Abstract

This paper provides an overview of the cleaning aspects of solar panels through a literature review. We first discuss the drawbacks of unwanted deposits on solar panels in terms of energy production and efficiency. Existing cleaning practices and technologies are then presented with an emphasis on factors such as the size of the facility, location, cost, and available resources. Finally, a comparative cost–benefit analysis is carried out using decision support tools and taking into account different relevant criteria to support users choose the right cleaning maintenance for their specific solar installation.

1. Introduction

Solar energy has gained increasing importance as a renewable energy source worldwide. With the growing awareness of environmental issues and the increasing demand for energy, solar energy offers a promising solution to address these challenges. Solar energy continues to grow at an impressive pace. In fact, in 2022, the global installed solar energy capacity exceeded 1000 gigawatts (GW), representing an increase of approximately 25% compared with the previous year. Solar energy currently accounts for about 4.5% of the total electricity production capacity worldwide [1]. This growth is mainly attributed to the declining costs of solar installations and the increasing adoption of renewable energy support policies in many countries.

According to the European Solar Thermal Industry Association, each additional kilowatt-hour (kWh) of solar production added to the electrical grid would decrease CO2 emissions by 238 g per kWh. These emissions reductions stem from the avoidance of 270 gCO2/kWh in the French and European electrical systems, with a deduction of 32 gCO2/kWh representing the emissions associated with the manufacturing and installation of photovoltaic systems [2]. Additionally, solar energy is abundant and widespread, providing an independent and sustainable energy source to meet the growing energy demand.

However, despite all these advantages, the efficiency of solar panels can be significantly impacted by a major issue: the accumulation of dust on their surfaces. Numerous studies have demonstrated that dust accumulation on solar surfaces can cause significant degradation of their solar conversion efficiency. The presence of dust on solar panels reduces the amount of sunlight reaching the photovoltaic cells, resulting in a decrease in electricity production. Dust acts as a barrier, blocking sunlight and thereby reducing the efficiency of the solar energy conversion process [3]. To illustrate the impact of dust on solar panels, experimental research has revealed alarming results. According to these studies, the efficiency of solar panels can decrease by 30 to 40 percent due to dust accumulation, leading to a reduction in power output of up to 86 percent [4]. These figures emphasize the critical importance of regular cleaning of solar panels to maintain their optimal performance. The rate of dust accumulation on solar module surfaces primarily depends on the concentration of airborne particles, the distribution of aerodynamic particle sizes, site location, and specific weather conditions [5]. Therefore, it is essential to develop effective methods of solar panel cleaning that are tailored to the local environmental conditions. However, there can be challenges in terms of cost, water usage, and access to installations, especially in areas where water resources are limited. Innovative solutions are constantly being developed to overcome these challenges. Technologies such as automated cleaning systems, anti-soiling coatings, and water-efficient cleaning methods are being studied to make solar panel cleaning more efficient, cost-effective, and environmentally friendly.

In the current literature, the issue of solar panel cleaning has garnered increasing interest. To avoid overloading this paper with references, let us mention that just in 2022–2023, the list of references [6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23] comprises a series of recent articles on the topic. These publications showcase innovative and up-to-date approaches for solar panel cleaning. They explore modern and efficient methods aimed at enhancing the performance and sustainability of solar installations. These recent articles reflect the heightened and continuous focus on optimizing solar energy production by leveraging technological advancements in the field of solar panel cleaning.

2. Deposits and Their Effects

The accumulation of dust on solar panels is a complex phenomenon influenced by a variety of environmental factors, as highlighted in [24]. These elements include wind movement and direction, temperature, solar irradiance, air pollution, atmospheric pressure, dust storms, volcanic activity, snow, and humidity. Each of these parameters plays a crucial role in the amount of dust deposited on the solar panels.

Simultaneously, geographical features and site-specific parameters, such as aridity, the height of the covering material for industrial solar modules, tilt angle, latitude, and longitude, significantly influence the dust accumulation process. These local factors add an additional dimension to understanding how dust settles on solar panels, taking into account the specifics of each context.

Regarding the nature of the dust, it is essential to consider various sources, such as soil, sand, clay, bacteria, carbon, and pollen. Each type of dust may exhibit distinct characteristics that impact the performance of solar panels, necessitating specific approaches for cleaning and maintenance to ensure optimal efficiency.

2.1. The Impact of Dust on Solar Panel Production

The deposition of particles such as dirt and other impurities can lead to various consequences for solar panels. The accumulation of dirt on the panels, as illustrated in Figure 1, restricts the amount of sunlight reaching the cells, creating shading and increasing the temperature. These factors reduce the overall efficiency of the solar system, impacting its operation [25].

Figure 1.

Dust accumulation on the surface of solar panels.

The research assessed the impact of dirt on solar panels by dispersing quantities of 4 g and 8 g of dirt on panels installed at a 35° angle facing south. Power, current, and voltage levels were recorded every hour from 9:30 a.m. to 4:30 p.m. The results indicated a significant difference in voltage values between panels with dirt and uncontaminated panels. This difference gradually decreased until 2:00 p.m. when the curves converged. Panels with 8 g of dirt exhibited slightly higher voltages compared with those with 4 g of dirt [26].

Chena, Y et al. [27] also investigated the impacts of deposits on solar panels. Field trials have demonstrated that as the amount of dust increases, the short-circuit current, open-circuit voltage, and power output of solar panels all diminish. A dust amount of 10 g/m2 can result in a decrease in the maximum power of solar panels by approximately 34% [27]. Table 1 illustrates the loss of output power from photovoltaic panels as a function of dust accumulation.

Table 1.

The reduction in solar intensity received by photovoltaic panels as a function of density g/m2. Data from [28].

Saidan, M et al. [27] measured losses caused by the accumulation of dust on the photovoltaic surface in Baghdad through experiments. The findings indicated that under natural exposure conditions, PV performance decreases by 6.24%, 11.8%, and 18.74% on a daily, weekly, and monthly basis, respectively [27]. This is because of the interaction between sunlight and dust [29]. Some of the solar intensity is absorbed by the dust and transformed into heat, while another portion is scattered on the dust’s surface. Only a fraction of the light intensity reaches the solar panel, reducing the energy entering the panel [29].

2.2. The Impact of Bird Debris and Tree Foliage on Solar Panel Production

Bird debris can also pose a threat to solar panels. When a solar panel becomes obstructed by debris like leaves, dust, bird droppings, or other obstacles, it can significantly diminish its efficiency depending on the panel layout.

