Abstract

In this study, a Life Cycle Assessment (LCA) was conducted to evaluate the environmental impact of osmotically dehydrated, fresh-cut, pre-packaged potatoes compared to conventional untreated ones. The case study focused on a small processing line in Naxos Island, Greece, aiming to extend shelf-life by up to 5 days. The analysis covered the full value chain, from cultivation to household consumption, considering changes in energy and material use, transport volumes, waste generation, and cultivation demand. Three scenarios were assessed: (i) conventional untreated potatoes, (ii) dehydrated potatoes using market glycerol, and (iii) dehydrated potatoes using glycerol from vegetable oil treatment. Systems and life cycle inventories (LCI) were modelled in OpenLCA v2.4 software with the ecoinvent v3.11 database, applying the Environmental Footprint (EF) method, v3.1. The selected impact categories included the following: global warming potential, water use, freshwater ecotoxicity, freshwater and marine eutrophication, energy resource use, particulate matter formation, and acidification. Results showed that applying osmotic dehydration (OD) improved environmental performance in most, but not all, categories. When market glycerol was used, some burdens increased due to glycerol production. However, using glycerol from vegetable oil treatment resulted in reductions of 25.8% to 54.9% across all categories compared to the conventional scenario. Overall, OD with alternative glycerol proved to be the most environmentally beneficial approach.

1. Introduction

The market for pre-packaged fruit and vegetable products has experienced rapid growth in recent years, primarily due to their convenience and the resulting increase in consumer demand. In 2023, the market size was estimated at 29.16 USD billion, with projections estimating it reaching 42.2 USD billion by 2032 at a CAGR of 4.41% [1].

One such product on the market is fresh-cut, pre-packaged potatoes, typically intended for frying. The market size of fresh-cut or uncut potato products results in considerable waste generation. According to De Laurentis et al., approximately 12.3% of the edible portion of fresh potatoes purchased from households ends up as waste [2]. The respective ratio for food services was estimated by Beretta et al. at 16.6% [3]. For retailers, Caldeira et al. estimated a 2% loss of fresh potatoes, which can be mostly attributed to general quality degradation [4]. Respective waste for fresh-cut pre-packaged potato products can be even greater, as the peeling and cutting of potatoes considerably shortens their shelf-life. In addition, a significant mass percentage of potatoes cultivated ends up as waste at the cultivation, wholesaler, and processing stages, with Miller et al. estimating these losses to be as much as 25.3%, 4.9%, and 13.5% of the mass of cultivated potatoes, respectively, a total of 43.7% [5] and Mouroun et al. suggesting 26%, 6%, and 12%, respectively, as well as a 2% loss during the serving of a final French fries product [6].

Given the large and growing market size of fresh-cut potatoes, such percentages translate to tonnes of food waste with environmental, economic, and societal implications. From an environmental perspective, increased waste leads to greater demand for municipal waste collection and treatment services, as well as a higher direct impact due to the decomposition of organic matter in landfills and the generation of Greenhouse Gases (GHG), such as methane. Indirectly, large volumes of edible food waste lead to overcultivation and overproduction, which significantly increases the environmental impact across the entire value chain. From an economic perspective, edible food waste generation by households, food services, and retailers represent a direct financial loss for all stakeholders and is increasingly vulnerable to inflation. In addition, inefficient consumption can result in fluctuating and unpredictable demand patterns which can potentially disrupt the entire value chain. From a societal perspective, avoidable food waste could be redirected to support food-insecure groups before being discarded. Reduction and/or repurposing food waste is a key target in European and international sustainability goals, including the Sustainable Development Goal 2 and 12, the U.S. Food Loss and Waste 2030 Champion program, and the Waste and Resources Action Program (WRAP) in UK [7,8,9]. To effectively address these challenges, producers need to adopt novel approaches to prevent quality degradation and extend the shelf-life of their products.

Quality degradation in fresh-cut potatoes occurs primarily due to “browning” of the flesh after cutting, affecting their appearance, taste, nutritional value, and more [10,11]. This colour change in potatoes is caused by the enzymatically catalysed oxidation of phenolic compounds into dark-coloured polymeric compounds, known as melanins. Preventing browning requires inhibiting enzyme activity during the initial stages of the enzymatic reaction, as well as removing oxygen from the potato’s cut surface, as browning is an oxidative reaction.

Several technologies have been developed or studied to extend the shelf-life of freshcut potatoes such as the application of non-thermal technologies and edible coatings [12]. Tsakiri-Mantzorou et al. examined the application of edible coatings with encapsulated antimicrobial and antibrowning agents via the emerging electrospinning process and conventional spray drying on both the quality and shelf-life of fresh-cut potatoes [13]. The study examined the extraction of polysaccharides from potato peels using ultrasound/microwave-assisted extraction (UAE/MAE), optimized via central composite design (CCD) and response surface methodology (RSM). UAE yielded the highest starch recovery (216.55 ± 10.37 mg amylose/g of potato peel). The edible coatings were formulated using a blend of starch, pectin, and chitosan. Rosemary essential oil and ascorbic acid were chosen for their antimicrobial and antioxidant properties and incorporated either in free form or encapsulated using spray drying (SP) and electrospinning (EL). Over a 14-day storage period at 4 °C, the coated potato samples showed enhanced visual quality, reduced browning and enzymatic activity, less weight loss, improved texture, and decreased microbial counts relative to untreated samples. Coatings based on potato starch and pectin containing encapsulated rosemary essential oil and ascorbic acid proved most effective in suppressing browning and microbial growth [13].

Osmotic dehydration (OD) is another effective approach which has been also studied, standalone or in combination with other techniques. Katsouli et al. examined the shelf-life enhancement of fresh-cut potatoes through the application of pulsed electric fields (PEF) and high-pressure (HP) treatments prior to the OD [10]. The study examined the effect of different PEF, HP, and OD conditions and concluded that treatments with PEF at 0.5 kV/cm, 200 pulses or HP at 400 MPa for 1 min prior to OD at 35 °C for 120 min improved both texture and colour retention. The study also examined the addition of antibrowning agents such as ascorbic acid and papain to the osmotic solution. Combining PEF or HP with OD and antibrowning agents improved both quality and microbial stability during refrigerated storage. Untreated potatoes showed colour degradation and microbial growth by the second and sixth day of storage, respectively, while pre-treated potatoes maintained colour and microbiological stability after six days of storage [10].

Dermesonlouoglou et al. also examined the effect of PEF in combination with OD on modified-atmosphere-packaged (MAP) fresh-cut and fried potatoes [11]. Fresh-cut potato strips from Naxos Island in Greece were osmotically dehydrated using a solution containing 20% glycerol, 5% sodium chloride, and 1% ascorbic acid at 35 °C for 120 min. The treated and untreated samples were packaged in MAP (0.2% O2 + 12% CO2) and stored at 4, 8, and 12 °C. Colour, texture, sensory characteristics, and microbial stability were monitored during storage. After opening the packages, the samples were deep-fried at 180 °C for up to 8 min, and the oil content in the fries was quantified. Sensory evaluation was conducted for both raw and fried samples. Untreated potatoes showed colour degradation starting on the third day of storage at 4 °C and microbial growth by day six. Pre-treated potatoes maintained colour and microbiological stability for up to 15 and 18 days of storage, respectively. OD pre-treatment also reduced oil uptake during frying by up to 30% [11].

Mari et al. also examined the effect of OD and ohmic heating (OH) for browning mitigation and shelf-life extension [14]. OD was optimized by adjusting solution concentration and immersion time, while OH parameters were fine-tuned by adjusting electric field strength and heating duration, guided by the response surface methodology (RSM) and full factorial design. Treated potato samples were evaluated in terms of weight loss, colour retention, enzyme activity, microbial stability, and sensory quality. OD proved most effective, achieving low weight loss (5.2%), minimal discoloration, a 50% reduction in polyphenol oxidase (PPO) activity, and a 3 log CFU/g reduction in microbial load. OH, while less effective in preservation, delivered the highest sensory scores (acceptability score of 8.5). The combination of OD with OH did not enhance product quality [14].

The aforementioned studies indicate that OD is one of the most effective approaches, while other techniques may support OD but not fully substitute it. The fact that OD, even as a standalone method, can enhance product quality and extend shelf-life to a degree comparable to more complex methods—combined with its relatively simple equipment and operational requirements—makes it a particular attractive approach, especially for smaller businesses with limited resources or technical expertise.

When assessing the value of novel processing approaches, addressing the potential environmental impact is essential. The environmental impact of potatoes and potato products has been extensively studied but mostly in terms of cultivation and different cultivation methods, which is arguably the most significant factor [15,16]. In addition, studies have examined the food waste generated at different stages of the production of potato products; however, these studies are rarely linked with Life Cycle Assessment (LCA). A common approach to integrating food loss/waste in LCA studies has not yet been developed, leading to the adoption of different approaches that can lead to non-comparable results [17].

Mouron et al. examined the environmental profile of the Swiss supply chain for French fries and the effect of food loss reduction, treatment, and process modification in an analysis covering cultivation to frying [6]. The analysis examined both treatment and aversion of losses and concluded that both the impact related to losses and the effect of the treatment or aversion on said impact was not that drastic, especially for the latter. That conclusion, however, can be attributed to the low losses considered in the overall value chain. Specifically, the study considered no losses at retailers, and only 2% losses for households during serving; the analysis excluded the potential losses related to expiration (or quality degradation in general) before the product is sold or consumed in retailers and households, respectively. When accounted, the overall losses can be significantly higher, increasing the environmental impact due to overcultivation and larger volumes of organic and plastic (packaging) waste that must be processed.

