Abstract

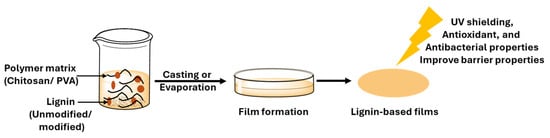

Lignin, an abundant and renewable biopolymer, has gained significant attention as a sustainable modifier and building block in polymeric materials. Recent advancements highlight its potential to tailor mechanical, thermal, and barrier properties of polymers while offering a greener alternative to petroleum-based additives. This review provides an updated perspective on the incorporation of lignin into various polymer matrices, focusing on lignin modification techniques, structure–property relationships, and emerging applications. Special emphasis is given to recent innovations in lignin functionalization and its role in developing high-performance, biodegradable, and recyclable materials such as polyurethanes, epoxy resins, phenol-formaldehyde resins, lignin-modified composites, and lignin-based films, coatings, elastomers, and adhesives. These lignin-based materials are gaining attention for potential applications in construction, automated industries, packaging, textiles, wastewater treatment, footwear, supporting goods, automobiles, printing rollers, sealants, and binders.

1. Introduction

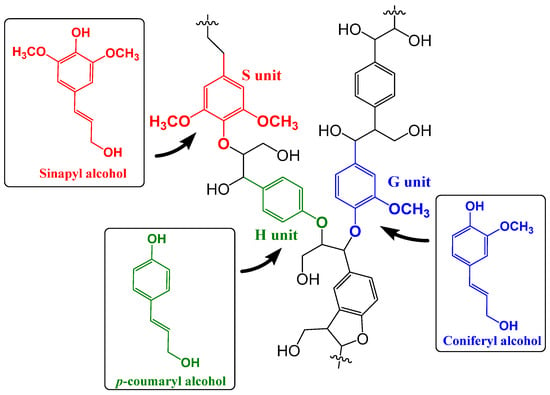

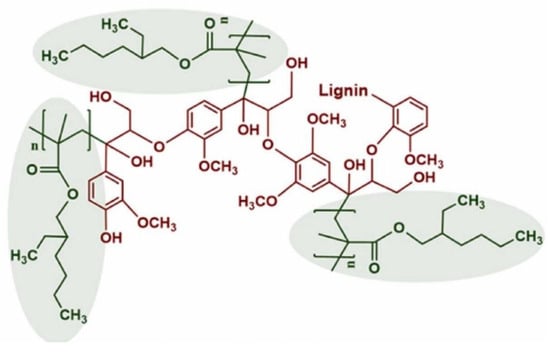

Lignin is a complex organic biopolymer found in the plant cell walls, providing rigidity and resistance to decay. It is an abundant byproduct of the pulp and paper industry (~50 million tons of lignin), ethanol and textile industry (~30 million tons of lignin), and the agricultural sector [1,2]. However, less than 2% of lignin from these sources is currently utilized, with the remaining predominantly burned as low-cost fuel, raising significant environmental concerns [3,4,5]. Therefore, converting lignin into value-added products is crucial for addressing future economic and ecological challenges. Lignin is mainly composed of monolignol units [p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S)]. interconnected through aryl ether or carbon–carbon bonds to form their three-dimensional (3D) network (Figure 1) [6]. The various functionalized aromatic groups present in lignin make it a promising candidate to replace petrochemicals. Additionally, lignin is naturally hydrophilic, and its rigid structure imparts unique properties to polymer matrices.

Figure 1.

Schematic representation of the structure of lignin, composed of monolignol units.

Due to its aromatic hydroxyl functionalities and abundant π–π conjugation, lignin offers biocompatibility, flame retardancy, UV resistance, antibacterial and antioxidant activities, thermal stability, and the ability to modify mechanical properties [7,8,9]. These characteristics have made lignin the focus of numerous studies and reviews, highlighting its versatility as a polymer additive. It has been successfully incorporated into lignin-derived polyurethanes (PUs), epoxy resins, phenol-formaldehyde resins, polyesters, polylactic acid (PLA), bio-based fillers, additives, films, coatings, stimuli-responsive, and biomedical materials [10,11,12,13,14,15,16,17,18,19,20,21,22]. The incorporation of lignin in these materials offers a more sustainable and often higher-performing alternative to their petrochemical-based counterparts [23,24].

Despite lignin’s abundance, its heterogeneity, complexity, and structural variability challenge its comprehensive study and utilization. To address these issues, lignin can be extracted, depolymerized, or chemically and physically modified to produce smaller derivatives with enhanced functionalities [25,26,27]. Also, depending upon the extraction method, lignin can be categorized into different types such as kraft lignin, alkali lignin, soda lignin, hydrolyzed lignin, etc., and the lignin composition is different in each lignin type [28,29,30]. Lignin can be discussed at several levels of structural complexity, which must be carefully distinguished. “Whole lignin” refers to the unmodified, extracted material, typically containing a wide molecular weight distribution and a mixture of structural subunits (e.g., kraft, soda, organosolv lignin). “Lignin fractions” are obtained through physical or chemical separation processes that reduce polydispersity or isolate particular molecular weight windows. “Lignin-derived monomers and oligomers”, on the other hand, are breakdown products obtained by depolymerization techniques such as oxidative cleavage, hydrogenolysis, or solvolysis. These distinct forms vary not only in reactivity and solubility but also in their suitability for incorporation into polymer matrices. As such, clarity in terminology is critical when interpreting or comparing the literature on lignin-based polymers.

This review aims to classify and analyze current strategies for lignin incorporation into polymer matrices across diverse synthetic routes and applications, including polyurethanes (PUs), resins, PLA composites, and lignin-based films, coatings, and adhesives. Emphasis is placed on chemical modifications, structure–property relationships, and sustainability metrics. Moreover, lignin can be utilized in more applications, ranging from hydrogels or aerogels [31,32,33,34,35,36], capacitors, or lithium–sulfur batteries, [37,38,39,40,41], light-driven shape memory polymers [42,43], pH-sensitive lignin-based polymers, [44]. several nano lignin applications [45,46,47,48,49], and as an application in high-sulfur content materials [50,51,52,53,54], which will not be discussed in this review.

2. Lignin as a Precursor in Polyurethanes (PUs)

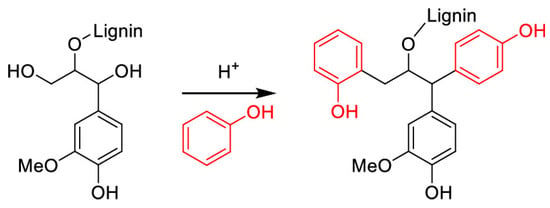

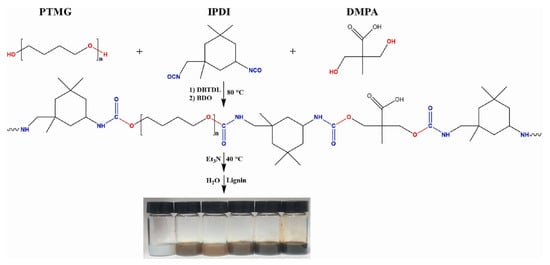

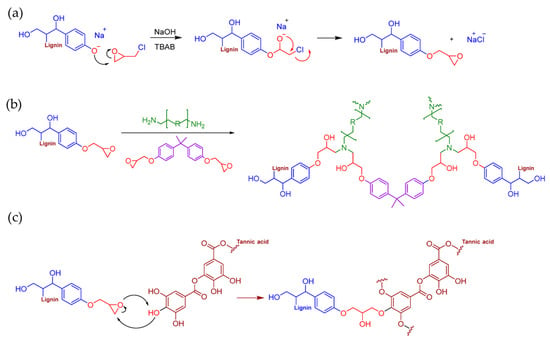

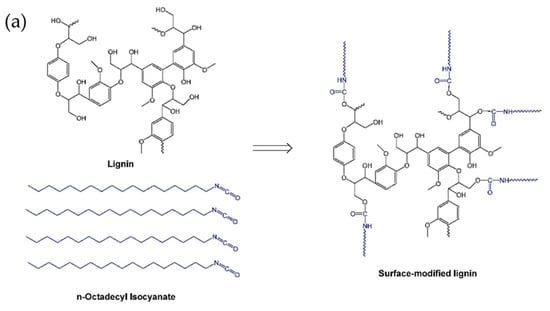

Polyurethane (PU) is one of the most versatile polymers, and it is used in different industries, including coating, adhesive, textile, foams, sealants, automotive, and aerospace [55,56,57]. PUs are synthesized through a step-growth addition polymerization process by reacting polyols (compounds containing multiple hydroxyl groups) with diisocyanates (compounds containing two isocyanate groups). The reaction typically involves the formation of urethane linkages. Traditional PU production relies on petroleum-based polyols, but the hydroxyl groups in lignin provide an opportunity for its utilization as a renewable polyol alternative, providing biodegradability, cost-effectiveness, and reduced environmental impact (Scheme 1a). Despite its potential, lignin’s complex, irregular structure and low reactivity due to limited available hydroxyl groups hinder its direct use. To enhance its compatibility and reactivity with isocyanates, lignin is often chemically modified through hydroxy alkylation, phenolation, methylation, esterification, and amination methods to increase the number of accessible hydroxyl groups and improve solubility and dispersion within polymer matrices [58,59,60]. Such modifications significantly improve the performance and processability of lignin-based PUs (Table 1). This section will explore the most recent approaches to integrating unmodified and modified lignin into PU formulations, including synthesis pathways of lignin-based non-isocyanate and waterborne polyurethanes (Scheme 1).

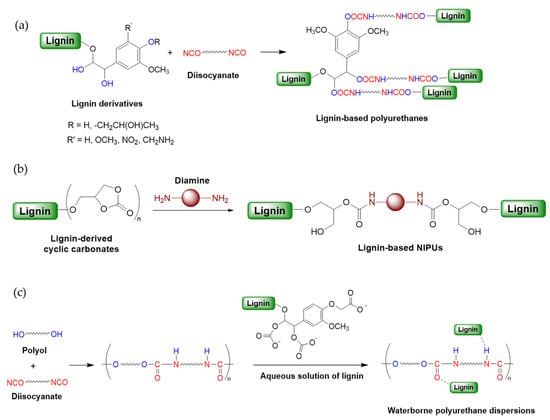

Scheme 1.

General reaction scheme for lignin-based polyurethane formation. (a) Traditional isocyanate pathway from unmodified or modified lignin (b) Non-isocyanate pathway from cyclic carbonate functionalized lignin and amines (c) Waterborne polyurethane synthesis pathway from auqeous solution of lignin.

Table 1.

Summary of the lignin-based polyurethanes.

2.1. Unmodified Lignin-Based Polyurethanes

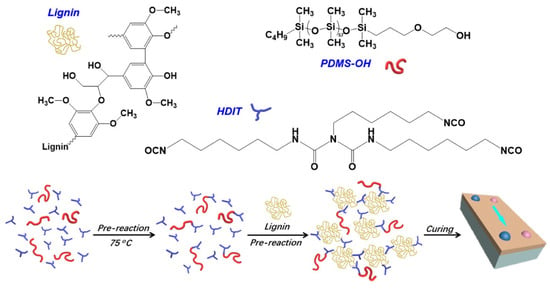

Chen et al. developed a lignin-based PU coating with anti-smudge and anti-UV properties in their study [61]. Lignin-based coatings (lig-PU-PDMS) were prepared using lignin as polyols, hexamethylene diisocyanate trimer (HDIT) as the crosslinking agent, and a small amount of monocarbinol-terminated poly-dimethylsiloxane (PDMS-OH) as the dewetting agent (Figure 2). The hardness (HIT) and elastic modulus (EIT) of lig-PU-PDMS coatings were measured by nanoindentation. When the PDMS-OH content increased from 0 to 5.0 wt.%, HIT decreased from 260.1 to 226.8 MPa, and EIT decreased from 4.7 to 4.1 GPa. After 400 h of UV aging, the HIT and EIT of lig-PU-PDMS (0 wt.%) increased by 16.9% and 16.1%, respectively, while those of lig-PU-PDMS (5.0 wt.%) increased by only 11.9% and 10.9%. Moreover, the coatings maintained good mechanical properties even after UV aging, with lignin protecting the PU from UV damage. The aromatic skeleton and conjugated structure of lignin provide the coatings with extraordinary UV-blocking capability and increase the strength of the PU coating. However, the study focused on a specific lignin type, indicating that further research may be necessary to adjust the process for other lignin sources.

Figure 2.

Preparation method for lignin-based PU coating (lig-PU-PDMS) [61]. Used with permission, copyright 2023 American Chemical Society.

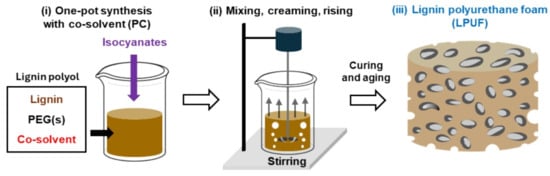

In another study, Zhang and coworkers introduced a method to address the high viscosity of lignin, which limits its processability and application in lignin-based polyurethane foams (PUFs) [62]. Organosolv lignin was dissolved in green co-solvent (propylene carbonate) to reduce the viscosity and reacted with diphenylmethane-4,4′-diisocyanate (MDI) to form the lignin-based PUFs using a one-pot synthesis method (Figure 3). The lignin content varied from 20 to 80 wt.% and equal weights of propylene carbonate and lignin were used. Compared to mixtures without the co-solvent, those with the co-solvent exhibited lower viscosity, even at higher lignin content. Thermogravimetric analysis (TGA) showed increased thermal stability and higher char yield formation with lignin addition, attributed to its aromatic structure. Additionally, the lignin-based PUFs demonstrated enhanced hydrophobicity, with the water contact angle rising from 100 to 140 degrees as lignin content increased. Mechanical analysis indicated that, without the co-solvent, PUFs with low lignin content had slightly higher strength than the control PUF due to mechanical interlocking and hydrogen bonding between lignin and the matrix. However, higher lignin content reduced strength, as the brittle PU cells and non-uniform foam structure acted as rigid foams. In contrast, higher lignin content with the co-solvent resulted in greater strength than the control PUF. The study successfully demonstrated the substitution of (up to 80 wt.%) petroleum polyol with unmodified lignin, preventing viscosity issues and maintaining favorable properties.

Figure 3.

Illustration of the one-pot synthesis of lignin polyurethane foam using a co-solvent [62]. Used with permission, copyright 2024 Elsevier.

