Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets

Abstract

1. Introduction

2. Results

2.1. Characterization of the Ingredients

2.1.1. Physicothermal Properties

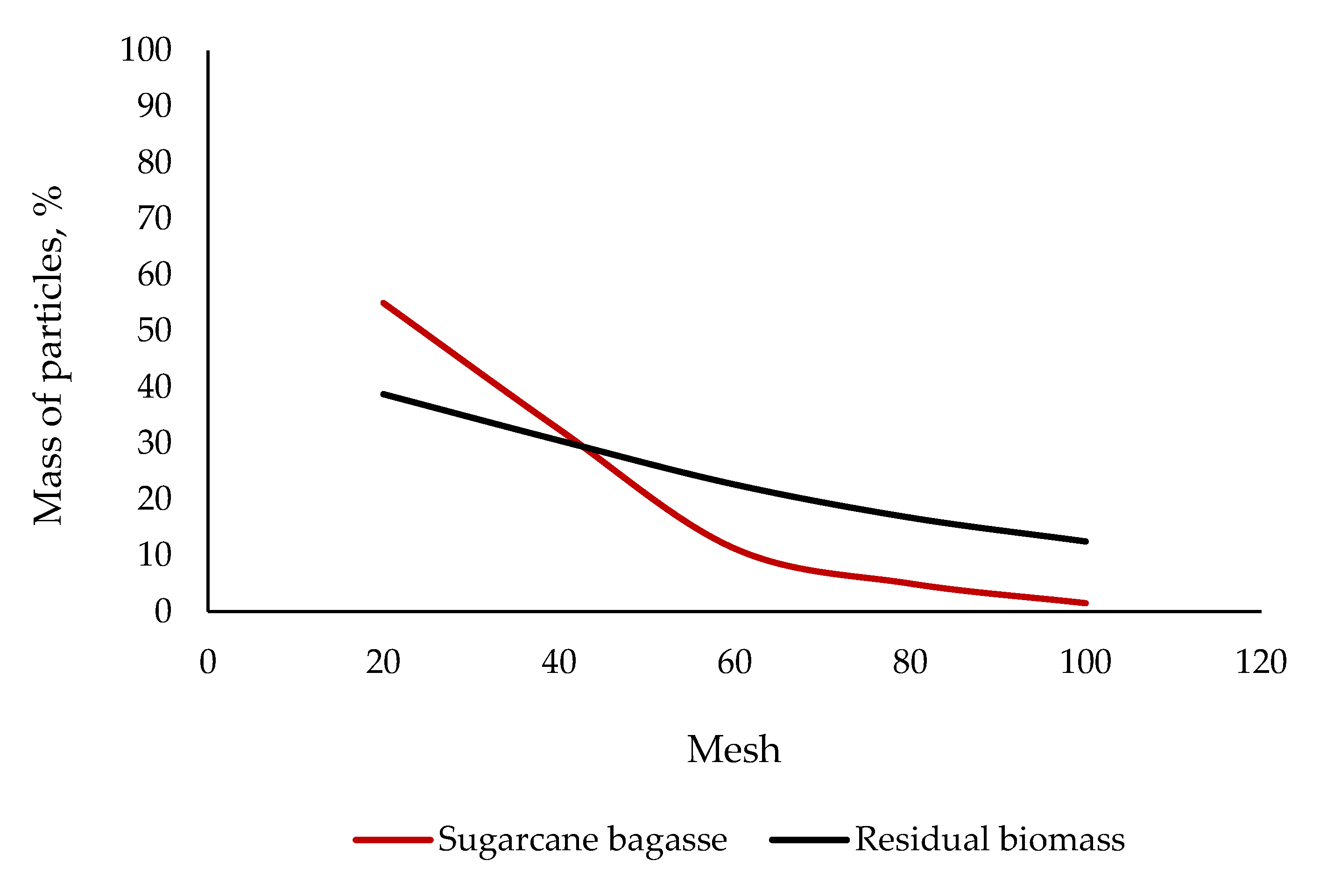

2.1.2. Distribution of Particles’ Size

2.2. Effect of Supportive Material on the Quality of Hybrid Non-Wood Pellets

2.2.1. Quality of Hybrid Non-Wood Pellets

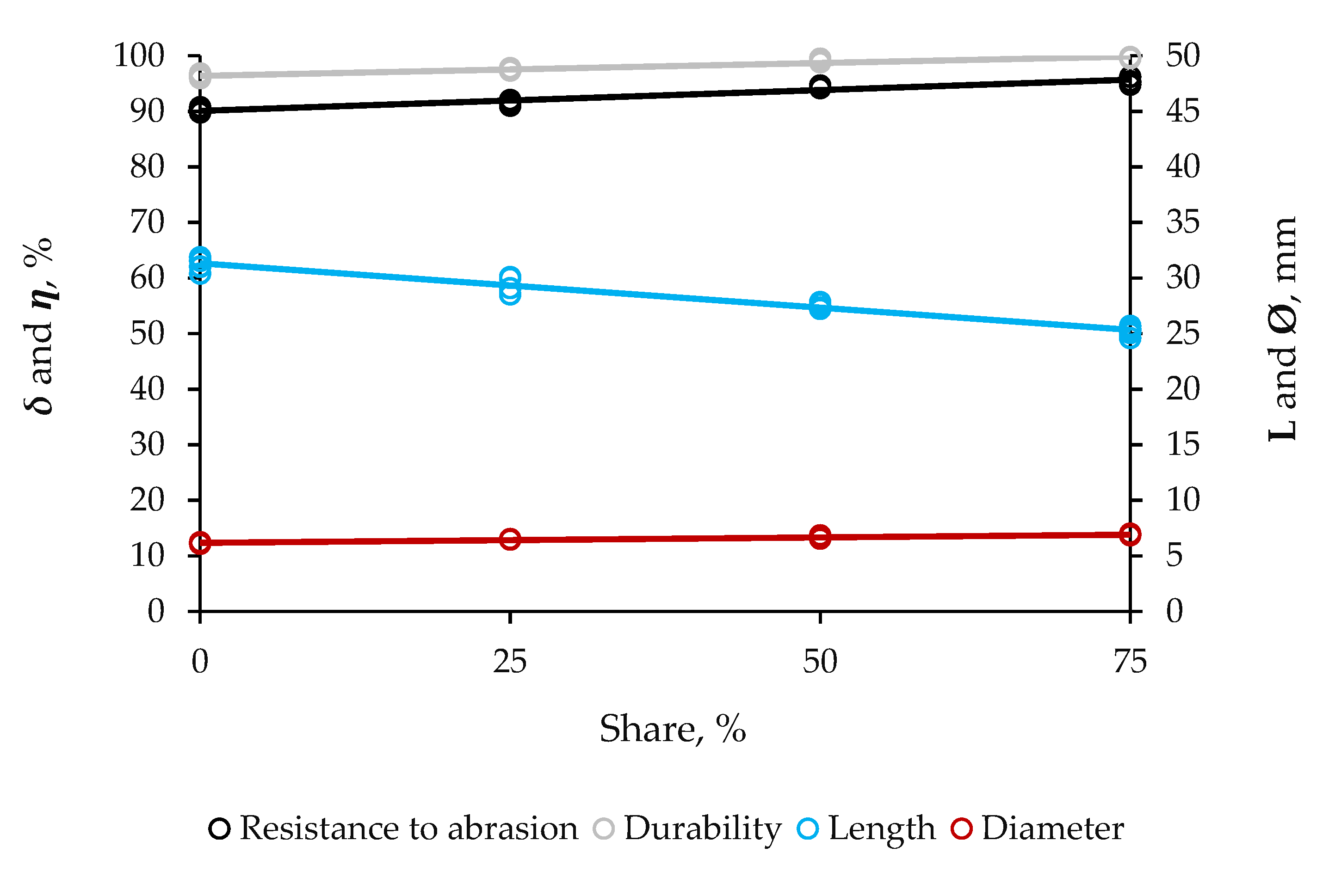