In general, underestimation of potential food waste does not accurately depict the environmental potential of approaches that effectively prevent quality degradation. Overall, to the best of our knowledge, a number of studies have examined the potential food losses of potatoes at retailers and households, others have examined the effect of shelf-life extension in said losses, but few studies have coupled these analyses under an LCA to estimate the environmental benefits of waste reduction. One such example is the study conducted by Parajuli et al., where the potential losses on each stage of the examined potato products in the value chain were addressed when conducting an LCA [18]. The study compared fresh potatoes, chips, frozen fries, and dehydrated flakes and estimated that, for the latter, waste from retailers and consumers was reduced from 0.16 kg/kg to 0.09 kg/kg and 0.24 kg/kg to 0.18 kg/kg, respectively, compared to fresh potatoes. Consequently, the environmental impact of dehydrated potato was lower, indicating 0.65 kg CO2 eq. for Global Warming Potential (GWP100) compared to 0.97 kg CO2 eq. The study did not focus on the effect of shelf-life extension on waste generation in detail. It is also notable that the functional unit (FU) for all products examined was 1 kg of product, despite the possibility of these products having different values (nutritious or calorific) and thus functionality.

In this study, an LCA was conducted to evaluate the environmental impact of osmotically dehydrated fresh-cut, pre-packaged potatoes, intended for frying, and to compare it to conventional, untreated fresh-cut potatoes. For the dehydrated potatoes, both the use of market glycerol and glycerol from the treatment of used vegetable cooling oil were examined. The case study selected was a small processing line located in Naxos Island in Greece, where OD was examined and applied in the scope of the national project “Fresh4ever”, estimating the enhancement of the product’s shelf-life by up to 5 more days, which was especially valuable for the product intended for retailers in mainland Greece (Athens) [19]. The information on the infrastructure and operations was provided by the processing line operators. The analysis considered all stages of the product’s value chain, from the cultivation of potato tubers to the consumption at households, and examined all the different results of OD application, including the increased energy and material (additives and water) demand of the processing line, the difference in product volumes transported to retailers, the reduction of waste due to the enhanced shelf-life, the difference in energy requirements for storage, and the difference in raw potato tubers required.

2. Materials and Methods

2.1. The LCA Methodology

The LCA was conducted according to the standardized methodology proposed by ISO14040:2006 and 14044:2006 and the International Life Cycle Data (ILCD) Handbook [20,21,22]. LCA considers the entire life cycle of a product, from raw material extraction and acquisition to energy and material production and manufacturing to use and end of life treatment and final disposal [20,21,22]. According to these standards, the LCA studies comprise four phases, including (1) the goal and scope definition, (2) the Life Cycle Inventory analysis (LCI), (3) the Life Cycle Impact Assessment (LCIA), and (4) the result’s interpretation.

2.2. Goal of the Study

The goal of the LCA was to evaluate the environmental impact of osmotically dehydrated fresh-cut, pre-packaged potatoes, intended for frying, and compare it to conventional, untreated fresh-cut potatoes. For the dehydrated cut potatoes, both the use of market glycerol and glycerol recovered from the treatment of used vegetable cooking oil were examined. The LCA aimed to assess the sustainability potential of introducing OD in the fresh-cut potato supply chain by (i) evaluating potential reductions in food waste and associated cultivation demands; (ii) considering extended shelf-life and nutritional concentration, and (iii) comparing environmental trade-offs from additional processing steps and glycerol sourcing. This study did not aim to make comparative assertions intended for public disclosure. The results are intended solely for scientific research purposes. Extended lifespans and reduced wastes suggest a reduction in cultivation and processing volume requirements; however, the dehydration of potatoes results in significant weight loss, suggesting higher raw potato tuber requirements for the packaging of the same amount of product. However, the reduction of waste is expected to reduce the raw potato tuber requirements on the basis of the same quantity consumed at households. In addition, the new dehydrated product had a significantly higher dry matter content, suggesting lesser volumes needed to be consumed to get the same calorific or nutritious value. Lastly, it is noted that the analysis was conducted to assess and compare the different systems with the use of primary and literature data, and no analysis on statistical significance or uncertainty was conducted on the environmental impact and its potential reduction.

2.3. Scope of the Study

2.3.1. Product Systems, Function, and Functional Unit

The study evaluated three product systems. The base case scenario involved conventionally processed, raw cut potatoes. Two alternative scenarios were also assessed, both involving osmotically dehydrated cut potatoes. In alternative scenario 1, the dehydration process used market glycerol, while in alternative scenario 2, the glycerol was sourced from the treatment of used vegetable cooking oil. Henceforth, the conventional, untreated potatoes are referred to as “raw cut potatoes” and “base case scenario”, and the osmotically dehydrated potatoes are referred to as “dehydrated cut potatoes” and “alternative scenario 1”, when market glycerol is used, or “alternative scenario 2”, in case of glycerol from vegetable cooking oil treatment. The function of each product system was to deliver ready-to-fry, fresh-cut potato products to consumers with equivalent nutritional value. Accordingly, this study defined 1 kg of dry matter of fresh-cut potato product delivered to households as the functional unit (FU) by which processing line requirements, household requirements, and waste generation were balanced out to assess the cultivation needs, which were a major contributor in the overall impact.

2.3.2. System Descriptions and Boundaries

The LCA study followed a cradle-to-grave approach. In particular, to accurately compare the environmental impact of the different potato products, the analysis considered all stages in their value chains, from cultivation to household consumption (unpacking, but not frying). End-of-Life (EoL) management was also included. These stages were the following: (1) potato cultivation, (2) wholesaler handling (storage and transportation to the processing line), (3) processing, (4) transportation from processing line location to Athen’s city centre, (5) retail storage and distribution, and (6) consumption at households. In addition, EoL management was considered including collection and treatment of solid waste (peels and potato waste and plastic packaging) and wastewater treatment throughout the entire value chain.