2.2.1. Series Configuration

Let us consider two solar panels, designated as A and B, that are connected in series. Each panel consists of two rows of solar cells: A1 and A2 for panel A, and B1 and B2 for panel B. If one of the rows of solar cells, such as A1, is shaded, it will impact the production of the entire panel A.

In this scenario, bypass diodes, also known as “freewheeling” diodes, play a crucial role. They enable the electric current to bypass the shaded row (A1), thus preventing a complete interruption of the current in the circuit. However, even with the bypass diodes in action, the overall production of panel A will be reduced due to shading on row A1.

Given that the solar panels are connected in series, the current flowing through panels is identical. Additionally, the output voltage of the panels adds up. Therefore, if one of the panels, specifically panel A, is shaded, its ability to generate current is hindered. It is important to note that this limitation does not only apply to the shaded panel; it also affects all the other panels connected in series.

The bypass diodes, by allowing the current to bypass the shaded portion, play an essential role in maintaining a continuous current flow in the circuit. However, despite this feature, the overall production of all panels in series will still be constrained by the reduced production of the shaded panel. This interaction between shaded panels and bypass diodes requires careful management to optimize the overall efficiency of the solar system [29].

2.2.2. Parallel Configuration

Imagine we have two solar panels, labeled C and D, connected in parallel. Each panel consists of two rows of solar cells (C1, C2 for panel C, and D1, D2 for panel D). Shading affects the first row of each panel (C1 and D1).

In this parallel configuration, if C1 is shaded:

- The current from C2 is not affected by shading on C1.

- The current from D1 is not affected by shading on C1.

- The total system current is the sum of the currents from C2 and D1. Bypass diodes allow current to bypass C1 and D1.

- Current production from C2 and D2 is not as affected by shading on C1 and D1.

The total current is the sum of the currents from C2 and D2. When solar panels are connected in parallel, the output voltage remains constant, while the output current adds up. If one panel is shaded, it only affects the production of that specific panel. The other unshaded panels continue to generate their normal current. The bypass diode allows current to bypass the shaded portion, but this does not affect the production of other unshaded panels in parallel as significantly. This parallel configuration provides an advantage in shading scenarios, as overall energy production is less affected compared with panels connected in series.

2.3. The Concentration and Type of Deposits Depend on the Region

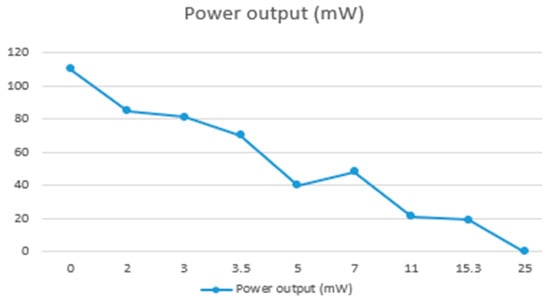

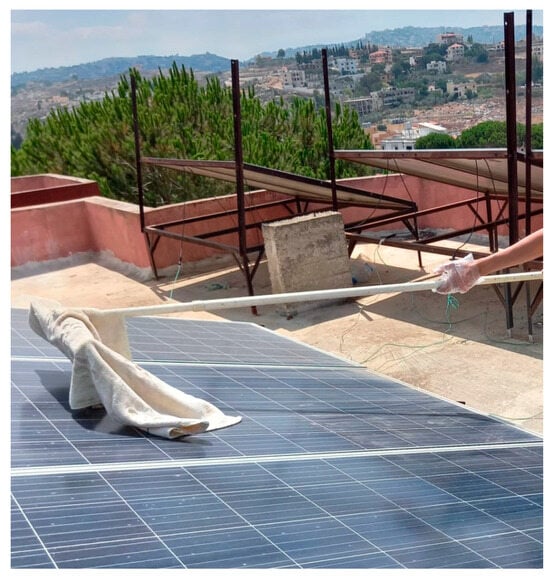

In arid or desert regions where dust and particles are abundant, solar panels tend to rapidly accumulate deposits of dirt and dust. Dust particles can form a thick layer on the panel surface, significantly reducing their ability to absorb solar light. This reduction varies depending on the amount of dust accumulated on the panel, as illustrated in Figure 2. Deposits can also cast shadows on solar cells, leading to a decrease in electricity production [30].

A study conducted by the University of Sharjah in the United Arab Emirates evaluated the performance of solar panels in a desert environment. According to this study, dust on solar panels can result in a reduction in energy conversion efficiency of up to 20% in just one week of exposure [31]. Another study conducted by the University of California, San Diego examined the impact of dust on the performance of photovoltaic panels in the Mojave Desert, United States. According to this study, dust can reduce the efficiency of converting solar energy into electricity by up to 35%, depending on the quantity and nature of the dust present [32].

Figure 2.

The impact of the accumulated dust quantity on solar panel production. Data from [32].

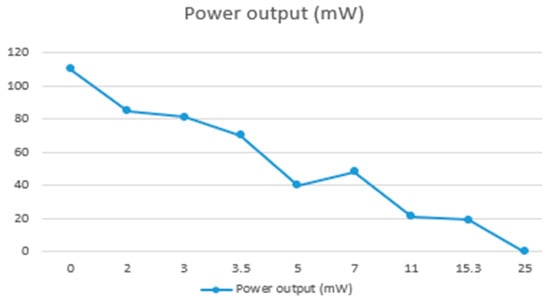

Most studies on dust accumulation and soiling effect on solar panels primarily originate from Asia, as shown in Figure 3. Saudi Arabia is the country with the highest number of research and studies on the soiling effect on solar panels worldwide [33]. There are two main reasons that can explain the dominance of Asia in studies on dust accumulation on solar panel surfaces. Firstly, Asia accounts for a significant portion of new solar installations, representing approximately 60% of all new solar installations worldwide [34]. Secondly, there are vast arid and semi-arid regions in Asia [35]; Asia is considered one of the driest, windiest, and dustiest environments in the world, where the interaction of dust with clouds has a significant impact on the regional climate of Asia. Africa is considered one of the regions with the highest sand and dust accumulation on Earth [34].

Figure 3.

Contribution Impact of dust on PV panels in different continents. Data from [34].

