Abstract

In this study, the influence of freeze/thaw cycles on the mechanical and thermal properties of bricks and mortar as building parts of masonry walls, as well as the influence on the masonry wall itself is investigated. At the material level, the influence of freeze and thaw cycles on the mechanical and thermal properties of masonry components (bricks and mortar) was investigated; at the construction level, the influence of freeze and thaw cycles on the mechanical and thermal properties of a masonry wall was studied. To study the influence of freezing on the energy demand characteristics of masonry buildings, in terms of energy conservation and greenhouse gas emission, a case study was investigated on a typical structure of a historical building located in Croatia, that had undergone a process of energy certification. The applied freeze/thaw regime negatively influenced the compressive strength and the thermal properties of bricks and mortar, as well as the mechanical and thermal properties of the wall. Considering the thermal properties of the material before and after its exposure to freeze/thaw cycles, we concluded that the annual energy consumption, the heating costs, and the CO2 emission of a family house could increase up to 3.7% after frost action in the studied case.

1. Introduction

The durability of buildings has become one of the most pressing issues in contemporary building construction. Often the basic properties of buildings weaken after only ten years. The numerous causes of building deterioration manifest in terms of the partial or full building destruction, extension and remodeling, repurposing, etc. The most frequent cause of masonry structure deterioration is humidity/moisture. Regardless of the manner, it entered the wall, humidity can cause an entire range of building degradation mechanisms, i.e., chemical processes that alter the masonry unit and the building properties. Therefore, the buildings no longer perform in the manner in which they were designed to, which is indicated by means of wall surface damage, spalling, change in color, crumbling, increased permeability, cracking, swelling, or shrinkage. The most significant building degradation mechanisms caused by moisture include [1,2] mineral alteration, salt crystallization, freezing/thawing damage, and biological colonization. The freezing action in a masonry unit/brick occurs when the temperature drops below 0 °C, at which point the process of water freezing inside the brick is initiated. The expansion of ice results in the increase of stresses within the material. The intensity of the stress caused by freezing depends on the number of pores in the material and on the level of its saturation [3]; a higher proportion of pores causes greater stress, whereas, in the case of a low saturation level, the stress is negligible because the free space in the pores allows the water to expand during freezing. If the generated stress exceeds the brick strength, the brick will be damaged, owing to the repeated freezing and thawing cycles. Apart from affecting the mechanical properties of masonry units, humidity has a negative effect on their thermal properties as well. The thermal conductivity value of porous building materials increases rapidly with the increase in their moisture content; consequently, the insulation capacity decreases and the heat loss increases [4,5,6,7,8,9,10,11,12,13,14,15]. The increase in the thermal conductivity of a material with the increase in its moisture content is the direct result of the fact that water, which has replaced the air in the pores of the material, has a thermal conductivity value of 0.61 W/(mK) at air temperature [16], which is twenty-four times higher than that of air. Although the conductivity coefficient increases continuously with the increase in the moisture level of the material, it is necessary to stress that the initial increase in the moisture content causes a sharp increase in the conductivity coefficient. The sharper increase in the value of the coefficient at a lower moisture level is explained by the fact that during the wetting of the material, water first fills the finer pores and capillaries, whose effect on the thermal conductivity is more significant than that of the larger pores. The thermal conductivity increases additionally in the case where water freezes within the material because the thermal conductivity value of ice exceeds 2.0 W/(mK) [17], which is approximately four times higher than that of water.

The decreased mechanical properties of wall units owing to the influence of humidity and, consequently, owing to the influence of freeze/thaw cycles, will directly affect the walls, which consist of such units. At present, the estimation of the actual energy performance of buildings has become a priority to achieve energy conservation; therefore, it is important to evaluate the thermal performance of masonry considering all influencing parameters on the energy performance of buildings. Recent research performed conducted Litti et al. [13] on areas that were detected to be wet revealed thermal transmittance values that were more than three times higher than those of the dry areas on the same masonry surface. Considering the aforementioned points, it is extremely important to quantify the actual thermal transmittance of the wall and the influencing factors in order to be able to plan optimal refurbishment interventions.