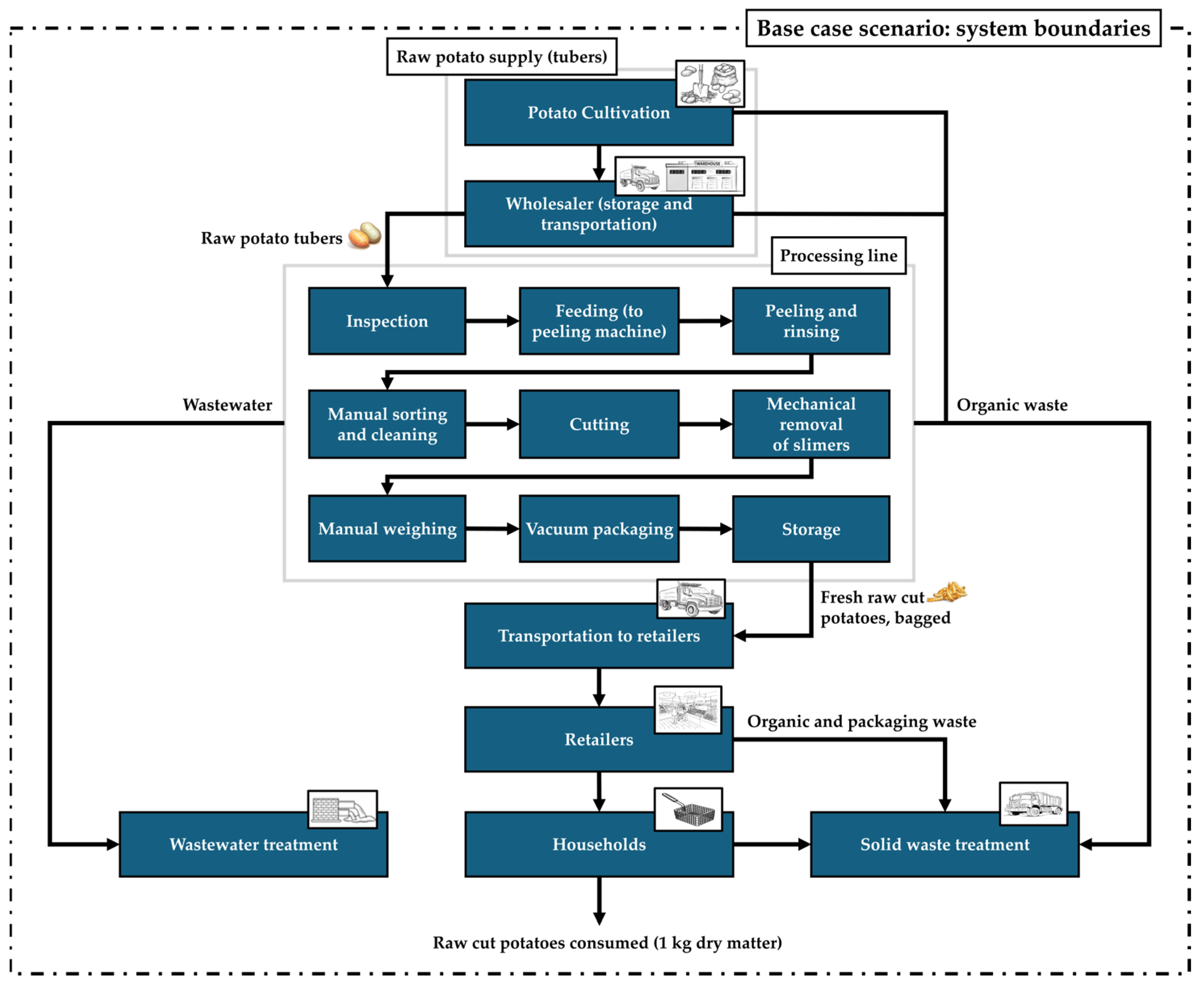

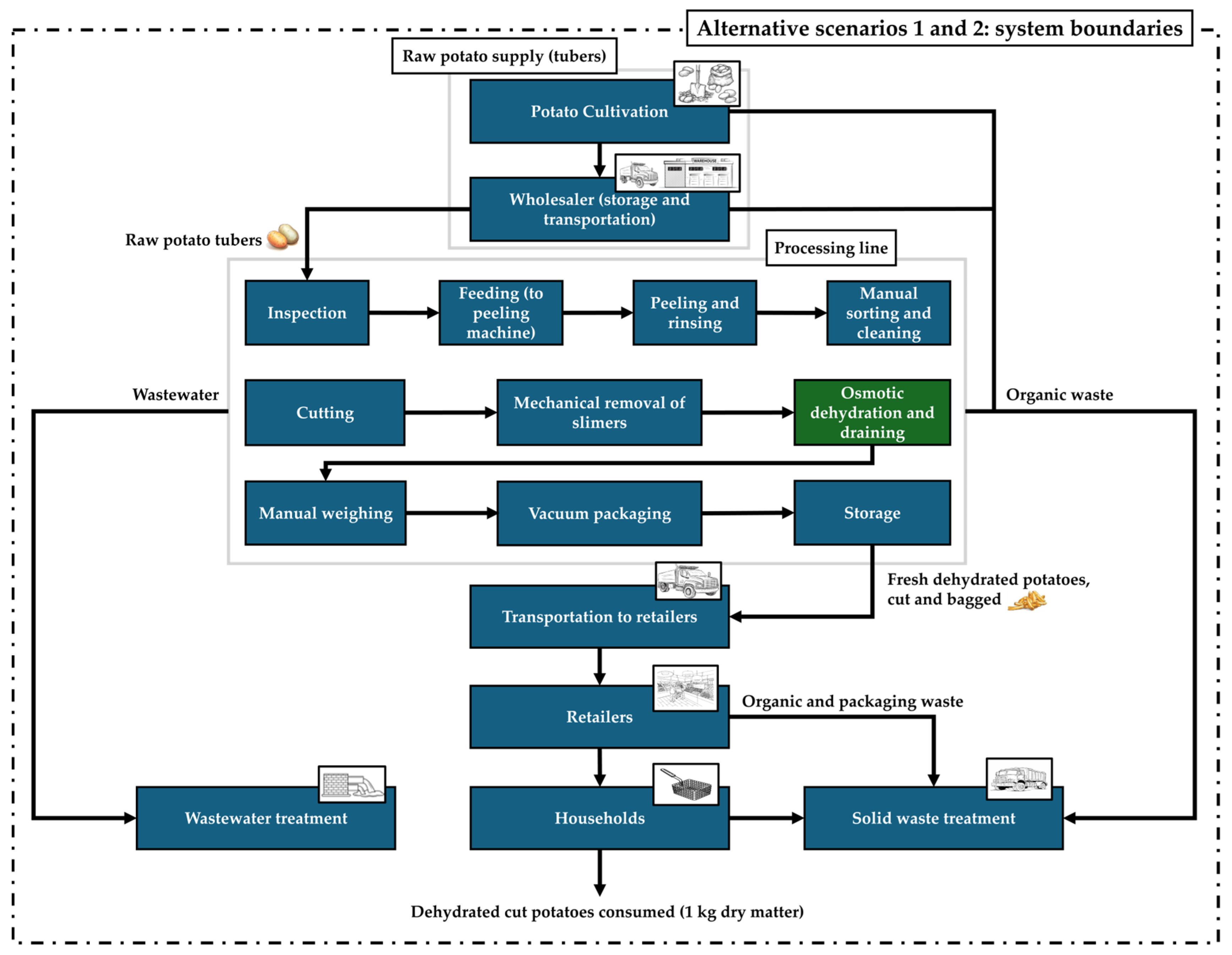

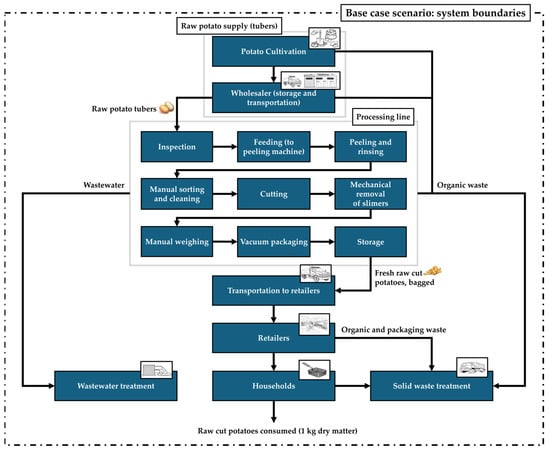

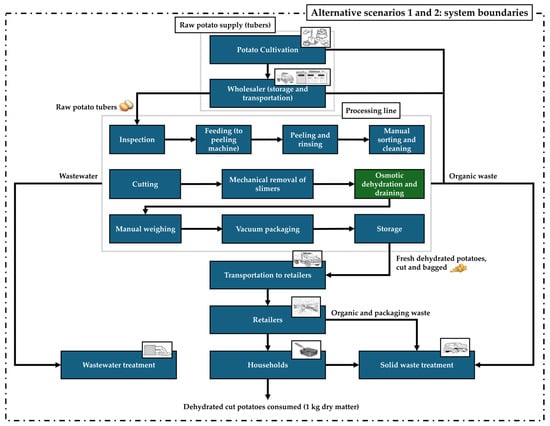

For raw cut potatoes, the processing line, as defined by the operators, consisted of the following steps: (1) reception of tubers from wholesaler, (2) macroscopic inspection of tubers and selection of appropriate sizes, (3) feeding, (4) peeling and rinsing, (5) manual sorting and removal of blemishes, (6) cutting into the desired shape, (7) mechanical removal of slimers, (8) manual weighing, (9) vacuum or modified atmosphere packaging, and 10) storage (~1 day before transported to retailers). For dehydrated cut potatoes, OD and draining of immersed potatoes was introduced between the mechanical removal of slimers and manual weighing. The system boundaries for raw cut potatoes and dehydrated cut potatoes are presented in Figure 1 and Figure 2, respectively. It is noted that the analysis did not consider the frying of the potatoes at the households. It was concluded that comparison at a fry basis would consider fries of similar characteristics and consequently dry matter content, and therefore the analysis could be reduced to the dry matter content while also being applicable to fries of different characteristics to address different consumer preferences. It is also noted that the only difference between the alternative scenarios lay in the production method of the glycerol used; however, this aspect is not shown in Figure 2.

Figure 1.

Base case scenario: raw-cut-potato system boundaries.

Figure 2.

Alternative scenarios 1 and 2: dehydrated-cut-potato system boundaries.

2.3.3. LCIA Methodology and Impact Categories’ Definitions

According to ISO, the impact categories to be examined and reported must be defined prior to conducting the LCI, as they significantly affect data and LCI completeness requirements. In this study, a comprehensive LCI was constructed including all relevant inputs, outputs, emissions to air, and discharges to water and soil, therefore all impact categories could potentially be assessed. To identify the most relevant impact categories for the systems under study, the Environmental Footprint (EF) version 3.1 method was used due to its built-in normalization and weighting functionalities. The impact categories reported were decided by applying the method’s integrated normalization and weighting for identifying the categories where the examined systems had the most significant impact. An inclusion criterion was set whereby the reported impact categories must cumulatively account for at least 80% or more of the system’s total single-score impact. It is noted that if an impact category met these criteria in at least one scenario, it was consistently reported across all scenarios for comparability.

Based on the methodology, the selected impact categories included Climate Change (Global Warming Potential–GWP); water use; Ecotoxicity: Freshwater; Eutrophication: Freshwater; Eutrophication: Marine; energy resources: Non-Renewable; particulate matter formation; and acidification. It is noted that these indicators were decided after the collection of the LCI, the modelling of the systems in OpenLCA v2.4 and the generation of results.

2.4. Life Cycle Inventory

This section presents the methodology used to define the LCI. The methodology is presented in subsections by type of input/output present in the examined systems, rather than by stage/process, due to the relatively small number of different inputs/outputs and the interdependence of same-type inputs/outputs of sequential stages, requiring examination in parallel (presented thoroughly in the “Solid waste generation and treatment” and “Electricity consumption” subsections).

