Application of the Directed Cone Method for the Identification of Mathematical Models of Electromechanical Systems

Abstract

1. Introduction

2. Review of Modeling Methods for Electromechanical Systems

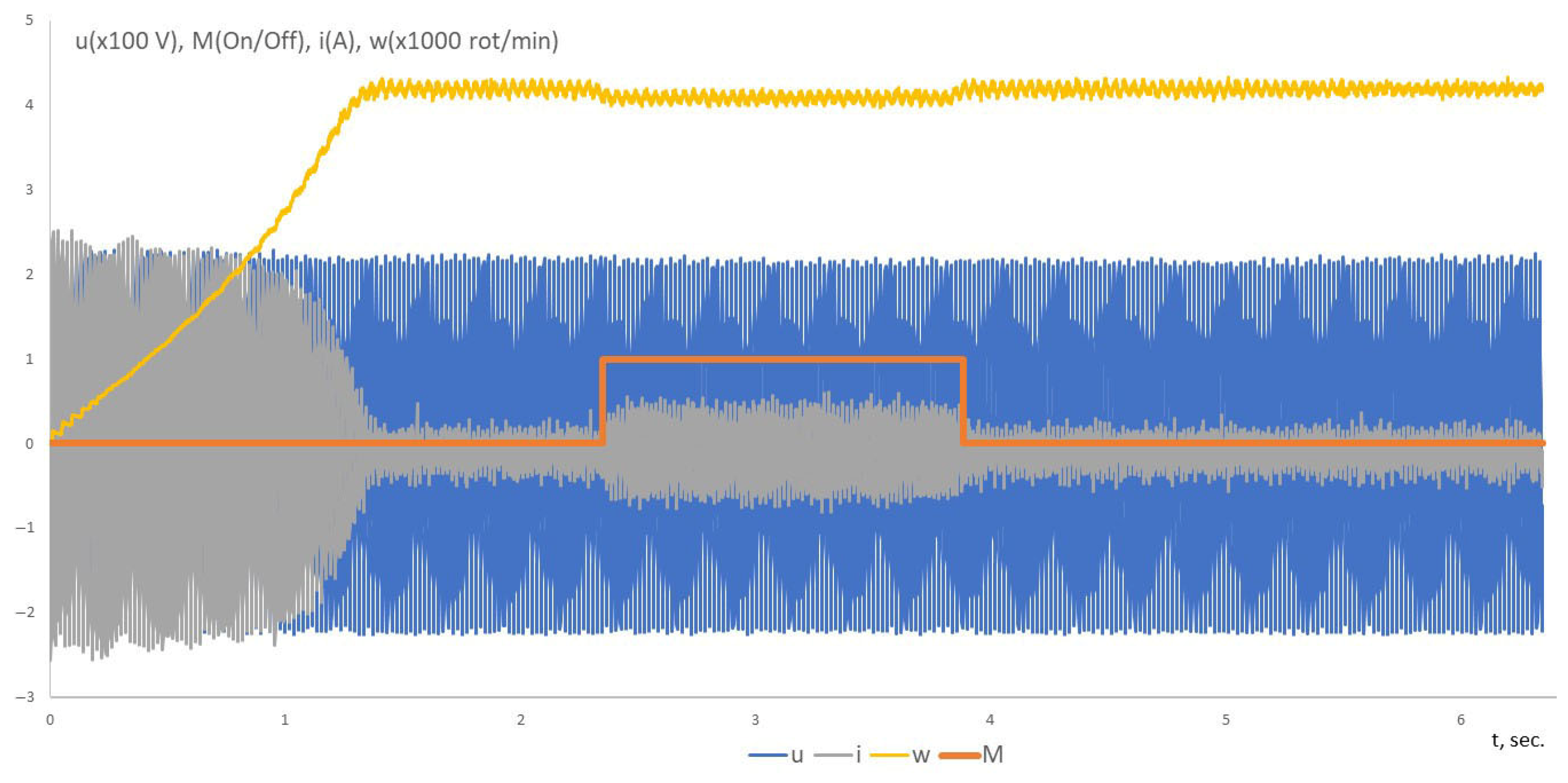

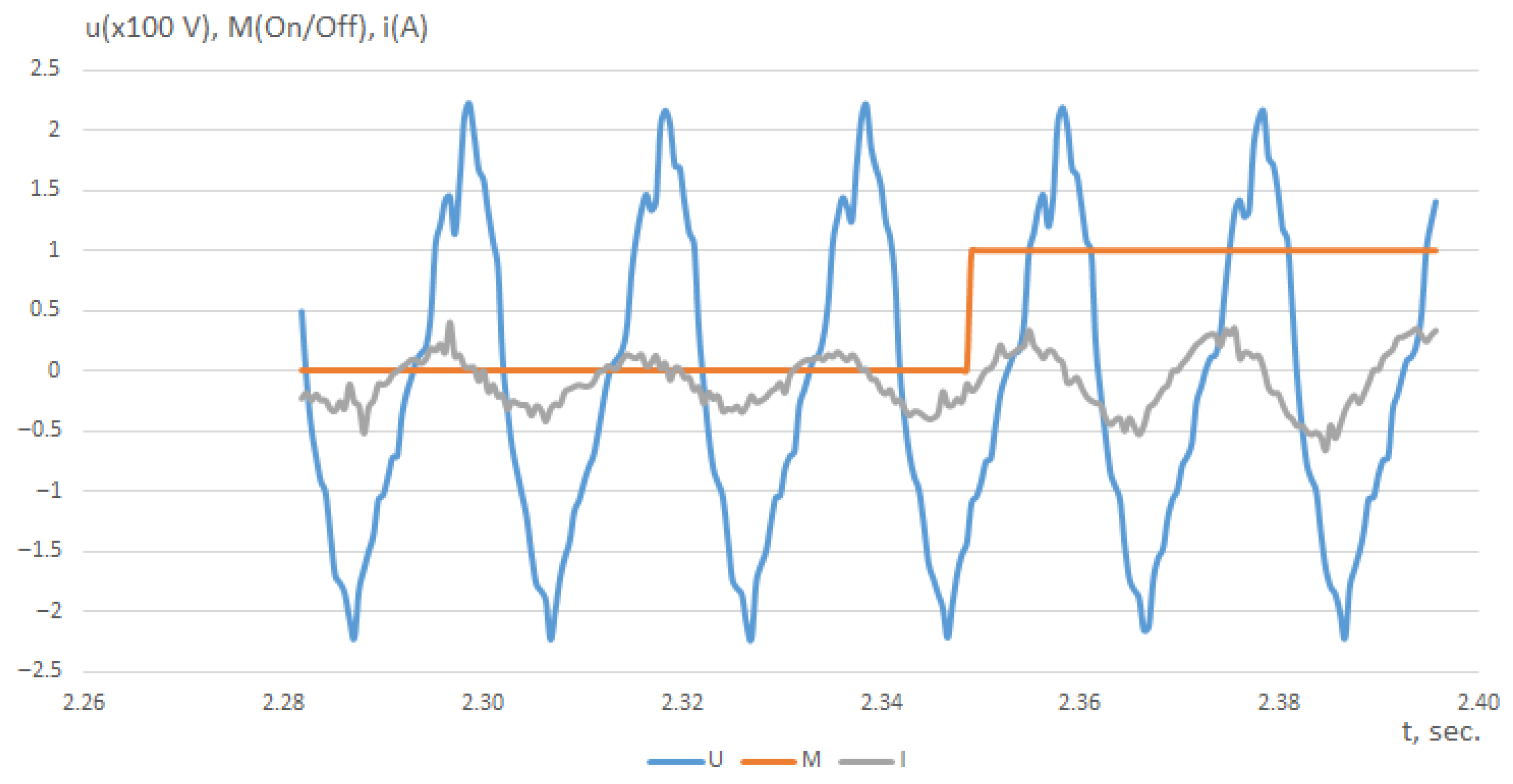

3. Materials and Methods

3.1. Problem Statement

3.2. Review of Directed Cone Methods in the Identification of Mathematical Models

3.3. Method for Improving the Directed Cone Approach

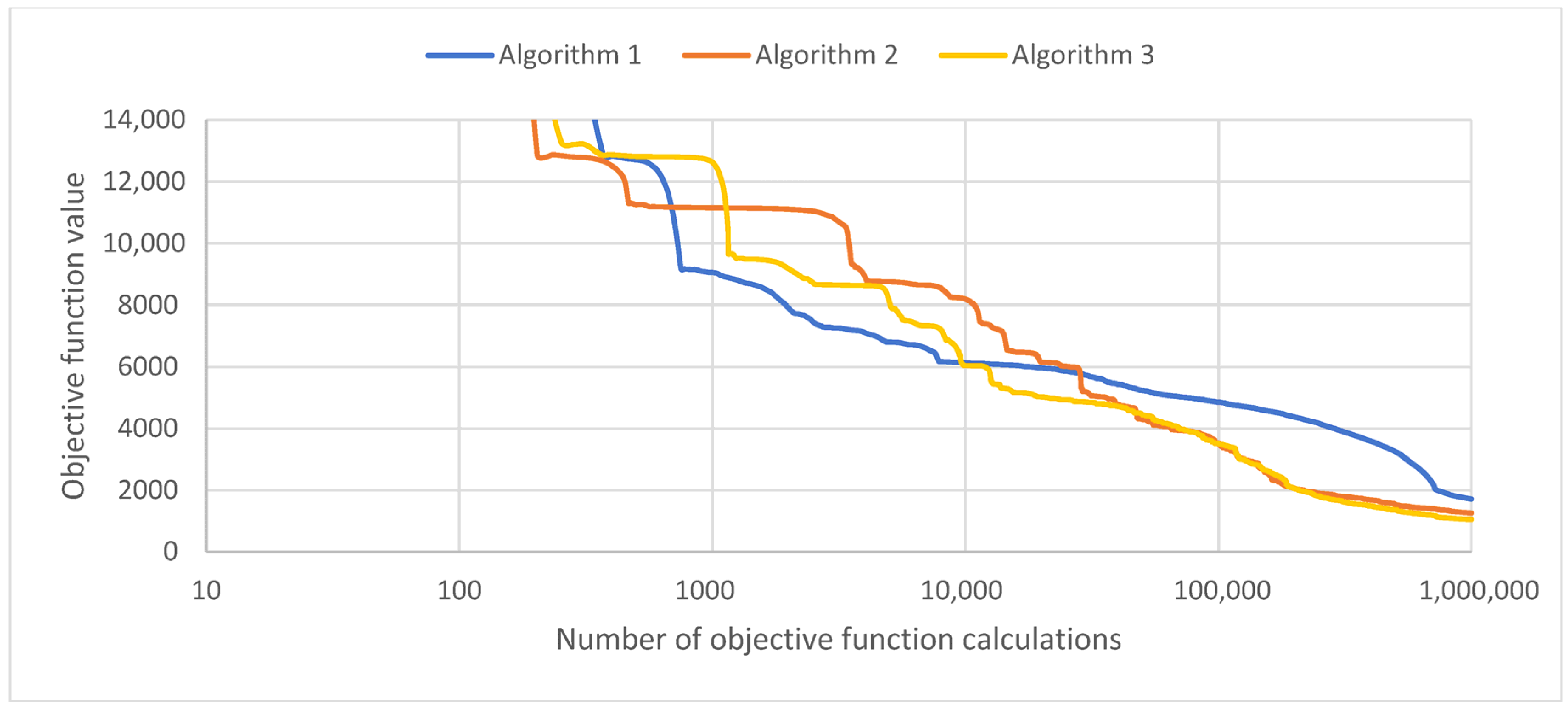

4. Result and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SRM | Switched Reluctance Motor |

| EMT | Electromechanical Transducer |

| EC | Electronic Commutator |

Appendix A

| 0 | 0 | 0 | 0 | 1.381 | 0 | 1.946 | 2.158 |

| −1.745 | 0 | −2.297 | 0.132 | 1.277 | 0 | 1.978 | 2.237 |

| 1.063 | 0 | 0.483 | 0.117 | 1.48 | 0 | 1.828 | 2.282 |

| 1.154 | 0 | 0.602 | 0.231 | 1.322 | 0 | 1.944 | 2.31 |

| 1.279 | 0 | 0.674 | 0.228 | 1.474 | 0 | 1.893 | 2.436 |

| 1.392 | 0 | 0.837 | 0.341 | 1.35 | 0 | 1.767 | 2.478 |

| 1.531 | 0 | 0.92 | 0.324 | 1.216 | 0 | 1.845 | 2.523 |

| 1.665 | 0 | 1.065 | 0.362 | 1.228 | 0 | 1.767 | 2.638 |

| 1.456 | 0 | 0.8 | 0.402 | 1.376 | 0 | 1.932 | 2.728 |

| 1.608 | 0 | 0.95 | 0.481 | 1.21 | 0 | 1.729 | 2.767 |

