Abstract

Aluminium is an attractive material for proton-exchange-membrane fuel cell bipolar plates as it has a much lower density than steel and is easier to form than both steel and graphite. This work focused on the development of amorphous carbon films deposited using closed-field unbalanced magnetron sputtering (CFUBMS) in order to improve the corrosion resistance of aluminium bipolar plates and to enhance fuel cell performance and durability. Chromium and tungsten adhesion layers were used for the coatings. It was possible to achieve good electrical conductivity and high electrochemical corrosion resistance up to 70 °C on polished Aluminium alloy 6082 by tuning the deposition parameters. Coatings with a tungsten adhesion layer showed better corrosion resistance than those with a chromium adhesion layer. In situ, accelerated stress testing of single cells was performed using uncoated and coated Al6082 bipolar plates. Both coatings resulted in improved fuel cell performance compared to uncoated aluminium when used on the cathode side of the fuel cell.

1. Introduction

Proton-exchange-membrane fuel cells (PEMFCs) are an attractive energy source due to their potential for reducing carbon footprints. Bipolar plates (BPPs) are one of the main components of these fuel cells, due to their volume, weight, cost and functionality [1]. Stainless steel is the most common material used for the production of metallic BPPs, especially for automotive applications [2]. Aluminium could be a suitable alternative, most importantly owing to its light weight (approximately 60% less than stainless steel); its use for BPPs would enable a considerable increase in the PEMFC specific power. Aluminium is also cheaper than stainless steel and easily formable. Nevertheless, insufficient corrosion resistance and the loss of surface conductivity as a result of oxide formation have so far restricted aluminium BPPs from wider application. The USA Department of Energy (DOE) has set target values of <1 µA cm−2 for corrosion current density, and 10 mΩ cm2 for the area-specific resistance [3]. Therefore, appropriate surface coatings are essential in order to make aluminium BPPs technologically and commercially viable. Increasing research effort has been dedicated to developing such coatings.

The coatings applied to PEMFC aluminium BPPs can be broadly divided into carbides [4], nitrides [5,6], nickel and nickel alloys [7,8,9,10,11], conductive polymer composites [12,13] and carbon coatings [14,15,16]. The use of double-layer and multilayer coatings comprising the above, such as Ni-P coatings with a titanium oxynitride (TiNO) layer on top [17], or a corrosion-resistant layer followed by a conductive layer [18], has also been reported.

Narasimharaju et al. [5] reviewed the use of nitride coatings on aluminium-based bipolar plates. The results presented, whilst promising in terms of reducing the corrosion rate of aluminium, do not satisfy the stringent requirements for PEMFC BPPs and indicate challenges, such as coating porosity and adhesion issues, which require further development to overcome.

Similarly, the use of nickel and nickel alloys prepared by electroless plating remains far from achieving corrosion targets, at least on the cathode side [8]. The use of a double-layer Ni-P/TiNO coating [17] resulted in better corrosion performance, nearly achieving the DOE target for the corrosion current density on the cathode side. The ICR of this coating, however, was well above the DOE target.

There are still many gaps in the research and deployment of coated aluminium bipolar plates for PEMFCs. The critical factors that determine the suitability of aluminium bipolar plates are high corrosion resistance and conductivity, as well as the durability of the coatings within fuel cell operating conditions. These targets have not yet been fully met for aluminium BPPs.

Carbon coatings have been extensively evaluated for BPPs based on stainless steel and titanium [19,20,21] but there are not many reports on their use for aluminium-based BPPs. Mirzaee Sisan et al. [15] evaluated the corrosion resistance of sputtered carbon coatings on stainless steel and aluminium substrates. They found that whilst a 200 nm thick coating was sufficient to prevent the corrosion of stainless steel, coatings of up to 600 nm were not sufficient to provide adequate protection to aluminium bipolar plates. Our previous work [16] focused on the development of carbon coatings deposited using closed-field unbalanced magnetron sputtering (CFUBMS) for aluminium BPPs used in low-temperature (55 °C) PEMFCs. This work aims to improve the coatings to enable their use in conventional PEMFCs running at 70–80 °C.

2. Materials and Methods

2.1. Coating Preparation

Carbon coatings were deposited using a Teer CF-800 CFUBMS system (Teer Coatings Ltd., Droitwich, UK). Aluminium alloy grade 6082 with T6 temper was obtained from Goodfellow Advanced Materials in a thickness of 1 mm and was cut to 50 × 50 mm2 coupons. Table 1 shows the composition of Al6082 [22]. A witness sample of M42 tool steel (30 mm diameter, 3 mm thick) was used in each deposition for thickness measurement and quality control monitoring.

Table 1.

Composition of Al6082 alloy.