The LCI analysis estimated the amount of solid waste (potatoes, potato peels, and packaging) generated at each stage. This step was important because the amount of waste directly affected the energy and material requirements of each stage in relation to the useful output. The examined systems and LCI were modelled using OpenLCA v2.4 software and ecoinvent database v3.11. The cumulative LCI collected, datasets utilized, and clarifications/justifications on modelling choices and the dataset selection are included in Table S1 of the Supplementary Material. It is noted that potato cultivation was modelled using existing ecoinvent datasets, so no LCI needed to be collected.

2.4.1. Solid Waste Generation and Treatment

Biowaste (potatoes and potato peels) and/or packaging waste was identified at various processes throughout the examined value chains including the following: (1) potato cultivation (potato tubers unfit to be sold to wholesaler), (2) wholesaler (potato tuber losses during storage and transportation), (3) inspection (potato tubers unfit for further processing), (4) peeling and rinsing (potato weight discarded as peels), (5) mechanical removal of slimer (removal of slimers), (6) retailers (potatoes and packaging, due to expiration, mostly because of reduced sales), and (7) households (potatoes expiring before consumed and the packaging of both the consumed and discarded product).

Losses at cultivation were included in the ecoinvent dataset selected. The volume of waste generated in all other stages was estimated by drawing data from the literature. Losses at the wholesaler, inspection (before feeding the peeler), and peeling stages were estimated according to Miller et al. and redefined as percentages of the volumes imputed from the previous stage (Miller et al. presented losses at the different stages as percentages of the initial-potato-cultivated potato quantity) [5], and the redefined losses were 6.56%, 2.7%, and 15%, respectively. Miller’s study also considered losses during the storage and transportation of the product to retailers. In the present study, these losses were considered negligible, due to the short period of storage (~1 day) and the relatively limited transportation distances. The losses reported by Miller et al. for the wholesaler, inspection, and peeling stages were based on freshly peeled potatoes, which was consistent with the product scope of this study. Therefore, their reported waste percentages were directly applicable and used without further adjustment. Losses during the mechanical removal of slimers from cutting were calculated according to Somsen’s study which suggested that the loss percentage during cutting is proportional to the desired cut size [23]. For 13 mm (which was the cut size suggested by the manufacturer of the potato cutter used in the processing line of this study), the losses are estimated at 7%.

According to Caldeira et al., losses of fresh potatoes at the retailers were estimated at 2% [4]. At the household level, losses were estimated at 12.3% by De Laurentis et al. [2]. It is noted that at retailers and households were the stages where differences in shelf-life came into play, significantly affecting the generated waste. Shelf-life variations could also impact storage at the processing line if products were stored for extended periods, potentially leading to non-negligible waste. These losses were connected to fresh unpeeled, uncut potatoes which had a significantly higher shelf-life than cut potatoes, raw or dehydrated. To examine the effect of shelf-life on the losses, the shelf-life ratio (SLR) methodology proposed by Casson et al. was applied, estimating the potential food waste (PFW) of a product (P) of a studied shelf-life (SSL) based on a reference shelf-life (RSL) and food waste ratio (FWR) for the same product [24]. The methodology is elaborated in Equations (1) and (2).

where the following is used:

- SLR is the shelf-life ratio;

- RSL is the reference shelf-life;

- SSL is the studied shelf-life;

- PFW is the potential food waste;

- P is the total amount of the examined product;

- FWR is the food waste ratio (food waste/P).

The original study [24] examined beef as the product for different packaging methods resulting in different shelf-lives. Nevertheless, Casson et al.’s methodology has also been adapted to other studies examining the food waste of vegetable products. Tsouti et al. used the methodology to estimate the difference in food waste for fresh tomato products that differed in the packaging process [25]. In their study, the methodology was applied to different stages of the value chain. Specifically, for each different packaging scenario of fresh tomatoes, the study applied the methodology to the stages of the value chain where the products were differentiated and thus presented different lifespans (stages after packaging, i.e., distribution, retail, and consumption). For stages that were not affected by packaging differentiation (i.e., tomato agricultural production and storage prior to packaging), the lifespan was not impacted, and as a result, the food waste ratios across the different scenarios were identical.

In this current study, the methodology was applied for raw and dehydrated cut potatoes, using fresh unpeeled, uncut potatoes as reference. It was considered that food waste in retailers was mostly generated due to fluctuations in demand, resulting in the product’s expiration before being sold. Therefore, considering the same functionality for all products (intended for French fries), they were treated as equivalent products subjected to the same demand patterns and fluctuations, and thus Casson’s methodology was applicable. It was also assumed that, while fresh unpeeled, uncut potatoes can serve other functionalities (i.e., baked in oven), the FWR reported would be nearly identical. The versatility of fresh unpeeled, uncut potatoes would result in reduced food waste since they could be used in dishes were pre-cut potatoes could typically not; however, the difference is FWR can be considered negligible [2,3,4]. Utilizing the data of the abovementioned studies and the SLR methodology, the overall food waste for the different products, up to the retailers’ stages, is presented in Table 1 (waste at households was examined separately). It was considered that fresh unpeeled, uncut potatoes had approximately a 14-day shelf-life after reaching retailers, raw cut potatoes had 7, while dehydrated potatoes had 12 [3]. Fresh unpeeled, uncut potato waste was used to estimate the waste of raw cut potatoes, which was then used to estimate the waste of dehydrated potatoes. Data for fresh unpeeled, uncut potatoes were used only when data of raw cut potatoes were unavailable (i.e., retailers and household consumption).

Table 1.

Food waste generated for each product, up to the retailer’s stage.

Each potato product was considered to enter the retailers’ shelfs at a standard shelf-life for given storage and transportation parameters (for example, all raw cut potatoes entering the shelf last 6 days before quality degradation, considering 1 day of storage and approximately 12 h on the road/sea). The same did not apply when it came to households. At this stage, their lifespan depended on how long they spent on the retailer’s shelf before being purchased. For example, raw cut potatoes that spend 2 days at the retailers would have a 4-day lifespan at the household before degradation began. To correctly estimate the waste generated at households, each batch of potato products was examined as a separate product with a distinct lifespan. For uncut, unpeeled potatoes, it was considered that the 12.3% waste reported by the literature (De Laurentis et al.) would correspond to an average lifespan of ~6.5 days (ranging from 0 to 13 days, depending on when they were purchased by consumers) [2]. Then, unpeeled, uncut potato waste at the household level was calculated according to the SLR for each batch, with the 6.5-day lifespan serving as the RSL. Then, the waste for each batch of raw and dehydrated cut potatoes was calculated using Casson’s methodology.

Table 2 presents the relationship between the days spent at retail, the lifespan at the household for each potato product, and the respective SLR and percentage of waste.

Table 2.

Estimation of waste at households, depending on the time spent at retail for each potato product.

For all stages prior to retailers, the waste was solely biowaste (potato and peels), while at the retailer and household, plastic packaging waste was introduced. All waste prior to reaching the retailers was produced on Naxos Island and was collected by municipal waste collection services and transported to Naxos’s sanitary landfill, approximately 11 km from the farm and fresh-cut potatoes’ processing line. Waste produced after distribution to retailers was produced in Attica and collected by municipal trucks to be sent to the waste treatment facilities in the Attica Region. Since mainland Greece has different waste treatment methods and sites available, the exact method or distance to be covered was unspecified, and waste management for both organic waste and packaging was simulated by ecoinvent datasets representing the Greek waste management market for municipal solid and plastic (polyethylene) wastes.

2.4.2. Electricity Consumption

Electricity consumption was associated with (1) the use of equipment in the processing line and (2) refrigeration of potatoes in the processing line storage, retailers, and households.

The type of equipment used was provided by the processing line operator. For some pieces of equipment, the exact model was also provided. For other pieces, assumptions were made on the model used, based on the type of equipment and the line’s capacity. Electricity consumption for each piece of equipment was estimated according to the manufacturer’s specifications. In case both nominal power and processing capacity were provided, the electricity consumption per kg of processed potato was calculated accordingly. In case of only nominal power being available, the processing capacity was considered equal to the overall system bottleneck (piece of equipment with the lowest capacity, assuming continuous production). The potato peeler was the system’s bottleneck, with 340 kg/h capacity. Therefore, for pieces of equipment where the capacity was unknown, it was considered that they operated at nominal power with a production rate of 340 kg/h. Most of this equipment included feeding bunkers, elevators, conveyors, and roller tables, which are not typically characterized by capacity, as in practice bunker volume or structural integrity are the only indicators of a bottleneck. Non-continuous operation could be assumed as an alternative to better utilize higher capacity equipment; however, since most of this equipment was used for conveying and connecting processing units rather than for processing itself, it must operate in accordance with the processing equipment bottlenecks. The main limitation of the chosen approach was the assumption that these pieces of equipment needed to operate at nominal power, while in practice they may allow for power adjustments to accommodate reduced conveying rates. Nevertheless, as highlighted by the LCI collected data, electricity consumption was not a significant contributor to the overall environmental impact. Therefore, any potential inaccuracy in electricity consumption was considered negligible. In addition, since this equipment was used across all three scenarios, any minor inaccuracies in impact assessment results would be consistent and comparable, thus not affecting comparisons. The equipment used and the corresponding electricity consumption is summarised in Table S2 of the Supplementary Material.

For storage, it was considered that 0.13 kWh was required to store 1 ton of potatoes for 1 day [26]. For all scenarios, it was assumed that potato tubers before processing can be stored in shady environments without the need of refrigeration, especially considering that they were only stored for a short period of time before being processed (potato tubers are commonly distributed in retail unrefrigerated for several days). After processing, both raw cut and dehydrated cut potatoes were stored for 1 day on the processing line premises, before being transported to retailers.