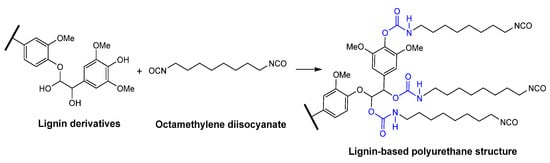

The inherent complexity and heterogeneity of lignin can lead to inconsistent performance in polyurethane applications when it is directly incorporated into the formulation without prior modification. To address this issue, Li et al. fractionated industrial alkali lignin using green solvents to study the effect of different molecular weight fractions on polyurethane foam (PUF) properties [63]. The dispersity and hydroxy content gradually decreased during fractionation, yielding lower molecular weight lignin in the initial steps. Fractionated lignin was used as a polyol source, with octamethylene diisocyanate as the isocyanate to synthesize PUFs (Figure 4). The impact of different lignin fractions was studied using 2 wt.% of lignin, and the substitution degree of lignin was evaluated using the lowest molecular weight fraction, which contained higher hydroxy group content. Lignin derivatives from low-molecular-weight fractions formed flexible PU, while the high molecular weight of lignin fractions formed rigid PU due to their high aromatic density. Lower molecular weight lignin improved mechanical strength, while higher molecular weight lignin enhanced thermal stability. When the substitution degree of lignin increased from 2% to 30%, elongation at break peaked at 834% with 5% substitution, then declined. Tensile strength increased with a 15% lignin substitution before decreasing with further additions.

Figure 4.

The reaction mechanism between lignin derivatives and octamethylene diisocyanate. Used with permission, copyright 2024 Elsevier.

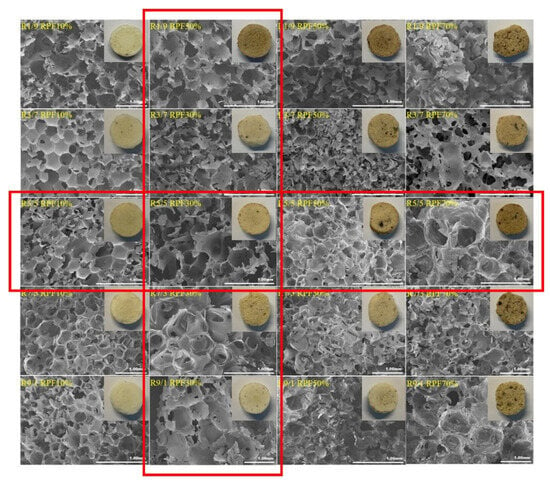

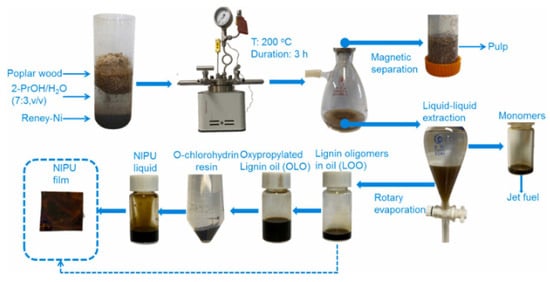

In another study, lignin oligomers derived from poplar sawdust through catalytic upstream biorefining (CUB) were used as a partial polyol substitute for synthesizing rigid polyurethane foams (RPFs) [64]. The lignin oligomers were extracted from crude CUB oils produced with varying 2-propanol/water ratios (1/9, 3/7, 5/5, 7/3, and 9/1 v/v) in the pulping liquors. These oligomers, rich in hydroxyl groups, reacted with isocyanates to create the polyurethane networks. The chemical composition of the pulping liquor significantly influenced the properties of the lignin oligomers and, consequently, the physical characteristics of the RPFs. Increased substitution of lignin oligomers led to an increase in apparent density but reduced compressive strength. Among all formulations, RPFs with 30% polyol substitution using lignin oligomers extracted with a 7/3 2-propanol/water ratio (R7/3) demonstrated the optimal balance, achieving the highest compressive strength and the lowest apparent density. Morphological analysis (Figure 5) revealed that these lignin oligomers, with their higher hydroxyl content, facilitated the formation of highly crosslinked nano-sized complexes, creating a stable polyurethane network that effectively supported the cellular foam structure.

Figure 5.

SEM images of RPFs synthesized using catalytic upstream biorefining (CUB) lignin oligomers as polyol substitutes [64]. Used with permission, copyright 2023 Elsevier.

2.2. Chemically Modified Lignin-Based Polyurethanes

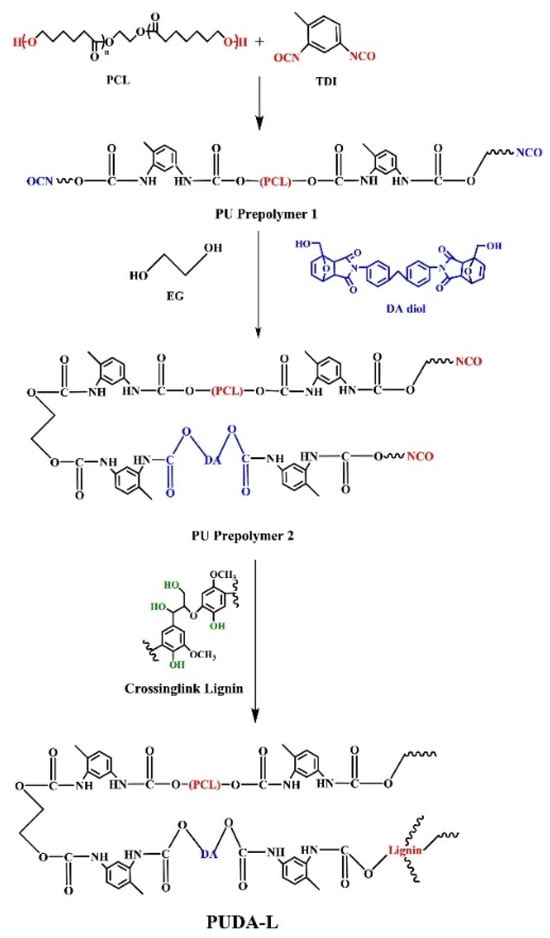

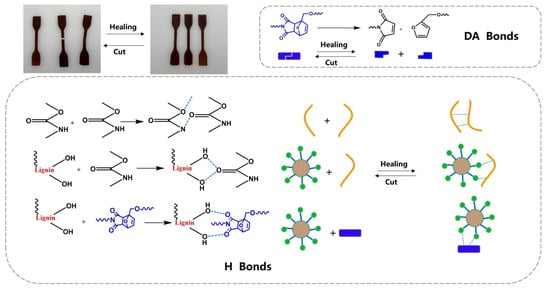

Du et al. developed a lignin-based self-healing polyurethane elastomer (PUDA-L) by integrating hydroxylated-modified lignin, Diels–Alder (DA) bonds, and hydrogen bonds into the polymer matrix [65]. Hydroxylation modification of lignin increases its hydroxyl content, enhancing crosslinking density and improving mechanical properties. At the molecular level, hydroxylation increases the number of reactive –OH groups on lignin, enhancing its ability to form urethane bonds with isocyanates. This leads to a denser crosslinked network, improving tensile strength and elasticity. The addition of DA diol as a chain extender promotes self-healing properties, while polycaprolactone (PCL) was selected as the soft segment due to its ability to enhance melting crystallization and self-healing efficiency (Figure 6). Figure 7 illustrates the self-healing mechanism of elastomers, which is driven by multiple molecular interactions. Lignin incorporation improves the thermal stability and rigidity of polyurethane, leading to higher glass transition (Tg) and energy storage moduli (E’). However, in DA-modified elastomers, the overall impact of lignin on thermal stability is less pronounced due to the strong crosslinking network. Mechanical testing showed that an optimal PCL–DA diol–TDI (toluene diisocyanate) ratio of 1:1:2.5 maximized tensile strength (25.2 MPa), while excessive or insufficient DA diol and higher lignin addition negatively affected mechanical performance. The optimized PUDA-L formulation achieved an elongation at a break of 500% and a self-healing efficiency of up to 100%, offering excellent durability, flexibility, and self-healing capabilities. The study provides valuable insights into the development of bio-based, high-performance polyurethane elastomers for applications in innovative coatings, sensors, and flexible electronics.

Figure 6.

Preparation method of lignin self-healing polyurethane elastomer (PUDA-L) [65]. Used with permission, copyright 2023 Elsevier.

Figure 7.

Self-healing mechanism of lignin-based self-healing polyurethane elastomer [65]. Used with permission, copyright 2023 Elsevier.

In another study, Falireas and coworkers employed an acid-catalyzed phenolation method (Figure 8) to modify lignin chemically, enhancing its reactive sites for polyurethane (PU) synthesis [66]. The acid-catalyzed phenolation increases the number of phenolic hydroxyl groups in lignin, enhancing its nucleophilicity and reactivity with isocyanate groups. This leads to more urethane bonds and higher crosslinking density in the polymer network. The enhanced mechanical and adhesive properties observed in pMDI-based systems can be attributed to strong interactions between the aromatic rings of phenolated lignin and pMDI, including π–π stacking and hydrogen bonding. This molecular interaction causes the superior performance of the phenolated lignin-based PU framework. Hydrolysis lignin (HL) was used as the lignin source for polymer preparation. A series of phenolated lignin-based polyurethane (PhLPU) films were formulated using phenolated lignin (0–60 wt.% of PhL) and polytetrahydrofuran as a polyol mixture, with either an aromatic poly[(phenyl isocyanate)-co-formaldehyde]. (pMDI) or an aliphatic hexamethylene diisocyanate trimer (HDI) as the isocyanate source. The study examined the significant impact of PhL concentration and the chemical structure of the isocyanate on the thermal stability and mechanical performance of PU films. Thermal analysis results showed that increasing the phenolated lignin content enhanced the thermal stability of the films, with HDI-based films exhibiting a higher maximum decomposition temperature compared to those made with pMDI. Mechanical performance testing revealed that PhLPU films with pMDI demonstrated superior strength characteristics compared to films with HDI trimer. The adhesive strength was evaluated using single-lap shear tests, with PhLPU films exhibiting comparable shear strengths to commercially available PU adhesives. Overall, the study highlights the effectiveness of the phenolation process in increasing the chemical reactivity of lignin, facilitating the development of high-performance PU films and adhesives, and contributing to the advancement of sustainable material solutions.

Figure 8.

The replacement of aliphatic hydroxyl groups by ortho-/para-bound phenol through acid-catalyzed phenolation of lignin [66]. Used with permission, copyright 2024 American Chemical Society.

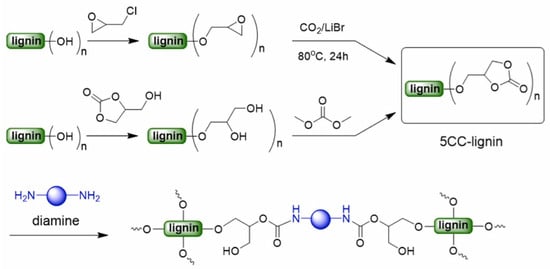

Liang et al. developed lignin-based polyols (LPs) by introducing hydroxyl groups into kraft lignin through liquefaction with polyethylene glycol (PEG). The PEG-mediated liquefaction involves acid-catalyzed transetherification between the ether linkages in PEG and the phenolic hydroxyl groups on lignin. This reaction yields lignin-polyether oligomers with enhanced hydroxyl group availability, improving solubility, molecular flexibility, and reactivity toward isocyanates during subsequent polyurethane formation. Increased hydroxyl content also promotes better crosslink density and phase dispersion within the resulting PU network. These LPs were then used to synthesize lignin-based polyurethane foams (LPUFs) by reacting them with hexamethylene diisocyanate (HDI), replacing 20–100 wt.% of conventional polyols (Figure 9) [67]. The inherent rigidity of lignin significantly enhanced the thermal and mechanical properties of the resulting foams. At 60% LP substitution, the foam exhibited a peak compressive stress of 86.80 kPa at 70% strain, which was approximately four times greater than the control polyurethane foam. This improvement was attributed to the reinforcing effect of lignin’s benzene ring structure. However, increasing LP content to 100% led to a decline in compressive stress (50.96 kPa), likely due to phase separation hindering optimal crosslinking. Additionally, the incorporation of lignin reduced the water contact angle and water absorption due to its hydrophobic nature and the reduced porosity of the foams. Biodegradation studies further demonstrated that LPUFs with 100% LP substitution degraded by 17.36% over 180 days, significantly improving compared to the 4.36% degradation observed in pure PUFs.

Figure 9.

Lignin modification and preparation procedure of lignin-based polyurethane [67]. Used with permission, copyright 2024 American Chemical Society.

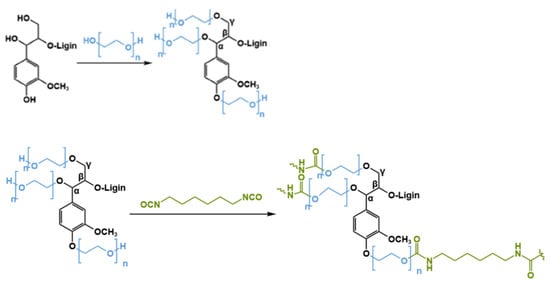

Oily wastewater poses significant environmental challenges and is produced across various sectors, including oil refining, food processing, automotive maintenance, shipping, construction, metalworking, and oil extraction [75,76]. Foams are one of the ideal solutions to separate oil from water due to their variable porosity and lightweight properties. Chen and coworkers enzymatically hydrolyzed lignin and liquefied it into a lignin-based polyol. Then, polyols were reacted with diisocyanate to produce synthesized lignin-based polyurethane foam (LPUF) [68]. The LPUF was further modified by in situ polymerization of dopamine on the foam surface under weakly alkaline conditions to deposit polydopamine (PDA) particles, followed by surface modification using phytic acid (PA) to prepare LPUF/PDA/PA foams (Figure 10). LUPF was degraded entirely in an alkali medium within 5 h, which was attributed to the presence of lignin. The LPUF/PDA/PA exhibited excellent superhydrophilicity with a water contact angle of 0° and underwater superoleophobicity with oil contact angles exceeding 150°, achieving over 99% oil–water separation efficiency for various mixtures while maintaining high performance after ten cycles. Additionally, it demonstrated good adsorption capacities for methylene blue (67.1 mg/g), rhodamine B (96.1 mg/g), and copper sulfate (98.2 mg/g) and could completely degrade under weak alkaline conditions after use. However, some limitations of LPUFs include challenges in scalability, durability, complex fabrication processes, limited versatility, potential environmental degradation, and chemical leaching, demanding further research to enhance their performance and sustainability.

