Abstract

This paper presents an analysis of the costs, failure rate, vulnerability, and safety of electric, hybrid, and internal combustion vehicles (EV, HEV, and ICEV), including a review of literature sources, calculations, and investigations. Many literature sources do not provide information on maintenance costs (including repairs and servicing) and limit themselves to energy costs only. However, this cost is not the total cost of the maintenance of a vehicle. There is a lack of analysis of the difference between the maintenance and operating costs of vehicles. Similarly, vulnerability is difficult to determine in vehicles that are used for a short time in the market. The article presents an analysis of literature sources and industry reports on electromobility on maintenance costs, determines the failure rate, calculates vulnerability indices based on a survey, and carries out an expert risk assessment using the FMEA method. In the surveyed companies, the largest percentage of repairs are maintenance and service, mechanical, electrical and electronic, bodywork, and other repairs for each vehicle. Some of the most common faults in electric and hybrid vehicles are battery failures. The only hazard with a tolerable impact is the lack of sufficient data in the maintenance analysis. This risk can be mitigated in subsequent stages of product readiness once more data have been analysed.

1. Introduction

Every machine in the operating phase should fulfil the purpose for which it was designed and manufactured. The suitability of a machine to meet societal needs is expressed by its operational quality. This is characterised by a set of characteristics that, shaped in the design and manufacturing phases, determine the actual degree to which it meets the current requirements of the user. Operational quality is defined by such characteristics as:

- Suitability:

- Reliability (reparability, serviceability, durability, non-damaging, diagnosability, durability, safety, work quality, productivity, throughput, material loss, process cleanliness);

- cost-effectiveness (application efficiency, acquisition costs, and operating costs).

Operational susceptibility, therefore, will determine the degree of adaptability of the machine to operation under established conditions determined by the characteristics of the operating system and environmental conditions [1,2]. We can divide it into:

- -

- Vulnerability in use—this is the adaptation of the equipment to the realisation of the mechanism of use. It depends on the operational susceptibility, adaptation to the operating system, availability of the device (this results from the reliability of the equipment or machinery, its speed, and ease of start-up), efficiency (determined by the technical parameters of the equipment and machinery), scope of its use, ergonomics, non-obtrusiveness to the natural environment, and user safety.

- -

- Service and repair vulnerability— the equipment’s adaptability to refilling of operating fluids, adjustment, overhaul and inspection, and lubrication. It is determined by the susceptibility to maintenance and repair, storage, condition monitoring, and transport, as well as the safety of handling and ergonomics;

- -

- Diagnostic vulnerability—the adaptation of a device or machine to perform a series of actions that enable obtaining information about its technical condition in a non-invasive way. This facilitates decision-making about the further operation or use of the equipment or machine.

It is also very important to adapt the machinery or equipment to its overhaul and maintenance requirements (lubrication, cleaning, and maintenance). According to the Encyclopaedia of Management, maintenance susceptibility occurs when the lubrication systems are mechanised and centralised and the lubricants that are used are the same for the whole machine. Maintenance vulnerability (maintenance technology), therefore, is determined by standardisation of parts, convenience of the conditions under which the overhaul takes place (e.g., possibility of ventilating the room, availability of spare parts, separability of parts, ease of assembly of parts and their reconditioning, easy transport, and ease of adjustment of assembly [1,2,3,4].

Despite the numerous advantages and benefits of using BEVs (battery electric vehicles), potential users express concerns about the maintenance and use of battery electric cars. Drivers are concerned about their limited range and insufficient charging capabilities. They may have to change their travel routines when they switch from a conventional gasoline vehicle (with an internal combustion engine) to a BEV. The concern that the vehicle has insufficient range to reach its destination has been shown to be a significant obstacle to the acceptance on BEVs in the market. In a survey carried out among electric vehicle technology enthusiasts and potential buyers, range limitations were considered the biggest problem. Range anxiety among drivers arises when they are not able to predict the battery’s remaining range or when their trips are unexpectedly extended. A possible solution to this problem is better (more efficient) use of battery capacity by providing drivers with more reliable range estimates [5]. Other literature data indicate three concerns that prevent potential consumers from accepting BEVs [6,7,8], as follows:

- -

- The first is the limited driving range on electric power only, which refers to the total distance a BEV can travel with a fully charged battery (in this study, the driving range is called the battery range). Drivers are concerned about finding public charging stations when they need to charge an electric vehicle because charging stations are not as ubiquitous as gas stations.

- -

- Another problem is the long charging time and the inconvenience associated with it. Unlike refuelling an internal combustion engine vehicle (ICEV), which can be done in minutes, a full charge of a BEV can take several hours, depending on the battery capacity and the charging power.

- -

- The third problem is the relatively high price of BEVs.

Concern about battery capacity is currently one of the biggest barriers to the purchase of an EV. The solutions to this problem include two main options for extending the range of a BEV: increased battery capacity and better availability of fast charging infrastructure [9,10].

With growing environmental concerns and energy crises, the automotive industry is undergoing a profound technological transformation from internal combustion engine vehicles (ICEVs) to low-emission vehicles (LEVs). LEVs consist of battery electric vehicles (BEVs), hybrid electric vehicles (HEVs), and fuel cell electric vehicles (FCEVs). Technological changes could revolutionise the fundamentals of the automotive industry [11]. In particular, the drivetrain of BEVs can replace components of the drivetrain of ICEVs with battery packs, an electric motor, and a charger [12]. As an emerging clean-energy technology, BEVs are enjoying increasing global interest and are experiencing continued growth in many countries’ markets. Many studies focus on technological innovation (TI) at the national level, which has the advantage of explaining how to improve LEV technology development over time due to the close relationship between embedded territoriality and spatially dispersed external effects. However, the mode of innovation and product characteristics in the BEV industry are changing [11].

The actual distance an electric vehicle can travel with a fully charged battery varies considerably in real-world driving conditions due to a number of factors, including driving style, traffic conditions, terrain, ambient temperature, and the use of air conditioning and other auxiliary systems (auxiliary operations such as defrosting and heating consume 10 to 50 percent of the energy) [13]. To determine the optimal (minimum) required battery range, the following key factors must be considered:

- -

- Users’ travel requirements (e.g., travel distance and travel start and end locations);

- -

- Charging infrastructure (e.g., the locations of home, work, and public charging stations); and

- -

- Individual charging behaviour (e.g., in what conditions drivers charge BEVs) [8].

An analysis of literature sources indicates a continued increase in the number of BEVs on the market and the development of systems that support energy management. In recent years, the concept of charge scheduling has also emerged to optimise travel time and distance. All these activities are aimed at increasing the users’ awareness of the operation and use of BEVs, reducing fear of BEV use, and increasing the number of these vehicles on the market.