Physicomechanical

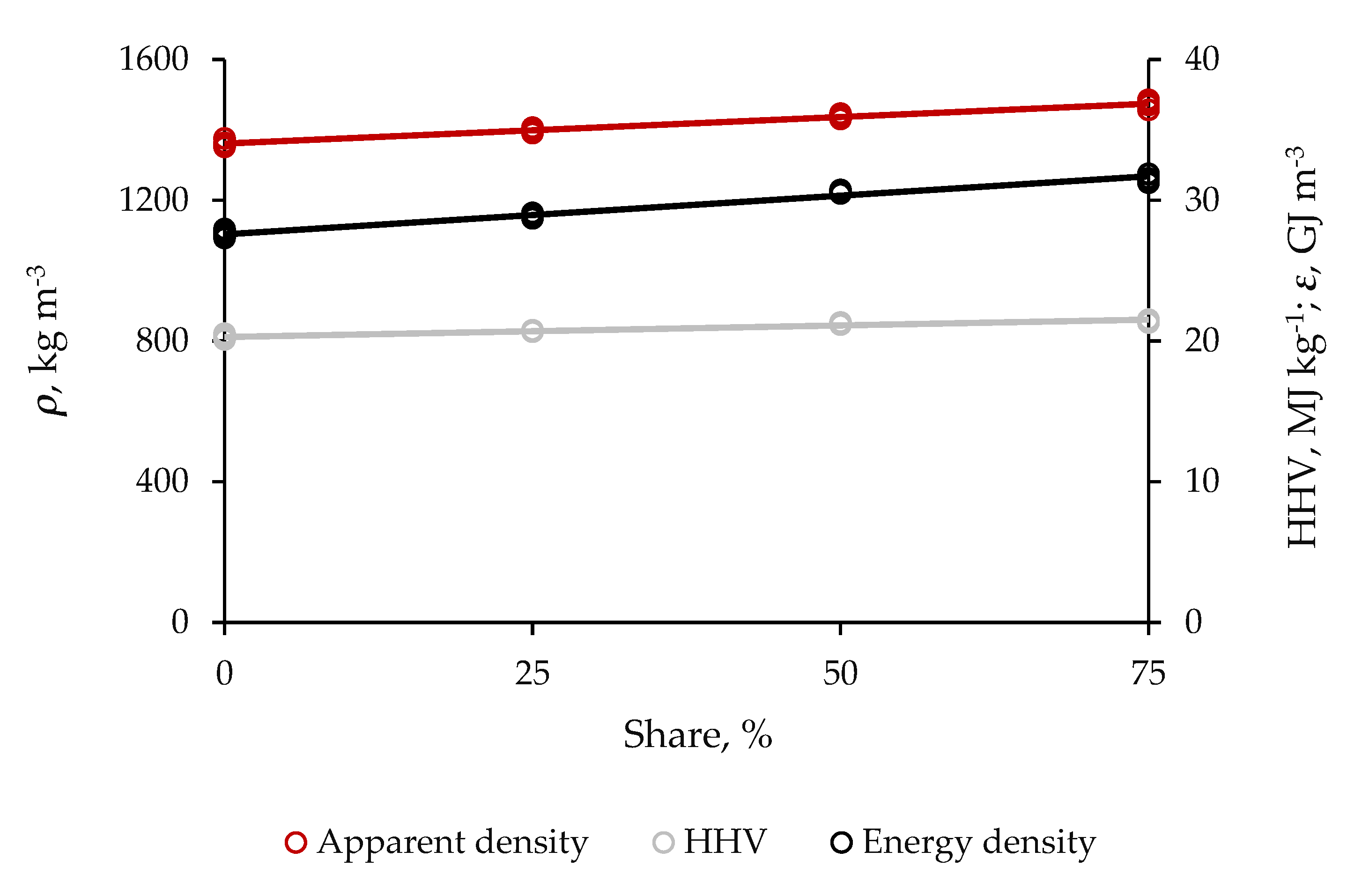

Physicothermal

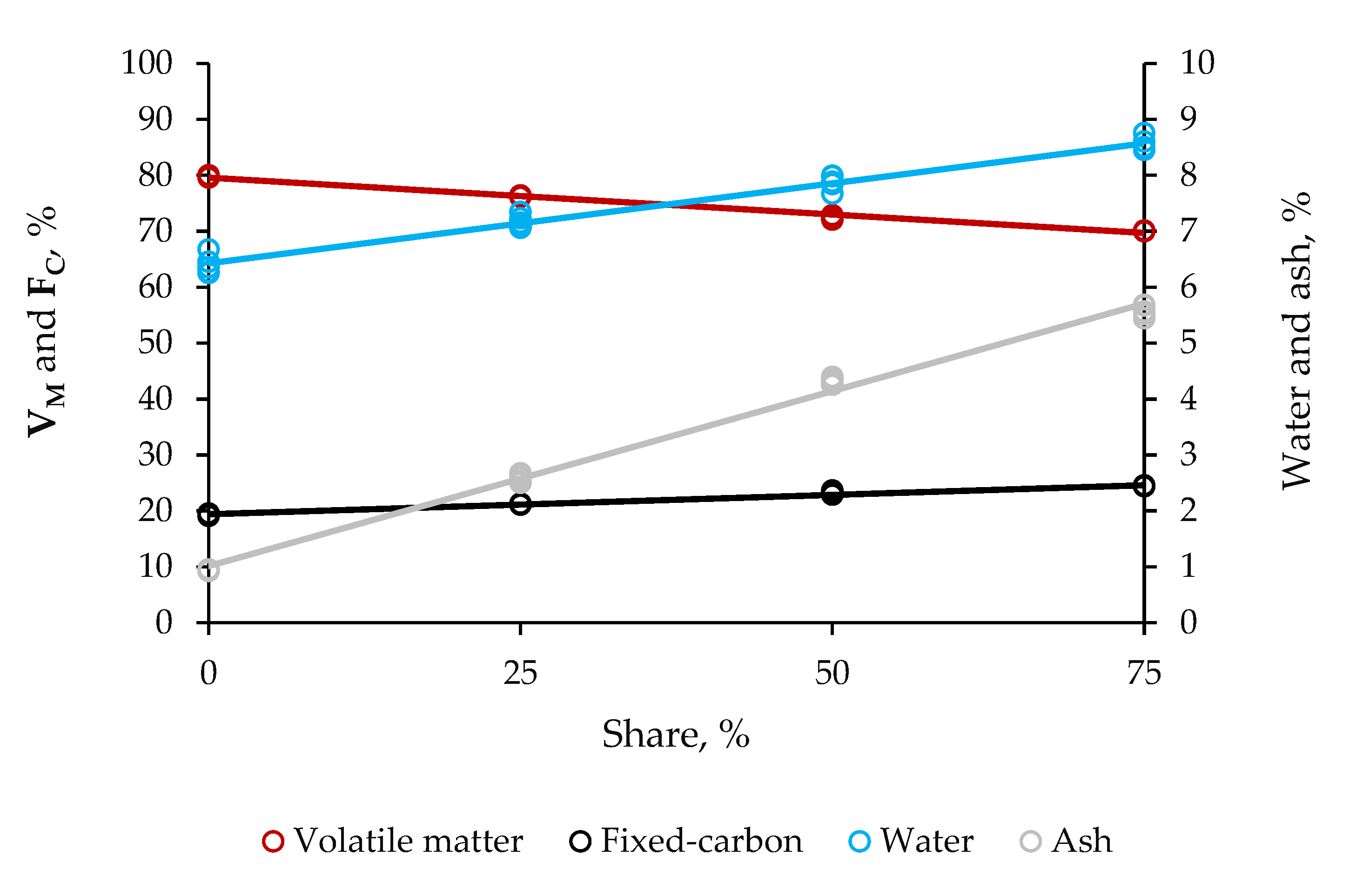

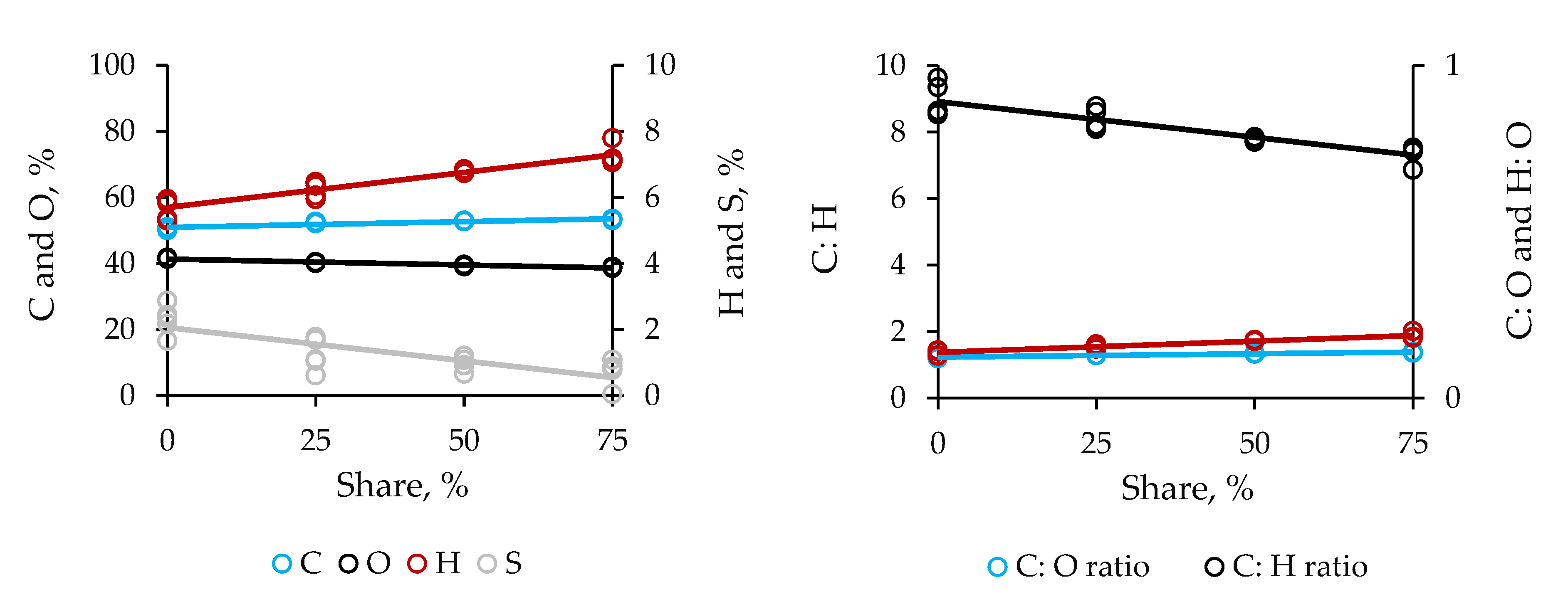

Physicochemical

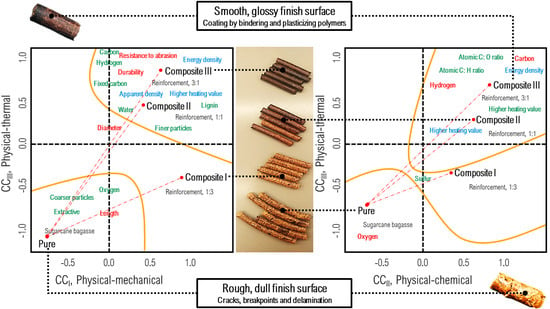

2.3. Canonical Correlations between Characteristics of the Ingredients and Quality of Hybrid Non-Wood Pellets

3. Discussion

3.1. Characterization of the Ingredients

