Abstract

This study investigates the factors influencing the energy consumption and reliability of haul trucks in open-pit mines and quarries, where fuel costs and the environmental impact are significant. Traditional analysis of haulage systems often overlooks crucial aspects such as energy efficiency in the specific mining environment and the effect of road configurations on truck performance. As sustainability becomes increasingly important, reducing fuel consumption not only reduces costs but also reduces greenhouse gas emissions. A key focus of the study is the link between haul truck reliability and overall efficiency. Frequent breakdowns increase maintenance costs, lead to unplanned downtime, and increase fuel consumption, all of which have an impact on the environment. Reliable transport systems, on the other hand, improve efficiency, reduce costs, and support sustainability goals. The authors analyze the energy consumption of trucks in relation to vehicle performance parameters and transport route characteristics. Discrete modeling of the transport system showed the impact of the operating environment on the variability of energy consumption and vehicle reliability. The study highlights the importance of understanding specific energy consumption in order to optimize the choice of transport system, as transport costs are a major cost of resource extraction. By analyzing the effect of road quality on vehicle performance, the authors suggest that improvements to the road surface can more easily improve vehicle reliability and energy intensity than changes to other road design elements. The study presents a quantitative analysis of the impact of haul road conditions on the operational efficiency of haul trucks in mining environments. Through discrete simulation models, two scenarios were analyzed. Total operational time decreased by 11.2% when road quality improved, demonstrating the critical role of surface maintenance. Additionally, breakdown times were reduced by 44%, maintenance by 15%, and empty travel by 9% in the optimized scenario. These findings underscore the necessity of maintaining optimal road conditions to prevent substantial efficiency losses and increased maintenance costs.

1. Introduction

Open-pit mining operations depend primarily on haulage trucks for transporting extracted materials, with their cost-effectiveness closely tied to fuel consumption and fluctuating prices. Selecting an optimal haulage system requires a thorough analysis of operational and reliability parameters to ensure both efficient and continuous production.

Fuel consumption in haulage is determined by several interrelated factors: haul road configuration and condition, route topology, and vehicle characteristics. Yet, practitioners often emphasize acquisition and maintenance expenses, underestimating how gradients, surface type, and ambient operating conditions influence both energy use and failure rates.

Reliability strongly affects energy performance: frequent breakdowns or unscheduled maintenance increase downtime and labor costs and contribute to inefficient fuel use due to disrupted operating cycles and added strain on damaged components. Therefore, a dependable haulage system is key to sustaining production and optimizing fuel efficiency.

This study examines the relationships among truck performance parameters, haul route features, and specific fuel consumption under varying operational conditions. We enhance conventional fuel-consumption models by integrating reliability metrics and quantifying how challenging environments—such as increased road roughness, steep gradients, and extreme temperatures—impact both failure rates and energy intensity. Using data from articulated haulage trucks at a limestone mine in southern Poland, we calibrate specific fuel-consumption models that account for vehicle characteristics and transport conditions.

Our results reveal how energy consumption varies with truck technical parameters and operational environments, underscoring the importance of incorporating reliability assessments into efficiency evaluations. Given that haulage constitutes a substantial portion of total extraction costs, these findings support informed decisions on haulage system selection and maintenance planning.

An analysis of the impact of the operating environment on reliability, technological parameters, and energy intensity was performed for the best-fit transportation medium at a limestone mine in southern Poland.

Literature Review

The selection of the means of transportation was described in []. The fuel consumption of mining trucks depending on different parameters is described in detail in [,,]. The use of multi-criteria methods in the selection of trucks is presented in []. A comparative analysis of energy consumption in haulage is discussed in []. Discrete simulations analyzing the effectiveness of hauling transport in mining are presented in []. Haul truck fuel consumption modeling under random operating conditions is described in [].

The analysis of fuel consumption in a large surface mine has also been described in []. A long-term analysis of haulage over half a year’s operation in a mine was carried out in []. The impact of payload utilization on fuel consumption has been reported in [,], and improvements in the energy efficiency of haul trucks in open pit mines have also been discussed in [,]. The use of models based on neural networks or machine learning to reduce fuel consumption in mining transport has been presented in [,,]. Additionally, the application of machine learning to predict the fuel consumption of haul trucks in open pit mines was demonstrated in [].

The issue of haul roads has been simulated and analyzed in [], where geotechnical tests were used to provide a mine with an optimal transport solution. The impact of haul roads has also been described in [,,,,,]. A mixed model proposed in [] optimized machine selection to reduce costs while lowering greenhouse gas (GHG) emissions. Reducing the mining footprint by adapting the haulage fleet and their reliability was described in []. The impact of reliability on energy consumption and GHG emissions of the mining haulage fleet was presented in []. Analyses of equipment failure in mining were described in [,,]. The machine failure rate was analyzed using the Monte Carlo method in []. Monte Carlo simulation was also applied in the analysis of technological processes and the transport road network in []. The preventive maintenance of mining equipment was discussed in [], and the high operating costs associated with haulage due to machine age and availability were highlighted in []. Similar analyses were presented in []. A performance model and cost–benefit analysis for hybrid electric mining trucks, emphasizing their potential to reduce operational costs and emissions, was provided in []. A novel haul road design methodology for open-pit mines aimed at enhancing truck efficiency was proposed in []. Stochastic optimization approaches to integrated mining value chains, with emphasis on mineral transportation systems, were reviewed in []. Monte Carlo methods were applied to address probabilistic challenges in mining engineering, including transport optimization, in [].

Reliability and maintainability analyses for mining drills were conducted in [], demonstrating how equipment performance impacts overall efficiency. Scraper load times and fleet sizes to minimize emissions during material transport were investigated in []. Reliability analysis and cost modeling of overhauled engines in mining dumpers, providing maintenance optimization insights, were the focus in [,]. Greenhouse gas emissions and energy intensity in granite mining were assessed in [], advocating for sustainable practices. An artificial neural network-based methodology for identifying road surface conditions and their effects on mining vehicles was introduced in []. Simulation techniques were applied in [,] to evaluate production targets and human reliability factors in open-pit mining operations. Haulage system optimization using discrete event simulation and mixed-integer programming for deep underground mines was explored in [].