The growing energy crisis and ongoing pollution problems have forced the replacement of vehicles powered by traditional fuels with electric cars [14,15]. In 2020, the transportation sector accounted for 27% of total U.S. greenhouse gas (GHG) emissions, and more than 97% of these GHG emissions were carbon dioxide (CO2) emissions from fossil fuel vehicles, as indicated by U.S. EPA data from 2022 [16]. Globally, the major emitter of air pollutants and GHGs is the transportation segment. Numerous studies point to the use of electric vehicles as promising for the environment with low CO2 emissions and moving towards sustainability. Climate change is forcing us to find alternative energy sources and solutions to protect the environment and air [17,18,19].

The article presents issues related to the operation and use of electric, hybrid, and internal combustion vehicles. It analyses operating costs (servicing and repairs), failure rates, and the safety of electric, hybrid, and internal combustion vehicles. The final issue addressed in this thesis is the calculation of vulnerability indices for electric and hybrid vehicles. The purpose of the publication is to analyse the maintenance costs, failure rate, safety, and vulnerability of electric and hybrid vehicles compared to internal combustion vehicles. The intermediate goal is to present all four aspects of the use of electric and hybrid vehicles compared to internal combustion vehicles, which, through their presence on the market for a long time, have been extensively analysed. A study was conducted to analyse the maintenance costs of electric and hybrid vehicles based on available literature sources. An assessment of the significance of the change for electric and hybrid vehicles (considering them as a system, according to Regulation No. 402/2013) was determined using the FMEA method for risk assessment. Finally, an estimation of vulnerability indicators based on the RAMS standard and available literature was applied.

2. Materials and Methods

2.1. Costs

An analysis of literature sources on the maintenance, servicing, and repair costs of electric, hybrid, and combustion-powered vehicles was carried out. Literature sources of scientific publications from the last 5 years were used in the analysis. In addition, a survey was used to determine the rates for vehicle servicing and maintenance. A total of 50 car workshops and authorised service centres from the largest cities in Poland participated in the survey. The survey comprised 10 questions in various forms. The results are presented in Section 3.1. The research was carried out using a quantitative method with the use of modern research methods, and the entire study was carried out through an electronic survey. A total of 50 interviews were scheduled, and the target group was car repair shops and authorised car service centres. The survey was conducted using a wide range of ways to reach respondents, both in the form of direct contact and via the Internet. Telephone interviews were conducted using an electronic survey on mobile devices, an online survey on social media, and an online survey sent by email. The survey was conducted between 4 May and 15 June 2023.

Prices for services were converted using the exchange rate from the National Bank of Poland on 27 July 2023.

2.2. Failure Rate

A questionnaire survey involving workshops, cars, and authorised vehicle services from the largest cities in Poland was carried out to determine the breakdown and susceptibility to breakdown, repair, and servicing of electric, hybrid, and internal combustion vehicles. Fifty questionnaires were obtained for the survey. The survey consisted of 10 questions of a different nature, concerning the most frequently repaired and serviced parts of these vehicles. The research was carried out using a quantitative method with the use of modern research methods, and the entire study was carried out through an electronic survey. A total of 50 interviews were scheduled, and the target group was car repair shops and authorised car service centres. The survey was conducted using a wide range of ways to reach respondents, both in the form of direct contact and via the Internet. Telephone interviews were conducted using an electronic survey on mobile devices, an online survey on social media, and an online survey sent by email. The survey was conducted between 4 May and 15 June 2023. The main statistical analysis used in this paper is descriptive statistics, which summarises data using indicators such as mean and median.

2.3. Safety

2.3.1. Preliminary Definition of the System under Change

The system subject to change relevance assessment is an intelligent fleet management system for electric vehicles and charging stations implemented to optimise maintenance costs and the introduction of low-carbon transport by businesses. It is a business-facing system that will develop a decision-making model for transitioning to and investing in car charging systems, together with a business model and economic analyses to assist in making business decisions to maintain and/or expand or move away from investing in charging systems. The system will be part of stimulating decision-making in the purchase of electric cars by companies that own car fleets and use them in their business in a rational way, taking into account the needs of the company. Research on the operational vulnerability of alternative energy vehicles was carried out, and the significance of the change was assessed in relation to the operational vulnerability of alternative energy vehicles.

2.3.2. Technical System

The system will allow decisions to be made regarding the transition and investment in electric car charging systems. The system will identify economic analyses that will assist in making business decisions to maintain, develop, or move away from investing in charging systems. The results will allow decisions on the purchase of electric cars to be made by companies that own car fleets and use them in their business in a rational way, taking into account the needs of the company.

2.3.3. Information System

As far as the functionality of the system is concerned, it will be possible to connect external data sources such as electricity tariffs (cost per kWh), method of charging (alternating current, direct current, etc.), charging times, fuel prices, vehicle prices, vehicle characteristics, characteristics of the client’s territory/area (mountains, plains), tax relief/surcharges, weather conditions, the driver’s driving style, and vehicle load. The system assumes the possibility of entering company parameters such as typical routes, driving style of the driver, average mileage, and owned resources (e.g., a photovoltaic power plant). The system will make it possible to calculate the level of profitability of investment in an electric vehicle fleet, including in terms of maintenance parameters.

2.3.4. Human Factor

The system will indicate the possibility of making business decisions concerning the transition and investment in electric car charging systems for businesses using the car fleet. The system assumes the possibility of generating reports on the payback period, the level of savings, investment suggestions, and a hierarchy of decision options so that the business can select the option that is beneficial for the company.

2.4. Criteria and Determination of the Significance of the Change

2.4.1. Failure Consequence

At the current stage of the project, the Team considered that, with regard to the effects of a system failure, the significance of the changes in relation to technology, the IT system, and the human factor is relatively low. The failure will not directly affect the security of the organisation’s processes (in terms of human and technical factors) but may affect the stability of the Product’s operation in the market. Problems over the implementation of a project at an advanced research level may directly affect the financial performance of the organisation. In the opinion of the Team with regard to the consequences of failure, the change does not have a significant impact on the safety of its operation. The Project Product will not have a significant impact on road transport safety.

2.4.2. Novelty

In terms of innovativeness, an innovative system will be introduced, which will enable businesses to make decisions on the transition of their vehicle fleet to electric vehicles (alternative energy sources) and investments in charging stations. At the stage of assessing the innovativeness of the system, the Team considered that the solutions introduced to the system in the design and production areas are innovative and non-standard—both in relation to the initial state of the system and on a national scale.

