Digital Twin Approach for Fault Diagnosis in Photovoltaic Plant DC–DC Converters

Abstract

1. Introduction

2. State-of-the-Art

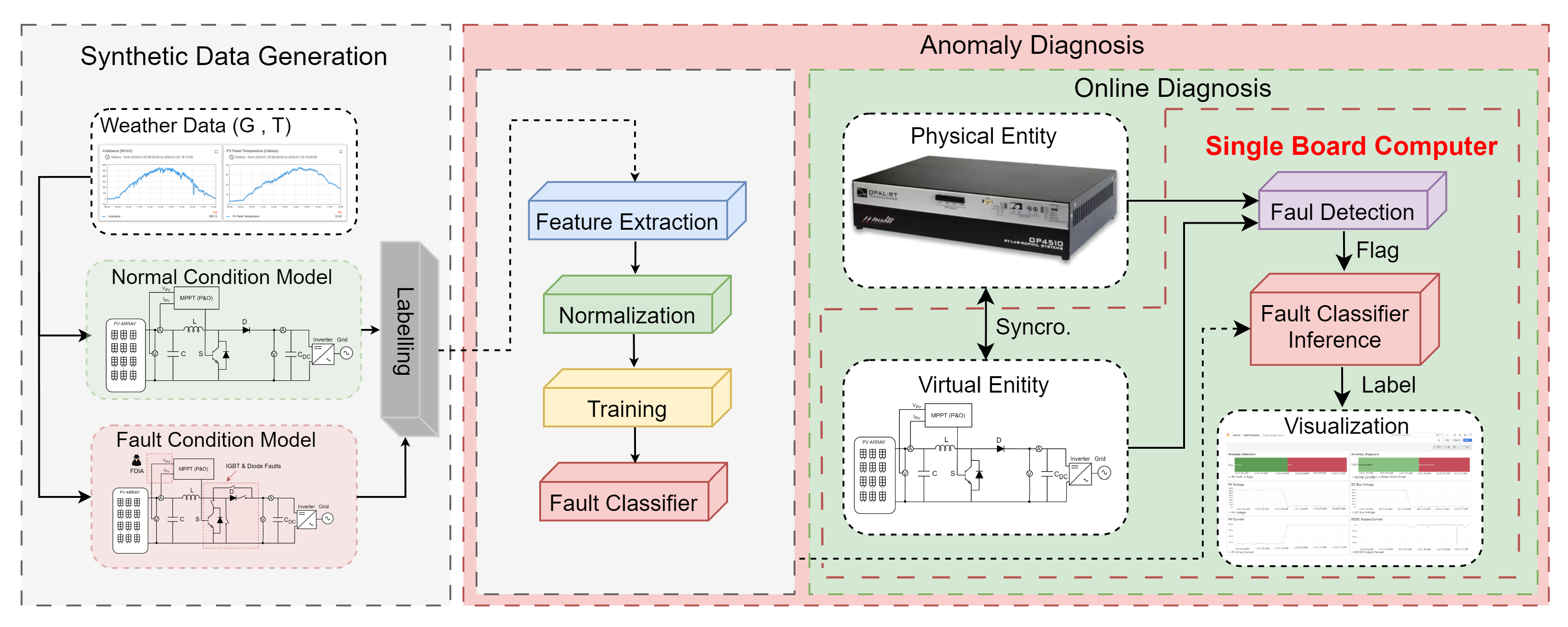

- Hybrid Digital Twin-Based Fault Diagnosis Framework: This work proposes a complete system that combines FMI-based [19] emulation (FMU), real-time data acquisition, feature extraction, and machine learning-based classification. This hybrid approach enables both fault detection and identification (diagnosis) in DC–DC converters within PV systems.

