Numerical Simulation of Dynamic Mechanical Properties of Concrete under Uniaxial Compression

Abstract

:1. Introduction

2. Establishment of the Dynamic Base Force Element Equilibrium Equation

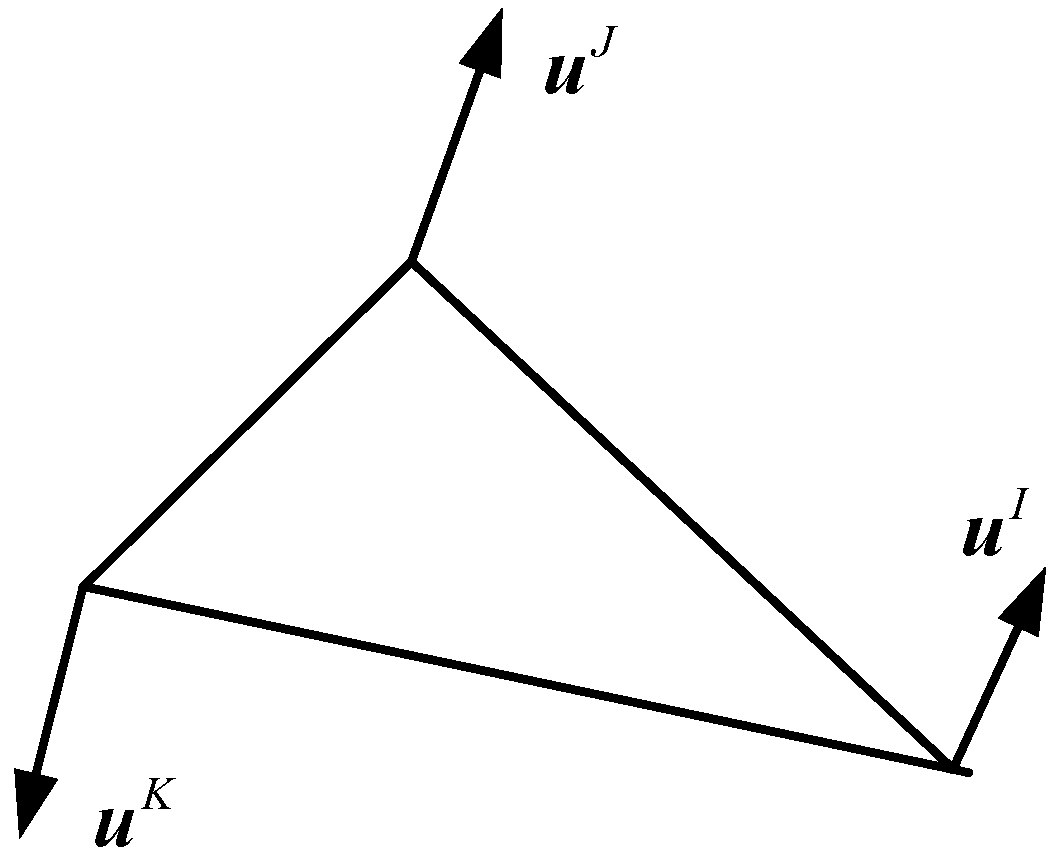

