaviour of Al-Si-Cu-Mg casting alloys in T6 temper. Int. J. Cast Met. Res. 2003, 15, 531–543. [Google Scholar] [CrossRef]

- Tabibian, S.; Charkaluk, E.; Constantinescu, A.; Szmytka, F.; Oudin, A. TMF criteria for Lost Foam Casting aluminum alloys. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 349–360. [Google Scholar] [CrossRef]

- Moridi, A.; Azadi, M.; Farrahi, G.H. Thermo-mechanical stress analysis of thermal barrier coating system considering thickness and roughness effects. Surf. Coatings Technol. 2014, 243, 91–99. [Google Scholar] [CrossRef]

- Garat, M.; Laslaz, G. Improved Aluminium Alloys for Common Rail Diesel Cylinder Heads. Trans. Am. Foundry Soc. 2007, 115, 1–8. [Google Scholar]

- Zhang, B.; Liu, J.; Zhang, S.; Zhang, S.; Hu, X. Tensile ductility improvement of AlSi9Cu1 alloy by chemical composition optimization. China Foundry 2017, 14, 80–84. [Google Scholar] [CrossRef][Green Version]

- Fuoco, R.; Moreira, M. Fatigue cracks in aluminum cylinder heads for diesel engines. Int. J. Met. 2010, 4, 19–32. [Google Scholar] [CrossRef]

- Thompson, S.; Cockcroft, S.L.; Wells, M. a. Advanced light metals casting development: Solidification of aluminium alloy A356. Mater. Sci. Technol. 2004, 20, 194–200. [Google Scholar] [CrossRef]

- Abdulwahab, M.; Madugu, I.A.; Yaro, S.A.; Hassan, S.B.; Popoola, A.P.I. Effects of multiple-step thermal ageing treatment on the hardness characteristics of A356.0-type Al-Si-Mg alloy. Mater. Des. 2011, 32, 1159–1166. [Google Scholar] [CrossRef]

- Huter, P.; Renhart, P.; Oberfrank, S.; Schwab, M.; Grün, F.; Stauder, B. High- ad low-cycle fatigue influence of silicon, copper, strontium and iron on hypo-eutectic Al-Si-Cu and Al-Si-Mg cast alloys used in cylinder heads. Int. J. Fatigue 2016, 82, 588–601. [Google Scholar] [CrossRef]

- Tabibian, S.; Charkaluk, E.; Constantinescu, A.; Guillemot, G.; Szmytka, F. Influence of process-induced microstructure on hardness of two Al-Si alloys. Mater. Sci. Eng. A 2015, 646, 190–200. [Google Scholar] [CrossRef]

- Carrera, E.; Alejandro González, J.; Talamantes-Silva, J.; Colás, R. Effect of the delay in time between cooling and aging in heat-treated cast aluminum alloys. Metall. Mater. Trans. B Process Metall. Mater. Process Sci. 2011, 42, 1023–1030. [Google Scholar] [CrossRef]

- Zhang, B.; Garro, M.; Leghissa, M.; Giglio, A.; Tagliano, C. Effect of Dendrite Arm Spacing on Mechanical Properties of Aluminum Alloy Cylinder Heads and Engine Blocks; SAE Technical Paper; SAE International: Troy, MI, USA, 2005. [Google Scholar]

- Merhy, E.; Rémy, L.; Maitournam, H.; Augustins, L. Crack growth characterisation of A356-T7 aluminum alloy under thermo-mechanical fatigue loading. Eng. Fract. Mech. 2013, 110, 99–112. [Google Scholar] [CrossRef]

- Barlas, B.; Massinon, D.; Meyer, P.; Cailletaud, G.; Guillot, I.; Morin, G. A Phenomenological Model for Fatigue Life Prediction of Highly Loaded Cylinder Heads; SAE Technical Paper; SAE International: Troy, MI, USA, 2006. [Google Scholar]

- Thomas, J.J.; Verger, L.; Bignonnet, A.; Charkaluk, E. Thermomechanical design in the automotive industry. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 887–895. [Google Scholar] [CrossRef]

- Sasaki, K. Low cycle thermal fatigue of aluminum alloy cylinder head in consideration of changing metrology microstructure. Procedia Eng. 2010, 2, 767–776. [Google Scholar]

- Ovono Ovono, D.; Guillot, I.; Massinon, D. Study on low-cycle fatigue behaviours of the aluminium cast alloys. J. Alloys Compd. 2008, 452, 425–431. [Google Scholar] [CrossRef]

- Dowling, N.E. Mechanical Behavior of Materials, 4th Intern. ed.; Pearson: Harlow, UK, 2013; ISBN 978-0273764557. [Google Scholar]

- ASTM E1251-17a. Standard Test Method for Analysis of Aluminum and Aluminum Alloys by Spark Atomic Emission Spectrometry. ASTM Int. 2017. [Google Scholar]

- D-Lab Metal Analysis. Available online: http://www.degerforslab.se/en-us/Services/Metal-Analyses#al (accessed on 25 June 2019).