Prior to the deposition, the substrates were ultrasonically cleaned in acetone for 15 min, followed by drying in warm air. The samples were arranged onto the substrate holder and introduced into the coating chamber at a substrate-to-target distance of 15 cm. The chamber was then evacuated to a pressure of 0.0027 Pa (2 × 10−5 torr). Argon (99.998% purity) was then admitted, allowing the chamber to reach the desired deposition pressure. The coupons were first ion-cleaned by applying a pulsed DC bias voltage of −350 V, during which the magnetrons (2 with chromium or tungsten (both 99.5% purity) and 2 with isotropic graphite targets) were operated at 0.4 A. The coupons were then sputtered with a 0.5 µm Cr or W layer, followed by a gradient layer with increasing carbon and decreasing metal content. Finally, a top layer of pure carbon was deposited using the two carbon targets, during which the pulsed DC substrate bias was reduced to the desired voltage. The coating thickness, including both the interlayer and the top carbon layer, was measured using the ball cratering method. The errors in measurements were within ±50 nm of the reported values. Table 2 summarises the deposition parameters for the coatings.

Table 2.

Deposition parameters for carbon coatings.

2.2. Characterisation

Coating thickness was measured using the ball-cratering method. Analysis of the topography of the test plates, as well as post-mortem analysis of the tested plates were performed using a Hitachi TM3030 scanning electron microscope (SEM) ( Hitachi High-Technologies Corporation, Tokyo, Japan), fitted with a Bruker EDX. EDX was conducted at an accelerating voltage of 15 kV with a working distance of 9.90 mm. The spectrometer was calibrated based on the Full Width at Half Maximum (FWHM) of Cu Kα at 8.04 keV. The count accumulation time was set to 15 min to ensure reliable elemental mapping. The Interfacial Contact Resistance (ICR) of the coated plates was measured using the method described in [16] at a compressive stress of 140 MPa.

2.3. Corrosion Testing

Corrosion testing was carried out in a three-electrode setup, where the aluminium coupon (working electrode) and a platinum mesh (counter-electrode) were submerged in a 1 mM H2SO4 electrolyte. The reference electrode, Hg/Hg2SO4/K2SO4 (at 0.68 V vs. SHE), was connected to the electrolyte compartment by a salt bridge. The electrolyte was heated to the desired temperature. All standard potentials mentioned in this work are vs. the standard hydrogen potential (SHE). A PalmSens EmStat potentiostat (PalmSens, Houten, The Netherlands) was used to perform potentiostatic measurements at 0.8 V vs. SHE for electrolyte concentrations of 1 mM, for a period of 1 h, with bubbling air to simulate the cathode corrosion environment.

2.4. Fuel Cell Testing

Single-cell fuel cell testing was performed using a Scribner 850e fuel cell station (Scribner LLC., Southern Pines, NC, USA) at the University of Birmingham. The test setup has been described fully elsewhere [16].

The membrane electrode assembly (MEA) used for the measurements was a Ballard catalyst-coated Nafion membrane (CCM) (Ballard Power Systems, Bend, OR, USA), with a catalyst loading of 0.4 mg cm−2. The operating temperature was 80 °C. A Freudenberg I2C6 gas diffusion layer (GDL) was used.

Single cells were manufactured using a graphite plate for the anode side and a coated aluminium plate for the cathode side. A serpentine geometry with a total length of 392.4 mm was used. The channels had a rectangular cross-section (1 mm wide and 1 mm deep), separated by 1 mm wide ribs. The active area was 20 mm × 20 mm.

Before the MEA underwent testing, it was conditioned at 80 °C with 100% relative humidity, an anode back-pressure of 150 kPa and a cathode back-pressure of 130 kPa, with an anode inlet of hydrogen and a cathode inlet of air (1.3 and 1.5 stoichiometry, respectively) for 15 h. Once the membrane was fully hydrated, the cell temperature was maintained as 80 °C, and the relative humidity was set to 75% for both the anode and cathode for the accelerated stress test (AST).

Then, charge cycles began every 2 min, changing the voltage between 0.6 V (1 min) and 0.9 V (1 min); the test was stopped after 300 cycles (10 h), when the polarisation curves and electrochemical impedance spectroscopy (EIS) results were obtained, before another 300 cycles. This was repeated a total of 10 times. The polarisation curve was recorded from open-circuit voltage (OCV) to 0.25 V with a step size of 0.05 V per point, and the dwell time of each point was 180 s to ensure the stabilisation of current density. EIS measurement was performed in the frequency range from 10 kHz to 0.1 Hz with an amplitude of 10% of the DC at 0.6 V. An equivalent circuit model, as seen in Figure 1, was employed to evaluate the single-cell behaviour and the ohmic losses. This model consists of an ohmic resistance connected in series with three parallel circuits. R1 represents the ohmic resistance of the cell. The charge transfer resistance at the anode and cathode are represented by R2 and R3, respectively. R4 is equivalent to the resistance to the mass transport losses. In addition, the constant phase elements (CPEs) were used to adjust the system’s response to an equivalent circuit model. The experimental data obtained were modelled using the ZView® software (version 4.1a) from Scribner.

