1. Introduction

As countries around the world look to improve existing power generation portfolios, advanced nuclear power technologies are being revisited and rapidly commercialized. High-temperature gas reactors are seeing renewed interest due to their ability for higher efficiencies, improved safety, and the potential for high-temperature industrial process heating. While Rankine Cycles (RC) may play a role even for high-temperature reactors, the Brayton Cycle (BC) offers many advantages at higher temperatures. This work looks to evaluate the existing body of work on nuclear Brayton Cycles, especially their compressors, and identify the research gaps that need to be addressed before they can be utilized with commercial reactors.

The BC is a thermodynamic cycle that is commonly used in gas turbines. A key characteristic is that the working fluid remains gaseous during the four key process steps, compression, heat input, expansion, and heat rejection, resulting in a significantly higher back work ratio compared to the RC, which does involve phase changes. The back work ratio in the BC refers to the proportion of the turbine’s work output that is required to drive the compressor. In other words, it is the fraction of the power generated by the turbine that is used to compress the incoming air (or other working fluid) in the compressor stage. In the BC, the compressor consumes a substantial portion of the power generated by the turbine, often about half. This high back work ratio means that the net work output (the useful work after subtracting the compressor’s power consumption) is sensitive to the efficiency of both the turbine and the compressor. Improving the isentropic efficiencies of either of these components can substantially reduce the back work ratio, thereby increasing the overall efficiency of the BC. Key benefits of the BC are its ability to operate at very high temperatures to achieve high overall efficiency and its simple and compact nature. These characteristics make it suitable for diverse applications in which low cost, simplicity, and small footprint can be important, such as electricity generation in terrestrial and space applications and propulsion systems in jet aircraft [

1,

2]. On the other hand, applications have been generally limited to ones combustion of noble (liquid or gaseous) fuels.

The BC power conversion system has garnered significant attention also in the realm of nuclear power generation due to its potential to enhance efficiency, reliability, footprint and overall performance of nuclear reactors. The BC’s prominence in nuclear power generation is primarily attributed to its high thermal efficiency and operational flexibility. Unlike traditional RCs, which rely on steam as the working fluid, the BC can utilize gases such as air, helium (He), nitrogen (N2), or supercritical carbon dioxide (sCO2). The lower specific volumes of these gases reduce the size and cost of the power conversion equipment. One of the key advantages of the BC in nuclear power applications is its ability to utilize at elevated temperatures, which can be delivered by advanced nuclear reactors, such as high-temperature gas-cooled reactors (HTGRs) and sodium-cooled fast reactors (SFRs). These reactors are designed to operate at temperatures exceeding 500 °C, making the BC potentially feasible choice for efficient heat-to-electricity conversion.

The choice of working fluid in the BC is a critical factor that influences the cycle’s performance, efficiency, and compatibility with the nuclear reactor. Different working fluids offer distinct advantages and challenges, making the selection process a complex task that requires a thorough understanding of thermodynamic properties and material compatibility. He, N

2, and sCO

2 are among the most commonly considered working fluids in nuclear BC applications. He is favoured for its excellent thermal conductivity and low density, which reduce the size and weight of the power conversion equipment. However, its high cost and potential for leakage pose challenges for long-term operation [

3]. N

2, on the other hand, is abundant and inexpensive, but its lower thermal conductivity and higher specific volume can limit the cycle’s efficiency [

4]. sCO

2 has emerged as a promising working fluid for BCs due to its unique thermophysical properties. Operating in the supercritical region, sCO

2 exhibits high density and low viscosity, which enhances heat transfer and reduces the size of the power conversion equipment. Additionally, sCO

2’s relatively low critical temperature and pressure make it suitable for integration with various reactor designs, including small modular reactors (SMRs) and advanced high-temperature reactors.

Compressors are integral to the BC because they are responsible for increasing the pressure of the working fluid before it enters the combustion or heat addition phase. The performance of the compressor directly impacts the overall efficiency of the cycle [

5]. In a nuclear BC system, the compressor must handle high-pressure ratios and operate efficiently over a wide range of temperatures and pressures [

4]. The design of the compressor is critical for maintaining the stability and efficiency of the BC. Advanced compressor designs, such as axial and centrifugal compressors, are employed to achieve high pressure ratios while minimizing aerodynamic losses. The compressor is also a particularly limiting component when considering dynamic operation, including load following [

6]. The use of multiple stages and variable geometry components allows for better control of the compression process, ensuring optimal performance under varying load conditions. Furthermore, the integration of advanced materials and cooling techniques helps to enhance the durability and reliability of compressors in high-temperature environments.

This review aims to elucidate the reasons behind the emphasis on BC power conversion systems in nuclear power generation and to explore the critical components—heat transfer working fluid selections and compressors—that play pivotal roles in the design and optimization of these systems.

Section 2 explains fundamentals of BCs for nuclear power applications.

Section 3 illustrates the selection criteria and performance characteristics of various working fluids used in BC systems, highlighting their specific advantages and challenges in the context of nuclear applications.

Section 4 evaluates the design and operational features of compressors, emphasizing advanced technologies that enhance efficiency and reliability under high-pressure conditions.

Section 5 reviews commercially developing nuclear reactors utilizing BCs, along with past operational experiences and lessons learned.

Section 6 concludes the review by summarizing key findings, highlighting the importance of BC power conversion systems in modern nuclear reactors and providing recommendations for future research and development to address remaining challenges and optimize system performance.

2. Fundamentals of Brayton Cycles for Nuclear Power Applications

The BC can be implemented in two primary configurations: open and closed systems. In an open BC, the working fluid (i.e., ambient air) is drawn from the environment, compressed, heated, expanded to produce work, and then exhausted back into the environment. This configuration is common in jet engines and gas turbine power plants, where the exhaust heat can be further utilized in a bottoming RC. In contrast, a closed BC recirculates the working fluid within a sealed system. The working fluid is compressed, heated, expanded, and then cooled before returning to the compressor. Although not as commonly used, the closed configuration is necessary in applications where the working fluid needs to be contained, which is the case for most working fluids other than air.

Several BC designs have been considered for nuclear power plant (NPP) applications. Simple (unrecuperated) BC designs feature a relatively high turbine outlet (exhaust) temperature, allowing for energy recovery in a heat recovery steam generator (HRSG) for additional power production in a bottoming steam RC, thereby significantly improving system efficiency or providing process steam. With multiple pressure HRSGs to maximize the recovered exergy from the flue gas, combined cycle efficiency of combustion gas turbines can exceed 60%, with the current world maximum over 64% [

7]. For off-design operation, compressors often employ variable inlet guide vanes (IGVs) and advanced materials, especially advanced blade-cooling techniques for turbine blades, allowing an increase in firing temperatures.

In addition to unrecuperated BC designs, advanced BC configurations, including those with recuperation and split compression and expansion processes, have been proposed to significantly enhance thermal efficiency and overall performance. The recuperated BC incorporates a heat exchanger (HX), known as a recuperator, to improve thermal efficiency. In this configuration, heat from the exhaust gases is used to preheat the compressed working fluid before it enters the primary heat source. By recovering some of the waste heat, the recuperated cycle reduces the amount of heat needed to reach the desired turbine inlet temperature, thereby improving overall cycle efficiency [

8]. However, the recuperated BC designs require an increased amount of working fluid per unit of power output and also a low pressure ratio (PR) to achieve a high degree of recuperation. In this design, higher relative pressure losses are unavoidable compared to the unrecuperated BC. Additionally, recuperation lowers the exhaust temperature, limiting the potential for other uses, such as cogeneration or combined cycles. The recuperated BC can be particularly advantageous in applications where standard gas turbine technology reaches its size limits, such as microturbines (where small airflow rates make high PR compressors and expanders unfeasible) or for BCs have heat input temperatures below approximately 1000 °C, such as NPPs.

Advanced BC designs may also incorporate split compression and expansion processes to enhance performance. Split compression involves dividing the compression process into multiple stages with intercooling between stages, which reduces the work required by the compressor. Similarly, split expansion divides the expansion process into multiple stages with reheating between stages. This approach maximizes the work extracted from the turbine and improves cycle efficiency, while also allowing for a higher degree of recuperation, which has a further positive impact on overall cycle efficiency [

9].

3. Nuclear Power Integrated Brayton Cycle—Working Fluids

The selection of working fluids in nuclear power integrated BC systems is paramount for achieving optimal performance and efficiency. This section reviews the characteristics and advantages of various working fluids used in these systems. Four major working fluids are discussed here: He, known for its inertness and high thermal conductivity; sCO2, valued for its high density and efficiency; N2, a versatile and readily available option; and air, commonly used in open BCs. The following subsections highlight the unique properties and applications of these fluids in nuclear power systems. The information in all the subsections is based on internet key word searches for documents that include “Nuclear”, “Power” and “Brayton Cycle”. Only high-quality papers that focussed on designing and calculating the efficiency of a nuclear Brayton Cycle were included. This review focuses on terrestrial nuclear applications only; therefore, all papers referencing space or lunar reactors were discarded.