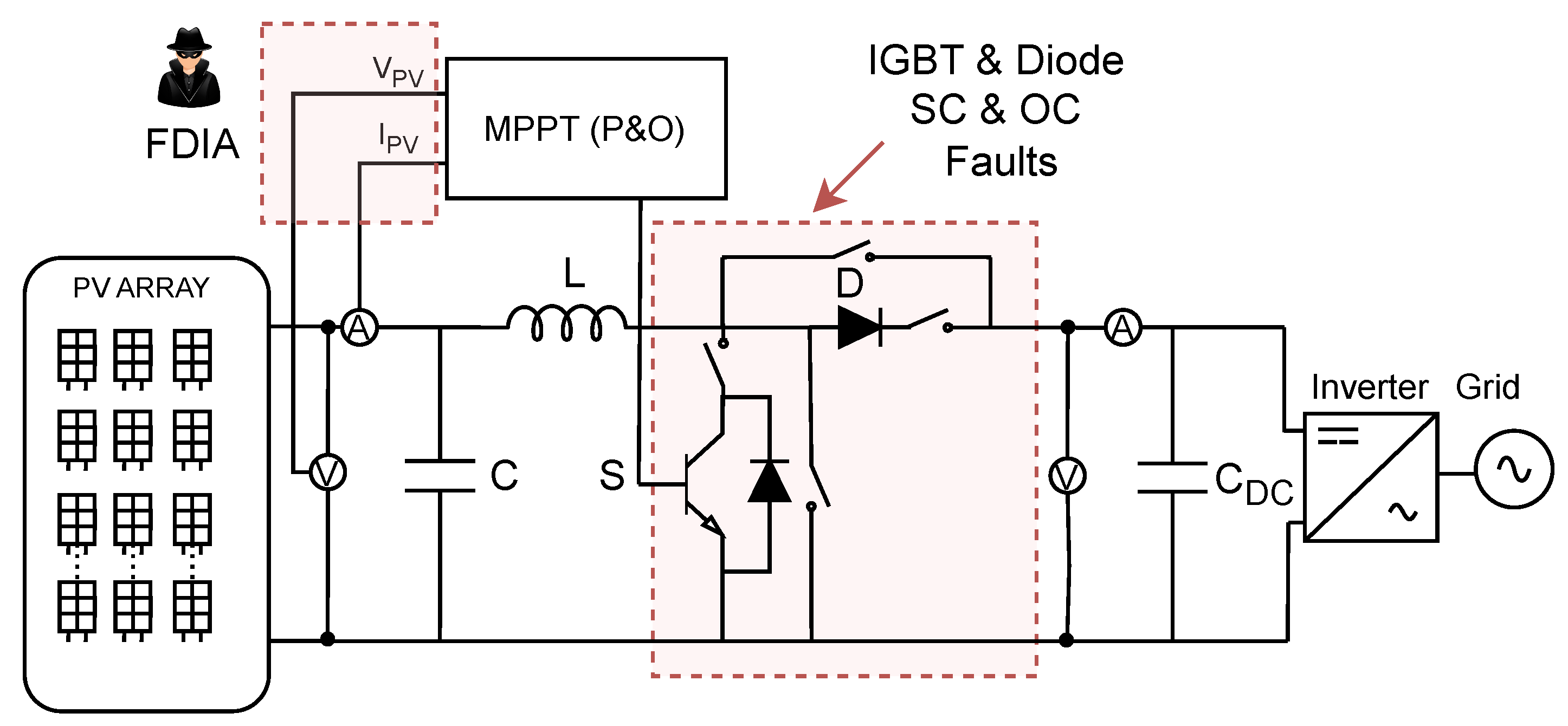

- Detection of Multiple Fault Types: The proposed method effectively identifies not only classical hardware faults such as IGBT and diode open/short circuits but also false data injection attacks (FDIAs) targeting voltage and current sensors. This extends fault coverage to cyber-physical threats.

- Scalable, Portable, and Low-Cost Architecture for Real-World Deployment: The proposed framework is designed with practical deployment in mind. Thanks to a physics-based normalization strategy, it maintains high performance across PV plants with different power ratings without requiring model retraining. Furthermore, the solution is fully compatible with low-cost embedded hardware such as Raspberry Pi 5 [20] and employs the FMI standard to ensure modularity and interoperability across different environments. These features make the system both scalable and portable, suitable for real-time operation in heterogeneous PV plants.

3. Photovoltaic Plant Digital Twin

3.1. Physical Entity

3.2. Virtual Entity

3.2.1. OpenModelica

3.2.2. FMI Standard Framework

3.2.3. Virtual Entity Validation

3.3. Information Management

3.4. Communications

3.5. Services

4. Digital Twin Implementation

4.1. Synthetic Data Generation Service

- Windowing: A time window was extracted to capture the dynamic behavior of the fault in the sample range of , corresponding to a duration of .

- Resampling: A decimation factor of was applied to reduce the original sequence of samples to:resulting in a compact matrix of dimensions 4 × 40, representing the four signal channels.

- Labelling: The labelling process was guided by Table 4, which defines the fault categories and their associated class labels. Given the common limitation of data availability in industrial PV environments, this approach was designed to maximize the diagnostic utility of the available samples, ensuring that each instance contributes effectively to the training and evaluation of the anomaly diagnosis system.

4.2. Anomaly Diagnosis Service

4.2.1. Offline Training

- Feature Extraction: Raw signal windows are transformed into structured representations through a designed feature extraction process. Each observation window, comprising multichannel time series data, is mapped to a feature vector consisting of different numerical descriptors. These features aim to capture relevant statistical, temporal, and spectral characteristics from each signal channel.Table 5 summarizes the feature groups extracted from the multichannel signal window. Each group captures a different aspect of the signal: basic statistical moments, spectral properties via FFT, time-frequency information using wavelet decomposition (db4, level 2), and dynamic behaviours of the DC bus voltage. These features are concatenated into a single vector and used as input for the fault classification model. The selected features in Table 5 were chosen based on their relevance to the electrical behavior of PV systems and their ability to capture different aspects of the signal. First-order statistics provide general descriptive metrics, spectral features obtained via FFT identify frequency-domain anomalies, wavelet-based descriptors capture localized transient phenomena, and features derived from the DC bus voltage reveal dynamics critical to fault identification. This combination ensures both high discriminative power and interpretability, avoiding overfitting by limiting feature redundancy.To reduce redundancy and improve generalisation, a two-stage feature selection strategy was applied.Stage 1: Low-variance filtering.A low-variance filter was used to eliminate nearly constant features that do not contribute discriminative information. Specifically, features with variance below a fixed threshold were removed:This threshold strikes a balance between filtering out noise and retaining meaningful variability in the data.Stage 2: Embedded feature selection via mean decrease in impurity (MDI).An embedded selector based on Mean Decrease in Impurity was employed using a random forest with 300 trees. Each feature was assigned an importance score , based on its contribution to impurity reduction across the forest. The subset of features was selected such that the cumulative importance satisfied:where n is the total number of features and is the number of selected features accounting for 95% of the total importance.Both steps were executed independently within each fold of the nested cross-validation procedure to avoid information leakage and overfitting.This approach consistently reduced the dimensionality of the feature space by approximately 60%, without degrading the macro-F1 performance, and yielded a compact, interpretable feature set that preserved the most relevant descriptors for fault classification.

