AC–DC Flyback Dimmable LED Driver with Low-Frequency Current Ripple Reduced and Power Dissipation in BJT Linearly Proportional to LED Current

Abstract

1. Introduction

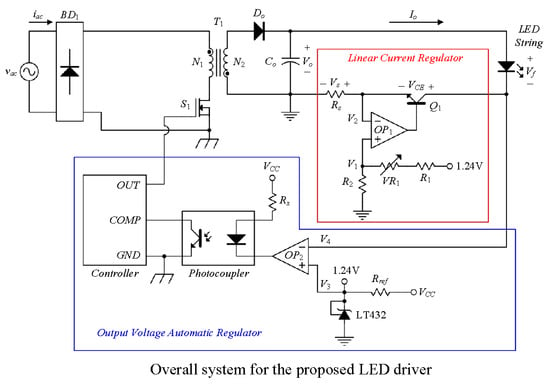

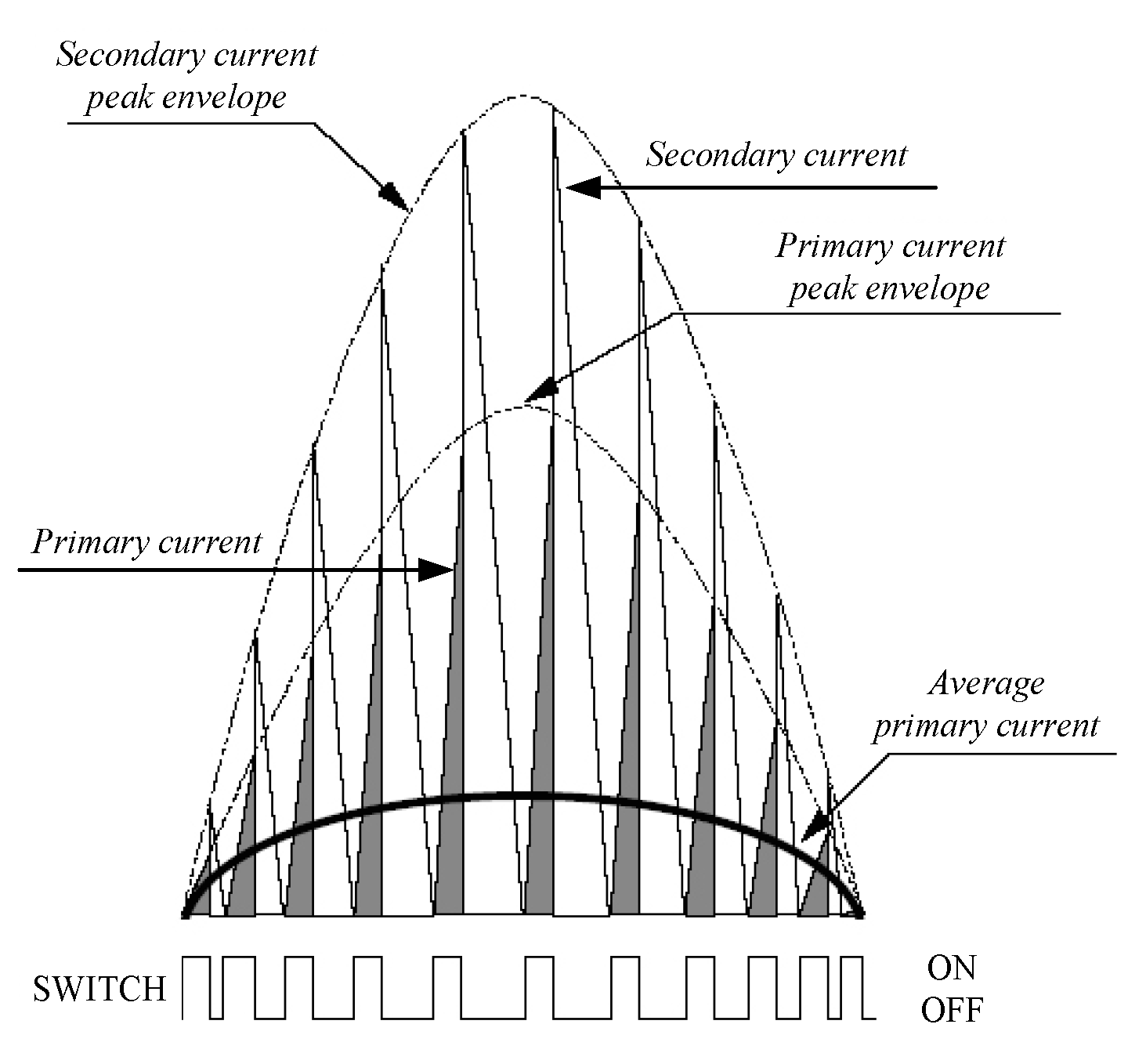

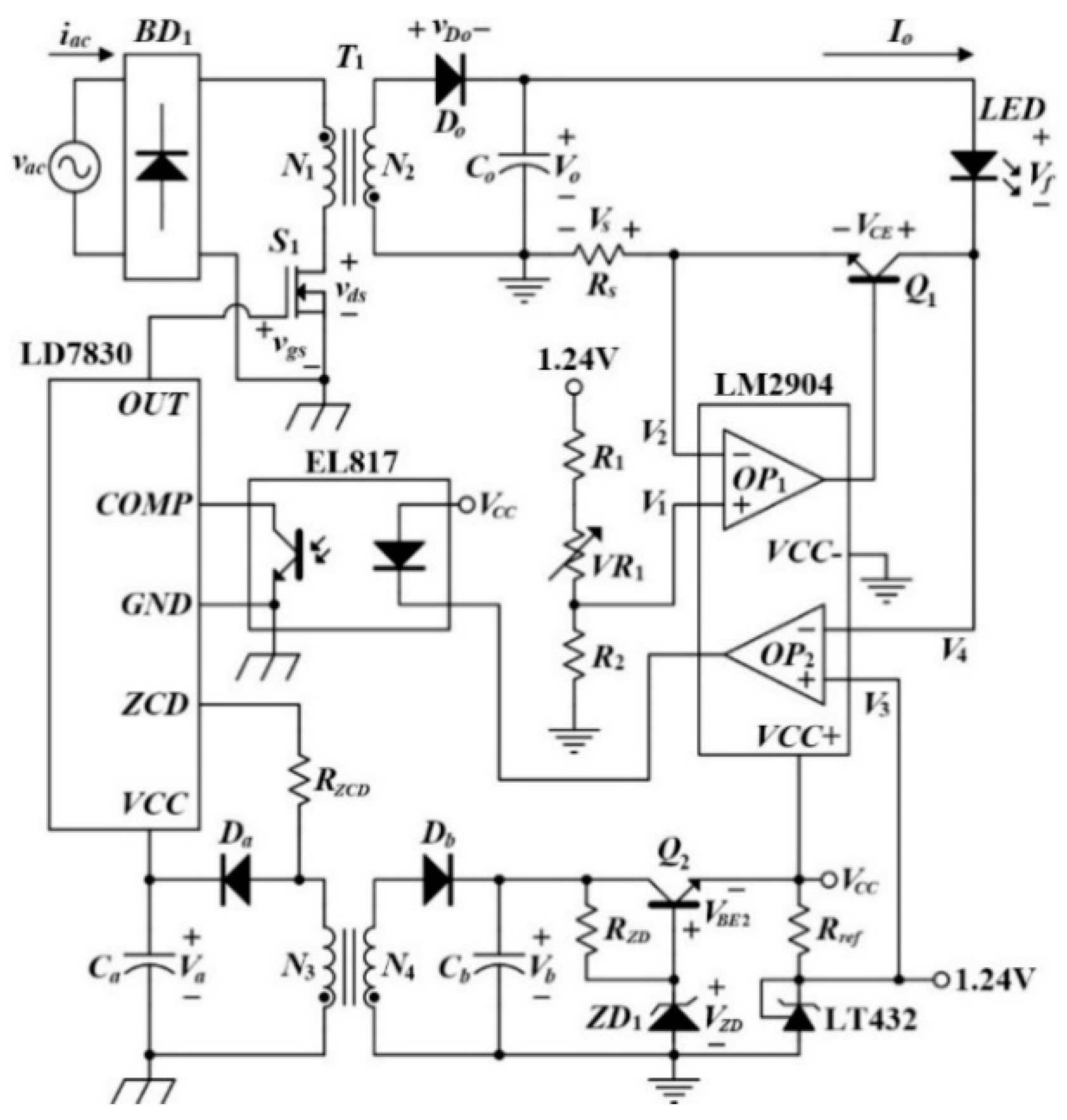

2. Basic Operating Principles of the Proposed Circuit