3.1. Helium

The BC designs which use He as a heat transfer medium are favoured for very high-temperature applications because He remains inert even at temperatures exceeding 1000 °C. Many high-temperature gas-cooled reactor (HTGR) concepts proposed by reactor vendors use He as the coolant, and consequently, many proposed designs aim to eliminate the need for the intermediate heat exchanger (IHX) by employing a direct BC. Of the forty-four designs for nuclear BCs reviewed in this study, ten articles focused on He-only cycles, with five opting for direct cycle designs. Wang and Gu [

10] conducted a parametric study to optimize a direct BC with He compared to indirect concepts using air and

. They found that the direct cycle did not provide a significant efficiency advantage but reduced the required PR of the system for a similar efficiency. Herranz et al. [

11] examined different configurations of direct He cycles for pebble bed reactors. Their study showed that intercooling significantly improved efficiency, while reheating did not enhance thermal or economic performance but did allow for improved power flexibility. Sato et al. [

12] based their research on the Gas Turbine High Temperature Reactor—300 (GTHTR—300) concept from the Japan Atomic Energy Research Institute (the original name of the Japan Atomic Energy Agency), which used a He gas turbine integrated within the primary loop of a nuclear reactor design. They investigated upgrading the core temperatures to achieve higher efficiency in a simple recuperated power cycle. Similarly, Gad-Briggs and Pilidis [

13] investigated high temperatures for direct cycles in their parametric studies of simple high-temperature BCs for gas reactors. Bae et al. [

14] focused on smaller HTGR applications, showing how achievable efficiencies decreased with decreasing system size.

While He is common a primary coolant for HTGRs, it is less common for BCs. Most indirect configurations that use He in BCs are alternative high-temperature reactor designs that are not cooled by gas. Peterson [

15] used a He BC with multiple reheats for an MSR design. Similarly, Ahn and Lee [

16] investigated multiple working fluids for a sodium-cooled fast reactor (SFR) with an indirect BC. They found that for a midrange outlet temperature (500 °C), s

significantly outperformed a He-optimized system. An SFR was also the basis for the work by Pérez-Pichel et al. [

17], who combined an indirect BC with an organic RC to improve efficiency. Despite the added complexity, the low outlet temperature of the SFR meant that the improved efficiency was small relative to other designs. The only design in the sample to consider an indirect cycle with He in both the primary and secondary cycle was the work by Oh and Moore [

18], who compared this concept with an s

cycle. Similarly to Ahn and Lee [

16], they found the He design to have lower efficiency, with their results showing a 6% decrease in thermal efficiency using He.

3.2. Supercritical

As was clear in the aforementioned studies, s

offers significant thermodynamic advantages over He in midrange temperatures due to a reduction in volumetric flow within the compressors [

18], giving higher efficiencies. s

cycles are much more compact, leading to smaller turbomachinery and HXs with lower capital expenditure. Dostal et al. [

19] investigated s

cycles for next-generation nuclear plants, primarily HTGRs, finding that they gave similar efficiencies as direct He cycles of much higher temperatures. They did, however, see a significant reduction in efficiencies in partial load operation, which could be a cause for concern for off-design operations.

BC designs can be categorized as direct and indirect configurations. Wright et al. [

20] used an s

direct BC concept in their work for a gas fast reactor. Kim et al. [

21] investigated a similar design but for a gas-cooled fast reactor (GFR) concept. A direct cycle was also employed in the work performed by Bae et al. for small thermal reactors [

14]. Hybrid working fluids have also been employed, with Hu et al. [

22] proposing a direct cycle with binary mixtures of s

and other additive gases for an HTGR. They showed that using He or krypton with s

could lead to improved thermodynamic performance, while bottoming cycles are not typically favoured with s

; however, Wu et al. [

23] found in their research that adding an organic flash cycle could improve second law efficiency and reduce cost.

In general, direct s

cycles are complex when used with nuclear reactors due to the higher density of s

compared to non-supercritical CO

2, which negatively impacts corrosion rates [

19]. Consequently, most s

concepts typically opt for an indirect cycle with an alternative core coolant. Yoon et al. looked to improve upon the power cycle of small- and medium-sized LWRs by using an s

cycle to simplify the power cycles for an equivalent efficiency [

24]. Ahn and Lee [

16] also looked at small- and medium-sized reactors but this time using an SFR concept. Park et al. looked at the advantages of indirect s

cycles for three different types of nuclear reactors, with the higher outlet temperatures of HTGRs giving an efficiency of over 50% [

25]. Beyond nuclear fission, s

cycles have also been employed for designs of fusion power plants using multiple heating stages for different temperatures [

26].

In terms of cycle design, recompression cycles are typically favoured with s

cycles. Several papers examined optimizing cycle design with nuclear s

recompression cycles [

27,

28]. Most studies report that recompression cycles have the best performance. For example, Luo and Huang [

29] did a comprehensive study of different cycles and inlet conditions for indirect s

cycles. They found that an intercooling cycle design performed better thermodynamically with a comparable cost to the recompression cycle.

3.3. Nitrogen

With the emergence of Generation IV nuclear reactor designs in the early 2000s, including GFR and the Very High Temperature Reactor (VHTR, later known as HTGR), interest in Brayton Cycles was renewed. These designs offered high outlet temperatures, and there was growing interest in sCO2 cycles to achieve high efficiencies in the mid-temperature range (500–700 °C) of core outlet temperature. As a result, N2 has taken a backseat to other working fluids that offer more favourable performance metrics and efficiencies in modern nuclear BC systems.

Although the only formerly operational nuclear BC (ML—1) utilized

as the working fluid, this gas has become less favoured in recent conceptual designs. Of the 44 designs surveyed, only four focused on N

2 BC, with all of these using an indirect cycle due to the potential for activation of naturally occurring N

2 in the core. The ML-1 was a water-moderated reactor cooled by N

2 with a closed BC design [

30]. It had an output of 330 kWe and was designed in 1961 as a prototype mobile reactor that could be mounted on two trailers for remote power generation. Although it achieved a high outlet temperature of 650 °C, its efficiency was limited to 10% due to its compact design and poor design choices. In the studies conducted by Wang and Gu, and Ahn and Lee, multiple fluids were compared in their designs. Wang and Gu [

10] examined Very High Temperature Reactors (VHTRs), while Ahn and Lee [

16] focused on sodium-cooled fast reactors (SFRs). In both studies, N

2 performed similarly to He and air, but it showed significantly worse performance than the sCO

2 cycles introduced in the papers. SFRs were also the focus of work by Olumayegun et al. [

31] and Park et al. [

32], who found the inert nature of N

2 favourable compared to steam RCs by eliminating the need for an intermediate loop. Both papers reported similar efficiencies of around 39% for a turbine inlet temperature of approximately 500 °C. Notably, all papers mentioned the above favoured designs with recuperation and intercooling, with none opting for a recompression cycle. Additionally, Jaszczur et al. [

33] analyzed an N

2-He binary mixture in their combined heat and power (CHP) study using BCs.

3.4. Air

Air has also been less popular in small modular reactor (SMR) BC designs over the past 20 years in spite of that fact that many new concepts have explored air BCs for microreactors. The advantage of air BCs is that they can operate in an open cycle configuration. Wang and Gu [

10] observed good performance from their air BC configuration compared to N

2 and He, primarily due to the elimination of losses in the IHX. McKellar and Guillen [

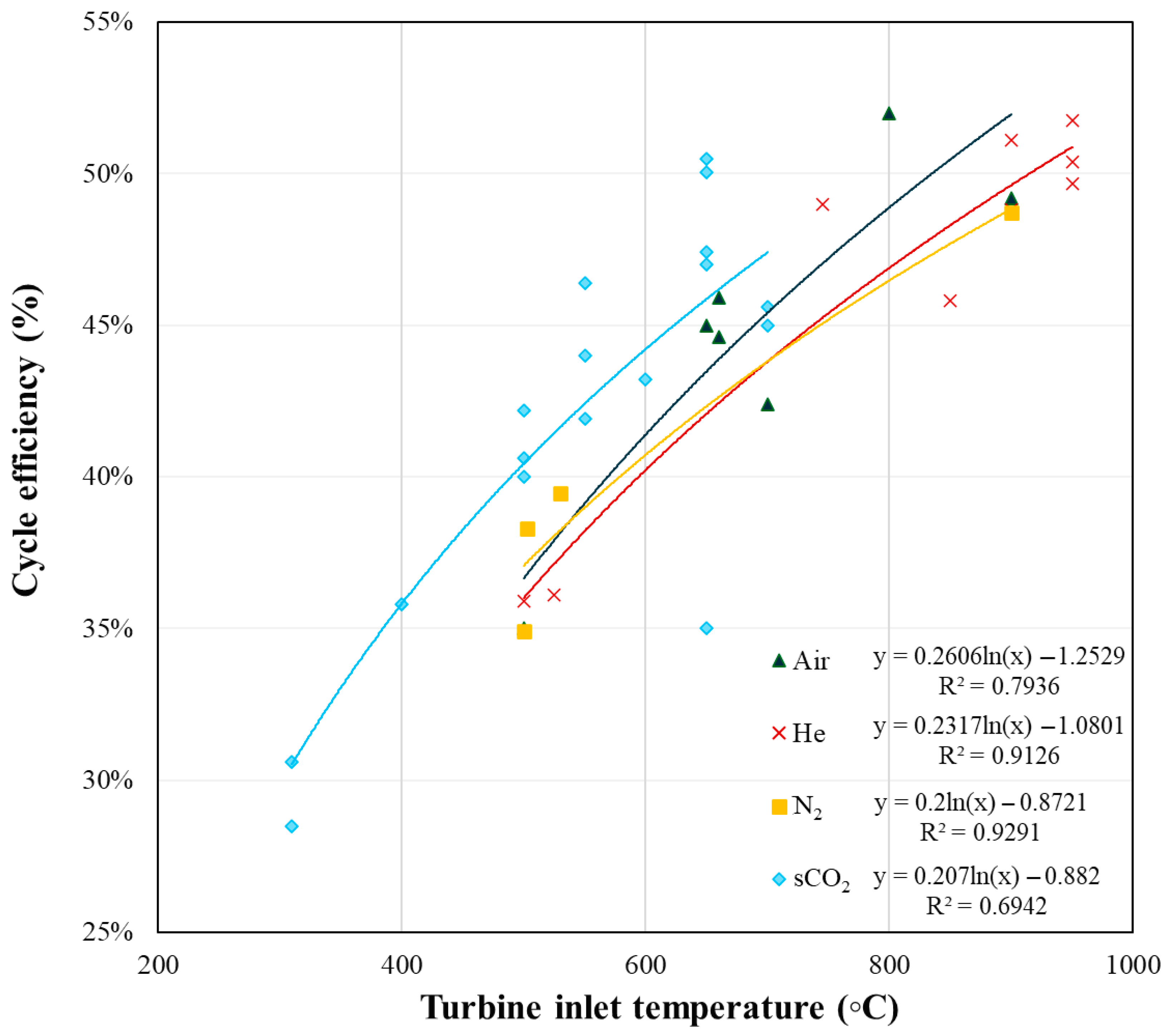

34] examined the effect of reactor outlet temperature in their study of recuperated air BCs for nuclear microreactors. They demonstrated a strong efficiency relationship to turbine inlet temperature, as detailed in

Figure 1.