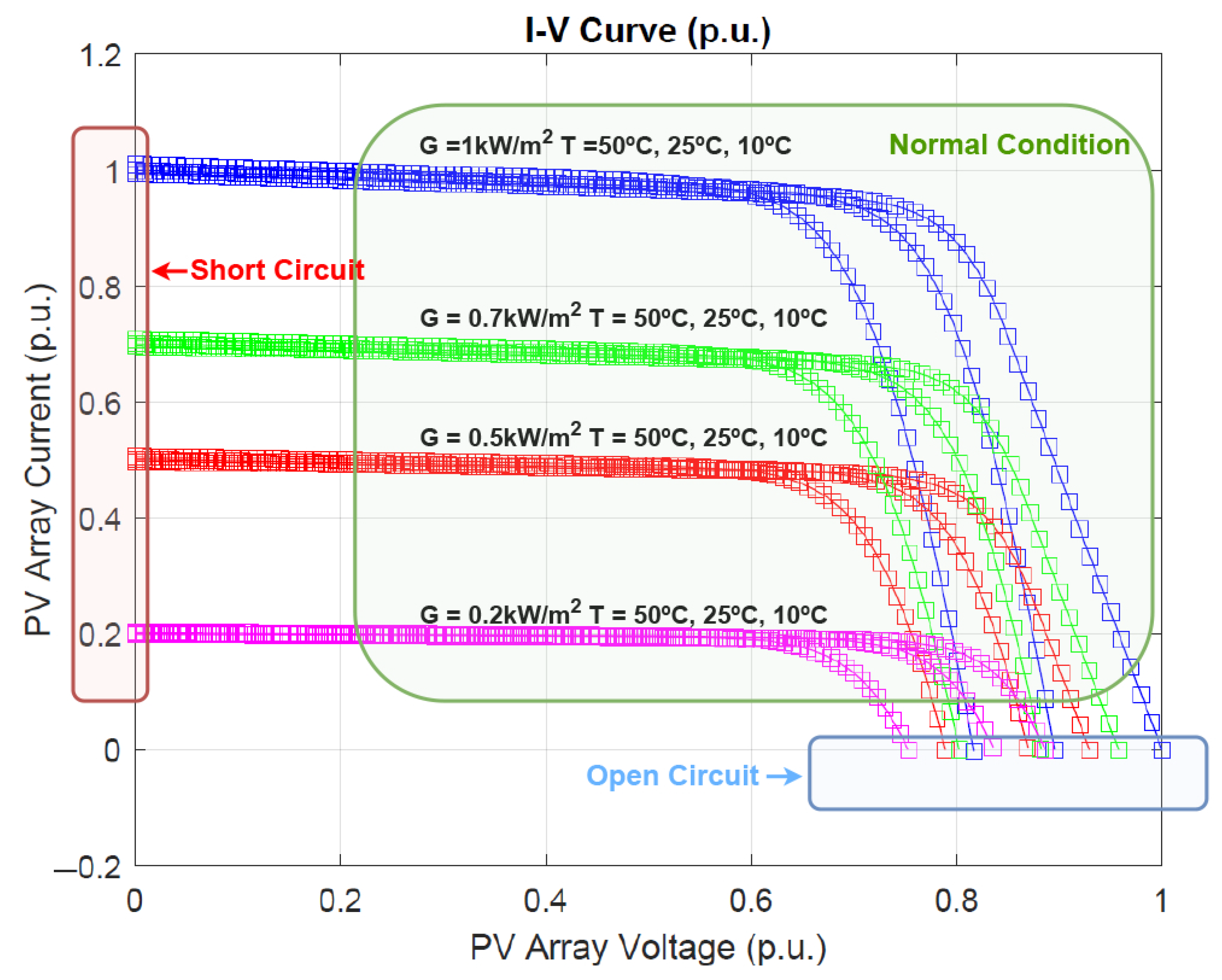

- Normalization: Each channel signal is normalized by its nominal value , which corresponds to a characteristic voltage or current level. This normalization strategy ensures compatibility and portability across PV plants with different power ratings, yielding input signals within a comparable range regardless of system scale:In practice, the normalization constants are selected based on standard operating conditions: (i) is normalized with respect to the short-circuit current (Isc) at 10 °C and 1000 W/m2 irradiance; (ii) is normalized with the open-circuit voltage (Voc) under the same standard conditions; (iii) is normalized using the nominal DC bus voltage plus a 10% margin to account for expected variations under normal operating conditions; and (iv) is normalized similarly to , as both currents typically have similar magnitudes.This normalization process, applied during the preprocessing stage, improves the robustness and generalization capability of the diagnostic method across different systems and environmental conditions.

- Fault Classifier Training: Table 6 presents the cross-validation performance (macro-averaged F1-score) and training times for the evaluated classification models. The goal of this comparison is to assess both the accuracy and computational efficiency of different algorithms in identifying fault types based on the extracted feature vectors. The selected hyperparameters for each model were chosen based on standard practices and preliminary tuning aimed at achieving a balance between performance and generalization. For ensemble-based methods such as Random Forest and Extra Trees, a moderately high number of estimators is used to ensure stability and low variance without incurring excessive computational cost. In gradient boosting models like XGBoost, typical configurations such as learning rate and tree depths of 3 to 6 were adopted to control model complexity and avoid overfitting. For the support vector machine (SVM) with RBF kernel, a regularization parameter of provided a good margin–flexibility trade-off, especially considering the high-dimensional feature space (134 descriptors). In the case of K-Nearest Neighbors, a small value of allowed the model to remain sensitive to local patterns while maintaining robustness. Among all models, Random Forest achieved the best performance, with an F1-macro score of 0.992, followed closely by XGBoost. The combination of extracted features and selected hyperparameters proved effective across multiple algorithmic families, highlighting the robustness of the proposed representation and its compatibility with a wide range of classifiers.

- Physics informed rules: To enhance the reliability and interpretability of the anomaly classification process, a set of deterministic, physics-informed rules is applied after the machine learning (ML) stage. These rules are specifically designed to handle cases where the ML model may produce ambiguous or conflicting fault labels. By using physical domain knowledge and signal characteristics, these rules help refine and guide the final classification decision. A key challenge lies in distinguishing between an open-circuit fault in the IGBT and one in the diode, as their waveform signatures are very similar. By incorporating this domain-specific knowledge into the learning process, the classification performance can be significantly improved.Table 7 shows two representative examples. In the first case, when the classifier simultaneously suggests an open-circuit fault in both the IGBT and the diode, the decision is made based on the comparison of voltage deltas before and after the transient. If the upward voltage jump () is greater than the downward jump (), the fault is attributed to an open IGBT. In the second case, when there is ambiguity between a current or voltage bias, the mean deviation from the nominal values is computed for both signals. The fault is attributed to the signal exhibiting the greater deviation, thereby indicating whether the anomaly is more consistent with a voltage or current bias. This rule-based postprocessing layer serves as a lightweight and interpretable mechanism to enhance diagnostic robustness and reduce false positives.

4.2.2. Online Diagnosis

- Data Acquisition and Storage:UDP packets are received every 1 ms, each containing eight double-precision values: PV plant power, emulation clock, irradiance, temperature, PV array voltage, PV array current, DC bus voltage, and DC–DC output current. From these, the last four measurements: PV array voltage, PV array current, DC bus voltage, and DC–DC output current, are used to construct a time-windowed observation vector for subsequent analysis and fault diagnosis.Each of these four signal channels is stored in a circular buffer of fixed length , defined as:

- Fault Detection: Fault detection is carried out using the virtual entity developed in the previous section. The detection mechanism relies on the comparison between emulated and real measurements from the physical system. When a significant discrepancy is observed i.e., a sudden deviation in the real power, current, or voltage compared to the virtual entity estimation, an alert flag is triggered. To determine whether or not a discrepancy is significant, a threshold is defined based on the results of prior validation tests. If the deviation between virtual and real values exceeds this threshold, the system considers that an anomaly or fault has occurred, activates the corresponding flag, and launches the classifier to identify the fault type. Data from the physical entity are received at a fixed timestep of . At each step, the simulated power , current , and voltage are computed by the FMU and compared with the real measurements from the HIL physical entity: .The absolute power error is calculated as:And the relative errors in voltage and current are defined as:where is a small constant added to avoid division by zero.These thresholds have been defined based on the validation tests presented in Section 3, where it was observed that, even on one of the worst-performing days, the error between the virtual and the physical entities was only 0.61%. Therefore, the selection of the threshold can be adjusted depending on how conservative the desired detector is, always considering the validation error margins established during validation.