Figure 10.

The preparation pathway of LPUF/PDA/PA and its degradation after usage in an alkali medium (after 5 h) [68]. Used with permission, copyright 2023 Elsevier.

2.3. Non-Isocyanate Polyurethanes (NIPUs)

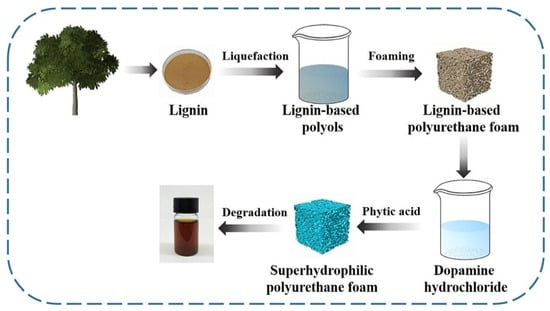

Due to the high toxicity associated with isocyanates, there is a growing demand for developing and producing non-isocyanate polyurethanes (NIPUs) as a safer and more sustainable alternative to traditional PUs [77,78]. There are several methods to prepare NIPUs. Among them, aminolysis of cyclic carbonates (CCs) are more interesting because this approach involves the nucleophilic ring-opening reaction of CCs with amines, forming urethane linkages through a straightforward and non-toxic process. This process can be further enhanced by introducing five-membered cyclic carbonate groups (5CCs) into lignin or by depolymerizing lignin derivatives through glycidylation, followed by cycloaddition with CO2 or oxyalkylation with glycerol carbonate to incorporate adjacent hydroxyl groups (Figure 11) [69]. Subsequently, transesterification with dimethyl carbonate allows the production of a series of NIPUs via the polyaddition of cyclic carbonate-functionalized lignin and diamines.

Figure 11.

Non-isocyanate pathway to form polyurethanes from 5-membered cyclic carbonate functionalized lignin (5CC-lignin and amines.) [71]. Used with permission, copyright 2023 Elsevier.

Yang and coworkers proposed using lignin oligomers derived from reductive catalytic fractionation (RCF oil) as a substitute for NIPU production (Figure 12) [69]. Sawdust was used as a renewable polyol source to produce lignin oligomers. These oligomers were oxypropylated and modified with phthalic anhydride and epichlorohydrin to form a cyclic carbonate (5CC) intermediate (Figure 13). This intermediate was reacted with various amines to synthesize NIPUs. The amino group content and molecular size of amines significantly impacted mechanical properties, though they had a minimal effect on thermostability. Additionally, at the molecular level, oxypropylation of lignin introduces flexible polyether side chains via grafting propylene oxide onto the hydroxyl groups. This significantly increases the number of aliphatic –OH groups, improving the reactivity of lignin with phthalic anhydride and epichlorohydrin for cyclic carbonate formation, and ultimately enhancing crosslinking density in the NIPU matrix. The flexible polyether chains contribute to improved toughness and tensile strength, while the rigid aromatic structure of lignin enhances thermal and UV resistance. The highest tensile strength (12.5 MPa) was achieved with polyether amine, while the highest Young’s modulus (88 MPa) was obtained with triethyltetraamine. The isophorone diamine-crosslinked NIPU exhibited the lowest mechanical properties. Moreover, the tensile properties, heat resistance, and UV resistance of the NIPUs were enhanced by the rigid benzene ring and phenolic groups in lignin. Although the mechanical properties of NIPUs were comparable to traditional PU, further research is needed to explore their durability and performance under real-world conditions. Additionally, scaling up this synthesis method may present challenges in terms of cost and efficiency.

Figure 12.

Preparation pathway of NIPU films from the lignin oligomers in the RCF oil [69]. Used with permission, copyright 2023 Elsevier.

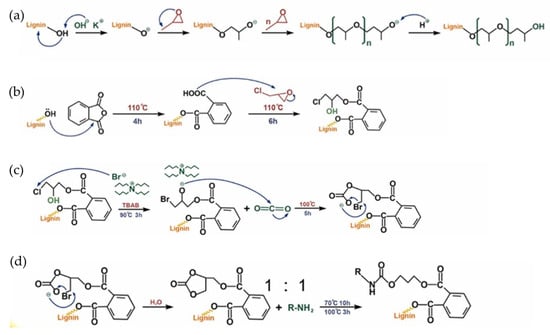

Figure 13.

(a) The mechanism of oxypropylation reaction, (b) o-chlorohydrin resin formation (c) cyclic carbonation, and (d) NIPUs synthesis [69]. Used with permission, copyright 2023 Elsevier.

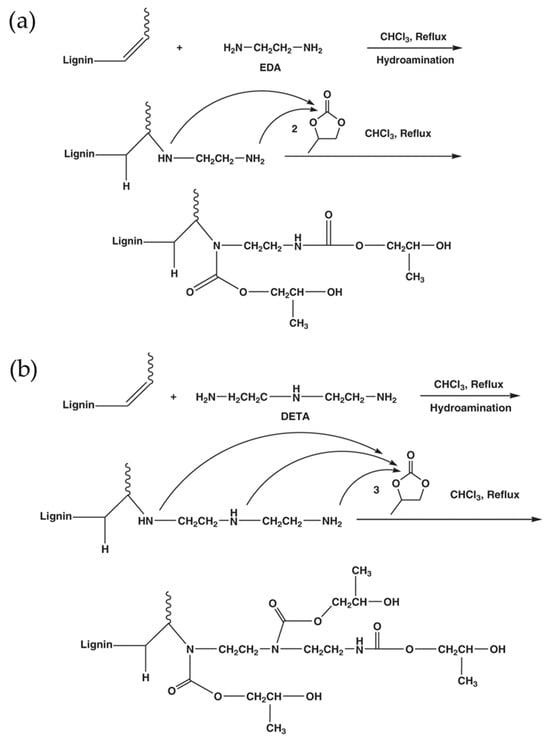

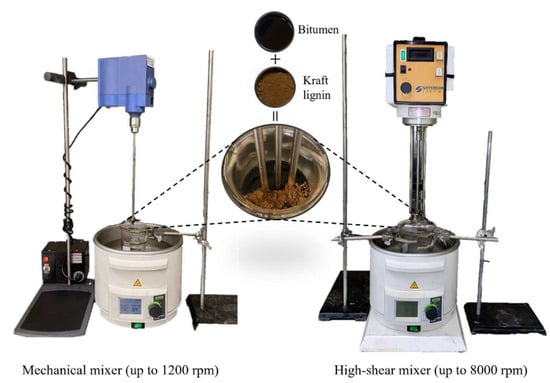

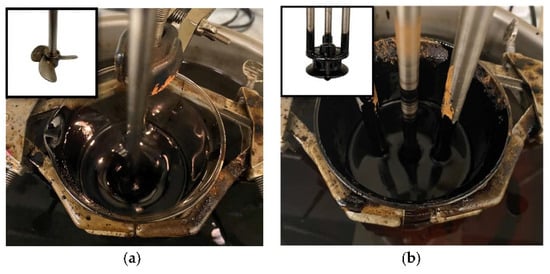

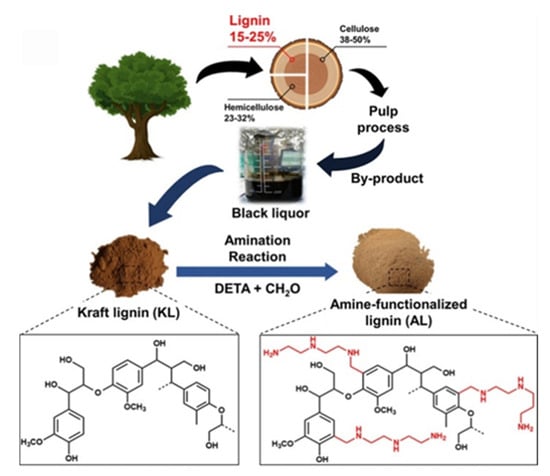

The previous method modified lignin with propylene carbonate to improve its solubility and reactivity. In the study by Najafi et al., lignin was initially modified with the amine, and the aminated product was next reacted with propylene carbonate (5CC) to enhance the hydroxy functionalities [70]. During the reaction, amination introduces nucleophilic amine groups onto the lignin backbone, which are then converted into hydroxyl groups through a ring-opening reaction with propylene carbonate. This two-step process significantly increases the hydroxyl number, thereby enhancing the lignin’s reactivity toward cyclic carbonate–amine systems in NIPU synthesis. The increased hydroxyl functionality also improves solubility and compatibility with other polyols. Furthermore, the reduced molecular weight of modified lignin may contribute to better dispersion and processability in polymer formulations. These structural changes explain the enhanced potential reactivity, although further studies are needed to correlate these modifications with final mechanical properties. In this work, lignin was extracted from raw liquor and then modified with diethylenetriamine (DETA) and ethylenediamine (EDA) to increase the number of functional groups and reactivity. The aminated lignin was further reacted with propylene carbonate using the Mannich reaction to prepare lignin-based polyols as an alternative to petroleum-based polyols to synthesize NIPU (Figure 14). This study did not address PU formation or the mechanical properties of the resulting polymers. However, evidence was provided through FT-IR analysis that the C-O bonds observed were due to urethane bonds in the modified lignin. GPC results revealed that lignin had been reduced to a lower molecular weight after modification, likely due to mechanical degradation during preparation. Additionally, the modified lignin-based polyol exhibited a much higher hydroxyl number (848–2220 mgKOH/g) than petroleum-based polyols, suggesting its strong reactivity potential. Therefore, further research is needed to apply this polyol in actual polyurethane production.

Figure 14.

The reaction of (a) ethylene diamine (EDA) and (b) diethylenetriamine (DETA) with unsaturated regions of lignin, followed by the reaction of aminated lignin with propylene carbonate to produce lignin-based polyols [70]. Under a Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/ accessed on 27 April 2025).

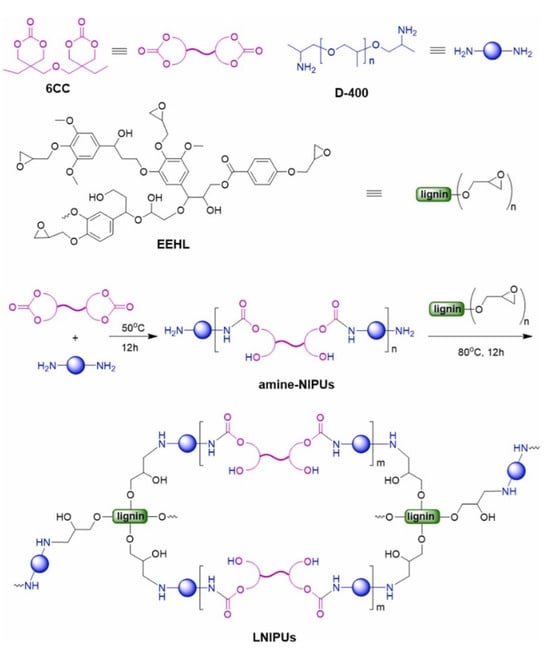

Although five-membered cyclic carbonates (5CCs) can be used to synthesize lignin-containing NIPUs, the process is complex and requires expensive metal-based catalysts due to the slow reaction between 5CCs and amines. Additionally, 5CCs have lower reactivity, leading to slower curing times, incomplete reactions, and reduced mechanical and thermal performance, such as weaker tensile strength and lower thermal stability. To improve these limitations, potential solutions include using more reactive six-membered cyclic carbonates (6CCs), modifying 5CCs to enhance their reactivity and mechanical properties, or blending 5CCs with 6CCs to create hybrid systems that optimize material performance by leveraging the strengths of both structures.

Zhang and colleagues introduced a novel lignin/NIPU hybrid polymer (LNIPU) using bis(6-membered cyclic carbonate) (6CC) to address the limitations associated with 5CC. This example demonstrates how the structural rigidity of lignin influences toughness but limits self-healing, highlighting a critical trade-off in designing dynamic crosslinked networks with high-performance and reprocessability. Initially, amine-terminated non-isocyanate polyurethanes (amine-NIPUs) were synthesized from bis(6-membered cyclic carbonate) (6CC) and polyether amine (D-400) and then crosslinked with epoxidized enzymatic hydrolysis lignin (EEHL) at 0–50% epoxy group molar ratios to form LNIPU networks (Figure 15) [71]. Increasing lignin content in LNIPUs led to significant improvements in properties like storage modulus, glass transition temperature (Tg), and crosslink density, and notable increases in tensile strength, Young’s modulus, and toughness. For instance, a material with 50% epoxy groups exhibited values of 20.25 MPa for tensile strength, 280.09 MPa for modulus, and 5.51 MJ/m3 for toughness, outperforming lignin-free versions. Adhesive strength also reached 24.5 MPa for bonding aluminum plates. Despite these gains, higher lignin content reduced elongation at break and self-healing efficiency, highlighting the need for optimized crosslinking strategies to improve overall material performance.

Figure 15.

Illustration of the synthesis pathways for preparing LNIPUs [71]. Used with permission, copyright 2023 Elsevier.