| 1.727 | 0 | 0.962 | 0.475 | … | … | … | … |

| 1.74 | 0 | 1.164 | 0.547 | −1.43 | 0 | −0.111 | 4.095 |

| 1.713 | 0 | 1.25 | 0.584 | −1.475 | 1 | −0.15 | 4.164 |

| 1.845 | 0 | 1.347 | 0.641 | −1.329 | 1 | −0.192 | 4.049 |

| 2.026 | 0 | 1.503 | 0.695 | −1.409 | 1 | −0.145 | 4.138 |

| 2.149 | 0 | 1.648 | 0.722 | 1.734 | 1 | −0.126 | 4.112 |

| 2.263 | 0 | 1.853 | 0.767 | 1.653 | 1 | −0.048 | 4.09 |

| 2.27 | 0 | 1.885 | 0.807 | 1.662 | 1 | −0.039 | 4.12 |

| 1.714 | 0 | 1.261 | 0.862 | 1.768 | 1 | −0.039 | 4.093 |

| 1.72 | 0 | 1.274 | 0.907 | 0.887 | 1 | −0.525 | 4.071 |

| 1.71 | 0 | 0.953 | 0.956 | 1.053 | 1 | −0.324 | 4.091 |

| 1.714 | 0 | 1.188 | 1.013 | 1.118 | 1 | −0.275 | 4.142 |

| 1.738 | 0 | 1.301 | 1.059 | 1.138 | 1 | −0.308 | 4.04 |

| 1.17 | 0 | 2.188 | 1.101 | 1.229 | 1 | −0.275 | 4.097 |

| 1.645 | 0 | 0.932 | 1.143 | 1.081 | 1 | −0.301 | 4.037 |

| 1.709 | 0 | 1.135 | 1.189 | 0.42 | 1 | −0.495 | 4.109 |

| 1.728 | 0 | 1.153 | 1.234 | 0.799 | 1 | −0.457 | 4.039 |

| 1.751 | 0 | 1.295 | 1.304 | −1.831 | 1 | −0.548 | 4.122 |

| 1.885 | 0 | 1.338 | 1.366 | −1.851 | 1 | −0.573 | 4.096 |

| 2.087 | 0 | 1.479 | 1.411 | −1.859 | 1 | −0.574 | 4.135 |

| 2.172 | 0 | 1.536 | 1.452 | −0.765 | 1 | 0.093 | 4.118 |

