Re-Imagining Waste: CBA-Modified High-Strength Mortar as a Blueprint for Greener Construction

Abstract

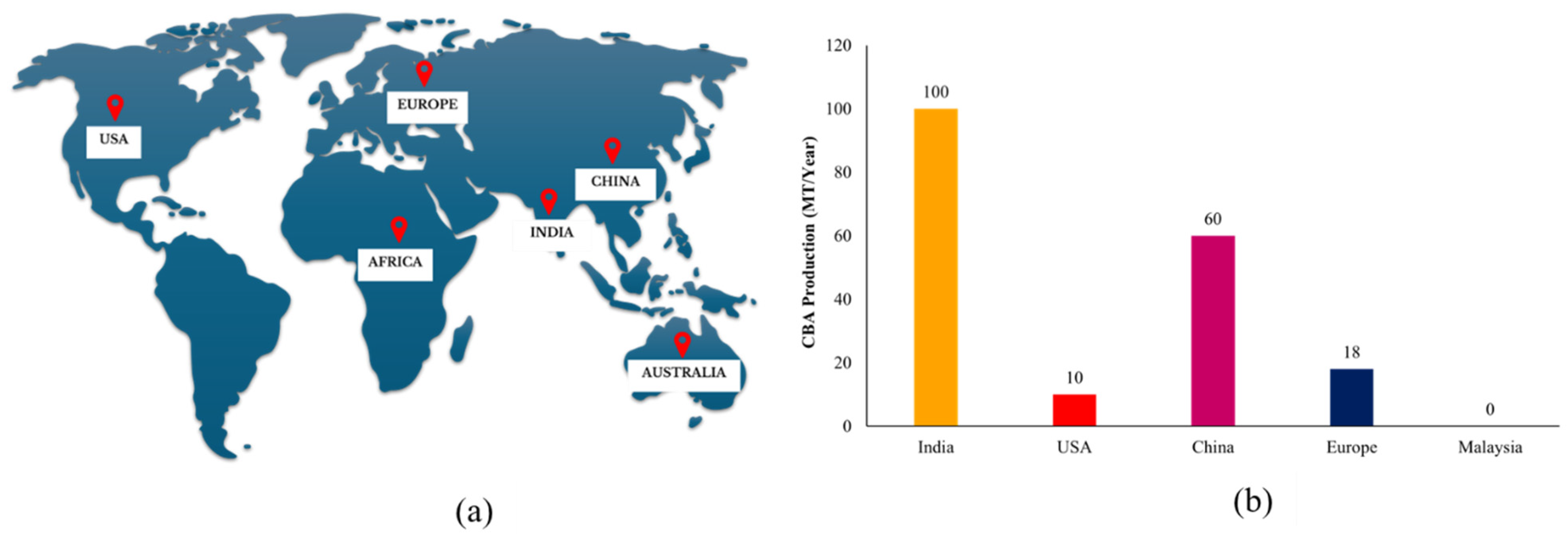

