Abstract

Nowadays, epoxy composites are elements of engineering materials and systems. Although they are known as versatile materials, epoxy resins suffer from high flammability. In this sense, flame retardancy analysis has been recognized as an undeniable requirement for developing future generations of epoxy-based systems. A considerable proportion of the literature on epoxy composites has been devoted to the use of phosphorus-based additives. Nevertheless, innovative flame retardants have coincidentally been under investigation to meet market requirements. This review paper attempts to give an overview of the research on flame retardant epoxy composites by classification of literature in terms of phosphorus (P), non-phosphorus (NP), and combinations of P/NP additives. A comprehensive set of data on cone calorimetry measurements applied on P-, NP-, and P/NP-incorporated epoxy systems was collected and treated. The performance of epoxy composites was qualitatively discussed as Poor, Good, and Excellent cases identified and distinguished by the use of the universal Flame Retardancy Index (FRI). Moreover, evaluations were rechecked by considering the UL-94 test data in four groups as V0, V1, V2, and nonrated (NR). The dimensionless FRI allowed for comparison between flame retardancy performances of epoxy composites. The results of this survey can pave the way for future innovations in developing flame-retardant additives for epoxy.

1. Introduction

Innovations are mainly born in a very disciplined manner, but sometimes they arise from serendipity. Regardless of the origin of innovative materials and systems, the identification and classification of systems in terms of explanatory variables requires the use of universal, well-accepted criteria. Nowadays, epoxy-based composites are elements of advanced systems [1,2,3]. There has been continued interest in the use of epoxy for developing a wide variety of general- and specific-purpose products such as adhesives, coatings, and medical devices thanks to the versatility of this thermosetting material [4,5,6,7]. Nevertheless, research outcomes reveal that epoxy is highly flammable, and one principally requires flame retardant materials for applications where epoxy should stand against fire [8,9,10,11,12]. In general, it has been understood that careful selection of additives is the first step in development of flame retardant polymer composites, but the performance of the material may additionally depend on the type and the amount of additives used individually or simultaneously [13,14]. Particularly, flame retardant epoxy composites consisting of phosphorus flame-retardant additives were the subject of different reports [15,16]. Moreover, combination of phosphorus and nonphosphorus additives was considered in the quest of higher flame retardancy performance [17,18,19]. In almost all reports, however, there was a lack of a correlation between the crosslinking state of resin in the presence of additives and flame retardancy.

In a previous work, we used two dimensionless indexes to correlate cure state with corrosion inhibition and flame-retardant properties of epoxy/Fe3O4 nanocomposites [20]. By the use of dimensionless Cure Index [21] and dimensionless Flame Retardancy Index (FRI) [22], it was demonstrated that the quality of cure in epoxy composites (Poor, Good, or Excellent) can be correlated to the performance of flame retardancy (Poor, Good, or Excellent). The FRI was also powerful in exploring the complementary actions of mineral and organic additives in polymer systems in terms of the peak of HRR (pHRR), the total heat release (THR), and the time to ignition (TTI) of neat polymer and polymer composites [23]. In this work, with the aim of recognizing the future ahead of innovations in flame-retardant epoxy composites, reports on flame-retardant epoxy composites were comprehensively reviewed and then classified as a function of their flame retardancy performance by the use of the FRI criterion. Classification was performed on account of phosphorus (P)-, nonphosphorus (NP)-, and combined P/NP-incorporated epoxy composites. In each class, comprehensive master tables were provided in which the polymer matrix, the additives, the content of additives, and cone calorimetry data including TTI, THR, and pHRR and the calculated FRI values were summarized. Moreover, the available UL-94 test data were provided and plotted similar to the FRI curves, but in four groups of V0, V1, V2, and nonrated (NR).

2. Epoxy Resins Containing Phosphorus-Based Flame Retardants

According to the literature, a variety of phosphorus-based flame retardants have been used in epoxy resins. Table 1 summarizes pHRR, THR, and TTI and the FRI values of epoxy/P systems. The percentage of incorporated flame retardant (FR) as well as the results of limiting oxygen index (LOI) and UL-94 test are given.

Table 1.

The flame retardancy performance of epoxy containing phosphorus-based (P) flame retardants in terms of FRI (* the name and percentage of incorporated flame retardant is given after each epoxy resin). Notes a to l on the bottom of the table are representative of composite systems containing woven or nonwoven fibers.

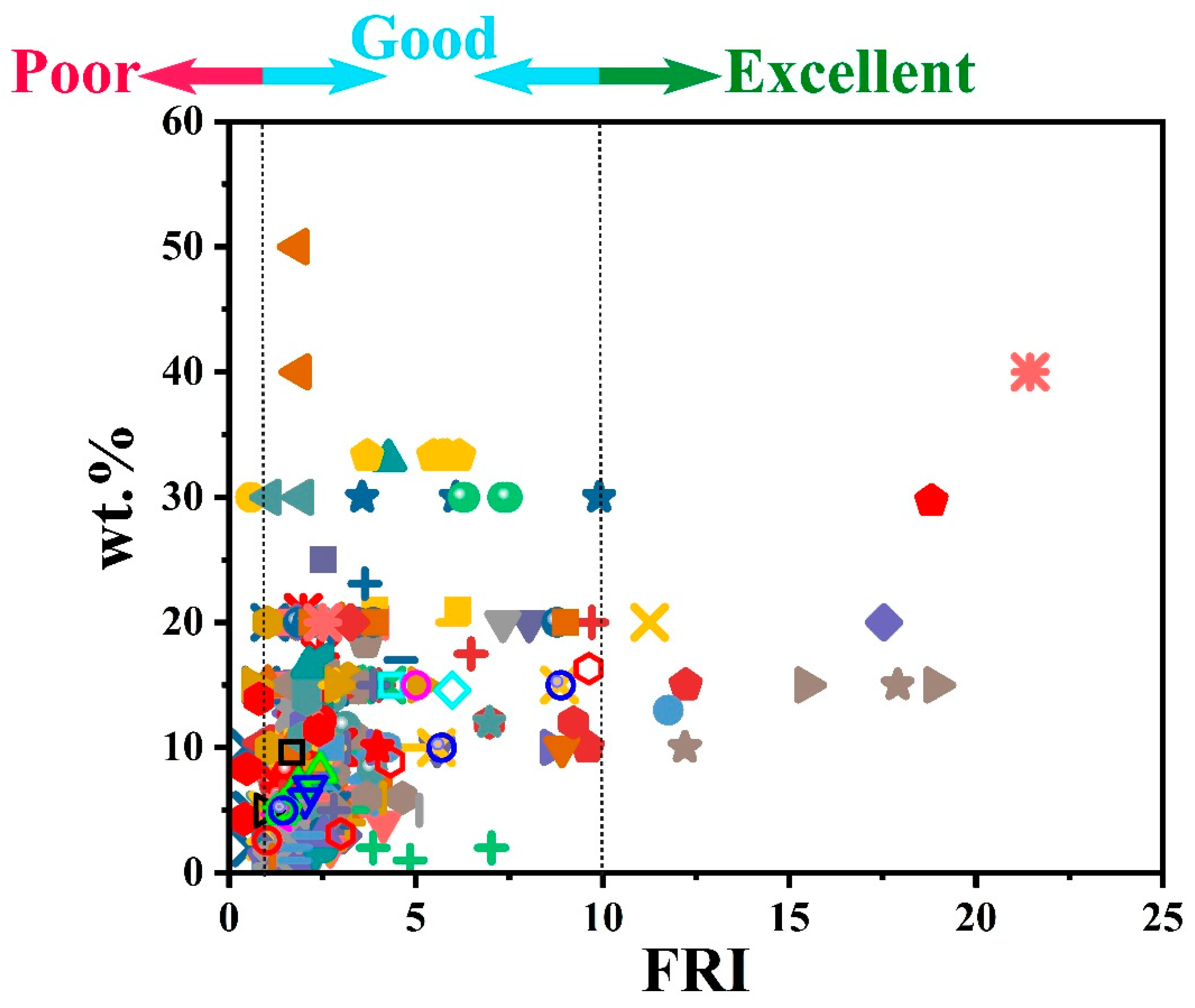

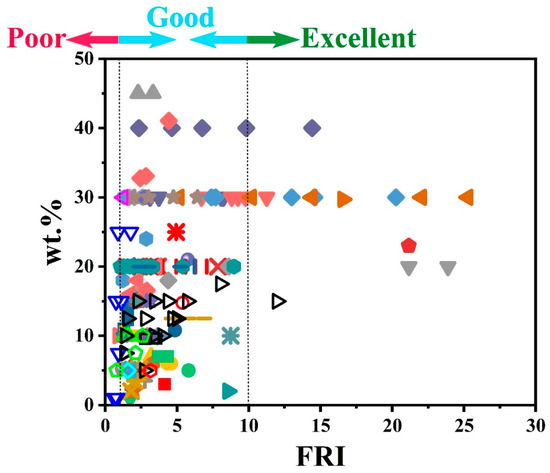

A brief yet informative view of the effect of the used P family of FRs on the flame retardancy performance of epoxy resins is given in Figure 1. It is apparent from the figure that all sorts of behavior, including Poor, Good, and Excellent flame-retardant performance, are achieved. This is the characteristic of dependency of flame retardancy performance on both the type and the content of the P type of FR. It can be observed that the majority of epoxy systems contains less than 20 wt.% of phosphorus flame retardants. For instance, a compromise between FRI and FR loading percentage was achieved by incorporation of encapsulated ammonium polyphosphate (APP- ) at 15 wt.% with an FRI value of 19. Detailed information about the type of phosphorus flame retardants was provided to the reader in the caption of Figure 1. Thus, innovations in design and manufacture of P type FR for epoxy should carefully meet the requirements based on the lesson learned from the multivariable behavior of flame retardancy brought about by P-type FR additives. Precise detection of the performance of each class of P-type FR in this table from one side and the chemical structure of the used FR from the other side should be balanced towards a high-performance FR for developing flame-retardant epoxy composites.

) at 15 wt.% with an FRI value of 19. Detailed information about the type of phosphorus flame retardants was provided to the reader in the caption of Figure 1. Thus, innovations in design and manufacture of P type FR for epoxy should carefully meet the requirements based on the lesson learned from the multivariable behavior of flame retardancy brought about by P-type FR additives. Precise detection of the performance of each class of P-type FR in this table from one side and the chemical structure of the used FR from the other side should be balanced towards a high-performance FR for developing flame-retardant epoxy composites.

) at 15 wt.% with an FRI value of 19. Detailed information about the type of phosphorus flame retardants was provided to the reader in the caption of Figure 1. Thus, innovations in design and manufacture of P type FR for epoxy should carefully meet the requirements based on the lesson learned from the multivariable behavior of flame retardancy brought about by P-type FR additives. Precise detection of the performance of each class of P-type FR in this table from one side and the chemical structure of the used FR from the other side should be balanced towards a high-performance FR for developing flame-retardant epoxy composites.

) at 15 wt.% with an FRI value of 19. Detailed information about the type of phosphorus flame retardants was provided to the reader in the caption of Figure 1. Thus, innovations in design and manufacture of P type FR for epoxy should carefully meet the requirements based on the lesson learned from the multivariable behavior of flame retardancy brought about by P-type FR additives. Precise detection of the performance of each class of P-type FR in this table from one side and the chemical structure of the used FR from the other side should be balanced towards a high-performance FR for developing flame-retardant epoxy composites.

Figure 1.

Flame retardancy analysis of epoxy resins containing phosphorus flame retardants in terms of the FRI values as a function of P type and content. Symbols are indicative of different types of phosphorus flame retardant used. Hollow symbols are indicative of fiber-incorporated composites with details earlier given in the bottom of Table 1 as a to l notes. Here:  FP1-4, FP1-6, FP1-8 [24],

FP1-4, FP1-6, FP1-8 [24],  DPO-PHE-11.68, DOPO-PHE-12.03 [25],

DPO-PHE-11.68, DOPO-PHE-12.03 [25],  DOPO-T-2.34, DOPO-T-4.67, DOPO-T-6.99, DOPO-T-9.34 [26],

DOPO-T-2.34, DOPO-T-4.67, DOPO-T-6.99, DOPO-T-9.34 [26],  AEPP-5, AEPP-10, AEPP-15 [27],

AEPP-5, AEPP-10, AEPP-15 [27],  DiDOPO-3 [28],

DiDOPO-3 [28],  DiDOPO-10, DiDOPO-11 [29],

DiDOPO-10, DiDOPO-11 [29],  DiDOPO-7 [30],

DiDOPO-7 [30],  DiDOPO-1, DiDOPO-5, DiDOPO-10 [31],

DiDOPO-1, DiDOPO-5, DiDOPO-10 [31],  DiDOPO-1, DiDOPO-5, DiDOPO-10, DiDOPO-15, DiDOPO-20 [32],

DiDOPO-1, DiDOPO-5, DiDOPO-10, DiDOPO-15, DiDOPO-20 [32],  PPMS-15, PPMS-EG-15 [33],

PPMS-15, PPMS-EG-15 [33],  PPMS-MWCNT-5, PPMS-MWCNT-10, PPMS-MWCNT-15, PPMS-15 [34],

PPMS-MWCNT-5, PPMS-MWCNT-10, PPMS-MWCNT-15, PPMS-15 [34],  DPIPP-7.5, DPIPP-15, DPPIO-7.5, DPPIO-15 [35],

DPIPP-7.5, DPIPP-15, DPPIO-7.5, DPPIO-15 [35],  IDOP-5, IDOP-10, IDOP-15 [36],

IDOP-5, IDOP-10, IDOP-15 [36],  PPAP-5 [37],

PPAP-5 [37],  AlPBu-10, AlPBu-11, AlPBu-12 [38],

AlPBu-10, AlPBu-11, AlPBu-12 [38],  MPL-DOPO-2.5, MPL-DOPO-5, DDM-DOPO-2.5, DDM-DOPO-5 [39],

MPL-DOPO-2.5, MPL-DOPO-5, DDM-DOPO-2.5, DDM-DOPO-5 [39],  ATZ-6 [40],

ATZ-6 [40],  P-KC-30, DOPO-30 [41],

P-KC-30, DOPO-30 [41],  DHPP-OH-BAC-5, DHPP-OH-BAC-10, DHPP-OH-BAC-15 [42],

DHPP-OH-BAC-5, DHPP-OH-BAC-10, DHPP-OH-BAC-15 [42],  PPAP-5, PPAP-10, PPAP-20 [43],

PPAP-5, PPAP-10, PPAP-20 [43],  [Dmim]Tos-2.4, [Dmim]Tos-4, [Dmim]Tos-7.5 [44],

[Dmim]Tos-2.4, [Dmim]Tos-4, [Dmim]Tos-7.5 [44],  MPhP-10, MPhP-15, MPhP-20 [45],

MPhP-10, MPhP-15, MPhP-20 [45],  MDOP-0.96, MDOP-1.9, MDOP-3.75, MDOP-7.24 [46],

MDOP-0.96, MDOP-1.9, MDOP-3.75, MDOP-7.24 [46],  AlPi-7, MPP-7 [47],

AlPi-7, MPP-7 [47],  A-BP-9 [48],

A-BP-9 [48],  CLEP–DOPO–POSS-2.91 [19],

CLEP–DOPO–POSS-2.91 [19],  CuPP-1, CuPP-2, CuPP-4, CuPP-6, CuPP-8 [49],

CuPP-1, CuPP-2, CuPP-4, CuPP-6, CuPP-8 [49],  DOP-ABZ-15, DOP-ABZ-17.5, DOP-ABZ-20 [50],

DOP-ABZ-15, DOP-ABZ-17.5, DOP-ABZ-20 [50],  DOPO-7.11, BPD-3.38, BPD-6.71, BPD-10.04, BPD-13.41 [51],

DOPO-7.11, BPD-3.38, BPD-6.71, BPD-10.04, BPD-13.41 [51],  DOPO-7.7, HPCP-8.2 [52],

DOPO-7.7, HPCP-8.2 [52],  DOPO-TPMP-2.5, DOPO-TPMP-5, DOPO-TPMP-7.5, DOPO-TPMP-10 [53],

DOPO-TPMP-2.5, DOPO-TPMP-5, DOPO-TPMP-7.5, DOPO-TPMP-10 [53],  HB-DPPA-2 [54],

HB-DPPA-2 [54],  APP-21, EDA-APP-21 [55],

APP-21, EDA-APP-21 [55],  CP-6B-3 [56],

CP-6B-3 [56],  PM-2, PM-6, PM-βCD-2, PM-βCD-6 [57],

PM-2, PM-6, PM-βCD-2, PM-βCD-6 [57],  PSA-10, PSA-20 [58],

PSA-10, PSA-20 [58],  BPA-BPP-9 [59],

BPA-BPP-9 [59],  DOPO-9.1, PEPA-9.1, DOPO-PEPA-5.7, DOPO-PEPA-7.4, DOPO-PEPA-9.1 [60],

DOPO-9.1, PEPA-9.1, DOPO-PEPA-5.7, DOPO-PEPA-7.4, DOPO-PEPA-9.1 [60],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [61],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [61],  HPCTP-7.46, HPCTP-11.19, HPCTP-14.92, DOPO-6.97, DOPO-10.46, DOPO-13.94 [62],

HPCTP-7.46, HPCTP-11.19, HPCTP-14.92, DOPO-6.97, DOPO-10.46, DOPO-13.94 [62],  TP-12.42, TNTP-14.36 [63],

TP-12.42, TNTP-14.36 [63],  DOPO-7, BNP-7, BNP-11, BNP-14.7, BNP-18.4 [64],

DOPO-7, BNP-7, BNP-11, BNP-14.7, BNP-18.4 [64],  DOPO-7, DTB-7, DTB-10, DTB-15, DTB-20 [65],

DOPO-7, DTB-7, DTB-10, DTB-15, DTB-20 [65],  DOPO-7.7, HPCP-8.2 [66],

DOPO-7.7, HPCP-8.2 [66],  DOPO-7.1 [67],

DOPO-7.1 [67],  DOPO-7, DOPO-TMT-7, DOPO-TMT-10.4, DOPO-TMT-13.9, DOPO-TMT-17.3, DOPO-TMT-20.8 [68],

DOPO-7, DOPO-TMT-7, DOPO-TMT-10.4, DOPO-TMT-13.9, DOPO-TMT-17.3, DOPO-TMT-20.8 [68],  HMCP-3.4, HMCP-6.8, HMCP-10.2, HMCP-13.6, HMCP-17 [69],

HMCP-3.4, HMCP-6.8, HMCP-10.2, HMCP-13.6, HMCP-17 [69],  DOPO-bp-3.4, DOPO-bp-6.7, DOPO-bp-13.5 [70],

DOPO-bp-3.4, DOPO-bp-6.7, DOPO-bp-13.5 [70],  CTP-DOPO-10.6 [71],

CTP-DOPO-10.6 [71],  PMTMPS-11 [72],

PMTMPS-11 [72],  PUTMPS-12, [73],

PUTMPS-12, [73],  APHP-2, APHP-4, APHP-6 [74],

APHP-2, APHP-4, APHP-6 [74],  APHP-6, DOPO-6 [75],

APHP-6, DOPO-6 [75],  HP-1001-COOH-10, HP-1001-COOH-20, HP-1001-COOH-30, HP-1001-COOH-40, HP-1001-COOH-50 [76],

HP-1001-COOH-10, HP-1001-COOH-20, HP-1001-COOH-30, HP-1001-COOH-40, HP-1001-COOH-50 [76],  TAD-4 [77],

TAD-4 [77],  DOPO-10, TAD-6, TAD-8, TAD-10, TAD-12 [78],

DOPO-10, TAD-6, TAD-8, TAD-10, TAD-12 [78],  PAz-APP-10, PAz-APP-15 [79],

PAz-APP-10, PAz-APP-15 [79],  DETA-APP-10, DETA-APP-15 [80],

DETA-APP-10, DETA-APP-15 [80],  DOPO-8.3, Trif-DOPO-11.7, Trif-DOPO-14 [81],

DOPO-8.3, Trif-DOPO-11.7, Trif-DOPO-14 [81],  TOD-2, TOD-4, TOD-6 [82],

TOD-2, TOD-4, TOD-6 [82],  DOPO-DDM-10, DOPO-DDE-10, DOPO-DDS-10 [83],

DOPO-DDM-10, DOPO-DDE-10, DOPO-DDS-10 [83],  DPP-POSS-5, DPOP-POSS-5, DOPO-POSS-5 [84],

DPP-POSS-5, DPOP-POSS-5, DOPO-POSS-5 [84],  ATH-DOPO-10, ATH-DOPO-20, pATH-DOPO-10 [85],

ATH-DOPO-10, ATH-DOPO-20, pATH-DOPO-10 [85],  BPS-BPP-9 [86],

BPS-BPP-9 [86],  PN-15, PSi-25 [87],

PN-15, PSi-25 [87],  BDMPP-14 [88],

BDMPP-14 [88],  ATCP-15 [89],

ATCP-15 [89],  ATCP-15 [90],

ATCP-15 [90],  DOPO-4.5, DOPO-ABZ-7.5, DOPO-ABZ-10 [91],

DOPO-4.5, DOPO-ABZ-7.5, DOPO-ABZ-10 [91],  DMT-3.3, DMT-6.6, DMT-10, DMT-13.5, DMT-17 [92],

DMT-3.3, DMT-6.6, DMT-10, DMT-13.5, DMT-17 [92],  APP-10, APP-MMT-10 [93],

APP-10, APP-MMT-10 [93],  DOPO-6, DOPO-MMT-6 [94],

DOPO-6, DOPO-MMT-6 [94],  APHP-10, BDP-10 [95],

APHP-10, BDP-10 [95],  FIPF-20, FTBF-20 [96],

FIPF-20, FTBF-20 [96],  PPDAB-10 [97],

PPDAB-10 [97],  BP-5, BP-9, BP-15 [98],

BP-5, BP-9, BP-15 [98],  PS-APP-2, PS-APP-5, PS-APP-10, PS-APP-15, PS-APP-20 [99],

PS-APP-2, PS-APP-5, PS-APP-10, PS-APP-15, PS-APP-20 [99],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [101],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [101],  DOPO-5 [102],