Exploring the integration of air BCs with bottoming RCs reveals potential efficiency improvements for advanced nuclear reactor designs. Andreades et al. [

35] investigated such a concept for a Fluoride Salt-Cooled High-Temperature Reactor (FHR) using a simple BC combined with an RC. They found similar efficiency to a recuperated BC at the turbine inlet temperature. Zohuri et al. [

36] also found good efficiency from an open-air BC for small Molten Salt Reactors (MSRs) and Lead-Cooled Fast Reactors (LFRs) by incorporating multiple reheat stages in their design. They also explored adding a bottoming RC to this BC design, finding that it only improved the efficiency by about 1%.

3.5. Literature Summary

After reviewing forty-four recent studies, general trends in cycle type, working fluid, and turbine inlet temperature were identified. In case the turbine inlet temperature was not provided in the paper, the reactor outlet temperature was used instead. The efficiencies of cycle designs are shown in

Figure 1 with the working fluids also listed. It is worth noting that the cycle efficiencies increase roughly logarithmically with turbine inlet temperature. It can be observed that the s

cycles offer improved performance compared to other working fluids, but their effectiveness is limited by their operating temperature range. The s

cycles had turbine inlet temperatures ranging from the 300 °C to 700 °C. Notably, at high temperatures, designs with He inert gas dominate, although air and

designs have also been conceptualized within these temperature ranges.

Although different assumptions used in the literature make it difficult to extract overall trends in cycle designs, some items stand out. For example, every reviewed design incorporating an s cycle utilized recompression. By examining designs with specific working fluids, we can also assess the impact of design choices on expected efficiency trends. An example is intercooling in He cycles, which is linked to a 0.673 percentage point increase in efficiency compared to designs without intercooling. These trends are still subtle, and more data would be needed for a comprehensive analysis of bulk data trends related to cycle design.

Table 1 summarizes previous studies of Brayton Cycle systems utilizing nuclear power with various heat transfer fluids.

4. Nuclear Power Integrated Brayton Cycle—Compressors

A compressor, essential to the BC, is a mechanical device engineered to elevate the pressure of gas by decreasing its volume, a process achieved through the input of mechanical work typically supplied by an external power source, such as an electric motor or a turbine. The compressed gas then flows to the next stage of the BC, which is typically the combustion chamber in gas turbines or the HX in nuclear reactors before it undergoes thermodynamic processes of expansion to produce work.

Compressor designs can be broadly categorized into two types: dynamic and volumetric. Dynamic types include axial radial configurations. Each design has its unique characteristics and applications, tailored to specific operational needs. Axial compressors are commonly employed in high-efficiency gas turbine engines due to their ability to handle large volumes of airflow with minimal losses. They operate by accelerating the gas through a series of rotating and stationary blades arranged in stages, each stage incrementally increasing the pressure of the gas. The design and manufacturing precision required for each stage are critical to maintaining efficiency and operational stability, making axial compressors more suitable for applications where high efficiency is paramount. Radial compressors, also known as centrifugal compressors, utilize a rotating impeller to increase the velocity of the gas, which is then converted to pressure energy in a diffuser. Radial compressors are robust and simpler in design compared to axial compressors and are often used in applications requiring moderate PRs and where space constraints are a concern. Their ability to handle varying flow rates with relatively high pressure gains in a single stage makes them advantageous for certain industrial and aerospace applications. Volumetric compressors include positive displacement compressors such as piston, screw, and scroll compressors, which work by trapping a specific volume of gas and then compressing it by reducing the volume. These compressors are typically used in lower flow rate applications and can handle a wide range of gases.

A notable feature in some dynamic compressors is controllability of the IGV, positioned at the compressor inlet. These vanes can be dynamically adjusted to control the angle at which the gas enters the first stage of the compressor, optimizing the inlet conditions to enhance the efficiency and operational flexibility of the compressor. By altering the flow angle, IGVs can improve the aerodynamic performance of the compressor stages in off-design operation, reduce the likelihood of flow separation, and manage the surge margin effectively.

Compressor design is limited by thermodynamic maximums, such as pressure, temperature, and the number of intercoolers. For instance, increasing the PR of BC can improves efficiency but also raises the temperature, which can lead to material limits and reduced compressor life due to thermal stresses and potential creep. In nuclear reactor applications, especially in direct cycles, radiation-related issues must be considered. Materials used in compressors must withstand radiation without significant degradation, necessitating the use of radiation-tolerant alloys and coatings. The number of intercoolers affects the overall cycle efficiency and the thermal management of the compressor, as intercooling reduces the work required for compression by lowering the temperature of the gas between stages.

Outlet temperature limits for industrial compressors typically range from 350 to 400 °C [

37], although there are exceptions. For example, the He temperature of the Xe-100 circulator design is only 260 °C [

38], likely due to its hermetic design with insulation and cooling limitations. While it is technically feasible to reach higher temperatures, the use of specialized materials and additional development requirements for manufacturers would likely increase the product’s cost, especially in small-scale manufacturing. In contrast, air compressors in gas turbines, which benefit from serial manufacturing, can have outlet temperatures reaching up to around 550 °C for power applications (based on ambient air compression with a PR of 36 and isentropic efficiency of 90%) or even 610 °C (with a PR of 47 in the largest jet engines).

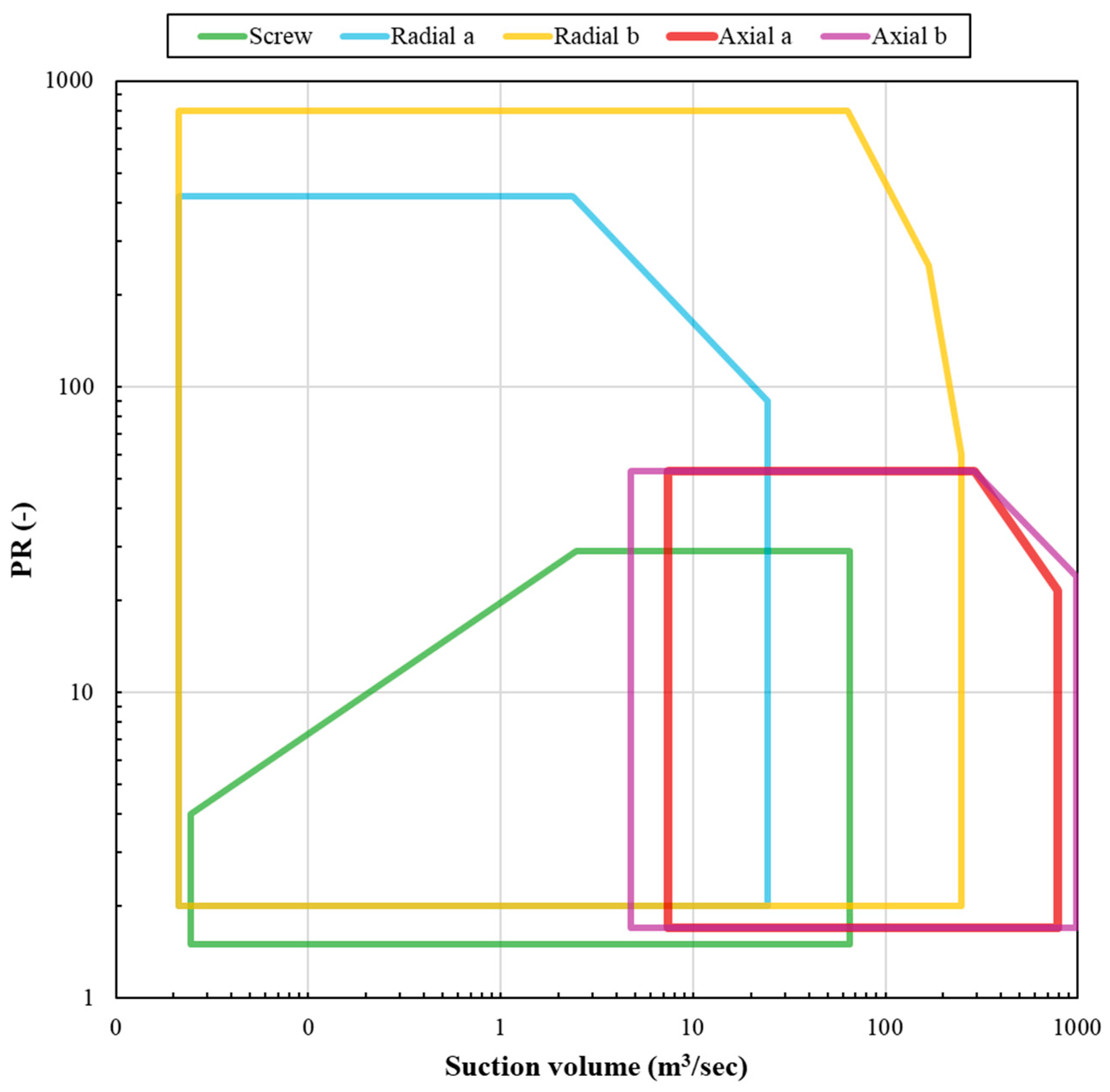

Operation maps are essential tools for understanding compressor performance. These maps plot parameters, such as PR and flow rate, for different operational conditions, providing insight into the compressor’s behaviour under varying loads. While these maps are often developed for air, they can provide a good estimate for other gases with varying isentropic exponents and density/temperature variations. Based on a combination of the values in these performance maps, along with modifications referencing industrial compressors, an operational map for this work was developed primarily for air compressors; see

Figure 2. These maps help engineers select and design compressors that meet specific application requirements, ensuring optimal performance and reliability.