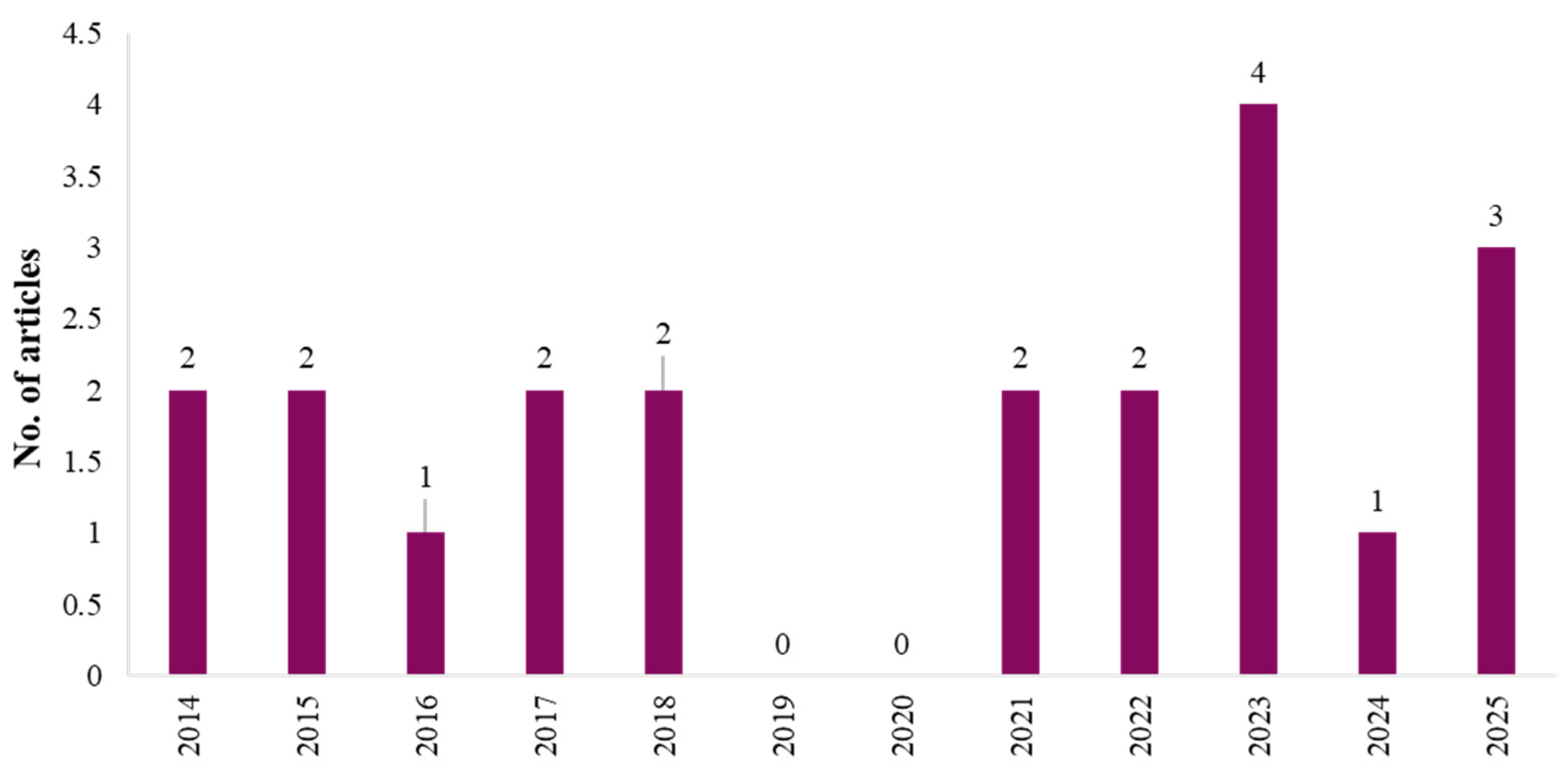

1. Introduction

1.1. CBA as an Aggregate or Cement Replacement in Mortar and Concrete

1.2. Other Applications of CBA