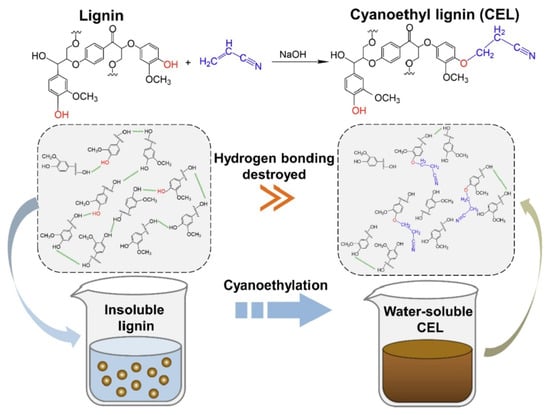

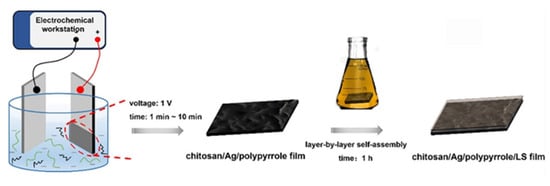

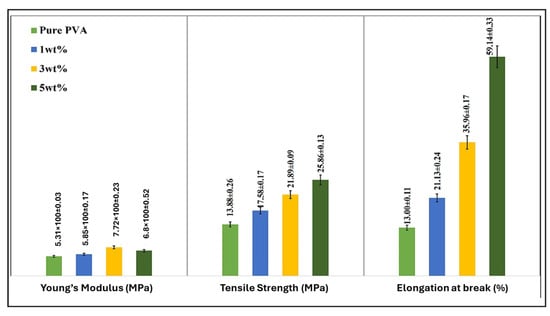

2.4. Waterborne Polyurethanes (WPUs)

Waterborne polyurethane (WPU) is an environmentally friendly polyurethane dispersed in water rather than organic solvents, thus reducing volatile organic compounds. Despite their significant advantages, WPUs encounter challenges related to mechanical performance, water resistance, drying times, and formulation complexity [72,73,74,79]. In response, Ng et al. developed a 3-aminopropyltriethoxy silane (APTES) functionalized kraft lignin-filled film to improve the reinforcing ability of WPUs [72]. Kraft lignin was functionalized by stirring it in a 2 wt.% APTES solution and subsequently mixed with WPU dispersion at varying proportions (0–2 wt.%) for comparison with unfunctionalized lignin. The films containing functionalized lignin demonstrated superior thermal stability compared to those with unfunctionalized lignin due to improved bonding. The optimal lignin loading was determined to be 0.5 wt.%, as higher concentrations resulted in agglomeration and reduced material properties. At this loading, functionalized lignin led to a 9% increase in ultimate tensile strength compared to pure WPU (from 8.05 MPa to 8.77 MPa), while unfunctionalized lignin yielded only a 0.3% improvement. Furthermore, films with functionalized lignin exhibited a lower Young’s modulus and higher elongation at break, indicating enhanced flexibility and improved deformation resistance. This research demonstrates the potential of lignin as a reinforcement filler to enhance mechanical properties and thermal stability in WPUs; however, further investigations are necessary to address issues related to water resistance, drying times, and formulation complexity.

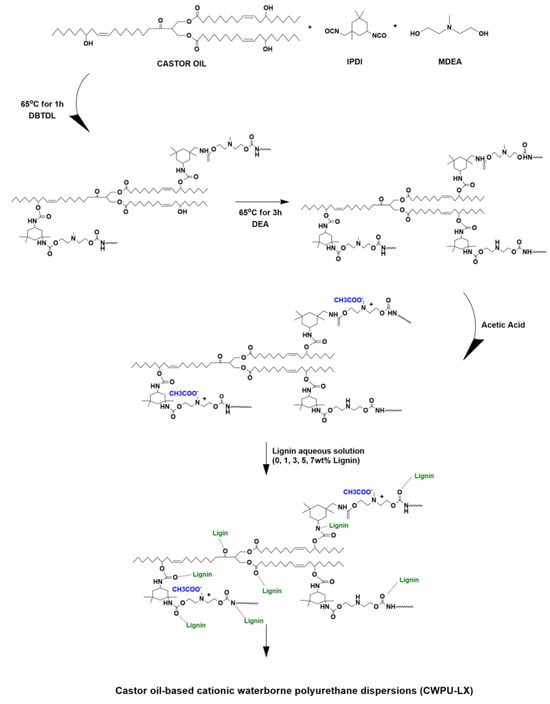

In another study by Fan and co-workers, WPU emulsions were developed using lignin nanoparticles (LNPs) derived from enzymatic hydrolysis lignin (EHL) [73]. The nanoscale dispersion of LNPs enhances interfacial bonding with the polyurethane matrix, contributing to better mechanical reinforcement and UV resistance without sacrificing flexibility—demonstrating the utility of nano-lignin as a multifunctional additive. A series of WPU composites (Figure 16) was formulated by varying the LNP content from 0 to 5 wt.%. Notably, the incorporation of 5 wt.% LNPs led to significant enhancements in the overall performance of the composites, particularly in terms of durability and UV resistance when compared to neat WPU. Kim et al. introduced an innovative approach to synthesizing WPU by incorporating lignin into a castor oil-based cationic waterborne polyurethane system [74]. This strategy remarkably reduced the solvent required for polymer synthesis by 50%. Lignin was incorporated in varying amounts (0–7 wt.%) to produce WPU composites (Figure 17). The results demonstrated that lignin improved mechanical properties, thermal stability, solvent resistance, UV resistance, and antibacterial activity. The composite containing 7 wt.% lignin exhibited a significantly higher tensile strength (5.57 MPa) than pure WPU (1.10 MPa). This data demonstrates that lignin acts not only as a passive filler but as an active reinforcing phase, contributing to load-bearing via π–π stacking and hydrogen bonding with the castor oil-based polyurethane segments. Furthermore, this composite displayed remarkable ethanol resistance and achieved 97.27% antibacterial activity against Escherichia coli (E. coli), compared to only 1.58% for the pure WPU.

Figure 16.

Preparation procedure of various lignin-based WPU emulsions [73]. Under a Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/ accessed on 27 April 2025).

Figure 17.

Schematic illustration of the preparation mechanism for castor oil-based cationic waterborne polyurethane incorporating lignin [74]. Under a Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/ accessed on 27 April 2025).

3. Lignin as a Precursor in Thermosets and Crosslinked Polymer Networks

3.1. Epoxy Resins

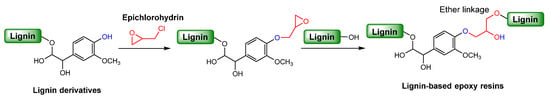

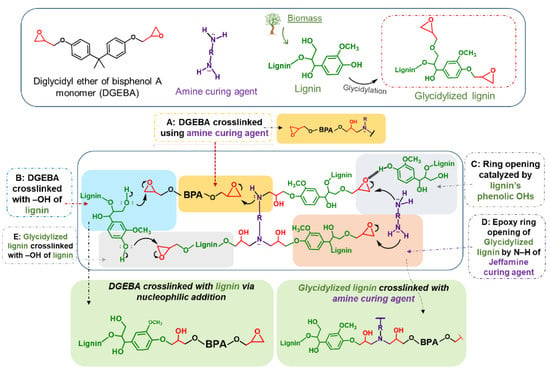

Epoxy resins are reactive pre-polymers that form crosslinked thermosets through curing reactions with various co-reactants, and they are widely used in applications such as coatings, adhesives, electrical insulation, and reinforced composites. Among them, the most commonly used epoxy resin reactant is diglycidyl ether of bisphenol A (DGEBA), which is synthesized from fossil-derived bisphenol A (BPA) [80,81]. However, the extensive use of BPA has raised significant environmental and health concerns, prompting the search for sustainable alternatives. Lignin is a promising substitute for BPA in the development of bio-based epoxy resins. Functionalization of lignin through glycidylation, typically via reaction with epichlorohydrin, introduces epoxy groups that enable the formation of crosslinked thermoset networks with ether linkages upon curing (Scheme 2). This section will discuss the use of lignin as a renewable feedstock to enhance the performance of epoxy resins while reducing dependence on petroleum-based polymers. Lignin types, modification methods, applications, and key properties for lignin-derived resins are summarized in Table 2.

Scheme 2.

Synthesis pathways of lignin-based epoxy thermosets.

Table 2.

Summary of thermoset and crosslinked polymer networks synthesized from lignin-based monomers and oligomers.

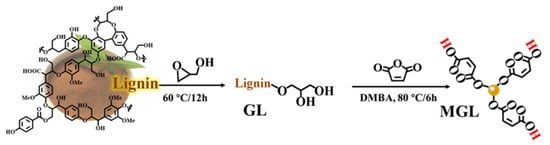

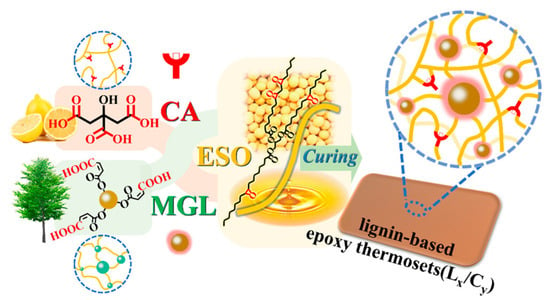

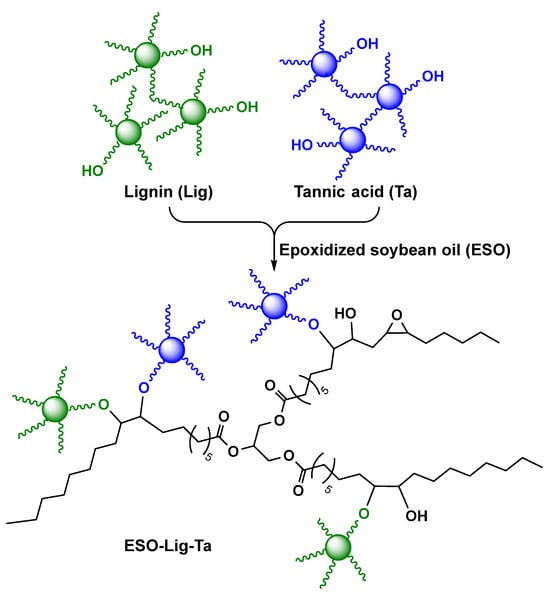

Zhou et al. developed fully bio-based epoxy thermosets using modified lignin (MGL) as a rigid crosslinker, combined with citric acid (CA) and epoxidized soybean oil (ESO) [82]. To enhance solubility, reactivity, and compatibility, lignin was chemically modified through glycidylation with glycidol to produce glycidylated lignin (GL), followed by maleation with maleic anhydride to introduce carboxyl groups, yielding MGL (Figure 18). In here, the glycidylation introduces epoxide groups that enhance compatibility and reactivity with the epoxidized soybean oil, promoting denser crosslinking. Maleation introduces carboxyl groups, which further increase hydrogen bonding and crosslinking potential with citric acid, thereby enhancing mechanical strength and rigidity. The thermosets were prepared by varying the MGL-COOH to CA-COOH ratios (L10/C0, L8/C2, L5/C5, L0/C10) while maintaining a fixed epoxy-to-carboxyl molar ratio of 1:0.8 (Figure 19). Dynamic mechanical analysis (DMA) revealed an increase in glass transition temperature (Tg) from 17.1 °C (L0/C10) to 96.5 °C (L10/C0) with higher MGL content, indicating greater rigidity and crosslink density. Thermogravimetric analysis showed similar degradation temperatures at 5% weight loss (T5%) of 322–328 °C in nitrogen and 308–312 °C in air across all lignin-modified compositions. Mechanical testing demonstrated a rise in tensile strength from 0.6 MPa (L0/C10) to 33.2 MPa (L8/C2) and an increase in tensile modulus from 2.0 MPa to 480.5 MPa with higher MGL content. The highest elongation at break (55.1%) was observed for L5/C5, while L10/C0 exhibited the lowest (9.3%). These thermosets displayed superior tensile strength compared to previously reported lignin-based systems and showed degradability in alkaline conditions due to ester bond hydrolysis. This result illustrates how glycidylation followed by maleation significantly increases the crosslinking efficiency and mechanical rigidity of lignin-epoxy networks, while preserving green degradability pathways, thereby balancing performance and sustainability.

Figure 18.

Lignin modification to synthesize glycidylated lignin (GL) and multicarboxyl lignin (MGL) [82]. Used with permission, copyright 2023 American Chemical Society.

Figure 19.

Preparation procedure for lignin-based epoxy thermosets (Lx/Cy) [82]. Used with permission, copyright 2023 American Chemical Society.

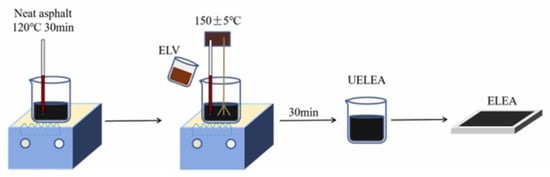

Conventional epoxy asphalt is a thermosetting material that is difficult to recycle [96]. Song et al. developed a lignin-based vitrimer system (ELV) to replace conventional epoxy asphalt, incorporating dynamic covalent ester-exchange bonds for recyclability [83]. Enzymatic lignin (EL) was reacted with epichlorohydrin (ECH) under alkaline conditions to obtain lignin epoxy resin (LER). EL was esterified with maleic anhydride (MA) to obtain carboxylated lignin (EL-COOH). The lignin-based vitrimer system (ELV) was prepared by the Zn2+ catalyzed reaction of LER and EL-COOH in the presence of polyethylene glycol 400 (PEG 400). ELV (10–30 wt.%) was then introduced into base asphalt to produce different lignin-based epoxy asphalt systems (ELEA, Figure 20). ELEA exhibited improved high-temperature stability, with a higher softening point as ELV content increased. The glass transition temperature (Tg) remained stable (8–10 °C), ensuring good low-temperature performance. ELEA-20 (20 wt.% of ELV) showed comparable thermal stability to base asphalt (initial decomposition at 287 °C) and higher maximum decomposition temperature (470 °C vs. 454 °C). ELEA-20 met tensile strength (>1.5 MPa) and elongation at break (>200%) requirements for steel bridge deck pavement. Increasing ELV content enhanced tensile strength but reduced ductility. The dynamic covalent bonds in ELEA enable high-temperature restructuring, offering potential for recovery and recycling.

Figure 20.

Illustration for the synthesis of lignin-based epoxy asphalt systems [83]. Used with permission, copyright 2023 Elsevier.

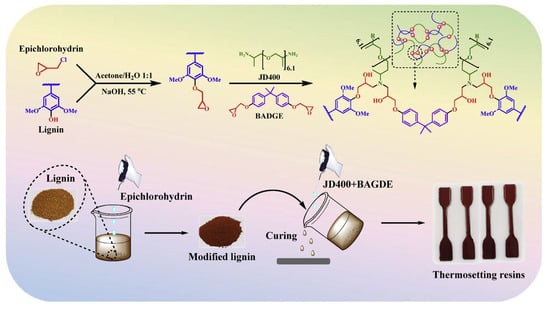

Zou and coworkers developed low-carbon, bio-based epoxy thermosetting materials using industrial alkali lignin [84]. Their approach highlights the advantage of fractionation for controlling molecular weight distribution, which directly impacts processability, epoxy functionalization efficiency, and mechanical consistency in the final resin network. To achieve better uniformity and lower molecular weight, the lignin was fractionated with acetone (F_ASL) and subsequently epoxidized with epichlorohydrin, introducing epoxy groups onto the lignin backbone (F_ASLM). This modification enhanced lignin’s reactivity, enabling partial substitution of petroleum-based bisphenol A diglycidyl ether (BADGE) in epoxy resin formulations. The thermosetting resin was prepared by blending F_ASLM (5–10 wt.%) and BADGE in varying proportions, with polyetheramine (JD400) as the crosslinking agent (Figure 21). Thermal stability analysis revealed a significant improvement, with the degradation temperature (T5%) increasing from 200–230 °C for unmodified lignin to 270–290 °C for epoxidized lignin. The cured resins containing 5% and 10% F_ASLM demonstrated enhanced thermal properties, with T5% reaching 315 °C and 289 °C, respectively, compared to pure BADGE. Mechanical properties also improved with lignin incorporation. The 5% F_ASLM resin exhibited a tensile strength of 4.6 MPa and an elongation at the break of 315.5%, outperforming pure BADGE (4.19 MPa, 161.16%). At 10% lignin content, tensile strength increased to 5.42 MPa, with elongation at break reaching 255.32%. However, at lignin concentrations above 10%, agglomeration issues were observed, and higher lignin content (above 20%) necessitated elevated curing temperatures, limiting its substitution potential. While epoxidation improved lignin’s compatibility with BADGE, further optimization is needed to enhance interface compatibility and maximize lignin incorporation without compromising material properties.