4.1. Air Compressors

Air compressors are standard technology integral to BCs, especially in power production, where they are well-developed for combustion gas turbines. Commercial applications of these compressors vary widely, from microturbines like the C30, which had a power output of 30 kW using a high-speed radial compressor [

40], to larger systems. Despite the C30 being discontinued, the smallest available models now offer outputs of 65 kW [

41]. Efforts have been made to scale down these systems even further to the millimetre scale, providing power outputs ranging from 10 to 100 W [

42]. On the opposite end of the spectrum are multi-stage axial compressors used in large gas turbines, delivering power outputs exceeding 500 MW and operating at grid-synchronous speeds [

39,

43]. Notably, compressors generally consume about 30–50% of the total expander power, meaning the compressor power rating directly correlates with the net power output rating.

Industrial gas combustion turbines typically achieve PRs around 25, while aeroderivative gas turbines reach PRs of approximately 36. The highest PRs for air compressors are found in jet engines, with the GEnx engine achieving a PR of 47.4 during take-off and 58.1 at top-of-climb [

44]. Due to the simultaneous requirement for compression and power production by the expander, compressors and expanders (or at least a few stages of expanders that provide compressor power) are often manufactured on a single shaft. The isentropic efficiency of turbines in these systems can exceed 90% [

45], highlighting their effectiveness and efficiency in power generation processes.

4.2. N2 & Subcritical Compressors

compressors in BC systems, while not typically utilized in traditional gas turbines, benefit from extensive experience in the process, including natural gas processing and petrochemical industries. The behaviour of

closely mirrors that of air, making the transition to

compression relatively straightforward. The primary objective in these applications is to achieve different pressure levels rather than to optimize for power production, which means that the maximum efficiency of

compressors can be expected to be somewhat lower than that of compressors tuned for air. An important consideration for

compressors is sealing, as some leakage to the ambient environment is inevitable, especially with labyrinth seals. However, advanced sealing solutions such as dynamic, contactless dry-gas seals can reduce these leaks to near-negligible levels, while standard carbon ring seals, despite suffering from friction losses, are also commonly used [

44,

45,

46]. Subcritical

compressors share similarities with

compressors in terms of their roots in industries outside of traditional gas turbines. The primary goal for Subcritical

compressors is achieving various pressure levels, with a focus on maintaining efficiency. Given the unique properties of

, sealing becomes a critical issue as well.

Related to experience for nuclear applications,

turbomachinery was used in the 300 kW ML—1 nuclear direct BC. Nuclear applications were also in mind when converting the Capstone 30 kW microturbine to closed air and

BC. Experience with

then comes from circulators for the advanced gas reactor (AGR) in the UK. AGR

circulators were rated at about 5 MWe. During development, machines were thoroughly proof tested in non-nuclear systems with robust protocol and generally experienced no issues during operation [

47,

48].

4.3. He Compressors

He compressors are largely specialized for niche applications, particularly within nuclear systems featuring high-temperature gas-cooled reactors. Commercial He compressors are typically designed for specialty applications that require much lower quantities of He than what is needed for power applications, thus often using volumetric compressors [

47,

48,

49]. The development of He compressors for power applications, or even blowers as circulators, remains a specialized area of interest within the realm of nuclear technology. Theoretical designs of He compressors employing computational fluid dynamics (CFD) have predicted polytropic efficiencies exceeding 90% for systems up to 300 MW, utilizing a highly loaded axial design [

50]. Although additional research has aimed to further refine these designs, experimental validation is still pending [

48].

Several He test loops have been constructed to explore the potential of He BCs for nuclear power applications [

51]. One notable example is the Oberhausen II He gas turbine plant in Germany. The plant featured an intercooled and recuperated cycle with two compressors, demonstrating the feasibility and dynamics of He turbomachinery for future nuclear applications. The design parameters for these compressors, which are detailed in

Table 2, provide valuable insights into the operational characteristics and performance of He compressors in such advanced applications. The turbomachinery comprised two shafts, with the HP compressor (15 stages) and HP turbine (7 stages) at 5500 rpm, while the LP compressor (10 stages) and LP turbine (11 stages) drove a 3000 rpm generator. The high number of stages account for helium’s low density, and high isentropic exponent, which cause instability issues at high stage pressure ratios. The plant faced major operational issues, including rotor vibration and turbine vibration. The design speed of 5500 rpm could not be achieved in the high-pressure (HP) compressor. Design modifications were implemented, including reducing the bearing span by 600 mm and stabilizing the rotor, but the power output did not rise above 30 MWe. A blade failure at 11,000 h revealed forging defects, requiring improved inspection methods. Inefficiencies were directly attributed to turbomachinery shortcomings, including 5.3 MW from sealing/cooling flow leakage, 4 MW from HP compressor losses, and 3.9 MW from HP turbine inefficiencies. These results indicate that the challenges of He leakage not only affect He replacement requirements but also operational efficiency.

The High-Temperature He Test Facility (HHV), located in Jülich, Germany, and commissioned in 1979, was constructed in parallel with the Oberhausen II plant to test large He turbomachinery and He cycle components under conditions representative of a nuclear gas turbine system [

51]. Unlike Oberhausen II, which produced power, the HHV was a closed-loop test system designed to study compressor and turbine behaviour, rotor cooling, seal performance, and acoustic emissions at full operational conditions. The key parameters included a maximum He temperature of 850 °C and a system pressure of 5.0 MPa, simulating conditions expected in a future high efficiency nuclear gas turbine plant. The HHV featured a He turbomachine with a single-shaft design, an eight-stage axial compressor, and a two-stage axial turbine, all housed in a large pressure vessel. The compressor and turbine shared a single rotating assembly. The rotor was constructed by welding forged compressor and turbine discs together, with each compressor stage containing 56 rotor blades and 72 stator blades, while the turbine had 90 stator blades and 84 rotor blades per stage. The entire system operated at 3000 rpm, delivering 90 MW of compressor power, with 45 MW provided by an external synchronous motor and the remaining 45 MW recovered from the turbine output. One of the HHV’s unique features was its operation in which compression heat alone was used to elevate He temperature to 850 °C. This setup also allowed the facility to provide heat up to 1000 °C for short periods, facilitating hot gas duct, insulation, and high-temperature valve testing. During initial testing in 1981, the HHV reached its full design pressure and temperature, accumulating 1100 operational hours, with 325 h at maximum conditions. However, early tests revealed oil ingress into the He circuit, leading to contamination and requiring seal modifications. He leak rates were measured at 2.5–5.0 kg per day, considered acceptable compared to other closed-loop He systems. The cooling system for turbine discs and blade root attachments proved effective, ensuring material temperatures remained below 400 °C to prevent creep or thermal degradation. Acoustic emissions from the turbomachinery were also studied, as pressure fluctuations propagating at He’s high sonic velocity could induce vibrations in critical components. The highest recorded sound power level was 148 dB, but no significant damage to insulation or structural elements was observed.

The turbomachinery of the HTR300 nuclear plant experiment in Japan experienced several key technical challenges during the development phase. The dynamic stability of long, slender rotors, the optimization of labyrinth seals to minimize bypass flows, and the need for efficient cooling of turbomachinery components were critical aspects that required extensive testing. These issues were particularly relevant given the high-pressure and high-temperature operational conditions envisioned for the HTR300. The experimental work on He turbomachinery provided valuable insights into performance and reliability, focusing on reducing turbomachinery losses that impacted overall plant efficiency. Previous systems, like Oberhausen II, suffered from efficiency losses due to poor sealing, high pressure losses, and suboptimal designs. The HTR300 experiment aimed to improve these issues with better blade cooling and magnetic bearing systems. While theoretical efficiency gains were promising, technical challenges in He turbomachinery hindered commercialization. The findings emphasized the need for further research in material science, sealing technology, and control systems to make He-cooled nuclear gas turbines a viable power generation option.