| 1.998 | 0 | 1.424 | 1.487 | −0.792 | 1 | 0.127 | 4.086 |

| 2.126 | 0 | 1.441 | 1.541 | −0.296 | 1 | 0.025 | 4.109 |

| 2.268 | 0 | 1.618 | 1.63 | −0.223 | 1 | 0.318 | 4.065 |

| 2.256 | 0 | 1.691 | 1.674 | −0.288 | 1 | 0.239 | 4.111 |

| 2.15 | 0 | 1.789 | 1.749 | −0.173 | 1 | 0.33 | 4.092 |

| 2.185 | 0 | 1.864 | 1.779 | −1.499 | 1 | −0.435 | 4.047 |

| 2.102 | 0 | 1.873 | 1.822 | −1.243 | 1 | −0.082 | 4.121 |

| 1.746 | 0 | 1.929 | 1.911 | −1.101 | 1 | −0.013 | 4.038 |

| 1.53 | 0 | 1.952 | 1.965 | 1.257 | 1 | 0.358 | 4.075 |

| 1.379 | 0 | 1.953 | 2.008 | … | … | … | … |

| 1.162 | 0 | 2.036 | 2.046 | … | … | … | … |

References

- Shynkarenko, V.F.; Shymanska, A.A.; Kotliarova, V.V. Modeling of Electromechanical Systems; Igor Sikorsky Kyiv Polytechnic Institute: Kyiv, Ukraine, 2019; Available online: https://ela.kpi.ua/handle/123456789/38793 (accessed on 29 September 2025). (In Ukrainian)

- Cieślik, S. Mathematical Modeling of the Dynamics of Linear Electrical Systems with Parallel Calculations. Energies 2021, 14, 2930. [Google Scholar] [CrossRef]

- Dubas, F.; Boughrara, K. Mathematical Models for the Design of Electrical Machines. Math. Comput. Appl. 2020, 25, 77. [Google Scholar] [CrossRef]