In coastal regions, solar panels are exposed to salt deposits from sea air. Salt can settle on the panels and trigger undesirable chemical reactions, such as material corrosion. Additionally, the sea makes the air humid and rich in sodium chloride. When water containing sodium chloride evaporates, salt crystallizes and forms stubborn deposits on the panel surface. These deposits can be more challenging to remove with a simple water rinse and may require washing with soapy water or mechanical brushing, diminishing the efficiency of the solar panels [36]. A study published in the journal Solar Energy Materials and Solar Cells in 2012 demonstrated that salt-induced corrosion can lead to an efficiency loss of up to 40% in coastal environments [37].

Urban and industrial regions may experience higher levels of air pollution and contaminants due to factors such as traffic, coal-fired power plants, or heavy industries. Water alone is not sufficient for cleaning as the particle levels are high. This type of dirt is sticky and requires more cleaning effort [38].

In regions with regular rainfall and sufficiently inclined module angles, rainwater can effectively remove most of the dirt and deposits from the module surfaces. This reduces the need for frequent cleaning and minimizes performance losses due to soiling. However, special attention should be provided to plant growth, such as moss and lichen, which can develop over time and require specific cleaning to remove them and preserve the performance of the photovoltaic system [39].

The concentration of deposits can also vary based on weather conditions, such as sandstorms, pollution episodes, and even dew and humidity. If dew or humidity persists for extended periods without evaporation, water stagnation on the surface of solar panels may occur. This stagnant water can facilitate the growth of mold, algae, or other undesired organisms, which can affect panel performance and require more thorough cleaning. Dew or humidity can act as a bonding agent, allowing airborne dust particles to adhere to the panel surface and form more stubborn deposits. These factors can lead to faster deposit accumulation and, consequently, a more significant decrease in solar panel performance [40]. The amount of deposits also depends on the tilt of the cells: the lower the tilt, the greater the accumulated dust [40]. It is noted that energy losses are significant in fixed horizontal panels, reaching around 2.2%, whereas they are only 0.61% in panels tilted at 40° [41], as shown in Table 2.

Table 2.

Soiling losses at different tilt angles. Data from [42].

2.4. Influence of Seasonal Effecton Dust Accumulation

The conducted study in [43] focused on the design and experimentation of a self-cleaning system developed for photovoltaic (PV) installations under various climatic conditions in India. This system utilizes a sliding structure to clean solar panels and was compared with a traditional fixed system. The performance of both systems was assessed by monitoring the power output of the PV panels from December 2019 to April 2021. The results demonstrated that the self-cleaning system substantially improved the efficiency of the PV panels during different seasons compared with the fixed system.

During the summer, the self-cleaning system removed daily dust accumulation, resulting in an efficiency increase of 18.3%, see Table 3. In the harvest season, the decrease in performance was attributed to fluctuations in cloud cover affecting exposure time. The self-cleaning system did not exhibit improvement during this period. In the post-monsoon season, improved air quality and reduced dust accumulation led to an efficiency gain of 6.4%. In winter, the self-cleaning system effectively removed bird droppings, insects, and fallen leaves, resulting in an overall efficiency gain of 13.3%. Overall, the study highlighted the significant impact of seasonal changes on the efficiency of solar panel cleaning [43].

Table 3.

Efficiency variation in cleaned and uncleaned PV systems in the summer season. Data from [44].

3. Solar Panel Cleaning Systems

Solar panel cleaning systems are designed to remove dirt, dust, and other debris that can accumulate on the surface of solar panels and reduce their efficiency. There are several methods and technologies for cleaning solar panels as discussed in the following sections.

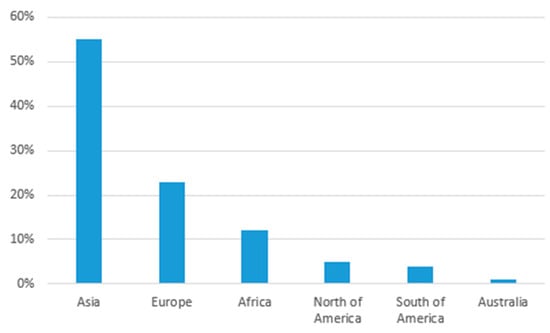

3.1. Manual Cleaning

This generally involves the intervention of professionals, as it can be hazardous and requires proper equipment. However, this method may have little to no impact on the annual performance of the panels unless performed regularly [44]. Manual cleaning tools are associated with high costs due to the significant amount of water used and the required workforce [45]. The workforce involved is primarily unskilled, which could lead to damage to the solar panels. Additionally, skilled workers may carry out inspections simultaneously, further increasing labor costs [46]. A visual illustration of this method can be seen in Figure 4, depicting a professional engaged in manually cleaning solar panels.

Figure 4.

Cleaning of photovoltaic panels.

3.2. Water Spray Nozzle Systems

Water-based cleaning systems for photovoltaic (PV) solar panels are specifically designed devices to clean solar panels using water as the primary cleaning agent. These systems aim to keep the surface of solar panels clean and free from dirt, dust, debris, and other contaminants that could reduce their energy efficiency. At the heart of this innovation lies an underground reservoir specially designed to store the water essential for cleaning operations (see Figure 5. This is not a simple tank but rather a central hub for water management. The reservoir incorporates an intelligent pressure sensor that monitors real-time fluctuations in water levels during cleaning cycles and records precipitation.

Figure 5.

Illustration of a cleaning system on various PV arrays equipped with nozzles.

To ensure uninterrupted water supply, the reservoir is connected to the city’s water network. This strategic connection allows the reservoir to automatically refill as soon as the water level reaches a critical threshold, thereby compensating for losses caused by cleaning and evaporation. This precise synchronization between water demand and replenishment helps to maintain uninterrupted cleaning operations.

Precise Water Flow Control: The cornerstone of these cleaning systems lies in meticulous control of water flow. This precision is achieved through a combination of sophisticated devices. A water meter equipped with a magnetic sensor is installed on the main water supply line, as shown in Figure 5. This meter accurately measures the amount of water added to the reservoir, providing an exact picture of net water consumption.

Data collected by the water depth sensor and the water meter are transmitted to a central data logger. This device plays a central role in regulating the inflow of water into the reservoir via a solenoid valve. Using this real-time information, the system automatically adjusts the amount of water entering the reservoir from the main water supply, thereby optimizing water usage, and minimizing waste [4].

Each PV module is equipped with three cleaning nozzles, as shown in Figure 5, which can be individually activated by a Programmable Logic Controller (PLC) unit through electric solenoid valves. The innovative aspect lies in the ability to adjust the height of the water conduits and nozzles using support studs, enabling experimentation with different heights to optimize the cleaning process.

