Abstract

Camelina (Camelina sativa L.) is a valuable source of seed oil, which contains above 30% of essential omega-3 fatty acid (alpha-linolenic acid, 18:3). On the one hand, this high content of linolenic acid is healthy and hence preferable, but on the other hand, highly unsaturated oils are easily deteriorated. The stabilization of such oils with respect to their oxidative changes is a significant problem in oil technology and is directly related to the quality of food, pharmaceutical and cosmetic products. Therefore, the aim of this work was to evaluate the effect of ascorbyl palmitate in various concentrations (0.1–2.0 mM) as an additional antioxidant in camelina seed oil during its autoxidation, by determination of oil induction periods and initial rates of oxidation. The results revealed that the added ascorbyl palmitate caused a decrease in oxidation rate, but in terms of oil stability, opposite effects were observed depending on its concentration. Thus, at low levels (0.1–0.2 mM), ascorbyl palmitate had a pro-oxidant effect and the induction period decreased; no effect was observed in its presence of 1.0 mM, whereas 2.0 mM ensured a much higher protective effect. Rosmarinic acid as an individual antioxidant (at 0.2 mM) increased the stability of camelina oil, while in a mixture (1:1) with ascorbyl palmitate at the same concentration, its effect/activity was significantly reduced.

1. Introduction

Climatic change severely impacts crop production in Europe and thus necessitates a search for new stress-tolerant plants with good qualities for human, animal or technical use. Plant breeding goals vary according to market and farmers’ needs, and selection of these crops has led to the registration of varieties with contrasting characteristics of grain and oil [1].

The oil extracted from Camelina sativa seeds contains more than 50% polyunsaturated fatty acids of which 35–40% are alpha-linolenic acid (18:3), an essential omega-3 fatty acid [2]. Camelina oil is a potentially important functional food ingredient providing beneficial essential fatty acids without the instability problems typical of highly unsaturated oils [3]. However, camelina is still grown as a non-food crop in some regions of Europe and North America and has limited use as a food oil [4]. Glucosinolates [5] and erucic acid (cis 13-22:1) are the major obstacles for consumption of camelina as a nutritionally complete food product due to their effects on the thyroid gland and the cardiovascular system [6,7]. Therefore, camelina oil with a maximum content of 50 g/kg erucic acid is allowed for human consumption [8] with a tolerable daily intake (TDI) of 7 mg/kg body weight (bw) per day [9]. This fact has led to the challenge of developing new varieties with low erucic acid by analogy with canola oil.

More than 3000 reports in the scientific literature on camelina have been analyzed [10] in the context of a detailed review recognizing its current and potential future uses. As a rich source of omega-3 fatty acids, phytosterols, especially β-sitosterol, tocopherols and carotenoids [11], the oil from camelina seeds has attracted attention from a nutritional perspective.

The high content of unsaturated fatty acids, on one hand, is among the main reasons for the health benefits of camelina oil, but on the other hand, that makes it easily susceptible to oxidation. Deterioration of oil quality leads not only to the loss of its organoleptic properties but also to a decrease in the biological activity, i.e., to the degradation of essential fatty acids and fat-soluble vitamins and to the formation of physiologically harmful substances. Therefore, stabilization of oils with respect to their oxidative changes is an important problem in oil technology and has a direct bearing on the quality of food, pharmaceutical or cosmetic products [12,13]. The stability of oils depends on various factors, which can generally be grouped into two main categories: physical factors (determined by the conditions under which the oxidation process takes place) and substrate factors. The latter comprise the fatty acid composition, chemical structure(s) of the lipid molecules, and presence of minor components, especially antioxidants (phenolic compounds, including tocopherols, sterols, natural pigments), metals with variable valence, etc., in oils [14]. In camelina oil the amount of these important bioactive compounds varies depending on the cultivar, geographic origin, environmental conditions, etc., but usually are in the ranges of 500–1100 mg/kg tocopherols [15,16,17], 700–900 mg/L other phenolic compounds [18], 120–170 mg/kg carotenoids [18,19,20], and 3200 mg/kg sterols [21].