The literature review did not identify any papers that simultaneously analyzed aspects of the influence of the operating environment on the failure intensity, energy consumption, and reliability of haulage tracks in mining, which the authors have attempted to address in the following analysis.

2. Materials and Methods

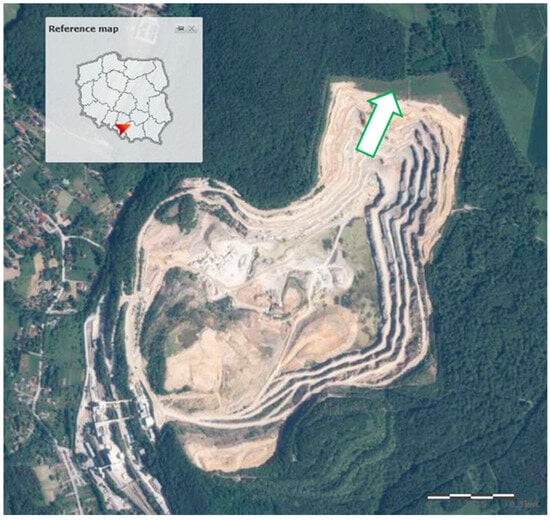

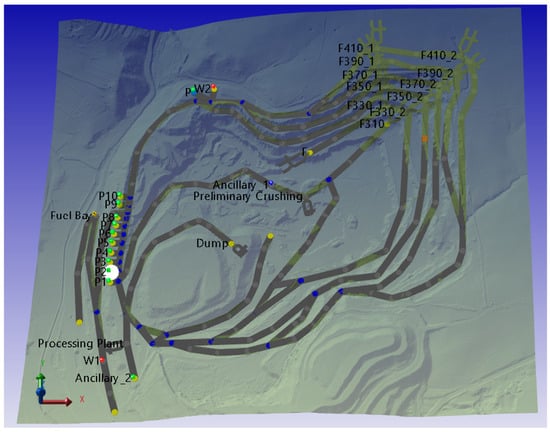

As part of the comparative analysis, in situ measurements of truck movement resistance were carried out on the main haul road of an open-cast limestone mine in southern Poland, as shown in Figure 1. Based on these measurements, as well as mining and geological data, a detailed 3D model of the quarry was developed. This model, incorporating the main process haul road (Figure 2), was implemented in the simulation program.

Figure 1.

Geographic location of the study area: mine site.

Figure 2.

Graphic visualization of the quarry with the main process hauling road marked (abbs: F—face, P—parking place for machines, W—workshops).

The simulation is based on discrete event modeling, which reproduces the operational and technological states of objects through successive activities, time units, or efficiency indicators []. It enables the testing of various solutions to a given problem without using physical resources and accounts for the variability of the operating environment by assigning random values to relevant technological parameters—independent of operator influence on the transport system.

The primary objective of the simulation model was to assess, over a medium-term horizon, the impact of technological parameters on transport efficiency and energy consumption within a mining operation. The model was developed based on a significant production task that reflected realistic operational requirements, ensuring that the analysis captured the complexity and variability of the transport process. A key assumption underlying the model was that the failure rate of the technological system correlated with the qualitative assessment of the operational environment. Since machine failure rates are typically evaluated over extended periods, the simulation was extended beyond a single work cycle (i.e., a day or a shift), allowing for a more comprehensive assessment of the interplay between system reliability and performance.

The production task model represented the annual production volume of a surface mine, encompassing all mining levels and operations. Production volumes were allocated to each face according to actual operational data from a selected calendar year. Mined material was categorized into two streams based on quality: ore destined for the processing plant and waste material transported to an internal stockpile. This structure enabled a realistic analysis of the material flow and associated transport logistics.

The simulation model included several categories of objects to accurately replicate the mining and transport processes, including:

- Road network: Featuring varying conditions and configurations for different operational scenarios.

- Loaders and excavators: Responsible for material extraction and loading.

- Haul trucks: Facilitating material transport within the mine.

- Plant facilities: Including the mine workings, waste dumps, and processing plant.

- Deposits: Representing the extracted material and its classification by quality.

By integrating these components, the simulation model provided a comprehensive tool for analyzing the impact of operational and environmental parameters on transport system performance, thereby supporting informed decision-making in mining operations.

All facilities were parameterized based on production flows and technological parameters obtained from real data. For the technological aspect, the most relevant parameters included:

- The bucket capacity of the loader.

- The payload and body capacity.

- Maneuvering time for loading and unloading.

- Actual fuel consumption during return transport and maneuvering while loading and unloading.

- Failure rate/failure intensity function λ(t).

The cumulative failure intensity function, denoted as λ(t), was formulated using the Weibull distribution density, as recommended in references [,,,]. The Weibull distribution is well-suited for analyzing time-to-failure data, given its flexibility in modeling various failure rates over time. The failure intensity distribution was determined for all machines based on service requests submitted to the maintenance and restoration system. These requests covered both major failures and minor defects identified either by the telemetry system or by operators. The Weibull distribution was also employed to model unplanned maintenance downtimes. When defining the failure intensity distribution, it was assumed that the mean number of failure events per unit of time changes with operating time. Consequently, the failure times were treated as random variables, and the total number of defective components was determined accordingly.

The analyzed mining fleet consisted of a group of six vehicles operating under similar conditions and with comparable mileage, as all were new machines recently put into operation. The operational and technical parameters of these trucks are summarized in Table 1. The impact of the operating environment on transport vehicles was examined for a fleet of Bell B40E (Figure 3) articulated dump trucks used in a limestone quarry. This type of vehicle is designed for transporting rock material or earth-rock masses on both paved surfaces and rough, uneven technological roads, even under adverse weather conditions.

Table 1.

Parameters of mine trucks used in the calculation procedure.

Figure 3.

Articulated truck Bell B40 used in an open pit mine.

The main feature of the simulation model was to evaluate the impact of technical and logistical parameters on transport efficiency and energy consumption in the medium term. A relatively large production task was chosen as the basis for the simulation. The transport process was modeled with the initial assumption that the intensity of the technological system failure is correlated with the qualitative assessment of the operating environment. Consequently, the analysis of a single work cycle, a day, or a few shifts would not be sufficient to evaluate these two parameters simultaneously since machine failure rates are usually evaluated over longer periods of time.