He compressors (or blowers) have also been used as circulators in several gas-cooled reactors over the years. Although the operating conditions for these circulators differ from those in a BC, valuable insights can still be gained from their design and operation. Due to He’s unique properties, these systems require a relatively high number of stages in axial compressor designs, even for small PRs [

52]. While aerodynamic design and rotor-dynamics plagued early efforts due to limited data and computational fluid dynamic capabilities, these issues are now manageable. A major issue with He compressors is sealing, as leaks can result in significant problems due to the difficulty of He separation, related costs, and energy intensity. Leakage rates from various facilities, shown in

Table 3 [

51], highlight this challenge. Potential solutions include hermetic enclosures, such as those expected to be used in the He circulator of the Xe-100 reactor design [

53], or Atlas Copco’s dynamic, contactless dry-gas seals [

44,

45,

46]. Challenges of using He compared to other fluids include using more turbine stages (increasing cost and complexity), extreme leakage challenges, and limited experiences in designing, building, and operating He turbomachinery [

48].

4.4. Supercritical Compressors

When starting from subcritical pressures in superheated regions and ending in supercritical pressures (away on the right side from vapour dome in P-V diagrams), compressors are an existing commercial and mature technology. Their applications can be found in natural gas processing and the petrochemical industry. Examples include internally geared compressors up to 205 bar and 5 MW [

44,

45,

46] or hermetically sealed, barrel type compressors up to 303 bar and 18 MW [

51,

52,

53,

54]. However, if the

is deep in the high-density area of the subcooled region, then the required action resembles pumping more than compression. These conditions are similar to those in

compression systems in carbon dioxide sequestration pilots or for power application in the Allam cycle. In the NET Power’s demonstration unit,

is first compressed by a LP

radial compressor with variable IGV from 25 bar at 34 °C to 90 bar at rate of 93 kg/s. After intercooling, the

is then pumped to 310 bar [

55,

56,

57].

For a typical s

Brayton power cycle, the compression step usually occurs near the critical point in a region with a large variation in density. Several s

test loops have been or are being constructed, including compressor and expander components. Systems have been built in a range spanning from 1 kW to 10 MW, with PR from 1.5 to 3. Regardless of the size, the compressor choice is always centrifugal, arguably owing to the high density with the design being somewhat close to the centrifugal pump. To add to the similarities with pumps, shrouded impellers are not uncommon. All the compressors operate at very high speeds, ranging from about 20–30 k rpm for the MW scale systems to over 50–80 k rpm for the 10–100 s kW scale systems, while smaller compressors can be designed for 200 k rpm. Most systems feature only a single-stage compressor [

58], although exceptions exist. For example, Sandia and Peregrin operated a 1 MWe system with a two-stage radial shrouded compressor with discharge pressures up to 420 bar (PR~4.7) at speed of 118 k rpm [

59].

The most extensively documented system is the ongoing 10 MWe STEP demonstration, which has two compressors installed for recompression BC operation: a main compressor for operation as both simple recuperated and recompression cycles and a recompressor (bypass compressor) only for the recompression cycle operation. The main compressor is a 2.7 MW single-stage centrifugal compressor operating at up to 27,000 rpm, driven through a gearbox by an electric motor with a variable frequency drive. It is equipped with variable IGV and is designed to operate with

in the temperature range of 34.6–45 °C with a nominal PR of 2.8. Published data indicates that the installed compressor achieved the design pressure target, but the range of flow rates with varying IGV was much smaller than predicted [

60,

61].

It can be seen that while several experiments have been performed, predicted performance can still differ considerably from actual. Actual fluid dynamics also pose challenges as identified in a new compressor design tested in [

62]. The issues include high stress, mechanical forces from pressures, bearings, seals, blade design, or corrosion related to impurities in working fluid. Only a limited number of institutes and companies have a detailed understanding of all these factors. Many practical aspects of the APOLLO programme (which preceded STEP) compressor development, including bearings or rotor-dynamics, are covered in [

63]. A design and operation report on Sandia’s first-in-the-world recompression s

cycle [

64] also details compressor development.

5. Nuclear Power Integrated Brayton Cycle—System

Several advanced reactor companies have announced plans to incorporate BC power conversion systems into their designs.

Table 4 lists several reactor vendors that plan on using BCs. These reactor designs feature higher core outlet temperatures than traditional LWRs, so BCs could potentially enhance plant efficiency while providing relatively compact systems. The most common choice among potential vendors is s

cycles. Air BCs and direct He cycles have also been selected by several vendors. Most of these designs are intended for microreactors rather than larger SMRs or gigawatt-scale reactors.

From the available information regarding commercial development, three general types of BCs were identified. The first type includes direct He cycles, which use primary coolant from the reactor core as the working fluid in a closed cycle. This approach is being pursued by General Atomics with their EM2, which is a direct closed He BC with an organic bottoming RC. It is reported that with a core outlet temperature of 850 °C, the expected efficiency is 53% with wet evaporative cooling and 48% with dry cooling [

65]. The second type of cycle is indirect open-air BCs. This approach is being pursued by vendors of microreactors, including eVinci and Xe Mobile. eVinci is a nominal 15 MWth/5 MWe system with a heat pipe reactor [

66]. Further specifics about cycle configurations are not publicly available, although a recuperated cycle is expected to avoid high pressures while achieving acceptable efficiency. The last type is an indirect s

cycle. This concept is considered by multiple reactor vendors, including USNC and Flibe Energy. USNC’s Pylon reactor, a microreactor designed for remote locations and industrial applications, features a compact, modular design. Recently, USNC announced a collaboration with Peregrine Turbine Technologies, which specializes in advanced thermal management and energy conversion, to enhance the efficiency and reliability of the Pylon’s power conversion system [

67]. Flibe Energy, a developer of molten salt reactors, is working on Lithium Fluoride Thorium Reactor (LFTR) technology [

68]. LFTR uses thorium as a fuel source, offering an alternative to traditional nuclear reactors. This reactor design uses a molten salt mixture, specifically lithium fluoride and thorium, to enable continuous, low-pressure operation with enhanced safety and efficiency. Flibe Energy has described their approach, including the use of an intermediate loop to transfer heat from the reactor core to the power conversion system. This system utilizes a recompression s

cycle. Additionally, they plan to implement evaporative wet cooling for waste heat rejection, ensuring effective thermal management and minimal environmental impact.

Table 4.

Literature summary—commercially developing US reactors with Brayton Cycles [

66,

69,

70,

71,

72,

73,

74,

75,

76,

77,

78].

Table 4.

Literature summary—commercially developing US reactors with Brayton Cycles [

66,

69,

70,

71,

72,

73,

74,

75,

76,

77,

78].

| Reactor Name | Vendor | Reactor Type | Power (MWth) | Power (MWe) | Working Fluid | Direct/Indirect | Cycle Type | Refs. |

|---|

| EM2 | General Atomics | GFR | 500 | 265 | He | Direct | Closed | [69,70] |

| eVinci | Westinghouse | HPR | <30 | - | Air | Indirect | Open | [66,71] |

| FRM | General Atomics | GFR | 100 | 42 | He | Direct | Closed | [72] |

| LFTR | Flibe Energy | MSR | 600 | 250 | s | Indirect | Closed | [73,74] |

| LOKI MMR | NANO Nuclear Energy | HTGR | 1 | n/a | s | Indirect | Closed | [75] |

| Xe Mobile | X Energy | HTGR | n/a | 5 | Air | Indirect | Open | [73,74,75,76] |

| Aurora | Oklo | SFR | n/a | n/a | s | Indirect | Closed | [77,78] |

5.1. Operational Experiences and Lessons Learned

This section provides a comprehensive overview of operational BC systems, including their design, characteristics, and lessons learned from their implementation. It highlights the integration and overall performance of BC systems, considering factors like efficiency, reliability, and operational challenges. Because of the paucity of existing systems within the nuclear space, this section is expanded to review existing systems regardless of application. Where relevant, a connection has been made to implications for nuclear systems.

5.1.1. Open Brayton Cycle Systems

Open BCs are a fully mature standard technology in combustion turbines, with capacities ranging from recuperated cycles of several dozen kW to simple cycle systems of several hundred MW at progressively higher combustion temperatures. These systems are commonly used in conjunction with a steam RC to form combined cycle configurations. Their compact design, fast installation, high efficiency, and small thermal inertia are among reasons they are the source of flexibility in electricity grids (dispatchable generation) as well as sources of baseload generation. Additionally, they are widespread in numerous air and sea applications [

41,

43,

79,

80].

5.1.2. Closed Brayton Cycle Systems

Indirect Air Cycles

The first closed BC test plant, the AK—36 plant, was built in Zurich, 1939, just four years after Ackeret and Keller patented the closed-cycle air gas turbine with split compression, intercooling, and recuperation. It achieved a system efficiency of 31.6% at 700 °C with nominal heat input 2 MW and accumulated hundreds of hours of operation. The operation results led to another experimental system in Coventry in 1949, utilizing 700 kW of heat at 600 °C while achieving about 25% efficiency.

Further development of BC systems with indirect heat supply via the exchange surfaces of an air heater and various degrees of split compression and split expansion recuperated systems led to about 20 fossil fuel fired air closed-cycle gas turbine plants being built in Europe by the early 1970s with a total operating time of about 750,000 h. These plants were primarily built under licences belonging to Escher Wyss, and the cycle for each installation was modified based on heat source parameters and CHP needs (e.g., two intercoolers for power-only applications). Several closed-cycle air gas turbine systems were also developed for maritime applications [

2,

81].