A common practice for increasing oil oxidative stability is the addition of antioxidants (natural or synthetic) to the lipid systems. Ascorbyl palmitate (AscPH) is considered a “synthetic” antioxidant and, as a fatty acid ester of ascorbic acid, is often used in fat-containing foods. However, it is regarded as a “natural” antioxidant because it is fully hydrolyzed to ascorbic acid and palmitate [22]. As additive E 304 (i), no maximum levels are specified and it shall be used in accordance with good manufacturing practice. As early as 1994, Frankel et al. [23] concluded that ascorbic acid is more effective in homogeneous lipid media (stripped corn oil), while its lipid-soluble analog ascorbyl palmitate is more active in corn oilin water emulsions. The authors even found some pro-oxidant effects of palmitate at a certain stage of oxidation of stripped corn oil. Four years later, Hamilton et al. [24] proved that palmitate in combination with tocopherol was either inert (in menhaden oil) or initially pro-oxidative (in Chilean fish oil). The likely influence of trace heavy metals was discussed. Most of the complex effects and paradoxes in antioxidants research were summarized and explained in detail in a review by Budilarto and Kamal-Eldin [25]. However, despite the large number of studies on the role of ascorbyl palmitate in lipid stabilization, there are still conflicting data.

Rosmarinic acid is a natural antioxidant with high efficiency, as well as other remarkable biological effects [26]. Although it has been intensively investigated, information about its effect on camelina seed oil stability is poor. Moreover, only rosemary extracts have been tested [16,27]. Froehlich et al. [16] examined the effect of various antioxidant formulations containing rosemary extract on the oxidative stability of highly unsaturated oils including camelina oil. Abramovic and Abram [27] investigated the protective effect of 0.2% rosemary extract on the oxidative stability of camelina oil by periodic determination of its peroxide value as well as the induction time measured by the Rancimat test (110 °C) during storage at room temperature. The results revealed that the presence of added extract extended the induction period of freshly obtained camelina oil by 60%.

Therefore, the aim of our work was to study in detail the possibility of stabilizing camelina oil by adding ascorbyl palmitate in a wide concentration range (0.004–0.08%). Also, an initial examination of a possible combination with rosmarinic acid was conducted.

2. Materials and Methods

2.1. Samples and Reagents

The camelina (Camelina sativa L.) variety Lenka was cultivated at the experimental field of the Agricultural University–Plovdiv, Bulgaria (42°8′49.05″ N/24°48′42.46″ E). Spring sowing and standard technology were used with minimal cultural practices and low input of nutrients before sowing, with only 30 kg/ha active substance of nitrogen. No additional pesticides were applied. The vegetation period was short (from end of March to beginning of June) and a good phytosanitary condition of the crop was maintained till the end. The seeds were harvested at full maturity, dried in a dark place at room temperature, and then milled; the oil was extracted as described below in Section 2.2. Solvents of HPLC grade were used for extraction and preparative thin-layer chromatography (TLC), whereas only iso-octane was of spectroscopic grade. Reagents for transmethylation, tocopherols and oxidative stability investigations were of analytical grade (Merck KGaA, Darmstadt, Germany; Sigma-Aldrich, St. Louis, MO, USA). Reference mixture of fatty acidsmethyl esters (FAME), ascorbyl palmitate and rosmarinic acid were from Sigma-Aldrich Co. (St. Louis, MO, USA).

2.2. Oil Content of the Seeds

Portions of 30 g (precisely weighed) milled seeds of camelina were extracted in Soxhlet apparatus with n-hexane (at 70 °C) for 8 h. Then the solvent was distilled in a rotary evaporator (at 40 °C) and the residue was weighted to calculate the oil content as follows:

where m was the mass [g], respectively, of the residue (oil) and the initial sample (camelina seeds). Three parallel determinations have been performed and the result is presented as mean value ± standard deviation. The oil was kept at −20 °C until analyses.

Oil content, % = (m oil/m seeds) × 100

2.3. Analysis of Fatty Acid Composition

After transesterification of oil with 1% methanolic sulfuric acid, the resulting fatty acid methyl esters (FAME) were firstly purified by preparative TLC [28] and then were analyzed by gas chromatography. A Shimadzu GC 2030 chromatograph equipped with a flame ionization detector and Simplicity Wax capillary column (30 m × 0.32 mm × 0.25 μm, Supelco) was used for the analysis, under the following conditions: a temperature program from 170 °C to 260 °C at 2 °C/min and 5 min held at the final temperature, injector and detector temperatures of 260 °C and 280 °C, respectively, and nitrogen as a carrier gas at a flow rate of 0.6 mL/min, split 1:50. The identification of peaks was according to retention times compared to that of the reference FAME mixture. Three parallel determinations of fatty acid composition were carried out. The results (relative % of each fatty acid) are presented as mean value ± standard deviation.