- Fault Classification: For this stage of the anomaly diagnosis service, the classifier developed in the previous section is utilized. When the detector flag is triggered, the classifier retrieves four signal traces, each consisting of 40 samples, to identify the type of anomaly. Once the anomaly has been classified, the result is sent to the database for storage and subsequent representation through the visualization service.

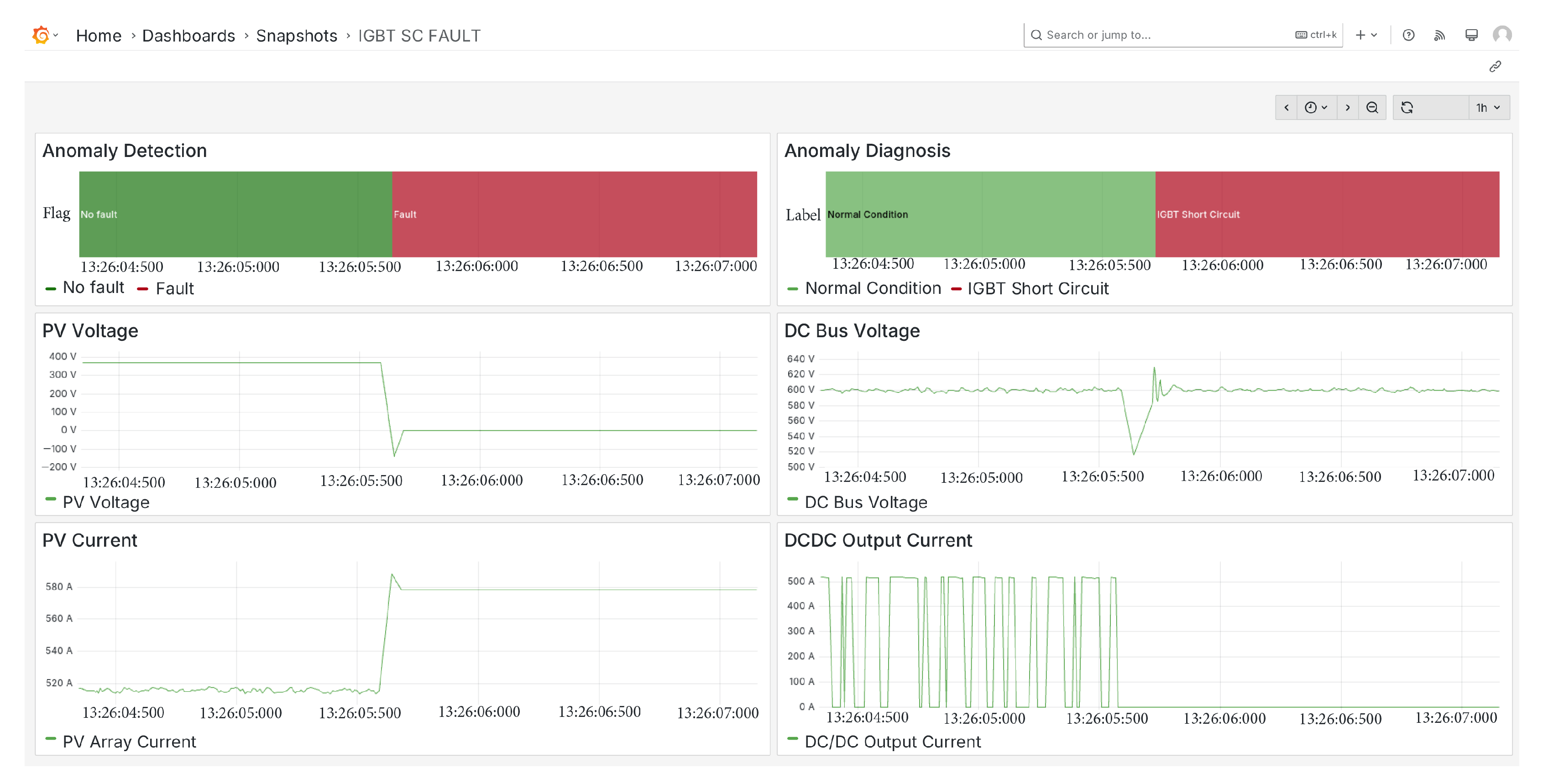

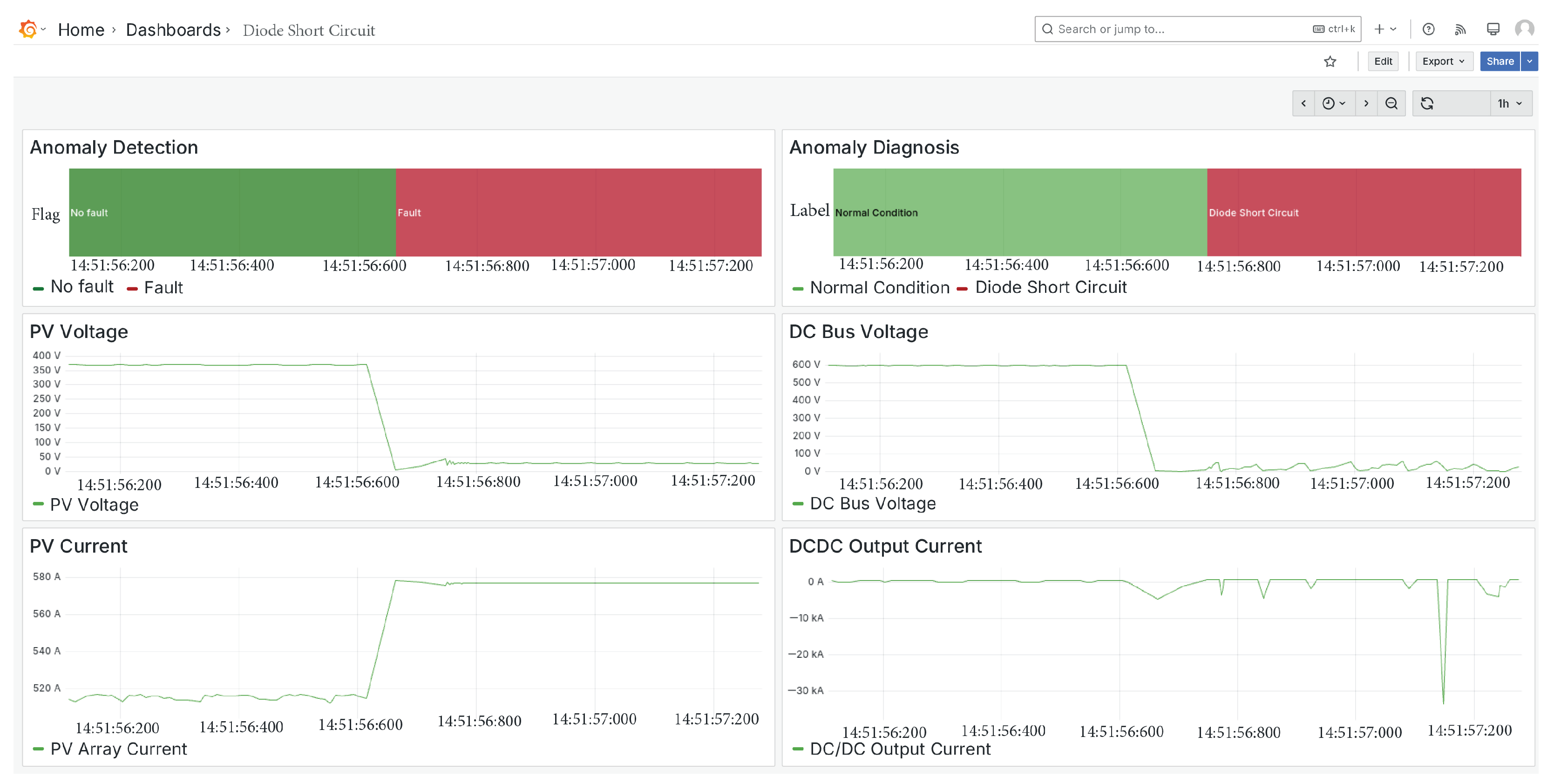

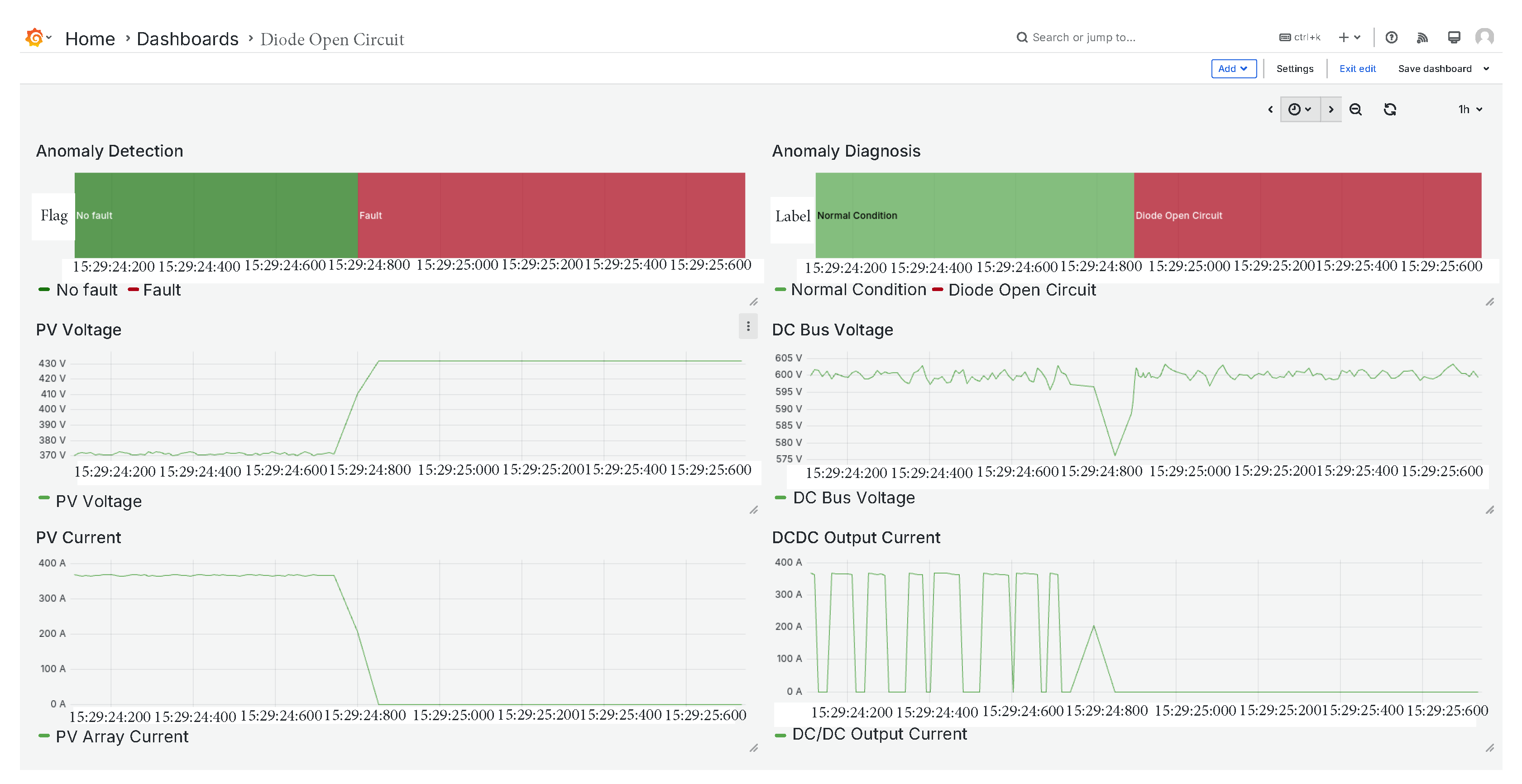

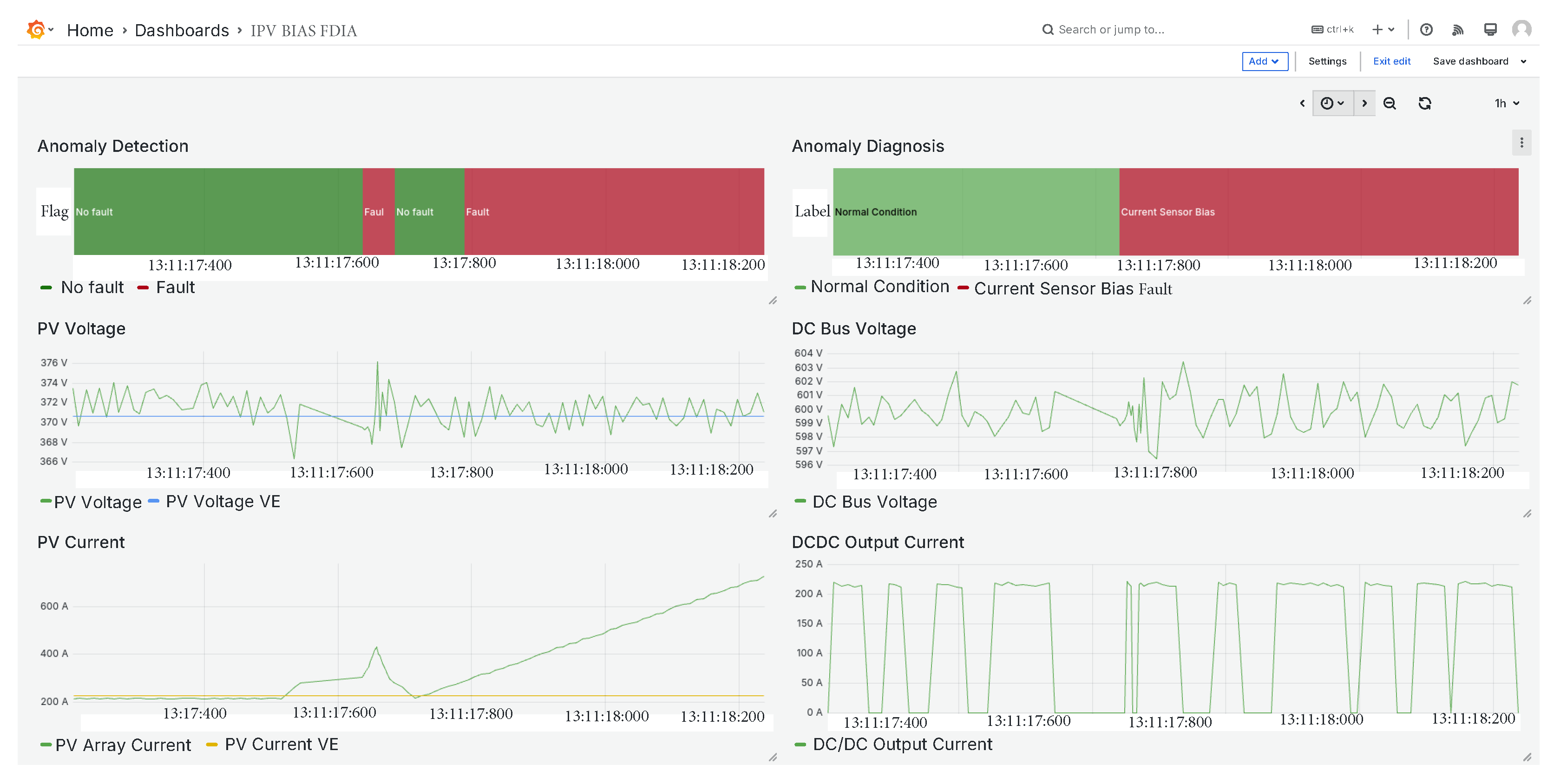

4.3. Visualization Service

4.4. DT Implementation and Cost Analysis

5. Results

5.1. Metrics by Fault Type

5.2. IGBT Short Circuit Fault

5.3. Diode Short Circuit Fault

5.4. IGBT Open Circuit Fault

5.5. Diode Open Circuit Fault

5.6. PV Array Current Sensor FDIA

5.7. PV Array Voltage Sensor FDIA

5.8. Deployment Analysis on a Low-Cost Platform

- 8 channels: CPU utilisation stabilises at 10 %.

- 96 channels: the load rises modestly to 17 %.

- 192 channels: even at the highest load, the CPU peaks at only 30 %.