It is considered that transportation from the processing line to the retailers took ~12 h (including loading of trucks, transportation from processing line to Naxos harbour, embarkation of trucks to the ships, transportation from Naxos harbour to Piraeus, disembarkation of trucks, transportation to retailers in Athen’s city centre, unloading of trucks, and any possible delays).

After reaching the retailers, raw cut potatoes spent between 0 and 6 days in the store-zero if they were sold “immediately”—six if they were never sold and must be discarded due to degradation. Approximately 1.5 days of the overall 7-day lifespan of the product was spent in storage at the processing facility and during transportation to retailers. As products are discarded at the end of day at retailers, the maximum time spent at retail was considered 6 days (rather than 5.5). Similarly, dehydrated cut potatoes spent between 0 and 11 days at retailers. Assuming standard daily sales (DS), the electricity (E) required for storage for both raw and dehydrated cut potatoes was calculated through Equations (3)–(6):

where the following was used:

- d is the day index;

- PS(d) is the average quantity stored during day d, in kg;

- DS is the daily sales, in kg;

- B is the batch entering retail at the beginning of day 1 (potatoes transported to the retailers), in kg;

- W is the product discarded at the end of the 6th or 11th day, depending on the product (raw or dehydrated cut potatoes), in kg;

- SL is the shelf-life of the product (6 or 11 days, depending on the product);

- E is the electricity consumption related to the refrigeration of said batch, in kWh (0.13 kWh/ton/day [26]).

For households, it was considered that the percentage of product discarded would spend the rest of its lifespan in the refrigerator, while the percentage of product consumed would spend approximately only half of its remaining lifespan in the refrigerator (since some products were consumed immediately after purchase, while others were consumed right before expiration/degradation). Table 3 presents the electricity consumption at the retailer and household stages, per 1 kg of potatoes consumed. Waste at retailers was calculated according to the percentages presented in Table 1 while waste at households was calculated based on the percentages presented in Table 2. The analysis showed that the percentage of products discarded at both retailers and households dropped from 35.56% to 24.02%, in the case of dehydrated potatoes.

Table 3.

Electricity consumption for storage at retail and households.

2.4.3. Additives for Osmotic Dehydration (Alternative Scenarios 1 and 2)

Data for the use of additives for OD was provided by experiments conducted by the National Technical University of Athens (NTUA) in the scope of the Fresh4ever project (Τ2ΕΔΚ-03121). In said experiments, 12 tons of raw cut potatoes were osmotically dehydrated, in 12 batches of 1 ton each. Before introducing the first batch, the tank was filled with 3.7 m3 of water and 1.3 tons of additives (glycerol, ascorbic acid, and salt). At the end of each batch, 420 L of water were extracted from the raw potatoes, which also absorbed 180 kg of additives. Before introducing the second batch, 420 L were extracted from the tank, and 180 kg of make-up additives were introduced to keep the solution’s composition the same. The complete LCI was provided by NTUA and is included in the Supplementary Material. Considering the initial solution and the make-up, 0.27 kg of solids (76.81% w/w glycerol, 3.92% w/w ascorbic acid, and 19.28% w/w salt) and ~0.28 L water inputs corresponded to 1 kg of raw potato introduced to OD. The respective outputs were 0.76 kg of dehydrated potato and ~0.79 kg of wastewater (88.65% w/w water, 8.68% w/w glycerol, 0.45% w/w ascorbic acid, and 2.23% w/w salt).

2.4.4. Water Use and Wastewater

Water was used in the cultivation of potato tubers, the rinsing of peeled potatoes, and the OD process (only for alternative scenarios). Cultivation was modelled using existing ecoinvent datasets, which included both water use and wastewater treatment. Water consumption for rinsing peeled potatoes was identified by Barbosa-Cánovas et al. at 3 L/kg of potato [27]. After rinsing, the used wastewater is disposed of in the sewers, without the need of further treatment, since in comprises 99% water and some dirt.

Water consumption and wastewater for OD is reported in the previous subsection. Wastewater from OD was disposed of in the sewers without the need of further treatment since it comprises mostly water and edible additives.

2.4.5. Plastic Use: Packaging and Plastic Waste

According to the processing line operator, the potatoes can be packaged in different capacity bags provided by the packaging machine manufacturer. For the purposes of this study, the 80 μm–25 × 40 cm bag (3 L capacity) provided by the manufacturer was considered as a suitable option for distributing the product to households. The bags were rectangular-shaped sealed bags without handles, and their volume (not empty volume/capacity) was calculated as 16 cm3. The bags can vary in material. For this study, polyethylene bags were examined. Considering the polyethylene density of 0.92 g/cm3, the empty bag’s mass was calculated at 14.72 gr per bag.

Since potatoes are packaged in a vacuum, it was considered that, when the bags were filled, all volume inside was potato (no air). For raw cut potatoes, the bulk density was estimated at 0.833 kg/L [28]. Therefore, the total kg of potatoes to be packaged in a single bag was ~2.5 kg/bag, translating to 5.89 gr polyethylene/kg potato. For dehydrated potatoes, the bulk density was calculated through Equations (7)–(9) (1.26 g/cm3, 2.17 g/cm3 and 1.65 g/cm3 are the densities of glycerol, sodium chloride/salt and ascorbic acid, respectively) [29,30,31].

where the following is used:

- SVG is the solid volume gained by the potatoes during OD (L/0.76 kg dehydrated potato).

- V is the volume of the 0.76 kg of dehydrated potato (L/0.76 kg dehydrated potato).

- Vo is the volume of the 1 kg raw potato before dehydration (L/ kg raw potato).

- WLV is the water volume loss from 1 kg of raw potato (L/ kg raw potato).

- ρ is the bulk density of the dehydrated potato.

- The ρ is calculated as 0.835 kg/L, translating to 5.876 gr polyethylene/kg potato.

2.4.6. Transportation of Product

The final product for all scenarios was first transported by refrigerated trucks (with a capacity of 3.5–7 tons) from the processing line to Naxos harbour, approximately 26 km. The trucks were then loaded inside ferries’ vehicle decks (they can be passenger ferries) and were transported to Piraeus, approximately 227 km. After disembarking, the trucks travelled to Athen’s city centre, the location of retailers, approximately 14 km.

2.4.7. Dry Matter Content

According to the documentation of the ecoinvent dataset used, cultivated potato tubers have a 78% moisture content in storage, which is in line with the moisture content reported for a common potato in the literature (75–85%) [32]. According to Almeida et al., potato peels and flesh have a moisture content of 77–85%, very close to the whole potato tuber moisture [33]. For the purposes of this study, the moisture content of peels and raw potato flesh was considered equal at 78% (22% solids). The moisture content of raw cut potatoes was considered constant throughout their entire value chain. Therefore, 1 kg of dry matter was equivalent to approximately 4.55 kg of raw cut potatoes. For dehydrated potatoes, the final moisture content (FMC) was calculated based on the data provided for dehydration, according to equation 10.

where the following was used:

- FMC is the final moisture content for the dehydrated potatoes;

- W0 is the original water content in 1 kg of the potato (in kg);

- WL is the water loss occurring in 1 kg of potato during dehydration (in kg);

- M is the total mass of the dehydrated potato (in kg).

- Accordingly, 1 kg of dry matter was equivalent to approximately 1.90 kg of dehydrated potatoes.