2.4. Determination of Conjugated Dines and Trienes Content

The content of conjugated dienes and trienes was evaluated by their absorbance at 232 nm and 268 nm, respectively, of a 1% solution of oil in iso-octane measured in a 1 cm quartz cuvette by Cecil Series 8000 UV/VIS spectrophotometer (Cecil Instrumentation Services Ltd.; Cambridge, UK) with reference of pure solvent. The results are presented as K232 and K268, respectively, as a mean value ± standard deviation of three parallel measurements.

2.5. Determination of Total Tocopherols Content

The following procedure [29] was applied: 100 milligrams (±10 mg) of oil were weighed and diluted with 5 mL of toluene. Then 3.5 mL and 0.5 mL of previously prepared solutions of 2,2′-bipyridine (0.07% w/v in 95% aqueous ethanol) and FeCl3.6H2O (0.2% w/v in 95% aqueous ethanol) were added, respectively, in that order. After holding the solution for one minute in the dark, its absorbance was read at 520 nm against a blank solution prepared as above without oil. The concentration of tocopherols in the oil sample, presented as [mg alpha-tocopherol/kg oil], was determined using a standard calibration curve prepared in the same way by standard tocopherol solutions of various concentrations. A Cecil Series 8000 UV/VIS spectrophotometer was used with a 1 cm quartz cuvette. All measurements were performed in triplicate.

2.6. Oxidation Procedure and Determination of the Kinetic Parameters

Peroxide value (PV, expressed as meqv O2/kg oil) was estimated by modified iodometric method [30]. The induction period (IP) was evaluated by the following procedure: 2 g oil were oxidized in a glass vessel at 100 °C by blowing a stream of air (100 mL/min) and the oil oxidation kinetics was monitored. Aliquots were taken in fixed time intervals and the degree of oxidation was estimated by iodometric determination of the primary products (hydroperoxides) as the peroxide value. The induction period (IP, hours) was determined by analyzing the tangents to both parts of the kinetic curves. Oxidation rates (R) were found by the tangents to the linear part of the kinetic curves. Samples containing ascorbyl palmitate or/and rosmarinic acid were prepared directly before oxidation by adding aliquot parts of acetone solutions of the compounds to the weighted (2 g) camelina oil substrate to achieve final concentrations of, respectively, 0.004%, 0.008%, 0.041% and 0.082% ascorbyl palmitate, and 0.007% rosmarinic acid.

All measurements were performed in triplicate.

3. Results and Discussion

3.1. Fatty Acid Composition

The camelina seeds had an oil content of 32.5 ± 1.7%. Camelina oil is among several oils rich in alpha-linolenic acid (18:3 ω-3) like perilla (Perilla frutescens L.) [31], flaxseed (Linum usitatissimum L.) [32], purslane (Portulaca oleracea L.) [33] and rosehip (Rosa canina L.) [34] seed oils, thus being a valuable source of the essential omega-3 fatty acid.

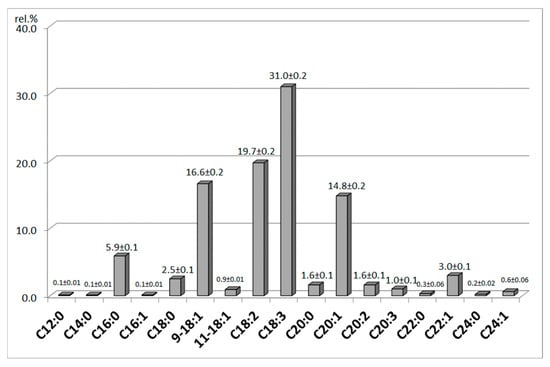

The studied camelina oil contained 31% alpha-linolenic acid, almost 20% linoleic acid (18:2 ω-6), ~17% oleic acid (18:1 ω-9), ~15% 20:1, and 13 other fatty acids below 6% (Figure 1), including erucic acid (22:1 ω-9) at an amount of 3%. These values are around the average fatty acid levels in camelina oil from different geographical areas and varieties [11,35,36].