1.3. Fresh and Hardened Properties of CBA Mortar

1.4. Significance of the Study

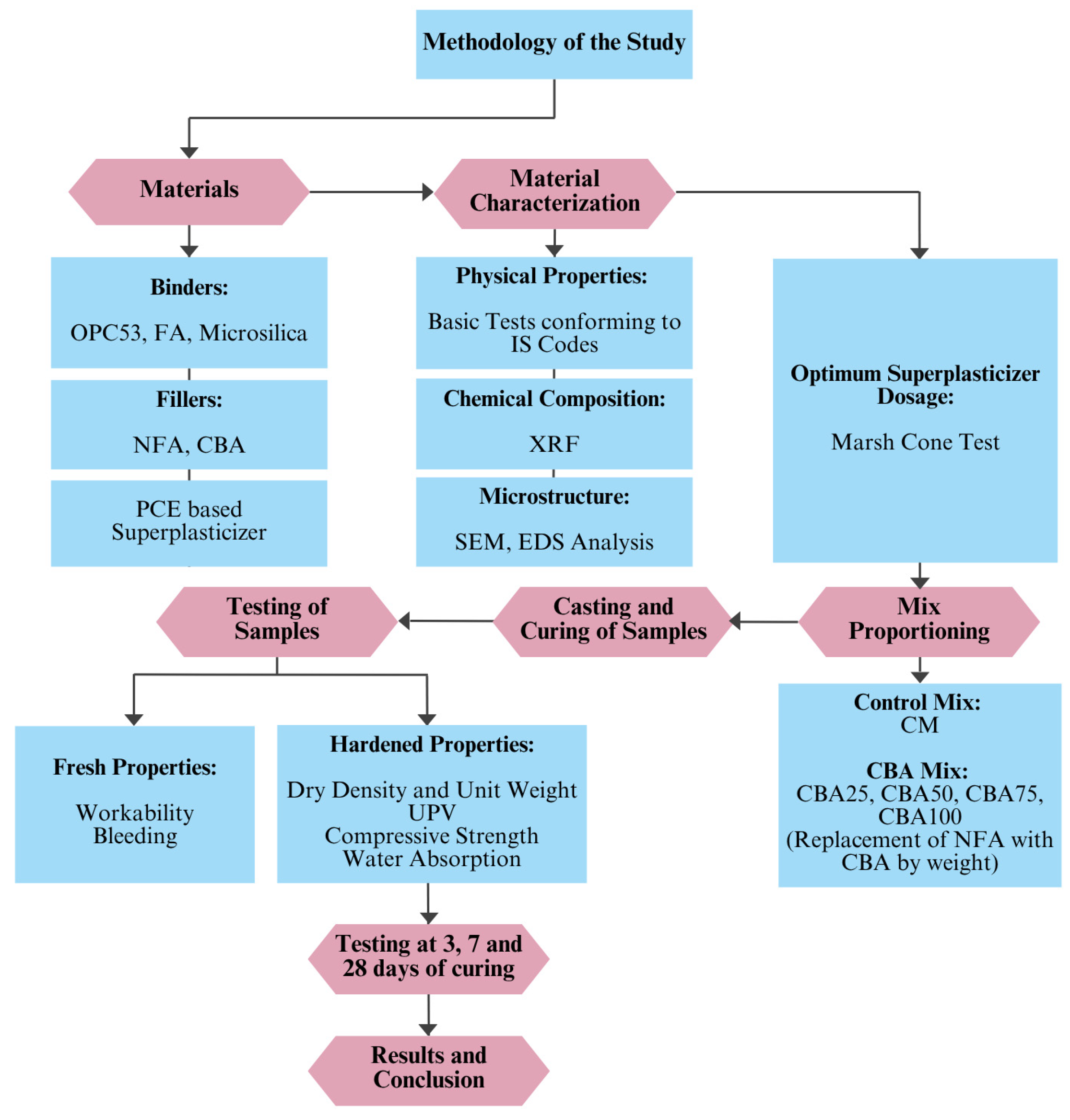

2. Experimental Programme