Figure 1.

An equivalent circuit representing a single fuel cell constituting resistors and constant-phase elements.

3. Results

3.1. Performance of Uncoated and Coated Non-Polished Aluminium Substrate

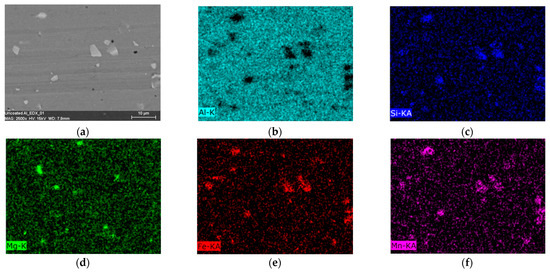

Aluminium alloy 6082 is widely used due to its good formability and corrosion resistance. However, if unprotected, it is prone to corrosion and pitting when exposed to harsh environments [23,24]. Figure 2 shows an SEM image of an ultrasonically cleaned Al6082 substrate, together with the EDX mapping of its surface. It can be seen that segregated particles, deficient in aluminium and made of the alloying elements, are present on the surface. This is a common feature on material with a T6 temper which has undergone a solution heat treatment followed by artificial ageing.

Figure 2.

(a) SEM image and EDX mapping of surface of as-received Al6082, showing distribution of (b) aluminium, (c) magnesium, (d) silicon, (e) iron and (f) manganese.

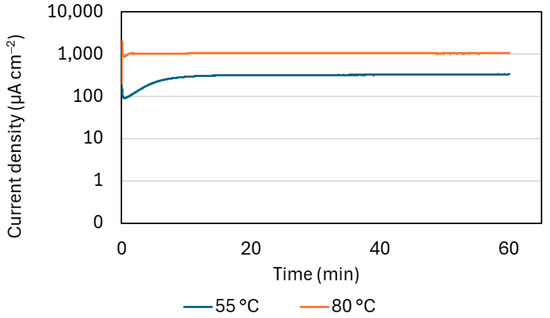

Figure 3 shows the corrosion test results for the uncoated aluminium alloy at 55 and 80 °C. It can clearly be seen that the cathodic corrosion is well above the DOE target of 1 µA cm−2 at both temperatures. Furthermore, the ICR of the alloy was 26 and 57 mΩ cm2 before and after corrosion testing, respectively. Despite aluminium’s good electrical conductivity, its ICR is high as a result of the non-conductive oxide layer that forms on its surface. This oxide layer grows thicker and more insulating during the corrosion test, reducing the conductivity further. Both the high corrosion rate and high ICR make is essential to coat this alloy with a suitable coating in order for it to be suitable as a BPP material.

Figure 3.

Corrosion performance of uncoated aluminium alloy at 55 and 80 °C.

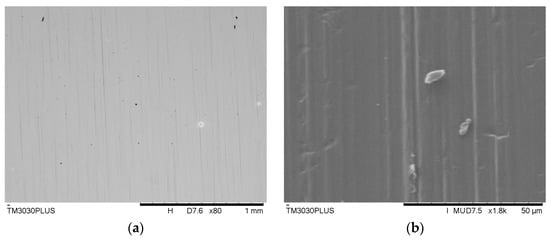

Figure 4 presents SEM images of a carbon coating (Cr-C1) deposited on this substrate using the parameters shown in Table 2. As can be seen, there are inclusions on the surface, where it is likely that the coating coverage of the surface may not be complete.

Figure 4.

SEM images of carbon-coated Al6082 at (a) 80×, and (b) 1800× magnifications.

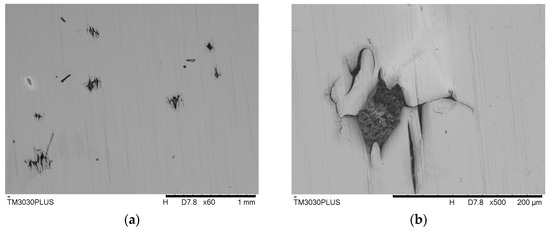

Images of the coated surface after being subjected to potentiostatic corrosion testing for one hour are shown in Figure 5. Areas of severe corrosion can be seen, where the coating has crumbled as a result of the substrate (dark areas) corroding underneath. This is not unexpected if defects or pinholes in the coating provide access points for the electrolyte to the aluminium. Due to its position in the galvanic series, aluminium is particularly prone to anodic corrosion when in contact with another, more noble material [25]. Both chromium and graphite are more noble than aluminium [26,27]; hence, the simultaneous exposure of these materials in the presence of an electrolyte due to a defect can result in the corrosion of aluminium, which progresses quickly, compromising the rest of the coating.

Figure 5.