The power required for cleaning operations is supplied by the photovoltaic modules integrated into the system. These solar panels capture solar energy and convert it into electricity to power the solenoid valves and control devices. This environmentally friendly approach reduces reliance on traditional energy sources, making the system more autonomous and sustainable. Figure 5 depicts a cleaning system across different PV arrays equipped with nozzles, the height of which can be adjusted. The water nozzles can also be fine-tuned to optimize the spray angle, water volume, and pressure. Please observe the shading on the modules due to the piping [47].

Adaptability to Changing Weather Conditions: The efficiency of cleaning operations largely depends on weather conditions. To optimize these operations based on environmental factors, a meteorological station is integrated into the system. Positioned above the ground, this station records a diverse range of data, including atmospheric pressure, temperature, relative humidity, wind speed and direction, as well as solar irradiance.

These meteorological data are used to adjust scheduled cleaning programs. For instance, in the event of imminent precipitation, the system can postpone cleaning to accommodate changing weather conditions. This responsiveness to environmental elements ensures effective and efficient cleaning, thereby contributing to maximizing the performance of the cleaned surfaces.

Intelligent Automation for Optimal Performance: All these technical components come together to create a highly automated and intelligent water-based cleaning system. Pre-programmed cleaning routines are managed by the central data logger. For instance, cleaning sequences can be scheduled to run at regular intervals, ensuring consistent and efficient maintenance of the surfaces.

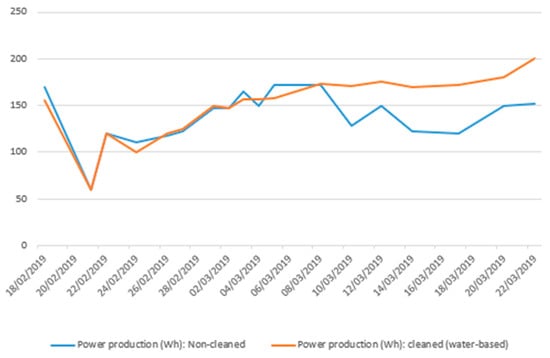

Assessing Water Cleaning Efficiency on Photovoltaic Panel Performance: The photovoltaic system was divided into two distinct sub-networks to evaluate the effectiveness of water cleaning on solar panel performance. Panel arrays connected to the same Maximum Power Point Tracking (MPPT) tracker were included in this study. Over a span of 20 days, two sets of panels were regularly cleaned with water, while the other sets remained uncleaned to serve as a reference group.

The water cleaning protocol was established with a 30 s wetting sequence for each module equipped with water jets. The results clearly demonstrated a significant improvement in the output power of the water-cleaned panel arrays compared with the uncleaned reference arrays. The average power of the cleaned arrays was 177 W, while that of the uncleaned arrays was 140 W, indicating an average increase of around 27% in power for the cleaned arrays (See Figure 6) [47].

Figure 6.

Difference between cleaned and uncleaned panels over a 20 day period. Data from [47].

These findings unequivocally demonstrate that water cleaning has a positive impact on solar panel performance. This enhancement can be attributed to the removal of dirt, dust, and other contaminants from the panel surface, enabling better capture of solar energy.

3.3. Truck-Mounted Cleaning

Cleaning truck-mounted solar panels, as illustrated in Figure 7, is a widely used method for maintaining large solar installations. This system involves the use of a truck or another vehicle equipped with a specially designed brush for cleaning solar panels. The truck moves between rows of photovoltaic modules, effectively cleaning each panel.

Figure 7.

Truck-mounted PV cleaning.

To prevent damage to the panels during cleaning, a brush pressure control system is employed. This system regulates the force with which the brush comes into contact with the panels, ensuring gentle cleaning without the risk of scratches or damage.

However, when cleaning truck-mounted solar panels, certain aspects need to be considered. Firstly, it is necessary to maintain a minimum distance between the rows of panels to allow the truck to pass through. This distance is determined based on the dimensions of the cleaning vehicle.

Additionally, an adequate maneuvering area should be provided at the end of the panel rows. This facilitates smooth U-turns for the truck and ensures seamless navigation during the cleaning process. Proper planning of the maneuvering space is crucial to ensure the efficiency and safety of the cleaning operation.

It is also important to note that the weight of the cleaning equipment mounted on the truck must comply with the manufacturer’s specified tolerances for the solar panels. This ensures that the load exerted on the panels during cleaning remains within recommended limits, avoiding any structural or mechanical damage.

It should be emphasized that cleaning truck-mounted solar panels carries a slightly higher risk of damage compared with other cleaning methods. Uneven ground conditions can create variations in brush pressure, potentially leading to panel damage. Therefore, it is essential to have specially trained and experienced workers to perform the cleaning in a safe and efficient manner [48].

3.4. The Electrodynamic Screen (EDS)

The revolution in solar panel maintenance is underway thanks to the Self-Cleaning Surface Technology (EDS), which is based on a meticulously crafted design. At the heart of this innovation lies a clever architecture that employs interdigitated electrodes arranged in a triphasic layout. These electrodes, designed for conductivity and parallel alignment offer unparalleled flexibility. Moreover, their versatility is further enhanced by the ability to make them transparent or reflective, thus opening the door to various applications. Printed with meticulous precision on substrates such as ultra-thin flexible glass and PET films, these electrodes seamlessly adapt to the curves of solar mirrors and flat photovoltaic panels. The resilience and longevity of this technology are ensured by careful encapsulation using edge-sealing products, creating a protective barrier against demanding environmental conditions. The current geometry of the EDS film, with an electrode width (w) of 80 µm and inter-electrode spacing (s) of 700 µm, is finely tuned to achieve a balance between the efficiency of the generated electrostatic field and the overall structural resistance of the device. This meticulous design elevates EDS to the status of an innovative and efficient solution for solar panel cleaning, thus contributing to the enhancement of solar energy production efficiency [49].

Enhancing Reflectivity with EDS Film Electrodes: Optimizing Solar Mirror Efficiency; The application of EDS film electrodes on solar mirrors aims to enhance their efficiency. These electrodes, printed on ultra-thin glass or PET films, play a crucial role in maximizing reflectivity. The objective is to minimize light absorption and ensure a significant portion of the incident solar energy is directed toward the collector. This strategic approach significantly contributes to the overall performance and efficiency of Concentrated Solar Power (CSP) installations, helping address challenges associated with curved or intricate mirror surfaces that are difficult to clean using conventional methods.