- (i)

- Horizontal scaling: When the channel count exceeds the real-time capacity of a single Raspberry Pi, extra boards can be added in a mesh and synchronised via NTP. Each node handles local acquisition and FMU-based diagnosis, whereas an MQTT broker [32] hosted on any node or a lightweight edge server will carry out the high-level diagnostics. The architecture scales linearly with the number of nodes while keeping per-device latency constant.

- (ii)

- Hot-plug detectors: Diagnostic algorithms are containerised as micro-services that can be loaded or unloaded without stopping the main loop. Adding a new fault type therefore introduces only the incremental CPU cost of its container, leaving existing detectors untouched.

- (iii)

- Adaptive off-loading: If sustained CPU utilisation exceeds 80%, the framework can switch to an off-load mode: (a) raw feature vectors are compressed and forwarded to the cloud, or (b) only anomaly flag detection is published, while detailed analysis is deferred to a more powerful backend.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FMI | Functional Mock-Up Interface Standard |

| FMU | Functional Mock-Up Unit |

| FDIA | False Data Injection Attack |

| DT | Digital Twin |

| PV | Photovoltaic |

| SBC | Single Board Computer |

| MiL | Model-in-the-Loop |

| SiL | Software-in-the-Loop |

| HIL | Hardware-in-the-Loop |

| SDM | Single Diode Model |

| OMEdit | OpenModelica Connection Editor |

| SCF | Short Circuit Fault |

| OCF | Open Circuit Fault |

References

- Wu, R.; Blaabjerg, F.; Wang, H.; Liserre, M.; Iannuzzo, F. Catastrophic failure and fault-tolerant design of IGBT power electronic converters—An overview. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 507–513. [Google Scholar] [CrossRef]

- Susinni, G.; Rizzo, S.A.; Iannuzzo, F. Two Decades of Condition Monitoring Methods for Power Devices. Electronics 2021, 10, 683. [Google Scholar] [CrossRef]

- Mohagheghi, S.; Harley, R.G.; Habetler, T.G.; Divan, D. Condition Monitoring of Power Electronic Circuits Using Artificial Neural Networks. IEEE Trans. Power Electron. 2009, 24, 2363–2367. [Google Scholar] [CrossRef]