Figure 21.

Schematic illustration of epoxidation using modified lignin [84]. Used with permission, copyright 2023 Elsevier.

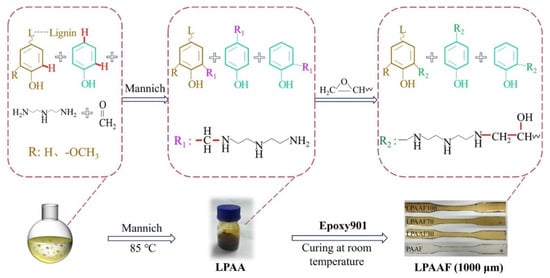

Li and coworkers utilized black liquor lignin, a byproduct of the pulping industry, to develop lignin-based epoxy composite films [85]. Their strategy exemplifies a cost-effective valorization route, converting underutilized industrial byproducts into functional curing agents. The resulting composites reveal how aromatic rigidity and functional group density of modified lignin can be tuned to reinforce resin network architecture. The black lignin was modified via a Mannich reaction with phenol, formaldehyde, and diethylenetriamine to produce lignin-based phenolic amine (LPAA), which served as a curing agent for bisphenol A-based epoxy resin (E901). Phenolation introduces additional phenolic hydroxyl groups onto the lignin backbone, increasing both hydrogen-bonding capacity and reactive sites for subsequent Mannich-type amine functionalization. This increases the crosslinking density and intermolecular interactions within the epoxy network. Furthermore, the incorporation of phenol increases the aromatic content of lignin, resulting in a stiffer and more thermally stable network. LPAA was synthesized with varying mass ratios of black liquor lignin to phenol: 30:70, 70:30, and 100:0. The resulting LPAA and E901 were then combined in a 1:0.1 mass ratio to form the composite film (LPAAF, Figure 22). Thermal analysis showed an improvement in the degradation temperature at 5% weight loss (T5%) compared to the control sample without lignin, with increasing black liquor lignin content enhancing thermal stability. The tensile strength of LPAAF increased with lignin content, reaching a maximum of 30 MPa for LPAAF70 (70 wt.% black liquor lignin in LPAA). However, elongation at break decreased due to the rigid three-dimensional lignin network. Inorganic chemicals from black liquor lignin were well dispersed in the films, and future studies are required to assess the long-term stability and durability of the composites.

Figure 22.

Preparation of lignin-based phenolic amine (LPAA) and epoxy resin (LPAAF) [85]. Used with permission, copyright 2023 Elsevier.

Pappa et al. explored the integration of kraft lignin (KL) into DGEBA-based epoxy resin systems to enhance sustainability and performance. Their work illustrates the importance of particle size and chemical compatibility. Nano-lignin incorporation preserved transparency and improved mechanical integrity, emphasizing that lignin processing form—micro vs. nano—has direct performance implications. KL was employed in various forms: as a direct additive, a partial replacement for the amine curing agent, and in a chemically modified form via glycosylation (GKL, Figure 23) [86]. Additionally, KL was used at both micro- and nanoscales, with nano-lignin (NLH) yielding transparent composites with notable improvements in thermal and mechanical properties. Glycidylated lignin enabled high substitution levels of bio-based epoxy content (up to 38 wt.%) while maintaining or enhancing composite performance. At 3 wt.% KL loading, tensile strength increased by 25% without compromising strain at break. Optimal improvements in tensile stress (3.1%), strain (35.2%), and stiffness (28.9%) were observed at 3 wt.% KL, while higher loadings (up to 9 wt.%) showed a trade-off with reduced strain but retained strength. Ball-milled KL (BMKL) composites showed moderate property enhancements even at 6 wt.% loading. Notably, NLH-based composites sustained or improved mechanical properties up to 30 wt.% loading, showing better stress, strain, and stiffness compared to the pristine polymer. GKL allowed substitution of up to 21 wt.% DGEBA (16.6 wt.% GKL content) with significant improvements in all mechanical metrics. These results highlight KL’s versatility and effectiveness in enhancing epoxy systems, particularly when chemically modified or nanoscaled, making it a strong candidate for greener, high-performance thermoset composites.

Figure 23.

Proposed mechanism for crosslinking of lignin/DGEBA/diamine to prepare epoxy resins [86]. Used with permission, copyright 2023 Elsevier.

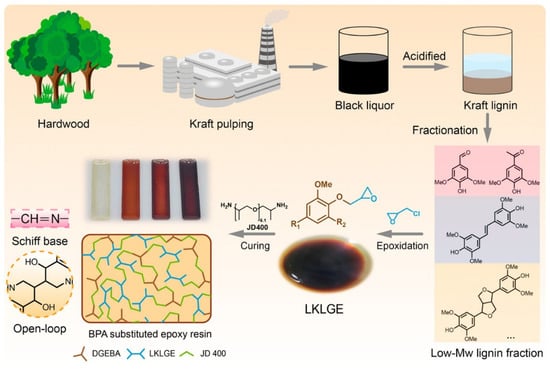

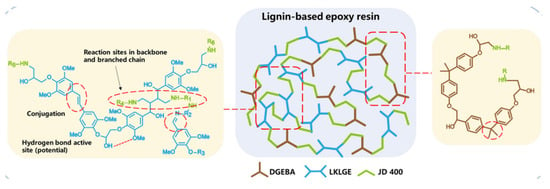

Xue and coworkers developed a lignin-based substitute for bisphenol A (BPA) for producing epoxy resin [87]. Kraft lignin was fractionated to produce low-molecular-weight (low-Mw) lignin, mainly consisting of syringaresinol (0–60 wt.%), to synthesize epoxy resins (Figure 24). The prepared epoxy resins with a 20% substitute amount exhibited the optimum properties. Thermal stability increased by 48%, and mechanical properties were significantly enhanced, with elongation improved by 239% and tensile stress by 144% compared to the BPA-based epoxy resin. The improved performance is attributed to the unique structural features of the lignin components: furan ring-opening of syringaresinol forming a flexible 3D crosslinked network, retention of conjugated C=C bonds in stilbene enhancing stress transfer, and Schiff base formation from aldoketones contributing to chain extension and flexibility (Figure 25).

Figure 24.

Preparation procedure of lignin-based epoxy resin using low-molecular-weight lignin glycidyl ether (LKLGE) [87]. Used with permission, copyright 2023 American Chemical Society.

Figure 25.

Toughening mechanisms in lignin-based epoxy resins and their impact on mechanical properties [87]. Used with permission, copyright 2023 American Chemical Society.

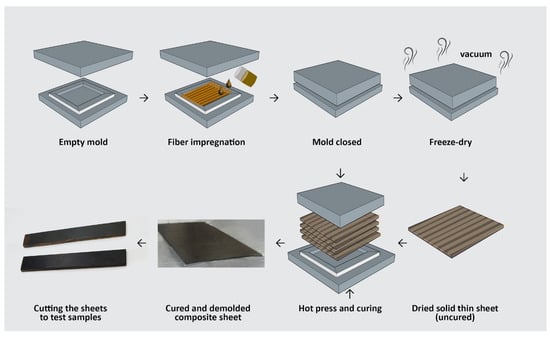

In another study, Bagheri and colleagues developed a bio-based epoxy resin to fully replace BPA [88]. In this approach, kraft lignin was epoxidized using a bio-derived epichlorohydrin (ECH) sourced from glycerol. The resulting resin was then used to impregnate unidirectional bamboo fibers, forming composite sheets for the fabrication of a water-based epoxy resin (Figure 26). During the reaction, epoxidation of kraft lignin introduces reactive epoxide rings onto the lignin structure, enhancing its ability to form covalent bonds during curing, which improves the network formation with curing agents and leads to better load transfer within the composite. The aromatic-rich structure of lignin promotes interfacial compatibility with bamboo fibers due to π–π and hydrogen-bonding interactions. When comparing the mechanical properties, the intial flexural strength of the lignin-based composite was lower than that of commercial epoxy, and the addition of 25 wt.% bamboo fibers significantly improved the flexural strength due to the strong interfacial bonding and natural compatibility between lignin and the bamboo fibers. Furthermore, the incorporation of fibers led to a notable increase in the flexural modulus, reinforcing the potential of this system to replace petroleum-based polymers.

Figure 26.

Schematic representation of the fabrication process for unidirectional, fully bio-based lignin epoxy/bamboo composites [88]. Under a Creative Commons Attribution (CC BY-NC-ND 4.0) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Gavrilović-Grmuša et al. developed a bio-based epoxy adhesive for wood applications by incorporating lignin and tannic acid as reactive components [89]. Specifically, kraft lignin was chemically modified through epoxidation to partially substitute diglycidyl ether of bisphenol A (DGEBA), a conventional petroleum-based epoxy monomer (Figure 27). The modified resin formulations included lignin in concentrations ranging from 5 to 15 wt.%. Notably, the lower lignin content (5 wt.%) yielded the highest tensile shear strength (10.87 MPa), comparable to that of the unmodified resin. However, as the proportion of lignin increased, a gradual decline in adhesive strength was observed. This reduction was attributed to excess lignin’s limited dispersion and reactivity within the epoxy matrix. The structural similarity and chemical compatibility between lignin and tannic acid enhanced the mixture’s homogeneity, thereby reducing lignin agglomeration and improving its interaction with the epoxy network.

Figure 27.

Proposed mechanism for (a) lignin epoxidation, (b) crosslinking of DGEBA, epoxy lignin, and amine hardener, and (c) crosslinking of epoxy lignin with tannic acid during curing [89]. Under a Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/ accessed on 27 April 2025).

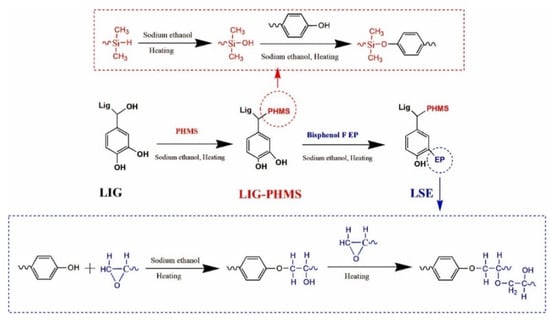

Li et al. developed a lignin-based silicone-modified epoxy resin to improve the mechanical performance of epoxy resins, which are widely used in electronic packaging. The synthesis involved two main steps (Figure 28): first, flexible silicone chains were grafted onto lignin (0–9 wt.%) through a condensation reaction between the Si–H groups of polyhydromethylsiloxane (PHMS) and the hydroxyl groups of lignin. In the second step, the modified lignin was incorporated into the epoxy matrix via additional condensation between the lignin hydroxyl groups and the epoxy resin [90]. Optimal mechanical performance was achieved at 3 wt.% lignin loading, where impact strength increased by 16.25%, tensile strength by 25.81%, bending modulus by 16.21%, and bending strength by 42.43% relative to neat epoxy resin. Moreover, elongation at break improved progressively with increasing lignin content, with a 37.86% enhancement observed at 3 wt.% lignin addition. Although higher lignin content reduced glass transition temperature and crosslink density, the modified resins still exhibited a desirable combination of toughness and strength.

Figure 28.

Synthesis of lignin-based silicone-modified epoxy resin [90]. Used with permission, copyright 2024 Elsevier.

3.2. Phenol-Formaldehyde Resins

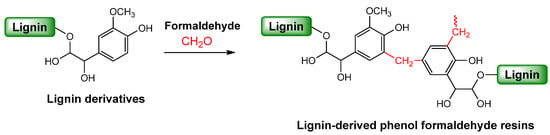

Phenol-formaldehyde (PF) resins are widely utilized in wood adhesives, molding compounds, and insulation materials due to their excellent mechanical strength, water resistance, thermal stability, and flame retardancy [97,98]. Traditionally, these resins are synthesized from petroleum-derived phenol and formaldehyde. However, the use of these chemicals raises significant environmental and health concerns due to the toxicity of both phenol and formaldehyde. In response, lignin as a low-cost, renewable aromatic polymer has garnered significant attention as a sustainable alternative. Lignin’s complex structure contains reactive phenolic and aliphatic hydroxyl groups, aldehydes, and carboxylic functionalities, which can participate in PF resin synthesis. Notably, the phenolic hydroxyl groups in lignin can undergo condensation reactions with formaldehyde, forming methylene bridges (–CH2–) between aromatic units, thereby mimicking the structure of conventional PF networks (Scheme 3). This reactivity makes lignin a promising substitute for phenol in the development of eco-friendly phenolic resins. This section will highlight the role of lignin in various lignin-derived PF resin formulations, emphasizing its potential to reduce environmental impact while maintaining or enhancing resin performance.

Scheme 3.

Synthesis of lignin-modified phenol-formaldehyde resins.