3.5. The “Wash Panel” Cleaning Robot

This robot is designed to clean rows of photovoltaic panels by horizontally moving a vertical brush across the panels, as shown in Figure 8. It has a length ranging from 1 to 16 m and is equipped with a 12 V battery, allowing it to be automatically deployed. Additionally, a water hose is attached to the robot to wet the panels during cleaning. The Wash Panel system is fully autonomous and has dual programmable functionality using a rain sensor and the use of water jets. It ensures consistent and uniform cleaning. This system is modular and can be remotely monitored and managed. It requires no additional framework, support, or additional guides. It can be installed on ground systems, buildings, sloping roofs, or canopies. For continuous monitoring, it sends text messages to mobile phones, enabling remote control from distant locations [45].

Figure 8.

The “Wash Panel” cleaning robot.

The components of the automated robot designed for cleaning solar panels have technical information and specifications as follows: Firstly, rotary brushes are mounted on the side plate structure, with a length of about 2 m. Furthermore, eight wheels, in conjunction with two axles, allow the robot to move smoothly and aid in its transportation, with these wheels moving on the top surface of the solar panels. Additionally, a set of four supporting wheels on each side of the robot moves along the frame of the solar panels to ensure a stable position. The brush driving motor and the wheel driving motor, each with a power of 25 W, utilize DC motors of the ZGX45RGG22.5i model for the brush (with a speed of 250 rpm) and ZGX45RGG36i for the wheels (with a speed of 150 rpm), supplied by Zheng Motor. The structure is augmented by the presence of a side plate as well as the integration of photoelectric sensors. These sensors, in autonomous mode, provide edge-falling protection for the solar panel cleaning robot during its operation. Lastly, the robot’s frame is constructed from aluminum pipe frames, combining strength and lightness for optimal efficiency [50].

Regarding the comparison of dust characteristics, Figure 9 highlights the differences between the solar panel before and after a thorough cleaning.

Figure 9.

Dust characteristics on the solar panels (a) before the cleaning (b) after the cleaning by using the 4 m modular robot.

To assess the effectiveness of the solar panel cleaning robot, a power plant was examined and compared in two adjacent areas, each containing 40 panels. Data were collected for two groups of panels within each set: (1) panels that were not cleaned (control group) and (2) panels that were cleaned by the robot. The overall electricity production of solar cells was compared for the day before and the day after cleaning. The results, presented in Table 4, demonstrate that solar panels cleaned by the robot experienced an increase of approximately 3.40% in their electricity production. However, it is important to note that the efficiency of the electricity production increase might be more significant if the solar panels were heavily soiled [50].

Table 4.

The comparison of the generated current before and after cleaning with robot. Data from [50].

3.6. Aerial Cleaning by Drones

Cleaning solar panels by drone involves using specially designed drones to remove contaminants such as dust, dirt, and impurities that accumulate on the surface of photovoltaic solar panels. By harnessing the powerful downward thrust of their motors, drones create a strong airflow directed towards the panels. This airflow effectively displaces small undesirable particles that have built up on the solar panels. As the drone’s propelled air passes over the panel’s surface, it ejects these particles, thereby distancing them from the surface. This cleaning action effectively rids the solar panels of dust and impurities, thereby enhancing their ability to efficiently capture and convert solar energy into electricity.

- Key Components for Solar Panel Cleaning Using Drones:

The main components used for cleaning solar panels with a drone include the drone itself equipped with propellers to generate downward airflow, as well as sensors and cameras to guide the drone and monitor the cleaning process. The drone is programmed to follow specific trajectories over the solar panels, using the airflow to remove dust and contaminants accumulated on their surface. See Figure 10.

Figure 10.

Drone used for panel cleaning.

- Optimizing Drone Trajectories for Precise and Efficient Solar Panel Cleaning:

Drones utilize advanced planning algorithms that take into account several key factors. At the beginning of the process, data about the layout of solar panels and the surrounding environment are collected. This information is used to create a virtual map of the area to be cleaned. Subsequently, elements such as the size, shape of the panels, the location of potential obstacles, and the amount of dirt present are considered. Using this information, the algorithm calculates the most efficient trajectory. These trajectories vary and include horizontal, vertical, and diagonal movements above the solar panels. Each trajectory is meticulously planned to enable the drone to cover the entire surface of the panels while leveraging the downward airflow generated by the drone’s propellers. This approach ensures uniform and comprehensive coverage of the surface, effectively removing unwanted particles such as dust and dirt [51].

- Influence of Drone Flight Patterns on Solar Panel Energy Production Efficiency Across Dust Levels:

Rehman, S et al. [51] conducted studies on the impact of varying dust levels (20 CC, 50 CC, and 100 CC (where CC denotes dust volume in Cubic Centimeter)) on optimal drone flight patterns and their influence on the efficiency of solar panel energy production. The data demonstrate that different flight patterns have a direct impact on cleaning performance and energy efficiency. Significant advantages of the horizontal flight pattern were observed for dust levels of 20 CC and 100 CC, while for a dust level of 50 CC, all flight patterns exhibited comparable efficiency. Specifically, the results showed an efficiency of 31.90% with a horizontal flight pattern for a dust level of 20 CC, 69.40% with the same pattern for a dust level of 100 CC, and comparable results for a dust level of 50 CC with different flight patterns.

3.7. The Resola Robot by Sinfonia

The Resola robot developed by Sinfonia stands out for its “autonomous” nature, in that, instead of being attached to rails, it is capable of moving from one panel to another to clean up accumulated dirt and debris. The Resola robot moves from one panel to another using its autonomous operating mode. Unlike traditional robots that are often attached to rails to move along solar panels, the Resola is equipped with intelligent movement mechanisms that allow it to move horizontally and autonomously from one panel to another without requiring rails or guides [52].

This autonomous movement mode is made possible through a combination of sensors and advanced navigation algorithms. The robot is capable of detecting the edges of solar panels and following precise trajectories based on the specific panel layout. These sensors, which may include proximity sensors, motion sensors, and cameras, enable the Resola to move with precision, avoid obstacles, and stay on the surface of the panels.

The robot is equipped with a cleaning brush, a wiper, detergent, and a water reservoir. It can also spray water stored in its reservoir. Additionally, the robot can operate in the dark thanks to infrared LED lights emitting specific wavelengths. The key components of the Resola robot include the cleaning brush, wiper, water, and detergent reservoir, rain sensors, and infrared LED lights. The brush and wiper provide mechanical cleaning, while the rain sensors and infrared lights enhance its autonomous functionality.