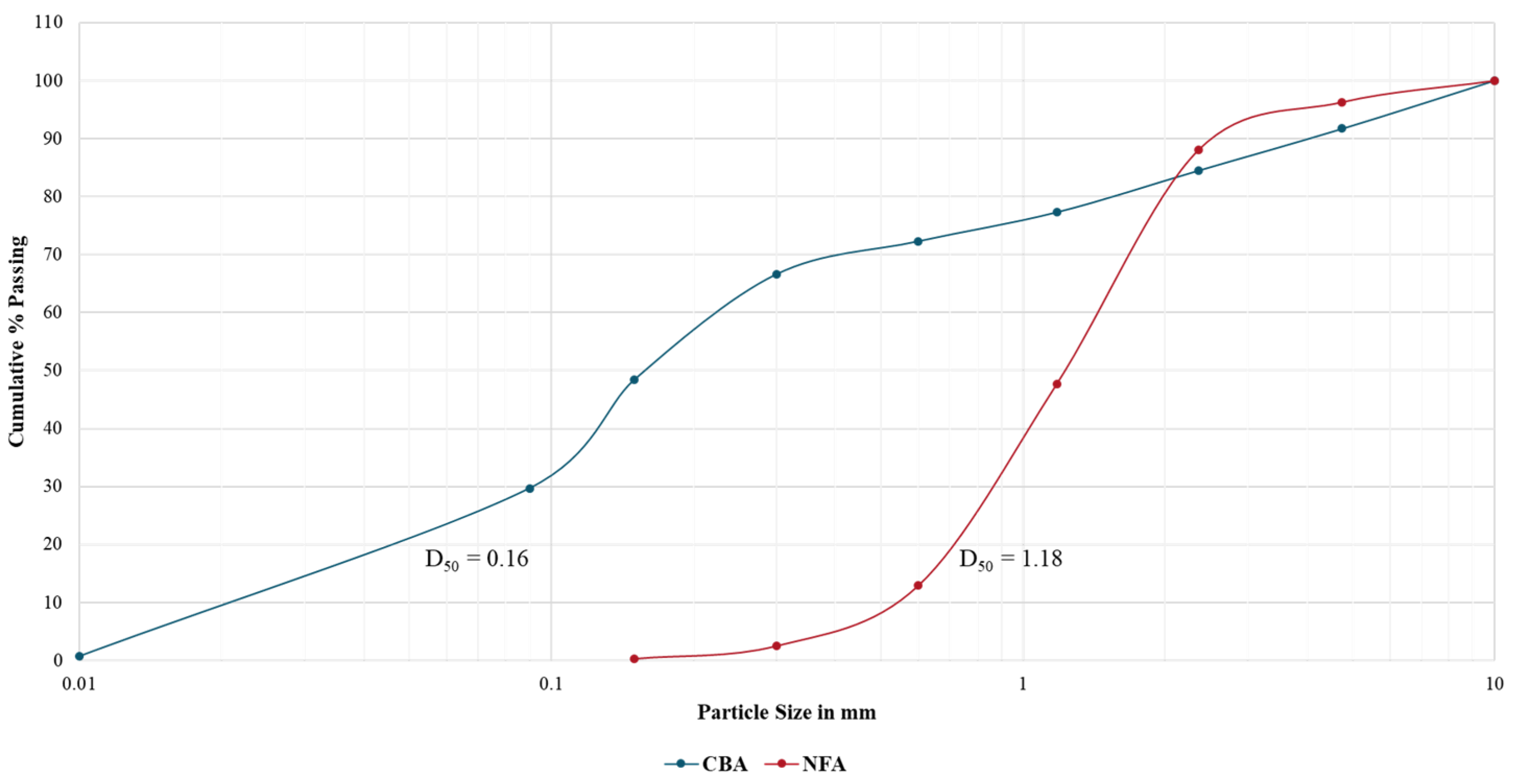

2.1. Materials and Methodology

| Binder | Parameter | Results | Conformity to the IS Code | IS Code Reference | |