DOPO-5 [102],  DOPO-6.3 [103],

DOPO-6.3 [103],  DOPO-6.3 [104],

DOPO-6.3 [104],  APP-MMT-10 [105],

APP-MMT-10 [105],  PEPA-5.2, APP-2.9, DOPO-6.3 [106],

PEPA-5.2, APP-2.9, DOPO-6.3 [106],  PCPBO-5, PCPBO-10, PCPBO-15, PCPBO-20 [107],

PCPBO-5, PCPBO-10, PCPBO-15, PCPBO-20 [107],  APP-15, GMA-APP-15 [108],

APP-15, GMA-APP-15 [108],  APP-12, MAPP-12 [109],

APP-12, MAPP-12 [109],  APP-12 [110],

APP-12 [110],  HAP-DOPO-9.3, HAP-DOPO-15.47 [111],

HAP-DOPO-9.3, HAP-DOPO-15.47 [111],  TGIC-DOPO-6.1, TGIC-DOPO-8.1, TGIC-DOPO-10.2, TGIC-DOPO-12.2 [112],

TGIC-DOPO-6.1, TGIC-DOPO-8.1, TGIC-DOPO-10.2, TGIC-DOPO-12.2 [112],  DOPP-19.6, DOPI-23.1 [113],

DOPP-19.6, DOPI-23.1 [113],  PMPC-10, PMPC-15, PMPC-20 [114],

PMPC-10, PMPC-15, PMPC-20 [114],  DOPO-5 [115],

DOPO-5 [115],  SIEPDP-Mg-Al LDH-4 [116],

SIEPDP-Mg-Al LDH-4 [116],  CBz-10, CBz-15, CBz-20 [118],

CBz-10, CBz-15, CBz-20 [118],  APP-5 [117],

APP-5 [117],  DOPMPA-10, DOPMPA-13 [119],

DOPMPA-10, DOPMPA-13 [119],  MFR-10, MFR-15, MFR-20 [9],

MFR-10, MFR-15, MFR-20 [9],  DOPO-COFs-0.4, DOPO-COFs-0.8, DOPO-COFs-1.6, DOPO-COFs-3.2, COFs-3.2 [17],

DOPO-COFs-0.4, DOPO-COFs-0.8, DOPO-COFs-1.6, DOPO-COFs-3.2, COFs-3.2 [17],  Mel-APP-20 [120],

Mel-APP-20 [120],  FR-1 [121],

FR-1 [121],  ArPN2-15, ArPO2-15, ArOPN2-15.6, ArOPO2-15.6 [122],

ArPN2-15, ArPO2-15, ArOPN2-15.6, ArOPO2-15.6 [122],  PMAIL-6 [123],

PMAIL-6 [123],  oDOPI-13.81, PZ -10.8, MPP-15 [124],

oDOPI-13.81, PZ -10.8, MPP-15 [124],  AHP-5 [125],

AHP-5 [125],  Mel-APP-29.7 [126],

Mel-APP-29.7 [126],  MPAlP-20, MPZnP-20, MPMgP-20, MPP-20, AlPi-Et-20, DOPAc-Bu-20 [127],

MPAlP-20, MPZnP-20, MPMgP-20, MPP-20, AlPi-Et-20, DOPAc-Bu-20 [127],  HPCTP-5, HPCTP-10, HPCTP-15 [128],

HPCTP-5, HPCTP-10, HPCTP-15 [128],  HPCTP-15 [129],

HPCTP-15 [129],  TPP-MMT-5 [130],

TPP-MMT-5 [130],  TPP-MMT-5 [130],

TPP-MMT-5 [130],  TPP-MMT-5 [130],

TPP-MMT-5 [130],  hbPPE-10, hbPPE-20 [131],

hbPPE-10, hbPPE-20 [131],  PZS-3, PZS@SrSn(OH)6-3 [132],

PZS-3, PZS@SrSn(OH)6-3 [132],  PEPA-TMAC-16.5, PEPA-TMAC-33 [133],

PEPA-TMAC-16.5, PEPA-TMAC-33 [133],  PCPS-1, PCPS-3, PCPS-5 [134],

PCPS-1, PCPS-3, PCPS-5 [134],  BP1-5, BP2-5, BP3-5, BP4-5, BP5-5 [135],

BP1-5, BP2-5, BP3-5, BP4-5, BP5-5 [135],  SDPS-10.4 [136],

SDPS-10.4 [136],  AOPH-NR-4.25, AOPH-C1-4.25, AOPH-C2-4.25, AOPH-C3-4.25 [137],

AOPH-NR-4.25, AOPH-C1-4.25, AOPH-C2-4.25, AOPH-C3-4.25 [137],  BHAAPE-5, BHAAPE-10, BHAAPE-20 [138],

BHAAPE-5, BHAAPE-10, BHAAPE-20 [138],  APP-10 [139],

APP-10 [139],  PZS-2, PZS@MoS2-2, PZS@MoS2-3 [140],

PZS-2, PZS@MoS2-2, PZS@MoS2-3 [140],  DBPDA-βCD-3 [141],

DBPDA-βCD-3 [141],  BP-PZN-0.5, BP-PZN-1, BP-PZN-2, BP-Bulk-2 [142],

BP-PZN-0.5, BP-PZN-1, BP-PZN-2, BP-Bulk-2 [142],  HPPA-2, HPPA-SH-mSiO2-2 [143],

HPPA-2, HPPA-SH-mSiO2-2 [143],  P-MOF-0.5, P-MOF-1, P-MOF-2 [144],

P-MOF-0.5, P-MOF-1, P-MOF-2 [144],  CZrP-2, CZrP-4, CZrP-6, ZrP-6 [145],

CZrP-2, CZrP-4, CZrP-6, ZrP-6 [145],  DMMP-HNT-20 [146],

DMMP-HNT-20 [146],  S600-20, AlPi-20, MPP-20 [147],

S600-20, AlPi-20, MPP-20 [147],  SiO2@PZM-1, SiO2@PZM@Cu-1, SiO2@PZM@Cu-2 [148],

SiO2@PZM-1, SiO2@PZM@Cu-1, SiO2@PZM@Cu-2 [148],  FR@PZS-0.5, FR@PZS-1, FR@PZS-3, PZS-3 [149],

FR@PZS-0.5, FR@PZS-1, FR@PZS-3, PZS-3 [149],  APP-5 [150],

APP-5 [150],  DOPO-POSS [151],

DOPO-POSS [151],  APP-30, M(APP & PER)-30 [152],

APP-30, M(APP & PER)-30 [152],  TPPi-15, TPPa-15, TPPO-15 [153],

TPPi-15, TPPa-15, TPPO-15 [153],  PMP-11.4, DOPO-13.9, RP-4.3, OP-8.3 [154],

PMP-11.4, DOPO-13.9, RP-4.3, OP-8.3 [154],  IFR-30, IFR-30, IFR-30 [155],

IFR-30, IFR-30, IFR-30 [155],  BPE-33.3, EPE-33.3, BBPE-33.3, BOPE-33.3, HBPE-33.3 [156],

BPE-33.3, EPE-33.3, BBPE-33.3, BOPE-33.3, HBPE-33.3 [156],  IFR-30, IFR-30, IFR-30, IFR-30 [157],

IFR-30, IFR-30, IFR-30, IFR-30 [157],  EGM-5, EGM-15 [158],

EGM-5, EGM-15 [158],  PCTS-Fe-OMMT-1, PCTS-Fe-OMMT-3, PCTS-Fe-OMMT-5 [159],

PCTS-Fe-OMMT-1, PCTS-Fe-OMMT-3, PCTS-Fe-OMMT-5 [159],  APP-20, APP-40 [160],

APP-20, APP-40 [160],  DOPOph-RGNO-1, DOPOph-RGNO-2, DOPOph-RGNO-3 [161],

DOPOph-RGNO-1, DOPOph-RGNO-2, DOPOph-RGNO-3 [161],  Mel-APP-9.59 [120],

Mel-APP-9.59 [120],  FP1-2.6 [24],

FP1-2.6 [24],  PEC-5.2, PEC-6.9, PEC-8.1 [162],

PEC-5.2, PEC-6.9, PEC-8.1 [162],  DOPP-5.9, DOPI-6.9 [113],

DOPP-5.9, DOPI-6.9 [113],  Mel-APP-14.6 [126],

Mel-APP-14.6 [126],  IFR-4.7 [163,164],

IFR-4.7 [163,164],  APP-5 [150],

APP-5 [150],  APP-3.15, APP-8.88, APP-16.32 [165],

APP-3.15, APP-8.88, APP-16.32 [165],  MP-5, DOPO-5 [166],

MP-5, DOPO-5 [166],  IFR-5, IFR-10, IFR-15 [167],

IFR-5, IFR-10, IFR-15 [167],  APP-15 [168],

APP-15 [168],  APP-15 [168].

APP-15 [168].

FP1-4, FP1-6, FP1-8 [24],

FP1-4, FP1-6, FP1-8 [24],  DPO-PHE-11.68, DOPO-PHE-12.03 [25],

DPO-PHE-11.68, DOPO-PHE-12.03 [25],  DOPO-T-2.34, DOPO-T-4.67, DOPO-T-6.99, DOPO-T-9.34 [26],

DOPO-T-2.34, DOPO-T-4.67, DOPO-T-6.99, DOPO-T-9.34 [26],  AEPP-5, AEPP-10, AEPP-15 [27],

AEPP-5, AEPP-10, AEPP-15 [27],  DiDOPO-3 [28],

DiDOPO-3 [28],  DiDOPO-10, DiDOPO-11 [29],

DiDOPO-10, DiDOPO-11 [29],  DiDOPO-7 [30],

DiDOPO-7 [30],  DiDOPO-1, DiDOPO-5, DiDOPO-10 [31],

DiDOPO-1, DiDOPO-5, DiDOPO-10 [31],  DiDOPO-1, DiDOPO-5, DiDOPO-10, DiDOPO-15, DiDOPO-20 [32],

DiDOPO-1, DiDOPO-5, DiDOPO-10, DiDOPO-15, DiDOPO-20 [32],  PPMS-15, PPMS-EG-15 [33],

PPMS-15, PPMS-EG-15 [33],  PPMS-MWCNT-5, PPMS-MWCNT-10, PPMS-MWCNT-15, PPMS-15 [34],

PPMS-MWCNT-5, PPMS-MWCNT-10, PPMS-MWCNT-15, PPMS-15 [34],  DPIPP-7.5, DPIPP-15, DPPIO-7.5, DPPIO-15 [35],

DPIPP-7.5, DPIPP-15, DPPIO-7.5, DPPIO-15 [35],  IDOP-5, IDOP-10, IDOP-15 [36],

IDOP-5, IDOP-10, IDOP-15 [36],  PPAP-5 [37],

PPAP-5 [37],  AlPBu-10, AlPBu-11, AlPBu-12 [38],

AlPBu-10, AlPBu-11, AlPBu-12 [38],  MPL-DOPO-2.5, MPL-DOPO-5, DDM-DOPO-2.5, DDM-DOPO-5 [39],

MPL-DOPO-2.5, MPL-DOPO-5, DDM-DOPO-2.5, DDM-DOPO-5 [39],  ATZ-6 [40],

ATZ-6 [40],  P-KC-30, DOPO-30 [41],

P-KC-30, DOPO-30 [41],  DHPP-OH-BAC-5, DHPP-OH-BAC-10, DHPP-OH-BAC-15 [42],

DHPP-OH-BAC-5, DHPP-OH-BAC-10, DHPP-OH-BAC-15 [42],  PPAP-5, PPAP-10, PPAP-20 [43],

PPAP-5, PPAP-10, PPAP-20 [43],  [Dmim]Tos-2.4, [Dmim]Tos-4, [Dmim]Tos-7.5 [44],

[Dmim]Tos-2.4, [Dmim]Tos-4, [Dmim]Tos-7.5 [44],  MPhP-10, MPhP-15, MPhP-20 [45],

MPhP-10, MPhP-15, MPhP-20 [45],  MDOP-0.96, MDOP-1.9, MDOP-3.75, MDOP-7.24 [46],

MDOP-0.96, MDOP-1.9, MDOP-3.75, MDOP-7.24 [46],  AlPi-7, MPP-7 [47],

AlPi-7, MPP-7 [47],  A-BP-9 [48],

A-BP-9 [48],  CLEP–DOPO–POSS-2.91 [19],

CLEP–DOPO–POSS-2.91 [19],  CuPP-1, CuPP-2, CuPP-4, CuPP-6, CuPP-8 [49],

CuPP-1, CuPP-2, CuPP-4, CuPP-6, CuPP-8 [49],  DOP-ABZ-15, DOP-ABZ-17.5, DOP-ABZ-20 [50],

DOP-ABZ-15, DOP-ABZ-17.5, DOP-ABZ-20 [50],  DOPO-7.11, BPD-3.38, BPD-6.71, BPD-10.04, BPD-13.41 [51],

DOPO-7.11, BPD-3.38, BPD-6.71, BPD-10.04, BPD-13.41 [51],  DOPO-7.7, HPCP-8.2 [52],

DOPO-7.7, HPCP-8.2 [52],  DOPO-TPMP-2.5, DOPO-TPMP-5, DOPO-TPMP-7.5, DOPO-TPMP-10 [53],

DOPO-TPMP-2.5, DOPO-TPMP-5, DOPO-TPMP-7.5, DOPO-TPMP-10 [53],  HB-DPPA-2 [54],

HB-DPPA-2 [54],  APP-21, EDA-APP-21 [55],

APP-21, EDA-APP-21 [55],  CP-6B-3 [56],

CP-6B-3 [56],  PM-2, PM-6, PM-βCD-2, PM-βCD-6 [57],

PM-2, PM-6, PM-βCD-2, PM-βCD-6 [57],  PSA-10, PSA-20 [58],

PSA-10, PSA-20 [58],  BPA-BPP-9 [59],

BPA-BPP-9 [59],  DOPO-9.1, PEPA-9.1, DOPO-PEPA-5.7, DOPO-PEPA-7.4, DOPO-PEPA-9.1 [60],

DOPO-9.1, PEPA-9.1, DOPO-PEPA-5.7, DOPO-PEPA-7.4, DOPO-PEPA-9.1 [60],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [61],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [61],  HPCTP-7.46, HPCTP-11.19, HPCTP-14.92, DOPO-6.97, DOPO-10.46, DOPO-13.94 [62],

HPCTP-7.46, HPCTP-11.19, HPCTP-14.92, DOPO-6.97, DOPO-10.46, DOPO-13.94 [62],  TP-12.42, TNTP-14.36 [63],

TP-12.42, TNTP-14.36 [63],  DOPO-7, BNP-7, BNP-11, BNP-14.7, BNP-18.4 [64],

DOPO-7, BNP-7, BNP-11, BNP-14.7, BNP-18.4 [64],  DOPO-7, DTB-7, DTB-10, DTB-15, DTB-20 [65],

DOPO-7, DTB-7, DTB-10, DTB-15, DTB-20 [65],  DOPO-7.7, HPCP-8.2 [66],

DOPO-7.7, HPCP-8.2 [66],  DOPO-7.1 [67],

DOPO-7.1 [67],  DOPO-7, DOPO-TMT-7, DOPO-TMT-10.4, DOPO-TMT-13.9, DOPO-TMT-17.3, DOPO-TMT-20.8 [68],

DOPO-7, DOPO-TMT-7, DOPO-TMT-10.4, DOPO-TMT-13.9, DOPO-TMT-17.3, DOPO-TMT-20.8 [68],  HMCP-3.4, HMCP-6.8, HMCP-10.2, HMCP-13.6, HMCP-17 [69],

HMCP-3.4, HMCP-6.8, HMCP-10.2, HMCP-13.6, HMCP-17 [69],  DOPO-bp-3.4, DOPO-bp-6.7, DOPO-bp-13.5 [70],

DOPO-bp-3.4, DOPO-bp-6.7, DOPO-bp-13.5 [70],  CTP-DOPO-10.6 [71],

CTP-DOPO-10.6 [71],  PMTMPS-11 [72],

PMTMPS-11 [72],  PUTMPS-12, [73],

PUTMPS-12, [73],  APHP-2, APHP-4, APHP-6 [74],

APHP-2, APHP-4, APHP-6 [74],  APHP-6, DOPO-6 [75],

APHP-6, DOPO-6 [75],  HP-1001-COOH-10, HP-1001-COOH-20, HP-1001-COOH-30, HP-1001-COOH-40, HP-1001-COOH-50 [76],

HP-1001-COOH-10, HP-1001-COOH-20, HP-1001-COOH-30, HP-1001-COOH-40, HP-1001-COOH-50 [76],  TAD-4 [77],

TAD-4 [77],  DOPO-10, TAD-6, TAD-8, TAD-10, TAD-12 [78],

DOPO-10, TAD-6, TAD-8, TAD-10, TAD-12 [78],  PAz-APP-10, PAz-APP-15 [79],

PAz-APP-10, PAz-APP-15 [79],  DETA-APP-10, DETA-APP-15 [80],

DETA-APP-10, DETA-APP-15 [80],  DOPO-8.3, Trif-DOPO-11.7, Trif-DOPO-14 [81],

DOPO-8.3, Trif-DOPO-11.7, Trif-DOPO-14 [81],  TOD-2, TOD-4, TOD-6 [82],

TOD-2, TOD-4, TOD-6 [82],  DOPO-DDM-10, DOPO-DDE-10, DOPO-DDS-10 [83],

DOPO-DDM-10, DOPO-DDE-10, DOPO-DDS-10 [83],  DPP-POSS-5, DPOP-POSS-5, DOPO-POSS-5 [84],

DPP-POSS-5, DPOP-POSS-5, DOPO-POSS-5 [84],  ATH-DOPO-10, ATH-DOPO-20, pATH-DOPO-10 [85],

ATH-DOPO-10, ATH-DOPO-20, pATH-DOPO-10 [85],  BPS-BPP-9 [86],

BPS-BPP-9 [86],  PN-15, PSi-25 [87],

PN-15, PSi-25 [87],  BDMPP-14 [88],

BDMPP-14 [88],  ATCP-15 [89],

ATCP-15 [89],  ATCP-15 [90],

ATCP-15 [90],  DOPO-4.5, DOPO-ABZ-7.5, DOPO-ABZ-10 [91],

DOPO-4.5, DOPO-ABZ-7.5, DOPO-ABZ-10 [91],  DMT-3.3, DMT-6.6, DMT-10, DMT-13.5, DMT-17 [92],

DMT-3.3, DMT-6.6, DMT-10, DMT-13.5, DMT-17 [92],  APP-10, APP-MMT-10 [93],

APP-10, APP-MMT-10 [93],  DOPO-6, DOPO-MMT-6 [94],

DOPO-6, DOPO-MMT-6 [94],  APHP-10, BDP-10 [95],

APHP-10, BDP-10 [95],  FIPF-20, FTBF-20 [96],

FIPF-20, FTBF-20 [96],  PPDAB-10 [97],

PPDAB-10 [97],  BP-5, BP-9, BP-15 [98],

BP-5, BP-9, BP-15 [98],  PS-APP-2, PS-APP-5, PS-APP-10, PS-APP-15, PS-APP-20 [99],

PS-APP-2, PS-APP-5, PS-APP-10, PS-APP-15, PS-APP-20 [99],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [100],  DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [101],