- Ahadi, A.; Ghadimi, N.; Mirabbasi, D. Reliability assessment for components of large scale photovoltaic systems. J. Power Sources 2014, 264, 211–219. [Google Scholar] [CrossRef]

- Gallardo-Saavedra, S.; Hernández-Callejo, L.; Duque-Pérez, O. Quantitative failure rates and modes analysis in photovoltaic plants. Energy 2019, 183, 825–836. [Google Scholar] [CrossRef]

- Liu, W.; Han, B.; Zheng, A.; Zheng, Z. Fault Diagnosis for Reducers Based on a Digital Twin. Sensors 2024, 24, 2575. [Google Scholar] [CrossRef]

- Fan, J.; Zhao, L.; Li, M. Research on Digital Twin Modeling and Fault Diagnosis Methods for Rolling Bearings. Sensors 2025, 25, 2023. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence Through Virtual Factory Replication. White Pap. 2014, 1, 1–17. [Google Scholar]

- MKP, M.R.; Ahmad, M.W. An Integrated Approach for Current Balancing and Open-Circuit Fault Diagnosis for Interleaved Boost Converter. IEEE Trans. Ind. Electron. 2024, 71, 13310–13318. [Google Scholar] [CrossRef]

- Ribeiro, E.; Cardoso, A.J.M.; Boccaletti, C. Fault-Tolerant Strategy for a Photovoltaic DC–DC Converter. IEEE Trans. Power Electron. 2013, 28, 3008–3018. [Google Scholar] [CrossRef]

- Kim, T.; Lee, H.W.; Kwak, S. Open-Circuit Switch-Fault Tolerant Control of a Modified Boost DC–DC Converter for Alternative Energy Systems. IEEE Access 2019, 7, 69535–69544. [Google Scholar] [CrossRef]

- Jamshidpour, E.; Poure, P.; Saadate, S. Photovoltaic Systems Reliability Improvement by Real-Time FPGA-Based Switch Failure Diagnosis and Fault-Tolerant DC–DC Converter. IEEE Trans. Ind. Electron. 2015, 62, 7247–7255. [Google Scholar] [CrossRef]

- Pazouki, E.; Sozer, Y.; De Abreu-Garcia, J.A. Fault Diagnosis and Fault-Tolerant Control Operation of Nonisolated DC–DC Converters. IEEE Trans. Ind. Appl. 2018, 54, 310–320. [Google Scholar] [CrossRef]

- Espinoza-Trejo, D.R.; Castro, L.M.; Barcenas, E.; Sanchez, J.P. Data-Driven Switch Fault Diagnosis for DC/DC Boost Converters in Photovoltaic Applications. IEEE Trans. Ind. Electron. 2024, 71, 1631–1640. [Google Scholar] [CrossRef]

- Jain, P.; Poon, J.; Singh, J.P.; Spanos, C.; Sanders, S.R.; Panda, S.K. A Digital Twin Approach for Fault Diagnosis in Distributed Photovoltaic Systems. IEEE Trans. Power Electron. 2020, 35, 940–956. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jamshidpour, E.; Poure, P.; Saadate, S.; Zolghadri, M.R. Open-and short-circuit switch fault diagnosis for nonisolated DC-DC converters using field programmable gate array. IEEE Trans. Ind. Electron. 2013, 60, 4136–4146. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Gorla, N.B.Y.; Malik, H.; Panda, S.K. A Fault Diagnosis and Postfault Reconfiguration Scheme for Interleaved Boost Converter in PV-Based System. IEEE Trans. Power Electron. 2021, 36, 3769–3780. [Google Scholar] [CrossRef]

- Givi, H.; Farjah, E.; Ghanbari, T. Switch and Diode Fault Diagnosis in Nonisolated DC–DC Converters Using Diode Voltage Signature. IEEE Trans. Ind. Electron. 2018, 65, 1606–1615. [Google Scholar] [CrossRef]

- Functional Mock-up Interface (FMI) Standard Project. Available online: https://fmi-standard.org/ (accessed on 20 January 2024).

- Foundation, R. Raspberry Pi 5. Available online: https://www.raspberrypi.com/products/raspberry-pi-5/ (accessed on 10 March 2025).

- NIST. Photovoltaic Testbeds. Available online: https://www.nist.gov/el/energy-and-environment-division-73200/heat-transfer-alternative-energy-systems/photovoltaic-1 (accessed on 24 October 2024).

- Opal RT Technologies. OP4510. Available online: https://www.opal-rt.com/ (accessed on 10 March 2025).

- de Brito, M.A.G.; Sampaio, L.P.; Luigi, G.; e Melo, G.A.; Canesin, C.A. Comparative analysis of MPPT techniques for PV applications. In Proceedings of the 2011 International Conference on Clean Electrical Power (ICCEP), Ischia, Italy, 14–16 June 2011; pp. 99–104. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Y.; Gou, B. A Data-Driven Method for IGBT Open-Circuit Fault Diagnosis Based on Hybrid Ensemble Learning and Sliding-Window Classification. IEEE Trans. Ind. Inform. 2020, 16, 5223–5233. [Google Scholar] [CrossRef]

- Salcedo, R.O.; Nowocin, J.K.; Smith, C.L.; Rekha, R.P.; Corbett, E.G.; Limpaecher, E.R.; Lapenta, J.M. Development of a Real-Time Hardware-in-the-Loop Power Systems Simulation Platform to Evaluate Commercial Microgrid Controllers; Technical Report; Lincoln Laboratory, Massachusetts Institute of Technology: Lexington, MA, USA, 2016. [Google Scholar]

- OpenModelica. Available online: https://openmodelica.org/ (accessed on 1 March 2025).

- Villalva, M.G.; Gazoli, J.R.; Filho, E.R. Comprehensive Approach to Modeling and Simulation of Photovoltaic Arrays. IEEE Trans. Power Electron. 2009, 24, 1198–1208. [Google Scholar] [CrossRef]

- Sierla, S.; Azangoo, M.; Rainio, K.; Papakonstantinou, N.; Fay, A.; Honkamaa, P.; Vyatkin, V. Roadmap to semi-automatic generation of digital twins for brownfield process plants. J. Ind. Inf. Integr. 2022, 27, 100282. [Google Scholar] [CrossRef]

- InfluxData. InfluxDB. Available online: https://www.influxdata.com/ (accessed on 1 March 2025).

- Grafana Labs Grafana. Available online: https://grafana.com/ (accessed on 1 March 2025).