2.4.3. Complexity of the Change

The system uses data obtained from external sources and company-specific parameters entered. The premise of the system is to support businesses in choosing a business model that suggests how and where to invest in a fleet of electrically powered vehicles and the infrastructure that powers them. The change has no significant impact on the operational security of the organisation’s core processes, such as transport.

2.4.4. Monitoring

The assumed change to introduce a smart system to manage the fleet of electric vehicles and charging stations to optimise maintenance costs and the introduction of low-carbon transport by companies can be fully monitored at every stage of its introduction. Monitoring is possible during the definition of the concept of the algorithms used, the development of the system, its maintenance, and its use by the end customer. In the Team’s opinion, at the current stage of the project with regard to monitoring, the change has no significant impact on the security of its operation.

2.4.5. Reversibility

The implementation of the system is fully reversible. The system can be discontinued at any time. Resignation has no impact on process security. The Team considered that, due to the reversibility, the change has no significant impact on the operation of the system.

2.4.6. Additionality

In terms of additionality, systems using algorithms to manage fleets of electric vehicles and charging stations to optimise maintenance costs and the introduction of low-carbon transport by companies, including the use of artificial intelligence algorithms to estimate and predict the operating costs of electric vehicles, have not previously been implemented. The Team considered that, due to the additionality, the change does not have a significant impact on the safety of the system.

2.5. Determination of the Significance of the Change (Significant/Significant)

The basis for assessing the significance of the change was developed by analysing and discussing the project’s implementation conditions and looking for sources of potential risks that may occur during the execution of the works, affecting their quality and the possibility of human error, as well as the potential impact of these changes on the transport system once they have been implemented. The analysis also took into account the development of predictive systems in the industry. According to the proposed methodology, the first criterion analysed was additionality—the changes were deemed not to affect the safety of the project’s implementation and operation (Table 1, Table 2 and Table 3). Following the guidelines of the guide [20], the innovation and complexity criteria were combined into a single ‘uncertainty’ parameter, which allowed the Team to build a matrix (Table 2) consisting of the ‘uncertainty’ parameters and the consequences of system failure (modelled on the risk matrix), which could take the following values:

Table 1.

Uncertainty and the Consequences of change [20].

Table 2.

Uncertainty and Consequences of change table [20].

Table 3.

Classification of change [20].

Overall, for the whole project, the Team estimated Uncertainty at a mean = 3 due to the following aspects:

- -

- The innovativeness of the system after the change—in relation to the baseline, it should still be considered innovative and non-standard, but increasingly identified in the market in the area of application mechanism.

- -

- The complexity of the change should be described as high, among other things, due to the use of polyoptimisation in the selection of optimal input data to optimise the route.

The Team estimated the Consequences (of system failure), that is, the plausible worst-case scenario in the event of a failure of the assessed system, taking into account risk mitigation measures, as marginal = “2” due to the following aspect:

- -

- The plausible worst-case scenario for failure is the need to call a tow truck or tow the vehicle to the nearest charging station.

The consequence of multiplying the weights assigned to the Uncertainty (3) and Consequences (2) criteria is a value of “6”. In this case, monitoring and, once again, reversibility should be taken into account. The Team considered that, in terms of monitoring and reversibility, the change has no significant impact on safety.

The Team, using the described methodology for assessing the significance of the change, identified the change resulting from the introduction of innovative IT solutions affecting road transport safety as not significant. The Team based its assessment on its own experience and guidelines for the application of the criteria for assessing the significance of the change.

2.5.1. FMEA Method

The milestones in the risk assessment process that condition the proper conduct of hazard management and related safety measures required by law are as follows:

- Risk analysis—that is, the process of systematically using all available information to identify hazards, which includes the identification and classification of hazards along with a preliminary determination of the risk acceptability level of hazards. As a result of these activities, a risk register is created for the system that is the area of analysis;

- Risk estimation—that is, the identification of scenarios and existing security measures for the identified threats and then estimating the magnitude of the consequences that may occur in the case of events occurring as a result of the identified threats;

- Risk valuation—that is, comparing the results of the risk estimate with the assumed criteria to determine whether an acceptable level of risk has been reached.

Due to the areas of risk management occurring at transport operators, the most commonly used method is FMEA (failure mode and effects analysis). This method has been used in the course of analysing the significance of a change [21,22].

Risk assessment using the FMEA method consists of the following steps:

- Analysis of all processes related to the Entity’s operations;

- The purpose of the stage is to review all processes implemented by the Entity. Possible risk areas should be analysed for processes/activities affecting the change.

Identification of threats:

The purpose of this stage is to list possible sources of risks in the enterprise, taking into account common risks and risks arising from third parties (including social risks), and to make a preliminary determination of consequences.

2.5.2. Risk Estimation

The purpose of the step is to quantify the identified risks for the entire risk area, starting with the determination on a scale of 1–10 of the factors affecting the risk, where:

W—the probability of occurrence of the hazard (possibility of occurrence of the hazard), determined by an index in the range of 1–10; the probability of occurrence has a relative meaning rather than an absolute value. The only way in which the incidence ranking can be lowered is to prevent or control the cause of the error causing the hazard by changing the process.

Z—the probability of detection of a hazard, specified in the range from 1 to 10, is the rating (ranking position) associated with the best control tool given in the process control tools column. Detection is a relative rating within a specific FMEA. In order to achieve lower ranking positions, as a rule, the planned control tool should be improved.

S—possible consequences of a transportation event as a result of hazard propagation, a value between 1 and 10, is the ranking level assigned to the most serious effect for a given type of hazard, causing error in the transportation industry.

The estimation of hazard risk is based on the product:

where

- W—is the probability of hazard formulation.

- Z—is the probability of identifying the hazard.

- S—is the consequence of the hazard,

The following are the tables of hazard formulation probability, hazard identification probability, and hazard consequences used during the analysis (Table 4, Table 5 and Table 6).

Table 4.

Probability of hazard formulation (W).

Table 5.

Probability of identifying the hazard (Z).

Table 6.

Consequence of the hazard (S).

Consideration should be given to the best control measure/method that is currently in use when making an estimate of the probability of detecting a hazard.

The R-value of the risk measure of a hazard takes a number from 1 to 1000. Hazards with an R-value of more than 121 are significant. An R-value of more than 150 indicates a critical hazard that significantly threatens the safety of the entire transportation system. Based on the risk matrix (Table 3), the risk value was identified as follows:

- Risk is intolerable, significantly threatening the security of the transportation system; corrective measures should be taken immediately; and risk class = 3.

- Risk is tolerable, corrective measures should be taken, and risk class = 2.

- Risk is acceptable, no action is required, and risk class = 1.

2.6. Vulnerability Indices

With reference to the literature, the indices calculated to determine the susceptibility of electric vehicles are shown in the equations below [23,24]:

- (a)

- MTTR (mean time to repair): average time to restoration,

- n—number of all maintenance activities.

