Abstract

This study develops and validates a weft knitted Mini-Jacquard in Peruvian Pima cotton as a print-free coloration strategy by integrating CAD-based pattern simulation with prototype manufacturing. A three-color design (red, blue, white) was programmed on a flat knitting machine using a 10 × 14 rapport. Color-wise yarn consumption was computed directly from the digital pattern, and the physical sample was characterized through combustion testing and optical micrographs. The prototype exhibited a yarn count of ~20/1 Ne, S-twist (~11.18 TPI), and 100% cellulosic composition. The blue yarn showed the highest consumption (≈73.81%), followed by white (≈19.65%) and red (≈6.55%), consistent with the digital rapport’s color distribution. The CAD stage ensured pattern fidelity and supported raw-material planning; the knitted sample showed a soft hand, dimensional stability, and sharp motif definition upon visual assessment. A sustainability and comparative analysis with chemical printing was conducted, revealing that the Mini-Jacquard achieved the highest design accuracy and tactile comfort, outperforming screen printing and heat transfer in geometric fidelity, chromatic homogeneity, and texture. The Mini-Jacquard optimized operational times (320 min/m2) compared to transfer printing (332 min/m2) and screen printing (740 min/m2), reducing process stages and complexity. Although Jacquard production involves higher energy costs ($34.8) and material expenses ($11.6), it provides greater structural value and durability, positioning it for high-end applications. Moreover, the Mini-Jacquard could reduce water consumption by approximately 90% and thermal energy use by 70%, eliminating chemical residues and extending fabric lifespan, thus offering high sustainability and circular potential. A transparent scenario-based analysis indicates substantial reductions in water and thermal-energy use when omitting printing/fixation/washing stages, along with the elimination of printing-stage effluents. Overall, design-integrated coloration via Mini-Jacquard is technically feasible and potentially eco-efficient for Pima-cotton value chains, with applications in apparel, accessories, and functional textiles.

1. Introduction

Peruvian extra-long staple cotton, internationally recognized for its softness, strength, and fiber purity, represents a strategic raw material for producing high-quality textiles that meet global standards [,]. Its prestige, particularly that of the Pima and Tangüis varieties, positions it as a key resource for both export markets and the development of innovative, value-added textile structures []. The present study focuses specifically on Peruvian Pima cotton, whose superior fiber characteristics enable high-performance fabrics suitable for advanced design and sustainable production.

Despite the aesthetic advantages of printed textiles, chemical printing and associated wet-finishing operations entail significant environmental and occupational health challenges. Workers exposed to reactive dyes and finishing chemicals are at risk of respiratory diseases and occupational dermatoses caused by sensitizing, irritant, or carcinogenic compounds, such as azo dyes widely used in printing [,]. Environmentally, coloration and finishing processes are major contributors to water pollution, responsible for nearly 20% of industrial wastewater worldwide []. Printing lines also generate gaseous, liquid, and solid wastes containing halogenated by-products, heavy metals, and formaldehyde, which threaten ecosystems when not properly treated []. Compared to printing, yarn dyeing offers a more controlled and potentially less polluting alternative, allowing coloration before fabric formation and reducing downstream chemical loads.

Jacquard technology has consolidated itself as one of the most versatile and sustainable routes for creating complex multicolored patterns without reliance on dyeing or surface printing. Through its capacity to control each yarn or needle individually, the Jacquard system allows pattern formation directly within the fabric structure, whether woven or knitted, thereby integrating color and motif through mechanical programming rather than chemical application [,]. Its versatility has been demonstrated in artistic textiles such as damasks, brocades, and tapestries [,,], as well as in advanced technical applications including molded seamless garments, smart/e-textiles, and protective fabrics [,,]. Recent innovations in double-jersey circular and warp-knitting Jacquard machines have expanded the range of patterns, textures, and color effects achievable with natural fibers like cotton [,,,].

In this context, the development of eco-efficient textiles that combine aesthetics, functionality, and environmental responsibility is of increasing importance. Mini-Jacquard weft-knits incorporate color and motif directly within the knitted architecture through controlled loop formation and yarn selection, eliminating the need for subsequent printing processes that are resource-intensive and polluting [,,,]. Therefore, the objective of this study is to design and develop a Mini-Jacquard weft-knit based on Peruvian Pima cotton that integrates aesthetic and functional performance within a print-free coloration strategy, contributing to sustainable innovation in the textile sector.

2. Materials and Methods

2.1. Raw Materials

Dyed Peruvian Pima cotton yarns in three colors (red, blue, and white) were sourced from a textile retailer in La Victoria, Lima, Peru. The yarns were dyed with reactive dyes with high fastness, suitable for apparel end-use. The yarns (Cotexsur, Lima, Peru) had a composition of 100% cotton, with a count of 20/1 Ne, a twist of 11.18 turns per inch, S-twist direction, and single-ply structure. A preliminary selection was performed to ensure yarn uniformity prior to knitting. A reference Mini-Jacquard pattern was selected from the knitting program library available at the facility (HQPDS 980 v1.5 knitting software, Zhejiang Hengqiang Technology Co., Ltd., Hangzhou, China), and the corresponding swatch was used as the baseline for academic validation (Figure 1).

Figure 1.

Reference pattern swatch used in this study.

2.2. Knitting Equipment

Mini-Jacquard samples were produced on a single-bed flat knitting machine (Accuratex, model Emprendedora HP, Lima, Peru) located at the Universidad Tecnológica del Perú (UTP) laboratories, Lima, Peru (Figure 2). The system was programmed for a three-color motif with a 10 × 14 repeat (rapport) using Hengqiang HQPDS 980 Plate Making (Zhejiang Hengqiang Technology Co., Ltd., Hangzhou, China). The machine’s technical specifications are summarized in Table 1.