The production task modeled in this study consists of simulating the annual production volume of a mine, including all levels of mining. In this simulation, production volumes were allocated to individual faces based on actual data from the selected calendar year. Production from each face was divided into two streams depending on the quality of the material mined. Most of the mined material was transported to the processing plant, positioned on the left side of the model. Material classified as waste was taken to an internal dump site.

3. Results of Analysis of Haul Truck Energy Consumption in Operation Environment

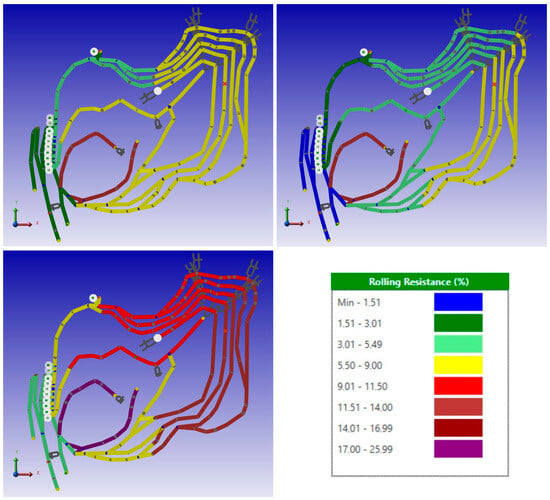

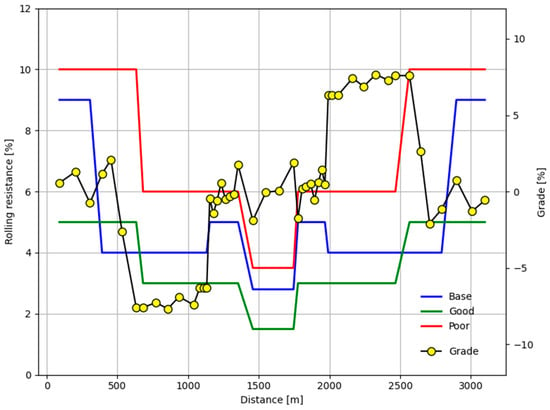

Variants of the scenario model were developed to represent three operational environmental states, symbolically named baseline, poor, and good. A key aspect of creating these model variants involved assessing the quality of individual transport road segments. In the baseline variant, this analysis was conducted through a direct evaluation of road quality using the Caterpillar Work Performance Handbook []. Each road section was defined as a segment of the transport route with a fixed gradient. Subsequently, corresponding rolling resistance values for these categories were incorporated into the model (Figure 4). These values, alongside the identified quality of transport roads for each model variant, are illustrated in Figure 5. All analyzed scenarios were implemented into the simulation program for discrete simulation, starting from the baseline scenario. Table 2 presents sample data obtained from the transport cycle simulation model for the basic (in situ) conditions of vehicle use in the quarry.

Figure 4.

Rolling resistance for three simulation scenarios (good conditions—top left, base conditions—top right, poor conditions—bottom).

Figure 5.

Rolling resistance for three simulation scenarios (good conditions—top left, base conditions—top right, poor conditions—bottom) for the analyzed route transportation.

Table 2.

The process time [in min] in baseline scenario of discrete modeling for the analyzed haul trucks fleet transportation process.

Table 3 shows the results of the base model. It takes into account all the parameters and details of the mining machine operation discussed above, as well as the effects of operating conditions.

Table 3.

Main technological parameters of the transport cycle for three variants of the basis operating environment.

Based on the discrete simulation model developed to replicate real operating conditions and facilities, simulation analyses of fuel consumption—calculated for individual road segments based on in situ measurements conducted at the mining facility—were performed for all three scenarios. The study developed three simulation scenarios—baseline, poor, and good conditions—to evaluate how different road qualities affect mining transportation performance. In the baseline scenario, road quality was directly assigned specific rolling resistance values to each fixed-gradient road segment. These resistance values were then used in the simulation model to calculate key operational parameters such as travel time, cycle time, and transportation productivity (as summarized in Table 3).

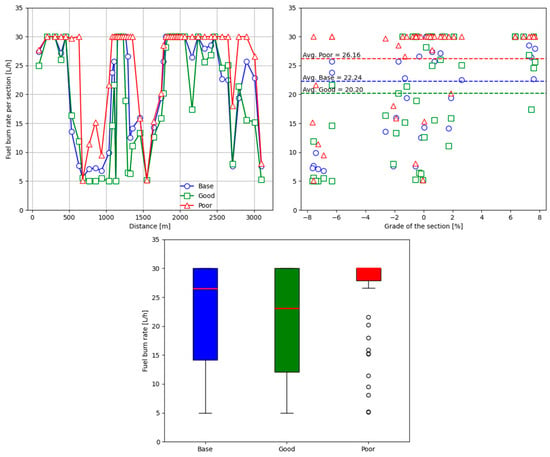

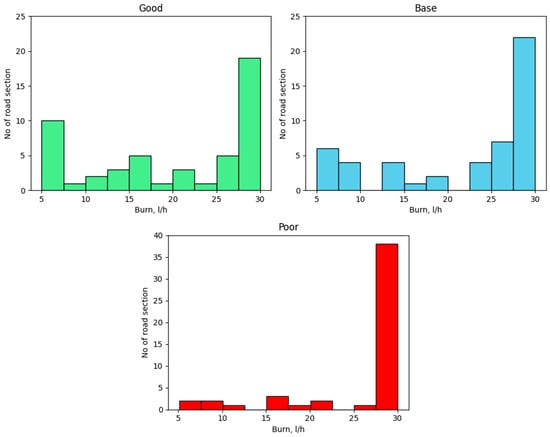

The six figures below (Figure 6 and Figure 7) focus on fuel consumption. They display the simulated fuel burn rates across the three scenarios, clearly demonstrating that improved road conditions (lower rolling resistance in the “good” scenario) lead to reduced fuel consumption, while deteriorated conditions (higher rolling resistance in the “poor” scenario) result in increased fuel usage. In particular, Figure 6, which illustrates the fuel burn rate for the haul road (main transportation route: F370-Crusher), underscores that even minor changes in route conditions can significantly affect fuel efficiency during transport tasks. Together, these figures highlight the critical impact of road quality on operational efficiency and fuel economy in mining transportation.