3. Basic Operating Concept

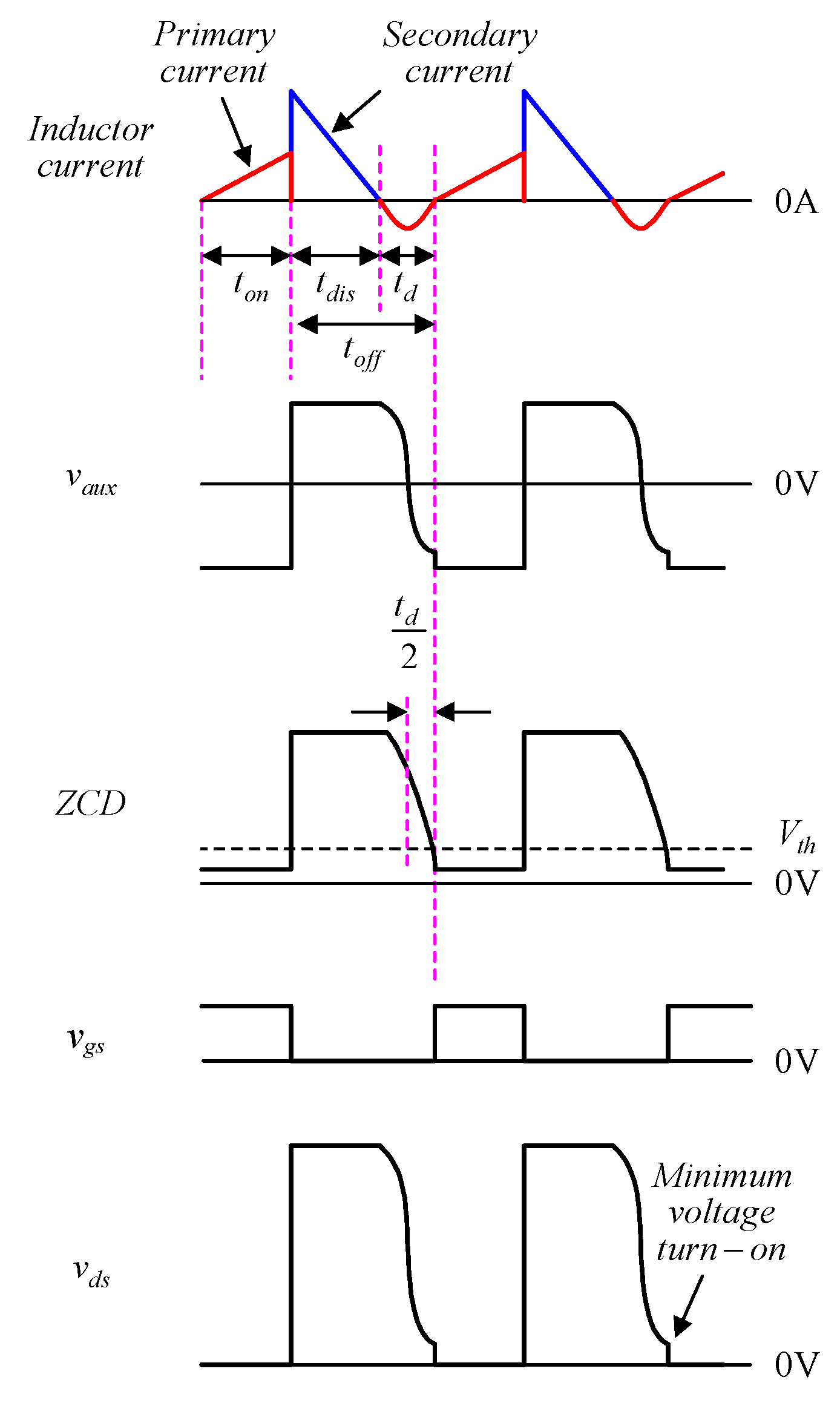

3.1. Reduction of Low-Frequency Output Current Ripple

3.2. System Stability Based on Simple Circuit Concept

3.3. Output Voltage Automatic Regulator

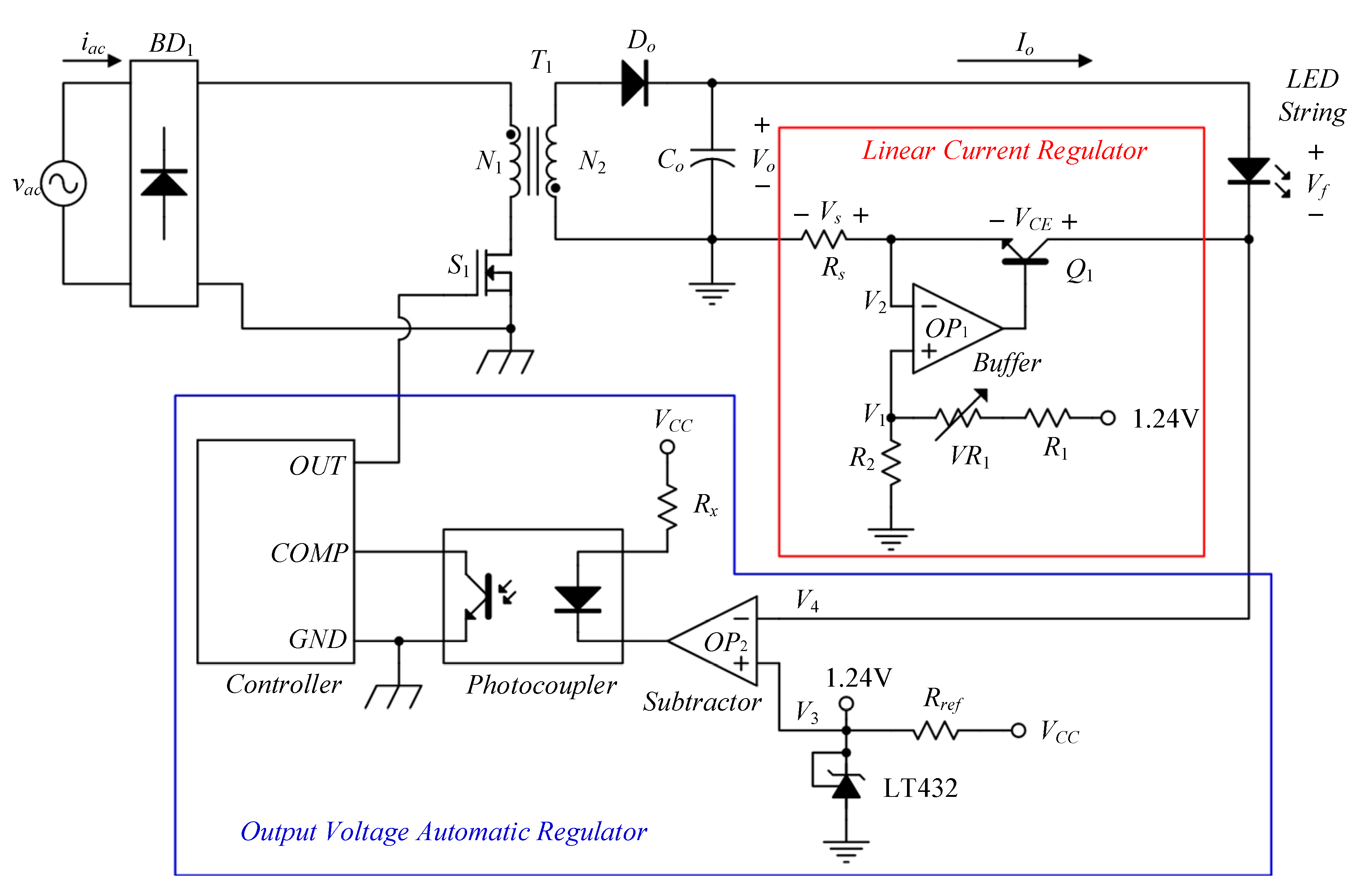

3.4. Operating Principle of CRM PWM Control

4. Design Considerations