Figure 2.

Flat knitting machine used in the study.

Table 1.

Technical specifications of the flat knitting machine.

2.3. Fabric Pattern Design Calculations and Analysis

The Mini-Jacquard structure was analyzed to determine technical parameters relevant for production feasibility and pattern fidelity. The workflow included: (i) pattern analysis and three-color distribution (red/blue/white); (ii) sample area, areal density (g·m−2), stitch/loop length (LM), yarn count (Ne), twist (twist per inch, TPI), and fiber composition by combustion; and (iii) longitudinal optical micrographs (≈250×) to document the knitted architecture. Micrographs were obtained using an upright optical microscope (BX53, Olympus Corporation, Tokyo, Japan) equipped with a digital camera (DP74, Olympus Corporation, Tokyo, Japan). Calculations followed standardized formulas and measurement practices commonly used in the textile industry (Table 2). A comparative analysis was then conducted to verify pattern fidelity, color uniformity, and fabric pattern stability prior to CAD simulation fine-tuning and physical sample production.

Table 2.

Standards, methods, and formulas used for fabric pattern analysis.

2.4. CAD Simulation of the Three-Color Mini-Jacquard

CAD simulation was implemented to verify technical feasibility, optimize the pattern, and estimate raw material consumption prior to knitting. An initial prototype grid was drafted in Excel (Microsoft Corporation, Redmond, WA, USA) to define column/course distribution and three-color sequencing, identify the 10 × 14 repeat, and compute color-wise yarn consumption based on the intended areal density and fabric geometry. The design was then transferred to Hengqiang HQPDS (v1.5; Zhejiang Hengqiang Technology Co., Ltd., Hangzhou, China), where pattern parameters were adjusted, minor inconsistencies were corrected, and the final simulation was generated to guide experimental production. This workflow ensured pattern fidelity, color uniformity, and efficient yarn use, enabling close correspondence between the digital and physical fabrics.

2.5. Fabrication of the Mini-Jacquard in Peruvian Pima Cotton

Physical production of the three-color Mini-Jacquard was carried out on the flat knitting machine described in Section 2.2 using high-quality Peruvian Pima cotton yarns. Machine settings were configured to implement the programmed color sequence and tensions, ensuring alignment with the digital pattern. During knitting, wale/course densities, color uniformity, and the correct integration of the three yarns were monitored to secure a stable and aesthetically precise fabric. The resulting sample was used for subsequent quality and fabric pattern assessments and to verify correspondence with the CAD simulation.

2.6. Comparative Technical, Economic, Process, and Sustainability Analysis of Mini-Jacquard Knitted Fabric Versus Chemical Printing

An experimental comparative analysis was conducted between the Mini-Jacquard knitted fabric and the most representative chemical printing techniques (screen printing and heat transfer). The procedure included CAD pattern simulation, prototype fabrication using Pima cotton, and the evaluation of operational parameters, energy consumption, process times, costs, and sustainability indicators. Total time per square meter (min/m2) and electrical energy consumption (kWh) were measured, while water and thermal resources required by each technique were estimated. The data obtained enabled quantitative comparisons of efficiency, environmental impact, and economic feasibility to determine the most eco-efficient and technically viable alternative.

3. Results and Discussion

3.1. Fabric Pattern Characteristics of the Three-Color Mini-Jacquard

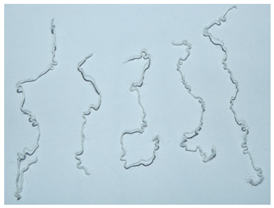

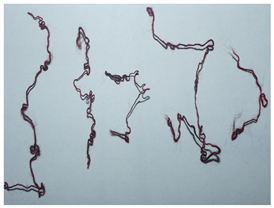

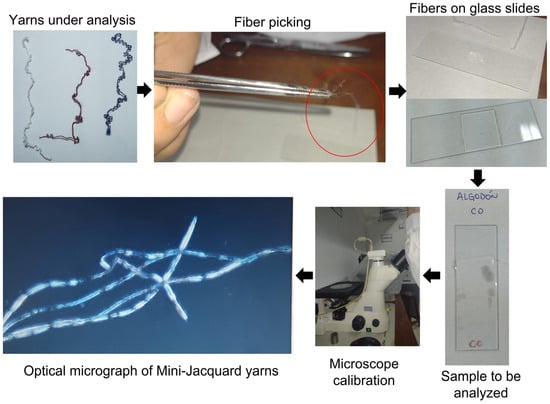

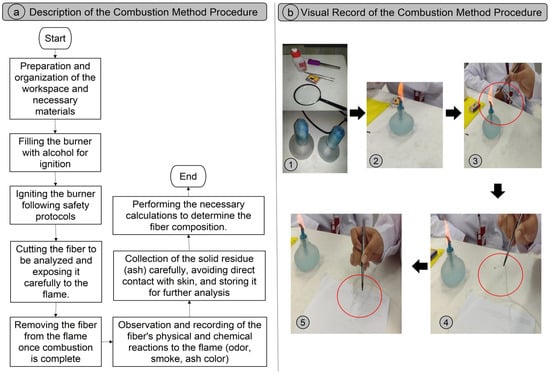

Figure 3 and Figure 4 illustrate the methods employed to identify fiber composition (optical micrographs and combustion), while Table 3 summarizes the fabric pattern parameters determined for the reference Mini-Jacquard sample knitted with 100% cotton. Reported metrics include sample geometry and areal density, yarn count (Ne), stitch/loop length (LM), mass by color, twist per inch (TPI), and twist direction, which together describe the material’s nature and provide a baseline for subsequent performance analyses.

Figure 3.