|---|---|---|---|---|---|

| OPC53 | Fineness (90µ) | 5.66% | Yes | IS 4031 (Part 1): 1996 | [23] |

| Consistency | 25% | Yes | IS 4031 (Part 4): 1988 | [24] | |

| Specific Surface | 480.54 m2/kg | Yes | IS 4031 (Part 2): 1988 | [25] | |

| Specific Gravity | 3 | Yes | IS 4031 (Part 11): 1988 | [26] | |

| STI * | 80 min | Yes | IS 4031 (Part 5): 1988 | [27] | |

| STF # | 230 min | Yes | IS 4031 (Part 5): 1988 | [27] | |

| Soundness | 1 mm | Yes | IS 4031 (Part 3): 1988 | [28] | |

| CS | IS 4031 (Part 6): 1988 | [29] | |||

| 3 days | 39.5 MPa | Yes | |||

| 7 days | 45.5 MPa | Yes | |||

| 28 days | 53 MPa | Yes | |||

| FA | Fineness (45µ) | 12% | Yes | IS 1727: 1967 | [30] |

| Specific Surface | 524.51 m2/kg | Yes | IS 3812 (Part 1): 2013 | [21] | |

| Specific Gravity | 2.19 | Yes | IS 1727: 1967 | [30] | |

| PAI | 1.29 | Yes | IS 1727: 1967 | [30] | |

| Microsilica | Fineness (45µ) | 2.2% | Yes | IS 1727: 1967 | [30] |

| Specific Surface | 64.84 m2/gm | Yes | IS 15388: 2003 | [22] | |

| Specific Gravity | 2.25 | Yes | IS 1727: 1967 | [30] | |

| Filler | Parameter | Results | Conformity to IS Code | Reference | |

|---|---|---|---|---|---|

| NFA | Specific Gravity | 2.66 | Yes | IS 2386 (Part 3): 1963 | [31] |

| Fineness Modulus | 3.52, Zone II | Yes | IS 2386 (Part 1): 1963 IS 383: 2016 | [32,33] | |

| Water Absorption | 1% | Yes | IS 2386 (Part 3): 1963 | [31] | |

| Compacted Bulk Density | 1047 kg/m3 | Yes | IS 2386 (Part 3): 1963 | [31] | |

| Uncompacted Bulk Density | 960 kg/m3 | Yes | IS 2386 (Part 3): 1963 | [31] | |

| CBA | Specific Gravity | 2.36 | Yes | IS 2386 (Part 3): 1963 | [31] |

| Fineness Modulus | 2.31, Zone II | Yes | IS 2386 (Part 1): 1963 IS 383: 2016 | [32,33] | |

| Water Absorption | 30% | Yes | IS 2386 (Part 3): 1963 | [31] | |

| Compacted Bulk Density | 620 kg/m3 | Yes | IS 2386 (Part 3): 1963 | [31] | |

| Uncompacted Bulk Density | 540 kg/m3 | Yes | IS 2386 (Part 3): 1963 | [31] | |

| Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | P2O5 | Mn2O3 | TiO2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 21.19 | 4.83 | 4.62 | 62.4 | 1.08 | - | - | 2.24 | - | - | - |

| FA | 62.27 | 20.65 | 5.48 | 3.04 | 0.69 | 1.26 | 0.08 | 0.1 | 0.02 | 0.06 | 1.4 |

| Microsilica | 90.25 | 0.65 | 0.7 | 0.55 | 0.75 | 1.45 | 0.7 | 0.35 | - | - | - |