4.1. Design of Magnetizing Inductance Lm

4.1.1. Step 1

4.1.2. Step 2

4.1.3. Step 3

4.1.4. Step 4

4.2. Design of Co

4.3. Design of Input Filter

4.4. Components Used

4.5. Design of LED Dimming Circuit

4.6. Design of Linear Current Regulator

4.7. Design of Output Voltage Automatic Regulator

4.7.1. Design of V3

4.7.2. Design of Rx and Rref

5. Experimental Results

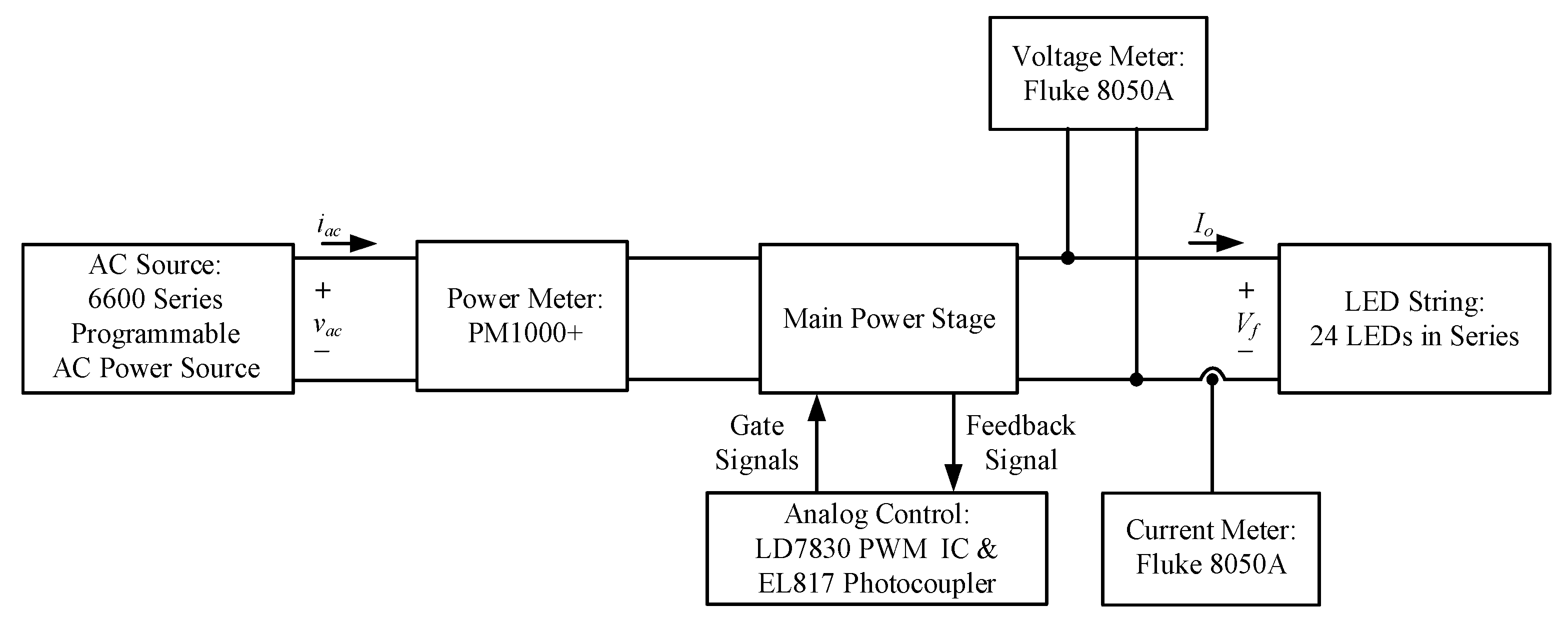

5.1. Test Bench for Measurements

5.2. Actual System Circuit

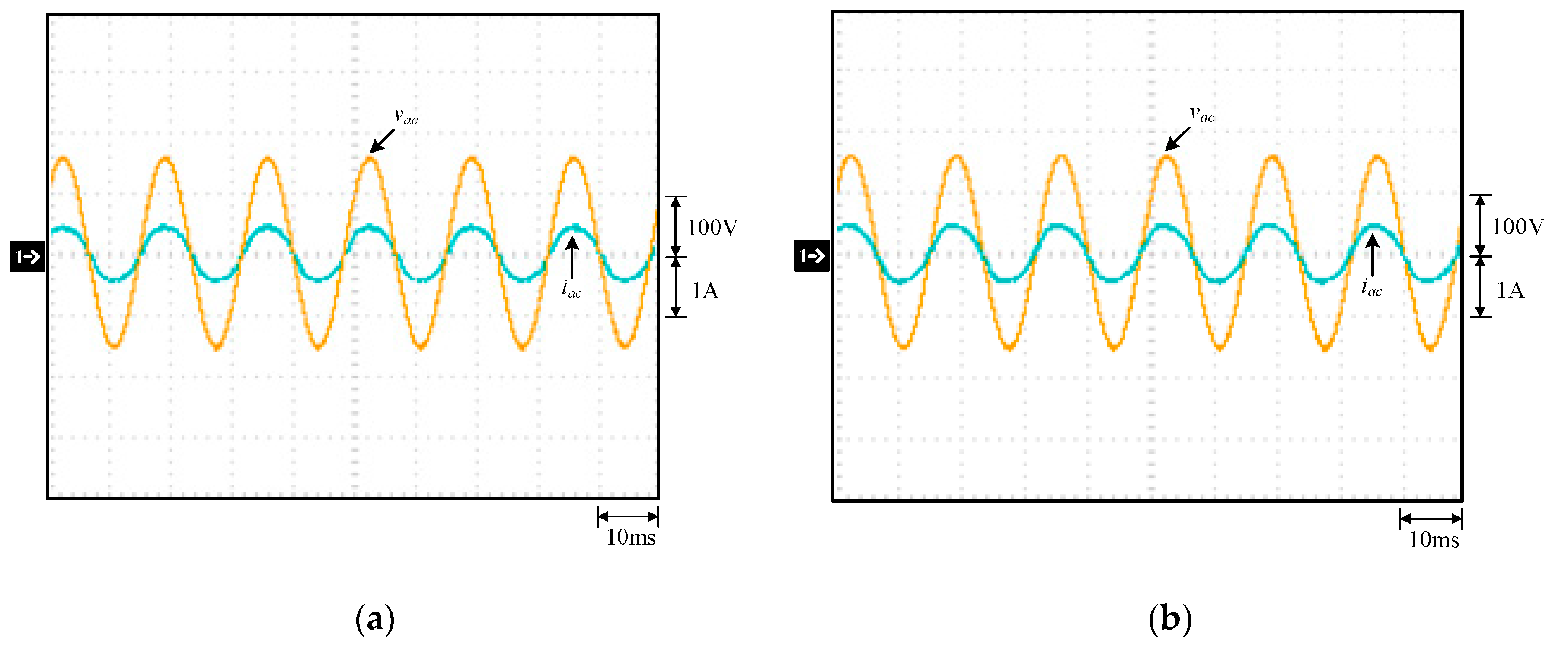

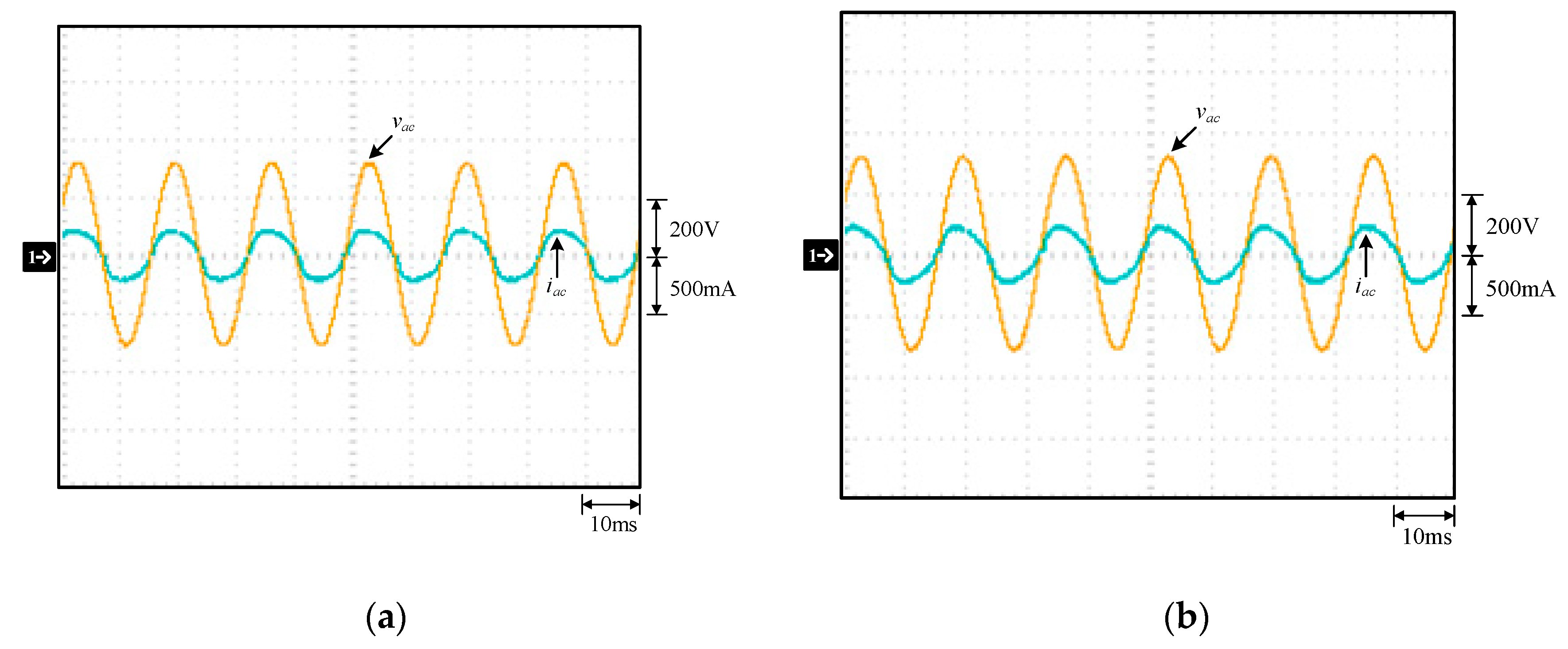

5.3. Measured Waveforms

- (1)

- For both methods, the higher the input voltage, the larger the input current distortion.