Sample preparation and optical microscopy of the Mini-Jacquard yarns (Peruvian Pima cotton). Note. The red circle indicates the number of fibers selected during the analysis.

Figure 4.

Combustion-test protocol for textile fiber identification. (a) Flowchart describing the procedure, (b) photographic record of the main steps (1–5). Note. The red circle indicates the number of fibers selected during the analysis.

Table 3.

Fabric pattern calculations and physical properties of the three-color Mini-Jacquard reference sample (100% cotton).

The fabric pattern analysis of the reference three-color Mini-Jacquard reveals clear differences among the yarns used. The blue yarn exhibits the greatest total stitch/loop length (LM = 91.0 cm), followed by red (80.7 cm) and white (51.0 cm), indicating that blue is the most prevalent component within the knitted structure. When mass is considered, red (0.0243 g) and blue (0.0258 g) both exceeded white (0.0145 g); thus, despite its shorter LM relative to blue, the red yarn contributes a higher relative mass than white. In terms of yarn count, values range from 19.59 Ne (red) to 20.81 Ne (blue), confirming that all yarns fall within a similar fineness band characteristic of Peruvian Pima cotton. In addition, the three yarns are single-ply and present a twist of 11.18 TPI in the S direction, which supports dimensional stability and sharp motif definition in the Mini-Jacquard.

Regarding fiber composition, the combustion method confirmed that all three yarns are 100% cotton, according to the formula specified in Section 2.3. The response to flame showed no melting or shrinking; instead, specimens drew away from the flame, burned rapidly without fusion, and produced a yellow flame. The resulting residue consisted of light, soft, and easily crumbled ash. In the optical micrograph analysis, longitudinal fabric pattern irregularities were observed along the fibers, with frequent convolutions (twists). Immature fibers were also identified, characterized by thin cell walls and subtle morphological variations.

These differences can be explained by the distribution of colors within the fabric design. Because the blue yarn occupies the largest proportion of course- and wale-wise sequences in the programmed repeat, it dominates the fabric surface, which accounts for its greater LM and mass. The red yarn, although shorter in LM than blue, shows a slightly coarser count (19.59 Ne versus 20.81 Ne for blue), which increases its specific mass contribution to the fabric despite its lower visual prevalence. By contrast, the white yarn, with an intermediate count (20.75 Ne), registers the lowest total LM, reducing its mass share. The fact that all yarns are single-ply with moderate, uniform twist ensures harmonized interaction among the three colors while maintaining differences in visual and fabric pattern predominance, conditions necessary for the Mini-Jacquard to preserve stability and avoid deformation after use or laundering []. Moreover, the combustion behavior is consistent with the cellulosic nature of cotton, a non-thermoplastic vegetable fiber that does not melt or shrink upon flame exposure, but rather burns rapidly and leaves a characteristic soft ash [].

Comparison with previous research shows good agreement. Toyoura et al. [] reported that, in multicolored Jacquard fabrics, uneven yarn distribution directly reflects the rapport and the stitch density assigned to each color, with one tone often dominating to achieve aesthetic uniformity. Similarly, Emek et al. [] highlighted that yarns with a lower Ne (coarser) tend to require less LM to cover equivalent surfaces, which is consistent with the red yarn’s higher mass contribution at shorter LM. Finally, studies on Pima cotton fabrics, such as Mertová et al. [], confirmed that the combination of single-ply construction and moderate twist favors fabric stability and durability, which is corroborated in the present sample. The composition results are also in line with those of Price and Horrocks [], who described cotton’s easy ignition, yellow flame, and soft ash, which match the properties identified in the analyzed yarns.

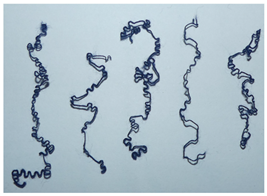

3.2. CAD Simulation of the Three-Color Mini-Jacquard Design

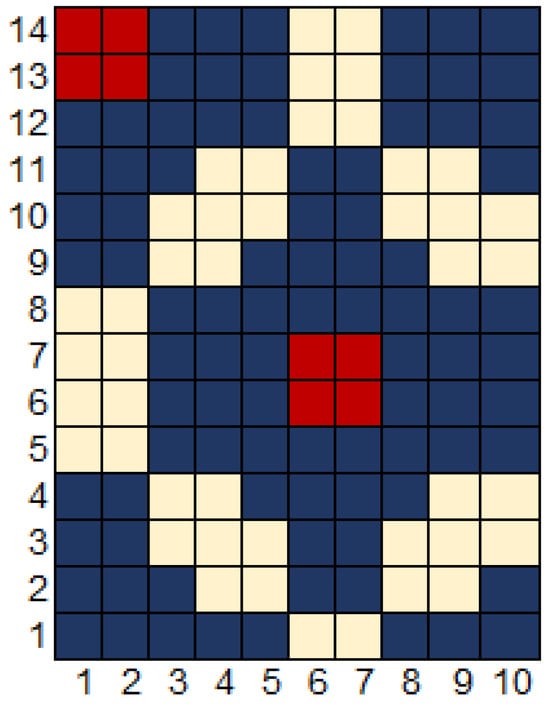

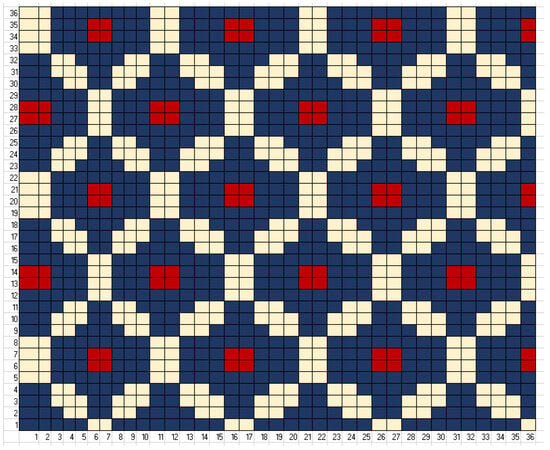

Figure 5 shows the 10 × 14 repeat (rapport) of the three-color Mini-Jacquard. Figure 6 presents the full-pattern representation on a 36 × 36 Excel grid, which corresponds to the minimum area required by the software to run the Mini-Jacquard program. Table 4 details the thread counts per color within the repeat, the corresponding mass used in the repeat, and the consumption share (%) of each color. Figure 7 displays the software simulation of the fabric.