Figure 6.

Fuel burn rate of the main transportation route P370-Crusher—illustrating how route changes affect the average hourly fuel consumption during transport task execution.

Figure 7.

Fuel burned on road section from F370 to the crusher for three scenarios on discrete event modeling.

The box plots summarize the distribution of fuel consumption for each driving style. The poor style box is shifted higher overall, reflecting its higher average consumption. Notably, the top whisker for poor is not visible because the 75th percentile coincides with the maximum value in this dataset. This means that there is no gap between the top of the box and the highest recorded data point, resulting in a ‘missing’ upper whisker. Meanwhile, the base and good styles show a wider range of values (longer whiskers), with good having the lowest median fuel consumption of the three.

These three graphs (Figure 7) illustrate how road conditions affect fuel consumption in poor, base, and good scenarios. In the top left graph, the red (poor) line generally shows higher fuel consumption compared to the blue (base) and green (good) lines. The top right graph compares fuel consumption with road gradient, showing that downhill sections (negative gradient) tend to consume less fuel, while uphill sections (positive gradient) consume more. The average fuel consumption is around 20 L per hour in the good scenario, 22 L per hour in the base scenario, and 26 L per hour in the poor scenario. In the lower box plot, the distribution of fuel consumption is clearly lowest in good conditions, highest in poor conditions, and moderate in base conditions. Overall, these results show that better road quality (lower rolling resistance) significantly reduces fuel consumption, while poorer conditions lead to an increase. While the conclusions may be obvious, the model allows us to quantitatively assess the phenomenon.

A critical component of the models was the assessment of the quality of individual road sections, as road conditions have a significant impact on rolling resistance and therefore fuel consumption. In particular, the ‘poor’ condition scenario showed the highest fuel consumption due to increased rolling resistance, while the ‘good’ condition scenario showed improved fuel efficiency. The ‘poor’ condition scenario resulted in the highest total travel time and fuel consumption, while the ‘good’ condition scenario achieved the lowest values for these metrics.

4. Results of Analysis Haul Truck Failure Intensity Function in Operation Environment

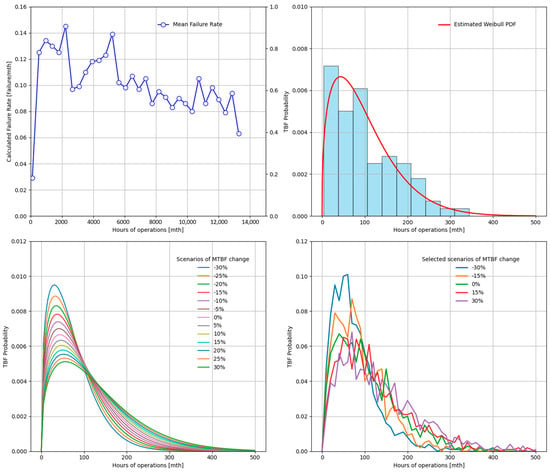

The modeling of the operating environment’s impact on vehicle performance represented by a breakdown of reliability states, was based on empirical data collected from the mining site. This dataset includes failure histograms for the entire fleet, covering a total of 13,000 machine hours of effective operational time (Figure 8 top left). In order to reconstruct the real operating conditions of machines over longer periods, the operating times of the road transport system (six articulated trucks) were examined, and failure processes were highlighted. The reliability analysis of the vehicle fleet was conducted over a one-year timeframe, assuming a total of 13,000 operating hours. This analysis was based on the mean failure rate of the articulated truck fleet, accounting for the cumulative operation time. Analyses of failure processes relied on the generated distribution patterns best fitting the data yielded by the reliability analysis, specifically the Weibull probability density function. The baseline, averaged failure rate for the analyzed vehicles is presented below in Figure 8, along with an approximation by Weibull distribution.

Figure 8.

Failure rate λ(t) for Bell B40E trucks over 13,000 h of operation, showing three discrete stages of mean failure rate versus intensity and the corresponding Weibull MTBF distributions under varying operating conditions.

Based on the baseline reliability model (Figure 8, top left), the failure rate intensity parameters were modeled as a function correlated with the operating environment. This included simulations of both improved and degraded conditions, corresponding to an increase or decrease in system reliability. The modeling was performed in 5% increments to assess the effect of environmental changes on the reliability parameters analyzed.

The upper plots in Figure 8 represent the input data: the top left plot shows a long-term operational dataset of 13,000 mths, while the top right plot derives the corresponding MTBF (Mean Time Between Failures), establishing the baseline. The lower graphs illustrate Weibull modeling scenarios: the lower left graph shows Weibull distributions under various MTBF adjustments (from −30% to +30%), while the lower right graph shows simulated probability density functions, highlighting the impact of these changes on the time-to-failure distributions.

The probability density functions (PDFs) for time to failure under different MTBF scenarios show how shifts in reliability affect failure rates. Positive shifts (e.g., +30%) extend the time to failure, shifting the peak further to the right and reducing the probability of early failures. The right-hand graph zooms in on the 0–500 operating hour range to highlight the early part of each distribution. Notably, the failure intensity beyond 500 h is minimal and therefore negligible for a practical assessment.

This approach provides a detailed picture of the system’s response to varying operating conditions and was implemented using ModelRisk software [], which applies a two-parameter Weibull model. The software uses maximum likelihood estimation to determine shape and scale parameters based on actual operating data. The distribution was selected based on the information capacity criteria applied in the program (Akaike, Schwartz, and Hannan–Quinn Information Criterion).

5. Modifications to Existing Operating Conditions at the Mine Site and Their Impact on the Analyzed Parameters of Haulers

Below are the results for the discrete simulation models for two hypothetical scenarios (poor and good) with the assumed step of change in the rolling resistance parameter depending on the surface condition ±15%. The results are presented for individual machine parks in the assumed variants and scenarios of the analysis. The change in environmental conditions between the two variants resulted in a difference in the total time required to complete the transport task. Under poor scenario conditions, the task duration was 158.8 working days, while under good scenario conditions, it was 144.5 working days.