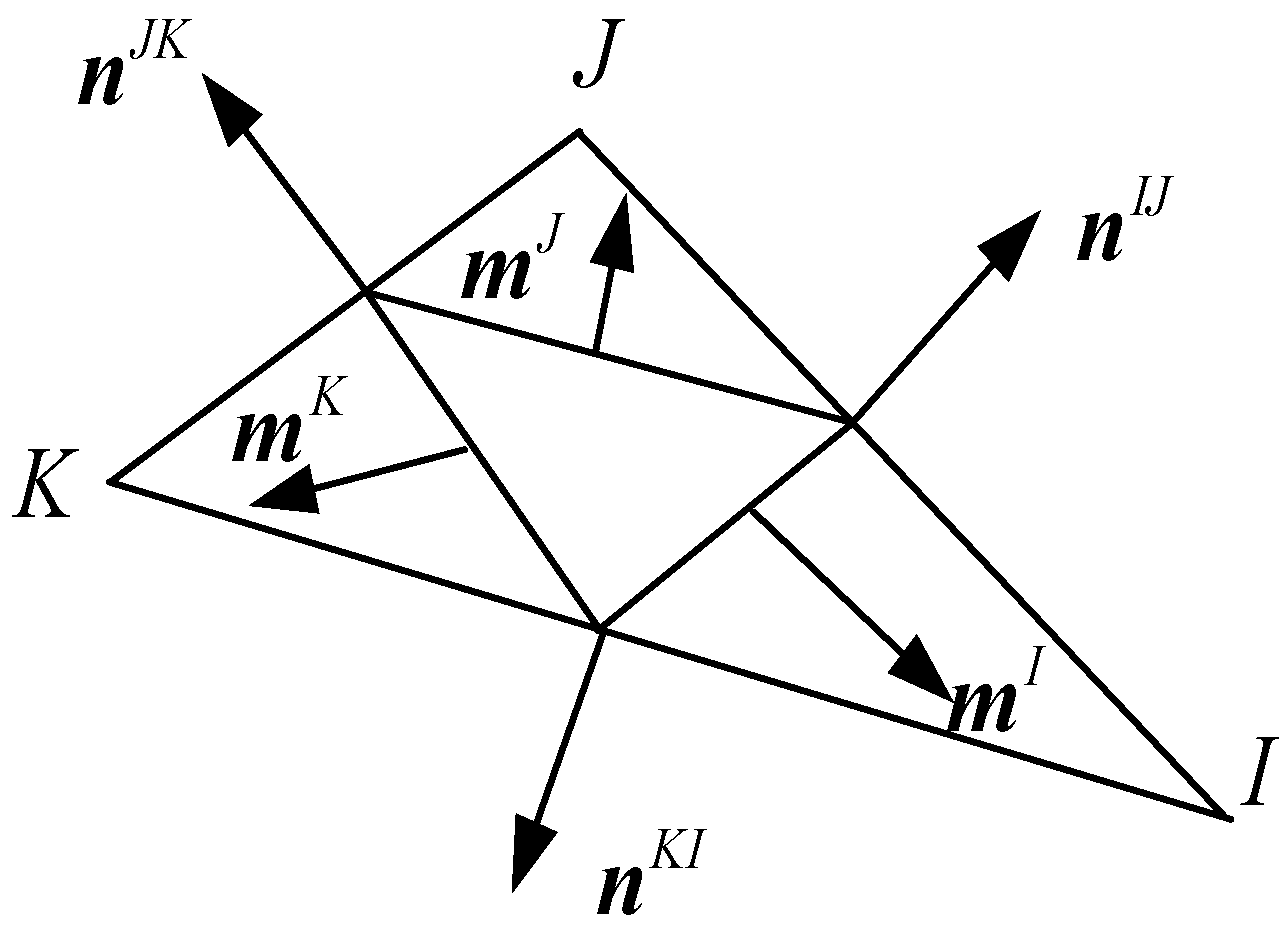

2.1. Base Force Element Stiffness Matrix

2.2. Damping Matrix and Mass Matrix

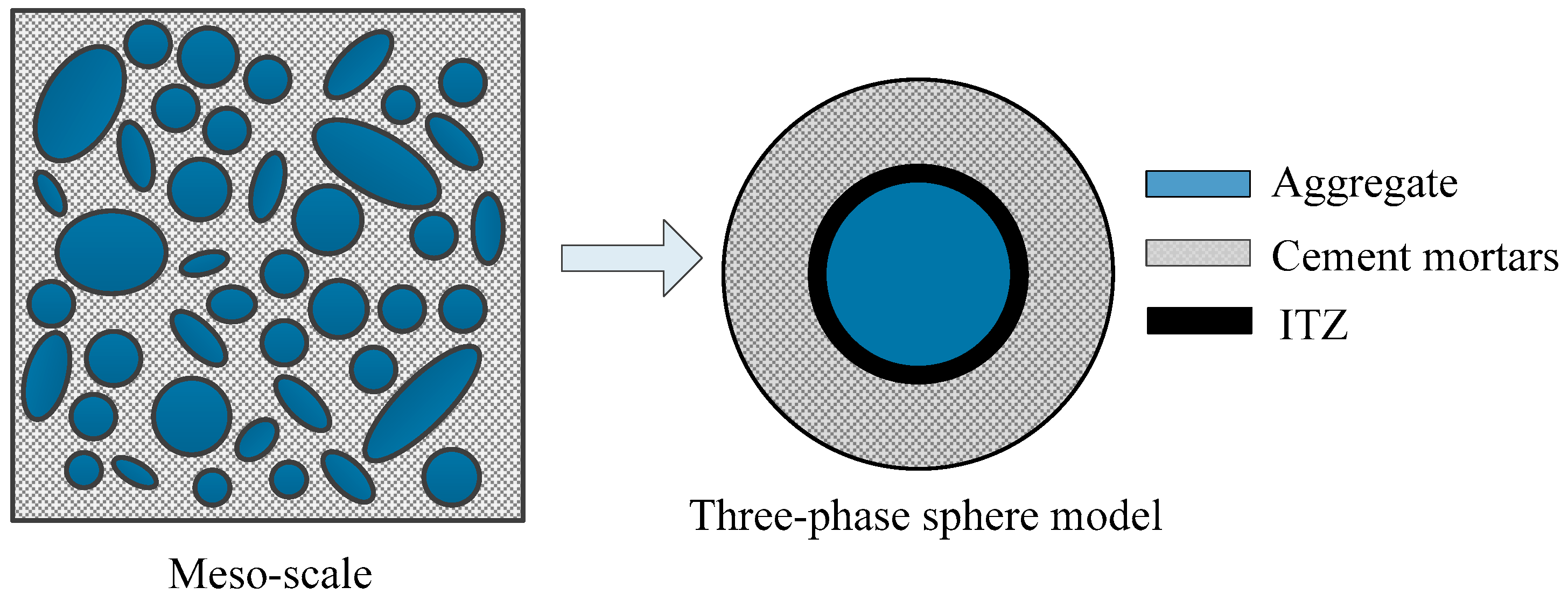

3. Meso-Structure of Concrete

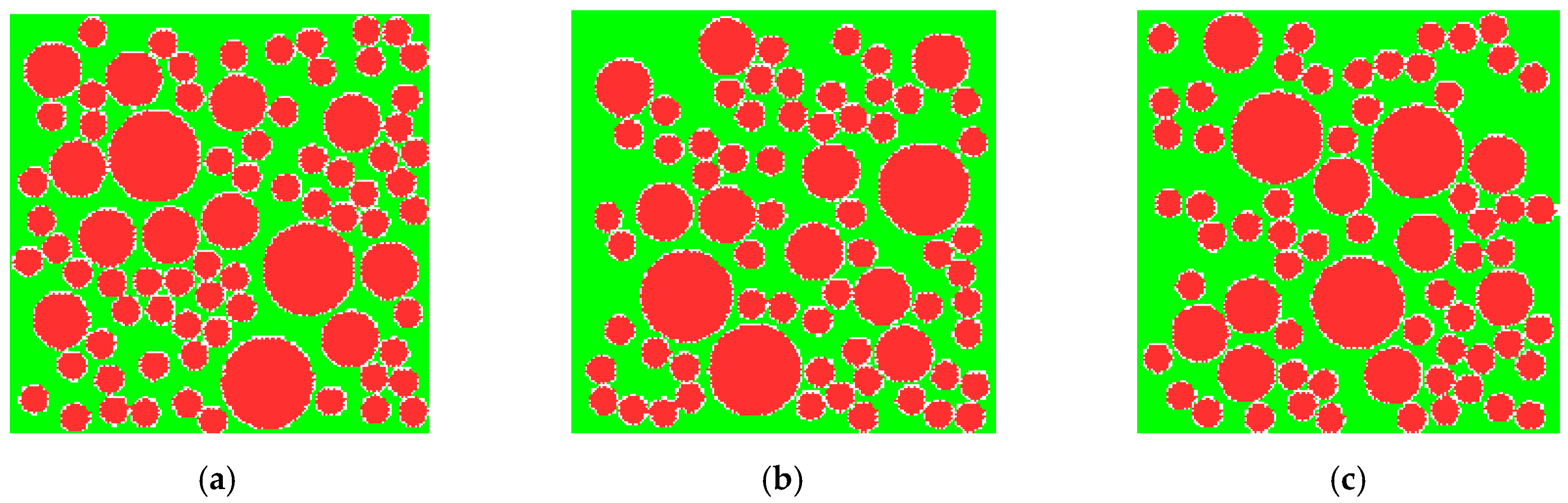