- Fassi, Y.; Heiries, V.; Boutet, J.; Boisseau, S. Toward Physics-Informed Machine-Learning-Based Predictive Maintenance for Power Converters—A Review. IEEE Trans. Power Electron. 2024, 39, 2692–2720. [Google Scholar] [CrossRef]

- MQTT.org. MQTT Protocol. Available online: https://mqtt.org/ (accessed on 24 January 2025).

| Reference | Transferability | Required Signals | Fast Variable DC Input Source | Type of Faults | Topology | Digital Twin Approach |

|---|---|---|---|---|---|---|

| [9] | Limited | Diode current and input current | None | Switch OCF | Interleaved boost converter | No |

| [10] | Limited | Control signals of the converter, input and output current and voltage | Yes | Switch OCF and SCF | Three level boost converter | No |

| [11] | Limited | Current and voltage signals | None | Switch OCF | Modified boost converter | No |

| [12] | Limited | Voltage and current signals | None | Switch OCF and SCF | Single switch boost converter | No |

| [13] | Limited | Control signals, inductor current, input and output voltages | None | Switch OCF and SCF | Nonisolated boost converter | No |

| [14] | Limited | PV current and voltage | Yes | Switch OCF and SCF | Single switch boost converter | No |

| [15] | Yes | System output and DT estimation | None | Switches OCF and SCF, sensor faults | Four switch buck-boost converter | Yes |

| [16] | Limited | Inductor current slope | None | Switch OCF and SCF | Nonisolated single-ended boost converter | No |

| [17] | Limited | Input current, switching frequency component, phase angle | Yes | Switch OCF | Interleaved boost converter | No |

| [18] | Limited | Diode voltage and IGBT control signal | None | Switch and Diode OCF and SCF | Single switch buck converter | No |

| This work | Yes | Input and output current and voltage | Yes | Switch and diode OCF and SCF, FDIA sensors | Single switch boost converter | Yes |

| Parameter | Value |

|---|---|

| Array Rated DC Power [kW] () | 100 |

| Module Model | SunPower SPR-305E-WHT-D, EE.UU |

| Module Rated Power [W] | 305.226 |

| Modules Per String | 5 |

| Number of Source Circuits | 66 |

| DC Bus Voltate [V] | 500 |

| Inverter Power [kW] | 100 |

| Comparison | NRMSE (%) | R2 |

|---|---|---|

| VE vs. Real | 6.05 | 0.93 |

| PE vs. Real | 5.92 | 0.93 |

| VE vs. PE | 0.61 | 0.99 |

| Faulty Component | Label |

|---|---|

| No fault | Normal Condition |

| IGBT OC | Open Circuit IGBT |

| IGBT SC | Short Circuit IGBT |

| Diode OC | Open Circuit Diode |

| Diode SC | Short Circuit Diode |

| FDIA Voltage Sensor | Voltage Sensor Fault |

| FDIA Current Sensor | Current Sensor Fault |

| Group | Features | Key Formulas |

|---|---|---|

| 1st-order Statistics | 4 × 8 | |

| FFT Spectrum | 4 × 2 | , |

| Wavelets db4 () | 4 × 6 | on A2, D2, and D1 |

| DC Bus Dynamics | 4 |

| Model | Key Parameters | F1 Score | Training Time [s] |

|---|---|---|---|

| Random Forest | 0.992 ± 0.010 | 2 | |

| XGBoost | , depth = 6 | 0.987 ± 0.022 | 4 |

| SVM–RBF | 0.973 ± 0.031 | 14 | |

| KNN | 0.964 ± 0.035 | <1 | |

| Extra Trees | 300 trees | 0.962 ± 0.029 | 2 |

| Conflicting Case | Physical Metric | Decision |

|---|---|---|

| IGBT OC vs. Diode OC | , | OC |

| Current vs. Voltage Bias | vs. | Voltage Bias ⇐ first is greater |

| Parameter | Value |

|---|---|

| Array Rated DC Power [kW] () | 271 |

| Module Model | Sharp NU-U235F2, Japan |

| Module Rated Power [W] | 235 |

| Modules Per String | 12 |

| Number of Source Circuits | 96 |

| DC Bus Voltate [V] | 600 |

| Inverter Power [kW] | 260 |

| Fault Type | Precision (P) | Recall (R) | F1-Score |

|---|---|---|---|

| Current Sensor Bias | 0.918 | 0.804 | 0.857 |

| Diode Open Circuit | 0.901 | 1.000 | 0.948 |

| Diode Short Circuit | 1.000 | 1.000 | 1.000 |

| IGBT Open Circuit | 1.000 | 0.890 | 0.942 |

| IGBT Short Circuit | 1.000 | 1.000 | 1.000 |

| Normal Condition | 0.998 | 1.000 | 0.999 |

| Voltage Sensor Bias | 0.825 | 0.926 | 0.873 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hueros-Barrios, P.J.; Rodríguez Sánchez, F.J.; Martín Sánchez, P.; Santos-Pérez, C.; Sangwongwanich, A.; Novak, M.; Blaabjerg, F. Digital Twin Approach for Fault Diagnosis in Photovoltaic Plant DC–DC Converters. Sensors 2025, 25, 4323. https://doi.org/10.3390/s25144323

Hueros-Barrios PJ, Rodríguez Sánchez FJ, Martín Sánchez P, Santos-Pérez C, Sangwongwanich A, Novak M, Blaabjerg F. Digital Twin Approach for Fault Diagnosis in Photovoltaic Plant DC–DC Converters. Sensors. 2025; 25(14):4323. https://doi.org/10.3390/s25144323

Chicago/Turabian StyleHueros-Barrios, Pablo José, Francisco Javier Rodríguez Sánchez, Pedro Martín Sánchez, Carlos Santos-Pérez, Ariya Sangwongwanich, Mateja Novak, and Frede Blaabjerg. 2025. "Digital Twin Approach for Fault Diagnosis in Photovoltaic Plant DC–DC Converters" Sensors 25, no. 14: 4323. https://doi.org/10.3390/s25144323

APA StyleHueros-Barrios, P. J., Rodríguez Sánchez, F. J., Martín Sánchez, P., Santos-Pérez, C., Sangwongwanich, A., Novak, M., & Blaabjerg, F. (2025). Digital Twin Approach for Fault Diagnosis in Photovoltaic Plant DC–DC Converters. Sensors, 25(14), 4323. https://doi.org/10.3390/s25144323