SEM images showing carbon coating after 1 h potentiostatic corrosion test, at (a) 60×, and (b) 500× magnifications.

The above results show the importance of a defect-free substrate in order to achieve a defect-free coating. Hence, the subsequent experiments were performed on a mirror-polished Al6082 substrate.

3.2. Performance of Coating on Polished Aluminium Substrate

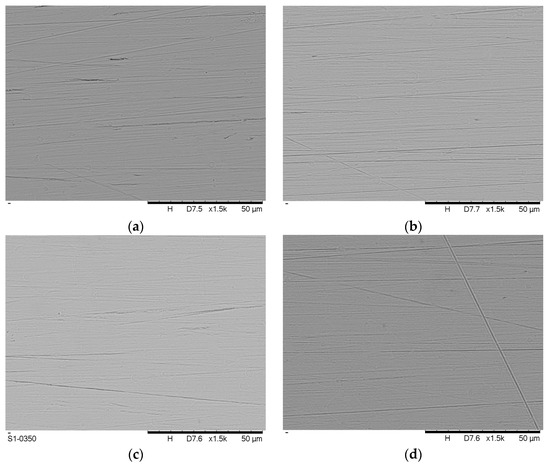

Carbon coatings with varied deposition parameters (Table 2, Cr-C2–Cr-C5) were deposited in order to find the optimum coating for corrosion protection of the aluminium substrate. Figure 6 shows SEM images of these coatings, demonstrating the fairly smooth surface without excessive inclusions and defects.

Figure 6.

SEM images of carbon-coated Al6082 plates: (a) Cr-C2, (b) Cr-C3, (c) Cr-C4 and (d) Cr-C5.

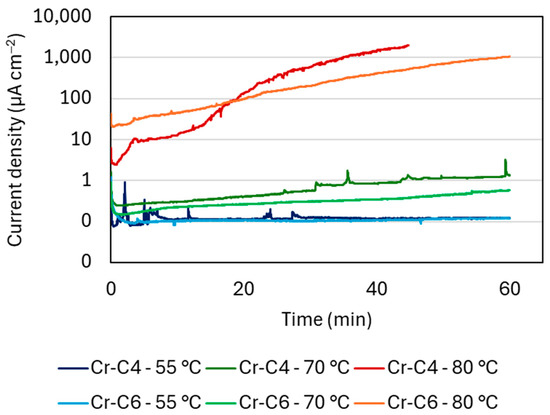

The coated samples were subjected to potentiostatic testing at 55 °C. All plates, with the exception of Cr-C4, showed significant corrosion, indicating that the coatings were not sufficiently dense to prevent the corrosion of the aluminium alloy. Cr-C4, however, performed well and achieved a cathodic current density of 0.12 µA cm−2. This coating was also tested 70 and 80 °C. The performance was good up to 70 °C, where the current density was 1.36 µA cm−2 after one hour of testing at 0.8 V against SHE. Increasing the temperature further to 80 °C resulted in severe corrosion, and the test was aborted after 45 min due to the corrosion current exceeding the measurement limit of the potentiostat. The effect of a thicker coating on corrosion protection was studied by depositing a coating (Cr-C6) with a carbon layer deposition time of 180 min, hence doubling the thickness of this layer and achieving an overall coating thickness of 1.5 µm. As expected, the thicker coating provided better protection, with current densities after one hour of 0.1, 0.6 and 1077 µA cm−2 at 55, 70 and 80 °C, respectively. Figure 7 shows the potentiostatic test results for these two coatings.

Figure 7.

Corrosion performance of C80-1.0 and C80-1.5 at different temperatures.

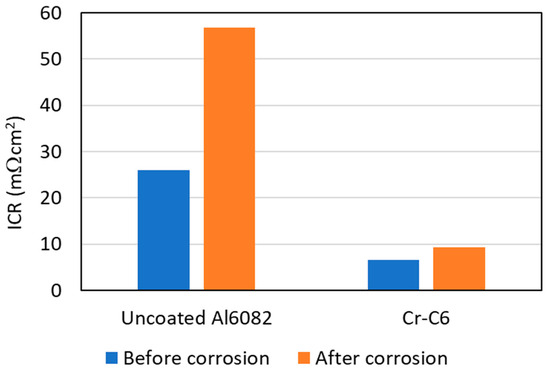

The ICR test results for Cr-C6 were compared with the results for uncoated Al6082. (Figure 8). Cr-C6 achieved ICR results within the USA DOE targets for PEMFC bipolar plate conductivity, both before and after corrosion testing.

Figure 8.

ICR of aluminium and coating before and after corrosion testing.