3.1. Random Aggregate Model

3.2. Mesh Generation Method and Element Attributes

4. Dynamic Behavior for Concrete Meso-Components

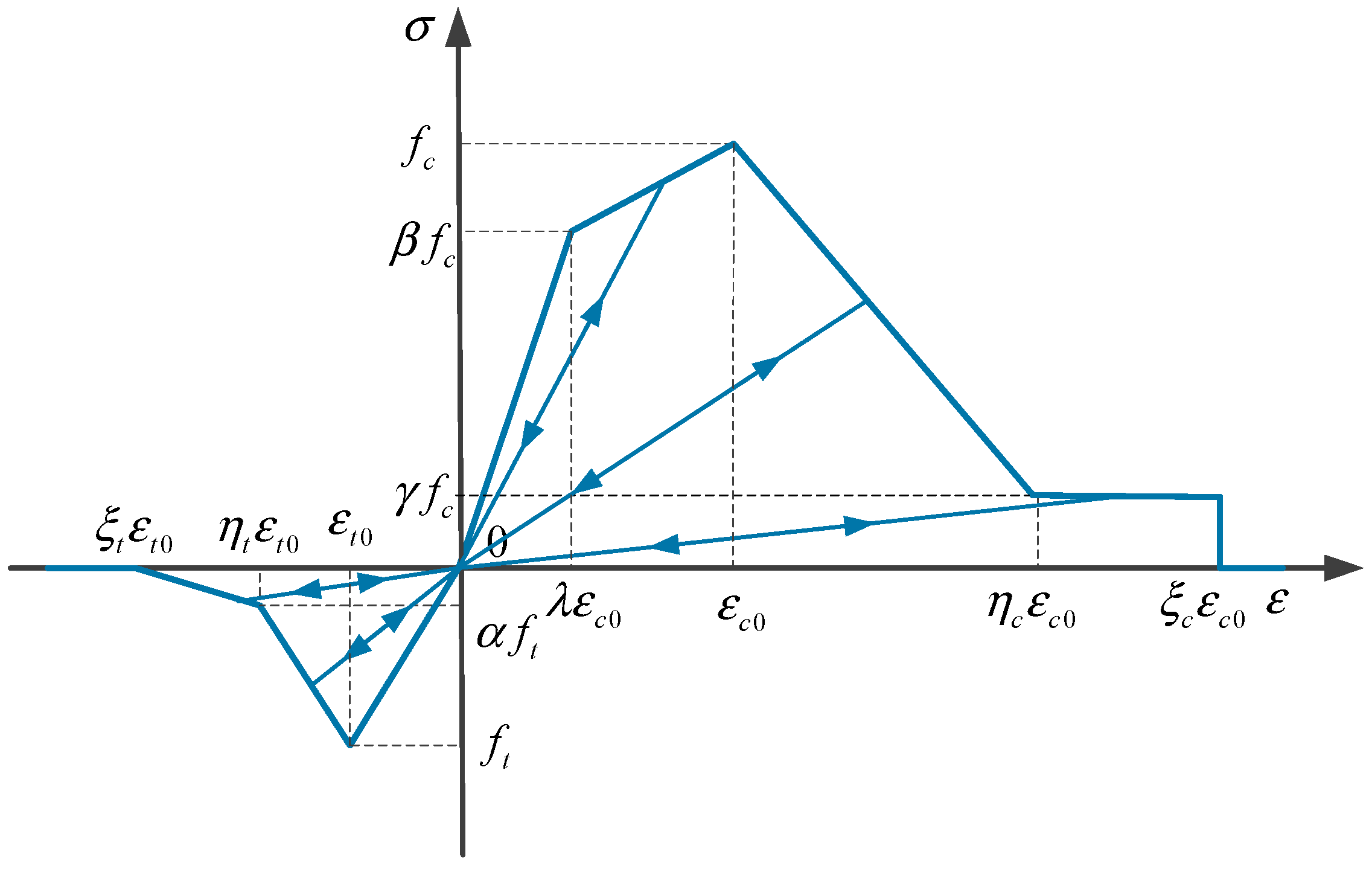

4.1. Concrete Dynamic Damaged Model