Figure 5.

Three-color repeat (10 × 14) drafted on an Excel grid for Mini-Jacquard programming.

Figure 6.

Full-pattern representation on a 36 × 36 Excel grid (minimum area required by the software for Mini-Jacquard).

Table 4.

Thread distribution and color-wise consumption within the Mini-Jacquard repeat.

Figure 7.

Software-based simulation of the three-color Mini-Jacquard fabric.

The CAD simulation reveals a marked predominance of the blue yarn in the repeat, accounting for 73.81% of the total consumption, while white accounts for 19.65% and red only 6.55%. This chromatic asymmetry does not derive from intrinsic yarn properties (count, composition, twist) but from the digital design architecture: the stitch distribution within the repeat and the minimum-area configuration required by the software lead to a higher frequency of blue yarns across the Excel grid, which translates into a greater LM and, consequently, higher raw material consumption.

Although the red yarn shares similar technical features with the others, it is underrepresented due to its marginal placement within the repeat, which reduces its contribution to both mass and area coverage. This disparity originates in the pre-established design pattern rather than in material constraints, underscoring the decisive role of pre-production design in shaping final yarn consumption.

This trend is consistent with previous reports on Jacquard and Mini-Jacquard fabrics, where the dominant color in the repeat typically accounts for more than 70% of the raw material consumption. Teli et al. [] emphasize that the initial design configuration exerts a stronger influence on consumption ratios than intrinsic yarn properties. Similarly, Zheng et al. [] demonstrate that, in knitted fabrics, repeat symmetry or asymmetry governs both chromatic stability and the fabric pattern balance of the final textile. In this sense, the present results corroborate the literature and highlight the need for optimized digital patterning to achieve more balanced color utilization without compromising motif fidelity.

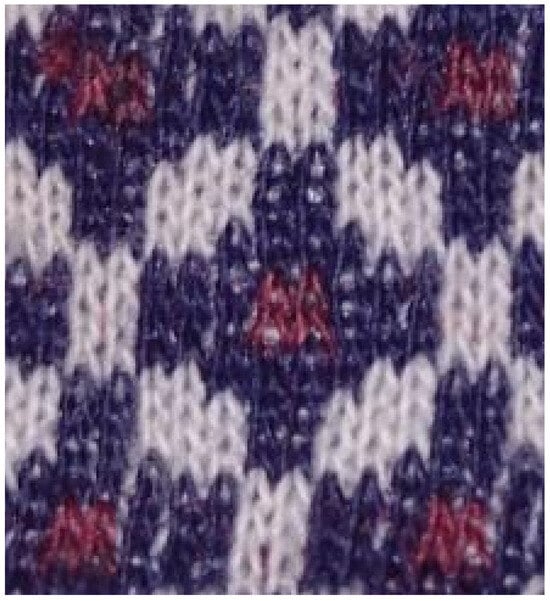

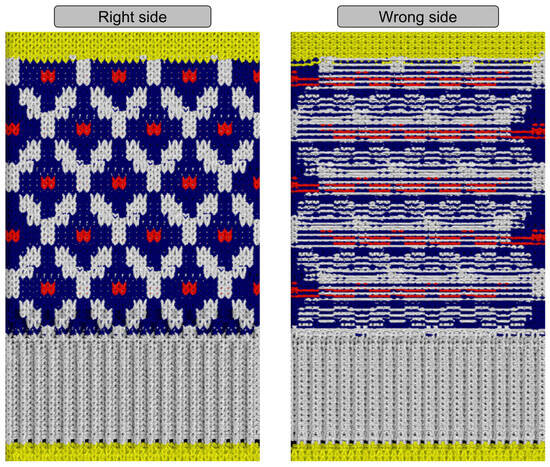

3.3. Weft-Knitted Mini-Jacquard Prototyping on the Single-Bed Flat Machine

Figure 8 shows the prototype of the three-color Mini-Jacquard knitted on a single-bed flat machine. The trial confirmed that the digital design was successfully materialized in the physical sample, faithfully reproducing the programmed motif in terms of contours, figure proportions, and color sequencing. This correspondence validates the technical feasibility of using CAD simulation as a preparatory stage for machine development.

Figure 8.

Three-color weft-knitted Mini-Jacquard prototype produced on a single-bed flat knitting machine. Note: The red circles indicate the regions magnified in the insets (rapport detail).

Structurally, the fabric exhibited regular loop formation and properly controlled yarn tension, which preserved motif symmetry and rhythm without distortions. The prototype displayed a firm surface with adequate drape, conditions suitable for applications in garments and decorative accessories. In addition, no local deformations were observed at color transition points, confirming motif stability under frequent changes. The continuity of design edges reflects effective control of floating loops, preventing snags or irregularities. Finally, the fabric showed uniform resistance to transverse stretching, demonstrating balanced stress distribution across the Mini-Jacquard structure, ensuring both stability and durability for practical applications.

On the reverse side, short floats typical of single-bed Jacquards were observed, corresponding to inactive yarns at specific points of the motif. These floats were uniform and did not result in excessive accumulation, thus contributing to the dimensional stability of the fabric. As a result, the reverse (Figure 8b) shows a distinct texture with greater surface density and opacity, while the front (Figure 8a) maintains a clear definition of the design.