Indirect s Cycles

Potential benefits of s

systems in terms of efficiency and footprint have resulted in construction of multiple experimental systems and a single commercial one. Experimental systems range in power from 1 kW to 300 kW laboratory systems in simple, recuperated, and recompression configurations. Two larger projects have been sponsored by the US Department of Energy (DOE), including Sunshot at 1 MW and STEP at 10 MW [

58]. The STEP system at the Southwest Research Institute (SWRI) has just been recently commissioned in a recuperated configuration using a 500 °C heat source with the plan to further increase inlet temperature over 700 °C and modify the system to a recompression configuration. This project serves as a frontier of future s

and very-high-temperature power applications [

82]. Commercial systems outside the nuclear industry are led by an Echogen 1–8 MWe recuperated cycle system for waste heat power generation with a maximal temperature of 485 °C [

58]. Other systems are under development, such as a 1 MWe system by Peregrine Turbine Technologies that leverages experience from Sandia National Laboratory (SNL) [

83]. In summary, the issues for development are related primarily to turbomachinery (addressed in dedicated section), HXs, and overall control systems.

Direct Cycles

A

closed cycle has been applied to a nuclear reactor ML—1 built for a mobile military application in 1961 and operated for 4 years. The system was designed for about 400 kW as direct cycle, where

was flowing directly through the reactor core, which was heated to 650 °C. With a pressure ratio (PR) of approximately 2.3, and a high-speed, 18–22k rpm turbine/compressor assembly, the system achieved a cycle efficiency 13.3% and overall plant efficiency of 9.7%. Due to numerous issues, including working fluid leaks, suboptimal performance of components resulting from choosing unproven designs rather than off-the-shelf components, and high maintenance costs, the programme was eventually shut down [

84,

85]. SNL conducted an experimental investigation of a 10 kW scale closed BC with air and

as part of a study of coupling nuclear reactors to Brayton power conversion systems [

86,

87].

Direct He Cycles

He has been used in turbomachinery in only a very few instances, which have been mostly experimental. The first fossil fuel-fired He gas turbine operated in a closed-cycle gas turbine system within a cryogenic facility at La Fleur Enterprises in Los Angeles in 1960. It provided refrigeration for air liquefaction, driven by fuel combustion. Oil ingress into the He closed loop was a challenge due to poor oil seal design. Despite successful operation, the system faced significant leakage challenges at higher pressures (max 1.8 MPa). This led to the use of a He cryogenic system in 1966 at an Escher Wyss air liquefaction plant in Phoenix, Arizona. The system, developed by Escher Wyss in Zurich, had an intercooled compressor with a PR of 2, a turbine inlet temperature of 660 °C, and a system pressure of 1.22 MPa. The compressor had 18 aerodynamic stages, corresponding to about 60 MW. Poor market conditions resulted in only 5000 h of operation before the plant was decommissioned.

The Oberhausen II He gas turbine plant, introduced above, was built in 1972. This facility was a fossil fuelled commercial CHP plant designed to produce 50 MWe of electricity and 53 MWth of thermal energy for district heating, utilizing a closed He BC [

51]. Its BC was an intercooled and recuperated (ICR) closed cycle using He at 750 °C and 2.85 MPa. As was described in

Section 3.3, major operational issues included rotor vibration and turbine blade failures, which prompted design modifications and adjustments. Power output, however, achieved only 30 MWe instead of 50 MWe. Initial He leakage was 45 kg/day, which was later reduced to 5–10 kg/day through seal welding. Performance analysis showed 20 MW of losses, 85% of which came from the turbomachinery. The plant operated for 24,000 h before shutting down in 1988 [

52].

The HTR300 nuclear plant experiment in Japan was part of broader studies focused on the feasibility of nuclear gas turbine power plants. The concept aimed to develop a closed-cycle gas turbine system using He as the working fluid to achieve higher thermal efficiency. The HTR300 was designed as a high-temperature reactor with a power output of 300 MWe. The primary goal of the experiment was to investigate the operational feasibility of large-scale He turbomachinery and assess its integration with nuclear heat sources. During the development phase, several key technical challenges were identified. One of the most significant issues was minimizing He leakage due to its low molecular weight and high permeability. Additionally, the turbomachinery components were another critical aspect that required extensive testing. These issues were particularly relevant given the high-pressure and high-temperature conditions envisioned for the HTR300. The experimental work on He turbomachinery provided valuable insights into performance and reliability, focusing on reducing turbomachinery losses that impacted overall plant efficiency.

5.2. Combined Heat and Power Operation and Flexibility

Among the systems reviewed, only a few considered CHP applications. In recuperated cycles, utilizing the thermodynamic benefits of cogeneration—where heat is used rather than rejected—is significantly limited by the achievable temperatures due to the recuperation process [

41]. Between 1949 and 1972, about 20 air BC systems with indirect heat transfer from external fuel combustion (typically coal) were built, mostly across Europe, achieving electrical efficiencies in the range of 25–30%. The ability to operate on different fuels and the possibility for the cogeneration of heat and power contributed to the popularity of the power plants at that time [

2,

81]. Subsequent improvements in steam cycle technology and increases in maximal steam pressures and temperatures, however, eventually made the steam cycle the preferred technology for CHP and power applications.

Regarding operational flexibility, BCs are generally very fast, particularly in combustion turbines, which have low thermal inertia and can quickly change heat rates. For nuclear systems, although heat input, rejection, and recuperation HXs add thermal capacity compared to simple combustion turbines, the limiting factor on flexibility likely remains the permissible rate of change in reactor thermal output, and eventually the reactor’s thermal inertia. While a significant drop in efficiency is typically associated with gas turbine partial load operation, the use of variable IGVs and regular management of working fluid charge into the closed cycle can partially mitigate this issue [

88].

6. Conclusions

In conclusion, the integration of BC systems into nuclear power generation presents a promising avenue for enhancing thermal efficiency and operational flexibility. The unique characteristics of BCs, including their ability to operate with gaseous working fluids and their compact designs, make them suitable for advanced nuclear reactor applications. This review has highlighted the significant advantages that BCs offers over traditional RC systems, particularly in terms of high-temperature operation, which are crucial for maximizing energy output in nuclear settings. It also notes the challenges as the high back work ratio or limited previous experience in nuclear systems.

The selection of working fluids is a critical aspect of BC design, influencing performance, efficiency, and compatibility with reactor systems. He, sCO2, N2, and air each present distinct benefits and challenges depending on the specific application. He is favoured for its inert nature and high thermal conductivity, making it suitable for very-high-temperature applications, particularly in HTGRs. However, its high cost and leakage potential limit its long-term use in certain configurations. On the other hand, sCO2 has emerged as a promising working fluid in midrange temperatures, offering compactness and high efficiency, albeit with concerns regarding corrosion and partial load performance. N2 and air, while less favoured in modern designs, still provide viable options, particularly for specific reactor configurations where cost, robustness and availability are paramount.

The compressor designs play pivotal roles in optimizing the performance of BC systems. Advanced compressor technologies, such as axial and centrifugal designs, enable efficient gas compression while managing the thermal and mechanical stresses associated with high-pressure operations. The integration of variable geometry components and advanced materials enhances operational flexibility and reliability, addressing challenges posed by varying load conditions.

Despite the promising attributes of BC systems, several challenges remain in their development and implementation. The operational experiences from various test facilities, including the Oberhausen II plant and the HHV, underline the complexity of designing and operating high-temperature gas turbines in nuclear applications. Issues such as high leakage rates, material degradation under extreme conditions, and the need for robust sealing technologies must be addressed to enhance the reliability and efficiency of these systems. The lessons learned from past experiences can guide future developments in BC technology, emphasizing the need for thorough testing and validation of designs before full-scale deployment.

As the nuclear industry continues to evolve, the potential for BC systems to contribute to a more sustainable and efficient energy landscape is increasingly recognized. The growing interest in SMRs and microreactors aligns with the compact nature of BC designs, enabling their integration into diverse applications, from remote power generation to advanced propulsion systems. The exploration of hybrid configurations, such as combining BCs with RCs in CHP systems, further opens avenues for enhancing overall efficiency and operational flexibility. The main research gaps identified are the need for better sealing technologies (especially for helium), better understanding of the design of systems and their control when operating at partial load, and materials that can handle the high temperatures and pressures of the advanced BCs proposed.

Author Contributions

Conceptualization, A.R., L.W., V.N., R.S. and J.K.; methodology, A.R., L.W. and V.N.; software, A.R., L.W. and V.N.; validation, A.R., L.W., J.K. and V.N.; formal analysis, A.R., V.N. and J.K.; investigation, A.R., V.N. and J.K.; resources, A.R., L.W. and J.K.; data curation, J.K. and A.R.; writing—original draft preparation, A.R., L.W., V.N. and J.K.; writing—review and editing, A.R., L.W., J.K. and V.N.; visualization, A.R. and J.K.; supervision, T.W., R.S., V.N. and J.K.; project administration, V.N., J.K. and T.W.; funding acquisition, TW. All authors have read and agreed to the published version of the manuscript.

Funding

This manuscript has been authored by a contractor of the U.S. Government for the U.S. Department of Energy, Office of Nuclear Energy (NE), under DOE-NE Idaho Operations Office Contract DEAC0705ID14517.

Data Availability Statement

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding author.

Acknowledgments

The U.S. Government retains, and the publisher, by accepting the article for publication, acknowledges that the U.S. Government retains a nonexclusive, paid-up, irrevocable, world-wide licence to publish or reproduce the published form of this manuscript, or allow others to do so, for U.S. Government purposes.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| BC | Brayton Cycle |

| CHP | Combined heat and power |

| CFD | Computational fluid dynamics |

| DOE | Department of Energy |

| GFR | Gas-Cooled Fast Reactor |

| He | Helium |

| HHV | High-Temperature Helium Test Facility |

| HRSG | Heat Recovery Steam Generator |

| HTGR | High-Temperature Gas-Cooled Reactor |

| IHX | Intermediate Heat Exchanger |

| IGVs | Inlet Guide Vanes |

| LWR | Light Water Reactor |

| MSR | Molten Salt Reactor |

| N2 | Nitrogen |

| NPP | Nuclear Power Plant |

| PR | Pressure Ratio |

| RC | Rankine Cycle |

| sCO2 | Supercritical Carbon Dioxide |

| SFR | Sodium-Cooled Fast Reactor |

| SMR | Small Modular Reactor |

| U.S. | United States |

| VHTR | Very-High-Temperature Reactor |

Appendix A. Compressor Maps, Maximum Efficiency, and Operation Range

Table A1 shows an overview of obtained compressor characteristics maps, preferably of flow rate vs. PR (or compression ratio, CR) with referenced efficiency. It is seen that obtaining the very high values often assumed in scientific papers are not necessarily realistic. Also, as the required PR increases, whether in a single- or multistage system, the attainable efficiency decreases.