4.2. Dynamic Increase Factor (DIF) for Concrete

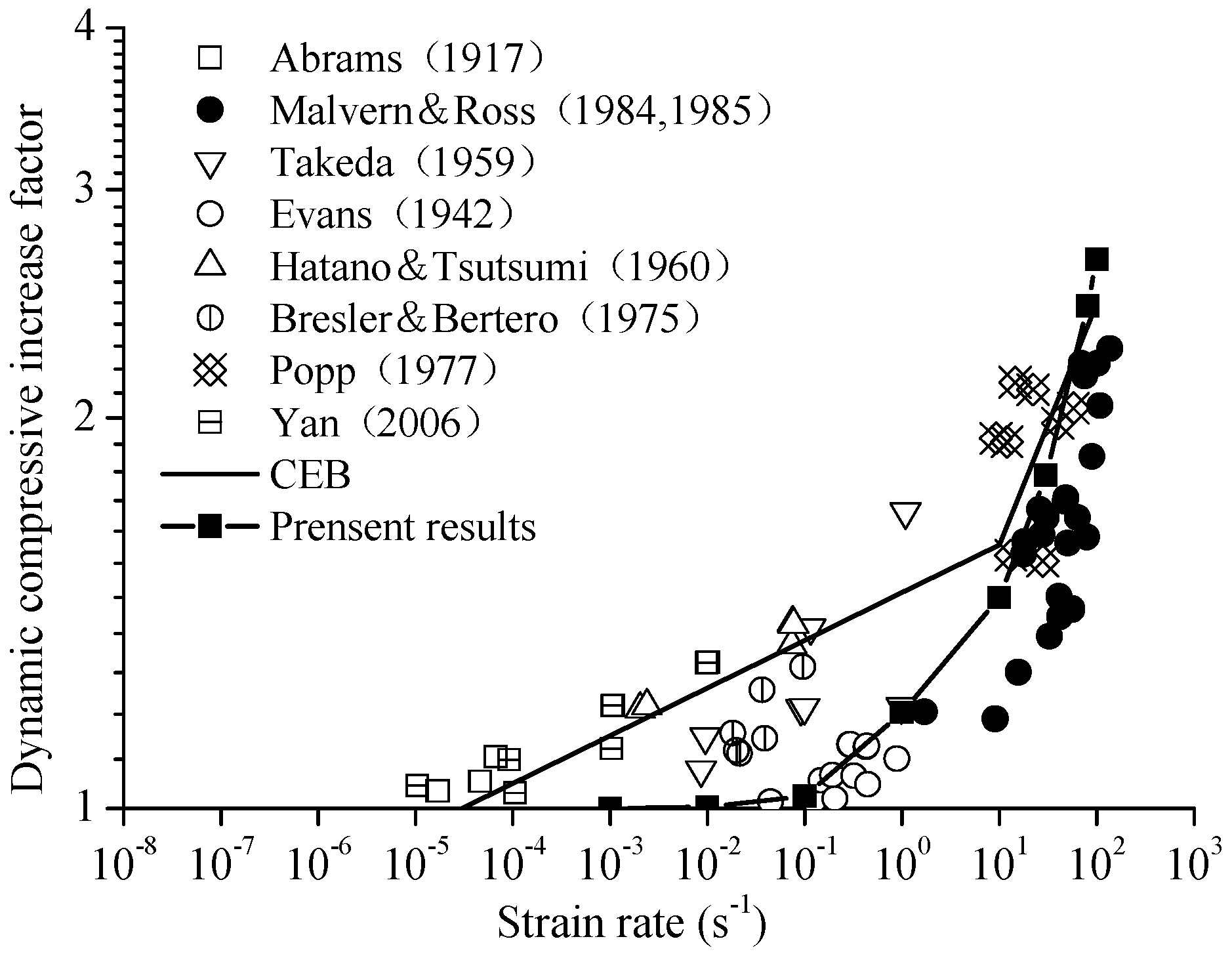

5. Numerical Examples and Results

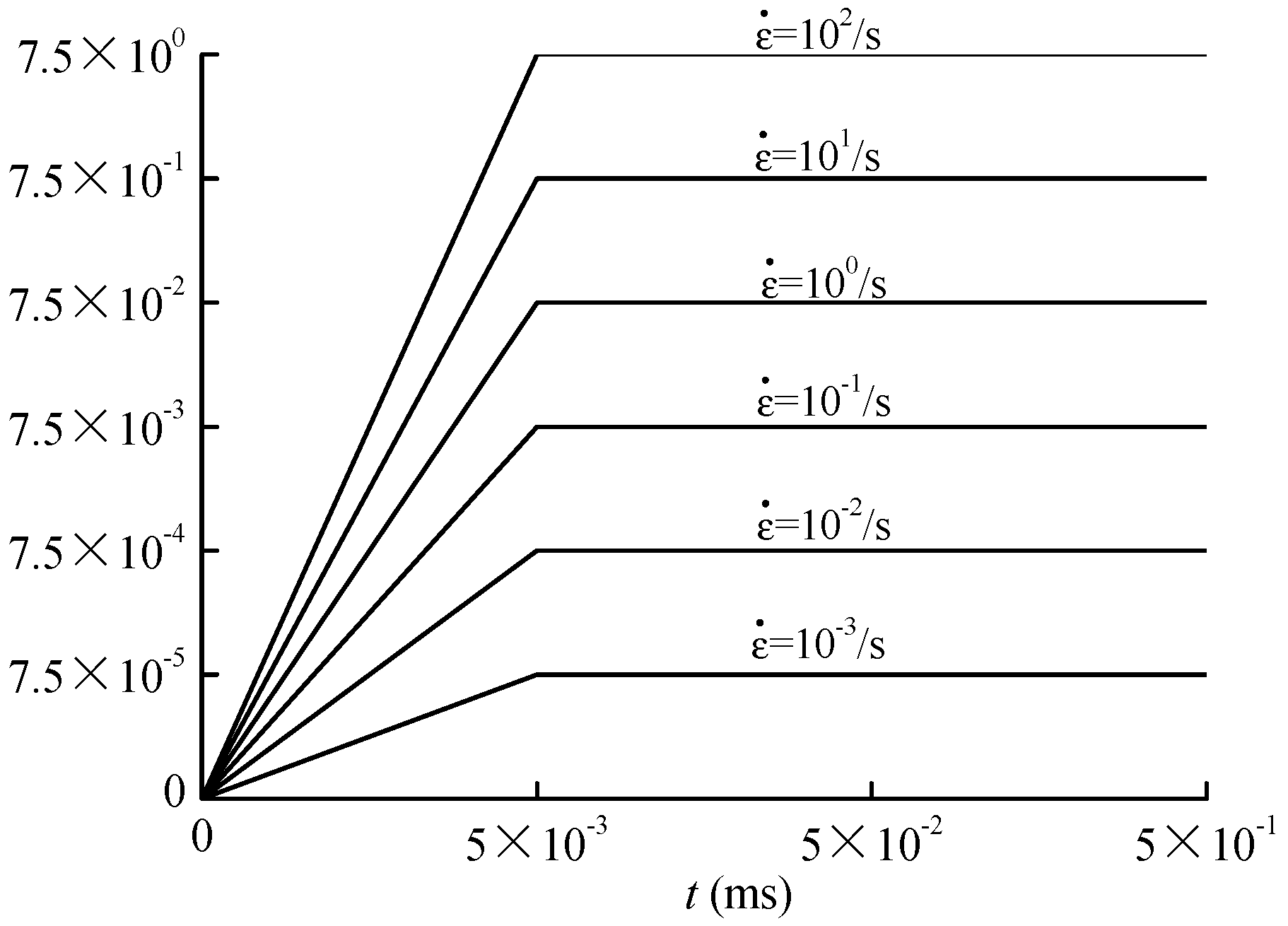

5.1. Boundary Conditions and Loading Model

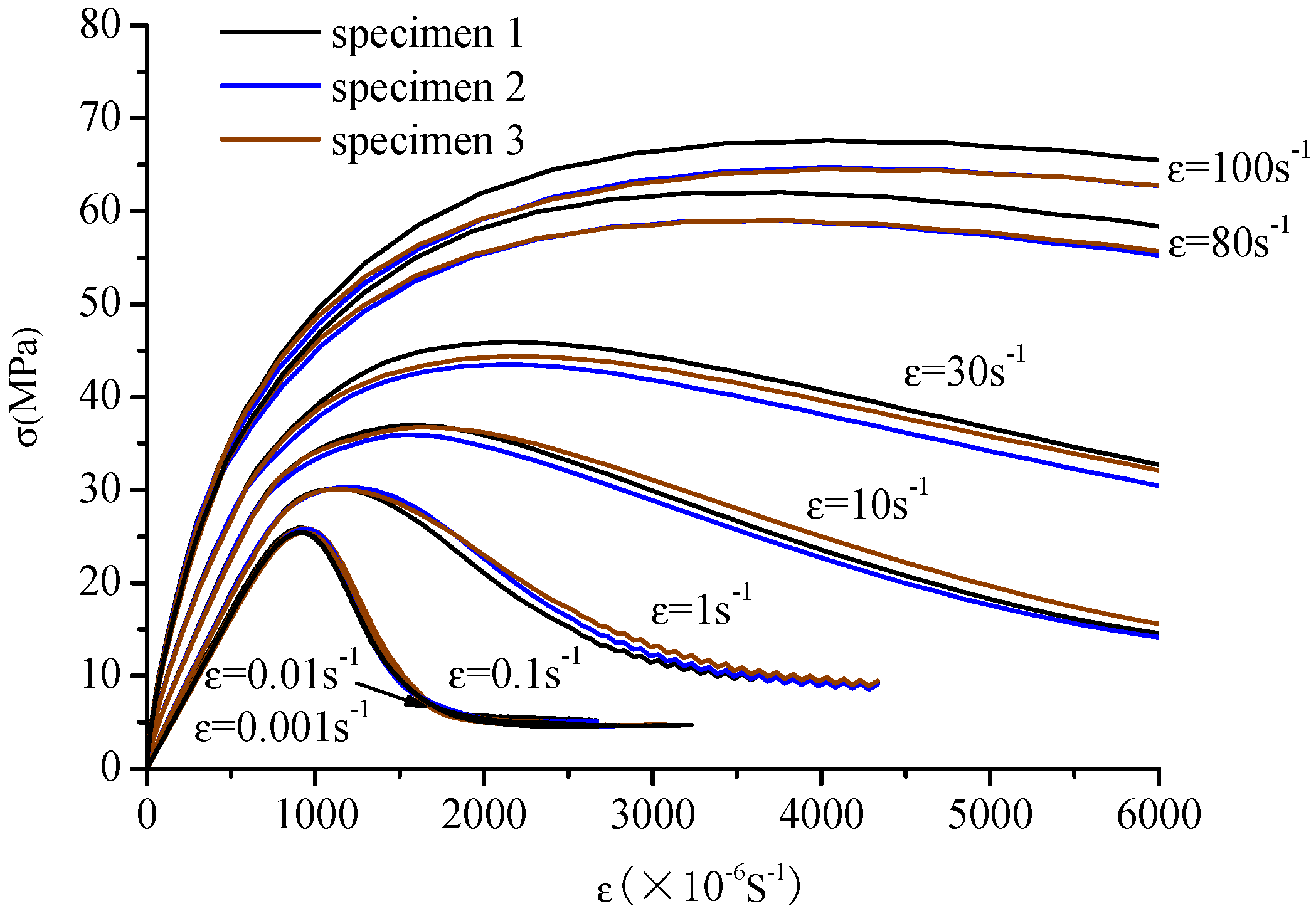