According to EN 771-1 [18], the freeze/thaw resistance category of a clay masonry unit shall be declared by the manufacturers in reference to its applicability to masonry, or elements subjected to passive, moderate, and severe exposure (F0, F1, and F2, respectively). However, there is also a possibility for manufacturers not to test all the properties of their product. This should be clearly indicated in the Declaration of Performance, marking the non-tested property as NPD (no performance determined). The same procedure is followed for the testing of the brick resistance to freeze/thaw cycles. In this manner, bricks that are not resistant to freeze/thaw cycles can be made available in the market. According to Reference [19], one out of eight brick types available in the market are non-resistant to freeze/thaw cycles. In larger buildings, the designer will prescribe the need for masonry units to be tested in freeze/thaw cycles. For smaller buildings, such as family houses, such a need is omitted; consequently, bricks that are not resistant to freeze/thaw cycles can be inbuilt. Family houses often remain unplastered, which directly allows atmosferills to affect the properties of the materials and the structure.

In this study, the influence of freeze/thaw cycles on the mechanical and thermal properties of bricks and mortar as building parts of masonry walls will be investigated, as well as the influence on a masonry wall itself. To study the influence of freezing on the energy demand characteristics of masonry buildings, in terms of energy conservation and greenhouse gas emission, a case study will be investigated on the typical structure of a historical building located in Croatia that has undergone a process of energy certification.

2. Experimental Part

The experimental part of the paper is divided into three subparts. The experimental part focused on the material level, the construction level, and a case study on the energy demand of masonry buildings as influenced by freeze/thaw cycles. In the part focused on the material level, the influence of the freeze/thaw cycles on the mechanical and thermal properties of masonry components (namely, bricks and mortar) was investigated. The second experimental part focused on the construction level, the influence of the freeze/thaw cycles on the mechanical and thermal properties of the masonry wall itself. In the third part, the impact of the freeze/thaw cycles on the energy efficiency of a real building was investigated.

2.1. Influence of the Freeze/Thaw Cycles on the Properties of Bricks and Mortar

Four types of full bricks available in the market and cement mortar with a cement-to-sand ratio of 1:3 were considered in the present study. Bricks 1 and 2 were hand-molded bricks, whereas bricks 3 and 4 were molded with an extrusion machine. The mortar was prepared with CEM II/B-M (P-S) 32.5R, with a density of 3050 kg/m3 and a water-to-cement ratio of 0.55. Mortar in its fresh state was tested for consistency according to EN 1015-3 [20], for density according to EN 1015-6 [21], and for the pore content according to EN 1015-7 [22]. The results of the tests on mortar in its fresh state are listed in Table 1.

Table 1.

Properties of mortar in its fresh state.

The mortar specimens were first stored in a polyethylene bag in the mold for two days, left for five days outside the mold, and finally, they were placed in the chamber under controlled conditions with a 65 ± 5% moisture content until the sample reached an age of 28 days, as prescribed in EN 1015-11 [23].

For assessing the effects of the freeze/thaw cycles on masonry materials, the bricks and mortar were subjected to compressive strength tests before and after their exposure to freeze/thaw cycles. The same properties were used for the estimation of the ratio. In this study, a higher compressive strength ratio means that the resistance of the material to the freeze/thaw action would be greater. Although European standards specify that the resistance of bricks to freezing/thawing cycles should be checked according to CEN/TS 772-22 [24], owing to the insufficient number of bricks for the manufacturing of the test wall, a different method, namely HRN B.D8.011 [25], was employed in the present work. According to HRN B.D8.011, the water-saturated samples were placed in the refrigerator and were exposed to a temperature of −20 ± 2 °C for 4 h. Next, the samples were immersed in water, where they were kept for 4 h at a temperature of 15 to 20 °C. This cycle was repeated 25 times and the condition of the sample was checked after every cycle. The brick was considered to be resistant to freezing/thawing cycles if the signs of damage were not visible on any of the tested samples after 25 cycles of freezing and thawing in water. In the present study, all observed bricks were estimated as resistant to freeze/thaw cycles according to HRN B.D8.011. The mortar specimens subjected to freeze/thaw cycles were treated in the same manner. The compressive strength of the brick specimens was tested according to EN 772-1 [26], whereas the compressive strength of the mortar specimen was tested according to EN 1015-11 [23]. The thermal conductivity and the thermal diffusivity of the mortar and of bricks 1 and 3, prior to and after their exposure to freeze/thaw cycles, were tested according to ISO 22007-2 [27]. Three tests were conducted for each of the observed properties observed in this study.