| CBA | 54.66 | 21.85 | 6.86 | 4.45 | 0.58 | 1.04 | 0.16 | 0.17 | 0.31 | 0.06 | 1.47 |

2.2. Mix Proportion

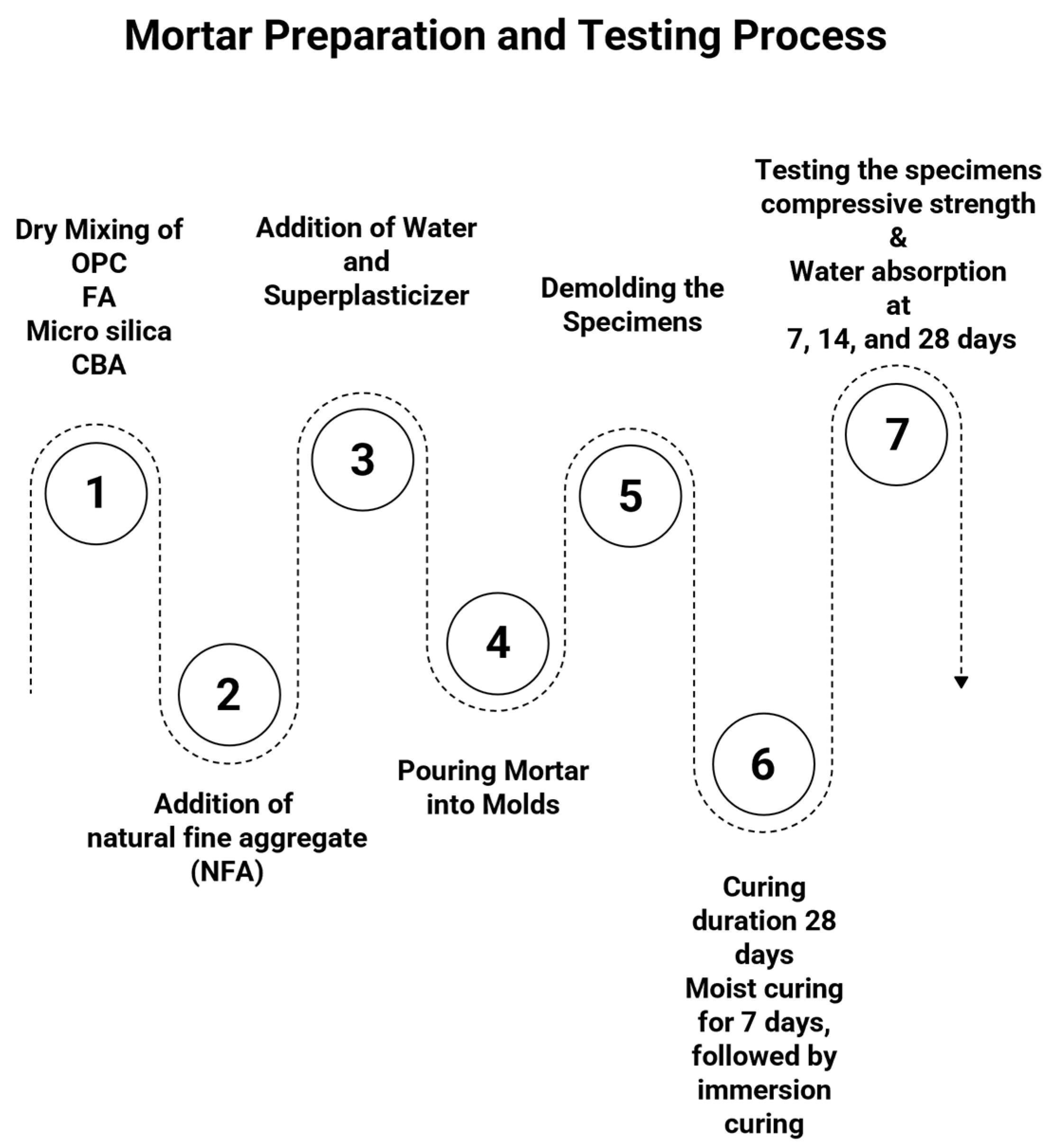

2.3. Mortar Mixing, Casting, and Curing of Samples

2.4. Experimental Details

2.4.1. Flow Table Test

2.4.2. Bleeding