Figure 1.

Fatty acids composition of oil from camelina (Camelina sativa L.) seeds.

Such a significant amount of unsaturated fatty acids, 89.3% in total, is beneficial for health, but, on the other hand, produces an oil susceptible to oxidation and results in easy deterioration of the quality.

3.2. Oxidative Stability

3.2.1. Current Status of Camelina Seed Oil

The spontaneous reaction of atmospheric oxygen with lipids, known as autoxidation, is the most common process leading to oxidative deterioration of oils [14], a complex process with a multi-step mechanism. Conjugated dienes and trienes are among the primary products of oxidation and their amounts enable fast and easy estimation of initial oil quality (immediately after extraction). Values of 2.1 for conjugated dienes and 0.6 for conjugated trienes (Table 1) result in good-quality camelina oil that is suitable for subsequent investigation of its oxidative stability (Section 3.2.2).

Table 1.

Conjugated dienes and trienes and peroxide value (PV) in seed oil of Camelina sativa L. (control sample *).

3.2.2. Kinetics of Lipid Autoxidation and Inhibition Effect of Antioxidants

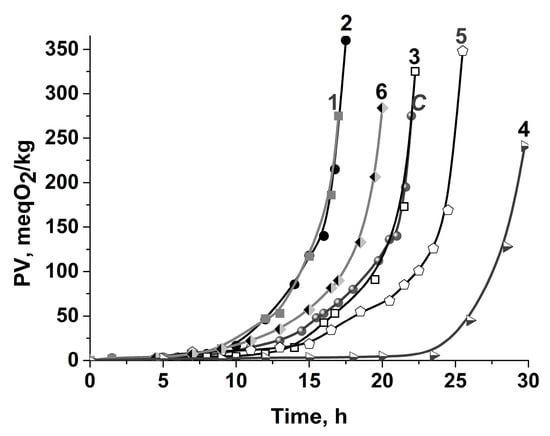

Figure 2 presents the kinetics of the accumulation of lipid peroxides (LOOH, the primary oxidation products) during bulk phase autoxidation of the oil. The respective kinetic parameters obtained after processing the curves are presented in Table 2.

Figure 2.

Kinetics of the accumulation of lipid hydroperoxides during autoxidation C of camelina seed oil at 100° before (control, C) and after addition of ascorbyl palmitate at concentrations of 0.1 mM, 0.2 mM, 1.0 mM and 2.0 mM (curves 1–4), with 0.2 mM rosmarinic acid individually (curve 5) and in an equimolar binary mixture with ascorbyl palmitate (curve 6).

Table 2.

Kinetic parameters (induction periods, IPA, and initial oxidation rates, R) characterizing camelina seed oil during autoxidation at 100 °C before (control sample, C) and after addition of ascorbyl palmitate (AscPH) and rosmarinic acid (RA).

Naturally occurring tocopherols (usually 700–800 mg/kg [11]) in camelina oil ensure some oxidative stability. In general, polyunsaturated oils are difficult to stabilize since the concentrations of their native antioxidants are optimal and, usually, fortification with additional amounts of tocopherols is ineffective. The addition of phenolic compounds to plant oils has limited effectiveness, and synergists which reinforce the antioxidant activity of native phenols (tocopherols) are recommended [37,38,39,40]. According to Froehlich et al. [16] delta-tocopherol and a blend of gamma- with some alpha- and delta-tocopherols have only a small effect on camelina oil stability, whereas pure alpha-tocopherol has no effect.

In terms of oil stability, opposite effects were observed depending on the concentration of AscPH. The induction period (IPA) decreased by 4–5 h compared to the control sample (IPC) in the presence of AscPH in concentrations of 0.1 mM and 0.2 mM (0.004 and 0.008%, respectively). No change in the presence of 1.0 mM (0.041%) AscPH was observed, but 2.0 mM (0.082%) ensured a higher level of oxidative stability (IPA > IPC) of the oil (Figure 2, Table 2). The addition of the ascorbyl palmitate at low concentrations to camelina seed oil did not significantly alter the oxidation rate (RA ≈ RC), while at higher concentrations, 1.0 mM and 2.0 mM, a pronounced decrease in RA was achieved (Table 2).