- Koutiri, I.; Bellett, D.; Morel, F.; Augustins, L.; Adrien, J. High cycle fatigue damage mechanisms in cast aluminium subject to complex loads. Int. J. Fatigue 2013, 47, 44–57. [Google Scholar] [CrossRef]

- Vogler, M. The Effect of Pre-Deformation on Ageing Behaviour of Aluminium Alloy A356.0-T7; Chalmers University: Göteborg, Sweden, 2016. [Google Scholar]

- ASTM International. ASTM E8/E8M standard test methods for tension testing of metallic materials 1. Annu. B. ASTM Stand. 4 2010, i, 1–27. [Google Scholar]

- ASTM International. ASTM E606/E606M—12: Standard Test Method for Strain-Controlled Fatigue Testing. Available online: http://www.astm.org/cgi-bin/resolver.cgi?E606E606M (accessed on 25 June 2019).

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.Q. Hot tensile deformation behaviors and constitutive model of an Al-Zn-Mg-Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Grieb, M.B.; Christ, H.J.; Plege, B. Thermomechanical fatigue of cast aluminium alloys for cylinder head applicationsexperimental characterization and life prediction. Procedia Eng. 2010, 2, 1767–1776. [Google Scholar] [CrossRef]

- Hunt, W.H.; Brockenbrough, J.R.; Magnusen, P.E. An Al-Si-Mg Composite Model System - Microstructural Effects on Deformation and Damage Evolution. Scr. Metall. Mater. 1991, 25, 15–20. [Google Scholar] [CrossRef]

- Samuel, E.H.; Samuel, A.M.; Doty, H.W. Factors Controlling the Type and Morphology of Cu-Containing Phases in 319 Al Alloy. AFS Trans. 1996, 30, 893–901. [Google Scholar]

- de la Sablonnière, H.; Samuel, F.H. Solution heat treatment of 319 aluminium alloy containing ~0.5 wt% Mg. Part 2—microstructure and fractography. Int. J. Cast Met. Res. 1996, 9, 213–225. [Google Scholar] [CrossRef]

- Shi, C.; Mao, W.; Chen, X.G. Evolution of activation energy during hot deformation of AA7150 aluminum alloy. Mater. Sci. Eng. A 2013, 571, 83–91. [Google Scholar] [CrossRef]

- Lin, Y.C.; Deng, J.; Jiang, Y.Q.; Wen, D.X.; Liu, G. Effects of initial δ phase on hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater. Sci. Eng. A 2014, 598, 251–262. [Google Scholar] [CrossRef]

- Sun, Z.C.; Zheng, L.S.; Yang, H. Softening mechanism and microstructure evolution of as-extruded 7075 aluminum alloy during hot deformation. Mater. Charact. 2014, 90, 71–80. [Google Scholar] [CrossRef]

- Azadi, M.; Shirazabad, M.M. Heat treatment effect on thermo-mechanical fatigue and low cycle fatigue behaviors of A356.0 aluminum alloy. Mater. Des. 2013, 45, 279–285. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Gamberini, A.; Messieri, S. Correlation between ultimate tensile strength and solidification microstructure for the sand cast A357 aluminium alloy. Mater. Des. 2009, 30, 4525–4531. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Jiang, Y.H.; Ma, Z.; Shan, S.F.; Jia, Y.Z.; Fan, C.Z.; Wang, W.K. Effect of cooling rate on solidified microstructure and mechanical properties of aluminium-A356 alloy. J. Mater. Process. Technol. 2008, 207, 107–111. [Google Scholar] [CrossRef]

- Wang, Q.G.; Caceres, C.H. On the strain hardening behaviour of Al-Si-Mg casting alloys. Mater. Sci. Eng. A 1997, 236, 106–109. [Google Scholar] [CrossRef]

- Snowden, K.U. Dislocation arrangements during cyclic hardening and softening in A1 crystals. Acta Metall. 1963, 11, 675–684. [Google Scholar] [CrossRef]

- Grosskreutz, J.C. The mechanisms of metal fatigue (I). Phys. Status Solidi 1971, 47, 11–31. [Google Scholar] [CrossRef]

- Runesson, K.; Chalmers, U. Constitutive Modeling of Engineering Materials—Theory and Computation, 7th ed.; Chalmers University of Technology: Göteborg, Sweden, 2005. [Google Scholar]

- Simulia, D.S.; Fallis, A.; Techniques, D. ABAQUS Documentation; Dassault Systèmes: Vélizy-Villacoublay, France, 2014. [Google Scholar]

- Sermage, J.P.; Lemaitre, J.; Desmorat, R. Multiaxial creep-fatigue under anisothermal conditions. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 241–252. [Google Scholar] [CrossRef]