The ‘poor’ scenario simulates conditions where the rolling resistance parameter is increased by 15%, reflecting deteriorated surface conditions at the mine site. Table 4 lists the total time (in unspecified units) for each operational phase for each hauler. The table also provides cumulative totals for each phase, which can be used to assess the overall impact on fleet performance.

Table 4.

Selected ‘poor’ scenario of discrete modeling for the vehicles analyzed.

In contrast, the ‘good’ scenario models a situation in which the rolling resistance parameter is reduced by 15%, representing an improvement in surface conditions. Table 5 offers a similar breakdown of operational times for each hauler. Comparing these numbers with those from the “poor” scenario allows for an assessment of how better surface conditions may reduce or shift the time spent on different operational activities.

Table 5.

Selected ‘good’ scenario of discrete modeling for the vehicles analyzed (15%).

Table 6 presents percentage differences across various operational phases for each hauler under adverse conditions. The data reveal several drawbacks of the ‘poor’ scenario. Notably, the breakdown phase shows marked increases (e.g., Bell_02 at 106%), indicating potential reliability issues under operating conditions. Maintenance also demonstrates inconsistent changes, hinting at challenges in service protocols. In contrast, operations like loading/unloading and loaded travel remain relatively unchanged, suggesting that while some functions are stable, critical areas prone to failure are significantly impacted in harsh environments.

Table 6.

First comparison for ‘poor’ scenario.

In contrast, Table 7 illustrates percentage changes under favorable conditions, where the overall trends indicate improved performance. The advantages of the ‘good’ scenario are evident in the reduction in downtime during breakdowns (e.g., reductions observed in Bell_01 and Bell_04), reflecting enhanced reliability. Moreover, consistent performance in loading/unloading and travel operations under improved conditions suggests effective operational stability. Although maintenance shows good results, the general trend is toward better efficiency, underscoring the benefits of optimized operational environments for fleet performance.

Table 7.

Second comparison for ‘good’ scenario.

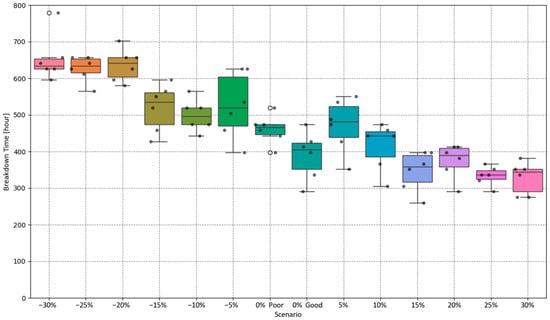

The simulation results summarized in Table 8 show a disproportionate relationship between the ‘poor’ and ‘good’ scenarios compared to the base case. Under deteriorated conditions (‘poor’ scenario), negative adjustments in the failure rates (−30%, −20%, −10%, and 0%) are associated with significantly increased downtime and maintenance times, as well as longer durations for technological operations, which in turn result in significantly higher total operating times. In contrast, under improved conditions (the ‘good’ scenario), the positive adjustments (0%, +10%, +20%, and +30%) lead to a reduction in total operating times, with the most favorable results observed for the +30% adjustment. However, the magnitude of the improvement is less pronounced than the deterioration observed in the ‘poor’ scenario.

Table 8.

Simulation results for selected variants of environment and failure rate.

This disproportion suggests that while optimizing operating conditions improves overall performance, the potential gains are somewhat limited compared to the adverse effects of deteriorating conditions. In essence, it appears that ‘the best is the enemy of the good’: improving the environment only modestly improves operational metrics, while a similar percentage deterioration in conditions has a disproportionately negative impact on the modeled parameters. This finding underscores the critical importance of preventing deterioration of the operating environment to avoid significant efficiency losses.

In modeling discrete operational processes, and in the absence of precise knowledge regarding the correlation between environmental operating conditions and vehicle performance, it is assumed that failure intensity adjusts in response to changing conditions. Specifically, as operating conditions improve, failure intensity decreases, whereas deteriorating conditions lead to an increase. The analysis period is not predetermined but is instead dictated by the transport task performed within the model. Consequently, failures, costs, task durations, and other factors continue to be generated until the haul trucks have fully transported the load. In the diagram (Figure 9), each point represents a single haul truck under analysis, with a range of failure probabilities. Simulations using imprecise Weibull distributions result in longer simulation times and more frequent failures. However, detailed knowledge of the exact process is limited due to the absence of identical mines required for experimental consistency. It is assumed that both poor and favorable conditions have varying effects on failure rates, with Weibull probability density values ranging from −30% to 30%, and that these effects are estimated based on simulated failure rates.

Figure 9.

Discrete simulation results for successive analyzed scenarios (better roads, lower failure intensity).

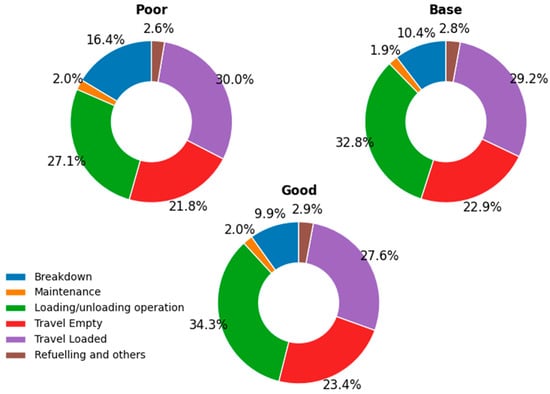

Pie charts (Figure 10) presenting data from all steps of the discrete simulation were created for three scenarios defined by technical and technological parameters. The analysis focused on a fleet of six trucks under each scenario, with associated indicators such as uptime, productivity, and others. Based on the simulation results obtained from the Haulsim software Version 3.0, a percentage breakdown of each component of the transport process was also produced for all analyzed scenarios.

Figure 10.

Pie charts displaying discrete simulation results for three scenarios, focusing on maintenance and other components of the transport process.

It should be emphasized that each percentage change in the proportion of a specific machine operating mode within the analyzed process corresponds to approximately 1.5 working days.