Tocopherol molecules are considered to be the first to react with peroxide radicals. The resulting tocopheryl radicals, relatively active, can participate in side reactions leading to chain propagation:

where AOH and AO• are the antioxidant molecule and its respective radical, LH is the lipid molecule, LOOH and LOO• are the respective lipid peroxide and its redical.

AO• +LH → AOH + L•

AO• + LOOH → AOH + LOO•

Our previous studies on alpha-tocopherol [41], presenting at 0.1 mM and 1.0 mM in stripped sunflower oil, in mixtures with AscPH in three different ratios (1:1, 1:5 and 1:10), demonstrated that there was a significant positive effect of the addition of palmitate when the tocopherol was present at the higher concentration of 1.0 mM (0.043%). In the current study, the total tocopherol content determined was 880 mg/kg oil, i.e., 0.088%. By varying the AscPH concentration in the range of 0.004–0.082% (Table 2), a drastic prolongation of IPA was observed only in the presence of ascorbyl palmitate at 0.082%, achieving a nearly equimolar ratio with native tocopherols (0.088%). At 1.0 mM (0.041%) AscPH had no effect on the oxidative stability of camelina seed oil but, interestingly, at concentrations much lower in comparison to those of tocopherols, AscPH exhibited some negative effects (Figure 2, curves 1, 2 and 6). The latter can be attributed to the fact that traces of moisture, phospholipids and also some minor components (except tocopherols) are present in non-stripped camelina oil. It is possible that the palmitoyl ester of ascorbic acid AscPH generates inverse micelles, which in turn can accelerate the decomposition of hydroperoxides [42].

In our study, 0.2 mM (~0.01%) rosmarinic acid (RA) ensured a 20% increase in the induction period IPA. On the one hand, RA prolonged IPA, but on the other hand, it increased the oxidation rate during the IPA (Table 2). To the best of our knowledge, two studies have been reported on the inhibitory ability of rosemary extracts on the oxidation of camelina oil [16,27], whereas similar results for pure rosmarinic acid are lacking. Abramovic and Abram [27] reported that the addition of rosemary extract ensures 40% lower PV after 11 months of storage of camelina oil. The kinetic curves 5 and 6 in Figure 2 and the results in Table 2 reveal that the activity of rosmarinic acid significantly decreased in the presence of an equimolar concentration of 0.2 mM ascorbyl palmitate. Therefore, it can be concluded that RA ensures a higher stability of the lipid substrate when present individually at 0.2 mM than in combination with AscPH (1:1) at the same concentration.

4. Conclusions

Ascorbyl palmitate (AscPH) ensured a higher level of oxidative stability of camelina seed oil at a concentration of 2.0 mM (0.082%), while no change was observed in the presence of 1.0 mM (0.041%). In the current study, the total tocopherol content determined was 880 mg/kg oil, i.e., 0.088%. By varying the AscPH concentration in the range of 0.004–0.082%, a drastic prolongation of induction period IPA was observed only in the presence of palmitate at 0.082%, achieving a nearly equimolar ratio with native tocopherols (0.088%). At 1.0 mM (0.041%), palmitate had no effect on IPA but decreases the initial oxidation rate. Interestingly, at concentrations of 0.004–0.008%, much lower in comparison to those of tocopherols, AscPH exhibited some negative effects. An amount of 0.2 mM (~0.01%) rosmarinic acid RA ensured a 20% increase in the induction period IPA. On the one hand, RA prolonged IPA but, on the other hand, it increased the oxidation rate during the IPA. The results obtained revealed that the activity of rosmarinic acid significantly decreased in the presence of equimolar concentration of 0.2 mM ascorbyl palmitate. Therefore, it can be concluded that RA ensures a higher stability to the lipid substrate when present individually at 0.2 mM than in combination with palmitate (1:1) at the same concentration. The studies published in this communication are at an early stage and more efforts are needed in the search for suitable antioxidant compositions for enrichment and stabilization of oil extracted from Camelina sativa seeds.