- (2)

- For both methods, any value of the input voltage affects the low-frequency output voltage ripple and current ripple slightly.

- (3)

- With the low-frequency current ripple improved, not only the output voltage ripple but also the output current ripple is reduced.

5.4. Electrical Data Comparisons

5.4.1. Efficiency Comparison

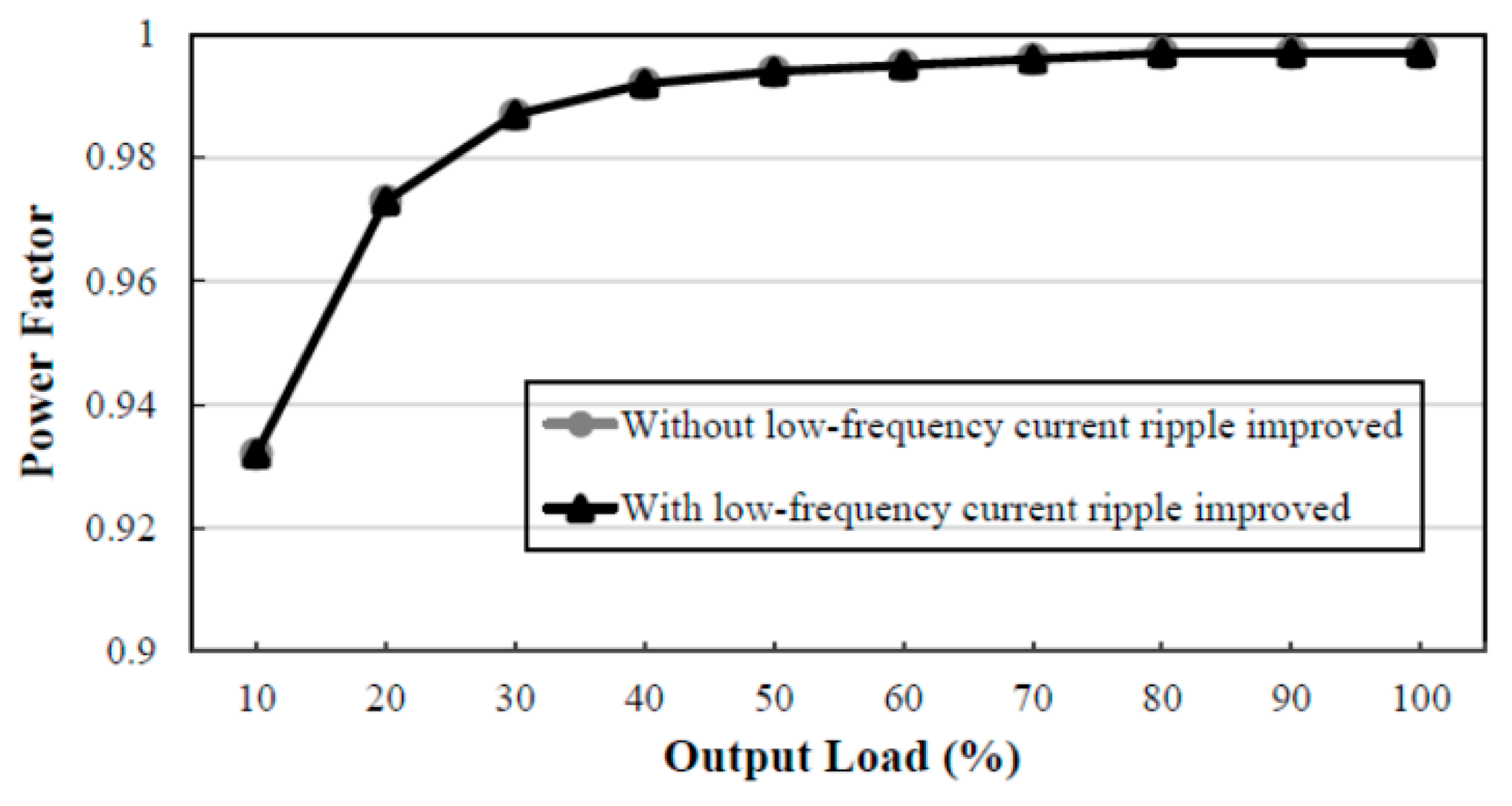

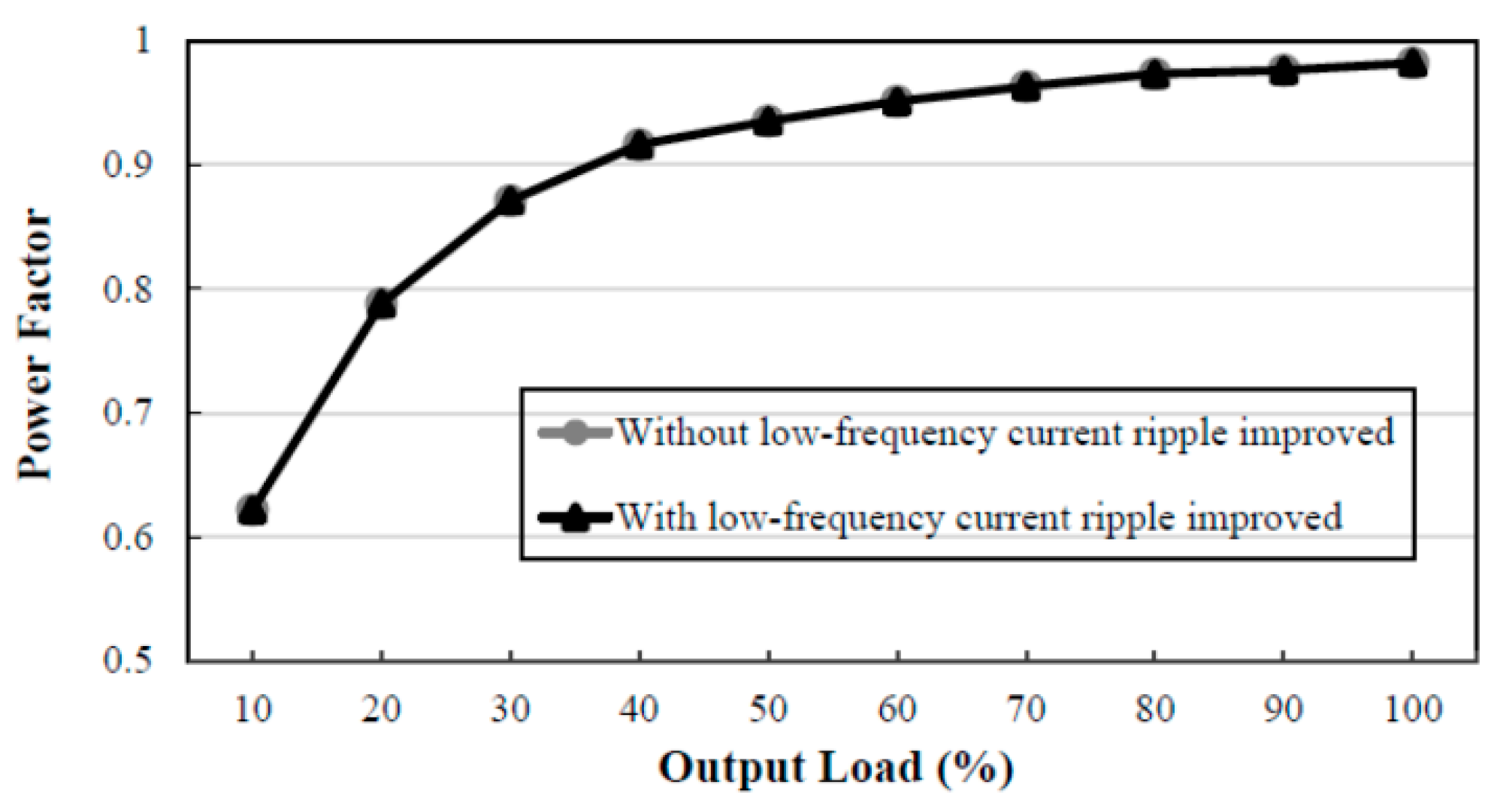

5.4.2. Power Factor Comparison

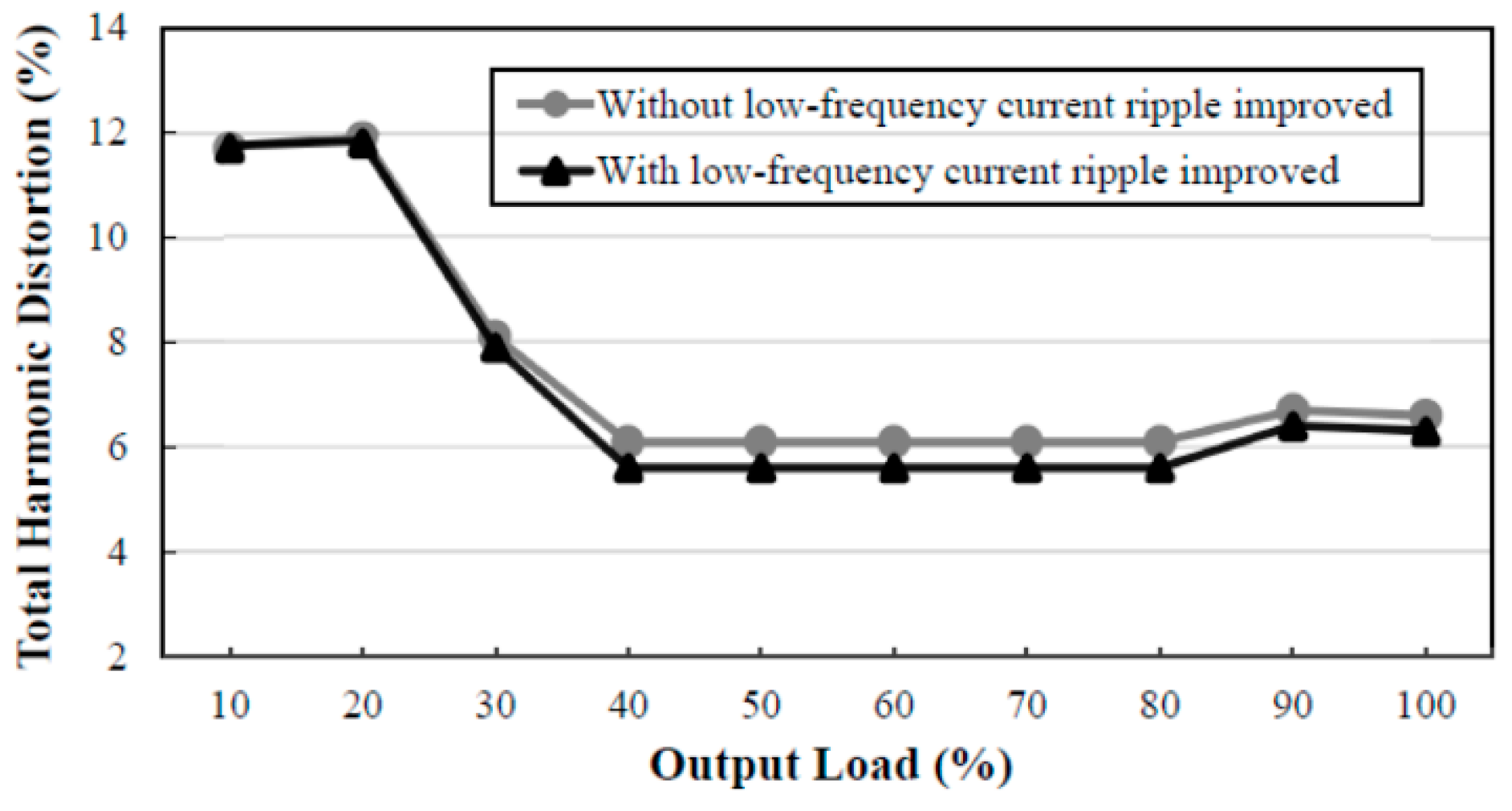

5.4.3. Total Harmonic Distortion Comparison

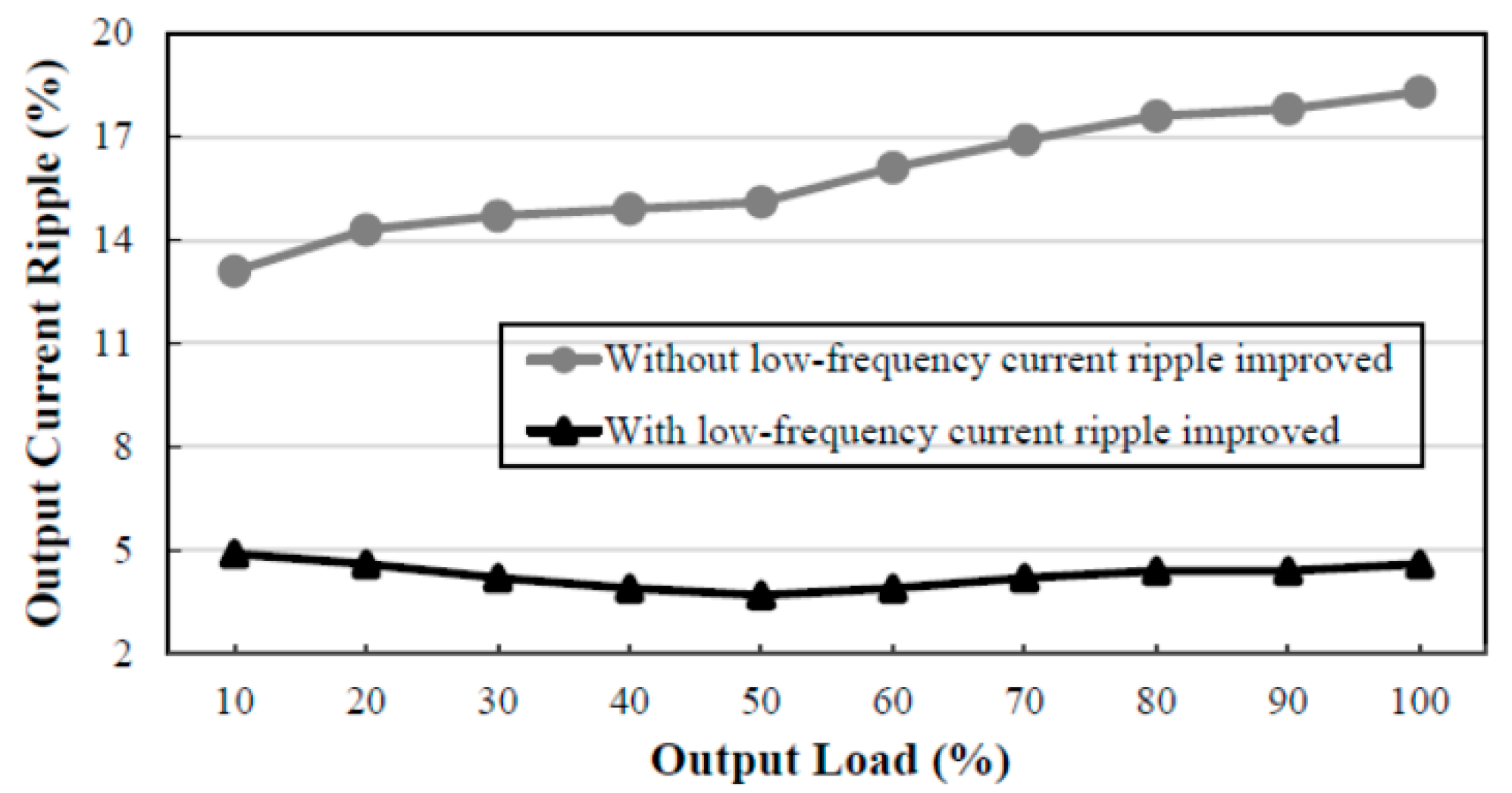

5.4.4. Output Current Ripple Comparison

6. Comparison

7. Conclusions

- (1)

- The performance on PF between the two is almost the same.

- (2)

- The performance on THD between the two is slightly different.

- (3)

- The maximum difference in efficiency between the compared and the proposed is around 1.2%.

- (4)

- The maximum difference in output current ripple percentage between the compared and the proposed is around 14%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- What is LED?-LEDinside. Available online: https://www.ledinside.com.tw/knowledge/20100108-27.html (accessed on 8 January 2018).