3. Results

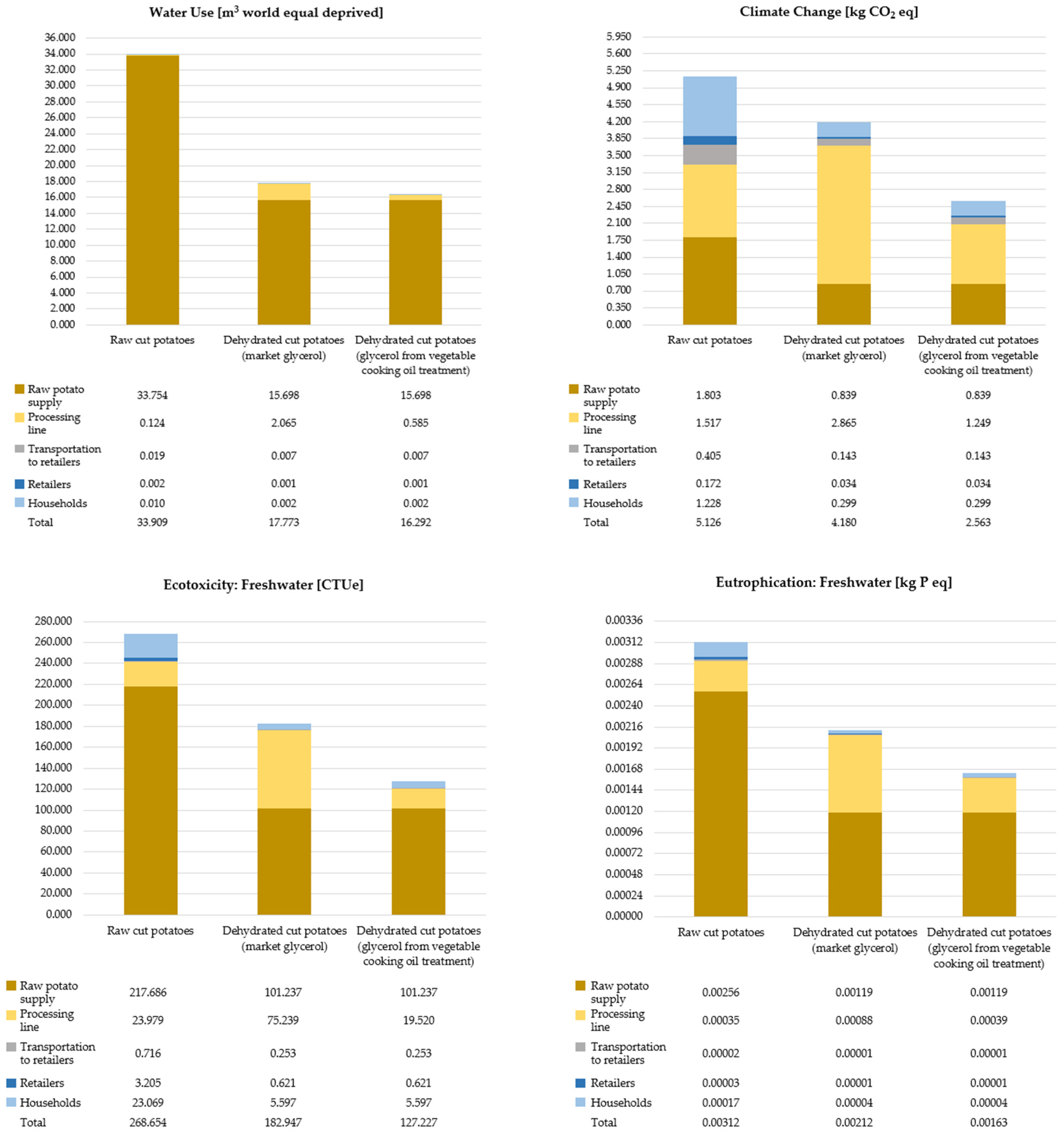

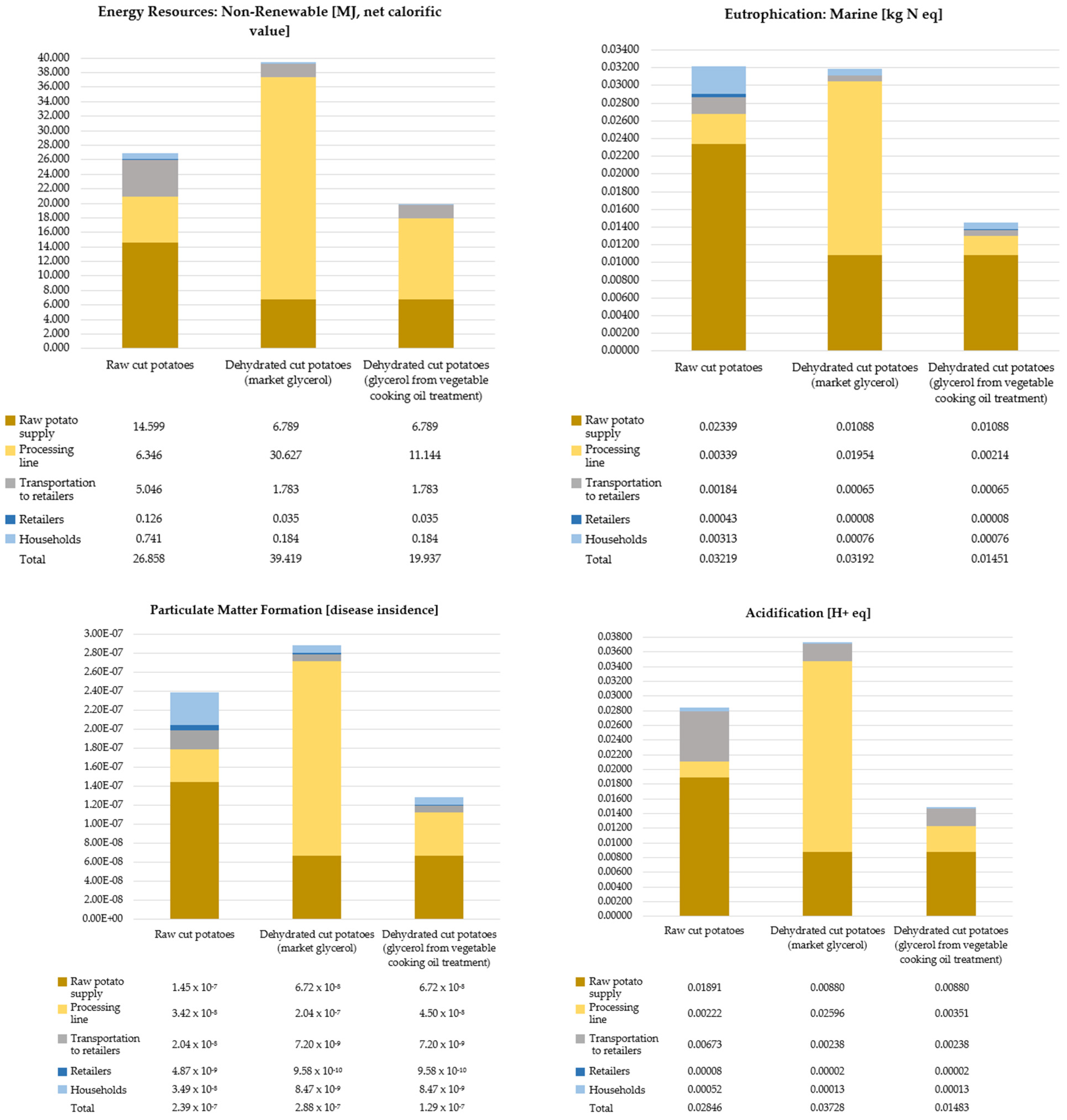

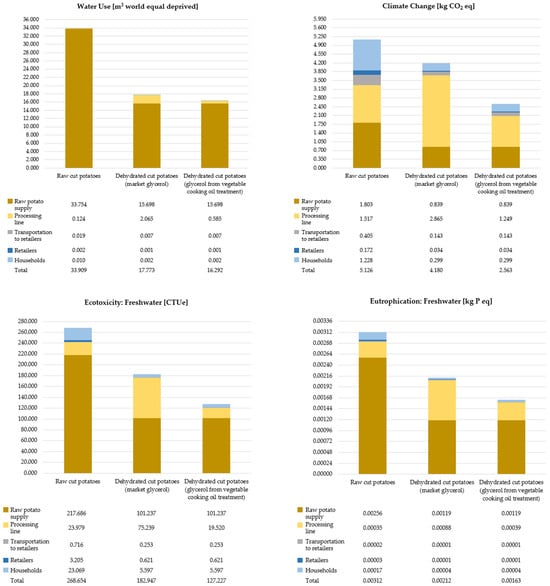

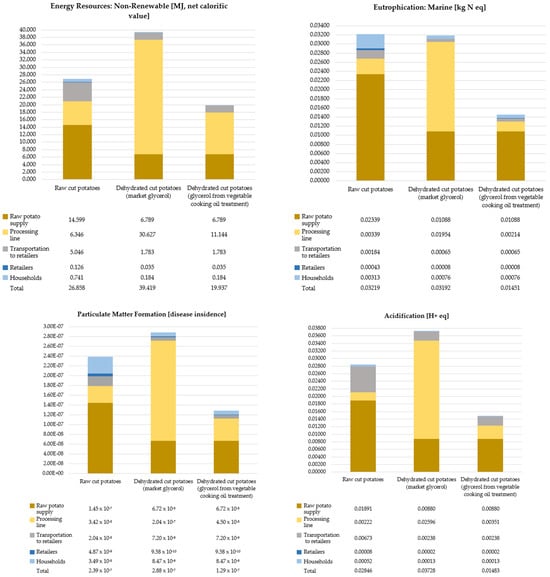

The LCIA results are presented in Figure 3 corresponding to the characterized results. A breakdown of the impact for each system/scenario is presented in the figure, below the graphs (from left to right, raw cut potatoes, dehydrated cut potatoes with the use of market glycerol, and dehydrated cut potatoes with the use of glycerol derived from vegetable cooling oil treatment). It is noted that the impact of the alternative scenarios (and the respective difference from the base case) was identical in all stages excluding the processing line.

Figure 3.

LCIA-characterized results for the three examined scenarios.

Extending the shelf-life of potato products resulted in significant waste reduction at retailers and especially households, which significantly reduced the direct impact related to municipal waste treatment. In addition, while extended shelf-life may result in slightly higher energy consumption for storage (products with longer shelf-life will spend more time in the refrigerator before consumed or thrown out), when allocating electricity consumption to the dry matter content, consumption was slightly lower. In the case of dehydrated cut potatoes, households presented a reduction of 75–75.7% across all impact categories. The lesser reduction was reported in water use while the biggest in ecotoxicity, specifically freshwater. In a similar manner, retailers also presented reductions of 69.2–80.6%, the lesser being in water use, due to decreased needs of municipal waste treatment due to waste aversion and slightly lesser electricity demands (in respect to potato dry matter stored), and the biggest in ecotoxicity, specifically freshwater.