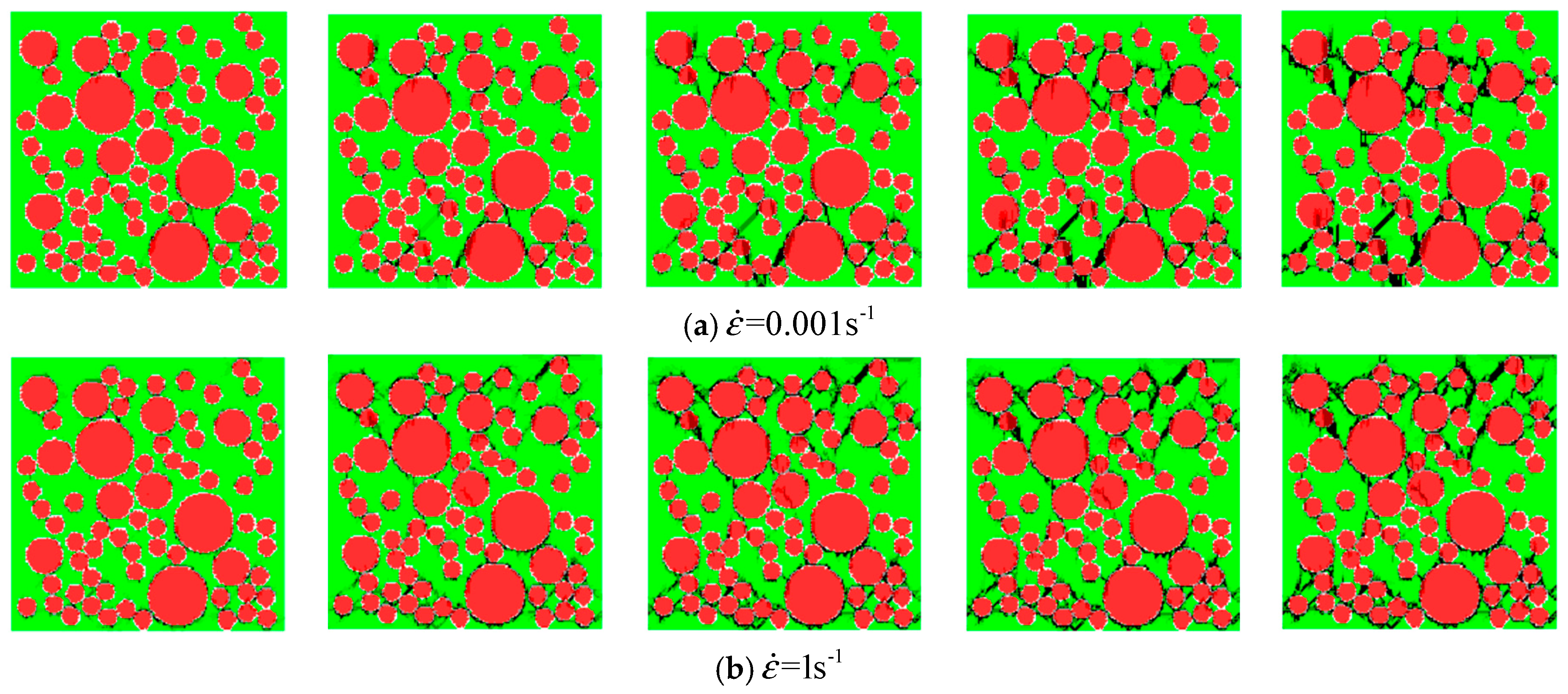

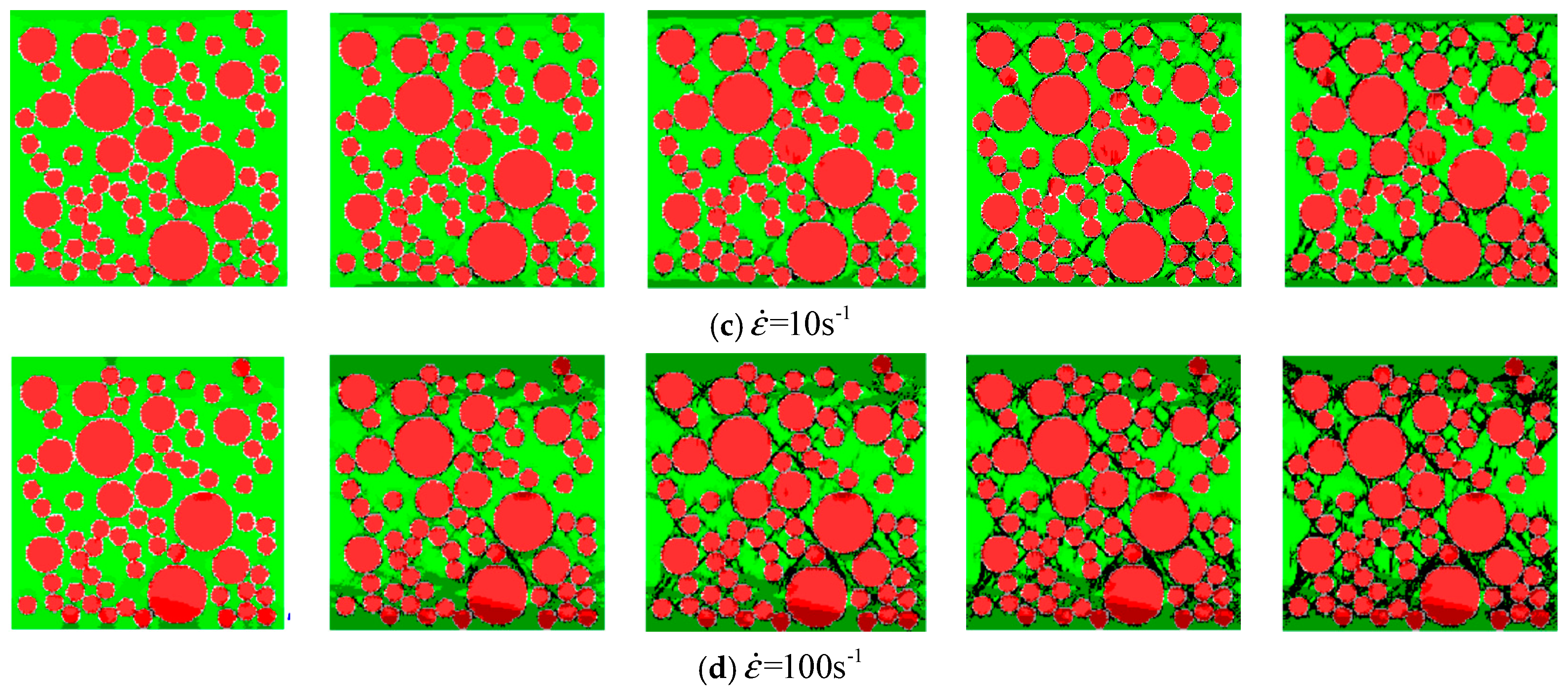

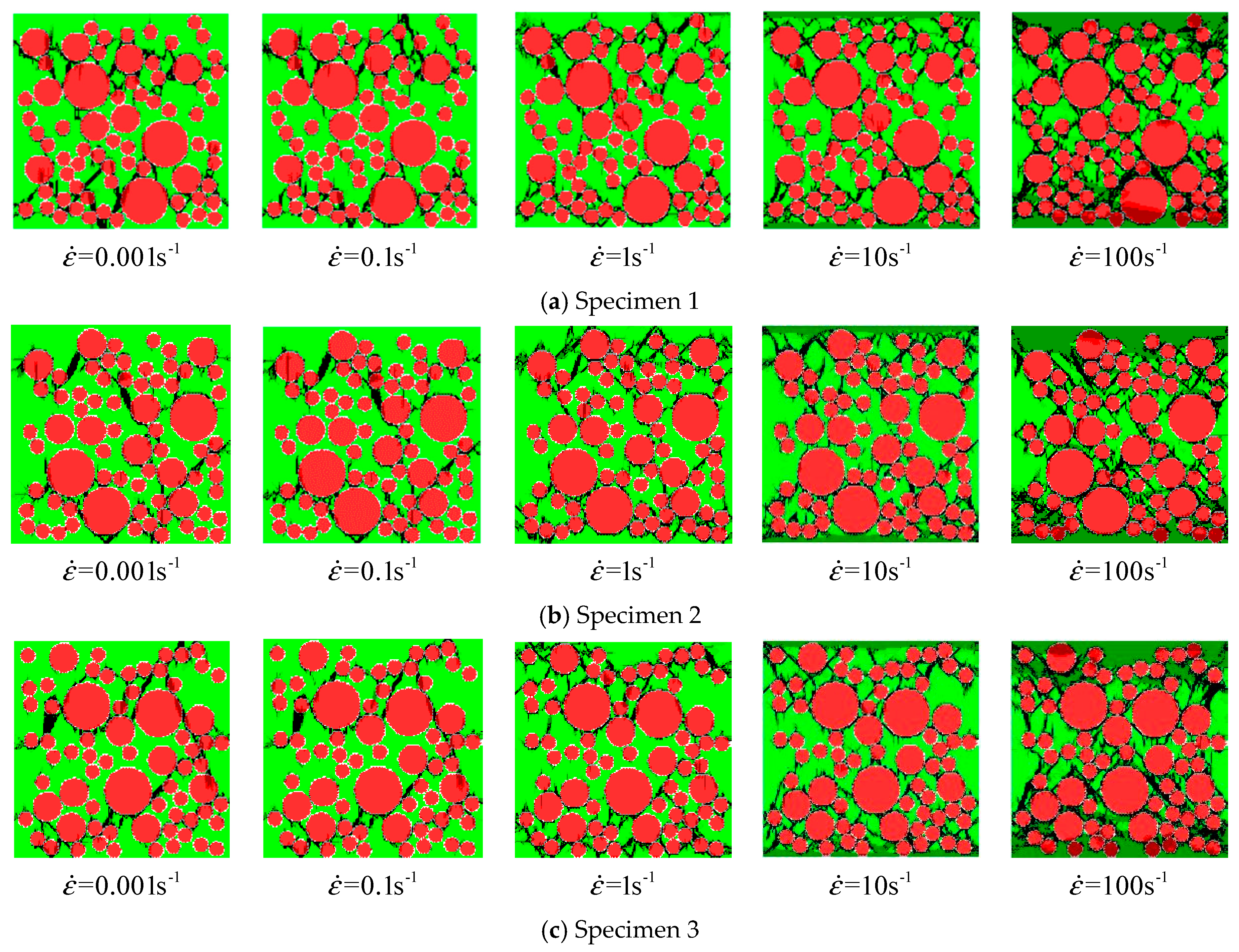

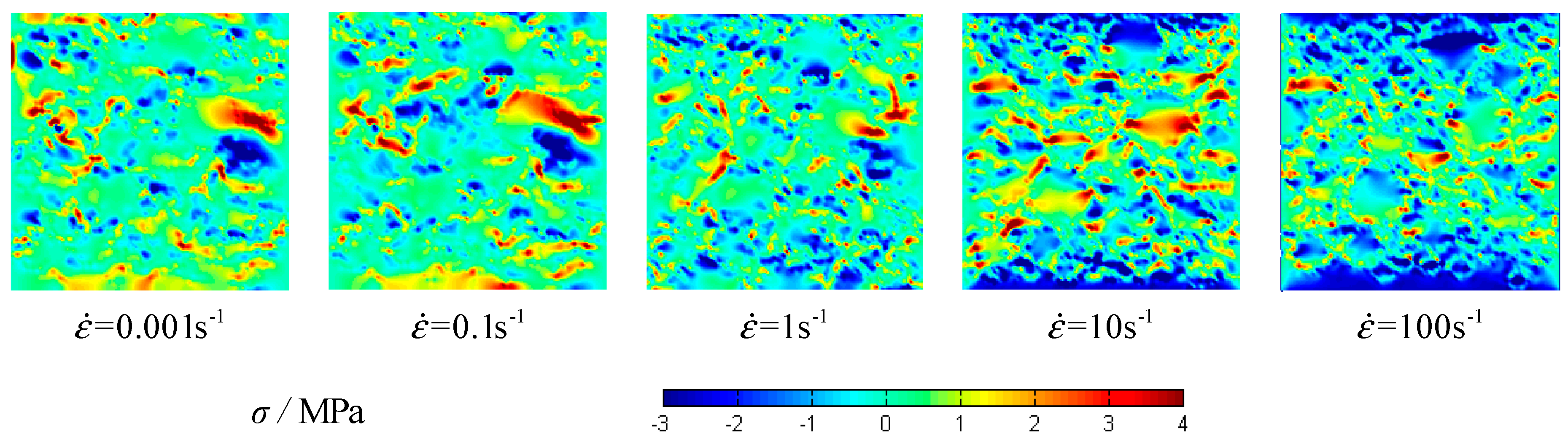

5.2. Dynamic Failure Behavior of Concrete under Uniaxial Compressive Stress

6. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bischoff, P.H.; Perry, S.H. Compressive behavior of concrete at high strain rates. Mater. Struct. 1991, 24, 425–450. [Google Scholar] [CrossRef]