DOPO-POSS-2.5, DOPO-POSS-5, DOPO-POSS-10 [101],  DOPO-5 [102],

DOPO-5 [102],  DOPO-6.3 [103],

DOPO-6.3 [103],  DOPO-6.3 [104],

DOPO-6.3 [104],  APP-MMT-10 [105],

APP-MMT-10 [105],  PEPA-5.2, APP-2.9, DOPO-6.3 [106],

PEPA-5.2, APP-2.9, DOPO-6.3 [106],  PCPBO-5, PCPBO-10, PCPBO-15, PCPBO-20 [107],

PCPBO-5, PCPBO-10, PCPBO-15, PCPBO-20 [107],  APP-15, GMA-APP-15 [108],

APP-15, GMA-APP-15 [108],  APP-12, MAPP-12 [109],

APP-12, MAPP-12 [109],  APP-12 [110],

APP-12 [110],  HAP-DOPO-9.3, HAP-DOPO-15.47 [111],

HAP-DOPO-9.3, HAP-DOPO-15.47 [111],  TGIC-DOPO-6.1, TGIC-DOPO-8.1, TGIC-DOPO-10.2, TGIC-DOPO-12.2 [112],

TGIC-DOPO-6.1, TGIC-DOPO-8.1, TGIC-DOPO-10.2, TGIC-DOPO-12.2 [112],  DOPP-19.6, DOPI-23.1 [113],

DOPP-19.6, DOPI-23.1 [113],  PMPC-10, PMPC-15, PMPC-20 [114],

PMPC-10, PMPC-15, PMPC-20 [114],  DOPO-5 [115],

DOPO-5 [115],  SIEPDP-Mg-Al LDH-4 [116],

SIEPDP-Mg-Al LDH-4 [116],  CBz-10, CBz-15, CBz-20 [118],

CBz-10, CBz-15, CBz-20 [118],  APP-5 [117],

APP-5 [117],  DOPMPA-10, DOPMPA-13 [119],

DOPMPA-10, DOPMPA-13 [119],  MFR-10, MFR-15, MFR-20 [9],

MFR-10, MFR-15, MFR-20 [9],  DOPO-COFs-0.4, DOPO-COFs-0.8, DOPO-COFs-1.6, DOPO-COFs-3.2, COFs-3.2 [17],

DOPO-COFs-0.4, DOPO-COFs-0.8, DOPO-COFs-1.6, DOPO-COFs-3.2, COFs-3.2 [17],  Mel-APP-20 [120],

Mel-APP-20 [120],  FR-1 [121],

FR-1 [121],  ArPN2-15, ArPO2-15, ArOPN2-15.6, ArOPO2-15.6 [122],

ArPN2-15, ArPO2-15, ArOPN2-15.6, ArOPO2-15.6 [122],  PMAIL-6 [123],

PMAIL-6 [123],  oDOPI-13.81, PZ -10.8, MPP-15 [124],

oDOPI-13.81, PZ -10.8, MPP-15 [124],  AHP-5 [125],

AHP-5 [125],  Mel-APP-29.7 [126],

Mel-APP-29.7 [126],  MPAlP-20, MPZnP-20, MPMgP-20, MPP-20, AlPi-Et-20, DOPAc-Bu-20 [127],

MPAlP-20, MPZnP-20, MPMgP-20, MPP-20, AlPi-Et-20, DOPAc-Bu-20 [127],  HPCTP-5, HPCTP-10, HPCTP-15 [128],

HPCTP-5, HPCTP-10, HPCTP-15 [128],  HPCTP-15 [129],

HPCTP-15 [129],  TPP-MMT-5 [130],

TPP-MMT-5 [130],  TPP-MMT-5 [130],

TPP-MMT-5 [130],  TPP-MMT-5 [130],

TPP-MMT-5 [130],  hbPPE-10, hbPPE-20 [131],

hbPPE-10, hbPPE-20 [131],  PZS-3, PZS@SrSn(OH)6-3 [132],

PZS-3, PZS@SrSn(OH)6-3 [132],  PEPA-TMAC-16.5, PEPA-TMAC-33 [133],

PEPA-TMAC-16.5, PEPA-TMAC-33 [133],  PCPS-1, PCPS-3, PCPS-5 [134],

PCPS-1, PCPS-3, PCPS-5 [134],  BP1-5, BP2-5, BP3-5, BP4-5, BP5-5 [135],

BP1-5, BP2-5, BP3-5, BP4-5, BP5-5 [135],  SDPS-10.4 [136],

SDPS-10.4 [136],  AOPH-NR-4.25, AOPH-C1-4.25, AOPH-C2-4.25, AOPH-C3-4.25 [137],

AOPH-NR-4.25, AOPH-C1-4.25, AOPH-C2-4.25, AOPH-C3-4.25 [137],  BHAAPE-5, BHAAPE-10, BHAAPE-20 [138],

BHAAPE-5, BHAAPE-10, BHAAPE-20 [138],  APP-10 [139],

APP-10 [139],  PZS-2, PZS@MoS2-2, PZS@MoS2-3 [140],

PZS-2, PZS@MoS2-2, PZS@MoS2-3 [140],  DBPDA-βCD-3 [141],

DBPDA-βCD-3 [141],  BP-PZN-0.5, BP-PZN-1, BP-PZN-2, BP-Bulk-2 [142],

BP-PZN-0.5, BP-PZN-1, BP-PZN-2, BP-Bulk-2 [142],  HPPA-2, HPPA-SH-mSiO2-2 [143],

HPPA-2, HPPA-SH-mSiO2-2 [143],  P-MOF-0.5, P-MOF-1, P-MOF-2 [144],

P-MOF-0.5, P-MOF-1, P-MOF-2 [144],  CZrP-2, CZrP-4, CZrP-6, ZrP-6 [145],

CZrP-2, CZrP-4, CZrP-6, ZrP-6 [145],  DMMP-HNT-20 [146],

DMMP-HNT-20 [146],  S600-20, AlPi-20, MPP-20 [147],

S600-20, AlPi-20, MPP-20 [147],  SiO2@PZM-1, SiO2@PZM@Cu-1, SiO2@PZM@Cu-2 [148],

SiO2@PZM-1, SiO2@PZM@Cu-1, SiO2@PZM@Cu-2 [148],  FR@PZS-0.5, FR@PZS-1, FR@PZS-3, PZS-3 [149],

FR@PZS-0.5, FR@PZS-1, FR@PZS-3, PZS-3 [149],  APP-5 [150],

APP-5 [150],  DOPO-POSS [151],

DOPO-POSS [151],  APP-30, M(APP & PER)-30 [152],

APP-30, M(APP & PER)-30 [152],  TPPi-15, TPPa-15, TPPO-15 [153],

TPPi-15, TPPa-15, TPPO-15 [153],  PMP-11.4, DOPO-13.9, RP-4.3, OP-8.3 [154],

PMP-11.4, DOPO-13.9, RP-4.3, OP-8.3 [154],  IFR-30, IFR-30, IFR-30 [155],

IFR-30, IFR-30, IFR-30 [155],  BPE-33.3, EPE-33.3, BBPE-33.3, BOPE-33.3, HBPE-33.3 [156],

BPE-33.3, EPE-33.3, BBPE-33.3, BOPE-33.3, HBPE-33.3 [156],  IFR-30, IFR-30, IFR-30, IFR-30 [157],

IFR-30, IFR-30, IFR-30, IFR-30 [157],  EGM-5, EGM-15 [158],

EGM-5, EGM-15 [158],  PCTS-Fe-OMMT-1, PCTS-Fe-OMMT-3, PCTS-Fe-OMMT-5 [159],

PCTS-Fe-OMMT-1, PCTS-Fe-OMMT-3, PCTS-Fe-OMMT-5 [159],  APP-20, APP-40 [160],

APP-20, APP-40 [160],  DOPOph-RGNO-1, DOPOph-RGNO-2, DOPOph-RGNO-3 [161],

DOPOph-RGNO-1, DOPOph-RGNO-2, DOPOph-RGNO-3 [161],  Mel-APP-9.59 [120],

Mel-APP-9.59 [120],  FP1-2.6 [24],

FP1-2.6 [24],  PEC-5.2, PEC-6.9, PEC-8.1 [162],

PEC-5.2, PEC-6.9, PEC-8.1 [162],  DOPP-5.9, DOPI-6.9 [113],

DOPP-5.9, DOPI-6.9 [113],  Mel-APP-14.6 [126],

Mel-APP-14.6 [126],  IFR-4.7 [163,164],

IFR-4.7 [163,164],  APP-5 [150],

APP-5 [150],  APP-3.15, APP-8.88, APP-16.32 [165],

APP-3.15, APP-8.88, APP-16.32 [165],  MP-5, DOPO-5 [166],

MP-5, DOPO-5 [166],  IFR-5, IFR-10, IFR-15 [167],

IFR-5, IFR-10, IFR-15 [167],  APP-15 [168],

APP-15 [168],  APP-15 [168].

APP-15 [168].

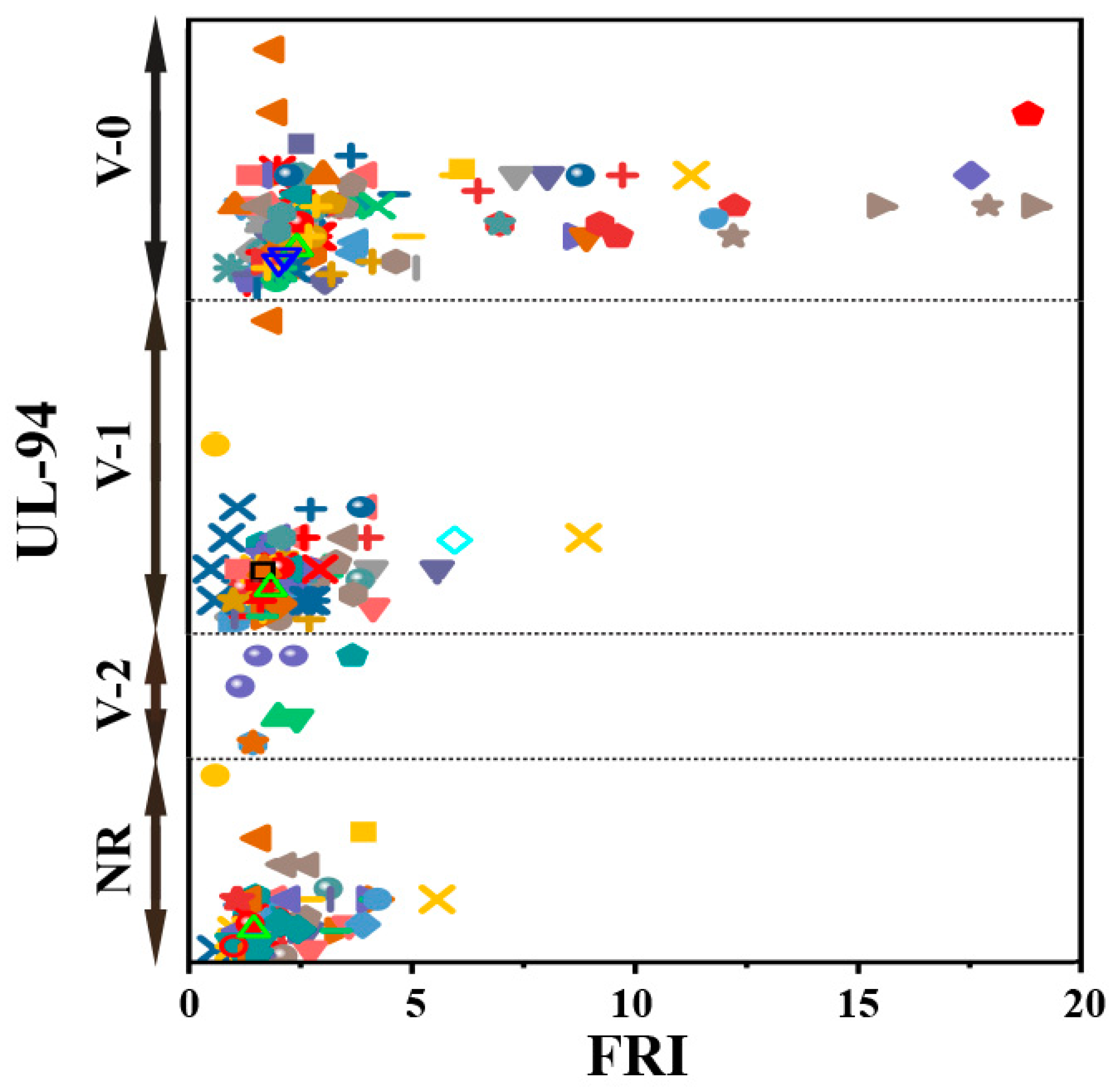

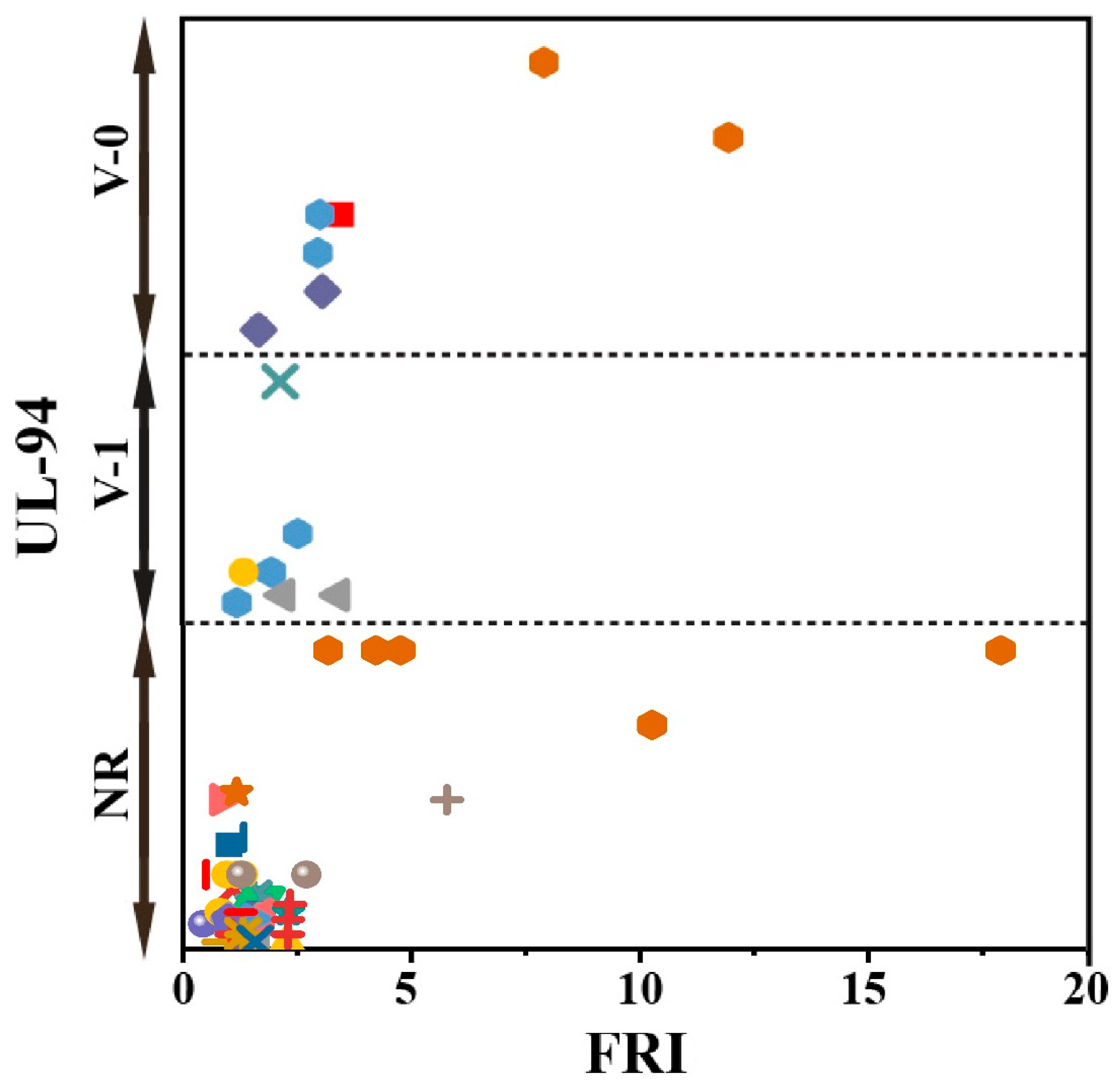

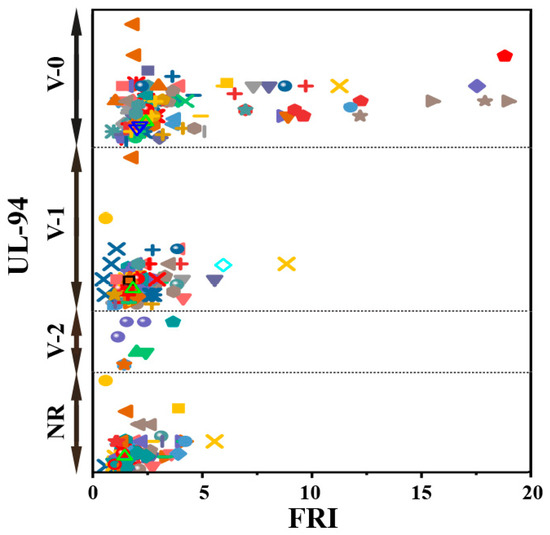

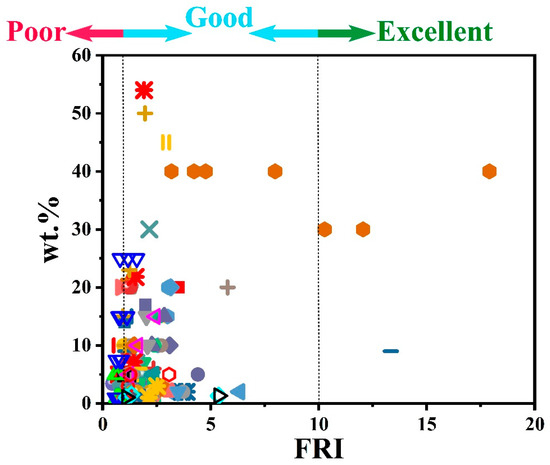

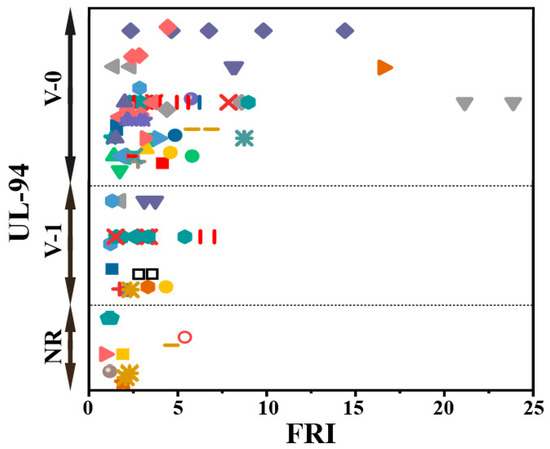

Although variation of FRI values according to the composition reflects the flame retardancy of epoxy composites from cone calorimetry angle (the most reliable test among those normally used for analysis of performance of flame retardants), other types of flame tests would give more insights into the real effect of one or complementary actions of two or more P type FR additives in epoxy. Based on available data, a brief view of the effect of the used P-based FRs on the flame retardancy performance of epoxy resins as a function of UL94 results is given in Figure 2. The distribution of data in this figure gives useful information about the efficiency of the FR system in harsh conditions. For instance, this figure suggests that V-0 performance in UL94 can be achieved even at the Poor category of flame retardancy performance in terms of FRI. It appears that it is not possible to roughly correlate the obtained results in UL94 to those obtained in cone calorimetry tests.