- Bu, W.; Li, J.; Lu, Y. Mathematical Modeling and Electromagnetic Characteristics Analysis of a Six-Phase Distributed Single-Winding BPMSM with 12 Slots and 2 Poles. Appl. Sci. 2025, 15, 2093. [Google Scholar] [CrossRef]

- Applications of Single Phase Induction Motor. GeeksforGeeks, 23 July 2025. Available online: https://www.geeksforgeeks.org/electrical-engineering/applications-of-single-phase-induction-motor/ (accessed on 30 October 2025).

- Baidak, Y. Single-Phase Motor of Hermetic Compressor Drive with Improved Performance Characteristics. Refrig. Eng. Technol. 2009, 118, 12–19. [Google Scholar]

- Baidak, Y. Mathematical Model of the Electric Motor of the Hermetic Compressor of the Refrigerating Appliance with a Single-Phase Winding. Refrig. Eng. Technol. 2009, 122, 6–15. [Google Scholar]

- Baidak, Y.; Smyk, V. Numerical Investigation of Refrigeration Machine Compressor Operation Considering Single-Phase Electric Motor Dynamic Characteristics. In Proceedings of the 10th International Conference on Compressors and Their Systems, IOP Conf. Ser. Mater. Sci. Eng. 2017, 232, 012081. [Google Scholar] [CrossRef]

- IEC 60034-30-1 ed1.0:2014; Rotating Electrical Machines—Part 30-1: Efficiency Classes of Line Operated AC Motors. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2014.