The results presented above are very promising and compare favourably with the reports in the literature for coated aluminium BPPs. For example, Zhang et al. [17] reported on the corrosion properties of TiNO and Ni-P/TiNO coatings on aluminium. Although the double-layer coating reduced the cathodic corrosion to 1.1 µA cm−2, the coating ICR was 50 mΩ cm−2, which is well above the DOE target and the values obtained in this work. González-Gutiérrez et al. [8] reported a cathodic corrosion of 261 µA cm−2 for their Ni-P coating under oxygen bubbling but without stating the temperature used. Ma et al. [28] present the potential of an amorphous carbon layer deposited from candle soot. This coating, however, was only tested to determine its electrochemical properties at room temperature, and furthermore, did not have the required conductivity to make the coating viable. To our knowledge, Srivastava et al. [29] are the only group who have reported achieving the DOE target for aluminium BPPs; however, this was possible through diffusion bonding of 25-micron-thick Ti foil to the aluminium substrate, followed by gold as a conductive layer. This method is unlikely to unveil the economic advantages of using aluminium as a bipolar plate material. These results confirm the potential of magnetron-sputtered carbon coatings for aluminium-based PEMFC BPPs. However, issues remain with the integrity of the coating being compromised, especially at higher operating temperatures, by the presence of even the smallest defect.

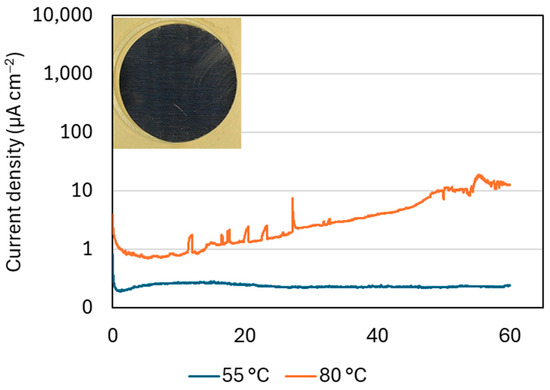

In our previous work [16], we looked at titanium as an alternative adhesion layer to chromium for carbon coatings. In this work, we looked at tungsten. Two reasons led to this selection. Firstly, tungsten is a well-established transition metal used in combination with carbon in the deposition of carbide and carbon coatings [30], and secondly, it has potential in improving the corrosion protection of aluminium [31]. A coating with a tungsten interlayer was deposited. Figure 9 shows the corrosion results for the W-C coating, as well as a picture of the sample after electrochemical testing. An interesting observation was that although presence of pits after corrosion testing was evident, the cathodic current density remained low, even at 80 °C. It appears that the presence of tungsten limits the galvanic corrosion of aluminium. Further investigation of this effect will be needed to establish the mechanism by which tungsten affects corrosion progress.

Figure 9.

The corrosion performance of W-C at 55 and 80 °C, and a picture of the corrosion-tested sample. The circular area tested for corrosion measured 10 cm2.

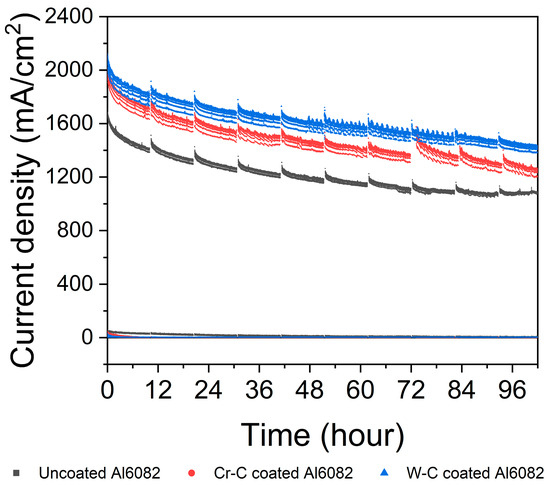

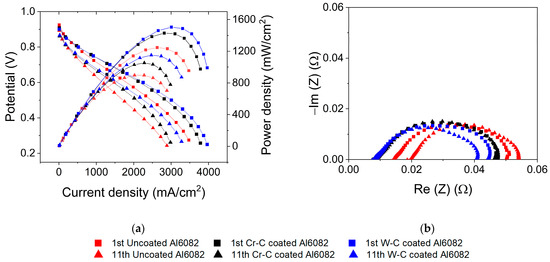

The in situ performance of Cr-C6 and W-C coatings was analysed by using them as bipolar plate coatings on the cathode side of Al6082 plates and comparing their performance with that of uncoated Al6082 bipolar plates and with each other. The aim was to evaluate the suitability of these coatings for fuel cell lifetime extension, another challenge for coated bipolar plates. Figure 10 shows current vs. time curves for cells using Cr-C coated, W-C-coated and bare Al6082 plates, operating under voltage cycling between 0.6 and 0.9 V for 100 h. Figure 11a,b compare the initial and final polarisation curves and EIS of the ASTs with bare, Cr-C-coated, and W-C-coated Al6082, respectively. Table 3 summaries the initial and final current densities, and the initial and final peak power densities, from the polarisation curves recorded at the beginning and end of the ASTs. The values from the equivalent circuit analysis are presented in Table 4 for various operating conditions.

