Bio-Enhanced Geopolymer Composites: Microstructural and Mechanical Insights from Sisal and Palm Fiber Reinforcement

Abstract

1. Introduction

2. Materials and Methods

2.1. Processing

2.1.1. Preparation of Fiber

2.1.2. Elaboration of the Mortar Geopolymer

2.2. Characterization Testing

2.2.1. Structural Analysis

2.2.2. Mechanical Properties

3. Results

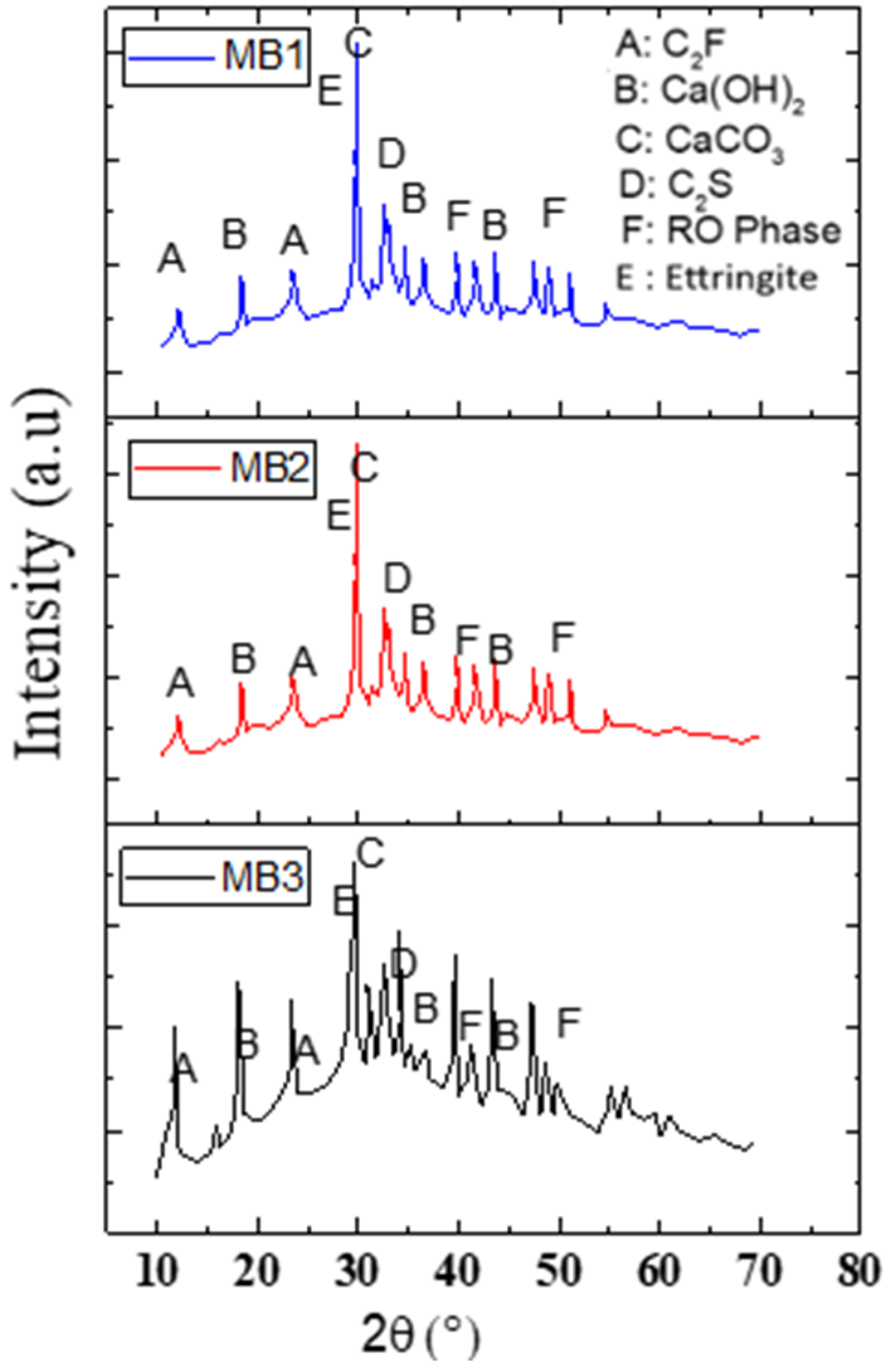

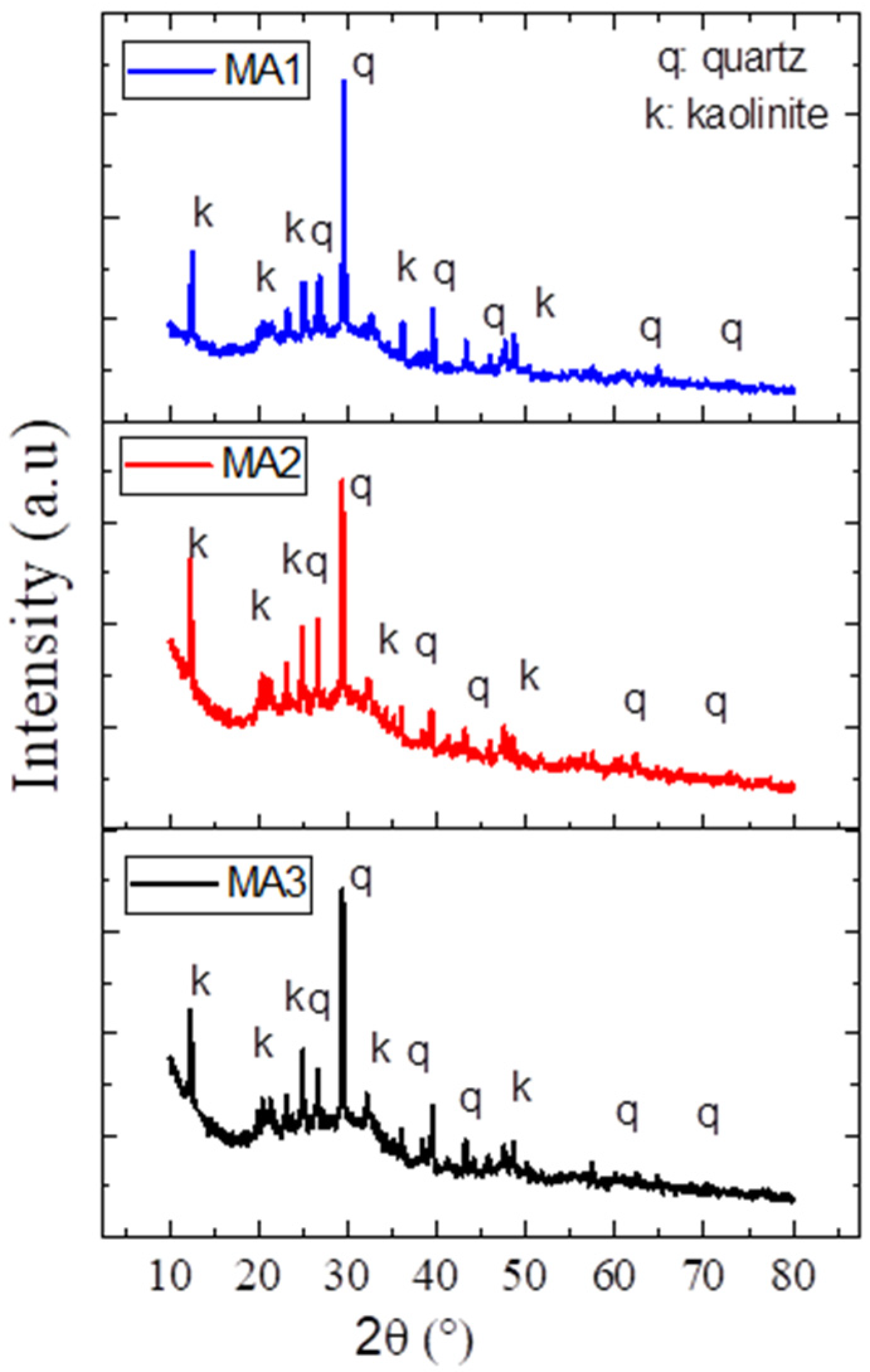

3.1. Structural Analysis (X-Ray Diffraction)

3.2. Morphological Test (SEM)

3.3. Thermal Analysis (TGA)

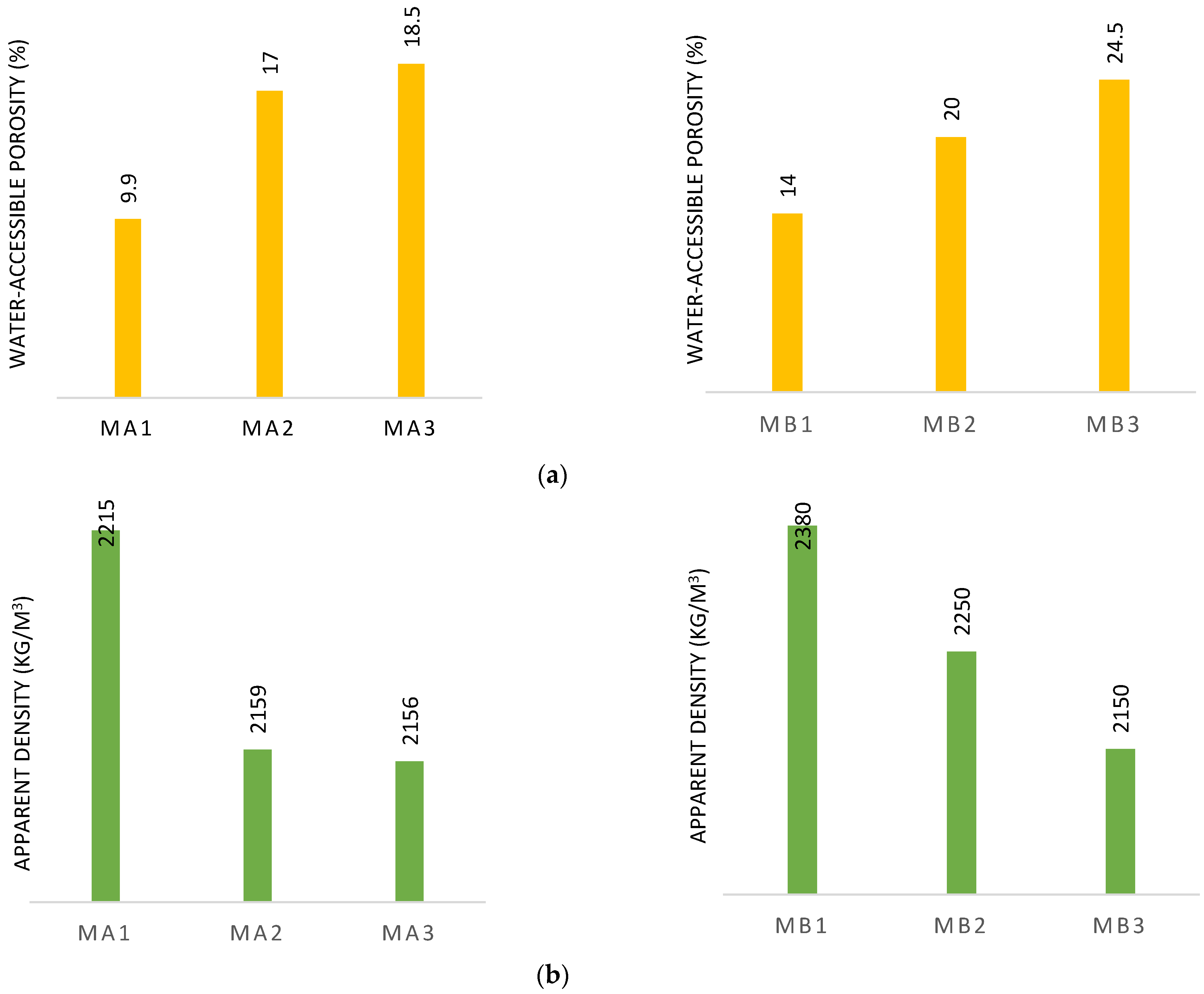

3.4. Physical Properties

3.5. Mechanical Properties

4. Discussion

5. Conclusions

- Granulated blast furnace slag (GGBS)-based geopolymers exhibit higher compressive strength than sand-based geopolymers, which is attributed to the denser and more compact microstructure induced by the calcium content of GGBS.