- International Electrotechnical Commission (IEC). IEC 60050, Section 411-31: Rotating Machinery—General, IEV ref. 411-31-10: Induction Machine—An Asynchronous Machine of Which Only One Winding Is Energized; IEC: Geneva, Switzerland, 1990. [Google Scholar]

- Baidak, Y.; Vereitina, I. Asynchronous Electric Motor with Single-Phase Stator Winding. Autom. Technol. Bus.-Process. 2023, 15, 76–82. [Google Scholar] [CrossRef]

- Opolskiy, Y.V.; Vasyura, A.S. Modern Approaches to Increasing the Efficiency of Induction Motors. Optoelectron. Inf.-Power Technol. 2018, 35, 81–88. (In Ukrainian) [Google Scholar] [CrossRef]

- Klee, H.; Allen, R. Simulation of Dynamic Systems with MATLAB and Simulink; CRC Press: New York, NY, USA, 2011. [Google Scholar]

- Tkachuk, V.I.; Osidacz, Y.V. Modeling of electromechanical processes in an electric drive with a valve jet engine. Electr. Power Electromech. Syst. 1995, 288, 83–90. [Google Scholar]

- Czornyy, O.P.; Lugovoy, A.V.; Rolkin, A.Y.; Sysyuk, G.Y.; Sadovoy, O.V. Modeling of Electromechanical Systems. Kremenczuk, Ukraine. 2001. 410p (In Ukrainian). Available online: https://elprivod.nmu.org.ua/files/modeling/%D0%A7%D0%BE%D1%80%D0%BD%D0%B8%D0%B9_%D0%9C%D0%BE%D0%B4%D0%B5%D0%BB%D1%8E%D0%B2%D0%B0%D0%BD%D0%BD%D1%8F%20%D0%95%D0%9C%D0%A1.pdf (accessed on 20 May 2024).