An evaluation of the impact of the Resola robot on energy production reveals a positive influence. Comparative tests between panels cleaned by the Resola and those left uncleaned demonstrated a notable increase in energy production of about 4.5% over a three-month period. Regular cleaning assisted by the robot maintained cleaner panel surfaces, contributing to better absorption of solar light and an increase in energy production.

3.8. Self-Cleaning and Tracking Solar Photovoltaic Panels

Bandam et al. [53] developed an innovative system aimed at optimizing the efficiency of solar panels by incorporating a self-cleaning and tracking mechanism. In this model, direct current (DC) motors were utilized, operating at speeds of 1000 RPM and 10 RPM for the cleaning and tracking operations respectively. A threaded rod was connected to the DC motor dedicated to cleaning. This threaded rod is equipped with a wiper that moves downward when the motor rotates in the forward direction, and vice versa. Consequently, the cleaning of the solar panels is performed by this wiper attached to the threaded rod.

For sun tracking, the system also integrates a microcontroller. This microcontroller plays a crucial role in facilitating both the automatic cleaning of the panels and their orientation based on the sun’s position. The necessary information for this operation is gathered from Light Dependent Resistors (LDRs). LDRs are sensitive to light intensity, and their resistance varies accordingly. Generally, their resistance increases in darkness and decreases significantly in the presence of light.

The algorithm developed by the researchers enables the microcontroller to process the data provided by the LDRs and generate commands for the DC motors. These commands are intended to ensure both effective panel cleaning and adjustment to follow the sun’s trajectory throughout the day.

4. Desirable and Undesirable Features for Solar Panel Cleaning Methods

A comprehensive overview of both desirable and undesirable features to consider when evaluating different methods for cleaning solar panels is summarized in Table 5. It delves into key factors such as efficiency, safety, cost-effectiveness, and environmental impact, providing criteria to measure and compare the strengths and weaknesses of the cleaning methods.

Table 5.

Desirable and undesirable features for solar panels cleaning systems.

To select the most promising cleaning method can be handled by weighting the different criteria by factors that depend on the user and the specific installation. Each solar project may indeed have unique needs and constraints. For instance, a user may prioritize cost-effectiveness if operating within a tight budget, while another user might emphasize efficiency if aiming to maximize energy production. Likewise, the geographical location of the installation, local weather conditions, the availability of water resources, and other environmental factors will play a crucial role in selecting the most suitable method. By considering these criteria and weighing them according to specific needs, one can arrive at a more informed choice tailored to each individual situation.

Selection of the most promising cleaning method can be made by weighing the various criteria by factors that depend on the user and the specific installation. Each solar project may indeed have unique needs and constraints. For example, one user may prioritize profitability if they are operating on a tight budget, while another user may emphasize efficiency if the aim is maximizing energy production. Likewise, the geographic location of the facility, local weather conditions, availability of water resources and other environmental factors will play a crucial role in choosing the most suitable method. By considering these criteria and weighting them according to specific needs, we can arrive at a more informed choice adapted to each individual situation.

5. Cost–Benefit Analysis

The Multi-Criteria Decision Analysis (MCDA) method is a decision analysis approach aimed at assisting decision-makers in making complex decisions while simultaneously considering multiple criteria or factors. It is particularly useful when you need to choose between different options or alternatives, each with its own pros and cons, and when you want to make a decision based on an overall assessment. In the context of evaluating solar panel cleaning methods, the MCDA method enables us to make an informed decision by taking various aspects into account, such as efficiency, safety, profitability, water conservation, environmental impact, and many others [54]. Table 6 provides a qualitative assessment of the different cleaning methods based on each criterion.

Table 6.

Multicriteria decision analysis (MCDA).

The table we created uses the MCDA method to evaluate each cleaning method based on these criteria. Each criterion is rated from 1 to 5, where 1 represents the least favorable performance and 5 the most favorable performance. These ratings are assigned based on each method’s ability to meet each criterion.

For example, for efficiency, a highly effective method will receive a high score (5), while a less effective method will receive a lower score (e.g., 3). This process is repeated for each criterion, allowing for the quantification of each method’s performance across all criteria.

The “Overall Score” is then calculated by averaging the ratings assigned to each method. This overall score provides a consolidated view of each method’s overall performance, taking into account all the criteria. It can serve as a guide to make an informed decision when selecting the solar panel cleaning method that best suits the specific needs of an installation, considering both technical and economic aspects [55].

The overall score is calculated as follows

where Ci is the weighting factor of the i-th criterion and N the number of criteria.

After using Multi-Criteria Decision Analysis (MCDA) to evaluate different solar panel cleaning technologies based on criteria such as cleaning efficiency, cost, durability, environmental impact, and ease of use, it is evident that the Resola robot by Sinfonia emerges as the best option. It is important to note that this conclusion is specific to our analysis and the criteria we chose.

6. Conclusions

This article provides a comprehensive overview of the cleaning aspects of solar panels through a literature review. Undesirable deposits on solar panels can have negative effects on energy production and efficiency. This article presents existing cleaning practices and technologies, with an emphasis on factors such as facility size, location, cost, and available resources.

Furthermore, a comparative cost–benefit analysis is conducted using one possible decision support technique, namely MCDA, taking into account different relevant criteria. This enables users to select the appropriate maintenance and cleaning method for their specific solar installation [56].

Overall, this paper highlights the importance of cleaning solar panels to optimize their energy production and efficiency. It provides readers with a thorough understanding of existing cleaning practices, as well as key factors to consider when choosing the appropriate cleaning method. This information can assist solar system owners and operators in making decisions to ensure the optimal performance of their solar panels with regard to cleaning.

Author Contributions

The paper was a collaborative effort among the authors. N.N. and A.R. collectively contributed to the survey of Solar Panel Cleaning Systems and Techniques. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Connaissance des Énergies. Available online: https://www.connaissancedesenergies.org/levolution-du-mix-electrique-mondial-en-2022-en-2-infographies-230413 (accessed on 12 August 2023).

- France Territoire Solaire. Available online: https://franceterritoiresolaire.fr/developper-le-solaire-permet-il-vraiment-de-diminuer-les-emissions-de-co2/ (accessed on 12 August 2023).