Figure 2.

Flame retardancy analysis of epoxy resins containing phosphorus flame retardants in terms of the FRI values as a function of UL-94 test results. Symbols are indicative of different types of phosphorus flame retardant used. Hollow symbols are indicative of fiber-incorporated composites with details earlier given in the bottom of Table 1 as a to l notes. The vertical variation in each category, i.e., V-0, V-1, V-2, and NR, is schematically representative of the amount of additive used. For example, among two data distinguished by different symbols having the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1), which have different vertical quantity both revealed V-1 behavior in UL-94 test, but the upper was an FR used in more quantity in preparation of epoxy composites.

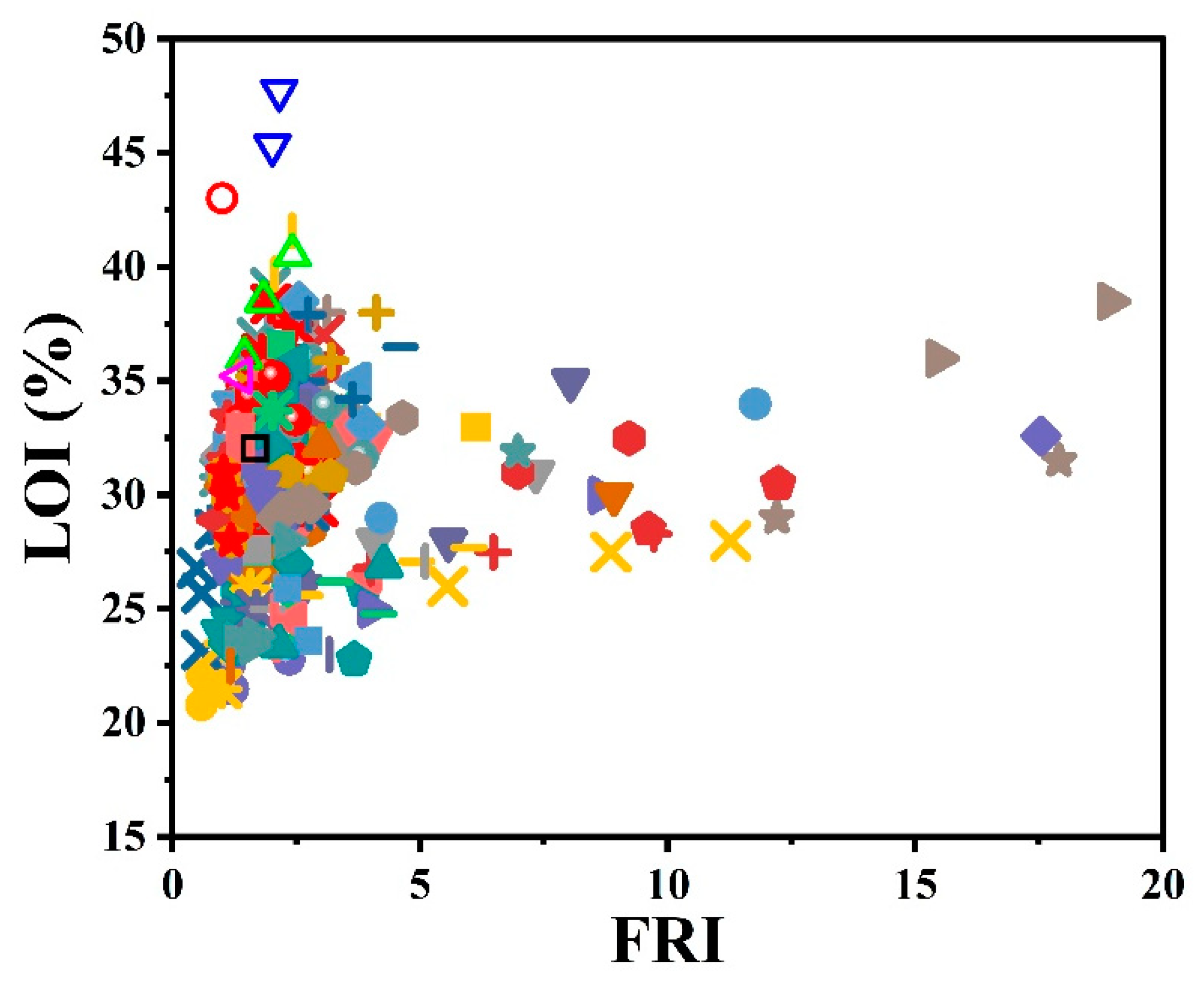

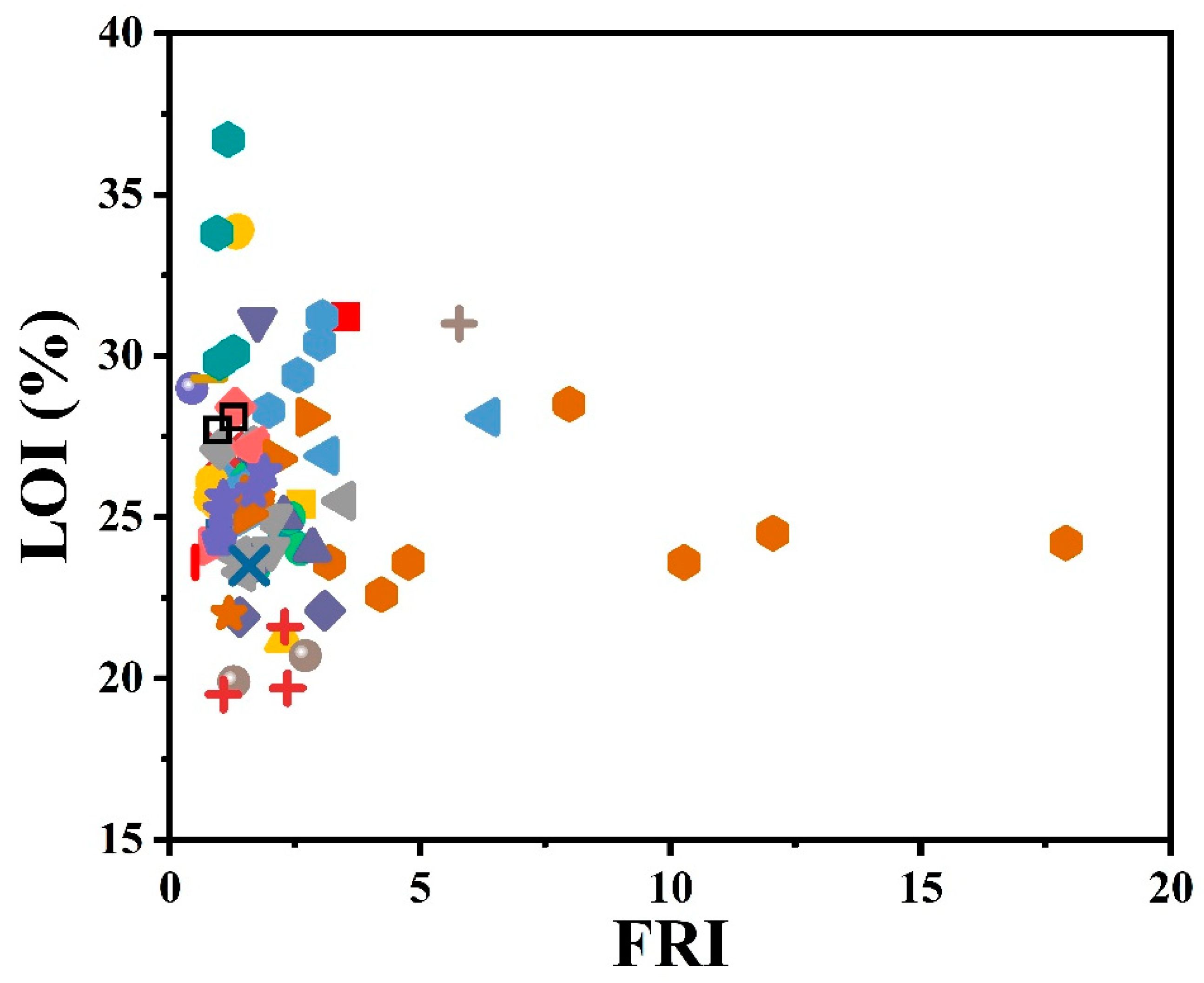

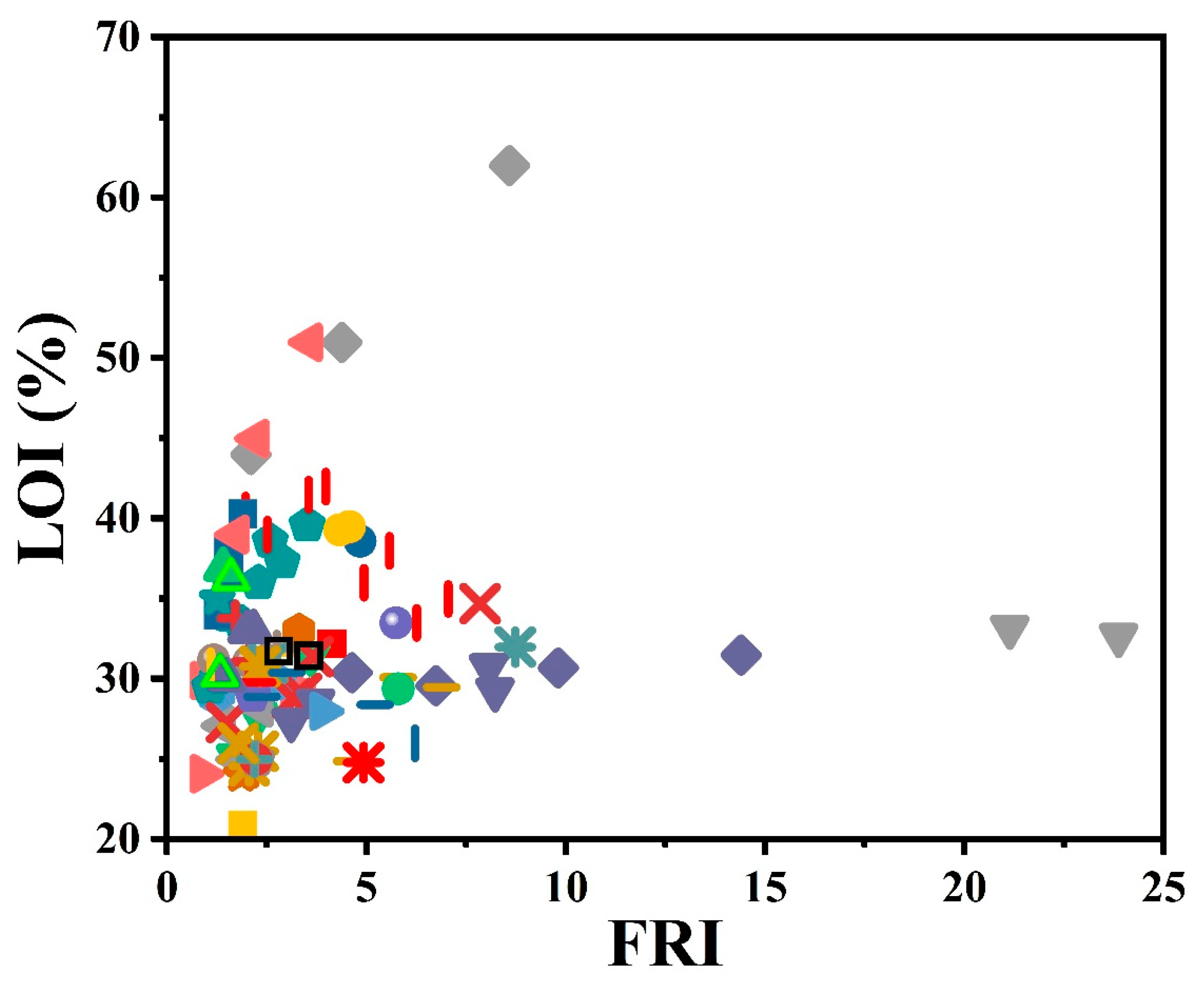

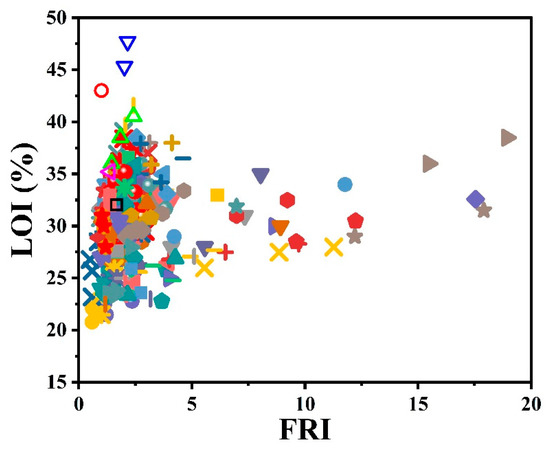

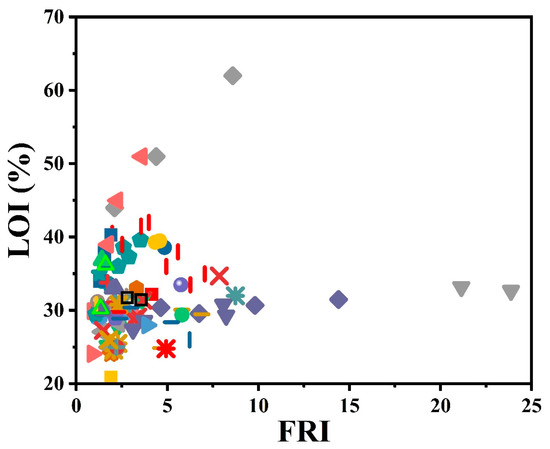

Another test of importance is the limiting oxygen index (LOI), which is demonstrative of flammability. A self-extinguishing behavior is expected when the LOI value is higher than 28. A brief overview of the effect of the used phosphorus-type flame retardants on the flame retardancy performance of epoxy resins as a function of LOI results is given in Figure 3. Surprisingly, the highest value obtained in LOI testing is located in the Good zone of FRI. The collection of data with FRI values below 5, where LOI% varies depending on the type of phosphorus additive and undoubtedly the content, is hidden behind these symbols.

Figure 3.

Flame retardancy analysis of epoxy resins containing phosphorus flame retardants in terms of the FRI values as a function of LOI test results. Symbols are indicative of different types of phosphorus flame retardant used. Hollow symbols are indicative of fiber-incorporated composites with details earlier given in the bottom of Table 1 as a to l notes.

3. Epoxy Resins Containing Nonphosphorus Flame Retardants

According to the literature, a variety of nonphosphorus FRs have been used in epoxy resins. Table 2 summarizes pHRR, THR, and TTI and the FRI values of epoxy/NP systems. The percentage of incorporated FR as well as the results of LOI and UL-94 test are also given for comprehensive determination of the behavior of this family of epoxy composites.

Table 2.

The state of flame retardancy performance of epoxy resins containing nonphosphorus flame retardants in terms of FRI (* the name and percentage of incorporated flame retardant is given after each epoxy resin). The notes a to h on the bottom of the table are representative of composite systems containing woven or nonwoven fibers.

From the comparison between Table 1 and Table 2, one can simply infer that the NP family is less effective in terms of the flame retardancy of the composite epoxy with respect to the P family of FR. The effect of the used NP-type FR on the flame retardancy performance of epoxy resins can be visually assessed in Figure 4. Moreover, detailed information about the type of NP additives is provided to the reader in the caption of Figure 4. The quality of epoxy composites containing NP additives suggests that even at high loading levels it is difficult to attain very high efficiencies. As an informative case, alumina Trihydrate (ATH,  ) has been used in a wide range of content in development of flame-retardant epoxy nanocomposites. It can be seen that at high loading rate (up to 30 wt.%), it gives the best results, Excellent in terms of FRI. It can be concluded that the NP class of additives are not individually responsible for high fire resistance of epoxy.

) has been used in a wide range of content in development of flame-retardant epoxy nanocomposites. It can be seen that at high loading rate (up to 30 wt.%), it gives the best results, Excellent in terms of FRI. It can be concluded that the NP class of additives are not individually responsible for high fire resistance of epoxy.

) has been used in a wide range of content in development of flame-retardant epoxy nanocomposites. It can be seen that at high loading rate (up to 30 wt.%), it gives the best results, Excellent in terms of FRI. It can be concluded that the NP class of additives are not individually responsible for high fire resistance of epoxy.

) has been used in a wide range of content in development of flame-retardant epoxy nanocomposites. It can be seen that at high loading rate (up to 30 wt.%), it gives the best results, Excellent in terms of FRI. It can be concluded that the NP class of additives are not individually responsible for high fire resistance of epoxy.

Figure 4.

Flame retardancy analysis of epoxy resins containing nonphosphorus flame retardants in terms of the FRI values as a function of NP type and content. Symbols are indicative of different types of NP type of FR used. Hollow symbols are indicative of fiber-incorporated composites with details earlier given in the bottom of Table 1 as notes a to h. Here:  3TT-3BA-20 [169],

3TT-3BA-20 [169],  GN-3 [28],

GN-3 [28],  MWCNT-0.8 [29],

MWCNT-0.8 [29],  OMMT-7 [30],

OMMT-7 [30],  OLDH-1, OLDH-5, OLDH-10 [31],

OLDH-1, OLDH-5, OLDH-10 [31],  MgAl-LDH-2, ZIF8-2, ZIF8@MgAl-LDH-2, ZIF67-2, ZIF67@MgAl-LDH-2 [170],

MgAl-LDH-2, ZIF8-2, ZIF8@MgAl-LDH-2, ZIF67-2, ZIF67@MgAl-LDH-2 [170],  TAT-20 [52],

TAT-20 [52],  TNB-1, TNB-5, TNB-10, TNB-15, TNB-20 [171],

TNB-1, TNB-5, TNB-10, TNB-15, TNB-20 [171],  Cu2O-21 [55],

Cu2O-21 [55],  MH-3, [56],

MH-3, [56],  TN-3.42 [63],

TN-3.42 [63],  EG-20 [66],

EG-20 [66],  TMT-8 [67],

TMT-8 [67],  TMT-7 [68],

TMT-7 [68],  OMMT-1 [77],

OMMT-1 [77],  TAIC-10 [78],

TAIC-10 [78],  TPT-14 [81],

TPT-14 [81],  HNT-5, HNT-10, HNT@PDA-5, HNT@PDA-10, HNT@PDA@Fe(OH)3-5, HNT@PDA@Fe(OH)3-10 [172],

HNT-5, HNT-10, HNT@PDA-5, HNT@PDA-10, HNT@PDA@Fe(OH)3-5, HNT@PDA@Fe(OH)3-10 [172],  MMT-6 [94],

MMT-6 [94],  OPS-5 [102],

OPS-5 [102],  OPS-4.1, PPSQ-4.1 [103],

OPS-4.1, PPSQ-4.1 [103],  OPS-4.1, OAPS-4.6 [104],

OPS-4.1, OAPS-4.6 [104],  OPS-4.1 [106],

OPS-4.1 [106],  ATH-40, C-40, U-40, BA-40, BO-40, MB-30, GB-30 [173],

ATH-40, C-40, U-40, BA-40, BO-40, MB-30, GB-30 [173],  ODPSS-5 [115],

ODPSS-5 [115],  Mg-Al LDH-4 [116],

Mg-Al LDH-4 [116],  T8POSS-10, TGIC-10 [174],

T8POSS-10, TGIC-10 [174],  RGO-1 [121],

RGO-1 [121],  HNT-2, LDH-2, LDH-4, LDH-6 [120],

HNT-2, LDH-2, LDH-4, LDH-6 [120],  AlO(OH)-30 [124],

AlO(OH)-30 [124],  ACS-2, ACS@SnO2-2, ACS@SnO2@NiO-2 [125],

ACS-2, ACS@SnO2-2, ACS@SnO2@NiO-2 [125],  ACS@SnO2@NiO-5 [125],

ACS@SnO2@NiO-5 [125],  OGPOSS-15 [129],

OGPOSS-15 [129],  EG-15 [33],

EG-15 [33],  CP-10, CP-15 [130],

CP-10, CP-15 [130],  CP-10, CP-15 [130],

CP-10, CP-15 [130],  CP-10, CP-15 [130],

CP-10, CP-15 [130],  SrSn(OH)6-3 [132],

SrSn(OH)6-3 [132],  SiO2-2, ZIF8-2, ZIF8@SiO2-2 [175],

SiO2-2, ZIF8-2, ZIF8@SiO2-2 [175],  MoS2-2, TNT-2, MoS2-TNT-1, MoS2-TNT-2, MoS2-TNT-3 [176],

MoS2-2, TNT-2, MoS2-TNT-1, MoS2-TNT-2, MoS2-TNT-3 [176],  Sep-2, Sep-4, Fe3o4–Sep-2, Fe3o4–Sep-4 [177],