2.2. Influence of the Freeze/Thaw Cycles on the Properties of a Masonry Wall

The influence of the freeze/thaw cycles on the mechanical properties of masonry walls was studied through the initial shear strength, which was tested using real wall sample. The influence of the freeze/thaw cycles on the thermal properties of a masonry wall was investigated using a computer simulation. The test specimens for the determination of the initial shear strength were manufactured by interconnecting three bricks using mortar, as per EN 1052-3 [28], where the mortar layer had a thickness of 10 mm. Six samples with a 250 mm thickness were prepared for each brick type (Figure 1). Three samples were used for the initial shear-strength testing at room temperature and the remaining three were used for the initial shear-strength testing after exposure to freeze/thaw cycles. The samples exposed to freeze/thaw cycles were subjected to a total of 25 freeze/thaw cycles, similar to the brick and mortar samples. Prior to being subjected to freeze/thaw cycles, the samples were immersed in water for 24 h.

Figure 1.

Wall specimens for the initial shear strength.

Based on the results of the laboratory tests before and after freezing the samples, the heat transfer modeling of the wall was made in the COMSOL Multiphysics v5.3a simulation software (COMSOL Multiphysics® v. 5.3a. COMSOL AB, Stockholm, Sweden) [29]. Two models were made, with brick 1 and 3 for two types of environmental conditions, i.e., before and after freezing (Table 2), to study the influence of freezing on the thermal properties of the wall. Brick 1 was chosen as a representative of the hand-molded bricks and brick 3 was chosen as a representative of the extruded brick. The walls were modeled using the tested thermal properties of the brick and mortar obtained from prior and after the samples had been subjected to freeze/thaw cycles.

Table 2.

Model definition.

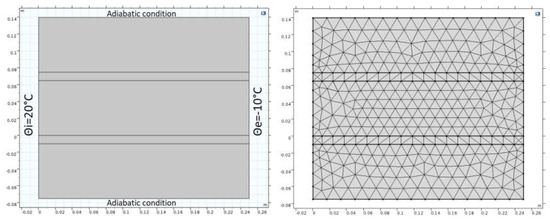

In this study, a steady heat transfer through a wall was analyzed, meaning that the internal and external temperatures were constant over time. The convection and radiation from the internal environment to the internal surface of the wall, as well as the convection and radiation from the external surface of the wall to the external environment, were considered in the heat transfer coefficient, i.e., the internal and external thermal resistance. The values of thermal resistance used in the simulation corresponded to typical values provided in the ISO 6946 [30] standard. This means that the values used in the present study for Rsi and Rse were 0.13 and 0.04 m2·K/W, respectively. The wall was modeled in correspondence to construction technology as a single-layer wall, with a thickness of 250 mm and mortar layer/joint thickness of 10 mm. The adiabatic conditions and the boundary settings of the models are shown in Figure 2.

Figure 2.

Adiabatic conditions and boundary settings of the models under the steady-state condition.

In addition, the theoretical thermal transmittance value (U-value) is an important factor for the evaluation of the energy performance and the achievement of energy conservation in buildings for all wall models before and after freezing. It was calculated according to the following equation [30]:

where R1 is the design thermal resistance of the layer, and Rsi and Rse are the internal and the external surface resistances, respectively, with values of Rsi = 0.13 and Rse = 0.04 m2·K/W.

U = 1/(Rsi + R1 + Rse), (W/m2·K)

2.3. Influence of the Freeze/Thaw Action on the Energy Efficiency of an Actual Building

For this purpose, a case study on a family house was investigated, which had undergone a process of energy certification. The house is in the Osijek-Baranja county, Croatia (some of the major characteristics of the building are listed in Table 3). The building has natural ventilation and a central heating system, in which gas is utilized as an energy source for heating. The building has external walls constructed entirely of clay bricks. For the purpose of this study, the thermal characteristics of the external walls—subjected to freeze/thaw cycles—have been replaced with the thermal characteristics of the bricks investigated in the present study, before and after freezing.

Table 3.

Major construction characteristics of the case-study building.