- NPi—date of withdrawal from use, i = 1, 2, …

- NZi—date of return to service, i = 1, 2, …

- (b)

- MTBM (mean time between maintenance): average time between planned maintenance activities,

- n—number of planned maintenance activities.

- UPi—activity start date i = 1, 2, …

- UZi—activity end date i = 1, 2, …

- (c)

- MDBM (mean distance between maintenance): average mileage between planned maintenance activities,

- n—number of planned maintenance operations.

- PUi—counter status at successive activities, i = 1, 2, …

- (d)

- MTTM (main time to maintain): average time for maintenance activities,

- n—number of all maintenance activities.

- UPi—activity start date i = 1, 2, …

- UZi—end date of activity i = 1, 2, …

In order to calculate the vulnerability indices for electric vehicles, a survey was carried out on a sample of 50 companies that also carry out repairs on passenger electric vehicles. The survey consisted of 10 questions. The results are presented in graphical and descriptive forms.

Summarising the Method of the Research

This paper divides the research into four sections: costs, vulnerability, failure rates, and safety. The following studies were conducted in each section:

- Costs—A literature analysis of the costs of maintaining and operating electric and/or hybrid vehicles was conducted. The analysis used literature items from recent years (2018–2023) and industry documents (e.g., reports). The purpose of this analysis was to indicate the cost of vehicle use and maintenance, as most sources report the cost of purchasing the vehicle and the cost of purchasing energy. The costs of repairing and servicing vehicles with an alternative source of propulsion are not reported.

- Failure rate—A questionnaire survey (described above) was conducted to understand the types of failures and repairs occurring in electric and hybrid vehicles compared to internal combustion vehicles. The study also aims to determine the repair time of electric and hybrid vehicles.

- Safety—In this section, a method was conducted to assess the significance of the change based on the said Regulation 402/2013, using the FMEA (failure modes and effects analysis) method. The FMEA method was carried out on the elements of the system according to the regulation in line with the procedure described. A team of experts (civil engineering and transportation disciplines), consisting of 10 people, participated in this method.

- Vulnerability—Vulnerability indices of vehicles were calculated based on the equation in Section 2.4 based on [23,24], assuming the values obtained during the conducted surveys.

3. Results

3.1. Costs of Maintenance and Operation of Electric Vehicles

A comparison of the production costs of electric cars and standard internal combustion engine cars leads to the conclusion that the former are higher due to the need for a battery instead of a fuel tank. Although the cost of batteries has fallen significantly over the past decade, electric vehicles are still more expensive to manufacture than comparable conventional vehicles. The prices of lithium-ion batteries fell by 85% between 2010 and 2018. Researchers around the world do not agree on a specific date when electric vehicles can achieve cost neutrality in relation to internal combustion engine cars, but they predict reaching price parity within the next 10 years [25]. Achieving price parity would therefore be the same as technological parity, which means equal prices for electric cars and internal combustion engine cars only in about 15 years [26,27,28,29].

In exchange for higher initial costs (purchase costs), electric vehicles offer a different set of features than internal combustion vehicles, due to the differentiation of electric drivetrains. Some of these differences may be preferred by consumers, as reflected in their willingness to pay a higher price for an electric vehicle. Examples of the advantages resulting from driving electric vehicles include achieving acceleration in less time and quieter engine operation compared to an internal combustion engine vehicle.

Electric vehicles have fewer moving parts in their structure than vehicles powered by an internal combustion engine. As a result, it is widely believed that EV owners will incur lower regular maintenance costs. A rational, forward-looking buyer will factor this benefit into his or her purchase decision. However, the short history of EVs limits our observable experience with maintenance costs, especially when it comes to larger single maintenance expenses that are likely to arise as the vehicle ages.

There are three main categories of ongoing car maintenance costs: costs not related to the engine technology, ongoing engine and/or drivetrain maintenance, and replacement of major components. The first category includes the cost of ongoing maintenance, such as insurance, tyre replacement, repair of electronic systems, and body work required due to environmental conditions (such as salt in winter). However, the other two categories of maintenance costs will differ. For internal combustion engines, ongoing engine maintenance is related to internal combustion. Oil and filters need to be changed, as well as spark plugs and other ignition system components. The simplicity of the electric drivetrain eliminates these costs.

The last category of costs—replacement of major components—applies to cars with both types of engines. Electric cars have batteries that are expensive and need to be replaced. Although the costs have come down significantly in recent years, it is still costly to replace a battery.

Whether the car owner pays for this directly or as part of the manufacturer’s warranty, it is a significant cost that is characteristic only of electric vehicles. On the other hand, internal combustion engine cars do not have expensive batteries, but they do have transmissions and gearboxes that eventually wear out and need to be replaced.

In a study by Rapson et al. (2021), the price of 1 kWh of energy is equal to USD 150. At that price, a 30 kWh battery (roughly comparable to the one in the Nissan Leaf) would cost $4500, and a 75 kWh battery for a Tesla Model 3 would cost $11,250. A battery replacement is comparable to the replacement of a gearbox in a vehicle. Installation of a refurbished gearbox costs between $1100 and $3400. The cost is undoubtedly higher for luxury brands. The replacement of a gearbox in a vehicle with an internal combustion engine costs about the same amount as replacing the battery in an electric car [30].

The disposal of used car batteries is another huge problem. In fact, to date, there are no convenient methods for recycling the main component of batteries (lithium), and the cost of recycling is higher than the cost of extraction. As a result, lithium is usually disposed of in landfills. Second, battery components such as lithium, cobalt, and manganese are mined in developing countries, where working conditions often do not comply with socially acceptable ethical principles. This, too, is a key factor that can influence the vehicle purchase decisions made by consumers [30].

According to [31], the falling prices of lithium-ion batteries, the falling prices of key components of EVs, and the increasing numbers of EVs manufactured will contribute to the achievement of equal prices for internal combustion engine cars and electric cars as early as 2024–2025. Prices of lithium-ion batteries are falling steadily worldwide, and this conclusion is supported by data from 2010, when the cost of such a battery was 1183 USD/kWh. By comparison, the price of a battery in 2019 was 156 USD/kWh. Similar downward trends are observed in the share of the price of lithium-ion batteries in the price of electric vehicles. By comparison, in 2015, the price of a battery accounted for 57.1% of a car’s value, and in 2021, it only accounted for 27.6%. The price of a battery is projected to make up 20.2% of the price of a vehicle in 2025.