3.1.1. Physicochemical Properties

3.1.2. Distribution of Particles’ Size

3.2. Quality and Potential Applications for the Hybrid Non-Wood Pellets

4. Materials and Methods

4.1. Pre-Production

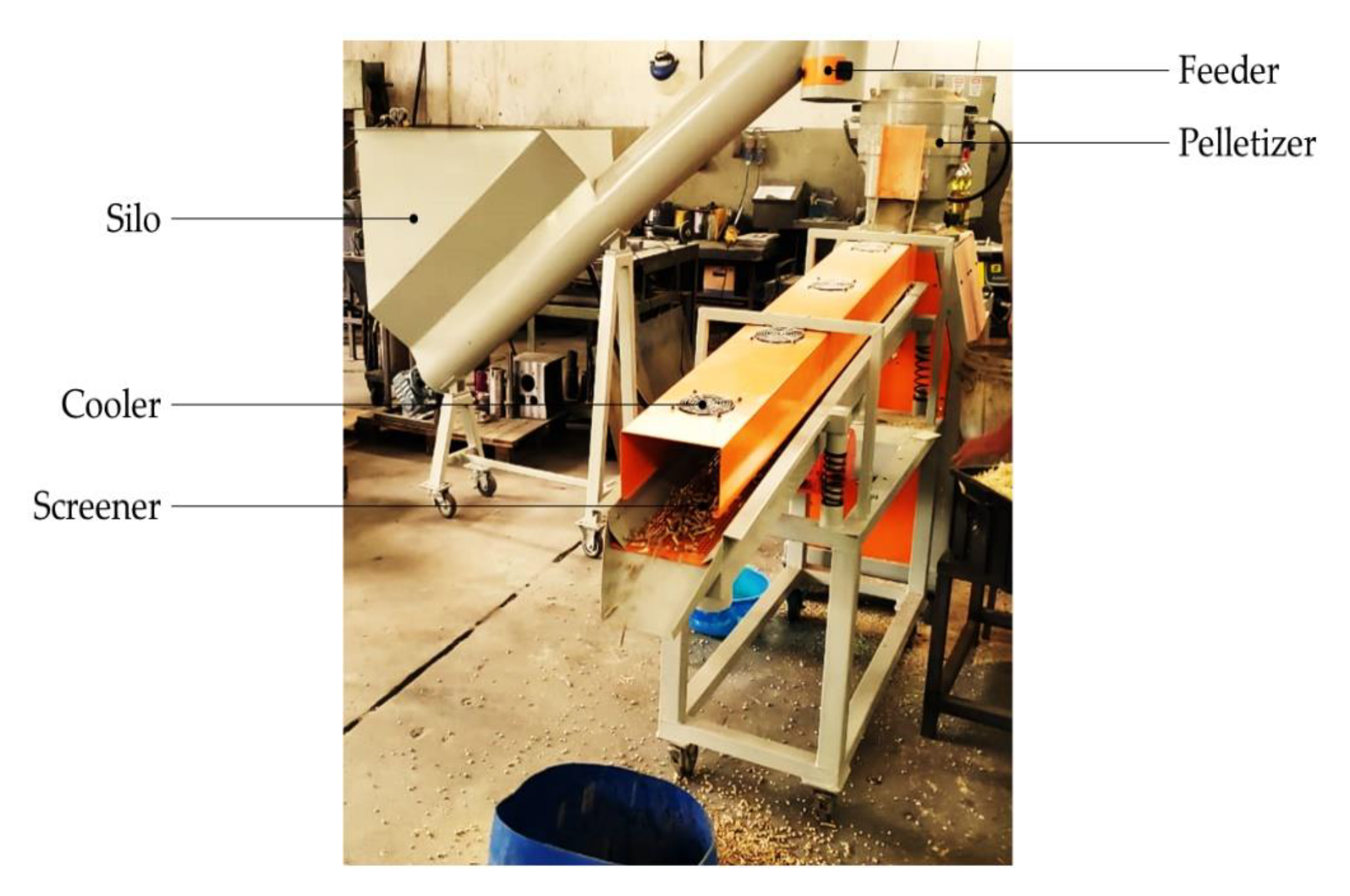

4.1.1. Infrastructure

4.1.2. Origination of the Starting Materials

Characterization

4.2. Production

4.2.1. Experiment

Planning

Setup

4.3. Post-Production

4.3.1. Quantitative Analysis

Physicomechanical

Physicothermal

Physicochemical

4.4. Data Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Rosales-Calderon, O.; Arantes, V. A review on commercial-scale high-value products that can be produced alongside cellulosic ethanol. Biotechnol. Biofuels 2019, 12, 240. [Google Scholar] [CrossRef] [PubMed]

- Rastogi, M.; Shrivastava, S. Recent advances in second generation bioethanol production: An insight to pretreatment, saccharification and fermentation processes. Renew. Sustain. Energy Rev. 2017, 80, 330–340. [Google Scholar] [CrossRef]

- Ding, J.; Huang, X.; Zhang, L.; Zhao, N.; Yang, D.; Zhang, K. Tolerance and stress response to ethanol in the yeast Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol. 2009, 85, 253. [Google Scholar] [CrossRef] [PubMed]