Sep-2, Sep-4, Fe3o4–Sep-2, Fe3o4–Sep-4 [177],  GNO-1, GNO-3, GN-Cu-1, GN-Cu-3 [178],

GNO-1, GNO-3, GN-Cu-1, GN-Cu-3 [178],  AlO(OH)-20 [147],

AlO(OH)-20 [147],  AlO(OH)-20, SiO2-20 [127],

AlO(OH)-20, SiO2-20 [127],  α-MnO2-0.5, α-MnO2-1, α-MnO2-2, δ-MnO2-0.5, δ-MnO2-1, δ-MnO2-2 [179],

α-MnO2-0.5, α-MnO2-1, α-MnO2-2, δ-MnO2-0.5, δ-MnO2-1, δ-MnO2-2 [179],  MoS2-2 [140],

MoS2-2 [140],  AI-POSS-7.2, AI-POSS-21.8, AI-POSS-54 [180],

AI-POSS-7.2, AI-POSS-21.8, AI-POSS-54 [180],  EG-9, HNT-9 [181],

EG-9, HNT-9 [181],  BN 2 μm-45, BT 2 μm-45 [182],

BN 2 μm-45, BT 2 μm-45 [182],  MnO2-2, MnO2@ZHS-0.5, MnO2@ZHS-1, MnO2@ZHS-2 [183],

MnO2-2, MnO2@ZHS-0.5, MnO2@ZHS-1, MnO2@ZHS-2 [183],  ILFR-5, BN-5, ILFR-fBN-5 [184],

ILFR-5, BN-5, ILFR-fBN-5 [184],  SH-mSiO2-2 [143],

SH-mSiO2-2 [143],  SCF-0.5, SCF-0.7, SCF-1, SCF-1.5 [185],

SCF-0.5, SCF-0.7, SCF-1, SCF-1.5 [185],  HNT-20 [146],

HNT-20 [146],  m-Clay-2.5, d-Clay-2.5 [186],

m-Clay-2.5, d-Clay-2.5 [186],  LDH-3, β-FeOOH-3, LDH-β-FeOOH-3 [187],

LDH-3, β-FeOOH-3, LDH-β-FeOOH-3 [187],  AHTSS-0.5, AHTSS-2, UMTHS-0.5, UMTHS-2 [188],

AHTSS-0.5, AHTSS-2, UMTHS-0.5, UMTHS-2 [188],  CS-MoS2-0.5, CS-MoS2-1, CS-MoS2-2, MoS2-2 [189],

CS-MoS2-0.5, CS-MoS2-1, CS-MoS2-2, MoS2-2 [189],  SiO2-1 [148],

SiO2-1 [148],  CNT-1, CCNT-1, TCNT-1, LDH-5, OLDH-5, MMT-5, OMMT-5, ATH-5 [150],

CNT-1, CCNT-1, TCNT-1, LDH-5, OLDH-5, MMT-5, OMMT-5, ATH-5 [150],  EG-5, EG-10, EG-15, EG-23, EG-50 [190],

EG-5, EG-10, EG-15, EG-23, EG-50 [190],  BT-3, BT-5, BFTDA-BT-3, BFTDA-BT-5, APUA-BT-3, APUA-BT-5 [191,192],

BT-3, BT-5, BFTDA-BT-3, BFTDA-BT-5, APUA-BT-3, APUA-BT-5 [191,192],  GN-2, Ni–Fe LDH-2 [193],

GN-2, Ni–Fe LDH-2 [193],  OAPOSS-MMT-2, OAPOSS-MMT-4, OAPOSS-MMT-6 [194],

OAPOSS-MMT-2, OAPOSS-MMT-4, OAPOSS-MMT-6 [194],  Na-magadiite-3, S-Na-magadiite-3, S-H-magadiite-3, OM-magadiite-3, S-OM-magadiite-3 [195],

Na-magadiite-3, S-Na-magadiite-3, S-H-magadiite-3, OM-magadiite-3, S-OM-magadiite-3 [195],  TBBA-17 [154],

TBBA-17 [154],  GN-2, Ce–MnO2-2, Ce–MnO2–GN-2 [196],

GN-2, Ce–MnO2-2, Ce–MnO2–GN-2 [196],  m-SiO2-2, Co−Al LDH-2, m-SiO2@Co−Al LDH-2 [197],

m-SiO2-2, Co−Al LDH-2, m-SiO2@Co−Al LDH-2 [197],  ZnS-2, GN-2, ZnS-GN-2 [198],

ZnS-2, GN-2, ZnS-GN-2 [198],  sep idra-2, sep idra-5, sep idra-10, sep anidra-2, sep anidra-5, sep anidra-10 [199],

sep idra-2, sep idra-5, sep idra-10, sep anidra-2, sep anidra-5, sep anidra-10 [199],  EG-5 [158],

EG-5 [158],  CTS-Fe-OMMT-3, CTAB-Fe-OMMT-3 [159],

CTS-Fe-OMMT-3, CTAB-Fe-OMMT-3 [159],  A-MWCNT(Polish)-0.05, A-MWCNT(Polish)-0.1, A-MWCNT(Polish)-0.5, A-MWCNT(Polish)-1, A-MWCNT(Polish)-5, C-MWCNT(Polish)-0.05, C-MWCNT(Polish)-0.1, C-MWCNT(Polish)-0.5, C-MWCNT(Polish)-1, C-MWCNT(Belgian)-0.05, C-MWCNT(Belgian)-0.5, CA-MWCNT(Polish)-0.05, CA-MWCNT(Polish)-0.1, CA-MWCNT(Polish)-0.5, CA-MWCNT(Polish)-1, CA-MWCNT(Polish)-5, A-MWCNT(Belgian)-0.05, A-MWCNT(Belgian)-0.1, A-MWCNT(Belgian)-0.5 [200],

A-MWCNT(Polish)-0.05, A-MWCNT(Polish)-0.1, A-MWCNT(Polish)-0.5, A-MWCNT(Polish)-1, A-MWCNT(Polish)-5, C-MWCNT(Polish)-0.05, C-MWCNT(Polish)-0.1, C-MWCNT(Polish)-0.5, C-MWCNT(Polish)-1, C-MWCNT(Belgian)-0.05, C-MWCNT(Belgian)-0.5, CA-MWCNT(Polish)-0.05, CA-MWCNT(Polish)-0.1, CA-MWCNT(Polish)-0.5, CA-MWCNT(Polish)-1, CA-MWCNT(Polish)-5, A-MWCNT(Belgian)-0.05, A-MWCNT(Belgian)-0.1, A-MWCNT(Belgian)-0.5 [200],  GNO-1 [201],

GNO-1 [201],  I.30E-3 [160],

I.30E-3 [160],  MoS2-2,GN-2, MoS2-GN-2 [202],

MoS2-2,GN-2, MoS2-GN-2 [202],  GNO-1 [161],

GNO-1 [161],  BNO-1, BNO-3 [203],

BNO-1, BNO-3 [203],  Vis-4.7, Ky-4.7 [163,164],

Vis-4.7, Ky-4.7 [163,164],  clay-1, clay-3, clay-5 [204],

clay-1, clay-3, clay-5 [204],  LDH-5, OLDH-1, CNT-1, CCNT-1, TCNT-1, ATH-5 [150],

LDH-5, OLDH-1, CNT-1, CCNT-1, TCNT-1, ATH-5 [150],  Mg(OH)2-1, Mg(OH)2-7.5, Mg(OH)2-15, Mg(OH)2-25, Al(OH)3-1, Al(OH)3-7.5, Al(OH)3-15, Al(OH)3-25, ZB-1, ZB-7.5, ZB-15, ZB-25 [205],

Mg(OH)2-1, Mg(OH)2-7.5, Mg(OH)2-15, Mg(OH)2-25, Al(OH)3-1, Al(OH)3-7.5, Al(OH)3-15, Al(OH)3-25, ZB-1, ZB-7.5, ZB-15, ZB-25 [205],  SWCNT-BP-1.06, MWCNT-BP-1.34, CNF-1.57 [206],

SWCNT-BP-1.06, MWCNT-BP-1.34, CNF-1.57 [206],  Vis-5, Vis-10, Vis-15 [167],

Vis-5, Vis-10, Vis-15 [167],  SWCNT-BP-1.06, MWCNT-BP-1.34 [207],

SWCNT-BP-1.06, MWCNT-BP-1.34 [207],  T8POSS-5, TGIC-5 [174].

T8POSS-5, TGIC-5 [174].

3TT-3BA-20 [169],

3TT-3BA-20 [169],  GN-3 [28],

GN-3 [28],  MWCNT-0.8 [29],

MWCNT-0.8 [29],  OMMT-7 [30],

OMMT-7 [30],  OLDH-1, OLDH-5, OLDH-10 [31],

OLDH-1, OLDH-5, OLDH-10 [31],  MgAl-LDH-2, ZIF8-2, ZIF8@MgAl-LDH-2, ZIF67-2, ZIF67@MgAl-LDH-2 [170],

MgAl-LDH-2, ZIF8-2, ZIF8@MgAl-LDH-2, ZIF67-2, ZIF67@MgAl-LDH-2 [170],  TAT-20 [52],

TAT-20 [52],  TNB-1, TNB-5, TNB-10, TNB-15, TNB-20 [171],

TNB-1, TNB-5, TNB-10, TNB-15, TNB-20 [171],  Cu2O-21 [55],

Cu2O-21 [55],  MH-3, [56],

MH-3, [56],  TN-3.42 [63],

TN-3.42 [63],  EG-20 [66],

EG-20 [66],  TMT-8 [67],

TMT-8 [67],  TMT-7 [68],

TMT-7 [68],  OMMT-1 [77],

OMMT-1 [77],  TAIC-10 [78],

TAIC-10 [78],  TPT-14 [81],

TPT-14 [81],  HNT-5, HNT-10, HNT@PDA-5, HNT@PDA-10, HNT@PDA@Fe(OH)3-5, HNT@PDA@Fe(OH)3-10 [172],

HNT-5, HNT-10, HNT@PDA-5, HNT@PDA-10, HNT@PDA@Fe(OH)3-5, HNT@PDA@Fe(OH)3-10 [172],  MMT-6 [94],

MMT-6 [94],  OPS-5 [102],

OPS-5 [102],  OPS-4.1, PPSQ-4.1 [103],

OPS-4.1, PPSQ-4.1 [103],  OPS-4.1, OAPS-4.6 [104],

OPS-4.1, OAPS-4.6 [104],  OPS-4.1 [106],

OPS-4.1 [106],  ATH-40, C-40, U-40, BA-40, BO-40, MB-30, GB-30 [173],

ATH-40, C-40, U-40, BA-40, BO-40, MB-30, GB-30 [173],  ODPSS-5 [115],

ODPSS-5 [115],  Mg-Al LDH-4 [116],

Mg-Al LDH-4 [116],  T8POSS-10, TGIC-10 [174],

T8POSS-10, TGIC-10 [174],  RGO-1 [121],

RGO-1 [121],  HNT-2, LDH-2, LDH-4, LDH-6 [120],

HNT-2, LDH-2, LDH-4, LDH-6 [120],  AlO(OH)-30 [124],

AlO(OH)-30 [124],  ACS-2, ACS@SnO2-2, ACS@SnO2@NiO-2 [125],

ACS-2, ACS@SnO2-2, ACS@SnO2@NiO-2 [125],  ACS@SnO2@NiO-5 [125],

ACS@SnO2@NiO-5 [125],  OGPOSS-15 [129],

OGPOSS-15 [129],  EG-15 [33],

EG-15 [33],  CP-10, CP-15 [130],

CP-10, CP-15 [130],  CP-10, CP-15 [130],

CP-10, CP-15 [130],  CP-10, CP-15 [130],

CP-10, CP-15 [130],  SrSn(OH)6-3 [132],

SrSn(OH)6-3 [132],  SiO2-2, ZIF8-2, ZIF8@SiO2-2 [175],

SiO2-2, ZIF8-2, ZIF8@SiO2-2 [175],  MoS2-2, TNT-2, MoS2-TNT-1, MoS2-TNT-2, MoS2-TNT-3 [176],

MoS2-2, TNT-2, MoS2-TNT-1, MoS2-TNT-2, MoS2-TNT-3 [176],  Sep-2, Sep-4, Fe3o4–Sep-2, Fe3o4–Sep-4 [177],

Sep-2, Sep-4, Fe3o4–Sep-2, Fe3o4–Sep-4 [177],  GNO-1, GNO-3, GN-Cu-1, GN-Cu-3 [178],

GNO-1, GNO-3, GN-Cu-1, GN-Cu-3 [178],  AlO(OH)-20 [147],

AlO(OH)-20 [147],  AlO(OH)-20, SiO2-20 [127],

AlO(OH)-20, SiO2-20 [127],  α-MnO2-0.5, α-MnO2-1, α-MnO2-2, δ-MnO2-0.5, δ-MnO2-1, δ-MnO2-2 [179],

α-MnO2-0.5, α-MnO2-1, α-MnO2-2, δ-MnO2-0.5, δ-MnO2-1, δ-MnO2-2 [179],  MoS2-2 [140],

MoS2-2 [140],  AI-POSS-7.2, AI-POSS-21.8, AI-POSS-54 [180],

AI-POSS-7.2, AI-POSS-21.8, AI-POSS-54 [180],  EG-9, HNT-9 [181],

EG-9, HNT-9 [181],  BN 2 μm-45, BT 2 μm-45 [182],

BN 2 μm-45, BT 2 μm-45 [182],  MnO2-2, MnO2@ZHS-0.5, MnO2@ZHS-1, MnO2@ZHS-2 [183],

MnO2-2, MnO2@ZHS-0.5, MnO2@ZHS-1, MnO2@ZHS-2 [183],  ILFR-5, BN-5, ILFR-fBN-5 [184],

ILFR-5, BN-5, ILFR-fBN-5 [184],  SH-mSiO2-2 [143],

SH-mSiO2-2 [143],  SCF-0.5, SCF-0.7, SCF-1, SCF-1.5 [185],

SCF-0.5, SCF-0.7, SCF-1, SCF-1.5 [185],  HNT-20 [146],

HNT-20 [146],  m-Clay-2.5, d-Clay-2.5 [186],

m-Clay-2.5, d-Clay-2.5 [186],  LDH-3, β-FeOOH-3, LDH-β-FeOOH-3 [187],

LDH-3, β-FeOOH-3, LDH-β-FeOOH-3 [187],  AHTSS-0.5, AHTSS-2, UMTHS-0.5, UMTHS-2 [188],

AHTSS-0.5, AHTSS-2, UMTHS-0.5, UMTHS-2 [188],  CS-MoS2-0.5, CS-MoS2-1, CS-MoS2-2, MoS2-2 [189],

CS-MoS2-0.5, CS-MoS2-1, CS-MoS2-2, MoS2-2 [189],  SiO2-1 [148],

SiO2-1 [148],  CNT-1, CCNT-1, TCNT-1, LDH-5, OLDH-5, MMT-5, OMMT-5, ATH-5 [150],

CNT-1, CCNT-1, TCNT-1, LDH-5, OLDH-5, MMT-5, OMMT-5, ATH-5 [150],  EG-5, EG-10, EG-15, EG-23, EG-50 [190],

EG-5, EG-10, EG-15, EG-23, EG-50 [190],  BT-3, BT-5, BFTDA-BT-3, BFTDA-BT-5, APUA-BT-3, APUA-BT-5 [191,192],

BT-3, BT-5, BFTDA-BT-3, BFTDA-BT-5, APUA-BT-3, APUA-BT-5 [191,192],  GN-2, Ni–Fe LDH-2 [193],

GN-2, Ni–Fe LDH-2 [193],  OAPOSS-MMT-2, OAPOSS-MMT-4, OAPOSS-MMT-6 [194],

OAPOSS-MMT-2, OAPOSS-MMT-4, OAPOSS-MMT-6 [194],  Na-magadiite-3, S-Na-magadiite-3, S-H-magadiite-3, OM-magadiite-3, S-OM-magadiite-3 [195],

Na-magadiite-3, S-Na-magadiite-3, S-H-magadiite-3, OM-magadiite-3, S-OM-magadiite-3 [195],  TBBA-17 [154],

TBBA-17 [154],  GN-2, Ce–MnO2-2, Ce–MnO2–GN-2 [196],

GN-2, Ce–MnO2-2, Ce–MnO2–GN-2 [196],  m-SiO2-2, Co−Al LDH-2, m-SiO2@Co−Al LDH-2 [197],

m-SiO2-2, Co−Al LDH-2, m-SiO2@Co−Al LDH-2 [197],  ZnS-2, GN-2, ZnS-GN-2 [198],

ZnS-2, GN-2, ZnS-GN-2 [198],  sep idra-2, sep idra-5, sep idra-10, sep anidra-2, sep anidra-5, sep anidra-10 [199],

sep idra-2, sep idra-5, sep idra-10, sep anidra-2, sep anidra-5, sep anidra-10 [199],  EG-5 [158],

EG-5 [158],  CTS-Fe-OMMT-3, CTAB-Fe-OMMT-3 [159],

CTS-Fe-OMMT-3, CTAB-Fe-OMMT-3 [159],  A-MWCNT(Polish)-0.05, A-MWCNT(Polish)-0.1, A-MWCNT(Polish)-0.5, A-MWCNT(Polish)-1, A-MWCNT(Polish)-5, C-MWCNT(Polish)-0.05, C-MWCNT(Polish)-0.1, C-MWCNT(Polish)-0.5, C-MWCNT(Polish)-1, C-MWCNT(Belgian)-0.05, C-MWCNT(Belgian)-0.5, CA-MWCNT(Polish)-0.05, CA-MWCNT(Polish)-0.1, CA-MWCNT(Polish)-0.5, CA-MWCNT(Polish)-1, CA-MWCNT(Polish)-5, A-MWCNT(Belgian)-0.05, A-MWCNT(Belgian)-0.1, A-MWCNT(Belgian)-0.5 [200],

A-MWCNT(Polish)-0.05, A-MWCNT(Polish)-0.1, A-MWCNT(Polish)-0.5, A-MWCNT(Polish)-1, A-MWCNT(Polish)-5, C-MWCNT(Polish)-0.05, C-MWCNT(Polish)-0.1, C-MWCNT(Polish)-0.5, C-MWCNT(Polish)-1, C-MWCNT(Belgian)-0.05, C-MWCNT(Belgian)-0.5, CA-MWCNT(Polish)-0.05, CA-MWCNT(Polish)-0.1, CA-MWCNT(Polish)-0.5, CA-MWCNT(Polish)-1, CA-MWCNT(Polish)-5, A-MWCNT(Belgian)-0.05, A-MWCNT(Belgian)-0.1, A-MWCNT(Belgian)-0.5 [200],  GNO-1 [201],

GNO-1 [201],  I.30E-3 [160],

I.30E-3 [160],  MoS2-2,GN-2, MoS2-GN-2 [202],

MoS2-2,GN-2, MoS2-GN-2 [202],  GNO-1 [161],

GNO-1 [161],  BNO-1, BNO-3 [203],

BNO-1, BNO-3 [203],  Vis-4.7, Ky-4.7 [163,164],

Vis-4.7, Ky-4.7 [163,164],  clay-1, clay-3, clay-5 [204],

clay-1, clay-3, clay-5 [204],  LDH-5, OLDH-1, CNT-1, CCNT-1, TCNT-1, ATH-5 [150],

LDH-5, OLDH-1, CNT-1, CCNT-1, TCNT-1, ATH-5 [150],  Mg(OH)2-1, Mg(OH)2-7.5, Mg(OH)2-15, Mg(OH)2-25, Al(OH)3-1, Al(OH)3-7.5, Al(OH)3-15, Al(OH)3-25, ZB-1, ZB-7.5, ZB-15, ZB-25 [205],

Mg(OH)2-1, Mg(OH)2-7.5, Mg(OH)2-15, Mg(OH)2-25, Al(OH)3-1, Al(OH)3-7.5, Al(OH)3-15, Al(OH)3-25, ZB-1, ZB-7.5, ZB-15, ZB-25 [205],  SWCNT-BP-1.06, MWCNT-BP-1.34, CNF-1.57 [206],

SWCNT-BP-1.06, MWCNT-BP-1.34, CNF-1.57 [206],  Vis-5, Vis-10, Vis-15 [167],

Vis-5, Vis-10, Vis-15 [167],  SWCNT-BP-1.06, MWCNT-BP-1.34 [207],

SWCNT-BP-1.06, MWCNT-BP-1.34 [207],  T8POSS-5, TGIC-5 [174].