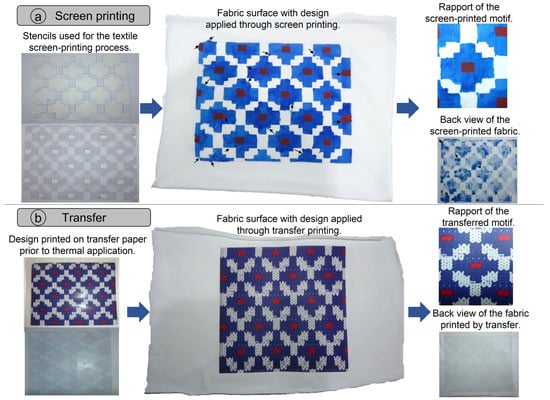

3.4. Sustainability Analysis and Comparison with Chemical Printing

Figure 9 summarizes the principal chemical-printing routes used in the textile industry, which apply synthetic pigments or dyes onto fabric surfaces. Representative techniques include screen printing and heat transfer, each with distinct application steps, resource demands, and aesthetic outcomes. These methods have expanded design possibilities and finishing diversity; however, they are also associated with intensive use of water, thermal energy, and chemical auxiliaries, raising substantial sustainability challenges.

Figure 9.

(a) Screen printing and (b) transfer printing techniques applied on Pima cotton fabrics (30/1 Ne, 175 g/m2, white), evidencing the visible effects of the textile design or pattern and their implications for resource consumption and effluent generation.

3.4.1. Textile Design Replication: Comparison Between Screen Printing, Heat Transfer, and Jacquard Weaving

The comparative analysis of textile design replication reveals significant discrepancies between surface printing techniques (screen printing and thermal transfer) and Jacquard fabric pattern weaving. In screen printing (Figure 9a), the pattern reproduction exhibited evident limitations in geometric fidelity, with symmetry distortions, loss of contour definition, and discontinuous lines resulting from the difficulty of controlling the viscosity and penetration of the printing paste. These irregularities were associated with chromatic heterogeneity, manifested in areas of excessive saturation, pigment migration, and localized tonal variations that compromise the homogeneity of the design. From a tactile perspective, the resulting finish showed high rigidity, surface roughness, and low breathability, while stains and ink bleeding were observed on the fabric’s reverse side, indicating low process stability. In contrast, thermal transfer printing (Figure 9b) achieved greater correspondence with the digital CAD design, approaching the defined color range; however, process control depended on critical parameters such as temperature, pressure, and transfer time, leading to dimensional deformations, scaling mismatches, and loss of sharpness in fine details. Additionally, the surface lacked structural relief, presenting a rigid texture and a thermal sensation unsuitable for user comfort. Conversely, the Mini-Jacquard (Figure 8) demonstrated superior performance, with a highly accurate replication of the CAD design enabled by the individualized control of warp and weft threads, which preserved the dimensional, chromatic, and aesthetic integrity of the pattern. The intrinsic structure of the fabric provided a soft texture, defined tactile reliefs, and characteristic floats on the reverse, resulting in an outstanding balance between aesthetics, functionality, and comfort.

3.4.2. Comparative Analysis of Operational Times Between Mini-Jacquard Weaving and Printing Techniques (Screen Printing and Transfer)

In the comparative analysis of the operational processes carried out in our research, the Mini-Jacquard weaving demonstrated remarkable efficiency compared to chemical printing techniques. For Jacquard, the steps included CAD design (60 min) and weaving (20 min), totaling 80 min per design, which, when projected per square meter of fabric (4 designs of 36 × 36 cm), amounts to approximately 320 min/m2. In transfer printing, the steps included design creation (40 min), design printing (10 min), heat curing of the design (15 min), and transfer printing (8 min), totaling 83 min per design or 332 min/m2. Screen printing, on the other hand, was significantly more time-consuming, considering templates (120 min), development (20 min), printing (15 min), and drying (30 min), reaching 185 min per design and 740 min/m2. This analysis shows that, despite requiring specialized equipment, Mini-Jacquard optimizes operational times per square meter of fabric compared to transfer and screen printing, significantly reducing total production time and simplifying the steps by being limited to CAD design and weaving, while printing techniques involve multiple stages with higher cumulative times, increasing operational complexity and resource consumption.

3.4.3. Cost Analysis: Mini-Jacquard Fabric vs. Screen Printing and Transfer Printing

The comparative cost analysis between Jacquard fabric, screen printing, and transfer printing reveals significant differences in the required investment, mainly due to energy consumption and materials used. In the case of Mini-Jacquard fabric, production using a flat knitting machine with continuous operation (220 V, single-phase) and an approximate consumption of 120 kWh/month represents an electricity expense of $34.8 (based on Peruvian rate), to which the yarn cost of $11.6 is added. This results in higher cumulative costs that reflect both the complexity of the produced patterns and the sophistication of the specialized equipment. In contrast, screen printing involves the purchase of inks ($18.9), screens ($1.5), and base cotton fabric at $4.6 per meter, in addition to high energy consumption during stages such as exposure and drying, which reaches up to 10 kWh, adding $1.85 to operational costs. Nevertheless, this method remains more cost-effective for large production volumes due to economies of scale []. Transfer printing, on the other hand, requires inputs such as specialized paper ($5.8), cotton fabric ($4.6), and energy consumption distributed across design, printing, pressing, and curing stages that exceed 13 kWh, resulting in an additional $2.5, positioning it at an intermediate cost level compared to screen printing and Jacquard. In summary, although screen printing and transfer printing provide accessible and scalable alternatives, Jacquard stands out for integrating the design directly into the fabric structure, which justifies its higher costs and positions it as the preferred option for high-end applications where the fabric pattern’s added value outweighs the economic difference [].