- Stakhiv, P.G.; Kozak, Y.Y.; Hoholyuk, O.P. Discrete Modeling in Electrical Engineering and Related Fields; Lviv Polytechnic: Lviv, Ukraine, 2014. (In Ukrainian) [Google Scholar]

- Habash, R. Sustainability and Health in Intelligent Buildings; Woodhead Publishing: Cambridge, UK, 2022; Available online: https://shop.elsevier.com/books/sustainability-and-health-in-intelligent-buildings/habash/978-0-323-98826-1 (accessed on 20 May 2024).

- Ferreira, A.; Aphale, S.S. A Survey of Modeling and Control Techniques for Micro- and Nano-Electromechanical Systems. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2011, 41, 350–364. [Google Scholar] [CrossRef]

- Wee, H.S.H.; Ahmad, N.S. Review and Comparative Analysis of System Identification Methods for Perturbed Motorized Systems. Comput. Model. Eng. Sci. 2025, 143, 1301–1354. [Google Scholar] [CrossRef]

- Dri, E.; Peretti, G.; Romero, E. Fault Detection in Configurable Switched-Capacitor Filters Using Transient Analysis and Dynamic Time Warping. Analog Integr. Circuits Signal Process. 2021, 108, 1–14. [Google Scholar] [CrossRef]

- Oh, J.; Yu, Y.S. Macro-Modeling for N-Type Feedback Field-Effect Transistor for Circuit Simulation. Micromachines 2021, 12, 1174. [Google Scholar] [CrossRef] [PubMed]

- Amick, B.W.; Gauthier, C.R.; Liu, D. Macro-Modeling Concepts for the Chip Electrical Interface. In Proceedings of the 2002 Design Automation Conference (DAC 2002), New Orleans, LA, USA, 10–14 June 2002; Available online: https://www.cs.york.ac.uk/rts/docs/SIGDA-Compendium-1994-2004/papers/2002/dac02/pdffiles/27_3.pdf (accessed on 10 May 2024).

- Kvatinsky, S.; Friedman, E.G.; Kolodny, A.; Schächter, L. Power Grid Analysis Based on a Macro Circuit Model. In Proceedings of the IEEE 26th Convention of Electrical and Electronics Engineers in Israel, Eilat, Israel, 17–20 November 2010; Available online: https://asic2.group/wp-content/uploads/2017/06/kvatinsky.pdf (accessed on 15 June 2024).

- Sass, L. Symbolic Modeling of Electromechanical Multibody Systems. Ph.D. Thesis, Université catholique de Louvain, Louvain, Belgium, 2004. Available online: https://dial.uclouvain.be/pr/boreal/object/boreal:5194/datastream/PDF_01/view (accessed on 25 July 2024).

- Tan, D.; Shi, C. Efficient Approximation of Symbolic Expressions for Analog Behavioral Modeling and Analysis. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2004, 23, 907–918. [Google Scholar] [CrossRef]

- Lin, Y.; Li, Y.; Madhusudan, M.; Sapatnekar, S.S.; Harjani, R.; Hu, J. MMM: Machine Learning-Based Macro-Modeling for Linear Analog ICs and ADC/DACs. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2024, 43, 4740–4752. [Google Scholar] [CrossRef]

- Pandit, S. Nano-Scale CMOS Analog Circuits: Models and CAD Techniques for High-Level Design; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Petrenko, A. Macromodels of Micro-ElectroMechanical Systems (MEMS). In Microelectromechanical Systems and Devices; IntechOpen: London, UK, 2012; pp. 155–190. Available online: https://cdn.intechopen.com/pdfs/33594/InTech-Macromodels_of_micro_electro_mechanical_systems_mems_.pdf (accessed on 20 December 2024).