T8POSS-5, TGIC-5 [174].

A brief overview of the effect of the NP used as FR in epoxy composite preparation and on the flame retardancy performance of epoxy resins as a function of UL-94 results is given in Figure 5. Since data are limited and spread over the plot, there is no conclusion about the relationship between FRI (cone calorimetry) and UL-94 analysis to be highlighted. Nevertheless, all sorts of behavior can be seen in the plot, depending on the type and content of NP type of FRs. It is worthy of note that the NR category of UL-94 constitutes a high proportion of the results.

Figure 5.

Flame retardancy analysis of epoxy resins containing nonphosphorus flame retardants in terms of the FRI values as a function of UL-94 test results. Symbols are indicative of different types of NP type of FR used in this figure. Hollow symbols are indicative of fiber-incorporated composites with details given in the bottom of Table 2 as notes a to h. The vertical variation in each category, i.e., V-0, V-1, V-2, and NR, is schematically representative of the amount of additive used. For example, among two data distinguished by different symbols having the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1), which have different vertical quantity both revealed V-1 behavior in UL-94 test, but the upper was an FR used in greater quantity in preparation of epoxy composites.

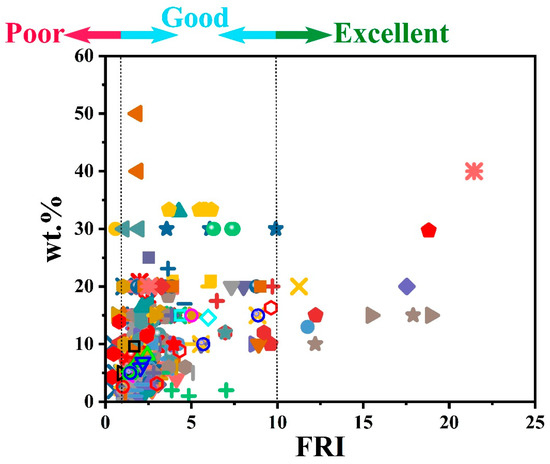

A brief overview of the effect of NP-type FR on the flame retardancy performance of epoxy resins as a function of LOI results is given in Figure 6. Surprisingly, the highest value obtained in LOI testing is located in Poor zone of FRI. On the other hand, Excellent flame retardancy seen at high FRI values has LOI of about 22%. From this perspective, it can be concluded that cone calorimetry is not monotonically representative of the character of FR when used in epoxy.

Figure 6.

Flame retardancy analysis of epoxy resins containing nonphosphorus flame retardants in terms of the FRI values as a function of LOI test results. Symbols are indicative of different types of NP flame retardant used. Hollow symbols are indicative of fiber-incorporated composites with details given in the bottom of Table 2 as notes a to h.

4. Epoxy Resins Containing Combinatorial Flame Retardant Systems

Assessing the flame retardancy performance of P- and NP-incorporated epoxy systems unraveled the inadequacy of using one FR additive alone when a high performance is required. The antagonism or synergism may be the result of using two or more FR systems in a given polymer matrix. In the case of epoxy, there have been some attempts towards combinatorial use of P and NP additives for the sake of higher performance. Table 3 summarizes pHRR, THR, TTI, and FRI values of epoxy/P/NP combinatorial flame-retardant systems. The percentage of incorporated FR as well as the results of LOI and UL-94 tests are also given.

Table 3.

The flame retardancy performance of epoxy containing combinatory flame retardants in terms of FRI (* the name and percentage of incorporated flame retardant is given after each epoxy resin). Notes a to i on the bottom of the table are representative of composite systems containing woven or nonwoven fibers.

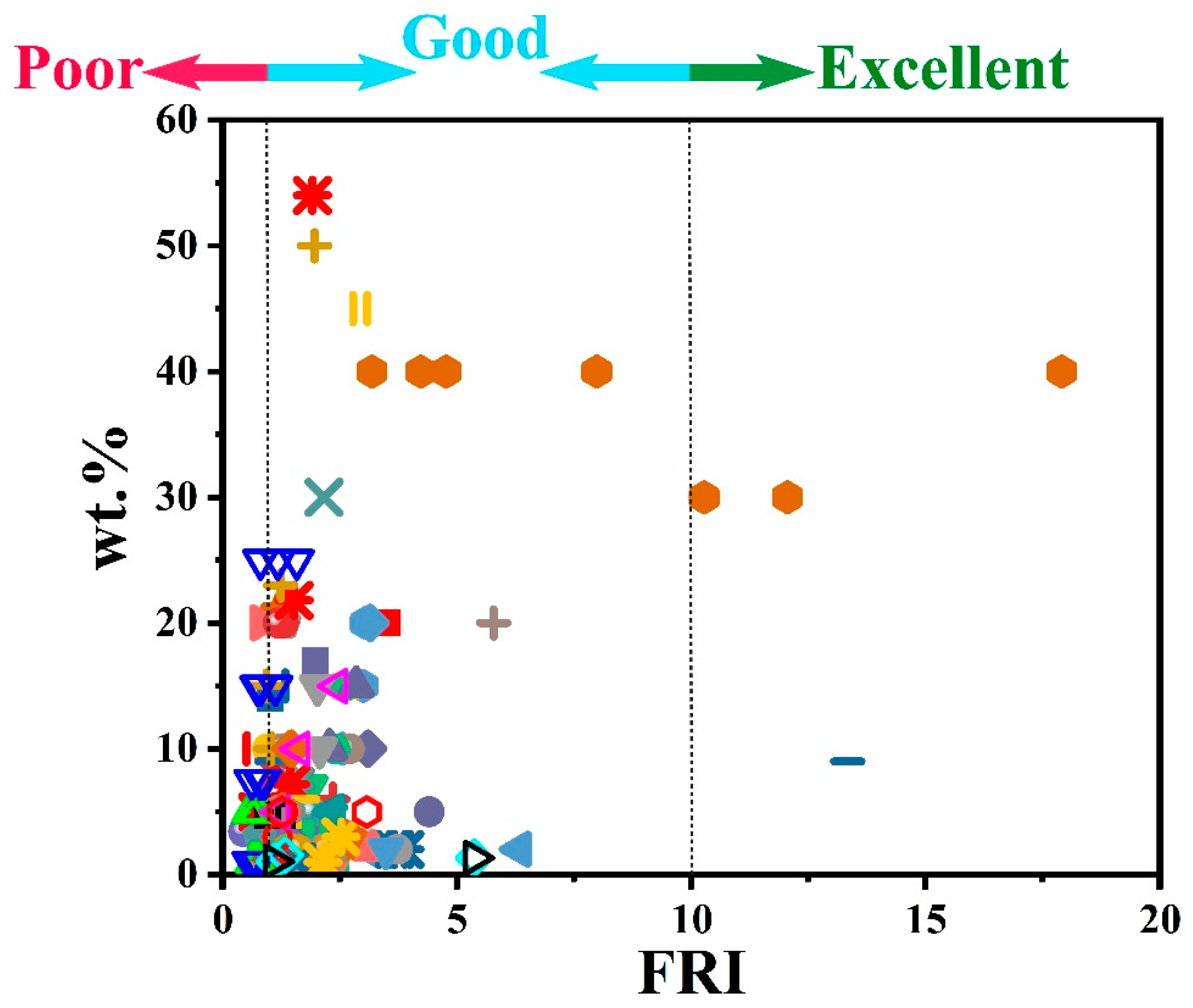

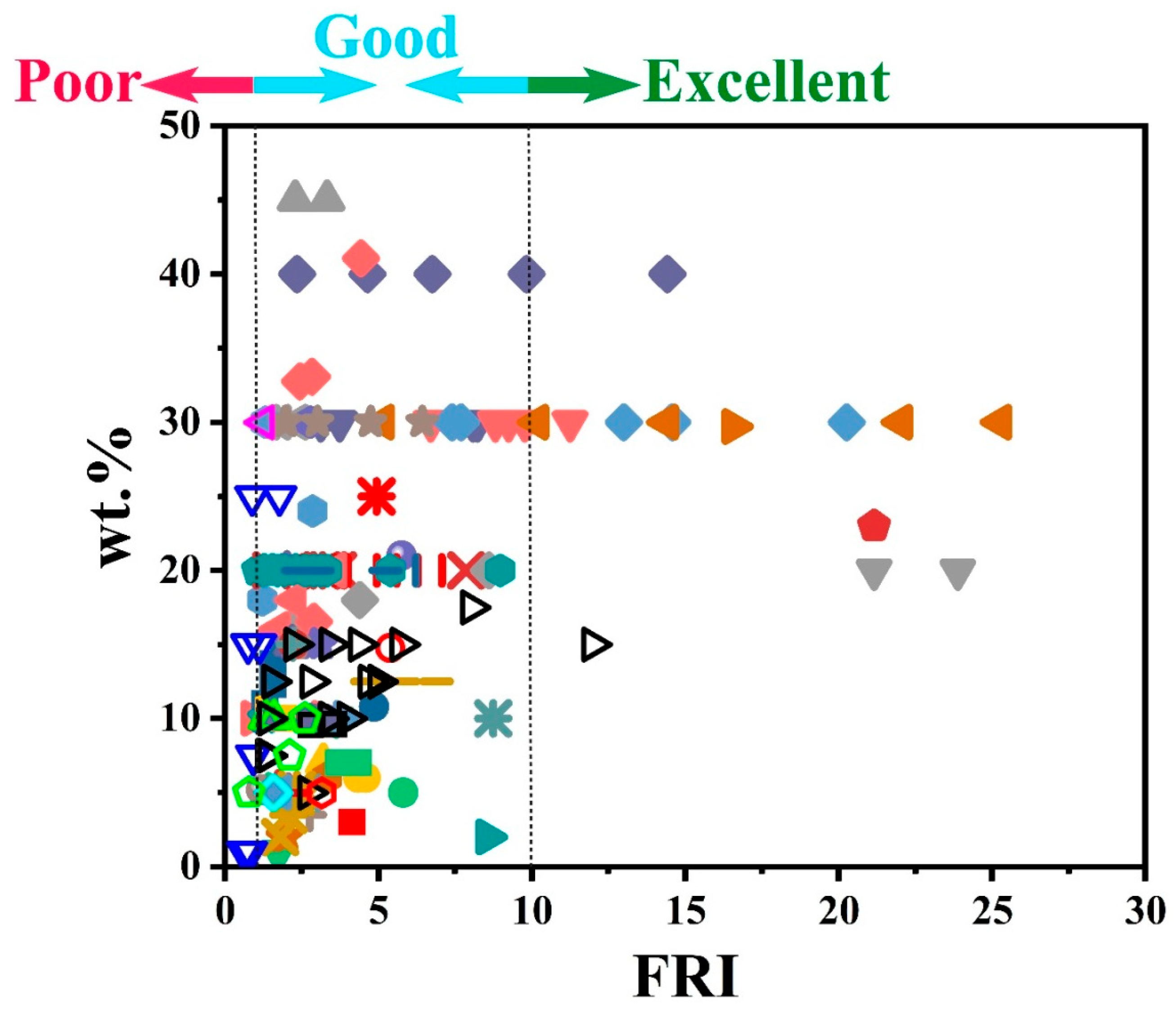

To give a more meaningful overview of the effect of combined P and NP additives on flame retardancy performance of epoxy, FRI values are calculated by using calorimetric data given in Table 3 and plotted in Figure 7. In this figure, the vertical axis shows the amount of additive system used in preparation of epoxy composites. The plot also reveals that three types of flame retardancy performances are observed, depending on the type of combinatorial systems as well as the amount of FR additives used. Attention should be paid to the fact that even at lower loading levels, careful coupling of one or more P and NP additives could lead to superiority of the FR system used, and there was a possibility for attaining higher performances compared to highly-filled systems (FR content ≥ 40). Thus, careful selection of complementary additives with disciplined loading can result in high flame retardancy performance.

Figure 7.

Flame retardancy analysis of epoxy resins containing combinatorial flame retardant systems in terms of the FRI values as a function of combinatorial flame retardants systems retardant type and content. Symbols are indicative of different types of combinatorial flame retardants systems used. Hollow symbols are indicative of fiber-incorporated composites with details earlier given in the bottom of Table 1 as notes a to i. Here:  DiDOPO-1.5/GN-1.5 [28],

DiDOPO-1.5/GN-1.5 [28],  DiDOPO-10/MWCNT-0.8 [29],

DiDOPO-10/MWCNT-0.8 [29],  DiDOPO-3.5/OMMT-3.5 [30],

DiDOPO-3.5/OMMT-3.5 [30],  DiDOPO-0.5/OLDH-0.5, DiDOPO-2.5/OLDH-2.5, DiDOPO-5/OLDH-5 [31],

DiDOPO-0.5/OLDH-0.5, DiDOPO-2.5/OLDH-2.5, DiDOPO-5/OLDH-5 [31],  IFR-40, IFR-39/CES-1, IFR-38/CES-2, IFR-37/CES-3, IFR-35/CES-5 [208],

IFR-40, IFR-39/CES-1, IFR-38/CES-2, IFR-37/CES-3, IFR-35/CES-5 [208],  DOPO-15/P-KC-15, DOPO-20/P-KC-10, DOPO-25/P-KC-5 [41],

DOPO-15/P-KC-15, DOPO-20/P-KC-10, DOPO-25/P-KC-5 [41],  mAPP-5/PER-5, mAPP-5/RCC-5, mAPP-5/ORCC-5 [209],

mAPP-5/PER-5, mAPP-5/RCC-5, mAPP-5/ORCC-5 [209],  PEPA–TMA-12/MCA-6, PEPA–TMA-16/MCA-8, PEPA–TMA-20/MCA-10 [210],

PEPA–TMA-12/MCA-6, PEPA–TMA-16/MCA-8, PEPA–TMA-20/MCA-10 [210],  ZIF8-1/MgAl-LDH-1, ZIF67-1/MgAl-LDH-1 [170],

ZIF8-1/MgAl-LDH-1, ZIF67-1/MgAl-LDH-1 [170],  TAT-18/DOPO-2, TAT-16/DOPO-4, TAT-14/DOPO-6, TAT-12/DOPO-8, TAT-18/HPCP-2, TAT-16/HPCP-4, TAT-14/HPCP-6, TAT-12/HPCP-8 [52],

TAT-18/DOPO-2, TAT-16/DOPO-4, TAT-14/DOPO-6, TAT-12/DOPO-8, TAT-18/HPCP-2, TAT-16/HPCP-4, TAT-14/HPCP-6, TAT-12/HPCP-8 [52],  EDA-APP-19/Cu2O-2 [55],

EDA-APP-19/Cu2O-2 [55],  CP-6B-3/MH-0.5 [56],

CP-6B-3/MH-0.5 [56],  IFR-20, IFR-19.5/HGM-0.5, IFR-19/HGM-1, IFR-18/HGM-2, IFR-16/HGM-4 [211],

IFR-20, IFR-19.5/HGM-0.5, IFR-19/HGM-1, IFR-18/HGM-2, IFR-16/HGM-4 [211],  APP-5/PSA-5 [58],

APP-5/PSA-5 [58],  MFAPP-6.25/PER-6.25, MFAPP-6.25/ST-6.25, MFAPP-6.25/OST-6.25 [212],

MFAPP-6.25/PER-6.25, MFAPP-6.25/ST-6.25, MFAPP-6.25/OST-6.25 [212],  EG-16/DOPO-4, EG-14/DOPO-6, EG-12/DOPO-8, EG-10/DOPO-10, EG-16/HPCP-4, EG-14/HPCP-6, EG-12/HPCP-8, EG-10/HPCP-10 [66],

EG-16/DOPO-4, EG-14/DOPO-6, EG-12/DOPO-8, EG-10/DOPO-10, EG-16/HPCP-4, EG-14/HPCP-6, EG-12/HPCP-8, EG-10/HPCP-10 [66],  TMT-8.3/DOPO-2.7, TMT-8.2/DOPO-4.1, TMT-8.1/DOPO-5.6, TMT-8/DOPO-7 [67],

TMT-8.3/DOPO-2.7, TMT-8.2/DOPO-4.1, TMT-8.1/DOPO-5.6, TMT-8/DOPO-7 [67],  DOPO-3/APHP-3, DOPO-4/APHP-2 [75],

DOPO-3/APHP-3, DOPO-4/APHP-2 [75],  TAD-4/OMMT-1 [77],

TAD-4/OMMT-1 [77],  FR-20/APP-10, FR-15/APP-15, FR-12/APP-18, FR-10/APP-20 [213],

FR-20/APP-10, FR-15/APP-15, FR-12/APP-18, FR-10/APP-20 [213],  ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [89],

ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [89],  ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [90],

ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [90],  APP-4/MMT-6 [93],

APP-4/MMT-6 [93],  DOPO-5/MMT-1 [94],

DOPO-5/MMT-1 [94],  BDP-6.7/PHP-3.3 [95],

BDP-6.7/PHP-3.3 [95],  OPS-2.5/DOPO-2.5 [102],

OPS-2.5/DOPO-2.5 [102],  DOPO-3.1/OPS-2.1, DOPO-3.1/PPSQ-2.1 [103],

DOPO-3.1/OPS-2.1, DOPO-3.1/PPSQ-2.1 [103],  DOPO-3.1/OPS-2.1, DOPO-3.1/OAPS-2.3 [104],

DOPO-3.1/OPS-2.1, DOPO-3.1/OAPS-2.3 [104],  OPS-2.5/DOPO-2.5 [105],

OPS-2.5/DOPO-2.5 [105],  OPS-2.1/PEPA-2.6, OPS-2.1/APP-1.4, OPS-2.1/DOPO-3.1 [106],

OPS-2.1/PEPA-2.6, OPS-2.1/APP-1.4, OPS-2.1/DOPO-3.1 [106],  ODPSS-2.5/DOPO-2.5 [115],

ODPSS-2.5/DOPO-2.5 [115],  BBO-10/PPA-10 [214],

BBO-10/PPA-10 [214],  T8POSS-5/TGIC-5 [174],

T8POSS-5/TGIC-5 [174],  APP-4.83/CoSA-0.17 [117],

APP-4.83/CoSA-0.17 [117],  CBz-8/BGN-2, CBz-13/BGN-2, CBz-18/BGN-2 [118],

CBz-8/BGN-2, CBz-13/BGN-2, CBz-18/BGN-2 [118],  Mel-APP-18/LDH-2, Mel-APP-18/HNT-2 [120],

Mel-APP-18/LDH-2, Mel-APP-18/HNT-2 [120],  oDOPI-17.76/MPP-15, AlO(OH)-30/oDOPI-11.05, MPP-15/PZ-1.54, AlO(OH)-30/PZ-3.08 [124],

oDOPI-17.76/MPP-15, AlO(OH)-30/oDOPI-11.05, MPP-15/PZ-1.54, AlO(OH)-30/PZ-3.08 [124],  AHP-4.5/ACS@SnO2@NiO-0.5 [125],

AHP-4.5/ACS@SnO2@NiO-0.5 [125],  Mel-APP-19.97/Talc-9.73 [126],

Mel-APP-19.97/Talc-9.73 [126],  MPP-10/MPZnP-10, AlPi-Et-10/MPZnP-10, DOPAc-Bu-10/MPZnP-10, AlO(OH)-10/MPZnP-10, MPZnP-10/SiO2-10, MPP-13.4/MPZnP-6.6, AlPi-Et-13.4/MPZnP-6.6, DOPAc-Bu-13.4/MPZnP-6.6, AlO(OH)-13.4/MPZnP-6.6, SiO2-13.4/MPZnP-6.6 [127],