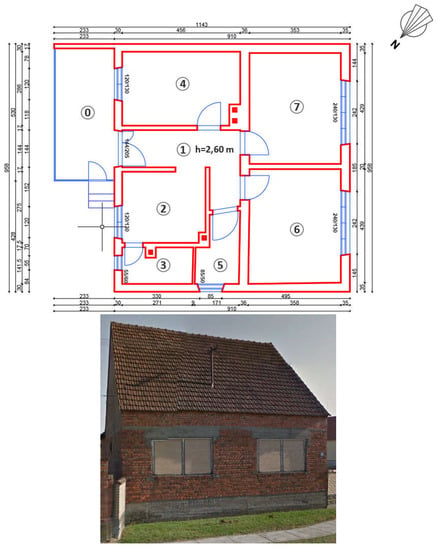

The ground floor layout and external view of the studied family house are presented in Figure 3.

Figure 3.

Layout of the ground floor and external view of the analyzed building.

Considering the characteristics of the building listed in Table 3, the annual energy consumption, heating costs, annual CO2 emissions, and the specific annual heating energy needs for referential climatic data were calculated according to EN ISO 13790 [31] using the values of the thermal properties for brick 1 and brick 3, before and after their exposure to freeze/thaw cycles.

2.4. Results and Discussion

The average values of the compressive strength and the thermal properties of the bricks and the mortar prior and after their exposure to freeze/thaw cycles, as well as the change in each of the aforementioned properties, are listed in Table 4, along with the corresponding standard deviations.

Table 4.

Properties of bricks and mortar prior and after their exposure to freeze/thaw cycles.

The average values of the initial shear strength of the wall specimens prior and after their exposure to freeze/thaw cycles, as well as the change in the value of each of the properties, are summarized in Table 5, together with the corresponding standard deviations.

Table 5.

Initial shear strength of wall samples prior and after their exposure to freeze/thaw cycles.

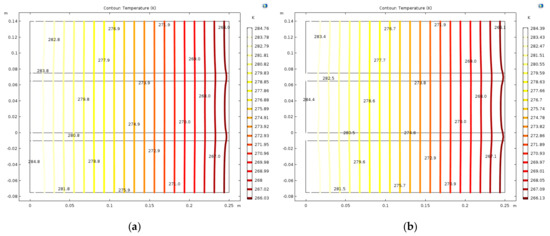

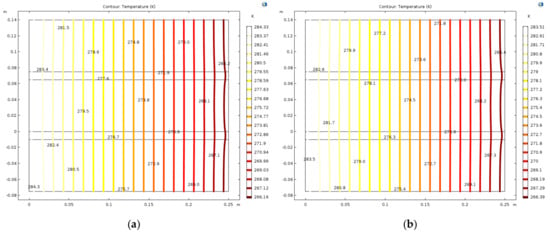

The isothermal contours of the presently studied models are illustrated in Figure 4 and Figure 5. The temperature and the heat flux distribution across the cross section were compared between the models both graphically and numerically, before and after freezing (Table 6).

Figure 4.

Isothermal contours in model 1: (a) Prior exposure to freeze/thaw cycles and (b) after exposure to freeze/thaw cycles.

Figure 5.

Isothermal contours in model 2: (a) Prior exposure to freeze/thaw cycles and (b) after exposure to freeze/thaw cycles.

Table 6.

Percentile difference in the temperature and the heat flux distribution across the cross-section in the x-direction.

The calculated thermal transmittance values for walls constructed using brick 1 and brick 3 before and after their freezing are listed in Table 7.

Table 7.

Calculated U-value of walls.

The annual energy consumption, heating costs, the annual CO2 emissions, and the specific annual heating energy for referential climatic data for the building that was constructed using brick 1 and brick 3, before and after their exposure to freeze/thaw cycles, are listed in Table 8.

Table 8.

Building major annual energy demand characteristics.

Observing the results in Table 4, it may be seen that the compressive strength of all materials (brick and mortar) decreased after their exposure to freeze/thaw cycles in the range of 14–27%. Moreover, the differences in the compressive strength ratios after and prior to the freeze/thaw actions were more pronounced in hand-made bricks (27% and 14%, respectively) than in extruded bricks (19% and 23%, respectively). This was probably caused by the greater uniformity in the molding of the extruded bricks. Meanwhile, the thermal conductivity and the thermal diffusivity increased in all materials in the range of 6–19% and 3–19%, respectively, after being exposed to freeze/thaw cycles. It should be noted that the changes in the thermal properties were less in the case of the hand-made bricks than in the case of the extruded bricks. The present authors expected that the brick with the highest decrease in compressive strength would achieve a higher increase in thermal properties; however, this was not the case. More specifically, it was shown by Martinez et al. [32] that materials with high open porosity are less durable during weathering. Meanwhile, the thermal properties of the material are more influenced by a closed porosity [33]. It is likely that the bricks with a higher compressive strength ratio after and before freeze/thaw cycles had a higher content of open pores, whereas the bricks with a higher thermal-properties ratio had a higher content of closed pores. By observing Table 5, it was clear that the values of the initial shear strength decreased after freezing for the wall samples; the change in the shear strength before and after the freeze/thaw cycles ranged from 6–11%.