- Koutiri, I.; Bellett, D.; Morel, F.; Pessard, E. A probabilistic model for the high cycle fatigue behaviour of cast aluminium alloys subject to complex loads. Int. J. Fatigue 2013, 47, 137–147. [Google Scholar] [CrossRef]

| Si | Cu | Mg | Ti | Fe | Mn | B | Others | Al |

|---|---|---|---|---|---|---|---|---|

| 6.8 | 0.53 | 0.35 | 0.12 | 0.10 | 0.07 | 0.0012 | <0.05 | Bal |

| Series | Nature of Test | Loading Conditions | Number of Tests/Replicas |

|---|---|---|---|

| 1 | Room Temperature Tensile Tests | Temperature: Room temperature (RT) Strain Rate: 0.01% s−1 | 3 |

| 2 | High Temperature Tensile Tests | Temperatures: 100, 150, 200, 250, 300 °C Strain Rate: 0.01% s−1 | 2 |

| 3 | Uniaxial, completely reversed, total strain-controlled fatigue tests | Temperatures: 150, 200, 250 °C Strain Rate: 1% s−1 | 2-3 |

| 4 | Dilatometry | Temperature Range: 25–360 °C Heating Rate: 1 °C min−1 Atmosphere: Nitrogen Contact Pressure: 30 cN | 1 |

| Temperature °C | Young’s Modulus E [GPa] | Offset Yield Strength Rp 0.2% [MPa] | Ultimate Tensile Strength Rm [MPa] | Maximum Strain before Fracture εf [%] |

|---|---|---|---|---|

| RT | 72 | 211 | 273 | 4.7 |

| 100 | 71 | 199 | 247 | 7.5 |

| 150 | 70 | 184 | 217 | 13.4 |

| 200 | 64 | 158 | 180 | 15.2 |

| 250 | 61 | 122 | 133 | 17.2 |

| 300 | 56 | 73 | 84 | >17.2 |

| Temperature | Young’s Modulus [GPa] | Offset Yield Strength [MPa] | H′ [MPa] | Cyclic Strain Hardening Coefficient n′ |

|---|---|---|---|---|

| 150 °C | 70 | 192 | 274 | 0.0572 |

| 200 °C | 64 | 177 | 321 | 0.0955 |

| 250 °C | 61 | 124 | 216 | 0.0889 |

| Temp. °C | Young’s Modulus [Pa] | Yield Stress at Zero Plastic Strain and Equiv. Stress (For Isotropic Hardening Model) [Pa] | Kinematic Hardening Parameter C1 [Pa] | Gamma 1 [–] | Kinematic Hardening Parameter C2 [Pa] | Gamma 2 [–] | Q-Infinity [Pa] | Hardening Parameter b [–] |

|---|---|---|---|---|---|---|---|---|

| 150 | 70.22 × 109 | 9.967 × 107 | 1.786 × 1011 | 1651 | 1.551 × 109 | 0 | −20 × 106 | 2.0 |

| 200 | 64.13 × 109 | 9.5 × 107 | 1.997 × 1011 | 2933 | 1.569 × 109 | 0 | −20 × 106 | 2.2 |

| 250 | 60.82 × 109 | 8.2 × 107 | 2.034 × 1011 | 4155 | 1.581 × 109 | 0 | −20 × 106 | 2.3 |

| Temperature [°C] | E [GPa] | σf′ [MPa] | b | εf′ | c | Transition Fatigue Life Nt |

|---|---|---|---|---|---|---|

| 150 | 70 | 421 | −0.096 | 0.3069 | −0.681 | 2727 |

| 200 | 64 | 346 | −0.087 | 0.0497 | −0.441 | 3745 |

| 250 | 61 | 231 | −0.073 | 0.2774 | −0.595 | 14004 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natesan, E.; Eriksson, S.; Ahlström, J.; Persson, C. Effect of Temperature on Deformation and Fatigue Behaviour of A356–T7 Cast Aluminium Alloys Used in High Specific Power IC Engine Cylinder Heads. Materials 2020, 13, 1202. https://doi.org/10.3390/ma13051202

Natesan E, Eriksson S, Ahlström J, Persson C. Effect of Temperature on Deformation and Fatigue Behaviour of A356–T7 Cast Aluminium Alloys Used in High Specific Power IC Engine Cylinder Heads. Materials. 2020; 13(5):1202. https://doi.org/10.3390/ma13051202

Chicago/Turabian StyleNatesan, Elanghovan, Stefan Eriksson, Johan Ahlström, and Christer Persson. 2020. "Effect of Temperature on Deformation and Fatigue Behaviour of A356–T7 Cast Aluminium Alloys Used in High Specific Power IC Engine Cylinder Heads" Materials 13, no. 5: 1202. https://doi.org/10.3390/ma13051202

APA StyleNatesan, E., Eriksson, S., Ahlström, J., & Persson, C. (2020). Effect of Temperature on Deformation and Fatigue Behaviour of A356–T7 Cast Aluminium Alloys Used in High Specific Power IC Engine Cylinder Heads. Materials, 13(5), 1202. https://doi.org/10.3390/ma13051202