- Romansky, R. An Approach for Mathematical Modeling and Investigation of Computer Processes at a Macro Level. Mathematics 2020, 8, 1838. [Google Scholar] [CrossRef]

- Arrillaga, J.; Watson, N. Power Systems Electromagnetic Transients Simulation; The Institution of Electrical Engineers: London, UK, 2003; 421p. [Google Scholar]

- Zadeh, L.A.; Desoer, C.A. Linear System Theory: The State Space Approach; Courier Dover Publications: Mineola, NY, USA, 2008. [Google Scholar]

- Viola, C.; Pavesi, D.; Weng, L.; Gobat, G.; Maspero, F.; Zega, V. Microelectromechanical System Resonant Devices: A Guide for Design, Modeling and Testing. Micromachines 2024, 15, 1461. [Google Scholar] [CrossRef]

- Santana, N.H.B.; Yahyaoui, I.; Oliveira, F.D.C.; Amorim, A.E.A.; Simonetti, D.S.L.; Rocha, H.R.O. Dynamic to Static Model Comparison and Hybrid Metaheuristic Optimization in Induction Motor Parameter Estimation. Electronics 2025, 14, 524. [Google Scholar] [CrossRef]

- Ljung, L. System Identification Toolbox for Use with MATLAB, Version 6; The MathWorks, Inc.: Natick, MA, USA, 2003. [Google Scholar]

- Kiss, G.R.; Horváth, M.; Szánthó, Z. MATLAB Simulink-Based Modelling and Performance Analysis of District Heating Substations for Renewable Energy Integration. Energies 2025, 18, 2370. [Google Scholar] [CrossRef]

- Naqvi, S.F.A. Mathematical Modeling & MATLAB Simulation of STATCOM Based Profile Controller for Self Excited Induction Generator. In Proceedings of the 2023 IEEE 12th International Conference on Communication Systems and Network Technologies (CSNT), Bhopal, India, 8–9 April 2023; pp. 975–982. [Google Scholar] [CrossRef]

- Silvestrov, A.; Ostroverkhov, M.; Spinul, L.; Serdyuk, A.; Falchenko, M. Structural and parametric identification of mathematical models of control objects based on the principle of rational complication. In Proceedings of the 2022 IEEE 3rd KhPI Week on Advanced Technology (KhPIWeek), Kharkiv, Ukraine, 3–7 October 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Lasdon, L.S.; Fox, R.L.; Ratner, M.W. Nonlinear optimization using the generalized reduced gradient method. RAIRO-Oper. Res.-Rech. Opérationnelle 1974, 8, 73–103. Available online: http://eudml.org/doc/104604 (accessed on 22 December 2024). [CrossRef]

- Rastrigin, L.A. Random Search in Optimization Problems for Multiparameter Systems; Air Force Systems Command, Foreign Technology Division: Wright-Patterson AFB, OH, USA, 1967; (English translation of Sluchainyi Poisk v Zadachakh Optimizatsii Mnogoparameticheskikh Sistem, Akademiia Nauk Latviiskoi SSR: Riga, USSR, 1965). [Google Scholar]

- White, R.C. A Survey of Random Methods for Parameter Optimization. EUT Report E 70-E-16; Technische Hogeschool Eindhoven: Eindhoven, The Netherlands, 1970; Available online: https://pure.tue.nl/ws/portalfiles/portal/4396577/7101031.pdf (accessed on 23 January 2024).

- Stakhiv, P.; Hoholyuk, O.; Hamola, O.; Melnyk, B.; Maday, V.; Melnyk, N. Application of the Rastrygin’s Method in Modeling of Complex Electrical Systems. In Proceedings of the 2023 24th International Conference on Computational Problems of Electrical Engineering (CPEE), Grybów, Poland, 10–13 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Duong, T.-T.; Pham, D.N.; Sattar, A. A study of local minimum avoidance heuristics for SAT. In Proceedings of the ECAI 2012, Frontiers in Artificial Intelligence and Applications, Montpellier, France, 27–31 August 2012; IOS Press: Amsterdam, The Netherlands, 2012; Volume 242, pp. 300–305. [Google Scholar]

- Bukashkin, S.A. Numerical Methods for Optimal Synthesis of Linear and Non-Linear Recursive Electronic Circuits. Ph.D. Thesis, Riga Aeronautical Institute, Riga, Latvia, 1989; 516p. [Google Scholar]