The above charts visualize how each scenario distributes the operating time between different processes within the transport cycle. Using a statistical approach with the Weibull distribution, the simulation captures the probabilistic nature of events such as breakdowns and maintenance. The detailed breakdown for each scenario allows direct comparison: inefficiencies (e.g., high empty runs and long loading/unloading times) are more pronounced in less favorable scenarios. Operational improvements (e.g., more loaded trips and balanced maintenance) are more noticeable in more technologically advanced or optimized scenarios. This analysis not only helps to identify areas for operational improvement but also supports decision making regarding fleet management and technology investments. Understanding the impact on process efficiency expressed in relative terms enables the transition to an economic analysis of the profitability of investments aimed at improving the operational environment.

6. Discussion

The simulation results demonstrate that in deteriorated conditions, more negative adjustments in the failure rate lead to longer operational downtimes, increasing total operation times. In improved conditions, positive failure rate adjustments correlate with enhanced performance, reducing both breakdown and total operation times, with the best performance observed at the highest adjustment (+30%). These findings underscore the significant impact that both environmental conditions and failure rate intensity modifications have on operational efficiency.

In addition to energy consumption, the operating environment plays a key role in determining vehicle reliability. There is a direct correlation between road conditions and vehicle failure rates: the more favorable the road conditions, the fewer the mechanical failures experienced by the vehicles, and conversely, poor hauling route conditions lead to a higher frequency of breakdowns. In adverse conditions, such as those encountered during winter months, increased wear and tear on trucks is inevitable, resulting in more frequent maintenance requirements, downtime, and, ultimately, higher costs. On the other hand, optimal road surfaces reduce mechanical strain, enhance fuel efficiency, and extend vehicle lifespans, thereby improving overall reliability and lowering operational costs.

7. Conclusions

This study demonstrates that the mining operating environment plays a critical role in determining both the energy consumption and reliability of haul trucks in surface mining. Simulation analyses covering a range of road conditions from optimal to poor indicate that adverse conditions can increase fuel consumption by up to 25% compared to baseline scenarios, while improved road surfaces can reduce consumption by approximately 12.5%. These findings highlight the importance of maintaining a high-quality hauling road infrastructure to reduce rolling resistance and improve operational efficiency.

The analysis confirms a strong correlation between road conditions and vehicle reliability. Poor road surfaces not only increase fuel consumption but also lead to a higher incidence of mechanical failures. This results in increased unplanned downtime, higher maintenance costs, and reduced operational efficiency. In contrast, investment in durable, weather-resistant roads can extend equipment life and optimize system performance by reducing the frequency and severity of breakdowns.

Our integrated approach—combining discrete event simulation with reliability modeling—provides a comprehensive framework for evaluating the interplay between energy consumption and mechanical performance under varying operating conditions. This framework can serve as a valuable decision support tool for mining operators, allowing them to assess the economic benefits of infrastructure improvements and strategic vehicle selection.

Furthermore, the methodology and results of this study are applicable beyond surface mining to underground mining and large construction projects where haulage over unpaved roads is common. This approach also provides a useful basis for comparing different vehicle types, such as diesel and electric trucks, in terms of efficiency and reliability.

Optimizing the haulage system through improved road infrastructure and careful vehicle selection leads to significant improvements in operational efficiency, reduced energy consumption, and increased vehicle reliability. These considerations are critical for mining operations seeking to improve cost-effectiveness and long-term sustainability. Ultimately, the impact of the operating environment on both energy efficiency and vehicle reliability must be considered for a more comprehensive evaluation of haulage systems.

Moreover, the approach of assessing energy consumption alongside vehicle reliability is applicable beyond surface mining. It extends to underground mining and major construction projects where unpaved, non-public roads are commonly used. The methodology also provides a valuable framework for comparing different vehicle types, such as diesel and electric trucks, in terms of efficiency and durability.

The simulation results quantitatively confirmed that road surface quality significantly impacts the operational efficiency of mining haul trucks. A transition from poor to good surface conditions reduced the total task completion time by 14.3 working days and decreased overall operational time by nearly 158,000 time units (11.2%). Moreover, breakdown incidents saw a 44% reduction, and maintenance times were cut by 15%, directly contributing to improved fleet reliability and lower operational costs. The analysis highlights that even modest improvements in surface conditions lead to notable gains in efficiency, while degradation has a disproportionately negative impact. Therefore, strategic investments in road maintenance are not only justified but necessary for optimizing fleet performance and reducing downtime.

In summary, optimizing the haulage system through infrastructure improvements and strategic vehicle selection leads to significant gains in efficiency, reduced energy consumption, and improved reliability. For mining operations seeking to reduce costs and improve sustainability, these factors are critical to long-term success. A comprehensive evaluation of haulage systems must consider both energy efficiency and vehicle reliability to maximize performance and economic viability.

In addition, the authors are actively pursuing further analyses that will cover both the technical-economic aspects and the environmental impacts of haulage systems in open-cast mining. These ongoing investigations, which will form the basis of a subsequent article in this series, aim to provide deeper insights into the long-term economic viability and sustainability of mining operations.

Author Contributions

Conceptualization, P.B., Z.K. and M.P.; methodology, P.B. and Z.K.; software, Z.K.; validation P.B. and Z.K.; formal analysis, P.B. and Z.K.; investigation, Z.K. and P.B.; resources, P.B. and M.P.; data curation, Z.K. and M.P.; writing—original draft preparation, P.B. and Z.K.; writing—review and editing, M.P.; visualization, Z.K.; supervision, P.B.; project administration, P.B. and M.P.; funding acquisition, M.P. and P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by AGH University of Krakow, Faculty of Civil Engineering and Resource Management; subsidy number: 16.16.100.215.