Waste aversion also resulted in a lesser amount of product needed to be transported to retailers in order to cover the same consumer demands. Therefore, transportation activities (including land and sea) and their respective impact were reduced by 64.7% (same reduction across all categories).

The impact of the processing line presented the most significant deviations across the examined systems. For raw cut potatoes, the processing line accounted for 26.9% of the total GWP and 23.6% of energy resources used, while for all other impact categories, its contribution was 14.3% or lower. The addition of the OD process affected the impact a lot. The significant weight loss due to dehydration resulted in higher amounts of potatoes that needed to be processed at the backstream processes (up to the mechanical removal of slimers), increasing the electricity and water use and waste generation in these stages by ~31.6%. However, with a moisture content of 47.4% over 78%, 1 kg of dry matter content of nutritious value corresponded to ~1.9 kg of dehydrated potatoes, compared to 4.55 kg of raw cut potatoes. When waste reduction in retailers and households was considered, it was observed that consuming 1 kg of dry matter at households required the production of only 2.50 kg of dehydrated cut potatoes compared to 7.08 kg of raw cut potatoes, resulting in a reduction of 53.5% in the requirements and impact of backstream processes.

Nevertheless, the dehydration process itself highly increased electricity and water consumption and most notably introduced the use of solid additives that can have a significant impact, especially glycerol, due to their production processes. When using market glycerol, the overall impact of the processing line was drastically increased. Water use was increased by 15.66 times, acidification by 10.7 times, particulate matter formation by 4.98 times, marine eutrophication by 4.77 times, energy resources use by 3.83 times, freshwater ecotoxicity by 2.14 times, and freshwater eutrophication by 1.51 times, while GWP presented the lowest increase, by 88.8%. Due to these impacts, the processing line accounted for more than 60% of overall value chain impact in five out of the eight categories reported, presenting the highest share in energy resources used, 77.7%. The lowest share was reported in water use, 11.6% (in the absence of OD, the share was only 0.4%).

Using less impactful glycerol produced through vegetable cooking oil treatment, the impact of the OD and the processing line was significantly reduced (compared to market glycerol). In this scenario, water use increased 3.71 times, energy resources used by 75.6%, acidification by 58.3%, particulate matter formation by 31.4%, and freshwater eutrophication by 11.3%, compared to raw cut potatoes. On the other hand, marine eutrophication was reduced by 36.9%, freshwater ecotoxicity by 18.6%, and GWP by 17.7%. The processing line this time accounted for less than 50% of the overall value chain impact in seven out of eight categories. The biggest share was in energy resources used, 55.9%, and the lowest in water use, 3.6%.

Raw potato supply (cultivation and wholesaler) was the most impactful for raw cut potatoes (base case), accounting for 99.5% in water use, 81.9% in freshwater eutrophication, 81% in freshwater ecotoxicity, 72.7% in marine eutrophication, 66.5% in acidification, 60.5% in particulate matter formation, 54.4% in energy resources used, and 35.2% in GWP. The reduced processing line requirements in case of dehydrated cut potatoes resulted in a 53.5% reduction in cultivation needs and corresponding impacts.

Table 4 presents the percentage difference in all reported impact categories of the dehydrated potato products, compared to conventional raw potato products. Overall, results showed that dehydrating potatoes with the use of glycerol derived from vegetable cooking oil was, consistently, the most environmentally beneficial approach.

Table 4.

Percentage difference of alternative scenarios from base case.

4. Discussion

The findings of the analysis highlight the importance of prolonging the shelf-life of fresh-cut potatoes or any other vegetable and fruit products when addressing food waste from the market and consumers. For the fresh-cut potato industry specifically, application of OD resulted in reduction of the environmental impact across most impact categories in the overall value chain due to waste generation aversion. These approaches are proven to be valuable towards meeting the goals for environmental and economic sustainability in agriculture, such as those defined by the Sustainable Development Goal 2 and 12, the U.S. Food Loss and Waste 2030 Champion program, and WRAP [7,8,9].

In addition, the economic benefits of these novel approaches should not be understated, especially for countries with strong agricultural potential. In Greece, agriculture is a key sector, delivering products of high quality, many of them protected designation products (PDO), due to favorable climate conditions, fertile soils, and traditional cultivation practices, yet arable land is scarce due to the country’s size and topology, constraining large-scale production. In that sense, approaches that reduce cultivation needs or enable higher cultivation efficiencies are especially valuable. This is most relevant for Greek Islands, where arable land is even more difficult to come by. In addition, the extended lifespan of products can open new avenues, which until recently were considered challenging, if not practically impossible. In the scope of the Fresh4ever project, the OD application on potato products was examined as a means to expand the local potato market of Naxos Island to mainland Greece, specifically Athens. Through continuous research and development, this, or other techniques, could be further promoted and utilized to extend the product’s shelf-life and reach beyond the Greek borders. Through penetration in the European Market, new revenue streams could enter the local island economy, which faces significant challenges, especially on “off-seasons” where tourism, arguably the biggest market of the island, is low. Promoting the application of novel production approaches could foster local agri-food entrepreneurship and incentivizes repatriation or decentralization, giving a new breath to the local economy and community. The importance of producing added value products should also not be understated, as it can further incentivize entrepreneurs who may consider traditional approaches as a not so profitable business.

To promote the adoption of these approaches, further reduction of both the environmental impact and production costs would be key. For OD, the use of additives, especially market glycerol, is the most significant environmental burden. Use of less impactful glycerol, such as from glycerol deriving from the treatment of vegetable cooking oil significantly reduces the impact. That being said, the process is still characterized by significant losses of used additives. Specifically for glycerol, approximately 33.3% of used glycerol are discarded along with wastewater. To further reduce the impact, it is necessary to examine the benefits of applying recovery methods in the processing line premises, such as distillation. Such circular strategies, if technologically and economically feasible, would improve the sustainability of the process and enhance its scalability for industrial application. Identifying and testing alternative osmotic agents with a lower environmental footprint, such as plant-based polyols or food-grade sugars is another potential solution to address the impact of additives use.

Nevertheless, coupling the environmental benefits of these approaches with the economic benefits of entrepreneurs or other involved parties (such as retailers and consumers) is essential for their promotion, and future studies on the economic aspect are warranted. To encapsulate the potential benefits of applying OD in freshly cut potato products, a comprehensive technoeconomic analysis is needed, which should not only consider production and processing costs but also evaluate the broader impacts on the value chain, including transportation, storage, and consumer behavior.

Especially for the latter, this current study was based on generalized methodologies of forecasting food waste in respect to shelf-life. Future studies should focus on the consumption and waste patterns, either through product-specific theoretical approaches or by monitoring and analysis of real-life consumption and waste data, collected through available statistics, surveys, and other tools. Statistical analysis could also help identify key factors contributing to waste generation, enabling the better design of products that align with consumer requirements and habits.

5. Conclusions

This study, conducted in the scope of the “Fresh4ever” project, evaluated the environmental-impact reduction potential of applying OD in a small fresh-cut potato processing line in the Naxos Island of Greece, with the use of both market glycerol and glycerol from treated, used vegetable cooling oil, for the enhancement of the product’s shelf-life by up to 5 days. The analysis covered all value chain stages, from potato cultivation to household consumption, and assessed OD effects on energy and material (additives and water) demand, transported product volume, waste reduction, storage energy requirements, and raw tuber needs, for the most holistic assessment.

Results showed that including OD with the use of glycerol deriving from the treatment of vegetable cooking oil (less impactful source) resulted in reductions of 25.8% to 54.9% across all impact categories reported. The most important reductions were in water use (51.6%) and climate change (50%). These benefits, despite the increased energy and material demand of the newly added OD, were a direct result of waste reduction due to the enhanced shelf-life. Specifically, the percentage of products discarded from both retailers and households dropped from 35.6% to 24%. OD also significantly affected the impact by reducing the household requirement due to the new product’s higher calorific value.

The results demonstrated the potential for sustainability in small-scale processing lines but also offered a model for broader industry adoption. Stakeholders can leverage these findings to make informed decisions on integrating innovative technologies, ultimately driving more sustainable practices and fostering long-term value for both businesses and the environment, aligning with European and international sustainability goals on food waste reduction.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/waste3020020/s1, Supplementary Materials: Life Cycle Assessment on Osmotically Dehydrated Cut Potatoes: Effects of Shelf-Life Extension on Cultivation, Waste and Environmental Impact Reduction.