MPP-10/MPZnP-10, AlPi-Et-10/MPZnP-10, DOPAc-Bu-10/MPZnP-10, AlO(OH)-10/MPZnP-10, MPZnP-10/SiO2-10, MPP-13.4/MPZnP-6.6, AlPi-Et-13.4/MPZnP-6.6, DOPAc-Bu-13.4/MPZnP-6.6, AlO(OH)-13.4/MPZnP-6.6, SiO2-13.4/MPZnP-6.6 [127],  HPCTP-10/OGPOSS-5, HPCTP-7.5/OGPOSS-7.5, HPCTP-5/OGPOSS-10 [129],

HPCTP-10/OGPOSS-5, HPCTP-7.5/OGPOSS-7.5, HPCTP-5/OGPOSS-10 [129],  CP-10/TPP-MMT-5 [130],

CP-10/TPP-MMT-5 [130],  CP-10/TPP-MMT-5 [130],

CP-10/TPP-MMT-5 [130],  CP-10/TPP-MMT-5 [130],

CP-10/TPP-MMT-5 [130],  MoS2-1/TNT-1 [176],

MoS2-1/TNT-1 [176],  APP-15/PER-HNT-10 [215],

APP-15/PER-HNT-10 [215],  S600-10/AlPi-10, S600-10/AlO(OH)-10, S600-10/MPP-10 [147],

S600-10/AlPi-10, S600-10/AlO(OH)-10, S600-10/MPP-10 [147],  SDPS-5.2/SPDM-5.2 [136],

SDPS-5.2/SPDM-5.2 [136],  AlPi-4.7/MPP-2.3, AlPi-4.5/MPP-2.25/Al2O3-0.25 [47],

AlPi-4.7/MPP-2.3, AlPi-4.5/MPP-2.25/Al2O3-0.25 [47],  APP-8/CSA-2, APP-7.5/CSA-2.5, APP-6.7/CSA-3.3 [139],

APP-8/CSA-2, APP-7.5/CSA-2.5, APP-6.7/CSA-3.3 [139],  BN 12 μm-33.75/BN 2 μm-11.25, BN 12 μm-33.75/BT 2 μm-11.25 [182],

BN 12 μm-33.75/BN 2 μm-11.25, BN 12 μm-33.75/BT 2 μm-11.25 [182],  IFR-30, IFR-29.5/FeP-0.5, IFR-29/FeP-1, IFR-28/FeP-2, IFR-27/FeP-3 [216],

IFR-30, IFR-29.5/FeP-0.5, IFR-29/FeP-1, IFR-28/FeP-2, IFR-27/FeP-3 [216],  IFR-30, IFR-29.5/αFeOOH-0.5, IFR-29/αFeOOH-1, IFR-28/αFeOOH-2, IFR-27/αFeOOH-3 [217],

IFR-30, IFR-29.5/αFeOOH-0.5, IFR-29/αFeOOH-1, IFR-28/αFeOOH-2, IFR-27/αFeOOH-3 [217],  IFR-30, IFR-29.5/iron oxide brown-0.5, IFR-29/iron oxide brown-1, IFR-28/iron oxide brown-2, IFR-27/iron oxide brown-3 [218],

IFR-30, IFR-29.5/iron oxide brown-0.5, IFR-29/iron oxide brown-1, IFR-28/iron oxide brown-2, IFR-27/iron oxide brown-3 [218],  Ni–Fe LDH-2/GN-2 [193],

Ni–Fe LDH-2/GN-2 [193],  APP-22.5/PER-7.5 [152],

APP-22.5/PER-7.5 [152],  IFR-30, IFR29.5/Fe-OMMT-0.5, IFR-29/Fe-OMMT-1, IFR-28/Fe-OMMT-2, IFR-27/Fe-OMMT-3 [219],

IFR-30, IFR29.5/Fe-OMMT-0.5, IFR-29/Fe-OMMT-1, IFR-28/Fe-OMMT-2, IFR-27/Fe-OMMT-3 [219],  APP-20/I.30E-3 [160],

APP-20/I.30E-3 [160],  Mel-APP-8.59/LDH-0.96, Mel-APP-8.65/HNT-0.96 [120],

Mel-APP-8.59/LDH-0.96, Mel-APP-8.65/HNT-0.96 [120],  Mel-APP-9.93/Talc-4.84 [126],

Mel-APP-9.93/Talc-4.84 [126],  , IFR-5/Vis-5, Ky-5/IFR-5 [163,164],

, IFR-5/Vis-5, Ky-5/IFR-5 [163,164],  ZB-0.5/Mg(OH)2-0.5, ZB-3.75/Mg(OH)2-3.75, ZB-7.5/Mg(OH)2-7.5, ZB-12.5/Mg(OH)2-12.5, ZB-0.5/Al(OH)3-0.5, ZB-3.75/Al(OH)3-3.75, ZB-7.5/Al(OH)3-7.5, ZB-12.5/Al(OH)3-12.5 [205],

ZB-0.5/Mg(OH)2-0.5, ZB-3.75/Mg(OH)2-3.75, ZB-7.5/Mg(OH)2-7.5, ZB-12.5/Mg(OH)2-12.5, ZB-0.5/Al(OH)3-0.5, ZB-3.75/Al(OH)3-3.75, ZB-7.5/Al(OH)3-7.5, ZB-12.5/Al(OH)3-12.5 [205],  MP-4.5/GN-0.5, DOPO-4.5/GN-0.5 [166],

MP-4.5/GN-0.5, DOPO-4.5/GN-0.5 [166],  PFR-25/ZB-5 [220],

PFR-25/ZB-5 [220],  IFR-2.5/Vis-2.5, IFR-2.5/Vis-5, IFR-2.5/Vis-7.5, IFR-2.5/Vis-10, IFR-2.5/Vis-12.5, IFR-5/Vis-2.5, IFR-5/Vis-5, IFR-5/Vis-7.5, IFR-5/Vis-10, IFR-7.5/Vis-2.5, IFR-7.5/Vis-5, IFR-7.5/Vis-7.5, IFR-10/Vis-2.5, IFR-10/Vis-5, IFR-12.5/Vis-2.5, IFR-15/Vis-2.5 [167],

IFR-2.5/Vis-2.5, IFR-2.5/Vis-5, IFR-2.5/Vis-7.5, IFR-2.5/Vis-10, IFR-2.5/Vis-12.5, IFR-5/Vis-2.5, IFR-5/Vis-5, IFR-5/Vis-7.5, IFR-5/Vis-10, IFR-7.5/Vis-2.5, IFR-7.5/Vis-5, IFR-7.5/Vis-7.5, IFR-10/Vis-2.5, IFR-10/Vis-5, IFR-12.5/Vis-2.5, IFR-15/Vis-2.5 [167],  T8POSS-2.5/TGIC-2.5 [174],

T8POSS-2.5/TGIC-2.5 [174],  IFR-2.5/Vis-2.5, IFR-3.75/Vis-3.75, IFR-7.5/Vis-2.5 [221].

IFR-2.5/Vis-2.5, IFR-3.75/Vis-3.75, IFR-7.5/Vis-2.5 [221].

DiDOPO-1.5/GN-1.5 [28],

DiDOPO-1.5/GN-1.5 [28],  DiDOPO-10/MWCNT-0.8 [29],

DiDOPO-10/MWCNT-0.8 [29],  DiDOPO-3.5/OMMT-3.5 [30],

DiDOPO-3.5/OMMT-3.5 [30],  DiDOPO-0.5/OLDH-0.5, DiDOPO-2.5/OLDH-2.5, DiDOPO-5/OLDH-5 [31],

DiDOPO-0.5/OLDH-0.5, DiDOPO-2.5/OLDH-2.5, DiDOPO-5/OLDH-5 [31],  IFR-40, IFR-39/CES-1, IFR-38/CES-2, IFR-37/CES-3, IFR-35/CES-5 [208],

IFR-40, IFR-39/CES-1, IFR-38/CES-2, IFR-37/CES-3, IFR-35/CES-5 [208],  DOPO-15/P-KC-15, DOPO-20/P-KC-10, DOPO-25/P-KC-5 [41],

DOPO-15/P-KC-15, DOPO-20/P-KC-10, DOPO-25/P-KC-5 [41],  mAPP-5/PER-5, mAPP-5/RCC-5, mAPP-5/ORCC-5 [209],

mAPP-5/PER-5, mAPP-5/RCC-5, mAPP-5/ORCC-5 [209],  PEPA–TMA-12/MCA-6, PEPA–TMA-16/MCA-8, PEPA–TMA-20/MCA-10 [210],

PEPA–TMA-12/MCA-6, PEPA–TMA-16/MCA-8, PEPA–TMA-20/MCA-10 [210],  ZIF8-1/MgAl-LDH-1, ZIF67-1/MgAl-LDH-1 [170],

ZIF8-1/MgAl-LDH-1, ZIF67-1/MgAl-LDH-1 [170],  TAT-18/DOPO-2, TAT-16/DOPO-4, TAT-14/DOPO-6, TAT-12/DOPO-8, TAT-18/HPCP-2, TAT-16/HPCP-4, TAT-14/HPCP-6, TAT-12/HPCP-8 [52],

TAT-18/DOPO-2, TAT-16/DOPO-4, TAT-14/DOPO-6, TAT-12/DOPO-8, TAT-18/HPCP-2, TAT-16/HPCP-4, TAT-14/HPCP-6, TAT-12/HPCP-8 [52],  EDA-APP-19/Cu2O-2 [55],

EDA-APP-19/Cu2O-2 [55],  CP-6B-3/MH-0.5 [56],

CP-6B-3/MH-0.5 [56],  IFR-20, IFR-19.5/HGM-0.5, IFR-19/HGM-1, IFR-18/HGM-2, IFR-16/HGM-4 [211],

IFR-20, IFR-19.5/HGM-0.5, IFR-19/HGM-1, IFR-18/HGM-2, IFR-16/HGM-4 [211],  APP-5/PSA-5 [58],

APP-5/PSA-5 [58],  MFAPP-6.25/PER-6.25, MFAPP-6.25/ST-6.25, MFAPP-6.25/OST-6.25 [212],

MFAPP-6.25/PER-6.25, MFAPP-6.25/ST-6.25, MFAPP-6.25/OST-6.25 [212],  EG-16/DOPO-4, EG-14/DOPO-6, EG-12/DOPO-8, EG-10/DOPO-10, EG-16/HPCP-4, EG-14/HPCP-6, EG-12/HPCP-8, EG-10/HPCP-10 [66],

EG-16/DOPO-4, EG-14/DOPO-6, EG-12/DOPO-8, EG-10/DOPO-10, EG-16/HPCP-4, EG-14/HPCP-6, EG-12/HPCP-8, EG-10/HPCP-10 [66],  TMT-8.3/DOPO-2.7, TMT-8.2/DOPO-4.1, TMT-8.1/DOPO-5.6, TMT-8/DOPO-7 [67],

TMT-8.3/DOPO-2.7, TMT-8.2/DOPO-4.1, TMT-8.1/DOPO-5.6, TMT-8/DOPO-7 [67],  DOPO-3/APHP-3, DOPO-4/APHP-2 [75],

DOPO-3/APHP-3, DOPO-4/APHP-2 [75],  TAD-4/OMMT-1 [77],

TAD-4/OMMT-1 [77],  FR-20/APP-10, FR-15/APP-15, FR-12/APP-18, FR-10/APP-20 [213],

FR-20/APP-10, FR-15/APP-15, FR-12/APP-18, FR-10/APP-20 [213],  ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [89],

ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [89],  ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [90],

ATCP-15/FRHA-1, ATCP-15/FRHA-3, ATCP-15/FRHA-5 [90],  APP-4/MMT-6 [93],

APP-4/MMT-6 [93],  DOPO-5/MMT-1 [94],

DOPO-5/MMT-1 [94],  BDP-6.7/PHP-3.3 [95],

BDP-6.7/PHP-3.3 [95],  OPS-2.5/DOPO-2.5 [102],

OPS-2.5/DOPO-2.5 [102],  DOPO-3.1/OPS-2.1, DOPO-3.1/PPSQ-2.1 [103],

DOPO-3.1/OPS-2.1, DOPO-3.1/PPSQ-2.1 [103],  DOPO-3.1/OPS-2.1, DOPO-3.1/OAPS-2.3 [104],

DOPO-3.1/OPS-2.1, DOPO-3.1/OAPS-2.3 [104],  OPS-2.5/DOPO-2.5 [105],

OPS-2.5/DOPO-2.5 [105],  OPS-2.1/PEPA-2.6, OPS-2.1/APP-1.4, OPS-2.1/DOPO-3.1 [106],

OPS-2.1/PEPA-2.6, OPS-2.1/APP-1.4, OPS-2.1/DOPO-3.1 [106],  ODPSS-2.5/DOPO-2.5 [115],

ODPSS-2.5/DOPO-2.5 [115],  BBO-10/PPA-10 [214],

BBO-10/PPA-10 [214],  T8POSS-5/TGIC-5 [174],

T8POSS-5/TGIC-5 [174],  APP-4.83/CoSA-0.17 [117],

APP-4.83/CoSA-0.17 [117],  CBz-8/BGN-2, CBz-13/BGN-2, CBz-18/BGN-2 [118],

CBz-8/BGN-2, CBz-13/BGN-2, CBz-18/BGN-2 [118],  Mel-APP-18/LDH-2, Mel-APP-18/HNT-2 [120],

Mel-APP-18/LDH-2, Mel-APP-18/HNT-2 [120],  oDOPI-17.76/MPP-15, AlO(OH)-30/oDOPI-11.05, MPP-15/PZ-1.54, AlO(OH)-30/PZ-3.08 [124],

oDOPI-17.76/MPP-15, AlO(OH)-30/oDOPI-11.05, MPP-15/PZ-1.54, AlO(OH)-30/PZ-3.08 [124],  AHP-4.5/ACS@SnO2@NiO-0.5 [125],

AHP-4.5/ACS@SnO2@NiO-0.5 [125],  Mel-APP-19.97/Talc-9.73 [126],

Mel-APP-19.97/Talc-9.73 [126],  MPP-10/MPZnP-10, AlPi-Et-10/MPZnP-10, DOPAc-Bu-10/MPZnP-10, AlO(OH)-10/MPZnP-10, MPZnP-10/SiO2-10, MPP-13.4/MPZnP-6.6, AlPi-Et-13.4/MPZnP-6.6, DOPAc-Bu-13.4/MPZnP-6.6, AlO(OH)-13.4/MPZnP-6.6, SiO2-13.4/MPZnP-6.6 [127],

MPP-10/MPZnP-10, AlPi-Et-10/MPZnP-10, DOPAc-Bu-10/MPZnP-10, AlO(OH)-10/MPZnP-10, MPZnP-10/SiO2-10, MPP-13.4/MPZnP-6.6, AlPi-Et-13.4/MPZnP-6.6, DOPAc-Bu-13.4/MPZnP-6.6, AlO(OH)-13.4/MPZnP-6.6, SiO2-13.4/MPZnP-6.6 [127],  HPCTP-10/OGPOSS-5, HPCTP-7.5/OGPOSS-7.5, HPCTP-5/OGPOSS-10 [129],

HPCTP-10/OGPOSS-5, HPCTP-7.5/OGPOSS-7.5, HPCTP-5/OGPOSS-10 [129],  CP-10/TPP-MMT-5 [130],

CP-10/TPP-MMT-5 [130],  CP-10/TPP-MMT-5 [130],

CP-10/TPP-MMT-5 [130],  CP-10/TPP-MMT-5 [130],

CP-10/TPP-MMT-5 [130],  MoS2-1/TNT-1 [176],

MoS2-1/TNT-1 [176],  APP-15/PER-HNT-10 [215],

APP-15/PER-HNT-10 [215],  S600-10/AlPi-10, S600-10/AlO(OH)-10, S600-10/MPP-10 [147],

S600-10/AlPi-10, S600-10/AlO(OH)-10, S600-10/MPP-10 [147],  SDPS-5.2/SPDM-5.2 [136],

SDPS-5.2/SPDM-5.2 [136],  AlPi-4.7/MPP-2.3, AlPi-4.5/MPP-2.25/Al2O3-0.25 [47],

AlPi-4.7/MPP-2.3, AlPi-4.5/MPP-2.25/Al2O3-0.25 [47],  APP-8/CSA-2, APP-7.5/CSA-2.5, APP-6.7/CSA-3.3 [139],

APP-8/CSA-2, APP-7.5/CSA-2.5, APP-6.7/CSA-3.3 [139],  BN 12 μm-33.75/BN 2 μm-11.25, BN 12 μm-33.75/BT 2 μm-11.25 [182],

BN 12 μm-33.75/BN 2 μm-11.25, BN 12 μm-33.75/BT 2 μm-11.25 [182],  IFR-30, IFR-29.5/FeP-0.5, IFR-29/FeP-1, IFR-28/FeP-2, IFR-27/FeP-3 [216],

IFR-30, IFR-29.5/FeP-0.5, IFR-29/FeP-1, IFR-28/FeP-2, IFR-27/FeP-3 [216],  IFR-30, IFR-29.5/αFeOOH-0.5, IFR-29/αFeOOH-1, IFR-28/αFeOOH-2, IFR-27/αFeOOH-3 [217],

IFR-30, IFR-29.5/αFeOOH-0.5, IFR-29/αFeOOH-1, IFR-28/αFeOOH-2, IFR-27/αFeOOH-3 [217],  IFR-30, IFR-29.5/iron oxide brown-0.5, IFR-29/iron oxide brown-1, IFR-28/iron oxide brown-2, IFR-27/iron oxide brown-3 [218],

IFR-30, IFR-29.5/iron oxide brown-0.5, IFR-29/iron oxide brown-1, IFR-28/iron oxide brown-2, IFR-27/iron oxide brown-3 [218],  Ni–Fe LDH-2/GN-2 [193],

Ni–Fe LDH-2/GN-2 [193],  APP-22.5/PER-7.5 [152],

APP-22.5/PER-7.5 [152],  IFR-30, IFR29.5/Fe-OMMT-0.5, IFR-29/Fe-OMMT-1, IFR-28/Fe-OMMT-2, IFR-27/Fe-OMMT-3 [219],

IFR-30, IFR29.5/Fe-OMMT-0.5, IFR-29/Fe-OMMT-1, IFR-28/Fe-OMMT-2, IFR-27/Fe-OMMT-3 [219],  APP-20/I.30E-3 [160],

APP-20/I.30E-3 [160],  Mel-APP-8.59/LDH-0.96, Mel-APP-8.65/HNT-0.96 [120],

Mel-APP-8.59/LDH-0.96, Mel-APP-8.65/HNT-0.96 [120],  Mel-APP-9.93/Talc-4.84 [126],

Mel-APP-9.93/Talc-4.84 [126],  , IFR-5/Vis-5, Ky-5/IFR-5 [163,164],

, IFR-5/Vis-5, Ky-5/IFR-5 [163,164],  ZB-0.5/Mg(OH)2-0.5, ZB-3.75/Mg(OH)2-3.75, ZB-7.5/Mg(OH)2-7.5, ZB-12.5/Mg(OH)2-12.5, ZB-0.5/Al(OH)3-0.5, ZB-3.75/Al(OH)3-3.75, ZB-7.5/Al(OH)3-7.5, ZB-12.5/Al(OH)3-12.5 [205],

ZB-0.5/Mg(OH)2-0.5, ZB-3.75/Mg(OH)2-3.75, ZB-7.5/Mg(OH)2-7.5, ZB-12.5/Mg(OH)2-12.5, ZB-0.5/Al(OH)3-0.5, ZB-3.75/Al(OH)3-3.75, ZB-7.5/Al(OH)3-7.5, ZB-12.5/Al(OH)3-12.5 [205],  MP-4.5/GN-0.5, DOPO-4.5/GN-0.5 [166],

MP-4.5/GN-0.5, DOPO-4.5/GN-0.5 [166],  PFR-25/ZB-5 [220],

PFR-25/ZB-5 [220],  IFR-2.5/Vis-2.5, IFR-2.5/Vis-5, IFR-2.5/Vis-7.5, IFR-2.5/Vis-10, IFR-2.5/Vis-12.5, IFR-5/Vis-2.5, IFR-5/Vis-5, IFR-5/Vis-7.5, IFR-5/Vis-10, IFR-7.5/Vis-2.5, IFR-7.5/Vis-5, IFR-7.5/Vis-7.5, IFR-10/Vis-2.5, IFR-10/Vis-5, IFR-12.5/Vis-2.5, IFR-15/Vis-2.5 [167],

IFR-2.5/Vis-2.5, IFR-2.5/Vis-5, IFR-2.5/Vis-7.5, IFR-2.5/Vis-10, IFR-2.5/Vis-12.5, IFR-5/Vis-2.5, IFR-5/Vis-5, IFR-5/Vis-7.5, IFR-5/Vis-10, IFR-7.5/Vis-2.5, IFR-7.5/Vis-5, IFR-7.5/Vis-7.5, IFR-10/Vis-2.5, IFR-10/Vis-5, IFR-12.5/Vis-2.5, IFR-15/Vis-2.5 [167],  T8POSS-2.5/TGIC-2.5 [174],

T8POSS-2.5/TGIC-2.5 [174],  IFR-2.5/Vis-2.5, IFR-3.75/Vis-3.75, IFR-7.5/Vis-2.5 [221].