In a comparative analysis of the cost of using electric cars and internal combustion engine cars, the cost of driving a distance of 100 kilometres in those two types of cars was compared. The analysis assumed charging the vehicle 80% from power outlets and 20% from public chargers. In addition, the energy consumption was assumed to be 15.3 kWh/100 km. With regard to the cost of use of an internal combustion engine car, the average price of gasoline was assumed to be equal to that prevailing in 2020, 0.94 USD/l, and the average mileage of an internal combustion engine car was assumed to be 6.7 l/100 km. Based on all these data, it was calculated that the cost of driving the distance of 100 km in an internal combustion engine car was USD 2.69, while for an electric car, it was equal to USD 2.00. Data were also projected on the total costs of 3 years of use of an electric car in relation to the distance travelled. Car models that are comparable in terms of operating parameters were used to project the costs: Volkswagen Golf 1.5 TSI DSG, Volkswagen Golf 2.0 TDI DSG (https://pspa.com.pl/wp-content/uploads/2020/08/kompendium_elektromobilnosci_raport_2020_S.pdf (accessed on 26 November 2023)), and Volkswagen e-Golf. The costs associated with the consumption of electricity, gasoline, and diesel over the various distances were as follows:

- 30,000 km, electricity: USD 0.61, gasoline (PB95): USD 1.28, diesel: USD 1.78

- 60,000 km, electricity: USD 1.21, gasoline (PB95): USD 3.76, diesel: USD 1.35;

- 90,000 km, electricity: USD 1.82, gasoline (PB95): USD 5.64, diesel: USD 5.34.

The savings achieved after 3 years of using an electric car were equal to USD 3.82 compared to gasoline and USD 3.52 compared to diesel fuel.

Another study (Harto, 2020) shows that the cost per mile for an internal combustion engine vehicle over the first two hundred thousand miles travelled is double that of an electric vehicle (0.03 USD/mile for an electric vehicle and 0.06 USD/mile for an internal combustion engine vehicle) [32].

The total repair and maintenance costs for electric vehicles and internal combustion engine vehicles were calculated. The average annual distance travelled was identified as 13,500 miles. The energy consumption was estimated at 4233 kWh each year. The cost of electricity was estimated based on California rates in 2021 at 0.199 USD/kWh. The average price of gasoline in 2021 on the west coast of the United States was 2.875 USD/gal, and the average mileage of a vehicle was 24.9 mpg. Taking all this data into account, it was estimated that the average total cost after 150,000 miles, including repairs and maintenance, was $4150 for an electric vehicle and $8350 for an internal combustion engine vehicle. These costs, divided into annual maintenance and so-called running costs, are equal to USD 1830 and USD 2716 for electric cars and internal combustion engine cars, respectively. This study was conducted for two vehicle models: the BMW iX3 (BEV) and the BMW X3 35i (ICEV) [33].

However, the cost of owning an electric vehicle includes not only the initial purchase cost but also variable costs incurred over the period of ownership, such as repair and maintenance costs and electricity costs [31,33]. When comparing a Chevrolet Bolt (BEV) and a Volkswagen Golf (ICEV), it can be concluded that electric vehicles contain only about 21% of the moving parts that an internal combustion vehicle contains. Because they contain fewer components (which are at risk of damage and need to be repaired), electric vehicles gain an advantage in this regard. With no components subject to wear and tear, EV owners avoid the regular costs of services and repairs typically associated with owning a vehicle, such as changes of oil, fan belts, air filters, timing belts, head gaskets, cylinder heads, and spark plugs. In addition, brake pads in electric vehicles have a longer life due to the electric engine’s ability to brake on its own, which reduces wear on the brake pedal and reduces the pressure on the brake pads on the wheels [31,33].

To compare the total maintenance costs for the SME sector for both an internal combustion engine vehicle and an electric vehicle, the following services included in a lease contract must be considered:

- -

- Financing

- -

- Taxes

- -

- Maintenance

- -

- Tyres (summer and winter, if applicable)

- -

- Insurance (comprehensive)

- -

- Energy budget: fuel or electricity

As with fuel, the price of electricity varies depending on location, but these regional variations can be greater for electricity than for fuel. Fast charging along a highway can be much more expensive than charging at home, for example. Therefore, users who use 60% home charging, 30% workplace charging, and 10% public charging were assumed for the analysis. The duration of the contract is 48 months, and the annual distance travelled is 30,000 km. The vehicles compared are the Volkswagen Golf (ICEV) and Volkswagen ID.3 (EV).

Vehicle lease costs vary from country to country and is influenced by factors such as the local tax system, labour costs, fuel costs, and government EV incentives. Depreciation, insurance, and tyres are more expensive for electric vehicles, but taxes, maintenance, and energy are cheaper. In 2021, the price of electricity (EUR/kWh) and gasoline (EUR/litre) increased. Obviously, an increase in this cost component will lead to an increase in the overall TCO. However, the impact of energy price increases on an electric vehicle compared to the impact of the same energy price increase on an ICEV is different because electricity costs are a smaller part of the total cost of ownership than fuel costs. In the case of the Volkswagen ID.3, energy accounts for 11% of the total ownership costs, while in the case of the Volkswagen Golf, energy accounts for 22% of those costs. An increase in the price of electricity, therefore, has a different impact than an increase in the price of gasoline/diesel. For example, when the price of both electricity and fuel increases by 50%, this results in a 6% increase in the total cost for the Volkswagen ID.3, but an 11% increase in the total cost for the Volkswagen Golf. This shows that the ID.3 is more immune to energy price fluctuations than the Golf. In addition, the EV can be charged from renewable energy sources, and fluctuations in energy costs will not be felt at a similar level as fuel prices increase [34]. Similar calculations can be found in the PKO BP S.A.’s Report, where two cars were compared in a long-term rental: the Nissan Qashqai 1.3 DIG-MHEV (ICEV) and the Nissan Leaf 40 kWh N-Connecta (EV). The total monthly costs of vehicle ownership are USD 515,81 and USD 477,86 for the ICEV and the BEV, respectively [35].

Based on the above information on maintenance and repair costs of electric vehicles and internal combustion engine vehicles, it can be deduced that:

- Battery prices for electric vehicles are steadily declining, which will result in price parity between internal combustion engine vehicles and electric vehicles within the next few years;

- Due to their design, electric vehicles have far fewer moving parts that are subject to damage or failure, and, therefore, the number of repairs and maintenance operations they require is lower compared to internal combustion engine vehicles;

- The total cost of ownership (TCO) of electric cars is also affected by electricity costs, but fluctuations in these costs have an insignificant effect on the change in the total cost of ownership of EVs.