- ES A1 Series Datasheet—EDISO. Available online: http://www.edison-opto.com.tw/tw/product/es_a1_series (accessed on 12 June 2015).

- Loo, K.H. Overview of LED Lighting and Requirements; PE-Workshop, The Hong Kong Polytechnic University: Hong Kong, China, 2011; pp. 1–61. [Google Scholar]

- Pousset, N.; Rougie, B.; Razet, A. Impact of current supply on LED colour. Lighting Res. Technol. 2010, 42, 371–383. [Google Scholar] [CrossRef]

- Poplawski, M.; Miller, N. SSL Flicker Fundamentals and Why We Care; U.S. Department Energy: Washington, DC, USA, 2014.

- U.S. Department of Energy. Solid State Lighting Technology Fact Sheet. Available online: https://www1.eere.energy.gov/buildings/publications/pdfs/ssl/flicker_fact-sheet.pdf (accessed on 1 March 2013).

- Wu, S. Single-stage high power factor flyback for LED lighting. Application Note; AN012, RICHTEK. 2014. Available online: http://www.richtek.com/~/media/AN%20PDF/AN012_TW.pdf (accessed on 1 April 2014).

- Zhao, S.; Ge, X.; Wu, X.; Zhang, J. Analysis and design considerations of two-stage AC-DC LED driver without electrolytic capacitor. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 2602–2610. [Google Scholar]