As observed in Figure 4 and Figure 5, the increase in the thermal conductivity after wall exposure to freeze/thaw cycles resulted in a decrease in the temperature gradient and an increase in the heat flux.

As observed in Table 7, the value of the thermal transmittance increased by 10% for the wall made of brick 3 and by 4% for the wall made of brick 1 after their exposure to freeze/thaw cycles. Such results were expected, considering that the thermal properties of brick 3, which were integrated to model 2, underwent a greater change when exposed to freeze/thaw cycles than that of brick 1, which were integrated to model 1 of the wall.

From Table 8, it was observed that when the thermal properties obtained via experimental testing after freezing were applied, the energy consumption, the heating costs, and the CO2 emission increased by more than 1% on an annual basis in the building made of brick 1, and by more than 3% in the building made of brick 3. Although the percentages may appear negligible, it should be emphasized that the influence of 1% and 3% refers to a single family house with a useful area of only 80.33 m2 and that the thermal properties were evaluated for only 60.42 m2 of the walls. If the entire life cycle of the building and the size of the building stock would be considered, the influence would become significantly higher.

3. Conclusions

Encouraged by the fact that clay brick units are often available in the market without a declaration regarding their resistance to freeze/thaw cycles, the authors investigated how freeze/thaw cycles affect such units and the walls in which they are built, in terms of to their exposure to the freeze/thaw action. The influence of the freeze/thaw cycles on the mechanical and thermal properties of masonry materials, as well as the mechanical and thermal properties of the masonry itself, was studied. Based on the results of the research, it may be concluded that by neglecting this property, the brick and the wall suffer from loss of mechanical and thermal properties, which is evident in the consumption of energy for the heating of the buildings, in which such types of bricks are installed. Ignoring the need for testing the freeze/thaw resistance on bricks/masonry units is often a consequence of the high demands of the devices required for testing this property, as well as the test sample massiveness. This points to the need for a new, simpler method—preferably focused on masonry units—that would enable manufacturers to test the brick resistance under freeze/thaw cycles as a part of their factory production control.

Author Contributions

Formal analysis, M.T. and H.K.; investigation, M.V.; methodology, I.N.G.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Radić, J. Trajnost konstrukcija 1; Hrvatska Sveučilišna Naklada: Zagreb, Croatia, 2010. [Google Scholar]

- Pavia, S.; Bolton, J. Stone, Brick and Mortar: Historical Use, Decay and Conservation of Building Materials in Ireland; Wordwell, Bray: Dublin, Ireland, 2002. [Google Scholar]

- Koroth, S.R. Evaluation and Improvement of Frost Durability of Clay Bricks—A Thesis in The Centre for Building Studies; Concordia University: Montreal, QC, Canada, 1997. [Google Scholar]

- Koronthalyova, O.; Matiasovsky, P. Thermal Conductivity of Fibre Reinforced Porous Calcium Silicate Hydrate-based Composites. J. Therm. Envel. Build. Sci. 2003, 27, 71–89. [Google Scholar] [CrossRef]

- Dos Santos, W.N. Effect of moisture and porosity on the thermal properties of a conventional refractory concrete. J. Eur. Ceram. Soc. 2003, 23, 745–755. [Google Scholar] [CrossRef]

- Ochs, F.; Heidemann, W.; Müller-Steinhagen, H. Effective thermal conductivity of moistened insulation materials as a function of temperature. Int. J. Heat Mass Transf. 2008, 51, 539–552. [Google Scholar] [CrossRef]

- Karamanos, A.; Hadiarakou, S.; Papadopoulos, A. The impact of temperature and moisture on the thermal performance of stone wool. Energy Build. 2008, 40, 1402–1411. [Google Scholar] [CrossRef]