Author Contributions

Conceptualization, A.S.-K., S.M. and M.M.; methodology, A.S.-K. and S.M.; formal analysis, A.S.-K. and S.T.; investigation, A.S.-K. and S.T.; resources, M.M.; writing—original draft preparation, A.S.-K. and S.M.; writing—review and editing, A.S.-K., S.M. and M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data supporting the findings of this study are available within the paper. Any raw data files are available from the corresponding author upon reasonable request.

Acknowledgments

The support of the Centre of Competence “Sustainable Utilization of Bio-resources and Waste of Medicinal and Aromatic Plants for Innovative Bioactive Products” (BIORESOURCES BG), project BG16RFPR002-1.014-0001, funded by the Program “Research, Innovation and Digitization for Smart Transformation” 2021–2027, co-funded by the EU, was greatly acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AscPH | Ascorbyl palmitate |

| RA | Rosmarinic acid |

| IPA | Induction period |

| R | Initial rate of oxidation |

References

- Montero-Muñoz, I.; Mostaza-Colado, D.; Capuano, A.; Mauri Ablanque, P.V. Seed and Straw Characterization of Nine New Varieties of Camelina sativa (L.) Crantz. Land 2023, 12, 328. [Google Scholar] [CrossRef]

- Afzal, M.F.; Khalid, W.; Armghan Khalid, M.; Zubair, M.; Akram, S.; Kauser, S.; Noreen, S.; Jamal, A.; Kamran Khan, M.; Al-Farga, A. Recent industrials extraction of plants seeds oil used in the development of functional food products: A Review. Int. J. Food Prop. 2022, 25, 2530–2550. [Google Scholar] [CrossRef]

- Xu, T.-T.; Li, J.; Fan, Y.-W.; Zheng, T.-W.; Deng, Z.-Y. Comparison of Oxidative Stability among Edible Oils under Continuous Frying Conditions. Int. J. Food Prop. 2015, 18, 1478–1490. [Google Scholar] [CrossRef]

- Arshad, M.; Mohanty, A.K.; Van Acker, R.; Riddle, R.; Todd, J.; Khalil, H.; Misra, M. Valorization of camelina oil to biobased materials and biofuels for new industrial uses: A review. RSC Adv. 2022, 12, 27230–27245. [Google Scholar] [CrossRef]

- Berhow, M.A.; Polat, U.; Glinski, J.A.; Glensk, M.; Vaughn, S.F.; Isbell, T.; Ayala-Diaz, I.; Marek, L.; Gardner, C. Optimized analysis and quantification of glucosinolates from Camelina sativa seeds by reverse-phase liquid chromatography. Ind. Crops Prod. 2013, 43, 119–125. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Mishra, A.S. Glucosinolates in animal nutrition: A review. Anim. Feed Sci. Technol. 2007, 132, 1–27. [Google Scholar] [CrossRef]

- Alim, M.A.; Iqbal, Z.; Dutta, P.C. Studies on the characterization and distribution of fatty acids and minor components of high-erucic acid mustard oil and low-erucic acid rapeseed oil. Emir. J. Food Agric. 2012, 24, 281–287. [Google Scholar]

- Commission Regulation (EU) 2019/1870. Available online: https://eur-lex.europa.eu/eli/reg/2019/1870/oj/eng (accessed on 1 August 2025).

- Scientific Opinion on erucic acid in feed and food. EFSA J. 2016, 14, 4593.

- Sydor, M.; Kurasiak-Popowska, D.; Stuper-Szablewska, K.; Rogoziński, T. Camelina sativa. Status quo and future perspectives. Ind. Crops Prod. 2022, 187, 115531. [Google Scholar] [CrossRef]

- Murphy, E.J. Camelina (Camelina sativa). In Industrial Oil Crops; AOCS Press: Champaign, IL, USA; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 207–230. [Google Scholar] [CrossRef]

- Wang, J.; Han, L.; Wang, D.; Sun, Y.; Huang, J.; Shahidi, F. Stability and stabilization of omega-3 oils: A review. Trends Food Sci. Technol. 2021, 118, 17–35. [Google Scholar] [CrossRef]

- Garcia-Mendoza, M.d.P.; Espinosa-Pardo, F.A.; Savoire, R.; Harscoat-Schiavo, C.; Cansell, M.; Subra-Paternault, P. Improvement of the oxidative stability of camelina oil by enrichment with phospholipid-quercetin formulations. Food Chem. 2021, 34, 128234. [Google Scholar] [CrossRef]