- Lee, S.; Do, H. Boost-integrated two-switch forward AC-DC LED driver with high power factor and ripple-free output inductor current. IEEE Trans. Ind. Electron. 2017, 64, 5789–5796. [Google Scholar] [CrossRef]

- Collin, A.J.; Djokic, S.Z.; Drapela, J.; Langella, R.; Testa, A. Light flicker and power factor labels for comparing LED lamp performance. IEEE Trans. Power Electron. 2019, 55, 7062–7070. [Google Scholar] [CrossRef]

- Matsuo, H.; Kurokawa, F.; Lee, B.; Akise, K. Suppression of the input current harmonics and output voltage ripple using the novel multiple-input AC-DC converter. In Proceedings of the 1997 IEEE International Telecommunications Energy Conference (INTELEC), Melbourne, Australia, 23–23 October 1997; pp. 710–714. [Google Scholar]

- Hahn, J.; Enjeti, P.N.; Pitel, I.J. A new three-phase power-factor correction (PFC) scheme using two single-phase PFC modules. IEEE Trans. Ind. Appl. 2002, 38, 123–130. [Google Scholar] [CrossRef]

- Kamnarn, U.; Chunkag, V. Analysis and design of a modular three-phase AC-to-DC converter using CUK rectifier module with nearly unity power factor and fast dynamic response. IEEE Trans. Power Electron. 2009, 24, 2000–2012. [Google Scholar] [CrossRef]