- Kang, Q.; Huybrechts, J.; Van der Bruggen, B.; Baeyens, J.; Tan, T.; Dewil, R. Hydrophilic membranes to replace molecular sieves in dewatering the bio-ethanol/water azeotropic mixture. Sep. Purif. Technol. 2014, 136, 144–149. [Google Scholar] [CrossRef]

- Zhu, G.; Yang, L.; Gao, Y.; Xu, J.; Chen, H.; Zhu, Y.; Wang, Y.; Liao, C.; Lu, C.; Zhu, C. Characterization and pelletization of cotton stalk hydrochar from HTC and combustion kinetics of hydrochar pellets by TGA. Fuel 2019, 244, 479–491. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Xiao, Z.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Assessment of plant biomass for pellet production using multivariate statistics (PCA and HCA). Renew. Energy 2019, 139, 796–805. [Google Scholar] [CrossRef]

- Malico, I.; Nepomuceno Pereira, R.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Mixed biomass pellets for thermal energy production: A review of combustion models. Appl. Energy 2014, 127, 135–140. [Google Scholar] [CrossRef]

- Mendoza Martinez, C.L.; Sermyagina, E.; de Cassia Oliveira Carneiro, A.; Vakkilainen, E.; Cardoso, M. Production and characterization of coffee-pine wood residue briquettes as an alternative fuel for local firing systems in Brazil. Biomass Bioenergy 2019, 123, 70–77. [Google Scholar] [CrossRef]

- Harun, N.Y.; Afzal, M.T. Effect of particle size on mechanical properties of pellets made from biomass blends. Procedia Eng. 2016, 148, 93–99. [Google Scholar] [CrossRef]

- Gil, M.V.; Oulego, P.; Casal, M.D.; Pevida, C.; Pis, J.J.; Rubiera, F. Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 2010, 101, 8859–8867. [Google Scholar] [CrossRef]

- Abdullah, H.; Wu, H. Biochar as a Fuel: 1. Properties and grindability of biochars produced from the pyrolysis of Mallee wood under slow-heating conditions. Energy Fuel. 2009, 23, 4174–4181. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Mustelier, N.L.; Almeida, M.F.; Cavalheiro, J.; Castro, F. Evaluation of pellets produced with undergrowth to be used as biofuel. Waste Biomass Valorization 2012, 3, 285–294. [Google Scholar] [CrossRef]

- Svedberg, U.; Samuelsson, J.; Melin, S. Hazardous off-gassing of carbon monoxide and oxygen depletion during ocean transportation of wood pellets. Ann. Occup. Hyg. 2008, 52, 259–266. [Google Scholar] [CrossRef]

- Munir, S.; Daood, S.S.; Nimmo, W.; Cunliffe, A.M.; Gibbs, B.M. Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour. Technol. 2009, 100, 1413–1418. [Google Scholar] [CrossRef]

- de Protásio, T.P.; Alves, I.C.N.; Trugilho, P.F.; Silva, V.O.; Baliza, A.E.R. Compactação de biomassa vegetal visando à produção de biocombustíveis sólidos. Pesqui. Flores. Bras. 2011, 31, 273. [Google Scholar] [CrossRef]

- De Almeida, L.F.P.; Sola, A.V.H.; Behainne, J.J.R. Sugarcane bagasse pellets: Characterization and comparative analysis. Acta Sci. Technol. 2017, 39, 461. [Google Scholar] [CrossRef][Green Version]

- Koppejan, J.; van Loo, S. The Handbook of Biomass Combustion and Co-firing; Routledge: Abington, UK, 2012; ISBN 978-1-136-55377-6. [Google Scholar]

- Gao, W.; Tabil, L.G.; Dumonceaux, T.; Espinel Ríos, S.; Zhao, R. Optimization of biological pretreatment to enhance the quality of wheat straw pellets. Biomass Bioenergy 2017, 97, 77–89. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Djatkov, D.; Martinov, M.; Kaltschmitt, M. Influencing parameters on mechanical–physical properties of pellet fuel made from corn harvest residues. Biomass Bioenergy 2018, 119, 418–428. [Google Scholar] [CrossRef]

- Hosseinizand, H.; Sokhansanj, S.; Lim, C.J. Co-pelletization of microalgae Chlorella vulgaris and pine sawdust to produce solid fuels. Fuel Process. Technol. 2018, 177, 129–139. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Wongsiriamnuay, T.; Tippayawong, N. Effect of densification parameters on the properties of maize residue pellets. Biosyst. Eng. 2015, 139, 111–120. [Google Scholar] [CrossRef]

- R: The R Project for Statistical Computing. Available online: https://www.r-project.org/ (accessed on 27 May 2020).