Figure 10.

AST of singles cells with bare, Cr-C-coated and W-C-coated Al 6082 bipolar plates at cyclic voltages between 0.6 and 0.9 V for 100 h of operation.

Figure 11.

(a) Initial and final polarisation curves and (b) initial and final EIS of single cells with uncoated, Cr-C-coated and W-C-coated Al6082 cathode side of bipolar plates.

Table 3.

Results of AST and polarisation curve of single cells with bare, Cr-C-coated and W-C-coated Al6082 bipolar plates.

Table 4.

Equivalent circuit element values for impedance analysis.

As can be seen, the uncoated Al6082 exhibits the lowest current density among all samples, with performance degradation of 36.4% at 0.6 V over the 100 h. This lower performance is expected, both as a result of its higher corrosion rate, and the higher electrical resistance of the oxide formed on the aluminium surface [32]. The W-C-coated Al6082 shows the highest initial current density and power density (2121 mA cm−2 and 1504 mW cm−2, respectively) due to the metallic-like conductivity of the W-C coating from its partially filled d-bands, which enhance the charge transfer efficiency [33]. After 100 h of voltage cycling, the W-C-coated Al6082 retains the highest final current density and power density (1425 mA cm−2 and 1151 mW cm−2, respectively). This may be attributed to the chemical inertness and strong adhesion of the coating, which mitigate acid-induced dissolution and microcrack propagation [34]. The EIS data reveal that, while the charge transfer resistance (R2 + R3) of W-C-coated Al6082 increases after AST, it is still lower than that of the Cr-C-coated Al6082, emphasising its retained interfacial stability despite minor surface degradation [34]. However, the total resistance of W-C-coated Al6082 decreases after AST due to less mass transport limitation. In contrast, Cr-C-coated Al6082 starts with comparable initial performance (2046 mA cm−2, 1428 mW cm−2) but degrades to 1256 mA cm−2 and 1053 mW cm−2 after 100 h of voltage cycling. This drop is associated with microcrack-induced corrosion, where chromium oxidises to soluble Cr3+ ions. It should be noted that the charge transfer resistance of Cr-C-coated Al6082 remains constant before and after AST, suggesting minimal interfacial degradation but persistent bulk corrosion (Cr3+ dissolution) that drives current/power losses [35]. Although the Cr-C-coated Al6082 shows lower performance compared to the W-C-coated Al6082, it still shows better performance than the uncoated Al6082, according to AST, and polarisation behaviour, implying that it has better protective benefits compared to the bare Al6082 plate. The uncoated Al6082 exhibits the lowest initial performance (1708 mA cm−2 and 1246 mW cm−2) due to its insulating oxide layer and further drops to 1086 mA cm−2 and 896 mW cm−2 after the AST. The EIS results confirm the above findings, where the uncoated aluminium plate shows the largest ohmic resistance (R1) and overall cell resistance (R total), which further increased after the AST. These results emphasise a good balance of conductivity and durability of the W-C coating, outperforming Cr-C and uncoated Al6082 in retaining both current and power densities under the simulated PEM fuel cell conditions.

4. Conclusions

Amorphous carbon coatings with chromium and tungsten adhesion layers (Cr-C and W-C) were deposited using closed-field unbalanced magnetron sputtering on aluminium alloy 6082 substrates and evaluated as bipolar plate coatings for PEMFCs. Potentiostatic corrosion testing at 0.8 V against SHE was performed at temperatures up to 80 °C in order to evaluate the corrosion resistance of the coatings in cathodic environments. It was found that the substrate plays an important role in the corrosion properties of coated plates, as defects in the substrate can translate into defects in the coating. This can provide areas of exposed substrate, which can be attacked by the electrolyte, resulting in accelerated corrosion. For both uncoated and coated aluminium, the corrosion current increased upon increasing the temperature from 55 to 80 °C, and at each temperature, coated plates showed lower corrosion current densities than uncoated plates. Uncoated and coated bipolar plates were also evaluated to test their performance on the cathode side of a single-cell PEMFC operated at 80 °C. The W-C coating showed the best performance, followed by Cr-C. As expected, the uncoated plate showed the poorest performance.

Author Contributions

Conceptualization, P.N. and H.S.; methodology, P.N. and K.Z.; investigation, P.N., K.Z., G.S. and S.F.; resources, H.S.; writing, P.N. and K.Z.; project administration, P.N. and S.F.; funding acquisition, P.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted as part of the project CB4AFC, co-funded by Innovate UK through the NATEP programme, project number 10028605. The support of Innovate UK is greatly appreciated.

Data Availability Statement

The data for this article are contained within the article.