- Pokorny, J.; Yanishlieva, N.; Gordon, M. Antioxidants in Food. Practical Applications; Woodhead Publishing Ltd.: Cambridge, UK, 2001. [Google Scholar]

- Plut, C.; Seyrig, C.; Leclerc, C. Huile de cameline. Phytotherapie 2010, 8, 105–108. [Google Scholar] [CrossRef]

- Froehlich, A.; O’Dea, G.; Hackett, R.; O’Beirne, D.; Ni Eidhin, D.; Burke, J. Stabilization of Camelina Oil with Synthetic and Natural Antioxidants. J. Am. Oil Chem. Soc. 2012, 89, 837–847. [Google Scholar] [CrossRef]

- Pathak, R.; Mohsin, M.; Mehta, S.S. An assessment of in vitro antioxidant potential of Camelina sativa L. seed oil and estimation of tocopherol content using HPTLC method. J. Sci. Res. 2021, 13, 589–600. [Google Scholar] [CrossRef]

- Kurasiak-Popowska, D.; Ryńska, B.; Stuper-Szablewska, K. Analysis of Distribution of Selected Bioactive Compounds in Camelina sativa from Seeds to Pomace and Oil. Agronomy 2019, 9, 168. [Google Scholar] [CrossRef]

- Chantsalnyam, B.; Otgonbayar, C.; Enkhtungalag, O.; Odonmajig, P. Physical and chemical characteristics and fatty acids composition of seeds oil isolated from Camelina sativa (L). cultivated in Mongolia. Mong. J. Chem. 2013, 14, 80–83. [Google Scholar] [CrossRef]

- Rakita, S.; Spasevski, N.; Savić, I.; Gajić, I.S.; Lazarević, J.; Dragojlović, D.; Duragić, O. Comparative Evaluation of Camelina Seed Oils Obtained by Cold-Pressing and Solvent Extraction. Foods 2024, 13, 3605. [Google Scholar] [CrossRef]

- Shukla, V.K.S.; Dutta, P.C.; Artz, W.E. Camelina oil and its unusual cholesterol content. J. Am. Oil Chem. Soc. 2002, 79, 965–969. [Google Scholar] [CrossRef]

- EFSA Panel on Food Additives and Flavourings (FAF); Younes, M.; Aquilina, G.; Castle, L.; Engel, K.H.; Fowler, P.; Fernandez, M.J.F.; Fürst, P.; Gürtler, R.; Husøy, T.; et al. Opinion on the re-evaluation of ascorbyl palmitate (E 304i) as a food additive in foods for infants below 16 weeks of age and the follow-up of its re-evaluation as a food additive for uses in foods for all population groups. EFSA J. 2020, 18, 6153. [Google Scholar] [CrossRef]

- Frankel, E.N.; Huang, S.-W.; Kanner, J.; Bruce German, J. Interfacial Phenomena in the Evaluation of Antioxidants: Bulk Oils vs. Emulsions. J. Agric. Food Chem. 1994, 42, 1054–1059. [Google Scholar] [CrossRef]

- Hamilton, R.J.; Kalu, C.; McNeill, G.P.; Padleyc, F.B.; Pierceb, J.H. Effects of Tocopherols, Ascorbyl Palmitate, and Lecithin on Autoxidation of Fish Oil. J. Am. Oil Chem. 1998, 75, 813–822. [Google Scholar] [CrossRef]

- Budilarto, E.S.; Kamal-Eldin, A. The supramolecular chemistry of lipid oxidation and antioxidation in bulk oils. Eur. J. Lipid Sci. Technol. 2015, 117, 1095–1137. [Google Scholar] [CrossRef]

- Nadeem, M.; Imran, M.; Gondal, T.A.; Imran, A.; Shahbaz, M.; Amir, R.M.; Sajid, M.W.; Qaisrani, T.B.; Atif, M.; Hussain, G.; et al. Therapeutic Potential of Rosmarinic Acid: A Comprehensive Review. Appl. Sci. 2019, 9, 3139. [Google Scholar] [CrossRef]

- Abramovic, H.; Abram, V. Effect of added rosemary extract on oxidative stability of Camelina sativa oil. Acta Agric. Slov. 2006, 87, 255–261. [Google Scholar] [CrossRef]