Sample Availability: Not available. |

| Property | Ingredient | |

|---|---|---|

| Sugarcane Bagasse | Residual Biomass | |

| Proximal | ||

| Water, % | 13.80 | 12.20 |

| Volatile matter, % | 76.35 | 69.85 |

| Fixed carbon, % | 15.40 | 24.30 |

| Ash, % | 8.25 | 5.85 |

| Structural | ||

| Cellulose, % | 43.80 | 41.30 |

| Hemicellulose, % | 27.70 | 28.70 |

| Lignin, % | 20.95 | 22.70 |

| Extractive, % | 7.55 | 7.30 |

| Elemental | ||

| C, % | 44.95 | 53.05 |

| H, % | 5.95 | 6.05 |

| O, % | 47.85 | 39.75 |

| N, % | - | - |

| S, % | 1.20 | 1.30 |

| Atomic C: O ratio | 0.90 | 1.30 |

| Atomic H: O ratio | 0.10 | 0.15 |

| Atomic C: H ratio | 7.55 | 8.75 |

| Physicothermal | ||

| Apparent density, kg m−3 | 560.05 | 590.15 |

| Higher heating value, MJ kg−1 | 17.65 | 21.85 |

| Energy density, GJ m−3 | 9.90 | 12.90 |

| Property | Assumption | Source of Variation | ||

|---|---|---|---|---|

| Normalcy | Homogeneity | Blending | Coefficient of Variation, % | |

| p-Value | p-Value | F-Value | ||

| Physicomechanical | ||||

| Length | 0.35 * | 0.50 * | 18.15 * | 1.05 |

| Diameter | 0.70 * | 0.30 * | 6.05 * | 1.80 |

| Resistance to abrasion | 0.05 * | 0.55 * | 10.20 * | 1.25 |

| Durability | 0.10 * | 0.70 * | 90.05 * | 0.25 |

| Physicothermal | ||||

| Apparent density | 0.85 * | 0.05 * | 44.50 * | 0.20 |

| Higher heating value | 0.65 * | 0.65 * | 15.05 * | 1.95 |

| Energy density | 0.70 * | 0.70 * | 27.30 * | 1.05 |

| Physicochemical | ||||

| Water | 0.25 * | 0.85 * | 105.15 ** | 0.70 |

| Volatile matter | 0.40 * | 0.55 * | 135.55 ** | 0.70 |

| Fixed carbon | 0.45 * | 0.40 * | 57.60 ** | 1.05 |

| Ash | 0.05 * | 0.10 * | 496.05 ** | 0.95 |

| C | 0.45 * | 0.20 * | 221.20 ** | 0.15 |

| H | 0.95 * | 0.15 * | 95.35 * | 0.80 |

| O | 0.55 * | 0.55 * | 105.45 ** | 0.75 |

| N | 0.50 * | 0.15 * | 0.05 | 0.05 |

| S | 0.50 * | 0.80 * | 25.75 * | 2.10 |

| Atomic C:O ratio | 0.70 * | 0.40 * | 230.95 ** | 0.80 |

| Atomic H:O ratio | 0.50 * | 0.75 * | 195.25 ** | 0.45 |

| Atomic C:H ratio | 0.90 * | 0.25 * | 10.50 * | 0.70 |

| Property | Parameter | r2 | |

|---|---|---|---|

| β0, Intercept | β1, Blending | ||

| Physicomechanical | |||

| Length, mm | 6.175 * | −0.010 * | 0.915 |

| Diameter, mm | 31.330 * | 0.080 * | 0.955 |

| Resistance to abrasion, % | 96.390 * | 0.045 * | 0.950 |

| Durability, % | 90.095 * | 0.075 * | 0.930 |

| Physicothermal | |||

| Apparent density, kg m−3 | 1361.100 ** | 1.510 ** | 0.970 |

| Higher heating value, MJ kg−1 | 20.280 * | 0.015 * | 0.940 |

| Energy density, GJ m−3 | 27.570 ** | 0.055 ** | 0.980 |

| Physicochemical | |||

| Water, % | 6.425 ** | 0.030 ** | 0.975 |

| Volatile matter, % | 79.560 ** | −0.130 ** | 0.990 |

| Fixed carbon, % | 19.400 ** | 0.070 ** | 0.985 |

| Ash, % | 1.010 ** | 0.060 ** | 0.995 |

| C, % | 50.920 * | 0.035 * | 0.945 |

| H, % | 5.695 * | 0.210 * | 0.875 |

| O, % | 41.330 * | −0.035 * | 0.945 |

| S, % | 2.060 * | −0.020 * | 0.645 |

| Atomic C:O ratio | 1.230 * | 0.005 * | 0.925 |

| Atomic H:O ratio | 0.135 * | 0.0005 * | 0.910 |

| Atomic C:H ratio | 8.915 * | 0.0215 * | 0.805 |

| Property | Pellet | Norm | ||||

|---|---|---|---|---|---|---|

| Composite | Pure | ISO 17225-2 | ISO 17225-6 | EN 1461-1 | USA PFI | |

| Potential application | Industrial | Industrial | Residential | Industrial | ||

| Apparent density, kg m−3 | 1405.25–1485.10 | 1375.15 | ≥600 | ≥600 | ≥600 | 608.7–746.9 |

| Heating value, MJ kg−1 | 20.70–21.45 | 20.50 | ≥16.5 | ≥14.5 | ≥16.5 | - |

| Length, mm | 25.70–30.10 | 31.90 | 3.15–40 | 3.15–40 | 3.15–40 | ≤42 |

| Diameter, mm | 6.50–6.85 | 6.05 | 6, 8, 12 ± 1 | 6–10 | 6, 8, 10 ± 1 | 5.84–7.25 |