- The influence of natural fibers, such as palm and sisal, on compressive strength is minimal, as matrix strength primarily determines overall performance. However, fibers affect material porosity: longer fibers improve flexural strength, particularly in GGBS-based matrices. Shorter fibers, on the other hand, increase porosity and reduce mechanical properties due to poor distribution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, S.S.; Pazhani, K.C.; Ravisankar, K. Fracture behavior of fiber reinforced geopolymer concrete. Curr. Sci. 2017, 113, 116–122. [Google Scholar] [CrossRef]

- Wang, T.; Fan, X.; Gao, C.; Qu, C.; Liu, J.; Yu, G. The influence of fiber on the mechanical properties of geopolymer concrete: A review. Polymers 2023, 15, 827. [Google Scholar] [CrossRef] [PubMed]

- Long, Q.; Zhao, Y.; Zhang, B.; Yang, H.; Luo, Z.; Li, Z.; Zhang, G.; Liu, K. Interfacial Behavior of Slag, Fly Ash, and Red Mud-Based Geopolymer Mortar with Concrete Substrate: Mechanical Properties and Microstructure. Buildings 2024, 14, 652. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef]

- Hilal, N.; Sor, N.H.; Faraj, R.H. Development of eco-efficient lightweight self-compacting concrete with high volume of recycled EPS waste materials. Environ. Sci. Pollut. Res. 2021, 28, 50028–50051. [Google Scholar] [CrossRef]

- Narayanaswamy, P.; Srinivasan, S.K.; Murugan, P. Developments and research on fire-induced progressive collapse behaviour of reinforced concrete elements and frame: A review. Environ. Sci. Pollut. Res. 2022, 30, 72101–72113. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, D.; Kumar, R.; Mehta, P.K. Development of an environmental-friendly durable self-compacting concrete. Environ. Sci. Pollut. Res. 2022, 29, 54167–54180. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Institut Géopolymère: Saint-Quentin, France, 2015. [Google Scholar]

- Provis, J.L.; van Deventer, J.S.J. (Eds.) Alkali Activated Materials: State-of-the-Art Report, RILEM TC 224-AAM; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A. An overview of the chemistry of alkali-activated cement-based binders. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Woodhead Publishing: New Delhi, India, 2015; pp. 19–47. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Mechanical behaviour and microstructural investigation of geopolymer concrete after exposure to elevated temperatures. Arab. J. Sci. Eng. 2020, 45, 3843–3861. [Google Scholar] [CrossRef]

- Kumar, M.L.; Revathi, V. Microstructural properties of alkali-activated metakaolin and bottom ash geopolymer. Arab. J. Sci. Eng. 2020, 45, 4235–4246. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Ghazali, N.B.; Yusoff, S.; Bashar, I.I. Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymer concrete. Constr. Build. Mater. 2017, 152, 964–977. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Warden, P.G.; Coutts, R.S.P. Mechanically pulped sisal as reinforcement in cementitious matrices. Cem. Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface characteristics of jute fiber systems in a cementitious matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- Merta, I.; Mladenovič, A.; Turk, J.; Šajna, A.; Pranjić, A.M. Life cycle assessment of natural fibre reinforced cementitious composites. Key Eng. Mater. 2018, 761, 204–209. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-ul-Hassan, M.; Khan, M.; Zhang, J.-L. Efficiency of supplementary cementitious materials and natural fiber on mechanical performance of concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Deifalla, A.F.; Ben Kahla, N.; El-Shorbagy, M.A. Concrete reinforced with sisal fibers (SSF): Overview of mechanical and physical properties. Crystals 2022, 12, 952. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Nicolas, R.S.; Brice, D.G.; Kilcullen, A.R.; Hamdan, S.; van Deventer, J.S. Influence of fly ash on water and chloride permeability of alkali-activated slag mortars and concretes. Constr. Build. Mater. 2013, 48, 1187–1201. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation of natural fiber in ternary blended cement composites containing metakaolin and montmorillonite. Corros. Sci. 2017, 120, 42–60. [Google Scholar] [CrossRef]