- Mar, J.D.; Litovsky, E.; Kleiman, J. Modeling and database development of conductive and apparent thermal conductivity of moist insulation materials. J. Build. Phys. 2008, 32, 9–31. [Google Scholar] [CrossRef]

- Jerman, M.; Černý, R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Abdou, A.; Budaiwi, I. The variation of thermal conductivity of fibrous insulation materials under different levels of moisture content. Constr. Build. Mater. 2013, 43, 533–544. [Google Scholar] [CrossRef]

- Pavlík, Z.; Fiala, L.; Vejmelková, E.; Černý, R. Application of Effective Media Theory for Determination of Thermal Properties of Hollow Bricks as a Function of Moisture Content. Int. J. Thermophys. 2013, 34, 894–908. [Google Scholar] [CrossRef]

- El Fgaier, F.; Lafhaj, Z.; Chapiseau, C.; Antczak, E. Effect of sorption capacity on thermo-mechanical properties of unfired clay bricks. J. Build. Eng. 2016, 6, 86–92. [Google Scholar] [CrossRef]

- Litti, G.; Khoshdel, S.; Audenaert, A.; Braet, J. Hygrothermal performance evaluation of traditional brick masonry in historic buildings. Energy Build. 2015, 105, 393–411. [Google Scholar] [CrossRef]

- Taoukil, D.; Sick, F.; Mimet, A.; Ezbakhe, H.; Ajzoul, T. Moisture content influence on the thermal conductivity and diffusivity of wood–concrete composite. Constr. Build. Mater. 2013, 48, 104–115. [Google Scholar] [CrossRef]

- Rhee-Duverne, S.; Baker, P. Research into the Thermal Performance of Traditional Brick Walls; English Heritage Report: London, UK, 2013. [Google Scholar]

- Çengel, Y.A. Heat Transfer: A Practical Approach; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Willems, W.M.; Dinter, S.; Schild, K. Vieweg Handbuch Bauphysik Teil 1; Vieweg: Wiesbaden, Germany, 2006. [Google Scholar]

- EN 771-1:2011 Specification for Masonry Units—Part 1: Clay Masonry Units; BSI: London, UK, 2011.

- Vračević, M. A Contribution to Durability of Masonry Structures. Ph.D. Thesis, Faculty of Civil Enginnering and Architecture Osijek, Osijek, Croatia, 2019. [Google Scholar]

- EN 1015-3:1999 Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table); BSI: London, UK, 1999.

- EN 1015-6:1999 Methods of Test for Mortar for Masonry. Determination of Bulk Density of Fresh Mortar; BSI: London, UK, 1999.

- EN 1015-7:1999 Methods of Test for Mortar for Masonry. Determination of Air Content of Fresh Mortar; BSI: London, UK, 1999.

- EN 1015-11:1999 Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar; BSI: London, UK, 1999.

- CEN/TS 772-22:2006 Methods of Test for Masonry Units. Determination of Freeze/Thaw Resistance of Clay Masonry Units; BSI: London, UK, 2006.

- HRN, B. HRN B.D8.011:1987. Glinene opeke, blokovi i ploče—Metode ispitivanja, točka 9. Provjeravanje postojanosti prema mrazu; Croatian Standards Institute: Zagreb, Croatia.

- EN 772-1:2015 Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength; BSI: London, UK, 2015.

- ISO 22007-2:2015 Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method; ISO: Geneva, Switzerland, 2015.

- EN 1052-3:2002 Methods of Test for Masonry. Determination of Initial Shear Strength; BSI: London, UK, 2002.

- COMSOL 5.3a Multiphysics Modeling Software. Available online: https://www.comsol.com/ (accessed on 4 March 2019).

- ISO 6946:2017 Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods; ISO: Geneva, Switzerland, 2017.

- ISO 13790:2008 Energy Performance of Buildings—Calculation of Energy Use for Space Heating and Cooling; ISO: Geneva, Switzerland, 2008.

- Martínez-Martínez, J.; Benavente, D.; Gomez-Heras, M.; Marco-Castaño, L.; García-del-Cura, M.Á. Non-linear decay of building stones during freeze-thaw weathering processes. Constr. Build. Mater. 2013, 38, 443–454. [Google Scholar] [CrossRef]

- Zaidan, S.A.; Hamood, A.F.; Ibrahim, S.N. Effect of Porosity on Thermal Conductivity and Flexural Strength of Ceramic Foam. Eng. Technol. J. 2016, 34, 610–620. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).