| Durability, % | 97.10–99.95 | 95.90 | ≥97.5 | ≥97.5 | ≥96.5 | ≥95 |

| Water, % | 7.05–8.75 | 6.70 | ≤10 | ≤12 | ≤10 | ≤10 |

| Ash, % | 2.65–5.45 † | 0.90 † | ≤0.7 | ≤6 | ≤1 | ≤2 |

| N, % | 0.00 | 0.00 | ≤0.3 | ≤1.5 | ≤0.5 | - |

| S, % | 0.90–1.05 † | 2.45 † | ≤0.04 | ≤0.2 | ≤0.05 | - |

| Feedstock | Quality | Reference | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Physicothermal | Physicomechanical | Chemical | |||||||||

| ρ, kg m−3 | HHV, MJ kg−1 | ε, GJ m−3 | L, mm | Ø, mm | δ, % | Water, % | Ash, % | N, % | S, % | ||

| Sugarcane bagasse plus residual biomass | 1485.10 | 21.45 | 31.85 | 30.10 | 6.85 | 99.95 | 8.75 | 5.45 | 0.00 | 1.05 | |

| Sugarcane bagasse | 1375.15 | 20.50 | 28.20 | 31.90 | 6.05 | 95.90 | 6.70 | 0.90 | 0.00 | 2.45 | |

| Sugarcane bagasse | 726.3 | 16 | - | 22.7 | 9.7 | 98.2 | - | 8.7 | 0.3 | 0.02 | Almeida et al. [21] |

| Olive leaves | <1000 | 19.65 | <19.65 | 12.3 | 6 | 88.6 | - | - | - | - | Garcia-Maraver et al. [25] |

| Olive prunings | >1000 | - | - | 24 | 6 | - | - | - | - | - | |

| Olive wood | >1000 | 17.5 | >17.5 | 28.7 | 6 | 91.7 | - | - | - | - | |

| Bamboo plus rice straw | 900–1350 | 15.4–18.25 | 13.85–24.6 | 13.6 | 6 | 94.1–99 | - | 2–16 | - | - | Liu et al. [24] |

| Chinese fir | 1110 | - | - | - | 7 | - | - | - | - | - | Jiang et al. [6] |

| Camphor | 1105 | - | - | - | 7 | - | - | - | - | - | |

| Rice straw | 1180 | - | - | - | 7 | - | - | - | - | - | |

| Treated wheat straw | 969–1035 | - | - | - | 6 | - | - | - | - | - | Gao et al. [23] |

| Corn stover with starch | - | - | - | - | 6 | 88–98.8 | 11–16 | - | - | - | Djatkov et al. [26] |

| Corn cob with starch | - | - | - | - | 6 | 77.9–99.2 | 8–15 | - | - | - | |

| Microalgae | 1192–1229 | 27.8 | - | - | 6 | 82–96.5 | - | 2.5 | - | - | Hosseinizand et al. [27] |

| Sawdust | 817–1038 | 19.4 | - | - | 6 | 29–85.8 | - | 0.1 | - | - | |

| Microalgae plus sawdust | 1155–1207 | 25.3 | - | - | 6 | 72.4–97.7 | - | 1.7 | - | - | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreira, B.R.d.A.; Viana, R.d.S.; Cruz, V.H.; Magalhães, A.C.; Miasaki, C.T.; Figueiredo, P.A.M.d.; Lisboa, L.A.M.; Ramos, S.B.; Sánchez, D.E.J.; Teixeira Filho, M.C.M.; et al. Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets. Molecules 2020, 25, 4219. https://doi.org/10.3390/molecules25184219

Moreira BRdA, Viana RdS, Cruz VH, Magalhães AC, Miasaki CT, Figueiredo PAMd, Lisboa LAM, Ramos SB, Sánchez DEJ, Teixeira Filho MCM, et al. Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets. Molecules. 2020; 25(18):4219. https://doi.org/10.3390/molecules25184219

Chicago/Turabian StyleMoreira, Bruno Rafael de Almeida, Ronaldo da Silva Viana, Victor Hugo Cruz, Anderson Chagas Magalhães, Celso Tadao Miasaki, Paulo Alexandre Monteiro de Figueiredo, Lucas Aparecido Manzani Lisboa, Sérgio Bispo Ramos, Douglas Enrique Juárez Sánchez, Marcelo Carvalho Minhoto Teixeira Filho, and et al. 2020. "Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets" Molecules 25, no. 18: 4219. https://doi.org/10.3390/molecules25184219

APA StyleMoreira, B. R. d. A., Viana, R. d. S., Cruz, V. H., Magalhães, A. C., Miasaki, C. T., Figueiredo, P. A. M. d., Lisboa, L. A. M., Ramos, S. B., Sánchez, D. E. J., Teixeira Filho, M. C. M., & May, A. (2020). Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets. Molecules, 25(18), 4219. https://doi.org/10.3390/molecules25184219