IFR-2.5/Vis-2.5, IFR-3.75/Vis-3.75, IFR-7.5/Vis-2.5 [221].

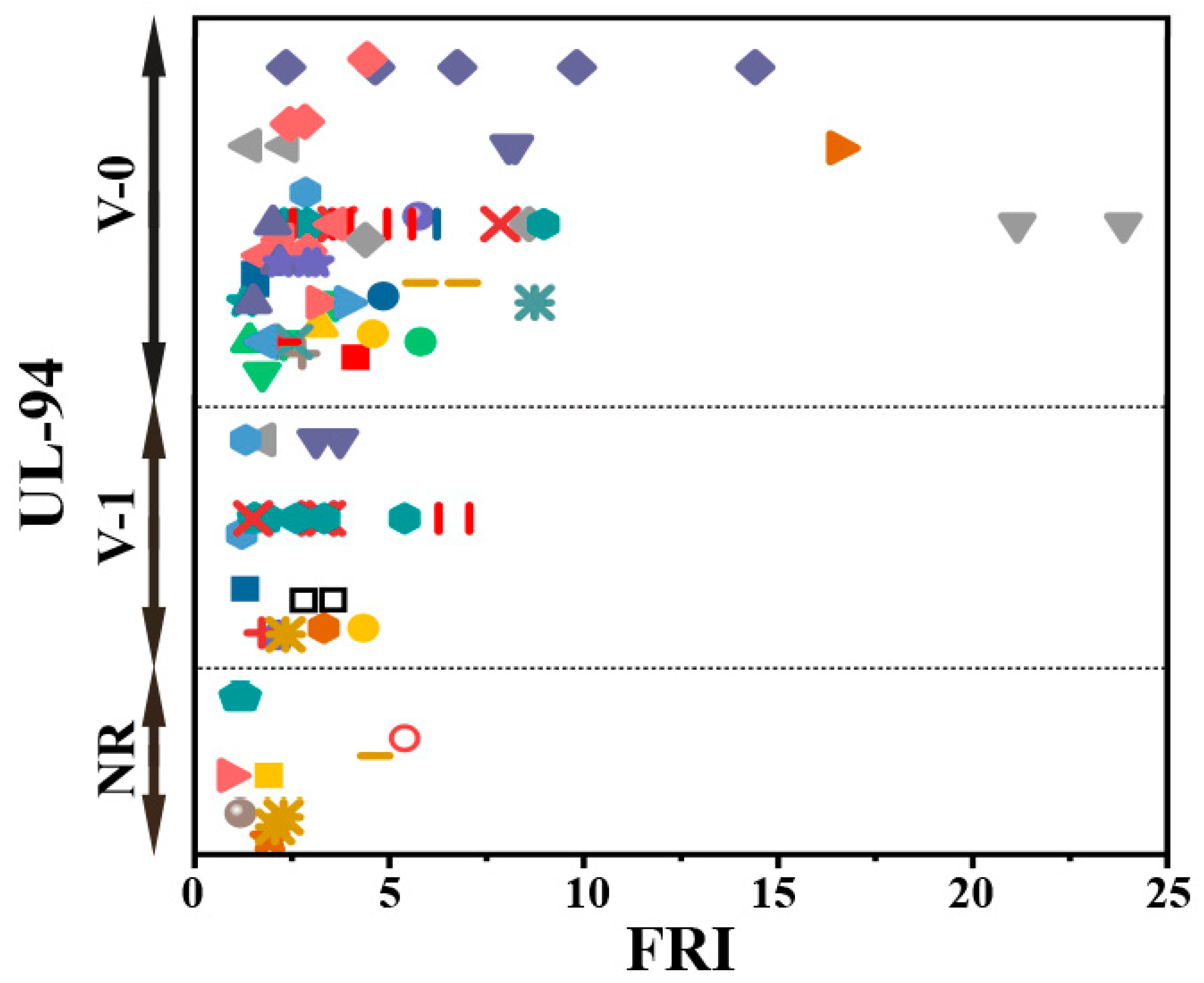

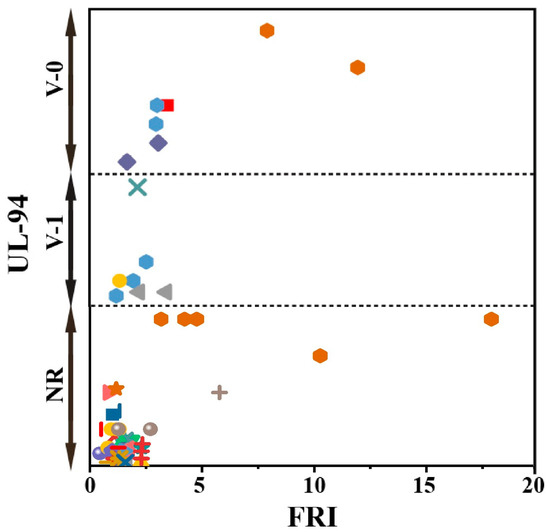

When looking at the UL-94 test results (considering the fact that there were some data in Table 3 for some systems to be plotted and discussed in Figure 8), it can be seen that, except for some data, the whole systems take Poor and Good labels based on FRI values. It is also interesting to note that for a given category, e.g., V-0, the amount of additive changes the FRI, and UL-94 testing does not make sense of such variations.

Figure 8.

Flame retardancy analysis of epoxy resins containing combinatorial flame retardants in terms of the FRI values as a function of UL-94 test results. Symbols are indicative of different types of combinatorial flame retardants used. Hollow symbols are indicative of fiber-incorporated composites with details given in the bottom of Table 1 as a to i notes. The vertical variation in each category, i.e., V-0, V-1, and NR, is schematically representative of the amount of additive used. For example, two data distinguished by different symbols have the same or very close FRI values (horizontal quantity) in a given category (e.g., V-1), but higher V-1 behavior in UL-94 testing means the FR was used in greater quantity.

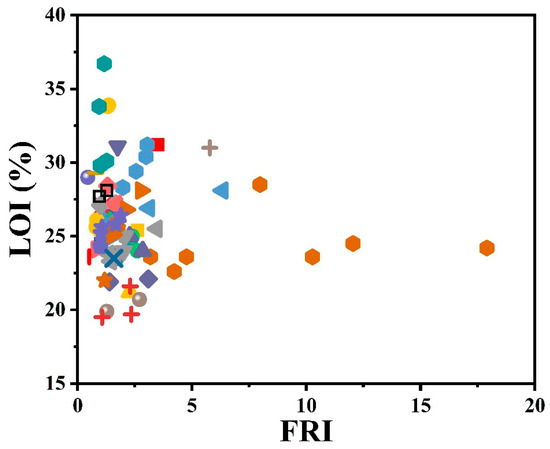

The more interesting outcome of this work is that LOI percent similarly detects Poor and Good behaviors, not principally Excellent performance (Figure 9). This suggests that development of innovative FR additives by combination of P and NP and using highly efficient synthesis routes is the essential step to be taken in the near future for developing flame retardant epoxy composites.

Figure 9.

Flame retardancy analysis of epoxy resins containing combinatorial flame-retardant systems in terms of the FRI values as a function of LOI test results. Symbols are indicative of different types of combinatorial flame-retardant systems used. Hollow symbols are indicative of fiber-incorporated composites with details given in the bottom of Table 1 as notes a to i.

5. Concluding Remarks and Future Perspective

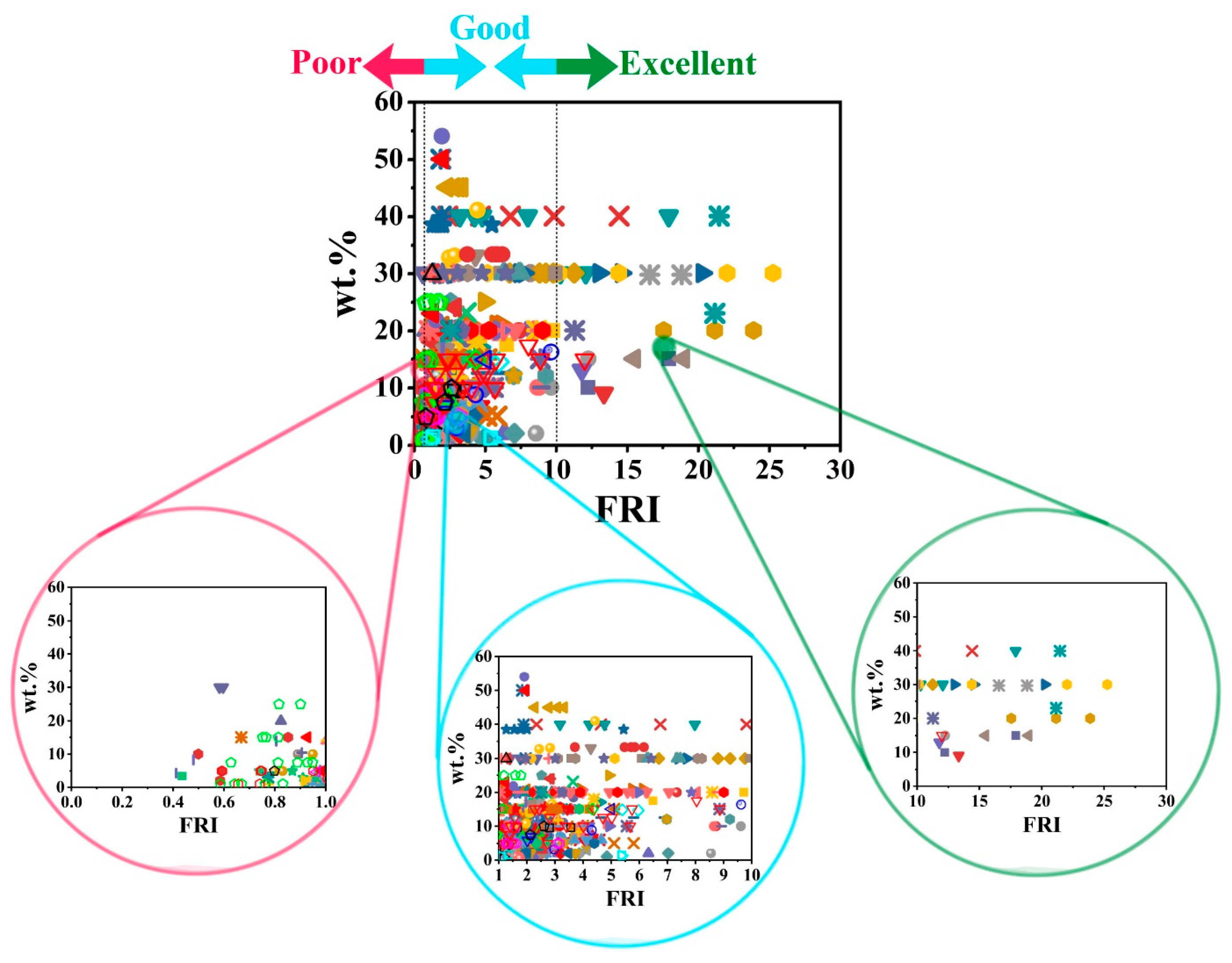

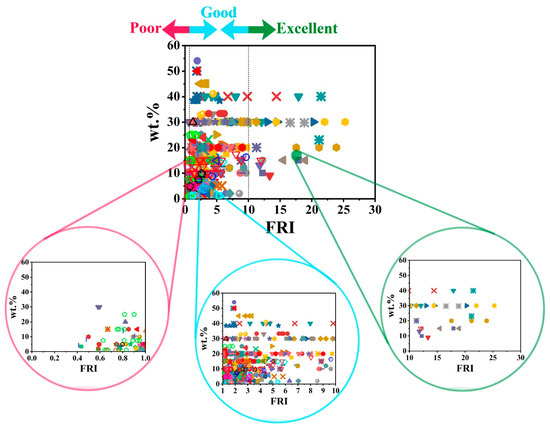

In previous sections, we categorized the flame-retardant properties of epoxy resins in terms of the universal FRI criterion and the content of flame retardants of three families. We also attempted to find possible correlations between cone calorimetry (reflected in FRI variations), UL-94, and LOI analyses. Since cone calorimetry is the best way to simulate real state combustion of polymers, here, we give a general picture of flame retardancy of epoxy resins (Figure 10). The Poor, Good, or Excellent flame retardancy cases are the result of the P, NP, or P/NP types of flame retardants used in preparation of epoxy composites as well as the FR loading. Each kind of behavior can be visualized by providing a full snapshot of the Poor, Good, and Excellent regions of the FRI to see how closely the data are collected in each zone. Overall, it can be seen that Poor and Good are the cases for majority of data, while the Excellent zone contains limited data. This highlights the difficulty of achieving high flame-retardant efficiency in epoxy composites when merely using flame retardants. Thus, development of innovative flame retardants through blending different FR families and making them reactive towards epoxy may result in a fully cured 3D network with high flame resistance. This requires the knowledge and experience of chemists and engineers who can adjust the performance of the system in a very disciplined manner. Moreover, using bio-based epoxy resins with limited environmental threats would be another solution to the question of “which FR additive(s) meet the requirements of highly flame-retardant epoxy composites?”.

Figure 10.

Overall flame retardancy behavior of epoxy resins regardless of the type of flame retardant. Poor, Good, and Excellent efficiencies are magnified to give a close-up of the data distribution.

Author Contributions

Conceptualization, H.V. and M.R.S.; methodology, H.V. and M.R.S.; validation, H.V. and M.R.S.; investigation, E.M., H.V. and M.R.S.; data curation, E.M.; writing—original draft preparation, H.V. and M.R.S.; writing—review and editing H.V., S.T. and M.R.S.; visualization, H.V., S.T. and M.R.S.; supervision, H.V., S.T. and M.R.S.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Tan, S.; Chow, W. Biobased epoxidized vegetable oils and its greener epoxy blends: A review. Polym. Plast. Technol. Eng. 2010, 49, 1581–1590. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xing, W.; Lu, H.; Lv, P.; Jie, G. Flame retardancy and thermal degradation mechanism of epoxy resin composites based on a DOPO substituted organophosphorus oligomer. Polymer 2010, 51, 2435–2445. [Google Scholar] [CrossRef]

- Ahmadi, Z. Epoxy in nanotechnology: A short review. Prog. Org. Coat. 2019, 132, 445–448. [Google Scholar] [CrossRef]

- Ahmadi, Z. Nanostructured epoxy adhesives: A review. Prog. Org. Coat. 2019, 135, 449–453. [Google Scholar] [CrossRef]

- Manouchehri, S.; Bagheri, B.; Rad, S.H.; Nezhad, M.N.; Kim, Y.C.; Park, O.O.; Farokhi, M.; Jouyandeh, M.; Ganjali, M.R.; Yazdi, M.K.; et al. Electroactive bio-epoxy incorporated chitosan-oligoaniline as an advanced hydrogel coating for neural interfaces. Prog. Org. Coat. 2019, 131, 389–396. [Google Scholar] [CrossRef]

- Wu, K.; Song, L.; Hu, Y.; Lu, H.; Kandola, B.K.; Kandare, E. Synthesis and characterization of a functional polyhedral oligomeric silsesquioxane and its flame retardancy in epoxy resin. Prog. Org. Coat. 2009, 65, 490–497. [Google Scholar] [CrossRef]

- Levchik, S.V.; Weil, E.D. Thermal decomposition, combustion and flame-retardancy of epoxy resins—A review of the recent literature. Polym. Int. 2004, 53, 1901–1929. [Google Scholar] [CrossRef]

- Liu, S.; Yu, B.; Feng, Y.; Yang, Z.; Yin, B. Synthesis of a multifunctional bisphosphate and its flame retardant application in epoxy resin. Polym. Degrad. Stab. 2019, 165, 92–100. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S. A review of current flame retardant systems for epoxy resins. J. Fire Sci. 2004, 22, 25–40. [Google Scholar] [CrossRef]

- Rad, E.R.; Vahabi, H.; de Anda, A.R.; Saeb, M.R.; Thomas, S. Bio-epoxy resins with inherent flame retardancy. Prog. Org. Coat. 2019, 135, 608–612. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Song, L.; Yu, B.; Shi, Y.; Yang, W.; Hu, Y. Flame retardancy and thermal properties of novel UV-curing epoxy acrylate coatings modified by phosphorus-containing hyperbranched macromonomer. J. Polym. Res. 2013, 20, 165. [Google Scholar] [CrossRef]

- Vahabi, H.; Saeb, M.R.; Formela, K.; Cuesta, J.-M.L. Flame retardant epoxy/halloysite nanotubes nanocomposite coatings: Exploring low-concentration threshold for flammability compared to expandable graphite as superior fire retardant. Prog. Org. Coat. 2018, 119, 8–14. [Google Scholar] [CrossRef]

- Vahabi, H.; Raveshtian, A.; Fasihi, M.; Sonnier, R.; Saeb, M.R.; Dumazert, L.; Kandola, B.K. Competitiveness and synergy between three flame retardants in poly (ethylene-co-vinyl acetate). Polym. Degrad. Stab. 2017, 143, 164–175. [Google Scholar] [CrossRef]

- Battig, A.; Markwart, J.C.; Wurm, F.R.; Schartel, B. Hyperbranched phosphorus flame retardants: Multifunctional additives for epoxy resins. Polym. Chem. 2019, 10, 4346–4358. [Google Scholar] [CrossRef]

- Zou, B.; Qiu, S.; Ren, X.; Zhou, Y.; Zhou, F.; Xu, Z.; Zhao, Z.; Song, L.; Hu, Y.; Gong, X. Combination of black phosphorus nanosheets and MCNTs via phosphoruscarbon bonds for reducing the flammability of air stable epoxy resin nanocomposites. J. Hazard. Mater. 2019, 383, 121069. [Google Scholar] [CrossRef]

- Mu, X.; Wang, D.; Pan, Y.; Cai, W.; Song, L.; Hu, Y. A facile approach to prepare phosphorus and nitrogen containing macromolecular covalent organic nanosheets for enhancing flame retardancy and mechanical property of epoxy resin. Compos. Part B Eng. 2019, 164, 390–399. [Google Scholar] [CrossRef]

- Duan, H.; Chen, Y.; Ji, S.; Hu, R.; Ma, H. A novel phosphorus/nitrogen-containing polycarboxylic acid endowing epoxy resin with excellent flame retardance and mechanical properties. Chem. Eng. J. 2019, 375, 121916. [Google Scholar] [CrossRef]

- Li, S.; Zhao, X.; Liu, X.; Yang, X.; Yu, R.; Zhang, Y.; Huang, W.; Deng, K. Cage–ladder-structure, phosphorus-containing polyhedral oligomeric silsesquinoxanes as promising reactive-type flame retardants for epoxy resin. J. Appl. Polym. Sci. 2019, 136, 47607. [Google Scholar] [CrossRef]

- Jouyandeh, M.; Rahmati, N.; Movahedifar, E.; Hadavand, B.S.; Karami, Z.; Ghaffari, M.; Taheri, P.; Bakhshandeh, E.; Vahabi, H.; Ganjali, M.R.; et al. Properties of nano-Fe3O4 incorporated epoxy coatings from Cure Index perspective. Prog. Org. Coat. 2019, 133, 220–228. [Google Scholar] [CrossRef]

- Jouyandeh, M.; Paran, S.M.R.; Jannesari, A.; Saeb, M.R. ‘Cure Index’ for thermoset composites. Prog. Org. Coat. 2019, 127, 429–434. [Google Scholar] [CrossRef]

- Vahabi, H.; Kandola, B.K.; Saeb, M.R. Flame retardancy index for thermoplastic composites. Polymers 2019, 11, 407. [Google Scholar] [CrossRef] [PubMed]