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Al-Goul, M.A.; Alawadhi, H. Effect of dust pollutant type on photovoltaic performance. Renew. Sustain. Energy Rev. 2014, 41, 735–744. [Google Scholar] [CrossRef]

- Gochhait, S.; Asodiya, R.; Hasarmani, T.; Patin, V.; Maslova, O. Application of IoT: A Study on Automated Solar Panel Cleaning System. In Proceedings of the 4th International Conference on Electrical, Control and Instrumentation Engineering (ICECIE), Kuala Lumpur, Malaysia, 26 November 2022. [Google Scholar] [CrossRef]

- Said, S.A.; Walwil, H.M. Fundamental studies on dust fouling effects on PV module performance. Sol. Energy 2014, 107, 328–337. [Google Scholar] [CrossRef]

- Myyas, R.N.; Al-Dabbasa, M.; Tostado-Véliz, M.; Jurado, F. A novel solar panel cleaning mechanism to improve performance and harvesting rainwater. Sol. Energy 2022, 237, 19–28. [Google Scholar] [CrossRef]

- Tilmatine, A.; Kadous, N.; Yanallah, K.; Bellebna, Y.; Bendaoudi, Z.; Zouaghi, A. Experimental investigation of a new solar panels cleaning system using ionic wind produced by corona discharge. J. Electrost. 2023, 124, 103827. [Google Scholar] [CrossRef]

- Nomeir, B.; Lakhouil, S.; Boukheir, S.; Ali, M.A.; Naamane, S. Recent progress on transparent and self-cleaning surfaces by superhydrophobic coatings deposition to optimize the cleaning process of solar panels. Sol. Energy Mater. Sol. Cells 2023, 257, 112347. [Google Scholar] [CrossRef]

- Ma, J.; Youn, J.-H.; Cho, H.; Park, J.; Kyung, K.-U. Highly efficient long-lasting triboelectric nanogenerator upon impact and its application to daily-life self-cleaning solar panel. Nano Energy 2022, 103, 107836. [Google Scholar] [CrossRef]

- Seifi, A.; Salari, D.; Khataee, A.; Çoşut, B.; Arslan, L.; Niaei, A. Enhanced photocatalytic activity of highly transparent superhydrophilic doped TiO2 thin films for improving the self-cleaning property of solar panel covers. Ceram. Int. 2023, 49, 1678–1689. [Google Scholar] [CrossRef]

- Jaiganesh, K.; Reddy, K.B.S.; Shobhitha, B.; Goud, B.D. Enhancing the efficiency of rooftop solar photovoltaic panel with simple cleaning mechanism. Mater. Today Proc. 2021, 51, 411–415. [Google Scholar] [CrossRef]

- Kawamoto, H.; Tanabe, J.; Kobayashi, Y. Airflow-assisted electrodynamic cleaning of sand deposited on solar panels. J. Electrost. 2021, 113, 103618. [Google Scholar] [CrossRef]

- Derakhshandeh, J.F.; AlLuqman, R.; Mohammad, S.; AlHussain, H.; AlHendi, G.; AlEid, D.; Ahmad, Z. A comprehensive review of automatic cleaning systems of solar panels. Sustain. Energy Technol. Assess. 2021, 47, 101518. [Google Scholar] [CrossRef]

- Ko, K.; Yoon, D.; Yang, S.C.; Lee, H.S. Brush-painted superhydrophobic silica coating layers for self-cleaning solar panels. J. Ind. Eng. Chem. 2021, 106, 460–468. [Google Scholar] [CrossRef]

- Li, D.; King, M.; Dooner, M.; Guo, S.; Wang, J. Study on the cleaning and cooling of solar photovoltaic panels using compressed airflow. Sol. Energy 2021, 221, 433–444. [Google Scholar] [CrossRef]

- Divya Vidya, K.; Abirami, S.; Jaganayaki, S.; Jayanthi, A.N. Solar panel cleaning robot. Int. J. Sci. Res. Eng. Manag. 2023. [Google Scholar] [CrossRef]

- Venkatnikhil, A.; Ravichandran, S.; Kumar, N.K.H. Rover Robot for Solar Panel Cleaning and Monitoring. In Proceedings of the IEEE North Karnataka Subsection Flagship International Conference (NKCon), Vijaypur, India, 20–21 November 2022. [Google Scholar] [CrossRef]

- Muhammad, A.B. Automatic Solar Panel Cleaning Benefits. Gobal J. Res. Eng. Comput. Sci. 2023, 3, 26–31. [Google Scholar]

- Jothi Venkatesh, K.; SankaraNarayanan, S.; Kannan, K.; Arjun, P. AI Based Solar Panel Cleaning Robot. Int. J. Eng. Technol. Manag. Sci. 2023, 7, 313–318. [Google Scholar] [CrossRef]

- Baballe, M.A. Review of the Literature on Robotic Solar Panel Cleaning. Glob. J. Res. Eng. Comput. Sci. 2023, 3, 21–25. [Google Scholar] [CrossRef]

- Omar, M.; Arif, A.; Usman, M.; Khan, S.S.; Larkin, S. Self-cleaning solution for solar panels. SAIEE Afr. Res. J. 2023, 114, 58–66. [Google Scholar] [CrossRef]

- Tripathi, A.K.; Aruna, M.; Ray, S.; Rao, N.G.; Vamshni Krishna, S.; Nandan, D. Development and Evaluation of Dust Cleaning System for a Solar PV Panel. J. Eng. Res. 2022. [Google Scholar] [CrossRef]

- Deb, D.; Bhargava, K. Water-free automated solar-panel cleaning. In Degradation, Mitigation, and Forecasting Approaches in Thin Film Photovoltaics; Elsevier: Amsterdam, The Netherlands, 2022; pp. 73–84. [Google Scholar]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Nahoui, A.; Haddad, Z.; Tahrour, F. Etude Expérimentale de L’effet de la Poussière et de Fientes des Oiseaux sur le Fonctionnement des Panneaux Solaires Photovoltaïques pour le Site de M’sila. Master’s Thesis, Université Mohamed Boudiaf, M’sila, Algérie, 2022. [Google Scholar]

- SciencePost. Available online: https://sciencepost.fr/depoussierer-panneaux-solaires-economies/ (accessed on 12 August 2023).

- Saidan, M.; Albaali, A.G.; Alasis, E.; Kaldellis, J.K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew. Energy 2016, 92, 499–505. [Google Scholar] [CrossRef]

- Majeed, R.; Waqas, A.; Sami, H.; Ali, M.; Shahzad, N. Experimental investigation of soiling losses and a novel cost-effective cleaning system for PV modules. Sol. Energy 2020, 201, 298–306. [Google Scholar] [CrossRef]

- Blog Seatronic. Available online: http://blog.seatronic.fr/fiches-pratiques/energie/production/panneaux-solaires/regulateur/ (accessed on 12 August 2023).