- Dzhala, V. Statistical global optimization algorithm with search step adaptation. Probl. Control Inform. 1997, 2, 90–94. [Google Scholar] [CrossRef]

- Kozak, Y.Y. Modification of Rastrigin’s guide cone method. Electron. Commun. Themat. Issue Probl. Phys. Biomed. Electron. 1997, 2 Pt 1, 424. (In Ukrainian) [Google Scholar]

- Stakhiv, P.G.; Kozak, Y.Y.; Selepyna, Y.R. Improving the optimization algorithm for identifying parameters of macromodels of electromechanical systems. Electr. Power Electromech. Syst. 2010, 666, 98–102. (In Ukrainian) [Google Scholar]

- Dyvak, M.; Melnyk, A.; Rot, A.; Hernes, M.; Pukas, A. Ontology of Mathematical Modeling Based on Interval Data. Complexity 2022, 2022, 8062969. [Google Scholar] [CrossRef]

- Dyvak, M.; Manzhula, V.; Melnyk, A.; Rusyn, B.; Spivak, I. Modeling the Efficiency of Biogas Plants by Using an Interval Data Analysis Method. Energies 2024, 17, 3537. [Google Scholar] [CrossRef]

- Tkachuk, V.; Klytta, M. Electronic commutator with parallel capacity storage for switched reluctance motor. Comput. Probl. Electr. Eng. 2011, 1, 107–112. Available online: https://ena.lpnu.ua:8443/server/api/core/bitstreams/17b751c9-d8a0-423e-84bf-95cdc024c503/content (accessed on 29 September 2025).

- Stakhiv, P.; Melnyk, B.; Hoholyuk, O.; Trokhaniak, S. Application of parallel computing technology for modelling complex dynamic objects. Comput. Probl. Electr. Eng. 2024, 14, 30–35. [Google Scholar] [CrossRef]

| Indicator | Algorithm 1 (Adaptation of the Step Size) | Algorithm 2 (Adaptation of Step Size and Hypercone Angle) | Algorithm 3 (Proposed) |

|---|---|---|---|

| Number of objective function evaluations | 1,000,029 | 1,000,026 | 1,000,001 |

| Relative accuracy of the macromodel, % | 0.85 | 0.63 | 0.53 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| 1.8005549 | 0.0021659 | ||

| −0.3947988 | 0.9659041 | ||

| −0.0368145 | 0.1000000 | ||

| −0.0022357 | −0.1850695 | ||

| 0.9983555 | 0.0067603 | ||

| −0.0005524 | 0.0048879 | ||

| 0.0055210 | 1.0000000 | ||

| −0.0012865 | −0.8589651 | ||

| −0.0018468 | 1.0000000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melnyk, B.; Dyvak, M.; Melnyk, A.; Tkacz, E.; Banasik, A.; Chwał, J.; Dzik, R. Application of the Directed Cone Method for the Identification of Mathematical Models of Electromechanical Systems. Energies 2025, 18, 5949. https://doi.org/10.3390/en18225949

Melnyk B, Dyvak M, Melnyk A, Tkacz E, Banasik A, Chwał J, Dzik R. Application of the Directed Cone Method for the Identification of Mathematical Models of Electromechanical Systems. Energies. 2025; 18(22):5949. https://doi.org/10.3390/en18225949

Chicago/Turabian StyleMelnyk, Bohdan, Mykola Dyvak, Andriy Melnyk, Ewaryst Tkacz, Arkadiusz Banasik, Joanna Chwał, and Radosław Dzik. 2025. "Application of the Directed Cone Method for the Identification of Mathematical Models of Electromechanical Systems" Energies 18, no. 22: 5949. https://doi.org/10.3390/en18225949

APA StyleMelnyk, B., Dyvak, M., Melnyk, A., Tkacz, E., Banasik, A., Chwał, J., & Dzik, R. (2025). Application of the Directed Cone Method for the Identification of Mathematical Models of Electromechanical Systems. Energies, 18(22), 5949. https://doi.org/10.3390/en18225949