3.2. Failure Rate

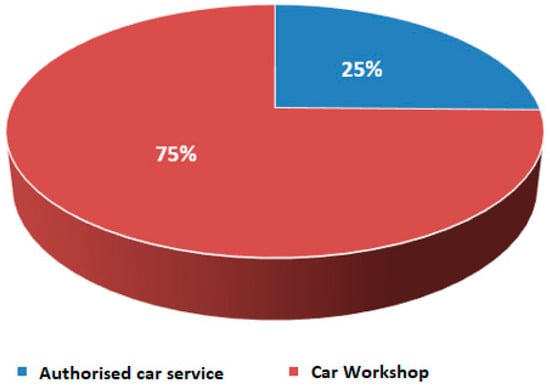

In question 1 on the type of company taking part in the survey, 75% of respondents were identified as a garage and 25% as an authorised repairer (Figure 1).

Figure 1.

Types of companies surveyed.

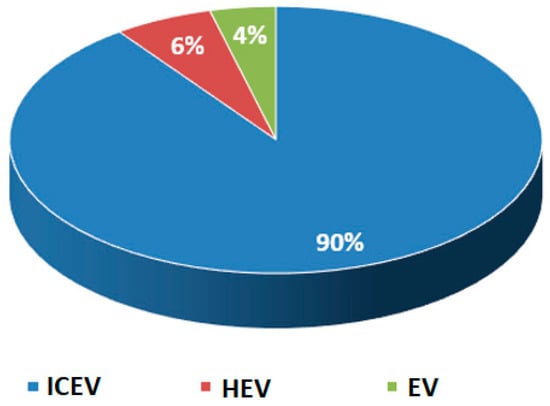

Respondents also answered the question, “Which types of vehicles are repaired/serviced in your company? What percentage of these repairs are individual vehicles?”. In 95% of the companies surveyed, internal combustion vehicles are the most commonly repaired, and these repairs account for over 90%. The remaining 10% of repairs in these companies are for hybrid and electric vehicles (Figure 2). The research was expanded in a telephone interview to include the average number of repaired vehicles per month among all surveyed car workshops and authorised service centres (respondents), which was 500 vehicles. Among all vehicles repaired per month, there were an average of 20 pieces of electric vehicles and an average of 30 pieces of hybrid vehicles. The remaining number of vehicles (average 450 pieces) included internal combustion vehicles.

Figure 2.

Which types of vehicles are repaired/serviced in your company?

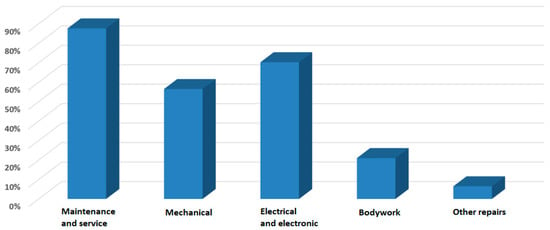

In the surveyed companies, the largest percentage of repairs are maintenance and service, mechanical, electrical and electronic, bodywork, and other repairs (Figure 3).

Figure 3.

Which repairs are undertaken in your company?

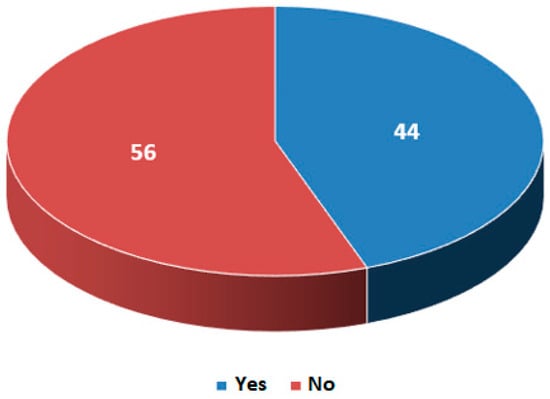

Referring to the literature sources for the most common faults in electric and hybrid vehicles, it was battery failures that were reported most by users. Figure 4 shows the responses to the question, “Are electric and hybrid vehicle battery failures reported?”. As many as 56% of negative responses were given to this question, and 44% of responses were positive.

Figure 4.

Are electric and hybrid vehicle battery failures reported?

Among the respondents giving a positive answer, a request was made to elaborate on the topic of battery failure. Table 7 shows the responses received:

Table 7.

Types of battery failure and repair in electric and hybrid vehicles.

Respondents were also asked what the most common failures of electric and hybrid vehicles are by make, model, vintage, and mileage of the vehicle. Table 8 and Table 9 summarise the answers given.

Table 8.

Types of failure in hybrid vehicles.

Table 9.

Types of failure in electric vehicles.

Based on the respondents’ answers, it can be seen that in hybrid and electric vehicles, there is no dependence on the make, model, mileage, and vintage of the vehicle on the type of failure. The failures vary widely, but the most common failure in electric vehicles is battery failure. In contrast, for hybrid cars, the most commonly cited failure is brake system failure. However, these do not depend on the combined vehicle characteristics.

The greatest variation among respondents’ answers occurred in the next question, which concerned the average repair time for an electric/hybrid vehicle. The responses yielded times ranging from 3 h to 7 days. Extremely, the time could extend to 14 days. The explanation for this discrepancy is the type of vehicle, the make and model, the condition of the vehicle, the availability of parts, the availability of a specialist with the appropriate competence to repair this type of vehicle, and the type of breakdown/fault. The average repair time (out of service) for an electric/hybrid vehicle, after discarding the extreme values, is 3 days.

The respondents then answered the question, “What are the inspection requirements for electric/hybrid vehicles?”. Several subcategories of questions were created in order to gain a closer insight into the specific operation of hybrid and electric vehicles.

Table 10 summarises the responses to the question asked. Annual maintenance is performed for both electric and hybrid vehicles, but this depends on the manufacturer’s guidelines and the mileage the vehicle has covered during its lifetime. However, mileage values are also different for each type (make and model) of car. The return to operation of the vehicle after servicing also varies. It depends on the availability of parts for the vehicle and the availability of a specialist with the skills and competence to repair electric and hybrid vehicles. The average lead time for an inspection of an electric or hybrid vehicle is a maximum of 1 day.

Table 10.

What are the requirements for vehicle inspections of HEV/BEV?

3.3. Safety

Within the scope of the amendment, additional risk areas have been identified as a result of the operational vulnerability analysis of alternatively powered vehicles (Table 11).

Table 11.

Register of hazard sources.

Technical factors:

- Insufficient data for maintenance analysis;

- Inconsistent data, making maintenance analysis calculations impossible;

- Insufficient analysis of the level of influence of individual inputs on the overall calculation (maintenance);

- Insufficient definition of the functionalities that the system for vehicle fleet management and charging stations should have.

Organisational factors:

- 5.

- Prediction of the scope of maintenance processes;

- 6.

- Prediction of the time span of maintenance processes.

Human factors:

- 7.