- Taneva, S.; Momchilova, S. Effect of the extraction method on the lipid composition of purslane (Portulaca oleracea L.) seed oil. Discov. Food 2024, 4, 112. [Google Scholar] [CrossRef]

- Pashaei, H.; Farhoosh, R. A new insight into the weight gain method to monitor and evaluate lipid peroxidation. Foods 2025, 14, 700. [Google Scholar] [CrossRef] [PubMed]

- Yanishlieva, N.; Popov, A.; Marinova, E. Eine Modifizierte Jodometrische Methode zur Bestimmung der Peroxidzahl in kleinen Lipidproben. C. R. Acad. Bulg. Sci. 1978, 31, 869–871. [Google Scholar]

- Bondioli, P.; Folegatti, L.; Rovellini, P. Oils rich in alpha linolenic acid: Chemical composition of perilla (Perilla frutescens) seed oil. Oilseeds Fats Crops Lipids 2020, 27, 67. [Google Scholar] [CrossRef]

- Saini, R.K.; Keum, Y.-S. Omega-3 and omega-6 polyunsaturated fatty acids: Dietary sources, metabolism, and significance—A review. Life Sci. 2018, 203, 255–267. [Google Scholar] [CrossRef]

- Zhou, Y.-X.; Xin, H.-L. Portulaca oleracea L.: A Review of Phytochemistry and Pharmacological Effects. BioMed Res. Int. 2015, 2015, 925631. [Google Scholar] [CrossRef]

- Taneva, S.; Konakchiev, A.; Totzeva, I.; Kamenova-Nacheva, M.; Nikolova, Y.; Momchilova, S.; Dimitrov, V. Super-critical carbon dioxide extraction as an effective green technology for production of high quality rose hip oil. Bulg. Chem. Commun. 2017, 49, 126–131. Available online: http://www.bcc.bas.bg/bcc_volumes/Volume_49_Special_B_2017/BCC2017-49-SE-B-126-131.pdf (accessed on 6 June 2025).

- Abramovic, H.; Abram, V. Physico-Chemical Properties, Composition and Oxidative stability of Camelina sativa oil. Food Technol. Biotechnol. 2005, 43, 63–70. [Google Scholar]

- Veljković, V.B.; Kostić, M.D.; Stamenković, O.S. Camelina seed harvesting, storing, pretreating, and processing to recover oil: A review. Ind. Crops Prod. 2022, 178, 114539. [Google Scholar] [CrossRef]

- Amorati, R.; Fiammetta, F.; Lucarini, M.; Pedulli, G.F.; Valgimigli, L. A Quantitative Approach to the Recycling of α-Tocopherol by Coantioxidants. J. Org. Chem. 2002, 67, 9252–9303. [Google Scholar] [CrossRef]

- Doert, M.; Grebenteuch, S.; Kroh, L.W.; Rohn, S. A ternary system of α-tocopherol with phosphatidylethanolamine and l-ascorbyl palmitate in bulk oils provides antioxidant synergy through stabilization and regeneration of α-tocopherol. Food Chem. 2022, 391, 133084. [Google Scholar] [CrossRef]

- Marinova, E.; Toneva, A.; Yanishlieva, N. Synergistic antioxidant effect of α-tocopherol and myricetin on the autoxidation of triacylglycerols of sunflower oil. Food Chem. 2008, 106, 628–633. [Google Scholar] [CrossRef]

- Bayram, I.; Decker, E. Analysis of the mechanism of antioxidant synergism between α-tocopherol and myricetin in bulk oil. J. Am. Oil Chem. Soc. 2023, 101, 477–492. [Google Scholar] [CrossRef]

- Slavova-Kazakova, A.; Kancheva, V. Synergism between DL-alpha-tocopherol and ascorbyl palmitate at various ratios in binary antioxidant compositions. Riv. It Sost. Gr. 2018, 95, 75–87. [Google Scholar]

- Villeneuve, P.; Bourlieu-Lacanal, C.; Durand, E.; Lecomte, J.; McClements, D.J.; Decker, E.A. Lipid oxidation in emulsions and bulk oils: A review of the importance of micelles. Crit. Rev. Food Sci. Nutr. 2023, 60, 4687–4727. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).