- Evans, R.H. Effect of rate of loading on the mechanical properties of some materials. J. Ice 1942, 18, 296–306. [Google Scholar] [CrossRef]

- Abrams, D.A. Effect of rate of application of load on the compressive strength of concrete. ASTM J. 1917, 17, 70–78. [Google Scholar]

- Bischoff, P.H.; Perry, S.H. Impact behavior of plain concrete loaded in uniaxial compression. J. Eng. Mech. 1995, 25, 685–693. [Google Scholar] [CrossRef]

- Ross, C.A.; Tedesco, J.W.; Kuennen, S.T. Effects of strain rate on concrete strength. Aci Mater. J. 1995, 92, 37–47. [Google Scholar]

- John, R.; Antoun, T.; Rajendran, A.M. Effect of strain rate and size on tensile strength of concrete. Shock Compression Condensed Matter 1992, 1994, 501–504. [Google Scholar]

- Malvar, L.J.; Crawford, J.E. Dynamic Increase Factors for Concrete. In Proceedings of the Twenty-Eighth DDESB Seminar, Orlando, FL, USA, 18–20 August 1998; pp. 1–17. [Google Scholar]

- Williams, M.S. Modeling of local impact effects on plain and reinforced concrete. Aci Struc. J. 1994, 91, 178–187. [Google Scholar]

- Kishen, J.M.C. Fracture of Rock-Concrete Interfaces: Laboratory Tests and Applications. ACI Struct. J. 2004, 101, 325–331. [Google Scholar]

- Erzar, B.; Forquin, P. Experiments and mesoscopic modelling of dynamic testing of concrete. Mech. Mater 2011, 43, 505–527. [Google Scholar] [CrossRef]

- Grote, D.L.; Park, S.W.; Zhou, M. Experimental characterization of the dynamic failure behavior of mortar under impact loading. J. Appl. Phys. 2001, 89, 2115–2123. [Google Scholar] [CrossRef]

- Grote, D.L.; Park, S.W.; Zhou, M. Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization. Int. J. Impact Eng. 2001, 25, 869–886. [Google Scholar] [CrossRef]

- Jin, X.C.; Hou, C.; Fan, X. Quasi-static and dynamic experimental studies on the tensile strength and failure pattern of concrete and mortar discs. Sci Rep. 2017, 7, 15305. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.B.; Gao, G.F.; Jing, L. Response of high-strength concrete to dynamic compressive loading. Int. J. Impact Eng. 2017, 108, 114–135. [Google Scholar] [CrossRef]

- Levi-Hevroni, D.; Kochavi, E.; Kofman, B. Experimental and numerical investigation on the dynamic increase factor of tensile strength in concrete. Int. J. Impact Eng. 2018, 114, 93–104. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Wu, L. Influence of free water content on the compressive mechanical behavior of cement mortar under high strain rate. Sadhana 2011, 36, 357–369. [Google Scholar] [CrossRef]

- Quast, M.; Curbach, M. Concrete under biaxial dynamic compressive loading. Procedia Eng. 2017, 210, 24–31. [Google Scholar] [CrossRef]

- Li, M.; Hao, H.; Shi, Y. Specimen shape and size effects on the concrete compressive strength under static and dynamic tests. Constr. Build. Mater. 2018, 161, 84–93. [Google Scholar] [CrossRef]

- Jurowski, K.; Grzeszczyk, S. Influence of Selected Factors on the Relationship between the Dynamic Elastic Modulus and Compressive Strength of Concrete. Materials 2018, 11, 477. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, Y.; Jiang, X. Inertial effect on concrete-like materials under dynamic direct tension. Int. J. Prot. Struct. 2018, 9, 377–396. [Google Scholar] [CrossRef]

- Simo, J.C.; Ju, J.W. Strain- and stress-based continuum damage model—II. Comput aspects. Int. J. Solids Struct. 1989, 23, 841–869. [Google Scholar] [CrossRef]

- Simo, J.C.; Ju, J.W. Strain- and stress-based continuum damage models—I. Formulation. Int. J. Solids Struct. 1987, 23, 821–840. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, R.; Dou, G.; Xu, J.; Du, X. Experimental and numerical study of reinforced concrete beams with steel fibers subjected to impact loading. Int. J. Damage Mech. 2018, 27, 1058–1083. [Google Scholar] [CrossRef]

- Jin, L.; Ding, Z.; Li, D.; Du, X. Experimental and numerical investigations on the size effect of moderate high-strength reinforced concrete columns under small-eccentric compression. Int. J. Damage Mech. 2018, 27, 657–685. [Google Scholar] [CrossRef]

- Li, W.S.; Wu, J.Y. A consistent and efficient localized damage model for concrete. Int. J. Damage Mech. 2018, 27, 541–567. [Google Scholar] [CrossRef]

- Wardeh, M.A.; Toutanji, H.A. Parameter estimation of an anisotropic damage model for concrete using genetic algorithms. Int. J. Damage Mech. 2017, 26, 801–825. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Banthia, N.; Yoon, Y.S. Nonlinear finite element analysis of ultra-high-performance fiber-reinforced concrete beams. Int. J. Damage Mech. 2017, 26, 735–757. [Google Scholar] [CrossRef]

- Liang, J.; Ren, X.; Li, J. A competitive mechanism driven damage-plasticity model for fatigue behavior of concrete. Int. J. Damage Mech. 2016, 25, 377–399. [Google Scholar] [CrossRef]

- Georgin, J.F.; Reynouard, J.M. Modeling of structures subjected to impact: concrete behavior under high strain rate. Cem. Concr. Compos. 2003, 25, 131–143. [Google Scholar] [CrossRef]

- Snozzi, L.; Caballero, A.; Molinari, J.F. Influence of the meso-structure in dynamic fracture simulation of concrete under tensile loading. Cem. Concr. Res. 2011, 41, 1130–1142. [Google Scholar] [CrossRef]

- Snozzi, L.; Gatuingt, F.; Molinari, J.F. A meso-mechanical model for concrete under dynamic tensile and compressive loading. Int. J. Fract. 2012, 178, 179–194. [Google Scholar] [CrossRef]

- Gatuingt, F.; Snozzi, L.; Molinari, J.F. Numerical determination of the tensile response and the dissipated fracture energy of concrete: role of the mesostructure and influence of the loading rate. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 3112–3130. [Google Scholar] [CrossRef]

- Gatuingt, F.; Snozzi, L.; Molinari, J.F. Determination of the Dynamic Tensile Response and Dissipated Fracture Energy of Concrete with a Cohesive Element Model. International Conference on Numerical Modeling Strategies for Sustainable Concrete Structures—SSCS 2012, June 2012, Aix en Provence, France. 2017. Available online: https://hal.archives-ouvertes.fr/hal-01624529 (accessed on 15 January 2019).