Data Availability Statement

The data can be accessed upon request to any of the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bodziony, P.; Patyk, M. The Influence of the Mining Operation Environment on the Energy Consumption and Technical Availability of Truck Haulage Operations in Surface Mines. Energies 2024, 17, 2654. [Google Scholar] [CrossRef]

- Kecojevic, V.; Komljenovic, D. Haul truck fuel consumption and CO2 emission under various engine load conditions. In Proceedings of the SME Annual Meeting and Exhibit and CMA 113th National Western Mining Conference 2011, Denver, CO, USA, 28 February–2 March 2011. [Google Scholar]

- Kecojevic, V.; Vukotic, I.; Komljenovic, D. Production, consumption and cost of energy for surface mining of bituminous coal. Min. Eng. 2014, 66, 51–57. [Google Scholar]

- Curi, A.; Felsch, W.S.; Rodovalho, E.C.; Meireles, B.P. Evaluation of Haul Trucks Performance in a CSN Mine. In Proceedings of the Mine Planning and Equipment Selection, Dresden, Germany, 14–19 October 2013. [Google Scholar] [CrossRef]

- Bodziony, P.; Kasztelewicz, Z.; Sawicki, P. The Problem of Multiple Criteria Selection of the Surface Mining Haul Trucks. Arch. Min. Sci. 2016, 61, 223–243. [Google Scholar] [CrossRef]

- Sahoo, L.K.; Bandyopadhyay, S.; Banerjee, R. Benchmarking energy consumption of truck haulage. In Green Energy and Technology; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Krysa, Z.; Bodziony, P.; Patyk, M. Discrete simulations in analyzing the effectiveness of raw materials transportation during extraction of low-quality deposits. Energies 2021, 14, 5884. [Google Scholar] [CrossRef]

- Golbasi, O.; Kina, E. Haul truck fuel consumption modeling under random operating conditions: A case study. Transp. Res. Part D Transp. Environ. 2022, 102, 103135. [Google Scholar] [CrossRef]

- Dindarloo, S.R.; Siami-Irdemoosa, E. Determinants of fuel consumption in mining trucks. Energy 2016, 112, 232–240. [Google Scholar] [CrossRef]

- Straka, M.; Rosová, A.; Lenort, R.; Besta, P.; Šaderová, J. Principles of computer simulation design for the needs of improvement of the raw materials combined transport system. Acta Montan. Slovaca 2018, 23, 163–174. [Google Scholar]

- Soofastaei, A.; Aminossadati, S.M.; Kizil, M.S.; Knights, P. A comprehensive investigation of loading variance influence on fuel consumption and gas emissions in mine haulage operation. Int. J. Min. Sci. Technol. 2016, 26, 995–1001. [Google Scholar] [CrossRef]

- Soofastaei, A.; Karimpour, E.; Knights, P.; Kizil, M. Energy-efficient loading and hauling operations. In Green Energy and Technology; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Soofastaei, A.; Fouladgar, M. Advanced analytics for haul trucks energy-efficiency improvement in surface mines. In Advanced Analytics in Mining Engineering: Leverage Advanced Analytics in Mining Industry to Make Better Business Decisions; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Siami-Irdemoosa, E.; Dindarloo, S.R. Prediction of fuel consumption of mining dump trucks: A neural networks approach. Appl. Energy 2015, 151, 77–84. [Google Scholar] [CrossRef]

- Bousonville, T.; Dirichs, M.; Kruger, T. Estimating truck fuel consumption with machine learning using telematics, topology and weather data. In Proceedings of the 2019 International Conference on Industrial Engineering and Systems Management, IESM 2019, Shanghai, China, 25–27 September 2019. [Google Scholar] [CrossRef]

- Terpstra, V.J.; Lara-Yejas, O.; Mokhtari, K.; Cruz, J.F.H.S.; de Mattos, M.P. Fuel optimization in mining trucks using machine learning. In Proceedings of the IISE Annual Conference and Expo 2021, Online, 22–25 May 2021. [Google Scholar]

- Alamdari, S.; Hossein Basiri, M.; Mousavi, A.; Soofastaei, A. Application of Machine Learning Techniques to Predict Haul Truck Fuel Consumption in Open-Pit Mines. J. Min. Environ. 2022, 13, 69–85. [Google Scholar] [CrossRef]

- Nurić, A.; Nurić, S. Numerical modeling of transport roads in open pit mines. J. Sustain. Min. 2019, 18, 25–30. [Google Scholar] [CrossRef]

- Douglas, R.A.; Lawrence, K. Optimizing haul road design—A challenge for resource development in Northern Canada. In Proceedings of the 2014 Transportation Association of Canada Conference and Exhibition: Past, Present, Future, ATC 2014, Montreal, QC, Canada, 28 September 2014. [Google Scholar]

- Richardson, S.; McIver, J. Improving Mine Haul Road Roughness to Reduce Haul Truck Fuel Consumption; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Coffey, J.; Nikraz, H.; Leek, C. Haul road rolling resistance and pavement condition. Aust. J. Civ. Eng. 2018, 16, 12–22. [Google Scholar] [CrossRef]

- Coffey, J.; Nikraz, H.; Leek, C. An investigation into opportunities for improvement of surface mine haul road functional design, construction and maintenance. Aust. Geomech. J. 2018, 53, 129–139. [Google Scholar]

- Li, X.; Gu, Q.; Ruan, S.; Feng, Z. Optimal transportation path planning of truck in open-pit mine under dynamic energy consumption. Meitan Xuebao/J. China Coal Soc. 2021, 46 (Suppl. S1), 590–600. [Google Scholar] [CrossRef]

- Hasan, H.; Octariando, R. The Effect of Road Grade on Dump Truck Fuel Consumption; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Saderova, J.; Rosova, A.; Kacmary, P.; Sofranko, M.; Bindzar, P.; Malkus, T. Modelling as a tool for the planning of the transport system performance in the conditions of a raw material mining. Sustainability 2020, 12, 8051. [Google Scholar] [CrossRef]

- Pascual, R.; Román, M.; López-Campos, M.; Hitch, M.; Rodovalho, E. Reducing mining footprint by matching haul fleet demand and route-oriented tire types. J. Clean. Prod. 2019, 227, 645–651. [Google Scholar] [CrossRef]

- Peralta, S.; Sasmito, A.P.; Kumral, M. Reliability effect on energy consumption and greenhouse gas emissions of mining hauling fleet towards sustainable mining. J. Sustain. Min. 2016, 15, 85–94. [Google Scholar] [CrossRef]

- Hall, R.A.; Daneshmend, L.K.; Lipsett, M.G.; Wong, J. Reliability analysis as a tool for surface mining equipment evaluation and selection. C. Bull. 2000, 93, 78–82. [Google Scholar]

- Yu, H.; Solvang, W.D.; Sun, X. A decision-support model for operational planning of surface coal mining considering equipment failure. In Proceedings of the 2016 International Symposium on Small-Scale Intelligent Manufacturing Systems, SIMS 2016, Narvik, Norway, 21–24 June 2016. [Google Scholar] [CrossRef]