3.4.4. Sustainability Analysis: Mini-Jacquard Fabric vs. Screen Printing, Transfer, and Other Printing Techniques

The sustainability profile of textile production processes varies widely depending on the technique employed, with the weft-knitted Mini-Jacquard pathway emerging as a more eco-efficient alternative compared to conventional chemical-printing methods. Commonly used chemical-printing techniques exhibit elevated environmental loads: for instance, screen printing may consume ≈11 L of water per 6 m of fabric and generate effluents with high concentrations of dyes and thickeners []. Sublimation, while efficient for detailed coloration, typically requires temperatures up to ~200 °C, with an energy demand of ≈1.8 kWh·m−2, reported as ~40% higher than digital printing in comparable conditions []. Digital printing itself, despite offering design precision, often uses ~30–50 g of reactive ink per meter, containing salts and dispersants that impair wastewater quality []. Such salts can decrease wastewater treatment efficiency by approximately 9–41% and 25–31%, respectively, across common removal pathways []. While screen printing has recently been highlighted as a platform for nanotechnology applications and smart textiles, such as conductive inks and functional coatings that improve durability in e-textiles, it remains resource-intensive under mass-production conditions [,]. By contrast, the three-color weft-knitted Mini-Jacquard developed in this study (Section 3.3) integrates motifs directly within the fabric architecture, thereby omitting the printing, fixation, and washing stages. Under scenario-based estimates, this pathway can yield potential reductions of ~90% in water consumption, ~70% in thermal-energy demand, and fully eliminate printing-stage chemical residues (inks/pigments and auxiliaries) [,].

From an economic and environmental standpoint, such savings also reduce input costs, operating expenses, and the need for repeated physical sampling during product development [,]. Moreover, from a circular economy perspective, Jacquard knitting reduces environmental burdens during manufacturing while extending product service life [,]. Unlike surface-printed textiles, which may fade or degrade after repeated high-temperature laundering, Jacquard-knitted designs maintain their contrast and uniformity because the color placement is structurally integrated []. This longer lifetime lowers replacement frequency and mitigates solid-waste generation, adding value for end users and enabling premium export pricing for Peruvian Pima cotton Jacquard products compared with chemically printed fabrics [,]. Collectively, while screen printing, transfer, sublimation, and digital printing continue to be widely employed in the textile industry, their high water, energy, and chemical demands underscore the pressing need for alternatives. The Mini-Jacquard approach demonstrates that integrating design into the fabric structure not only minimizes environmental impact but also strengthens product durability and market competitiveness, aligning closely with sustainable and circular industry goals.

4. Conclusions

The three-color Mini-Jacquard fabric prototype in Pima cotton demonstrates that integrating the design directly into the textile structure represents a technically and environmentally more efficient alternative compared to conventional chemical printing methods. In terms of resource consumption, the Mini-Jacquard technique enables estimated reductions of up to ~90% in water and ~70% in thermal energy by omitting the printing, fixation, and washing stages, while also eliminating chemical residues from inks and auxiliaries. From an operational perspective, the Mini-Jacquard process optimizes production time, requiring only 320 min/m2, compared to 332 min/m2 for transfer printing and 740 min/m2 for screen printing, simplifying the process steps and reducing operational complexity. This efficiency could also positively impacts operating costs by decreasing energy consumption and the need for repeated physical sampling during product development.

This approach offers a competitive, sustainability-aligned option for the Peruvian textile sector with potential applications across apparel and accessories. Future work should (i) optimize the process using organic or recycled fibers, (ii) evaluate sustainable finishing combinations that preserve motif fidelity, and (iii) conduct standardized performance tests (e.g., pilling, dimensional stability after laundering, bursting strength), including quantitative assessments of color fastness to washing and rubbing, alongside a formal life-cycle assessment to determine net environmental benefits across the supply chain.

Author Contributions

Conceptualization, R.S.-R. and P.J.M.-R.; Methodology, P.J.M.-R. and R.S.-R.; Software and data analysis, P.J.M.-R.; Original draft preparation, writing, review, and editing, P.J.M.-R. and R.S.-R.; Supervision, project administration, and funding acquisition, R.S.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. For further inquiries, please contact the corresponding author.

Acknowledgments

The authors gratefully acknowledge the Universidad Tecnológica del Perú (UTP) for providing access to its laboratories and equipment, which were essential for the production of the textiles developed in this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ragab, M.M.; Othman, H.; Hassabo, A. An Overview of Printing Textile Techniques. Egypt J. Chem. 2022, 65, 749–761. [Google Scholar] [CrossRef]

- Cruz-Grimaldo, C.; Nieves, M.; Vera, E.; Duran, M.; Morales, A.; Salazar, W.; Arbizu, C.I. Yield Predictions of ‘Del Cerro’ Cotton (Gossypium Hirsutum L.) Germplasm By Multispectral Monitoring In the North Coast of Peru. Chil. J. Agric. Res. 2025, 85, 15–26. [Google Scholar] [CrossRef]

- Morales-Aranibar, L.; Rivera, M.Y.; Gonzales, H.H.; Aranibar, C.G.; Gutiérrez, N.L.; Gomez, F.G.; Zuffo, A.M.; Aguilera, J.G.; Steiner, F. Comparative Analysis of Key Fiber Characteristics In White Pima Cotton (Gossypium barbadense L.): Native Accessions From the Peruvian Amazon. Agrosyst. Geosci. Environ. 2024, 7, e20517. [Google Scholar] [CrossRef]