- He, J.; Ruan, X.; Zhang, L. Adaptive voltage control for bidirectional converter in flicker-free electrolytic capacitor-less AC–DC LED driver. IEEE Trans. Ind. Electron. 2017, 64, 320–324. [Google Scholar] [CrossRef]

- Qiao, C.; Smedley, K.M. A topology survey of single-stage power factor corrector with a boost type input-current-shaper. IEEE Trans. Power Electron. 2001, 16, 360–368. [Google Scholar] [CrossRef]

- Gu, L.; Ruan, X.; Xu, M.; Yao, K. Means of eliminating electrolytic capacitor in AC/DC power supplies for LED lightings. IEEE Trans. Power Electron. 2009, 24, 1399–1408. [Google Scholar] [CrossRef]

- Wang, B.; Ruan, X.; Yao, K.; Xu, M. A method of reducing the peak-to-average ratio of LED current for electrolytic capacitor-less AC-DC drivers. IEEE Trans. Power Electron. 2010, 25, 592–601. [Google Scholar] [CrossRef]

- Lam, J.C.W.; Jain, P.K. A modified valley fill electronic ballast having a current source resonant inverter with improved line-current total harmonic distortion (THD), high power factor, and low lamp crest factor. IEEE Trans. Ind. Electron. 2008, 55, 1147–1159. [Google Scholar] [CrossRef]

- Ma, H.; Lai, J.; Feng, Q.; Yu, W.; Zheng, C.; Zhao, Z. A novel valley-fill SEPIC-derived power supply without electrolytic capacitor for LED lighting application. IEEE Trans. Power Electron. 2012, 27, 3057–3071. [Google Scholar] [CrossRef]

- Yau, Y.; Hwu, K.; Jiang, W. Two-phase interleaved boost converter with ZVT turn-on for main switches and ZCS turn-off for auxiliary switches based on one resonant loop. Appl. Sci. 2018, 10, 3881. [Google Scholar] [CrossRef]

- Available online: https://math.stackexchange.com/questions/2579556/infinity-divided-by-infinity (accessed on 11 August 2020).

- Erickson, R.W. Fundamentals of Power Electronics, 2nd ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Available online: https://www.st.com/resource/en/application_note/cd00004040-design-equations-of-highpowerfactor-flyback-converters-based-on-the-l6561-stmicroelectronics.pdf (accessed on 1 September 2003).

- Hwu, K.I.; Yau, Y.T.; Chang, Y.C. Full-digital AC-DC converter with PFC based on counting. IEEE Trans. Ind. Inform. 2015, 11, 122–131. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Input Voltage (vac) | 90–277 V ± 5% (85–295 V) |

| Input Voltage Frequency (fac) | 60 Hz |

| Maximum Output Voltage (Vo,max) | 86.4 V () |

| Maximum Output Current (Io,max) | 350 mA |

| Minimum Output Current (Io,min) | 35 mA |

| Converter Efficiency () | 85% |

| Minimum Switching Frequency (fs,min) | 55 kHz |

| LED String | 24 LEDs in series |

| Name | Symbol | Value | Unit |

|---|---|---|---|

| Maximum Output Voltage | Vo,max | 86.4 | V |

| Maximum Output Current | Io,max | 0.35 | A |

| Maximum Output Power | Po,max | 30.24 | W |

| Converter Efficiency | η | 85 | % |

| Minimum Input Voltage | vac,min | 85 | Vrms |

| Minimum Input Voltage | vac,max | 295 | Vrms |

| Minimum Switching Frequency | fs,min | 55 | kHz |

| Component | Part Name |

|---|---|

| S1 | IPA90R1K2 |

| Do | SFF1008G |

| Co | 390 uF/100 V Rubycon |

| T1 | A-CORE RM8 with N1 = 51, N2 = 46 |

| Q1 | 2SD1816 |

| OP1, OP2 | LM2904 |

| Rs | 0.2 Ω |

| R1 | 4.7 kΩ |

| R2 | 0.3 kΩ |

| VR1 | 100 kΩ |

| Rx | 10 kΩ |

| Rref | 4.7 kΩ |

| VCC | 12.3 V |

| Controller | LD7830 |

| Photocoupler | EL817 |

| Output Load [%] | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Traditional OCR [%] | 13.1 | 14.3 | 14.7 | 14.9 | 15.1 | 16.1 | 16.9 | 17.6 | 17.8 | 18.3 |

| Proposed OCR [%] | 4.9 | 4.6 | 4.2 | 3.9 | 3.7 | 3.9 | 4.2 | 4.4 | 4.4 | 4.6 |

| Improvement Traditional/Proposed | 2.7 | 3.1 | 3.5 | 3.9 | 4.1 | 4.1 | 4.1 | 4.0 | 4.0 | 4.0 |

| Output Load [%] | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Traditional OCR [%] | 10.9 | 13.0 | 13.9 | 14.3 | 14.6 | 15.4 | 16.1 | 16.5 | 16.9 | 17.1 |

| Proposed OCR [%] | 4.9 | 4.6 | 3.8 | 3.4 | 3.2 | 3.4 | 3.6 | 3.8 | 3.9 | 4.0 |

| Improvement Traditional/Proposed | 2.2 | 2.9 | 3.7 | 4.2 | 4.6 | 4.5 | 4.5 | 4.3 | 4.4 | 4.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yau, Y.-T.; Hwu, K.-I.; Liu, K.-J. AC–DC Flyback Dimmable LED Driver with Low-Frequency Current Ripple Reduced and Power Dissipation in BJT Linearly Proportional to LED Current. Energies 2020, 13, 4270. https://doi.org/10.3390/en13164270

Yau Y-T, Hwu K-I, Liu K-J. AC–DC Flyback Dimmable LED Driver with Low-Frequency Current Ripple Reduced and Power Dissipation in BJT Linearly Proportional to LED Current. Energies. 2020; 13(16):4270. https://doi.org/10.3390/en13164270

Chicago/Turabian StyleYau, Yeu-Torng, Kuo-Ing Hwu, and Kun-Jie Liu. 2020. "AC–DC Flyback Dimmable LED Driver with Low-Frequency Current Ripple Reduced and Power Dissipation in BJT Linearly Proportional to LED Current" Energies 13, no. 16: 4270. https://doi.org/10.3390/en13164270

APA StyleYau, Y.-T., Hwu, K.-I., & Liu, K.-J. (2020). AC–DC Flyback Dimmable LED Driver with Low-Frequency Current Ripple Reduced and Power Dissipation in BJT Linearly Proportional to LED Current. Energies, 13(16), 4270. https://doi.org/10.3390/en13164270