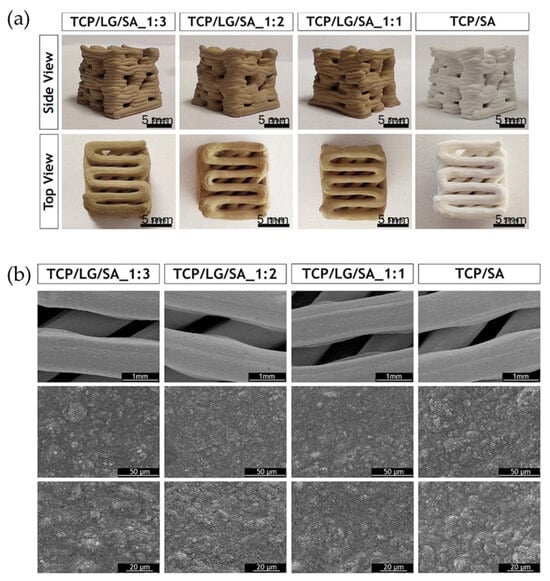

Rodrigues et al. investigated the development of lignin-based phenol-formaldehyde (LPF) resins using fractionated kraft lignin (KL) with lower molar mass fractions [91]. This example demonstrates how lignin fractionation is not merely a purification strategy, but a functional design tool that enhances solubility and reactivity, ultimately improving adhesive bond strength and resin homogeneity. The lignin was extracted from Eucalyptus urograndis wood using ethyl acetate, resulting in both soluble and insoluble fractions. The study explored the effect of substituting 25% and 50% of phenol with fractionated lignin to produce eco-friendly LPF resins. The fractionation process notably increased the total hydroxyl content and solubility of lignin, which are critical parameters for enhancing resin performance. Thermal analysis demonstrated that the inclusion of lignin improved the thermal stability and increased the glass transition temperature (Tg) of the resins. Among the various formulations, resins containing 25% soluble lignin fractions, cured at 150 °C, exhibited adhesive properties comparable to pure phenol-formaldehyde (PF) resins without lignin substitution. Furthermore, the adhesive bond strength of the soluble fraction LPF resins was significantly higher than that of the insoluble fraction LPF resins and non-fractionated KL-based resins. This superior performance highlights the beneficial role of lignin fractionation in optimizing the properties of bio-based resins. Overall, the study successfully demonstrated that a small percentage of soluble lignin fractions can effectively replace phenol in commercial PF resins, contributing to the synthesis of environmentally friendly adhesive systems.

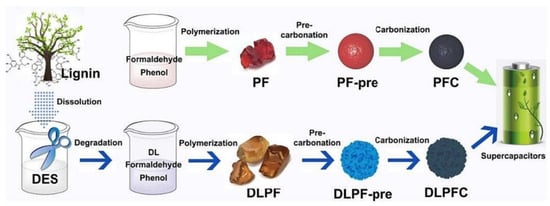

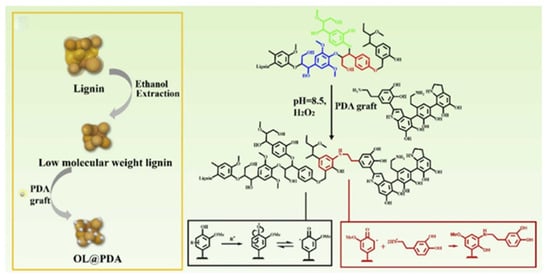

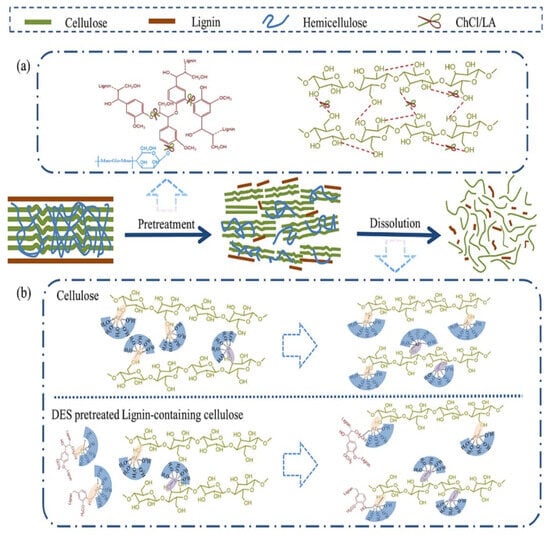

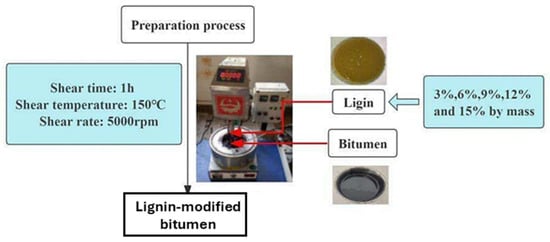

Li and coworkers deployed alkaline lignin with a deep eutectic solvent (DES) composed of p-toluenesulfonic acid and choline to prepare phenolic resin and porous carbon [92]. The depolymerized lignin was co-polymerized with phenol and formaldehyde to produce a lignin-based phenolic resin (DLPFC, Figure 29). A pure phenolic resin carbon (PFC) was also prepared similarly without lignin for comparison. The electrochemical performances of the prepared materials were obtained as supercapacitor electrodes. After the incorporation of lignin, DLPFC materials showed higher specific surface area, higher electrical conductivity, and better graphitization compared to pure resins. As a supercapacitor electrode, DLPFC exhibited higher specific capacitance (245.8 F/g at 0.25 A/g) than PFC (159.7 F/g) in a three-electrode system and had excellent cycling stability, retaining 97.6% capacitance after 10,000 cycles. In a two-electrode system, the DLPFC achieved an energy density of 3.9 Wh/kg at a power density of 125 W/kg, comparable to commercially available batteries.

Figure 29.

Schematic representation of lignin-based phenolic resin (DLPFC) preparation process and phenolic resin carbon (PFC) [92]. Used with permission, copyright 2023 Elsevier.

Galsino and coworkers used kraft lignin as a substitute for phenol in synthesizing phenol-formaldehyde (PF) resins [93]. Lignin was modified through a phenolation process to increase the reactivity of lignin and substituted phenol with varying proportions of phenolated kraft lignin (10–50 wt.%) to produce lignin–phenol-formaldehyde (LPF) resins. The LPF resins with phenol substitution above 20% (LPF30 and LPF20) showed superior shear strength compared to the control PF resin, and the highest shear strength was observed for the LPF30 resin (3.41 MPa). In TGA, the addition of kraft lignin reduced the thermal stability of the resins, resulting in lower decomposition temperatures and smaller amounts of carbonaceous residues. The curing of lignin-based resins occurred at lower temperatures with higher enthalpies than the PF resin. Overall, the study demonstrates the potential of using kraft lignin as a sustainable substitute for phenol (up to 30% substitution) in phenol-formaldehyde resins for structural composite applications, highlighting the need for further optimization and investigation.

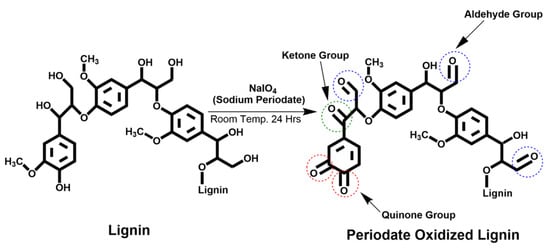

Bansode and coworkers explored the use of lignin as a substitute for phenol and formaldehyde in the preparation of phenol-formaldehyde (PF) wood adhesive resins [94]. Kraft lignin, derived from pine trees, was chemically modified using sodium periodate oxidation to introduce aldehyde functionalities (Figure 30). The oxidized lignin was then employed to partially or fully replace formaldehyde in synthesizing bio-based novolac PF (BNPF) resins. In the study, unmodified lignin was used to replace phenol, while oxidized lignin served as a formaldehyde replacement to produce BNPF resins. The tensile shear strengths of the resulting BNPFs were compared to those of commercially available novolac PF resins. Results showed that lignin-based PF resins exhibited superior dry adhesion strength compared to commercial PF resins. However, the wet adhesion strength of lignin-based resins was lower, likely due to the hydrophilic nature of lignin. Additionally, the curing temperature of the BNPF resins was reduced when formaldehyde was replaced with oxidized lignin. This reduction in curing temperature is attributed to the higher reactivity of periodate-oxidized lignin compared to formaldehyde when reacting with phenol or lignin.

Figure 30.

Schematic representation of the periodate oxidation of softwood lignin, targeting aromatic and aliphatic hydroxyl groups [94]. Used with permission, copyright 2023 American Chemical Society.

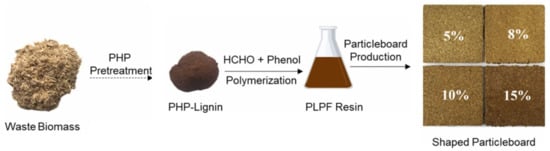

Zhao et al. developed lignin–phenol-formaldehyde (LPF) resins using unmodified lignin derived from phosphoric acid and hydrogen peroxide (PHP) pretreated biomass waste and evaluated their performance as wood adhesives [95]. The PHP-lignin-based LPF (PLPF, Figure 31) resins were compared with those synthesized from conventional alkali lignin (ALPF). Particleboards incorporating 5–15 wt.% LPF resin exhibited good dimensional stability and solvent resistance. However, the presence of resin adhesives hindered enzymatic hydrolysis, reducing cellulose-to-glucose conversion to 18.3%. An alkali pretreatment step significantly improved glucose conversion up to 57.8%, offering a promising detoxification strategy for recycling lignocellulosic composites. In adhesive performance, the bond strength of lignin-derived resins met the requirements for first-grade plywood (≥0.7 MPa), although the ultimate bonding strength of PLPF (2.16 MPa) and ALPF (1.59 MPa) was lower than that of pure PF resin (3.09 MPa). This reduction was attributed to the lower reactivity of lignin due to fewer reactive sites, higher molecular weight, and steric hindrance. Notably, PLPF outperformed ALPF, likely due to the higher hydroxyl content of PHP-lignin enhancing its reactivity with formaldehyde.

Figure 31.

Synthesis of phosphoric acid and hydrogen peroxide pretreated lignin–phenol-formaldehyde resins (PLPF) and particleboards [95]. Used with permission, copyright 2024 Elsevier.

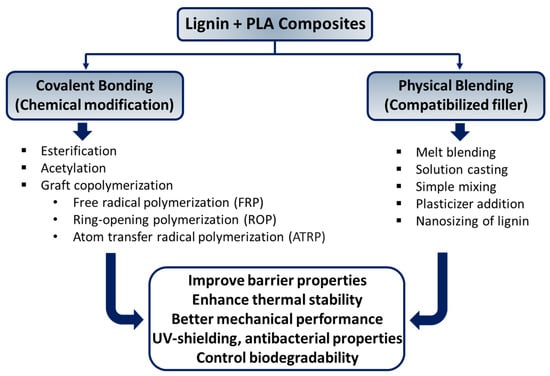

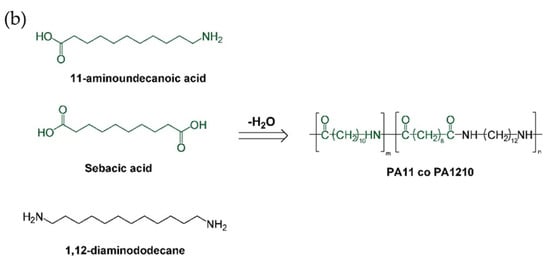

4. Polylactic Acid (PLA) Composites

Poly(lactic acid) (PLA) is a versatile aliphatic linear thermoplastic biodegradable polymer derived from fully renewable sources such as wheat, corn, rice, and sweet potatoes. It offers numerous advantages, including renewability, sustainability, biocompatibility, and compostability, making it an attractive candidate for eco-friendly materials. PLA production involves low energy consumption and generates minimal greenhouse gas emissions, further enhancing its appeal for various applications, including 3D printing [99,100]. However, PLA also exhibits several drawbacks, such as poor gas and water barrier properties, limited toughness, low glass transition temperature, hydrophilicity, and challenges with dispersion when blended with other components [101]. These limitations hinder its widespread use in commercial applications. PLA is often blended with natural additives like lignin and fibers to address these issues, to enhance its thermal stability, water barrier performance, crystallization behavior, mechanical strength, antimicrobial properties, and degradability (Scheme 4). This section explores recent advancements in the development of biodegradable composites, focusing specifically on incorporating lignin into PLA to improve its performance characteristics (Table 3).

Scheme 4.

Strategies for incorporating lignin into polylactic acid (PLA) systems.

Table 3.

Summary of the lignin-based PLA polymers.

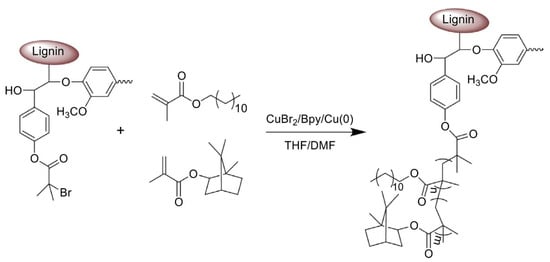

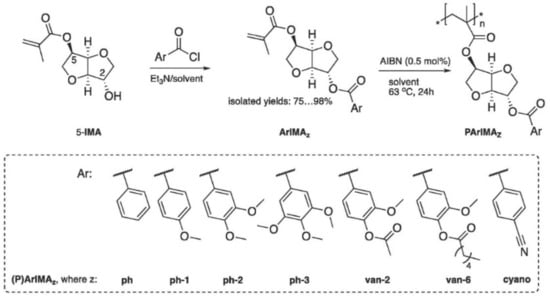

Shi and coworkers developed wholly bio-based composites by grafting lignin with lauryl methacrylate (LMA), a renewable plant-based fatty acid monomer, through free-radical polymerization to produce lignin graft copolymers (LG-g-PLMA) [102]. These copolymers (0–20 wt.% of LG-g-PLMA) were subsequently blended with polylactic acid (PLA) to create the composites. The long hydrophobic side chain of LMA was designed to improve the hydrophobicity, flexibility, and compatibility of lignin with PLA, while lignin was anticipated to contribute UV barrier properties to the composites. The incorporation of LG-g-PLMA significantly enhanced the crystallinity of PLA, increasing from 6.42% to 17.46%. When the LG-g-PLMA loading was below 9%, the thermal stability of the composites showed a slight improvement compared to pure PLA. However, the glass transition temperature (Tg) of the composites decreased with increasing LG-g-PLMA content. At a 5% LG-g-PLMA loading, the composites demonstrated a 42% increase in elongation at break and a 36% increase in tensile toughness compared to pure PLA. While the tensile strength of the composites declined from 55.6 MPa (pure PLA) to 26.5 MPa at 20% LG-g-PLMA loading, the composites exhibited a strong UV barrier effect, nearly completely blocking UV light at low LG-g-PLMA concentrations. The successful grafting of LMA onto the lignin via free-radical polymerization enhanced both the hydrophobicity and thermal stability of lignin. This modification also improved its compatibility with PLA and strengthened interfacial adhesion. As a result, the composites exhibited improved mechanical properties even at low LG-g-PLMA loading.