- Paithankar, A.; Chatterjee, S. Forecasting time-to-failure of machine using hybrid Neuro-genetic algorithm–a case study in mining machinery. Int. J. Min. Reclam. Environ. 2018, 32, 182–195. [Google Scholar] [CrossRef]

- Morad, A.M.; Pourgol-Mohammad, M.; Sattarvand, J. Application of reliability-centered maintenance for productivity improvement of open pit mining equipment: Case study of Sungun Copper Mine. J. Cent. South Univ. 2014, 21, 2372–2382. [Google Scholar] [CrossRef]

- Upadhyay, S.; Tabesh, M.; Badiozamani, M.; Askari-Nasab, H. A Simulation Model for Estimation of Mine Haulage Fleet Productivity. In Springer Series in Geomechanics and Geoengineering, Proceedings of the 28th International Symposium on Mine Planning and Equipment Selection—MPES 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 42–50. [Google Scholar]

- Angeles, E.; Kumral, M. Optimal Inspection and Preventive Maintenance Scheduling of Mining Equipment. J. Fail. Anal. Prev. 2020, 20, 1408–1416. [Google Scholar] [CrossRef]

- Topal, E.; Ramazan, S. A new MIP model for mine equipment scheduling by minimizing maintenance cost. Eur. J. Oper. Res. 2010, 207, 1065–1071. [Google Scholar] [CrossRef]

- Kristjanpoller, F.; Viveros, P.; Zio, E.; Pascual, R.; Aranda, O. Equivalent availability index for the performance measurement of haul truck fleets. Eksploat. I Niezawodn. 2020, 22, 583–591. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, Z.; Yang, J.; Cheng, R. Performance modeling and cost-benefit analysis of hybrid electric mining trucks. In Proceedings of the MESA 2016—12th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications—Conference Proceedings, Auckland, New Zealand, 29–31 August 2016. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. A new method for haul road design in open-pit mines to support efficient truck haulage operations. Appl. Sci. 2017, 7, 747. [Google Scholar] [CrossRef]

- Dimitrakopoulos, R.; Lamghari, A. Simultaneous stochastic optimization of mining complexes—Mineral value chains: An overview of concepts, examples and comparisons. Int. J. Min. Reclam. Environ. 2022, 36, 443–460. [Google Scholar] [CrossRef]

- Frydrýšek, K. Monte carlo probabilistic approach applied for solving problems in mining engineering. In Intelligent Systems for Computer Modelling. Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2016; Volume 423. [Google Scholar] [CrossRef]

- Gaurav, K.; Agrawal, A.K.; Chattopadhyaya, S.; Siddiqui, M.A.H. Reliability and maintainability analysis of universal drill machine at Saoner mines, Nagpur, India. IOP Conf. Ser. Mater. Sci. Eng. 2019, 691, 012014. [Google Scholar] [CrossRef]

- Kaboli, A.S.; Carmichael, D.G. Optimum scraper load time and fleet size for minimum emissions. Int. J. Constr. Manag. 2014, 14, 209–226. [Google Scholar] [CrossRef]

- Kishorilal, D.B. Cost modelling of overhauled engines used in dumpers. Int. J. Appl. Eng. Res. 2016, 11, 5516–5518. [Google Scholar]

- Kishorilal, D.B.; Mukhopadhyay, A.K. Reliability analysis of overhauled engines of dumpers. Appl. Mech. Mater. 2014, 592–594, 1756–1760. [Google Scholar] [CrossRef]

- Kittipongvises, S.; Chavalparit, O.; Sutthirat, C. Greenhouse gases and energy intensity of granite rock mining operations in Thailand: A case of industrial rock-construction. Environ. Clim. Technol. 2016, 18, 64–75. [Google Scholar] [CrossRef]

- Ngwangwa, H.M.; Heyns, P.S. Application of an ANN-based methodology for road surface condition identification on mining vehicles and roads. J. Terramechanics 2014, 53, 59–74. [Google Scholar] [CrossRef]

- Ozdemir, B.; Kumral, M. Appraising production targets through agent-based Petri net simulation of material handling systems in open pit mines. Simul. Model. Pract. Theory 2018, 87, 138–154. [Google Scholar] [CrossRef]

- Ozdemir, B.; Kumral, M. Analysing human effect on the reliability of mining equipment. Int. J. Heavy Veh. Syst. 2019, 26, 872–887. [Google Scholar] [CrossRef]

- Salama, A. Optimization Using Discrete Event Simulation and Mixed Integer Programming: Application on Haulage Systems for Deep Underground Mines. Licentiate Thesis, Luleå University of Technology, Luleå, Sweden, 2013. [Google Scholar]

- HaulSim: Haulage Simulation Software, version 3.0; HaulSim Company: Brisbane, Australia, 2018.

- Thompson, R.J.; Visser, A.T. Selection and maintenance of mine haul road wearing course materials. Inst. Min. Metallurgy. Transactions. Sect. A Min. Technol. 2006, 115, 140–153. [Google Scholar] [CrossRef]

- Barabady, J.; Kumar, U. Reliability analysis of mining equipment: A case study of a crushing plant at Jajarm Bauxite Mine in Iran. Reliab. Eng. Syst. Saf. 2008, 93, 341–361. [Google Scholar] [CrossRef]

- Bebbington, M.; Lai, C.D.; Zitikis, R. A flexible Weibull extension. Reliab. Eng. Syst. Saf. 2007, 92, 719–726. [Google Scholar] [CrossRef]

- Bodziony, P.; Patyk, M. Analysis of Utilisation States and Reliability Parameters of Process-Line Configuration for Low-Quality Rock Deposits. Adv. Sci. Technol. Res. J. 2021, 15, 126–133. [Google Scholar] [CrossRef]

- Caterpillar Inc. Caterpillar Performance Handbook, 45th ed.; Caterpillar Inc.: Peoria, IL, USA, 2020. [Google Scholar]

- ModelRisk Software (Akaike, Schwartz and Hannan-Quinn Information Criterion). Available online: https://www.vosesoftware.com/ (accessed on 27 April 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).