Table A1.

Overview of compressor characteristics of PR, flow rate, speed, and efficiency sources [

85,

86,

87,

89,

90,

91,

92,

93,

94,

95,

96,

97,

98,

99,

100,

101,

102,

103].

Table A1.

Overview of compressor characteristics of PR, flow rate, speed, and efficiency sources [

85,

86,

87,

89,

90,

91,

92,

93,

94,

95,

96,

97,

98,

99,

100,

101,

102,

103].

| Compressor Type | Manufacturer/Model/Type | Peak Efficiency | PR (CR) at Max Eff. | RPM at Max Eff. | Refs. |

|---|

| Turbocharger | gtx4292r | 80% | 3 | 72 k | [85,86,87,89] |

| TD05H-16G | 71–76% | 3 | 100 k | [86,87,89] |

| gm atlas 3500 | 79% | 2.5 | | [87,89,90] |

| T3—60 | 74% | 2.4 | 100 k | [91] |

| TO 4B | 74% | 2 | 84 k | [92] |

| Garett | 76–77% | 2.5–4 | 100 k | [93,94] |

| BorgWarner | 77% | <3 | | [95] |

| Other centrifugal | “typical” | 75–86% | | | [96] |

| Environmental control system compressor | 74% | (CR 1.5) | 55 k | [97] |

| “typical” | 76% | | | [98] |

| Axial | “typical” | 85% | | | [96] |

| “typical” | 85% | 11 | | [99] |

| LM2500 (20 MW scale GT) | 87% | 14 | | [100] |

| Turbofan compressor | 95% | (CR 1.8) | | [97] |

| - | 85% | 12 | | [98,99,100,101] |

| - | 85–82% | 12–18 | | [102] |

| - | 85% | 20–22 | | [102] |

| - | 90% | 2 | 2500 | [85,86,87,89] |

| - | >90% | | | [45] |

| - | 75% | 1.7 | | [103] |

A list of compressor maps with PR (or discharge pressure) and flow rate (volumetric or mass) references and a list of compressors of specific gas turbines are featured in

Table A2. These values were used to generate the applied compressor map in

Figure 2. Note that the values are generally valid primarily for air. For gas turbines, it is generally understood that pressure ratios of the latest frame (industrial) engines can go as high as 30:1; for aeroderivative machines, up to about 40:1 [

45]. The table, however, shows that the general trend is to keep the gas turbine systems with axial compressors at rather lower PRs. Also note that GE does not publicly report mass flow rates or PR for their industrial gas turbines.

Table A2.

Overview of compressor map sources and specific compressors for assessing their application range [

39,

45,

54,

55,

56,

57,

103,

104,

105,

106,

107,

108,

109,

110,

111,

112,

113,

114,

115,

116].

Table A2.

Overview of compressor map sources and specific compressors for assessing their application range [

39,

45,

54,

55,

56,

57,

103,

104,

105,

106,

107,

108,

109,

110,

111,

112,

113,

114,

115,

116].

| Type | Model | | Max PR | Note | Refs. |

|---|

| Radial, axial, screw, piston, sliding vane | General compressor map | | | | [104] |

| Radial, axial, screw, piston | General compressor map | | | | [39] |

| Radial, axial, screw, piston, sliding vane | General compressor map | | | | [105] |

| Axial | Elliott’s axial comp. map | 212 | 5.5 | | [103,104,105,106] |

| SGT5-8000H | 776 | 20 | Industrial | [104,105,106,107,108] |

| SGT5-8000H | 475 | 24 | Industrial (other config.) | [104,105,106,107,108] |

| SGT5-9000HL | 844 | 24 | Industrial | [104,105,106,107,108] |

| MHI M701J | 731 | 21 | Industrial | [109] |

| MHI 701G | 618 | 23 | Industrial | [109] |

| FT4000 | 291 | 36.3 | Aeroderivative | [110,111] |

| SGT-A35 | 86 | 25 | Aeroderivative | [104,105,106,107,108] |

| SGT750 | 97 | 25.6 | Aeroder.—industr. hybrid | [104,105,106,107,108] |

| MAN axial | 417 | 25 | Standalone comp., max 350 °C | [112] |

| GE nx | 987 | 47.4 | Jet engine | [45] |

| Radial | RB barrel comp. MAN | 64 | | Max 800 bar | [110,111,112,113] |

| RG Intern. Geared MAN | 167 | | Max 250 bar, 450 °C | [111,112,113,114] |

| RH centrif. MAN | 250 | | Max 60 bar | [112,113,114,115] |

| Atlas Copco | 133 | | Max 206 bar | [54,55,56,57] |

| MAN’s MOPICO comp. map | 19 | 2.1 | | [116] |

References

- Bhargava, R.K.; Bianchi, M.; De Pascale, A.; Negri di Montenegro, G.; Peretto, A. Gas Turbine Based Power Cycles-A State-of-the-Art Review. In Challenges of Power Engineering and Environment; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Frutschi, H.U. Closed-Cycle Gas Turbines: Operating Experience and Future Potential; ASME Press: New York, NY, USA, 2005. [Google Scholar]

- Wright, S.A.; Vernon, M.E.; Pickard, P.S. Concept Design for a High Temperature Helium Brayton Cycle with Interstage Heating and Cooling; Sandia National Laboratory: Albuquerque, NM, USA, 2013. [Google Scholar]

- Invernizzi, C.M.; Di Marcoberardino, G. An Overview of Real Gas Brayton Power Cycles: Working Fluids Selection and Thermodynamic Implications. Energies 2023, 16, 3989. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Li, H.; Yang, Y.; Bai, W.; Zhang, C.; Zhang, X.; Yao, M. Thermo-economic and environmental analyses of supercritical carbon dioxide Brayton cycle for high temperature gas-cooled reactor. Prog. Nucl. Energy 2024, 177, 105461. [Google Scholar] [CrossRef]

- Geng, X.; Ma, W.; Wang, J. Study on transient characteristics for bypass valve regulation and load rejection of microreactor with helium Brayton cycle. Prog. Nucl. Energy 2025, 179, 105527. [Google Scholar] [CrossRef]

- Siemens Energy. Keadby2 Power Station: The Future of Power Generation in the UK. 2024. Available online: https://www.siemens-energy.com/us/en/home/stories/power-generation-in-uk.html (accessed on 30 October 2025).

- Hai, T.; Singh, P.K.; Ghodratallah, P.; Majdi, H.S.; Eldin, S.M.; Sohail, M.; El-Salam, N.M.A.; El-Shafai, W. Thermal energy recovery from a Brayton cycle nuclear power plant for efficiency improvement via compressor inlet cooling: Thermoeconomic optimization. Case Stud. Therm. Eng. 2023, 52, 103734. [Google Scholar] [CrossRef]

- Rigby, A.C.G.; Williams, L.D.; Novotný, V.; Westover, T.; Saeed, R.; Kim, J. Technology Assessment of Heat Exchangers and Compressors to Enable High Efficiency Brayton Cycle Designs for Nuclear Power Plants. Available online: https://ssrn.com/abstract=5538702 (accessed on 30 October 2025).

- Wang, J.; Gu, Y. Parametric studies on different gas turbine cycles for a high temperature gas-cooled reactor. Nucl. Eng. Des. 2005, 235, 1761–1772. [Google Scholar] [CrossRef]

- Herranz, L.; Linares, J.; Moratilla, B. Power cycle assessment of nuclear high temperature gas-cooled reactors. Appl. Therm. Eng. 2009, 29, 1759–1765. [Google Scholar] [CrossRef]

- Sato, H.; Yan, X.L.; Tachibana, Y.; Kunitomi, K. GTHTR300—A nuclear power plant design with 50% generating efficiency. Nucl. Eng. Des. 2014, 275, 190–196. [Google Scholar] [CrossRef]

- Gad-Briggs, A.; Pilidis, P. Analyses of Simple and Intercooled Recuperated Direct Brayton Helium Gas Turbine Cycles for Generation IV Reactor Power Plants. J. Nucl. Eng. Radiat. Sci. 2017, 3, 011017. [Google Scholar] [CrossRef]

- Bae, S.J.; Lee, J.; Ahn, Y.; Lee, J.I. Preliminary studies of compact Brayton cycle performance for Small Modular High Temperature Gas-cooled Reactor system. Ann. Nucl. Energy 2015, 75, 11–19. [Google Scholar] [CrossRef]

- Peterson, P.F. Multiple-Reheat Brayton Cycles for Nuclear Power Conversion with Molten Coolants. Nucl. Technol. 2003, 144, 279–288. [Google Scholar] [CrossRef]

- Ahn, Y.; Lee, J.I. Study of various Brayton cycle designs for small modular sodium-cooled fast reactor. Nucl. Eng. Des. 2014, 276, 128–141. [Google Scholar] [CrossRef]