- Lack of motivation to enter the organisation;

- 8.

- Incorrect/negligent data entry.

Environmental factors:

- 9.

- Lack of technical capacity for maintenance data entry 10;

- 10.

- Lack of time for maintenance data entry.

3.4. Vulnerability

Taking all the survey responses into account, the operational vulnerability indices for hybrid and electric vehicles were calculated in Table 12 (based on formulas and detailed descriptions in Section 2.4).

Table 12.

Vulnerability indices for HEV/BEV.

The indicator MTTR for both electric and hybrid vehicles was 3 days. The MTBM for both electric and hybrid vehicles was 365 days. Maintenance is conducted on these vehicles annually. Similarly, in the case of MTTM, the value for both hybrid and electric vehicles was 1, which means that the average duration of maintenance for these types of vehicles is 1 day. The values of MDBM have varied; for electric vehicles, they were 5000 km, and for hybrid vehicles, they were 12,000 km. These values are the indicated mileage by not only vehicle manufacturers but also people who do repairs and maintenance.

4. Conclusions

The purpose of this paper was to analyse the operational vulnerability of alternatively powered vehicles and assess the significance of the change in relation to the operational vulnerability of alternatively powered vehicles. To this purpose, a survey was conducted among 50 respondents regarding the repair and maintenance of electric and hybrid vehicles. A literature analysis was also carried out regarding the repair and maintenance costs of hybrid and electric vehicles. And a FMEA analysis was carried out on significant and insignificant changes for individual system components. Vulnerability indices were also calculated according to literature formulas. In the present work, a number of research techniques and methods were used, which is an added advantage and increases the scientific value of the publication. The use of multiple research methods affects the interdisciplinary nature of the work and the use of the results in future work from different disciplines. The demonstration of several research methods in the work allows for a broad study of the problem, which, in this case, was cost, failure rate, safety, and vulnerability.

The experts analysed the risks using the FMEA method, and this analysis identified those with the greatest impact on the safety and correct operation of the EV fleet monitoring system and its use by users in the maintenance area. The only hazard with a tolerable impact is the lack of sufficient data in the maintenance analysis. This risk can be mitigated in subsequent stages of product readiness once more data have been analysed. Most of the vehicles repaired are internal combustion vehicles in car workshops and authorised car services. Electric and hybrid vehicle repairs account for only 10%. In the surveyed companies, the largest percentage of repairs are maintenance and service, mechanical, electrical and electronic, bodywork, and other repairs for both electric, hybrid, and internal combustion vehicles. Some of the most common faults in electric and hybrid vehicles are battery failures. It is also common for battery replacements to be carried out once mileage or terminal failure has been reached. However, it may be premature to conclude on the failures and repairs carried out on EVs and hybrids due to the short lifespan of the vehicles and their presence on the market. Furthermore, as the study indicates, the type of failure depends on the make, model, year of manufacture, or mileage achieved.

A considerable obstacle to servicing electric and hybrid vehicles is the lack of availability of parts on the market or the lack of appropriate staff with the required qualifications and competence. The waiting time for a vehicle to be repaired and thus taken out of service ranges from 1 to as many as 14 days in extreme cases. Adequate training in secondary schools for the required profession should be an essential part of sustainable development and the implementation of electromobility in any country in Europe or the world.

There is little literature data providing information on the repair/service costs of electric and hybrid vehicles. The publication reaches for data from reports from consumer research units. These are industry data. However, this shows the niche in this area and the opportunity for research in a broad area. Repair and servicing costs are among the key pieces of information for users or potential customers of electric vehicles. The costs of purchasing the vehicle and powering it are not sufficient information for vehicle maintenance.

Author Contributions

Conceptualisation, K.C. and I.K.; methodology, K.C. and I.K.; software, K.C.; validation, I.K.; formal analysis, K.C.; investigation, I.K.; resources, K.C.; data curation, I.K.; writing—original draft preparation, I.K.; writing—review and editing K.C.; visualisation, K.C.; supervision, I.K.; project administration, K.C.; funding acquisition, I.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviation

| Abbreviation | Expansion of the abbreviation |

| EV | electric vehicle |

| HEV | hybrid electric vehicle |

| ICEV | internal combustion engine vehicle |

| FMEA | failure mode and effects analysis) |

| LEV | low-emission vehicle |

| FCEV | fuel cell electric vehicle |

| TI | technological innovation |

| GHG | greenhouse gas |

| CO2 | carbon dioxide |

| MTTR | mean time to repair |

| MTBM | mean time between maintenance |

| MDBM | mean distance between maintenance |

| MTTM | main time to maintain |

| TCO | total cost of ownership |

References

- Kaźmierczak, J. Eksploatacja Systemów Technicznych; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2000. [Google Scholar]

- Wojciechowski, Ł.; Cisowski, T. Metoda Optymalizacji Procesu Eksploatacji w Ujęciu Bezawaryjności Pojazdu; Monografie Politechnika Lubelska; Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2018. [Google Scholar]

- Wornalkiewicz, W. Zasilanie alternatywne pojazdów samochodowych. Zesz. Nauk. Wyższej Szkoły Tech. W Katowicach 2022, 15, 21–50. [Google Scholar]

- The Encyclopaedia of Management. Available online: https://mfiles.pl/pl/index.php/Podatno%C5%9B%C4%87_eksploatacyjna (accessed on 10 June 2023).

- Li, J.; Liang, M.; Cheng, W.; Wang, S. Life cycle cost of conventional, battery electric, and fuel cell electric vehicles considering traffic and environmental policies in China. Int. J. Hydrogen Energy 2021, 46, 9553–9566. [Google Scholar] [CrossRef]

- Guo, J.; Jiang, Y.; Yu, Y.; Liu, W. A novel energy consumption prediction model with combination of road information and driving style of BEVs. Sustain. Energy Technol. Assess. 2020, 42, 100826. [Google Scholar] [CrossRef]

- Wicki, M.; Brückmann, G.; Quoss, F.; Bernauer, T. What do we really know about the acceptance of battery electric vehicles?—Turns out, not much. Transp. Rev. 2023, 43, 62–87. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, R.; Wang, H.; Cai, H. Optimal battery electric vehicles range: A study considering heterogeneous travel patterns, charging behaviors, and access to charging infrastructure. Energy 2020, 197, 116945. [Google Scholar] [CrossRef]

- Funke, S.A.; Plotz, P.; Wietschel, M. Invest in fast-charging infrastructure or in longer battery ranges? A cost efficiency comparison for Germany. Appl. Energy 2019, 235, 888–899. [Google Scholar] [CrossRef]