- Bahja, B.; Elouafi, A.; Tizliouine, A.; Omari, L.H. Morphological and structural analysis of treated sisal fibers and their impact on mechanical properties in cementitious composites. J. Build. Eng. 2021, 34, 102025. [Google Scholar] [CrossRef]

- Merta, I.; Poletanovic, B.; Dragas, J.; Carevic, V.; Ignjatovic, I.; Komljenovic, M. The influence of accelerated carbonation on physical and mechanical properties of hemp-fibre-reinforced alkali-activated fly ash and fly ash/slag mortars. Polymers 2022, 14, 1799. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Chen, L.; Zhang, M.; Liu, L.; Zhao, J.; Mu, Y. Analysis of melting reconstruction treatment and cement solidification on ultra-risk municipal solid waste incinerator fly ash–blast furnace slag mixtures. Environ. Sci. Pollut. Res. 2020, 27, 32139–32151. [Google Scholar] [CrossRef]

- Hawa, A.; Tonnayopas, D.; Prachasaree, W. Performance evaluation and microstructure characterization of metakaolin-based geopolymer containing oil palm ash. Sci. World J. 2013, 2013, 857586. [Google Scholar] [CrossRef] [PubMed]

- Lizcano, M.; Gonzalez, A.; Basu, S.; Lozano, K.; Radovic, M.; Viehland, D. Effects of water content and chemical composition on structural properties of alkaline activated metakaolin-based geopolymers. J. Am. Ceram. Soc. 2012, 95, 2169–2177. [Google Scholar] [CrossRef]

- NF EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. Association Française de Normalisation: Paris, France, 2022.

- Lizcano, M.; Kim, H.S.; Basu, S.; Radovic, M. Mechanical properties of sodium and potassium activated metakaolin-based geopolymers. J. Mater. Sci. 2012, 47, 2607–2616. [Google Scholar] [CrossRef]

- Li, Z.; Liu, S. Influence of slag as additive on compressive strength of fly ash-based geopolymer. J. Mater. Civ. Eng. 2007, 19, 470–474. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymers: Structures, Processing, Properties and Industrial Applications; Woodhead Publishing: New Delhi, India, 2009. [Google Scholar]

- Bernal, S.A.; De Gutierrez, R.M.; Pedraza, A.L.; Provis, J.L.; Rodriguez, E.D.; Delvasto, S. Effect of binder content on the performance of alkali-activated slag concretes. Cem. Concr. Res. 2011, 41, 1–8. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Microstructure development of alkali-activated fly ash cement: A descriptive model. Cem. Concr. Res. 2005, 35, 1204–1209. [Google Scholar] [CrossRef]

- Rahier, H.; Wastiels, J.; Biesemans, M.; Willen, R.; Van Assche, G.; Van Mele, B. Reaction mechanism, kinetics and high temperature transformations of geopolymers. J. Mater. Sci. 2007, 42, 2982–2996. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008; Chapter 1. [Google Scholar]

- Provis, J.L.; van Deventer, J.S.J. Geopolymerisation kinetics. 2. Reaction kinetic modelling. Cem. Concr. Res. 2007, 62, 2318–2329. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Al Bakri, A.M.; Nizar, I.K.; Saif, A.A. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr. Build. Mater. 2014, 50, 377–387. [Google Scholar] [CrossRef]

- Gao, X.; Yu, Q.L.; Yu, R.; Brouwers, H.J.H. Evaluation of hybrid steel fiber reinforcement in high performance geopolymer composites. Mater. Struct. 2017, 50, 165. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Lo, F.-C.; Lo, S.-L.; Lee, M.-G. Effect of partially replacing ordinary Portland cement with municipal solid waste incinerator ashes and rice husk ashes on pervious concrete quality. Environ. Sci. Pollut. Res. 2020, 27, 23742–23760. [Google Scholar] [CrossRef] [PubMed]