Conflicts of Interest

P.N., G.S., S.F. and H.S. were employed by Teer Coatings Limited. K.Z. declares that this research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Steele, B.C.H.; Heinzel, A. Materials for fuel cell technologies. Nature 2001, 414, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Leng, Y.; Ming, P.; Yang, D.; Zhang, C. Stainless steel bipolar plates for proton exchange membrane fuel cells: Materials, flow channel design and forming processes. J. Power Sources 2020, 451, 227783. [Google Scholar] [CrossRef]

- DOE Technical Targets for Polymer Electrolyte Membrane Fuel Cell Components. Available online: https://www.energy.gov/eere/fuelcells/doe-technical-targets-polymer-electrolyte-membrane-fuel-cell-components (accessed on 26 March 2025).

- Hung, Y.; Tawfik, H.; Mahajan, D. Durability and characterization studies of chromium carbide coated aluminium fuel cell stack. Int. J. Hydrogen Energy 2016, 41, 12273–12284. [Google Scholar] [CrossRef]

- Narasimharaju, S.; Rao, B.P.C.; Annamalai, K. Advancements and Characterisation of Nitride Coating Materials on Aluminium Alloy-Based Bipolar Plates for PEMFC’s Applications. MATEC Web Conf. 2024, 393, 01010. [Google Scholar] [CrossRef]

- Barranco, J.; Barreras, F.; Lozano, A.; Maza, M. Influence of CrN-coating thickness on the corrosion resistance behaviour of aluminium-based bipolar plates. J. Power Sources 2011, 196, 4283–4289. [Google Scholar] [CrossRef]

- González Gutiérrez, A.G.; Sebastian, P.J.; Magallón Cacho, L.; Borja Arco, E.; Campos, J.; Baron, A. Surface Modification of Aluminium Alloy 6061 for Bipolar Plate Application: Adhesion Characteristics and Corrosion Resistance. Int. J. Electrochem. Sci. 2018, 13, 3958–3969. [Google Scholar] [CrossRef]

- González Gutiérrez, A.G.; Pech-Canul, M.A.; Chan-Rosado, G.; Sebastian, P.J. Studies on the physical and electrochemical properties of Ni-P coating on commercial aluminium as bipolar plate in PEMFC. Fuel 2019, 235, 1361–1367. [Google Scholar] [CrossRef]

- Abo El-Enin, S.A.; Abdel-Salam, O.E.; El-Abd, H.; Amin, A.M. New electroplated aluminium bipolar plate for PEM fuel cell. J. Power. Sources 2008, 177, 131–136. [Google Scholar] [CrossRef]

- Fetohi, A.E.; Abdel Hamed, R.M.; El-Khatib, K.M.; Souaya, E.R. Ni–P and Ni–Co–P coated aluminium alloy 5251 substrates as metallic bipolar plates for PEM fuel cell applications. Int. J. Hydrogen Energy 2012, 37, 7677–7688. [Google Scholar] [CrossRef]

- Madadi, F.; Rezaeian, A.; Edris, H.; Zhiani, M. Improving performance in PEMFC by applying different coatings to metallic bipolar plates. Meter. Chem. Phys. 2019, 238, 121911. [Google Scholar] [CrossRef]

- Lee, C.-H.; Lee, Y.-B.; Kim, K.-M.; Jeong, M.-G.; Lim, D.-S. Electrically conductive polymer composite coating on aluminium for PEM fuel cells bipolar plate. Renew. Energy 2013, 54, 46–50. [Google Scholar] [CrossRef]

- Madwsley, J.R.; Carter, J.D.; Wang, X.; Niyogi, S.; Fan, C.Q.; Koc, R.; Osterhout, G. Composite-coated aluminium bipolar plates for PEM fuel cells. J. Power Sources 2013, 231, 106–112. [Google Scholar] [CrossRef]

- Lee, S.-J.; Huang, C.-H.; Chen, Y.-P. Investigation of PVD coating on corrosion resistance of metallic bipolar plates in PEM fuel cell. J. Mater. Process. Technol. 2003, 140, 688–693. [Google Scholar] [CrossRef]

- Mirzaee Sisan, M.; Abdolahi Sereshki, M.; Khorsand, H.; Siadati, M.H. Carbon coatings for corrosion protection of SS-316L and AA-6061 as bipolar plates for PEM fuel cells. J. Alloys Compd. 2014, 63, 288–291. [Google Scholar] [CrossRef]

- Navabpour, P.; Cooper, L.; Yang, S.; Yin, J.; Zhang, K.; El-Kharouf, A.; Sun, H. PVD coatings for lightweight bipolar plates. Surfaces 2024, 7, 812–823. [Google Scholar] [CrossRef]

- Zhang, J.; Jin, J.; Tao, Y.; Cao, R.; Kou, X.; Tian, X. Investigation of corrosion properties with Ni-P/TiNO coating on aluminium alloy bipolar plates in proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2022, 47, 22165–22179. [Google Scholar] [CrossRef]