- Alagarsamy, M. Assessing Genetic Variation In Gossypium barbadense L. Germplasm Based on Fibre Characters. J. Cotton Res. 2023, 6, 15. [Google Scholar] [CrossRef]

- Paste, V.; Tiwari, R.R.; Kamath, R. Evaluation of Respiratory Health of Polyester Dyeing and Printing Workers. Indian J. Physiol. Pharmacol. 2023, 67, 277–282. [Google Scholar]

- John, S.M.; Johansen, J.D.; Rustemeyer, T.; Elsner, P.; Maibach, H. Textile Workers. In Kanerva’s Occupational Dermatology; Springer: Berlin/Heidelberg, Germany, 2019; pp. 2325–2341. [Google Scholar]

- Kurade, M.B.; Jadhav, U.U.; Phugare, S.S.; Kalyani, D.C.; Govindwar, S.P. Global Scenario and Technologies for the Treatment of Textile Wastewater. In Current Developments in Bioengineering and Biotechnology: Advances in Eco-Friendly and Sustainable Technologies for the Treatment of Textile Wastewater; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–43. [Google Scholar]

- Zhou, Y.; Chen, T.; Zhang, X.; Chen, R.; Zhu, N.; Li, L.; Zhao, L.; Li, Z.; Wang, Y.; Jiang, G. Occurrence and Ecological Risk Assessment of Highly Toxic Halogenated Byproducts During Chlorination Decolorization of Textile Printing and Dyeing Wastewater. Environ. Sci. Technol. 2024, 58, 17970–17978. [Google Scholar] [CrossRef]

- Chae, Y.; Xin, J.H.; Hua, T. Color Prediction Models for Digital Jacquard Woven Fabrics. Color. Res. Appl. 2016, 41, 64–71. [Google Scholar] [CrossRef]

- Ng, M.C.; Zhou, J. Full-Colour Compound Structure for Digital Jacquard Fabric Design. J. Text. Inst. 2010, 101, 52–57. [Google Scholar] [CrossRef]

- Zeydan, M. Modelling the Woven Fabric Strength Using Artificial Neural Network and Taguchi Methodologies. Int. J. Cloth. Sci. Technol. 2008, 20, 104–118. [Google Scholar] [CrossRef]

- Peng, X.; Zhou, J. Double-Faced Shading Effect Digital Jacquard Fabric With A Weft-Backed and Warp-Wadded Structure. Text. Res. J. 2023, 93, 795–806. [Google Scholar] [CrossRef]

- Cong, H.; Li, X.; Zhang, A.; Zhang, Y.; Zhong, J. Modeling of Double-Layer Jacquard Fabrics for Pattern Simulation. Int. J. Cloth. Sci. Technol. 2018, 30, 698–709. [Google Scholar] [CrossRef]

- Carraro, F. The Weaver and the Machine. The Transmission of Know-How and Gestures In Art Textile Factories. Ethnol. Française 2022, 52, 159–172. [Google Scholar] [CrossRef]

- Arslan, P.; Ferreira, A.M.; Akpınarlı, H.F. Cultural Heritage, Collaborative Practices and Sustainable Fabric Design: Ottoman Sultans’ Life Stories on Jacquard Design. Adv. Intell. Syst. Comput. 2020, 970, 102–113. [Google Scholar]

- Liu, S.Y.; Yuan, G.X. Application of Visual Illusion Patterns on Modern Women’s Knitwear Design. J. Fiber Bioeng. Inform. 2021, 14, 89–100. [Google Scholar] [CrossRef]

- Chen, M.; Jiang, G.; Zhang, Y.; Li, X. Study on Two-Color Jacquard Processes for Wrap-Knitting Shoe Fabric. Adv. Text. Technol. 2020, 28, 36–41. [Google Scholar]

- Oxunov, R.; Qurbanov, B.; Dadamirzayeva, S.; Korabayev, S.; Ergashev, J. Research on the Effect of the Type of Raw Material on the Physical and Mechanical Properties of the Fabric Obtained By the Circular Needle Jacquard Knitting Machine. AIP Conf. Proc. 2024, 3045, 030046. [Google Scholar] [CrossRef]

- Seyam, A.M. Developments In Jacquard Woven Fabrics. In Specialist Yarn and Fabric Structures: Developments and Applications; Woodhead Publishing: Sawston, UK, 2011; pp. 223–263. [Google Scholar]

- Liang, J.; Cong, H.; Gao, Z.; Zhang, A.; Dong, Z. Computer-Aided Design of Weft-Knitted Two-Side Jacquard Fabric. Int. J. Cloth. Sci. Technol. 2021, 33, 122–136. [Google Scholar] [CrossRef]

- Chen, A.; Tan, J.; Tao, X.; Henry, P.; Bai, Z. Challenges In Knitted E-Textiles. Adv. Intell. Syst. Comput. 2019, 849, 129–135. [Google Scholar]

- Yan, T. Weft-Knitting Double-Sided Jacquard Fabric and Production Practice of Its One-Bath Multi-Color Dyeing Process. Adv. Text. Technol. 2020, 28, 62–65. [Google Scholar]

- Ng, M.C.; Zhou, J. Innovative Layered-Combination Mode for Digital Jacquard Fabric Design. Text. Res. J. 2009, 79, 737–743. [Google Scholar] [CrossRef]

- Price, D.; Horrocks, A.R. Combustion Processes of Textile Fibres. In Handbook of Fire Resistant Textiles; Elsevier: Amsterdam, The Netherlands, 2013; pp. 3–25. [Google Scholar]

- Berenguer, J.L.; Diaz-García, P.; Martinez, P.M. Determining the Loop Length During Knitting and Dyeing Processes. Text. Res. J. 2021, 91, 188–199. [Google Scholar] [CrossRef]