- Silva, F.d.A.; Filho, R.D.T.; Filho, J.d.A.M.; Fairbairn, E.d.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Bahja, B.; Omari, L.E.H.; Tizliouine, A.; Elouafi, A.; Salhi, H.; Chafi, M. Effect of Sisal fiber’s treatment on hydration and thermophysical properties of cement biocomposite. Adv. Cem. Res. 2024, 36, 46–54. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Filho, R.D.T. Cellulosic fiber-reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Bheel, N.; Mahro, S.K.; Adesina, A. Influence of coconut shell ash on workability, mechanical properties, and embodied carbon of concrete. Environ. Sci. Pollut. Res. 2021, 28, 5682–5692. [Google Scholar] [CrossRef]

- Kozub, B.; Pławecka, K.; Figiela, B.; Korniejenko, K. Geopolymer fly ash composites modified with cotton fibre. Arch. Mater. Sci. Eng. 2023, 121, 60–70. [Google Scholar] [CrossRef]

| Chemical Composition Wt.% | CaO | SiO2 | Al2O3 | Fe2O3 | TiO2 | K2O | Na2O | MgO |

|---|---|---|---|---|---|---|---|---|

| MK1200 | 0.6 | 55 | 39 | 1.8 | 1.5 | 1 | - | |

| GGBS | 43.9 | 37.6 | 10.26 | 0.33 | 0.81 | 0.26 | 0.22 | 6.93 |

| Desert Sand | 17.76 | 51.11 | 14.7 | 8.02 | 0.97 | 3.39 | 0.19 | 2.8 |

| Ratio% | SiO2/Al2O3 | Na2O/Al2O3 |

|---|---|---|

| MA | 1.98 | 0.013 |

| MB | 1.88 | 0.015 |

| Samples | MK (g) | GGBS (g) | Desert Sand(g) | NaOH | Sisal Fiber (Wt.%) | Palm Fiber (Wt.%) |

|---|---|---|---|---|---|---|

| MA1 | 450 ± 2 g | - | 450 ± 2 g | 2% | - | - |

| MA2 | 450 ± 2 g | - | 450 ± 2 g | 2% | 4% long fiber | - |

| MA3 | 450 ± 2 g | - | 450 ± 2 g | 2% | - | 4% long fiber |

| MB1 | 450 ± 2 g | 450 ± 2 g | - | 2% | - | - |

| MB2 | 450 ± 2 g | 450 ± 2 g | - | 2% | - | 4% shorts fiber |

| MB3 | 450 ± 2 g | 450 ± 2 g | - | 2% | - | 8% shorts fiber |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahja, B.; Tizliouine, A.; Omari, L.E.H. Bio-Enhanced Geopolymer Composites: Microstructural and Mechanical Insights from Sisal and Palm Fiber Reinforcement. Constr. Mater. 2025, 5, 77. https://doi.org/10.3390/constrmater5040077

Bahja B, Tizliouine A, Omari LEH. Bio-Enhanced Geopolymer Composites: Microstructural and Mechanical Insights from Sisal and Palm Fiber Reinforcement. Construction Materials. 2025; 5(4):77. https://doi.org/10.3390/constrmater5040077

Chicago/Turabian StyleBahja, Bouchra, Abdeslam Tizliouine, and Lhaj El Hachemi Omari. 2025. "Bio-Enhanced Geopolymer Composites: Microstructural and Mechanical Insights from Sisal and Palm Fiber Reinforcement" Construction Materials 5, no. 4: 77. https://doi.org/10.3390/constrmater5040077

APA StyleBahja, B., Tizliouine, A., & Omari, L. E. H. (2025). Bio-Enhanced Geopolymer Composites: Microstructural and Mechanical Insights from Sisal and Palm Fiber Reinforcement. Construction Materials, 5(4), 77. https://doi.org/10.3390/constrmater5040077