- Pérez-Pichel, G.; Linares, J.; Herranz, L.; Moratilla, B. Potential application of Rankine and He-Brayton cycles to sodium fast reactors. Nucl. Eng. Des. 2011, 241, 2643–2652. [Google Scholar] [CrossRef]

- Oh, C.H.; Moore, R.L. Brayton Cycle for High-Temperature Gas-Cooled Reactors. Nucl. Technol. 2005, 149, 324–336. [Google Scholar] [CrossRef]

- Dostal, V.; Hejzlar, P.; Driscoll, M.J. High-Performance Supercritical Carbon Dioxide Cycle for Next-Generation Nuclear Reactors. Nucl. Technol. 2006, 154, 265–282. [Google Scholar] [CrossRef]

- Parma, E.J.; Wright, S.A.; Vernon, M.E.; Fleming, D.D.; Rochau, G.E.; Suo-Anttila, A.J.; Tsvetkov, P. Supercritical CO2 Direct Cycle Gas Fast Reactor (SC-GFR) Concept; Sandia National Lab.: Albuquerque, NM, USA, 2011; p. 55. [Google Scholar]

- Kim, M.G.; Lee, J.I.; Hartanto, D.; Kim, Y.H. Conceptual Design of S-CO2 Cooled Micro Modular Reactor. In Proceedings of the Transactions of the Korean Nuclear Society Spring Meeting, Gwangju, Republic of Korea, 29–31 May 2013. [Google Scholar]

- Hu, L.; Chen, D.; Huang, Y.; Li, L.; Cao, Y.; Yuan, D.; Wang, J.; Pan, L. Investigation on the performance of the supercritical Brayton cycle with CO2-based binary mixture as working fluid for an energy transportation system of a nuclear reactor. Energy 2015, 89, 874–886. [Google Scholar] [CrossRef]

- Wu, C.; Wang, S.-S.; Li, J. Exergoeconomic analysis and optimization of a combined supercritical carbon dioxide recompression Brayton/organic flash cycle for nuclear power plants. Energy Convers. Manag. 2018, 171, 936–952. [Google Scholar] [CrossRef]

- Yoon, H.J.; Ahn, Y.; Lee, J.I.; Addad, Y. Potential advantages of coupling supercritical CO2 Brayton cycle to water cooled small and medium size reactor. Nucl. Eng. Des. 2012, 245, 223–232. [Google Scholar] [CrossRef]

- Park, J.H.; Park, H.S.; Kwon, J.G.; Kim, T.H.; Kim, M.H. Optimization and thermodynamic analysis of supercritical CO2 Brayton recompression cycle for various small modular reactors. Energy 2018, 160, 520–553. [Google Scholar] [CrossRef]

- Syblik, J.; Vesely, L.; Entler, S.; Stepanek, J.; Dostal, V. Analysis of supercritical CO2 Brayton power cycles in nuclear and fusion energy. Fusion Eng. Des. 2019, 146, 1520–1523. [Google Scholar] [CrossRef]

- Yu, G.-P.; Cheng, Y.-F.; Zhang, N.; Ming, P.-J. Multi-objective optimization and evaluation of supercritical CO2 Brayton cycle for nuclear power generation. Nucl. Sci. Tech. 2024, 35, 22. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, N.; Yuan, T.; Yu, G. A multi-index evaluation method of supercritical CO2 Brayton cycle for nuclear power plants design. Int. J. Green Energy 2024, 21, 2042–2064. [Google Scholar] [CrossRef]

- Luo, D.; Huang, D. Thermodynamic and exergoeconomic investigation of various SCO2 Brayton cycles for next generation nuclear reactors. Energy Convers. Manag. 2020, 20, 112649. [Google Scholar] [CrossRef]

- Kattchee, N. Army Gas-Cooled Reactor Systems Program. Initial Full Power and Limited Endurance Tests of the ML-1 Nuclear Power Plant. Final Test Report; Aerojet-General Nucleonics: San Ramon, CA, USA, 1963. [Google Scholar]

- Olumayegun, O.; Wang, M.; Kelsall, G. Thermodynamic analysis and preliminary design of closed Brayton cycle using nitrogen as working fluid and coupled to small modular Sodium-cooled fast reactor (SM-SFR). Appl. Energy 2017, 191, 436–453. [Google Scholar] [CrossRef]

- Park, J.H.; Yoon, J.; Eoh, J.; Kim, H.; Kim, M.H. Optimization and sensitivity analysis of the nitrogen Brayton cycle as a power conversion system for a sodium-cooled fast reactor. Nucl. Eng. Des. 2018, 340, 325–334. [Google Scholar] [CrossRef]

- Jaszczur, M.; Rosen, M.A.; Śliwa, T.; Dudek, M.; Pieńkowski, L. Hydrogen production using high temperature nuclear reactors: Efficiency analysis of a combined cycle. Int. J. Hydrogen Energy 2016, 41, 7861–7871. [Google Scholar] [CrossRef]

- McKellar, M.; Guillen, D. Effect of climate and component performance on optimized recuperated air Brayton cycles for nuclear microreactor power conversion. Prog. Nucl. Energy 2023, 162, 104761. [Google Scholar] [CrossRef]

- Andreades, C.; Cisneros, A.T.; Choi, J.K.; Chong, A.Y.K.; Fratoni, M.; Hong, S.; Huddar, L.R.; Huff, K.D.; Kendrick, J.; Krumwiede, D.L.; et al. Design Summary of the Mark-I Pebble-Bed, Fluoride Salt–Cooled, High-Temperature Reactor Commercial Power Plant. Nucl. Technol. 2016, 195, 223–238. [Google Scholar] [CrossRef]

- Zohuri, B.; McDaniel, P.J.; De Oliveira, C.R.R. Advanced Nuclear Open Air-Brayton Cycles for Highly Efficient Power Conversion. Nucl. Technol. 2015, 192, 48–60. [Google Scholar] [CrossRef]

- Novotný, V.; Kim, J.; Westover, T. Heat augmentation for process heating using light water nuclear reactors. Energy Rep. 2025, 13, 1416–1440. [Google Scholar] [CrossRef]

- Mulder, E. Overview of X-Energy’s 200 MWth Xe-100 Reactor. In Proceedings of the Presentation t o NUPIC Vendor Conference, Virtual, 16 June 2021. [Google Scholar]

- Kappis, W. Compressors in gas turbine systems. In Modern Gas Turbine Systems; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- do Nascimento, M.A.R.; de Oliveira Rodrigues, L.; dos Santos, E.C.; Gomes, E.E.B.; Dias, F.L.G.; Velásques, E.I.G.; Carrillo, R.A.M. Micro Gas Turbine Engine: A Review|IntechOpen. In Progress in Gas Turbine Performance; IntechOpen: London, UK, 2013. [Google Scholar]

- Backman, J.L.H.; Kaikko, J. Microturbine systems for small combined heat and power (CHP) applications. In Small and Micro Combined Heat and Power (CHP) Systems; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar]

- Epstein, A.H. Millimeter-Scale, Micro-Electro-Mechanical Systems Gas Turbine Engines. J. Eng. Gas Turbines Power 2004, 126, 205–226. [Google Scholar] [CrossRef]

- Siemens Energy Gas Turbine Portfolio. 2024. Available online: https://p3.aprimocdn.net/siemensenergy/d7e01f44-f091-44f2-bf71-b20b010483e1/GT-Portfolio-Brochure-2024__FINAL_Low_Resolution-pdf_Original%20file.pdf (accessed on 30 October 2025).

- GENX™ High Bypass Turbofan Engines. 2024. Available online: https://www.geaerospace.com/sites/default/files/2022-01/GEnx-Datasheet.pdf (accessed on 30 October 2025).

- Langston, L.S. GAS-TURBINE COMPRESSORS: Understanding Stall, Surge. Available online: https://www.ccj-online.com/combined-cycle-journal-number-50/gas-turbine-compressors-understanding-stall-surge/ (accessed on 30 October 2025).

- Efficient and Reliable High-Pressure CO2 Compressor Solutions from Atlas Copco Gas and Process. 2025. Available online: https://www.atlascopco.com/content/dam/atlas-copco/compressor-technique/gas-and-process/documents/Atlas_Copco_GAP_CO2_CCUS.pdf.coredownload.pdf (accessed on 30 October 2025).

- Nonboel, E. Description of the Advanced Gas Cooled Type of Reactor (AGR); Nordisk Kernesikkerhedsforskning: Roskilde, Denmark, 1996. [Google Scholar]

- Tian, Z.; Jiang, B.; Malik, A.; Zheng, Q. Axial helium compressor for high-temperature gas-cooled reactor: A review. Ann. Nucl. Energy 2019, 130, 54–68. [Google Scholar] [CrossRef]

- Helium Compressors. Available online: https://www.sauercompressors.com/gases/technical-gases/helium-compressors (accessed on 30 October 2025).

- Tian, Z.; Zheng, Q.; Jiang, B.; Jia, X.; Zhu, Q.; Yue, G. Research on the design method of highly loaded helium compressor based on the physical properties. J. Nucl. Sci. Technol. 2017, 54, 837–849. [Google Scholar] [CrossRef]

- McDonald, C.F. Helium turbomachinery operating experience from gas turbine power plants and test facilities. Appl. Therm. Eng. 2012, 44, 108–142. [Google Scholar] [CrossRef]

- Ming, L.; Yang, X.; Zhang, Y.; Wang, J. Experimental study on performance of helium high pressure compressors of HTR-10GT. Ann. Nucl. Energy 2019, 125, 318–327. [Google Scholar] [CrossRef]