- Park, S.W.; Xia, Q.; Zhou, M. Dynamic behavior of concrete at high strain rates and pressures: II. numerical simulation. Int. J. Impact Eng. 2001, 25, 887–910. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Hao, H. Mesoscale modelling of concrete tensile failure mechanism at high strain rates. Comput. Struct. 2008, 86, 2013–2026. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Hao, H. Modelling of compressive behavior of concrete-like materials at high strain rate. Int. J. Solids Struct. 2008, 45, 4648–4661. [Google Scholar] [CrossRef]

- Hao, H.; Hao, Y.; Li, Z.X. A numerical study of factors influencing high-speed impact tests of concrete material properties. In Proceedings of the 8th International Conference on Shock & Impact Loads on Structures, Adelaide, Australia, 2–4 December 2009; pp. 37–52. [Google Scholar]

- Hao, H.; Zhou, X.Q. Concrete material model for high rate dynamic analysis. In Proceedings of the Seventh International Conference on shock & impact loads on structures, Beijing, China, 17–19 October 2007; pp. 753–768. [Google Scholar]

- Cusatis, G. Strain-rate effects on concrete behavior. Int. J. Impact Eng. 2011, 38, 162–170. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, Q.; Huang, F. Experimental and numerical investigation on the dynamic tensile strength of concrete. Int. J. Impact Eng. 2005, 32, 605–617. [Google Scholar] [CrossRef]

- Zhou, W.; Tang, L.; Liu, X. Mesoscopic simulation of the dynamic tensile behavior of concrete based on a rate-dependent cohesive model. Int. J. Impact Eng. 2016, 95, 165–175. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Experimental and modeling study of dynamic mechanical properties of cement paste, mortar and concrete. Constr. Build. Mater. 2013, 47, 419–430. [Google Scholar] [CrossRef]

- Peng, Y.J.; Liu, Y.H.; Pu, J.W.; Zhang, L. Application of base force element method to mesomechanics analysis for recycled aggregate concrete. Math Probl. Eng. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Peng, Y.J.; Pu, J.W. Micromechanical investigation on size effect of tensile strength for recycled aggregate concrete using BFEM. Int. J. Mech. Mater. Des. 2016, 12, 525–538. [Google Scholar] [CrossRef]

- Peng, Y.J.; Chu, H.; Pu, J.W. Numerical simulation of recycled concrete using convex aggregate model and base force element method. Adv. Mater. Sci. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Peng, Y.J.; Dong, Z.L.; Peng, B.; Liu, Y.H. Base force element method (BFEM) on potential energy principle for elasticity problems. Int. J. Mech. Mater. Des. 2011, 7, 245–251. [Google Scholar] [CrossRef]

- Walraven, J.C.; Reinhardt, H.W. Theory and experiments on the mechanical behavior of cracks in plain and reinforced concrete subjected to shear loading. Heron. 1991, 26, 26–35. [Google Scholar]

- Du, X.L.; Jin, L.; Ma, G. A meso-scale analysis method for the simulation of nonlinear damage and failure behavior of reinforced concrete members. Int. J. Damage Mech. 2013, 22, 878–904. [Google Scholar] [CrossRef]

- Jayasuriya, A.; Adams, M.P.; Bandelt, M.J. Understanding variability in recycled aggregate concrete mechanical properties through numerical simulation and statistical evaluation. Constr. Build. Mater. 2018, 178, 301–312. [Google Scholar] [CrossRef]

- Nilsen, A.U.; Monteiro, P.J.M. Concrete: A three phase material. Cem. Concr. Res. 1993, 23, 147–151. [Google Scholar] [CrossRef]

- Agioutantis, Z.G.; Stiakakis, C.; Kleftakis, S. Numerical simulation of the mechanical behavior of epoxy based mortars under compressive loads. Comput. Struct. 2002, 80, 2071–2084. [Google Scholar] [CrossRef]

- Fakhari Tehrani, F.; Absi, J.; Allou, F. Heterogeneous numerical modeling of asphalt concrete through use of a biphasic approach: Porous matrix/inclusions. Comput. Mater. Sci. 2013, 69, 186–196. [Google Scholar] [CrossRef]

- Du, X.L.; Jin, L.; Ma, G. Numerical simulation of dynamic tensile-failure of concrete at meso-scale. Int. J. Impact Eng. 2014, 66, 5–17. [Google Scholar] [CrossRef]

- Comité Euro-International du Béton. CEB-FIP Model Code 1990; Redwood Books: Trowbridge, Wiltshire, UK, 1993. [Google Scholar]

- Dilger, W.H.; Koch, R.; Kowalczyk, R. Ductility of plain and confined concrete under different strain rates. ACI J. 1984, 81, 73–81. [Google Scholar]

| Mechanical Parameters | Cement Mortar | Interfacial Transition Zone (ITZ) | Aggregate |

|---|---|---|---|

| Density (kg/m3) | 2100 | 1700 | 2700 |

| Poisson’s ratio | 0.22 | 0.2 | 0.16 |

| Strength (tensile/compressive) (MPa) | 3.2/32 | 2.5/25 | 7/70 |

| 0.25 | 0.25 | 0.80 | |

| 0.85 | 0.65 | 0.90 | |

| 0.35 | 0.35 | 0.35 | |

| 0.3 | 0.3 | 0.3 | |

| 4/4 | 3/3 | 5/5 | |

| 10/10 | 10/10 | 10/10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Y.; Wang, Q.; Ying, L.; Kamel, M.M.A.; Peng, H. Numerical Simulation of Dynamic Mechanical Properties of Concrete under Uniaxial Compression. Materials 2019, 12, 643. https://doi.org/10.3390/ma12040643

Peng Y, Wang Q, Ying L, Kamel MMA, Peng H. Numerical Simulation of Dynamic Mechanical Properties of Concrete under Uniaxial Compression. Materials. 2019; 12(4):643. https://doi.org/10.3390/ma12040643

Chicago/Turabian StylePeng, Yijiang, Qing Wang, Liping Ying, Mahmoud M. A. Kamel, and Hongtao Peng. 2019. "Numerical Simulation of Dynamic Mechanical Properties of Concrete under Uniaxial Compression" Materials 12, no. 4: 643. https://doi.org/10.3390/ma12040643

APA StylePeng, Y., Wang, Q., Ying, L., Kamel, M. M. A., & Peng, H. (2019). Numerical Simulation of Dynamic Mechanical Properties of Concrete under Uniaxial Compression. Materials, 12(4), 643. https://doi.org/10.3390/ma12040643