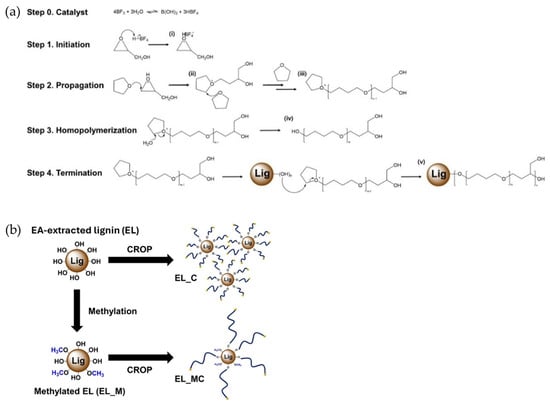

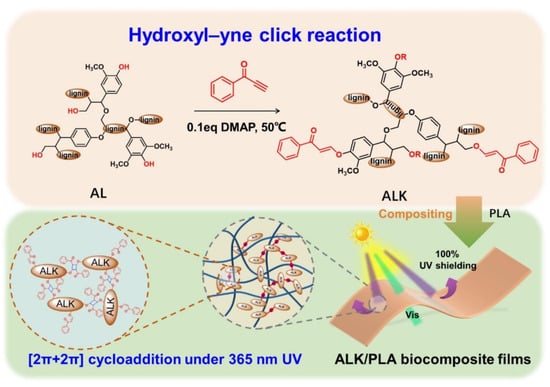

Kim et al. addressed the inherent brittleness and poor UV resistance of PLA by incorporating chemically modified lignin, leveraging cationic ring-opening polymerization (CROP) techniques to enhance material performance [103]. The modification involved ethyl acetate-extracted lignin (EL) subjected to CROP using tetrahydrofuran (THF) and glycidol (GLY) in the presence of a boron trifluoride (BF3) catalyst, resulting in EL_C and EL_MC (methylated EL) variants (Figure 32). The methylation of EL was specifically designed to regulate the hydroxyl content, optimizing compatibility with the PLA matrix. The CROP reaction was carried out to promote homopolymerization under starvation of the initiator (oxirane), leading to the formation of long polyether chains grafted onto the lignin core. The introduction of these polyether chains aimed to improve the compatibility and interfacial adhesion between the hydrophobic lignin and the non-polar PLA matrix. To fabricate lignin/PLA films, EL, EL_C, and EL_MC were individually dissolved in chloroform along with PLA, followed by solvent casting to produce films designated as EL_F (EL/PLA), EL_CF (EL_C/PLA), and EL_MCF (EL_MC/PLA). The glass transition temperatures (Tg) of the films followed a descending trend from EL_MCF to EL_CF, EL_F, and PLA, with the reduced Tg of the lignin-polyether (LPE)/PLA films indicating a plasticizing effect that enhanced the flexibility of the PLA matrix. Thermal stability (Tmax, maximum weight loss temperatures ) was highest for EL_MCF (395.86 °C), followed by EL_F (365.84 °C) and EL_CF (357.2 °C). EL_MCF showed superior mechanical properties with the highest elongation at break (297.7%) and toughness (39.92 MJ/m3) compared to EL_CF (242.07% and 28.19 MJ/m3) and neat PLA (72.58% and 18.41 MJ/m3). The tensile strength hierarchy was PLA (30.88 MPa) > EL_CF > EL_MCF > EL_F, with EL_F demonstrating poor mechanical properties. Additionally, the lignin/PLA films demonstrated remarkable UV-blocking capabilities. The EL_MCF film achieved outstanding UV protection, blocking 99.52% of UVA and 88.95% of UVB rays without significantly compromising transparency. These enhancements in mechanical performance and UV resistance underscore the potential of chemically modified lignin to expand the applicability of PLA in industries requiring durable and UV-stable materials.

Figure 32.

(a) The proposed mechanism of cationic ring-opening polymerization (CROP) reaction and (b) illustration for the preparation of EL_C and EL_MC [103]. Used with permission, copyright 2023 Elsevier.

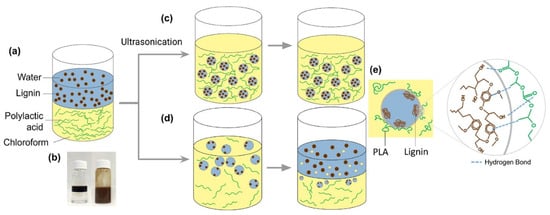

Yu et al. introduced lignin’s surface activity to stabilize reverse (water-in-oil) emulsions through interfacial interactions with polylactide (PLA) in the organic phase [104]. Unmodified alkali lignin was used to stabilize reverse (water-in-oil) emulsions through interfacial interactions with PLA in an organic, continuous phase (chloroform). Lignin was dispersed in the 1 M NaOH aqueous phase (up to 30 wt.%), while PLA was dissolved in chloroform (up to 10 wt.%). The aqueous lignin and PLA solutions were mixed in various ratios to form emulsions using ultrasonication (Figure 33). The emulsions were cast onto glass plates or coated onto hydrophilic substrates (glass or paper) to create composite films. The lignin–PLA interactions at the oil–water interface were critical for achieving long-term emulsion stability. Uniform composite films with lignin loadings as high as 95% (with PLA being the balance) were obtained by emulsion casting and coating onto hydrophilic substrates. The lignin–PLA films demonstrated enhanced UV-blocking properties, especially in the UV-A region, compared to a commercial sunscreen, while maintaining transparency. The presence of PLA in the continuous matrix of the film imparted water resistance to the coated hydrophilic substrates.

Figure 33.

Unstable water-in-oil emulsion to stable dispersion using lignin and PLA. (a) Schematic of separate oil and water phases with their constituents before emulsification. (b) Mixture appearance before and immediately after sonication. (c) Stable W/O emulsion with aqueous lignin droplets suspended in a continuous PLA organic phase. (d) Unstable W/O emulsion showing droplet coalescence and phase separation due to insufficient lignin or PLA. (e) Close-up of a droplet interface with adsorbed lignin and PLA molecules, highlighting proposed intermolecular interactions [104]. Used with permission, copyright 2023 American Chemical Society.

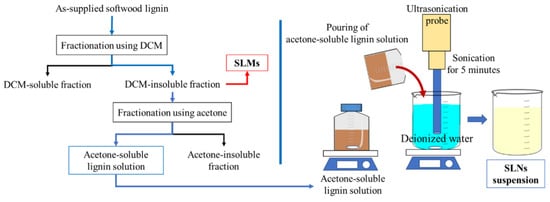

Banpean et al. investigated the impact of lignin nanoparticles (SLNs) and microparticles (SLMs) on the crystallization behavior of poly(L-lactic acid) (PLLA) [105]. Softwood kraft lignin was fractionated with dichloromethane (DCM) to produce DCM-insoluble lignin for SLMs, while SLNs were obtained by further fractionating SLMs with acetone, followed by ultrasonication and centrifugation (Figure 34). Composite films with 1 wt.% of either SLNs or SLMs were prepared via solution casting. Both additives enhanced PLLA’s crystallization rate, crystallinity, and nucleation density, with SLNs performing better due to their smaller size. The PLLA/SLN composite required less energy for nuclei formation and had lower folding surface energy than neat PLLA and PLLA/SLM composites. The glass transition temperature (Tg) of PLLA remained unaffected by the addition of SLMs and SLNs.

Figure 34.

Preparation procedure for lignin nanoparticles (SLNs) and microparticles (SLMs) [104]. Used with permission, copyright 2023 Springer Nature.

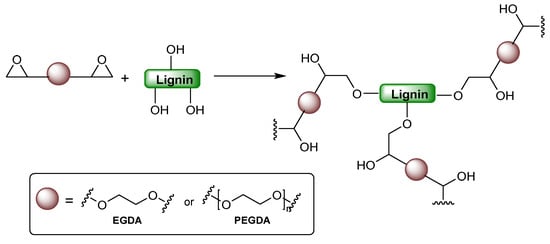

Shakoor Shar et al. used low-viscosity epoxy resins, ethylene glycol diglycidyl ether (EGDE), and poly(ethylene glycol) diglycidyl ether (PEGDE) as compatibilizers to enhance lignin dispersion in the PLA matrix (Figure 35) [106]. These epoxies form chemical linkages or hydrogen bonds with PLA and lignin, improving compatibility and interfacial adhesion. PLA/lignin bio-composites were prepared with 1, 3, and 5 phr lignin loadings. Lignin addition increased PLA’s onset degradation temperature by up to 15 °C and improved crystallinity. EGDE and PEGDE reduced the glass transition, crystallization, and melting temperatures, indicating their compatibilizing and plasticizing effects. Oxygen barrier properties were significantly enhanced, with PLA/EGDE/5LG and PLA/PEGDE/5LG showing up to 58.3% and 57.3% enhancement, respectively. Tensile strength observed only a modest increase (~15%), and compatibilizers did not significantly boost tensile strength. The composites demonstrated enhanced thermal stability, crystallinity, and oxygen barrier properties, showing promise for green packaging, though biodegradability was not assessed. This enhancement is attributed to a reduction in micro- and nanoscale porosity and the formation of a more tortuous diffusion path due to homogeneous dispersion of lignin domains within the polymer matrix. These effects collectively suppress oxygen permeability by limiting molecular transport, consistent with barrier improvements reported in lignin–polyester and lignin–PLA systems [115].

Figure 35.

Chemical illustration of the reactivity of ethylene glycol diglycidyl ether (EGDE) and poly(ethylene glycol) diglycidyl ether (PEGDE) with lignin.

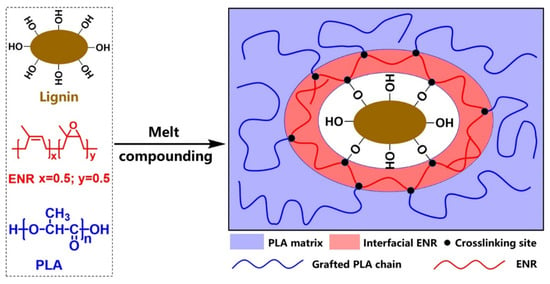

Poor mechanical properties limit the applications of PLA/lignin composites due to poor compatibility and low interfacial adhesion. Ou and coworkers addressed this by using epoxidized natural rubber (ENR) as a reactive compatibilizer, enabling the formation of interfacial crosslinking copolymers through reactions between ENR, PLA, and lignin during melt processing (Figure 36) [107]. The addition of ENR reduced interfacial gaps, blurred phase boundaries, and enhanced the elastic response, demonstrating improved compatibility. PLA/lignin/ENR composites were produced by melt compounding at 170 °C with a fixed PLA-to-lignin ratio (80:20) by changing the ENR content (1–10 wt.%). Increasing ENR content raised the glass transition temperature (Tg) of the composites due to reduced free volume and chain mobility. Mechanical testing showed that tensile strength and elongation at break for PLA/lignin (80/20) without ENR were 45.31 MPa and 2.9%, respectively. Tensile strength with 1 wt.% ENR increased by 15% to 52.03 MPa, and elongation at break improved by 77% to 4.6%. While higher ENR content (10 wt.%) further enhanced elongation at break to 20.1%, it reduced tensile strength to 38.37 MPa. Overall, ENR effectively enhanced the mechanical performance of PLA/lignin composites.

Figure 36.

Mechanisms of interfacial reactions in preparing epoxidized natural rubber (ENR) compatibilized PLA/lignin composites [107]. Used with permission, copyright 2023 Elsevier.

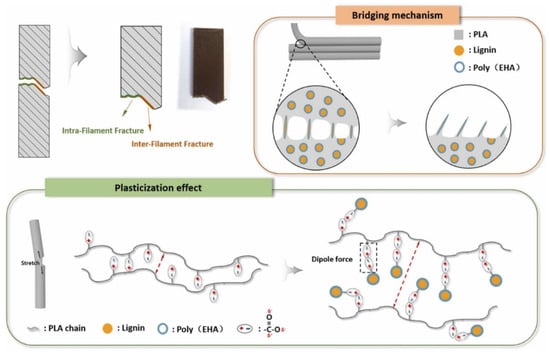

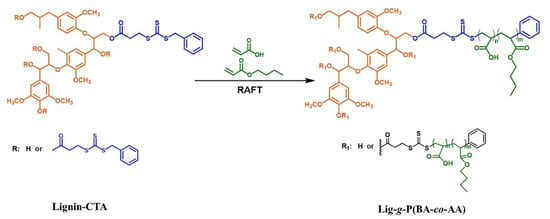

Ding and coworkers developed PLA/lignin biocomposites for 3D printing by chemically modifying the lignin through grafting 2-ethylhexyl acrylate (EHA) to produce modified lignin (e-Lignin, Figure 37) [108]. The grafting improved interfacial interactions between lignin and PLA, enhancing dispersion and mechanical properties. The low melt viscosity of e-Lignin facilitated thermo-rheological relaxation, promoting PLA molecular chain mobility and making composites suitable for fused deposition modeling (FDM) 3D printing. Different PLA/e-Lignin specimens were prepared, adding 0–15 wt.% of e-Lignin to assess the properties. The addition of e-Lignin showed lower glass transition temperatures (Tg) and improved thermal stability, with higher decomposition temperatures (T5%) and maximum weight loss temperatures (Tmax). Although the storage modulus (E′) was lower than pure PLA below 50 °C, indicating reduced stiffness, higher tan δ peaks suggested enhanced molecular chain mobility. While tensile strength and modulus decreased, the elongation at break and toughness significantly improved. The 10 wt.% e-Lignin composites showed the highest toughness (3.84 MJ/m3) and impact energy (6.36 KJ/m2) compared to pure PLA (1.16 MJ/m3, 2.12 KJ/m2, respectively) in 3D-printed specimens. The enhanced toughness and impact energy were due to the synergistic effects of plasticization and the bridging effect of e-Lignin (Figure 38). The composites maintained suitable melt viscosity for 3D printing, with improved interlayer adhesion due to better interfacial diffusion. However, the long-term performance and aging behavior of the 3D-printed composites need to be assessed.

Figure 37.

The predicted structure of e-Lignin by grafting 2-ethylhexyl acrylate (EHA) onto lignin [108]. Used with permission, copyright 2023 Elsevier.

Figure 38.

Proposed mechanism for the toughening effect in 3D-printed PLA/e-Lignin composites [108]. Used with permission, copyright 2023 Elsevier.