- Narasimharaju, S.; Rao, B.P.C.; Annamalai, K. Advancements in Multilayer Coatings on Aluminium Alloy-Based Bipolar Plates for PEMFC Application. Int. Res. J. Adv. Eng. Hub 2024, 2, 190–204. [Google Scholar] [CrossRef]

- Feng, K.; Shen, Y.; Sun, H.; Liu, D.; An, Q.; Cai, X.; Chu, P.K. Conductive amorphous carbon-coated 316L stainless steel as bipolar plates in polymer electrolyte membrane fuel cells. Int. J. Hydrogen Energy 2009, 34, 6771–6777. [Google Scholar] [CrossRef]

- Pukha, V.E.; Glukhov, A.A.; Belmesov, A.A.; Kabachov, E.N.; Khodos, I.I.; Khadem, M.; Kim, D.-E.; Karaseov, P.A. Corrosion-resistant nanostructured carbon-based coatings for applications in fuel cells based on bipolar plates. Vacuum 2023, 218, 112643. [Google Scholar] [CrossRef]

- Liu, R.; Jia, Q.; Zhang, B.; Lai, Z.; Chen, L. Protective coatings for metal bipolar plates of fuel cells: A review. Int. J. Hydrogen Energy 2022, 47, 22915–22937. [Google Scholar] [CrossRef]

- 6082 (AlSi1MgMn, 3.2315, H30, A96082) Aluminium. Available online: https://www.makeitfrom.com/material-properties/6082-AlSi1MgMn-3.2315-H30-A96082-Aluminum/ (accessed on 26 March 2025).

- Li, Z.; Peng, M.; Wei, H.; Zhang, W.; Lv, Q.; Zhang, F.; Shan, Q. First-principles study on surface corrosion of 6082 aluminium alloy in H+ and Cl−. J. Mol. Struct. 2023, 1294, 136570. [Google Scholar] [CrossRef]

- Yang, L.; Yang, S.; Huang, G. Investigation of electrochemical corrosion behaviours of 6082 aluminium alloy under simulate deicing agent conditions. J. Phys. Conf. Series 2021, 1838, 012004. [Google Scholar] [CrossRef]

- Ravi Sankar, A.; Das, S. Experimental analysis of galvanic corrosion of a thin metal film in a multilayer stack for MEMS application. Mater. Sci. in Semiconduct. Process. 2013, 16, 449–453. [Google Scholar] [CrossRef]

- Galvanic Corrosion vs. Electrode Potential. Available online: https://www.engineeringtoolbox.com/electrode-potential-d_482.html (accessed on 26 March 2025).

- Avoid Long-Term Problems with Our Galvanic Corrosion Chart. Available online: https://industrialmetalservice.com/metal-university/avoid-long-term-problems-with-our-galvanic-corrosion-chart/ (accessed on 26 March 2025).

- Ma, X.; Wang, T.; Gong, B.; Cao, H. Fast and low-cost deposition strategy for constructing amorphous carbon layer toward corrosion protection on aluminium alloy bipolar plates in proton exchange membrane fuel cell environments. J. Power Sources 2024, 623, 235479. [Google Scholar] [CrossRef]

- Srivastava, A.; Kenneth, A.R.; Smith, C.B. Coating developments towards enabling aluminium as a bipolar plate material for PEM fuel cells. J. Power Sources 2024, 582, 233513. [Google Scholar] [CrossRef]

- Glechner, T.; Hahn, R.; Zauner, L.; Risslegger, S.; Polcik, P.; Reidl, H. Structure and mechanical properties of reactive and non-reactive sputter deposited WC based coatings. J. Alloys Compd. 2021, 885, 161129. [Google Scholar] [CrossRef]

- Shaw, B.A.; Fritz, T.L.; Davis, G.D.; Moshier, W.C. The influence of tungsten on the pitting of aluminium films. J. Electrochem. Soc. 1990, 137, 1317–1318. [Google Scholar] [CrossRef]

- Lin, C.-H.; Tsai, S.-Y. An investigation of coated aluminium bipolar plates for PEMFC. Appl. Energy 2012, 100, 87–92. [Google Scholar] [CrossRef]

- Levy, R.B.; Boudart, M. Platinum-like behaviour of tungsten carbide in surface catalysis. Science 1973, 181, 547–549. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, L.; Deng, F.; Giles, S.A.; Prasad, A.K.; Advani, S.G.; Yan, Y.; Vlachos, D.G. Durable and self-hydrating tugsten carbide-based composite polymer electrolyte membrane fuel cells. Nat. Commun. 2017, 8, 418. [Google Scholar] [CrossRef]

- Ham, D.J.; Lee, J.S. Transition metal carbides and nitrides as electrode materials for low temperature fuel cells. Energies 2009, 2, 873–899. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).