- Kayseri, G.Ö.; Kirtay, E. Part 1. Predicting the Pilling Tendency of the Cotton Interlock Knitted Fabrics By Regression Analysis. J. Eng. Fiber Fabr. 2015, 10, 110–120. [Google Scholar] [CrossRef]

- Xie, J.; Gordon, S.; Long, H.; Miao, M. Twist Requirement for Blended Yarns. J. Text. Inst. 2017, 108, 852–855. [Google Scholar] [CrossRef]

- Arbataitis, E.; Mikucioniene, D.; Halavska, L. Flexible Theoretical Calculation of Loop Length and Area Density of Weft-Knitted Structures: Part I. Materials 2021, 14, 3059. [Google Scholar] [CrossRef]

- Long, J.; Shen, L. Development of Moisture-Absorbing and Quick-Dry Cool Mica/Coolmax/Cotton Fabric. Adv. Text. Technol. 2020, 28, 42–45. [Google Scholar]

- Toyoura, M.; Igarashi, T.; Mao, X. Generating Jacquard Fabric Pattern With Visual Impressions. IEEE Trans. Ind. Inform. 2019, 15, 4536–4544. [Google Scholar] [CrossRef]

- Emek, B.; Şardağ, S. The Investigation of Some Properties of Different Polyester/Elastane Yarns Obtained by Commingling Process and Woven Fabrics Obtained from These Yarns. Tekst. Ve Muhendis 2024, 31, 121–134. [Google Scholar]

- Mertová, I.; Moučková, E.; Neckář, B.; Vyšanská, M. Influence of Twist on Selected Properties of Multifilament Yarn. Autex Res. J. 2018, 18, 110–120. [Google Scholar] [CrossRef]

- Teli, M.D.; Khare, A.R.; Chakrabarti, R. Dependence of Yarn and Fabric Strength on the Structural Parameters. Autex Res. J. 2008, 8, 63–67. [Google Scholar] [CrossRef]

- Zheng, F.; Chen, F.; Liu, Y. Finite Element Modeling of Spherical Indentation Behavior of 3d Mesh Fabric At the Yarn Level. J. Ind. Text. 2023, 53, 15280837231209502. [Google Scholar] [CrossRef]

- Ramaiah, G.B.; Mequanent, A.; Legese, R.; Solomon, E.; Asfaw, D. Effect of Chemical Pre-treatment on Screen Printed Fabric Performance Properties. J. Phys. Conf. Ser. 2023, 2663, 012015. [Google Scholar] [CrossRef]

- Mu, X.; Jiang, G.; Guan, S.; Liu, H.; Li, B. Design and 3D Simulation of Weft-Knitted Jacquard Plush Fabrics. Autex Res. J. 2024, 24, 20240001. [Google Scholar] [CrossRef]

- Andajani, E.; Simangunsong, T.L.; Kusumawardhany, P.A. Water Saving Potential At Small Enterprise: Case Study Mandhegani Eco-Print Surabaya. IOP Conf. Ser. Earth Environ. Sci. 2023, 1268, 012061. [Google Scholar] [CrossRef]

- Toshikj, E.; Prangoski, B. Textile Sublimation Printing: Glcm Print Mottle Assessment of Black Printed Fabric. Medziagotyra 2023, 29, 375–381. [Google Scholar] [CrossRef]

- DiGregorio, S.J.; Hildreth, O.J. Particle-Less Reactive Inks. In Smart Multifunctional Nano-Inks: Fundamentals and Emerging Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 125–158. [Google Scholar]

- Merino-Ramirez, P.J.; Vásquez Espinoza, J.M. Application of Nanotechnology To Improve the Durability of Smart Textiles In the Health Sector: A Systematic Review of the Literature. In Proceedings of the 23rd Laccei International Multi-Conference for Engineering, Education and Technology (Laccei): Engineering, Artificial Intelligence, and Sustainable Technologies in Service of Society, Mexico City, Mexico, 16–18 July 2025. [Google Scholar] [CrossRef]

- Srivastava, A.; Parida, V.K.; Majumder, A.; Gupta, B.; Gupta, A.K. Treatment of Saline Wastewater Using Physicochemical, Biological, and Hybrid Processes: Insights Into Inhibition Mechanisms, Treatment Efficiencies and Performance Enhancement. J. Environ. Chem. Eng. 2021, 9, 105775. [Google Scholar] [CrossRef]

- Ng, F.; Zhou, J. Innovative Jacquard Textile Design Using Digital Technologies; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–221. [Google Scholar]

- Mancasi, N.V.; Cristian, I. Cad/Cam for Jacquard Weaving-the Path From Design To Woven Fabric. In Proceedings of the Elearning and Software for Education Conference, Bucharest, Romania, 23–24 April 2020; pp. 324–330. [Google Scholar]

- Mathur, K.; Seyam, A.F.; Hinks, D.; Donaldson, R.A. Prediction of Color Attributes Through Geometrical Modeling. Res. J. Text. Apparel. 2008, 12, 19–31. [Google Scholar] [CrossRef]

- Zhou, J.; Duan, L.; Luo, B.F. Design Principle and Method of Digital Multicolored Warp Jacquard Fabric. Adv. Mat. Res. 2014, 941, 1331–1335. [Google Scholar] [CrossRef]

- Cotton, L.; Hayward, A.S.; Lant, N.J.; Blackburn, R.S. Improved Garment Longevity and Reduced Microfibre Release Are Important Sustainability Benefits of Laundering In Colder and Quicker Washing Machine Cycles. Dye. Pigment. 2020, 177, 108120. [Google Scholar] [CrossRef]

- Holme, I. Innovative Technologies for High Performance Textiles. Color. Technol. 2007, 123, 59–73. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).