Cold Spray for Additive Manufacturing and Remanufacturing Applications

A special issue of Coatings (ISSN 2079-6412). This special issue belongs to the section "Functional Polymer Coatings and Films".

Deadline for manuscript submissions: 25 January 2026 | Viewed by 3347

Special Issue Editors

Interests: coatings; cold spray; additive manufacturing; tribological properties

Special Issues, Collections and Topics in MDPI journals

Interests: interface control and strengthening mechanisms of metal matrix composites; preparation and characterization of thermal spray coatings; development of advanced biomaterials and energy materials

Special Issue Information

Dear Colleagues,

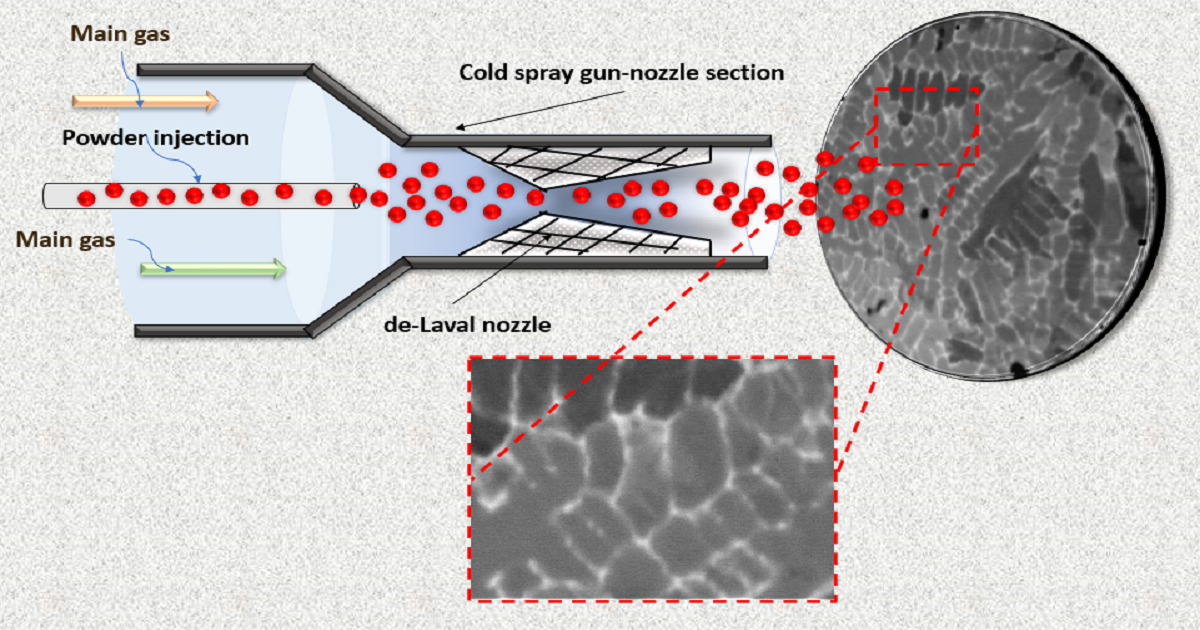

Cold Spray technology, a solid-state deposition process where particles are accelerated to supersonic velocities and bonded upon impact with a substrate, has gained significant traction in recent years. Originally developed for corrosion and wear-resistant coatings, Cold Spray has now emerged as a critical technique in the fields of additive manufacturing (AM) and remanufacturing. Unlike traditional thermal spray methods, Cold Spray operates at lower temperatures, preserving the inherent properties of feedstock materials and reducing thermal stresses. This unique characteristic makes it an ideal candidate for fabricating near-net-shape components and repairing high-value parts in industries ranging from aerospace to biomedicine.

The aim of this Special Issue is to compile cutting-edge research and advancements in the application of Cold Spray technology for additive manufacturing and remanufacturing. This compilation will provide a comprehensive overview of the current state of the art, highlight innovative approaches, and identify future directions for research and industrial applications. This Special Issue will serve as a valuable resource for researchers, engineers, and practitioners in the field, facilitating knowledge exchange and fostering collaboration. We are pleased to invite you to submit contributions from academia and industry, and researchers are encouraged to submit original research articles, review papers, and case studies that provide valuable insights into and advancements in the field of Cold Spray technology for additive manufacturing and remanufacturing applications.

The scope of this Special Issue cover, but is not limited to, the following topics:

- Novel Cold Spray materials and techniques for additive manufacturing;

- Cold Spray technology’s applications in surface repair, surface enhancement, functional coatings, and additive manufacturing in many fields, including the aerospace, armament, energy and power, electronic power, and medical equipment industries;

- Unique attributes of Cold Spray, such as a high deposition rate, high adhesion strength, solid-state bonding at low temperatures, etc.;

- The integration of artificial intelligence (AI) technology with Cold Spray helps to better realize toolpath and process optimization, as well as process control for industrial production campaigns;

- Cold Spray repair and remanufacturing of worn or damaged components;

- Characterization and testing of Cold-Sprayed components for additive manufacturing and remanufacturing applications;

- Challenges and opportunities related to implementing Cold Spray technology for additive manufacturing and remanufacturing.

We look forward to receiving your contributions.

Dr. Wen Sun

Dr. Ruitao Li

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Coatings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- cold spray additive manufacturing

- cold spray remanufacturing

- cold spray repair and restoration

- cold spray fundamentals

- cold spray of novel and functional materials

- artificial intelligence in cold spray

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.

Further information on MDPI's Special Issue policies can be found here.