Author Contributions

Conceptualization, S.K. and K.V.; methodology, S.K.; software, S.K.; validation, K.V.; formal analysis, S.K., C.D., C.B., M.K. (Magdalini Krokida), M.K. (Maria Katsouli) and E.D.; investigation, S.K., C.D., C.B., M.K. (Magdalini Krokida), M.K. (Maria Katsouli) and E.D.; resources, S.K., C.D., C.B., M.K. (Magdalini Krokida), M.K. (Maria Katsouli) and E.D.; data curation, S.K., C.D., C.B., M.K. (Magdalini Krokida), M.K. (Maria Katsouli) and E.D.; writing—original draft preparation, S.K.; writing—review and editing, K.V.; visualization, S.K.; supervision, K.V.; project administration, K.V.; funding acquisition, K.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fresh4ever project, project code T2EΔK-03121, in the framework of the National Recovery and Resilience Pan “Greece”2.0” funded by the European Union-NextGenerationEU.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The Data and Life Cycle Inventory (LCI) used in the study were a combination of foreground data provided in the scope of the Fresh4ever project, literature review, and ecoinvent v3.1 database. All data drawn from the literature were properly cited. The LCI constructed is available in the Supplementary Material. An LCI breakdown in respect to the individual processes/stages in the value chain can be provided upon request to licensed ecoinvent users, considering non-disclosure of foreground data and avoiding the violation of terms and conditions of ecoinvent on possible reverse engineering of results.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Global Pre Packed Fruit And Vegetables Market Research Report: By Product Type (Fresh Produce, Processed Produce, Frozen Produce), By Packaging Material (Plastic, Paper, Biodegradable), By Distribution Channel (Supermarkets and Hypermarkets, Convenience Stores, Online Retailers, Wholesalers) and By Regional (North America, Europe, South America, Asia Pacific, Middle East and Africa)—Forecast to 2032; 6 August 2024; p. 200. Available online: https://www.wiseguyreports.com/reports/pre-packed-fruit-and-vegetables-market (accessed on 10 April 2025).

- De Laurentiis, V.; Corrado, S.; Sala, S. Quantifying household waste of fresh fruit and vegetables in the EU. Waste Manag. 2018, 77, 238–251. [Google Scholar] [CrossRef]

- Beretta, C.; Stoessel, F.; Baier, U.; Hellweg, S. Quantifying food losses and the potential for reduction in Switzerland. Waste Manag. 2013, 33, 764–773. [Google Scholar] [CrossRef]

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- Miller, K.; Reichert, C.L.; Schmid, M.; Loeffler, M. Physical, Chemical and Biochemical Modification Approaches of Potato (Peel) Constituents for Bio-Based Food Packaging Concepts: A Review. Foods 2022, 11, 2927. [Google Scholar] [CrossRef]

- Mouron, P.; Willersinn, C.; Möbius, S.; Lansche, J. Environmental Profile of the Swiss Supply Chain for French Fries: Effects of Food Loss Reduction, Loss Treatments and Process Modifications. Sustainability 2016, 8, 1214. [Google Scholar] [CrossRef]

- Goal 12: Ensure Sustainable Consumption And Production Patterns. Available online: https://www.un.org/sustainabledevelopment/sustainable-consumption-production/ (accessed on 14 April 2025).

- US Food Loss and Waste 2030 Champions. Available online: https://www.usda.gov/about-food/food-safety/food-loss-and-waste/us-food-loss-and-waste-2030-champions (accessed on 14 April 2025).

- Transforming the World’s Broken Systems. Available online: https://www.wrap.ngo/what-we-do (accessed on 15 April 2025).

- Katsouli, M.; Dermesonlouoglou, E.; Dimopoulos, G.; Karafantalou, E.; Giannakourou, M.; Taoukis, P. Shelf-Life Enhancement Applying Pulsed Electric Field and High-Pressure Treatments Prior to Osmotic Dehydration of Fresh-Cut Potatoes. Foods 2024, 13, 171. [Google Scholar] [CrossRef] [PubMed]

- Dermesonlouoglou, E.; Seretis, G.; Katsouli, M.; Katsimichas, A.; Taoukis, P.; Giannakourou, M. Effect of Pulsed Electric Fields and Osmotic Dehydration on the Quality of Modified-Atmosphere-Packaged Fresh-Cut and Fried Potatoes. Foods 2025, 14, 420. [Google Scholar] [CrossRef] [PubMed]

- Drosou, C.; Sklirakis, I.; Polyzou, E.; Yakoumis, I.; Boukouvalas, C.J.; Krokida, M. Processing Fresh-Cut Potatoes Using Non-Thermal Technologies and Edible Coatings. Appl. Sci. 2024, 14, 11039. [Google Scholar] [CrossRef]

- Tsakiri-Mantzorou, Z.; Drosou, C.; Mari, A.; Stramarkou, M.; Laina, K.T.; Krokida, M. Edible Coating with Encapsulated Antimicrobial and Antibrowning Agents via the Emerging Electrospinning Process and the Conventional Spray Drying: Effect on Quality and Shelf Life of Fresh-Cut Potatoes. Potato Res. 2025, 68, 587–619. [Google Scholar] [CrossRef]

- Mari, A.; Andriotis, P.; Drosou, C.; Laina, K.-T.; Panagiotou, N.; Krokida, M. Enhancing Shelf-life Stability of Refrigerated Potatoes through Osmotic Dehydration and Ohmic Heating Optimization: A Strategy to Mitigate Enzymatic Browning. Potato Res. 2024. [Google Scholar] [CrossRef]

- Kumar, R.; Bhardwaj, A.; Singh, L.P.; Singh, G. Quantifying ecological impacts: A comparative life cycle assessment of conventional and organic potato cultivation. Ecol. Model. 2023, 486, 110510. [Google Scholar] [CrossRef]

- Economou, F.; Papamichael, I.; Voukkali, I.; Loizia, P.; Klontza, E.; Lekkas, D.F.; Vincenzo, N.; Demetriou, G.; Navarro-Pedreño, J.; Zorpas, A.A. Life cycle assessment of potato production in insular communities under subtropical climatic conditions. Case Stud. Chem. Environ. Eng. 2023, 8, 100419. [Google Scholar] [CrossRef]

- Corrado, S.; Ardente, F.; Sala, S.; Saouter, E. Modelling of food loss within life cycle assessment: From current practice towards a systematisation. J. Clean. Prod. 2017, 140, 847–859. [Google Scholar] [CrossRef]

- Parajuli, R.; Matlock, M.D.; Thoma, G. Cradle to grave environmental impact evaluation of the consumption of potato and tomato products. Sci. Total Environ. 2021, 758, 143662. [Google Scholar] [CrossRef] [PubMed]

- Fresh4ever Project. Available online: https://www.elke.ntua.gr/en/research_project/development-of-innovative-fresh-cut-potato-products-with-superior-organoleptic-characteristics-and-prolonged-shelf-life-fresh4ever/ (accessed on 14 April 2025).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- European Commission Joint Research Centre, Institute for Environmentand Sustainability. International Reference Life Cycle Data System (ILCD). In Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, Belgium, 2010. [Google Scholar]

- Somsen, D. Production Yield Analysis in Food Processing, Applications in the French-Fries and the Poulty-Processing Industries. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2004. Available online: https://edepot.wur.nl/121537 (accessed on 14 April 2025).

- Casson, A.; Giovenzana, V.; Frigerio, V.; Zambelli, M.; Beghi, R.; Pampuri, A.; Tugnolo, A.; Merlini, A.; Colombo, L.; Limbo, S.; et al. Beyond the eco-design of case-ready beef packaging: The relationship between food waste and shelf-life as a key element in life cycle assessment. Food Packag. Shelf Life 2022, 34, 100943. [Google Scholar] [CrossRef]

- Tsouti, C.; Papadaskalopoulou, C.; Konsta, A.; Andrikopoulos, P.; Panagiotopoulou, M.; Papadaki, S.; Boukouvalas, C.; Krokida, M.; Valta, K. Investigating the Environmental Benefits of Novel Films for the Packaging of Fresh Tomatoes Enriched with Antimicrobial and Antioxidant Compounds through Life Cycle Assessment. Sustainability 2023, 15, 7838. [Google Scholar] [CrossRef]

- Sáenz-Baños, M.; Latorre-Biel, J.I.; Martínez-Cámara, E.; Jiménez-Macías, E.; Longo, F.; Blanco-Fernández, J. Methodology for energy demand reduction of potato cold storage process. J. Food Process Eng. 2022, 45, e14127. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Fernández-Molina, J.J.; Alzamora, S.M.; Tapia, M.S.; López-Malo, A.; Chanes, J.W. Handling and Preservation of Fruits and Vegetables by Combined Methods for Rural Areas; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2003; Available online: https://www.fao.org/4/y4358e/y4358e00.htm (accessed on 10 April 2025).

- Bulk Density. Available online: https://www.mpd-inc.com/bulk-density/ (accessed on 22 April 2025).

- Tan, H.W.; Abdul Aziz, A.R.; Aroua, M.K. Glycerol production and its applications as a raw material: A review. Renew. Sustain. Energy Rev. 2013, 27, 118–127. [Google Scholar] [CrossRef]

- Sodium Chloride, PubChem—National Library of Medicine, National Center of Biotechnology Information (USA). Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Sodium-Chloride (accessed on 10 April 2025).

- Ascorbic Acid, PubChem—National Library of Medicine, National Center of Biotechnology Information (USA). Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Ascorbic-Acid (accessed on 10 April 2025).

- Norell, R.J.; Glaze, J.B., Jr.; Chahine, M.; Olsen, N. Measuring Potato Dry Matter Content on the Farm. University of Idaho Extension. 2016. Available online: https://www.uidaho.edu/-/media/UIdaho-Responsive/Files/Extension/publications/cis/cis1219.pdf?la=en (accessed on 14 April 2025).

- Almeida, P.V.; Gando-Ferreira, L.M.; Quina, M.J. Biorefinery perspective for industrial potato peel management: Technology readiness level and economic assessment. J. Environ. Chem. Eng. 2023, 11, 110049. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).