Makri et al. developed PLA composites incorporating lignin using two distinct techniques: conventional melt-mixing and in situ ring-opening polymerization (ROP) with reactive processing [109]. Composites containing 0.5 wt.% lignin or nano-lignin were investigated, with the in situ ROP method demonstrating a reduction in reaction time as catalyst content increased. Thermal analysis revealed that even at low lignin concentrations, the reactive processing method significantly influenced the thermal transitions of PLA. In the comparison of mechanical properties, the addition of 0.5 wt.% lignin or nano-lignin to neat PLA reduced the stress at break and elastic modulus, while elongation at break remained unaffected. Compared to conventional melt-mixing, where poor lignin dispersion and aggregation resulted in weakened properties, the in situ ROP method achieved superior mechanical performance due to enhanced lignin dispersion and improved interfacial bonding, maintaining or enhancing the material’s mechanical properties.

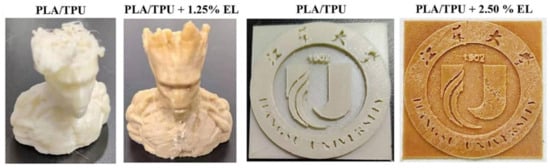

Murillo-Morales et al. investigated the use of enzymatically modified lignin (EL) as a nucleating agent to enhance the mechanical properties and biodegradability of polylactic acid/thermoplastic polyurethane (PLA/TPU) blends for 3D printing applications (Figure 39) [110]. Alkali lignin (AL), extracted from Bacillus ligniniphilus, was partially degraded using a laccase enzyme to produce EL. PLA/TPU blends with varying ratios (90:10, 85:15, and 80:20) were prepared, incorporating AL and EL in different concentrations (1.25–5.00 wt.% based on PLA weight). The lignin-based thermoplastic composites were extruded into filaments and processed using fused deposition modeling (FDM) for 3D printing. Notably, EL addition increased the elasticity modulus and elongation at break compared to AL filaments. The highest elasticity modulus (2.177 GPa) was observed with a low EL content (1.25 wt.%), representing a 239% increase compared to the control (0.9121 GPa). Additionally, the presence of EL led to a more moderate decrease in the molar mass than AL filaments, maintaining viscosity while enhancing elasticity. Overall, the incorporation of EL in PLA/TPU blends significantly improved the mechanical properties of the 3D-printed composites, providing tunable performance, a wood-like color, and enhanced biodegradability.

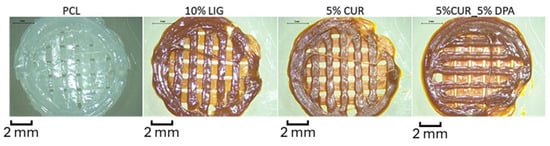

Figure 39.

Representative images of routine FDM 3D-printed objects using a PLA/TPU blend alone and a PLA/TPU blend incorporating bacterial enzymatically modified lignin (EL) [110]. Used with permission, copyright 2023 Elsevier.

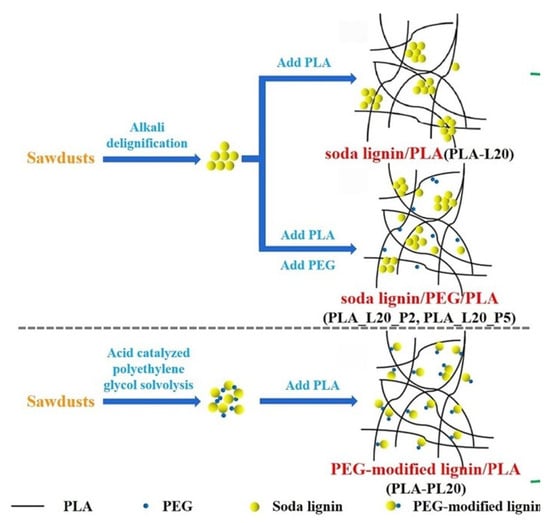

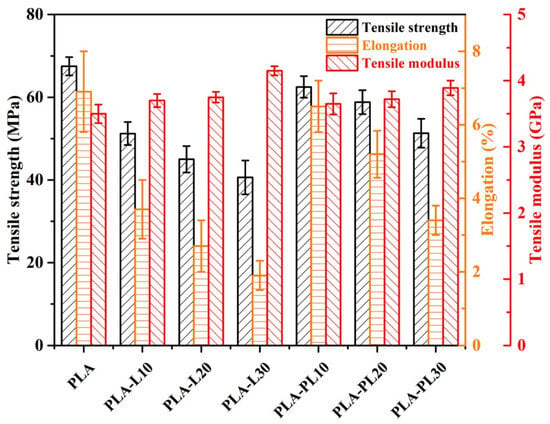

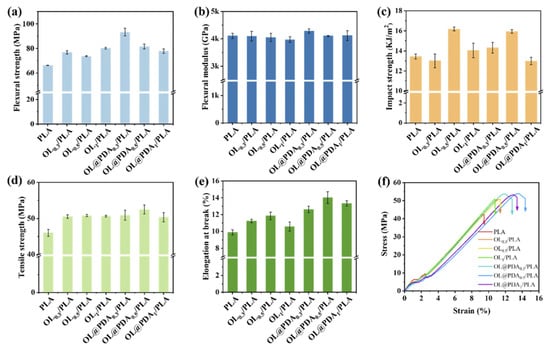

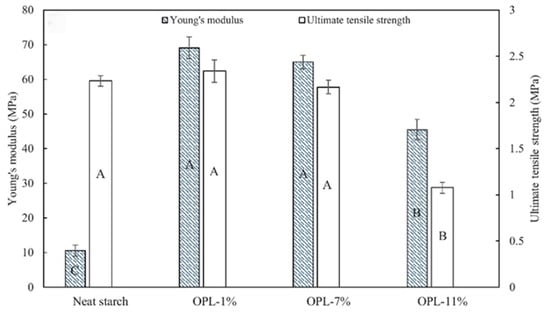

Ju et al. proposed a strategy to enhance the mechanical and thermal properties of polylactic acid (PLA) biocomposites by incorporating polyethylene glycol (PEG)-modified lignin as a functional filler [111]. Soda lignin and PEG-modified lignin were prepared from beech wood via steam blasting pretreatment, followed by two processes: alkali delignification and acid-catalyzed PEG solvolysis (Figure 40). The incorporation of PEG-modified lignin improved the heat resistance of the PLA matrix, enhancing its applicability in thermally demanding environments. Compared to pure PLA, the incorporation of unmodified soda lignin (PLA-L composites) showed a progressive reduction in tensile strength and elongation at break with increasing lignin content (Figure 41). This decline in mechanical properties is attributed to lignin’s tendency to disrupt the continuity of the PLA matrix, inhibiting the formation of a uniform, long-range polymer phase. However, the tensile modulus increased, with PLA-L30 exhibiting an 18.6% higher modulus than neat PLA. In contrast, composites containing PEG-modified lignin (PLA-PL) demonstrated significantly improved mechanical properties. PLA-PL10 composites exhibited a 22% higher tensile strength than PLA-L10, demonstrating the compatibilizing effect of PEG chains. Furthermore, PLA-PL30 showed a 26.4% increase in tensile strength and a 78.9% increase in elongation at break compared to pure PLA, indicating that up to 30 wt.% of PEG-modified lignin can enhance both strength and flexibility, improving the mechanical performance.

Figure 40.

Different methods of polyethylene glycol (PEG) incorporation for the preparation of lignin/PLA composites [111]. Used with permission, copyright 2024 Elsevier.

Figure 41.

Mechanical properties of neat PLA, PLA composites with unmodified soda lignin (PLA-L), and PLA composites with PEG-modified lignin (PLA-PL) [111]. Used with permission, copyright 2024 Elsevier.

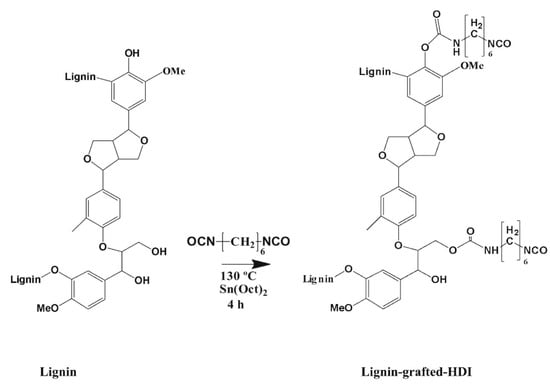

Beniwal and co-workers investigated the improvements in mechanical strength, thermal resistance, and oxygen barrier performance of polylactic acid (PLA) composites through the incorporation of lignin functionalized with hexamethylene diisocyanate (HDI) to form lignin-grafted polyurethane (L-g-HDI) structures (Figure 42) [112]. The lignin was chemically modified via a heterogeneous reaction in dimethyl sulfoxide, introducing urethane linkages through HDI-improved compatibility with the PLA by enhancing hydrogen bonding and intermolecular interactions between the lignin and polymer matrix. When blended with PLA, the crosslinked lignin significantly enhanced the mechanical properties of the resulting composites, particularly in terms of tensile strength and elongation at break, due to the interactions. Optimal mechanical performance was observed at 14 wt.% L-g-HDI loading, with a remarkable 231% increase in tensile strength, elongation at break reaching 37.8%, and a sixfold increase in Young’s modulus compared to neat PLA. However, further increases in filler content (16 wt.%) led to diminished mechanical performance due to filler agglomeration and disruption of the polymer phase continuity. In addition to mechanical enhancements, the incorporation of L-g-HDI resulted in increased crystallinity, improved thermal stability, and enhanced barrier and water-resistance properties.

Figure 42.

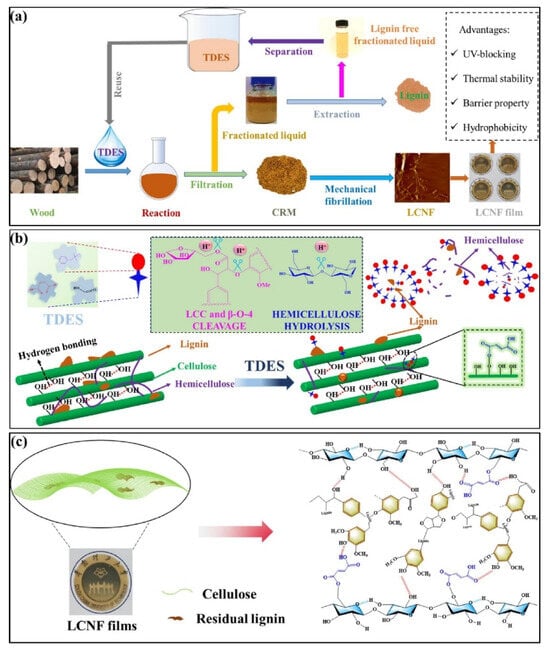

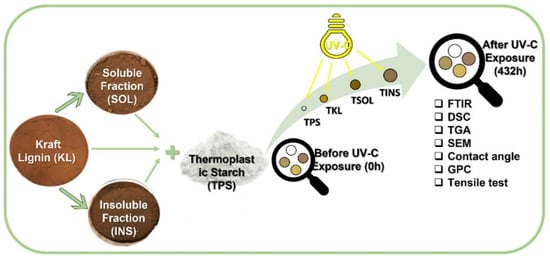

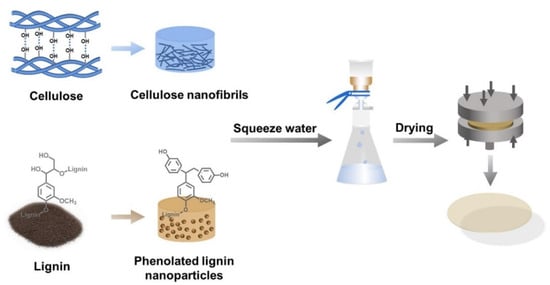

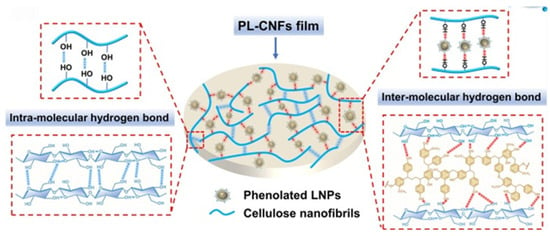

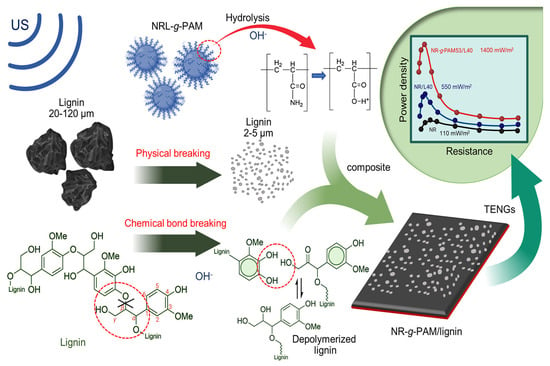

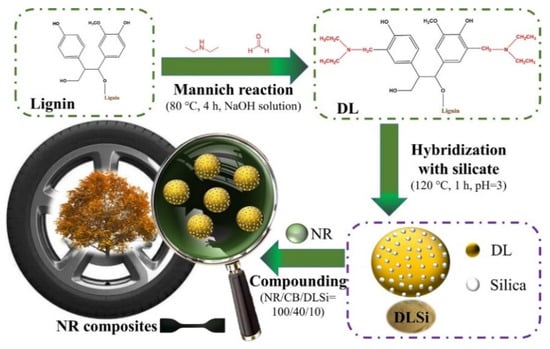

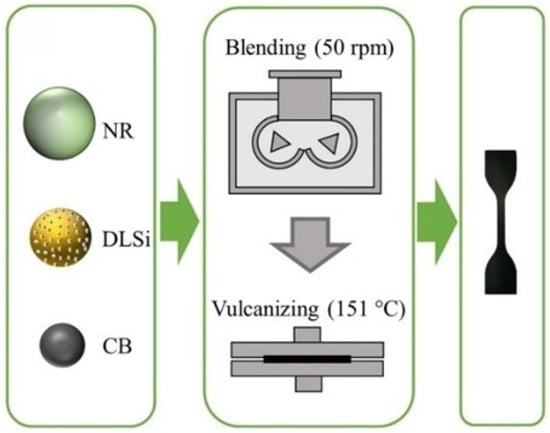

Schematic representation of the preparation method for lignin-grafted polyurethane (L-g-HDI) via the reaction of lignin molecules with hexamethylene diisocyanate (HDI) [112]. Used with permission, copyright 2024 Elsevier.