- LinkedIn. Available online: https://www.linkedin.com/pulse/how-protect-your-solar-from-bird-poo-climateshield-solar/ (accessed on 12 August 2023).

- Kazem, H.A.; Chaichan, M.T. The effect of dust accumulation and cleaning methods on PV panels’ outcomes based on an experimental study of six locations in Northern Oman. Sol. Energy 2019, 187, 30–38. [Google Scholar] [CrossRef]

- Nour-Eddine, I.O.; Lahcen, B.; Fahd, O.H.; Amin, B.; Aziz, O. Outdoor performance analysis of different PV technologies under hot semi-arid climate. Energy Rep. 2020, 6, 36–48. [Google Scholar] [CrossRef]

- Costa, S.C.; Diniz, A.S.A.; Kazmerski, L.L. Dust and soiling issues and impacts relating to solar energy systems: Literature review update for 2012–2015. Renew. Sustain. Energy Rev. 2016, 63, 33–61. [Google Scholar] [CrossRef]

- Menoufi, K. Dust Accumulation on the Surface of Photovoltaic Panels: Introducing the Photovoltaic Soiling Index (PVSI). Sustainability 2017, 9, 963. [Google Scholar] [CrossRef]

- Huang, J.; Wang, T.; Wang, W.; Li, Z.; Yan, H. Climate effects of dust aerosols over East Asian arid and semiarid regions. J. Geophys. Res. Atmos. 2014, 119, 11398–11416. [Google Scholar] [CrossRef]

- Grando, M.N.G.N.; Maletz, E.R.; Martins, D.; Simas, H.; Simoni, R. Robots for Cleaning Photovoltaic Panels: State of the Art and Future Prospects. Rev. Tecnol. Cienc. 2019, 35, 137–150. [Google Scholar] [CrossRef]

- Plischke, E. An adaptive correlation ratio method using the cumulative sum of the reordered output. Reliab. Eng. Syst. Saf. 2011, 107, 149–156. [Google Scholar] [CrossRef]

- Eco Green Energy. Available online: https://www.eco-greenenergy.com/fr/comment-tester-un-panneau-solaire-1-salt-mist-test-de-corrosion-saline/ (accessed on 12 August 2023).

- Marathe, S.A.; Patil, B.P. Mechanisms for Improving the Productivity of the Existing Photovoltaic Panels. In Proceedings of the International Conference on Computational Performance Evaluation (ComPE), Hillong, India, 4 July 2020. INSPEC Accession Number: 19986470. [Google Scholar] [CrossRef]

- Ekinci, F.; Yavuzdeğer, A.; Nazlıgül, H.; Esenboğa, B.; Mert, B.D.; Demirdelen, T. Experimental investigation on solar PV panel dust cleaning with solution method. Sol. Energy 2022, 237, 1–10. [Google Scholar] [CrossRef]

- Saravanan, V.S.; Darvekar, S.K. Solar Photovoltaic Panels Cleaning Methods: A Review. Int. J. Pure Appl. Math. 2018, 118, 1–17. [Google Scholar]

- Cano, J.; Tamizhmani, G.; Macia, N.F. Photovoltaic Modules: Effect of Tilt Angle on Soiling; Arizona State University: Tempe, AZ, USA, 2011. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, M.; Pachauri, R.; Babu, K.N.D. Design and development of self-cleaning PV sliding system. Clean Energy 2022, 6, 392–403. [Google Scholar] [CrossRef]

- Alshehri, A.; Parrott, B.; Outa, A.; Amer, A.; Abdellatif, F.; Trigui, H.; Carrasco, P. Dust mitigation in the desert: Cleaning mechanisms for solar panels in arid regions. In Proceedings of the Saudi Arabia Smart Grid Conference (SASG), Jeddah, Saudi Arabia, 14–17 December 2014. [Google Scholar] [CrossRef]

- Patil, P.A.; Bagi, J.S.; Wagh, M.M. A review on cleaning mechanism of solar photovoltaic panel. In Proceedings of the International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017. [Google Scholar] [CrossRef]

- ESI Africa. Available online: https://www.esi-africa.com/energy-efficiency/how-to-clean-your-pv-solar-panels/ (accessed on 12 August 2023).

- Alghamdi, A.S.; Bahaj, A.B.S.; Blunden, L.S.; Wu, Y. Dépoussiérage des modules solaires photovoltaïques par des systèmes de nettoyage automatisés. Energies 2019, 12, 2923. [Google Scholar] [CrossRef]

- Ferretti, N. PV Module Cleaning Market Overview and Basics; PI Photovoltaik-Institut Berlin AG: Berlin, Germany, 2018. [Google Scholar]

- Bernard, A.R.; Eriksen, R.; Horenstein, M.N.; Mazumder, M.K. Dust Settles, We Don’t: The Electrodynamic Screen—A Self-Cleaning Technology for Concentrated Solar Power Mirrors and Photovoltaic Panels; Cambridge University Press: Cambridge, UK, 2018; Volume 5. [Google Scholar]

- Chailoet, K.; Pengwang, E. Assembly of Modular Robot for Cleaning Various Length of Solar Panels. IOP Conf. Ser. Mater. Sci. Eng. 2019, 639, 012014. [Google Scholar] [CrossRef]

- Rehman, S.; Mohandes, M.A.; Hussein, A.E.; Alhems, L.M.; Al-Shaikhi, A. Cleaning of Photovoltaic Panels Utilizing the Downward Thrust of a Drone. Energies 2022, 15, 8159. [Google Scholar] [CrossRef]

- Renewable Energy World. Available online: https://www.renewableenergyworld.com/om/from-module-cleaning-robots-to-flying-drones-japans-growing-solar-o-m-market/#gref (accessed on 12 August 2023).

- Bandam, A.; Panchal, A.K. Self-cleaning and tracking solar photovoltaic panel for improving efficiency. In Proceedings of the 2nd International Conference on Advances in Electrical, Electronics, Information, Communication and Bio-Informatics (AEEICB), Chennai, India, 28 February 2016. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A review of multi-criteria decision-making applications to solve energy management problems: Two decades from 1995 to 2015. Renew. Sustain. Energy Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. An AHP-based multi-criteria model for sustainable supply chain development in the renewable energy sector. Expert Syst. Appl. 2020, 150, 113321. [Google Scholar] [CrossRef]

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F.; Zhao, J.-H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).