- Chang, T.-W. An indispensable role in promoting the electric vehicle Industry: An empirical test to explore the integration framework of electric vehicle charger and electric vehicle purchase behawior. Transp. Res. Part A 2023, 176, 103824. [Google Scholar] [CrossRef]

- Yuan, X.; Li, X. Mapping the technology diffusion of battery electric vehicle based onpatent analysis: A perspective of global innovation systems. Energy 2021, 222, 119897. [Google Scholar] [CrossRef]

- Zhu, T.; Wills, R.G.A.; Lot, R.; Kong, X.; Yan, X. Optimal sizing and sensitivity analysis of a battery-supercapacitor energy storage system for electric vehicles. Energy 2021, 221, 119851. [Google Scholar] [CrossRef]

- Dong, J.; Wu, X.; Liu, C.; Lin, Z.; Hu, L. The impact of reliable range estimation on battery electric vehicle feasibility. Int. J. Sustain. Transp. 2020, 14, 833–842. [Google Scholar] [CrossRef]

- Veza, I.; Zacky Asy’ari, M.; Idris, M.; Epin, V.; Rizwanul Fattah, I.M.; Spraggon, M. Electric vehicle (EV) and driving towards sustainability: Comparison between EV, HEV, PHEV, and ICE vehicles to achieve net zero emissions by 2050 from EV. Alex. Eng. J. 2023, 82, 459–467. [Google Scholar] [CrossRef]

- Wang, A. Economic efficiency of high-performance electric vehicle operation based on neural network algorithm. Comput. Electr. Eng. 2023, 112, 109026. [Google Scholar]

- Zhang, D.; Li, Y.; Li, Y.; Shen, Z. Service Failure Risk Assessment and Service Improvement of Self-Service Electric Vehicle. Sustainability 2022, 14, 3723. [Google Scholar] [CrossRef]

- Bukola, P.A. Electric vehicles survey and a multifunctional artificial neural network for predicting energy consumption in all-electric vehicles. Results Eng. 2023, 19, 101283. [Google Scholar]

- Mehmet, S.; Sami Yigiter, M.; Ozcan, M. Why are consumers switching to electric vehicles? Analyzing consumers preferences for electric vehicles. Case Stud. Transp. Policy 2023, 14, 101108. [Google Scholar]

- Zeng, S.; Tanveer, A.; Fu, X.; Gu, Y.; Irfan, M. Modeling the influence of critical factors on the adoption of green energy technologies. Renew. Sustain. Energy Rev. 2022, 168, 112817. [Google Scholar] [CrossRef]

- Expertise on the Practical Application of the Requirements of the Common Safety Method for Risk Assessment (CSM RA) by Rail Sector Entities Developed in the Form of a Guide. Available online: https://www.era.europa.eu/system/files/2022-11/Guide%20for%20the%20application%20of%20the%20Common%20Safety%20Methods%20on%20risk%20assessment%20%28EN%29.pdf (accessed on 10 June 2023).

- Chruzik, K. Assessment of the Significance of Change in Transport Systems; IBIMA: Madrid, Spain, 2019. [Google Scholar]

- Chruzik, K. Predictive risk management model in transport. Przedsiębiorczość I Zarządzanie 2018, XIX, 297–311. [Google Scholar]

- PN-EN 50126-1:2018-02; Specyfikowanie i Wykazywanie Niezawodności, Dostępności, Podatności Utrzymaniowej i Bezpieczeństwa (RAMS)—Część 1: Proces ogólny RAMS. Polish Committee for Standardization: Warszawa, Poland, 2020.

- Lewitowicz, J.; Kustroń, K. Podstawy Eksploatacji Statków Powietrznych—Własności i Właściwości Eksploatacyjne Statku Powietrznego tom 2; Wydawnictwo Instytutu Technicznego Wojsk Lotniczych: Warszawa, Poland, 2003. [Google Scholar]

- Global EV Outlook 2021, Accelerating Ambitions Despite the Pandemic. Available online: https://iea.blob.core.windows.net/assets/ed5f4484-f556-4110-8c5c-4ede8bcba637/GlobalEVOutlook2021.pdf (accessed on 10 June 2023).

- Feckova Skrabulakova, E.; Ivanova, M.; Rosova, A.; Gresova, E.; Sofranko, M.; Ferencz, V. On Electromobility Development and the Calculation of the Infrastructural Country Electromobility Coefficient. Processes 2021, 9, 222. [Google Scholar] [CrossRef]

- Bushnell, J.; Rapson, D. Energy Prices and Electric Vehicle Adoption. Natl. Bur. Econ. Res. 2021, 29093. [Google Scholar] [CrossRef]

- König, A.; Nicoletti, L.; Schröder, D.; Wolff, S.; Waclaw, A.; Lienkamp, M. An Overview of Parameter and Cost for Battery Electric Vehicles. World Electr. Veh. J. 2021, 12, 21. [Google Scholar] [CrossRef]

- EY and Eurelectric Raport 2021: Power Sector Accelerating e-Mobility. Can Utilities Turn EVs into a Grid Asset? Available online: https://assets.ey.com/content/dam/ey-sites/ey-com/en_gl/topics/power-and-utilities/power-and-utilities-pdf/power-sector-accelerating-e-mobility-2022-ey-and-eurelectric-report.pdf (accessed on 10 June 2023).

- Skowronska-Szmer, A.; Kowalska-Pyzalska, A. Key Factors of Development of Electromobility AMONG Microentrepreneurs: A Case Study from Poland. Energies 2021, 14, 764. [Google Scholar] [CrossRef]

- Raport PSPA (30.06.2020) Kompendium Elektromobilności, Infografiki Wydanie II. Available online: https://pspa.com.pl/wp-content/uploads/2020/08/kompendium_elektromobilnosci_raport_2020_S.pdf (accessed on 10 June 2023).

- Harto, C. Electric Vehicle Ownership Costs: Chapter 2—Maintenance; 2021; Available online: https://advocacy.consumerreports.org/wp-content/uploads/2020/09/Maintenance-Cost-White-Paper-9.24.20-1.pdf (accessed on 10 June 2023).

- Vilimovsky, A. Cost Comparison Between Electric And Internal Combustion-Engine Vehicles: A Case Study. Master’s Thesis, University of New York in Prague Empire State College, Prague, Czech Republic, 2021. [Google Scholar]

- Wetterhahn, J. Total Cost of Ownership: How Electric Vehicles and ICE Vehicles Compare; Report February; LeasePlan: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Raport PKO BP S.A. Floty Samochodów Kluczem do Elektromobilności. Podsumowanie Stanu i Potencjału Rozwoju Rynku Samochodów Elektrycznych w Polsce Oraz Podejście MSP do Elektromobilności; PKO Bank Polski: Warsaw, Poland, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).