2.4.3. Compressive Strength

2.4.4. Ultrasonic Pulse Velocity (UPV)

2.4.5. Morphology and Microstructural Analysis

3. Results and Discussion

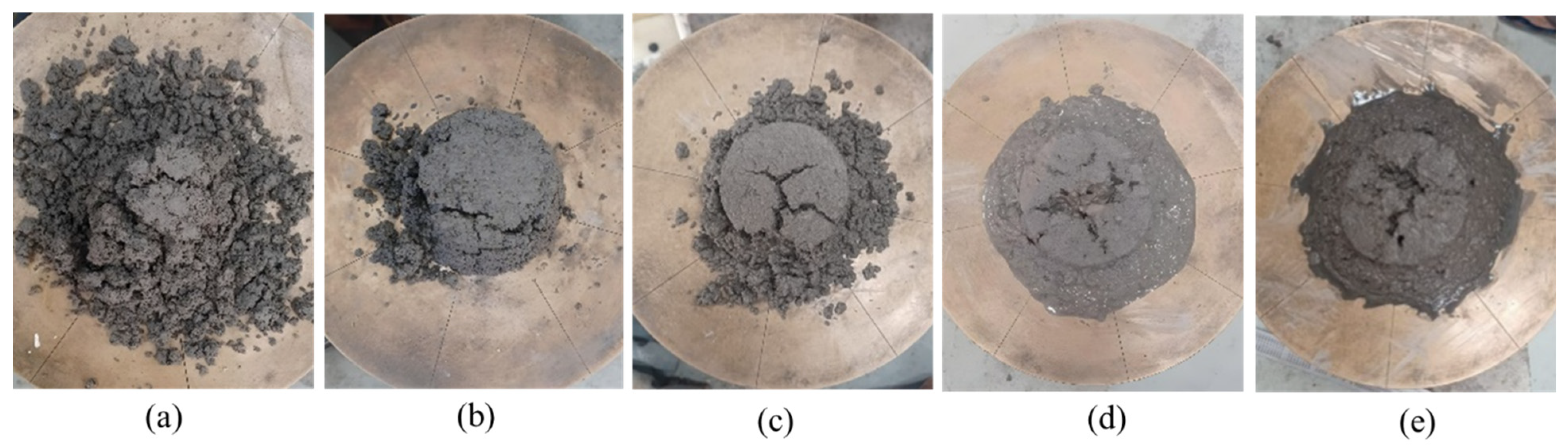

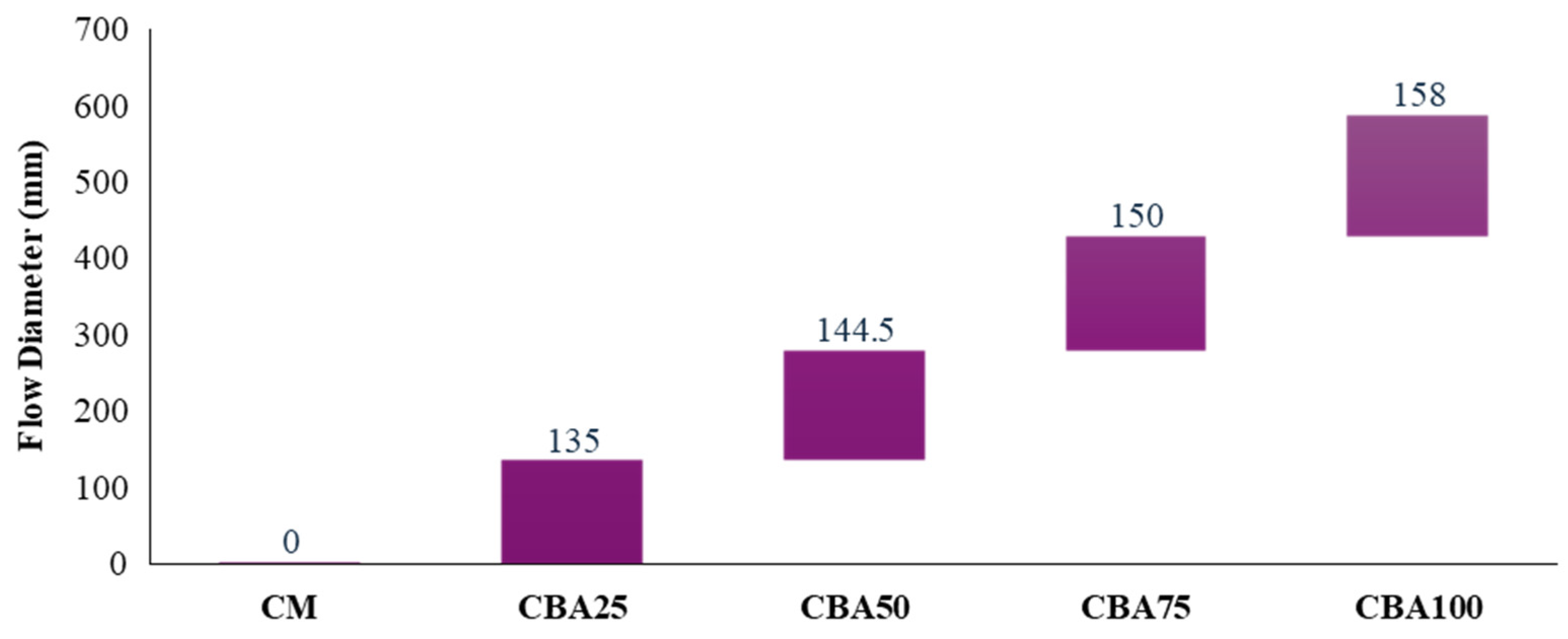

3.1. Fresh Properties of Mortar

3.2. Hardened Properties of Mortar

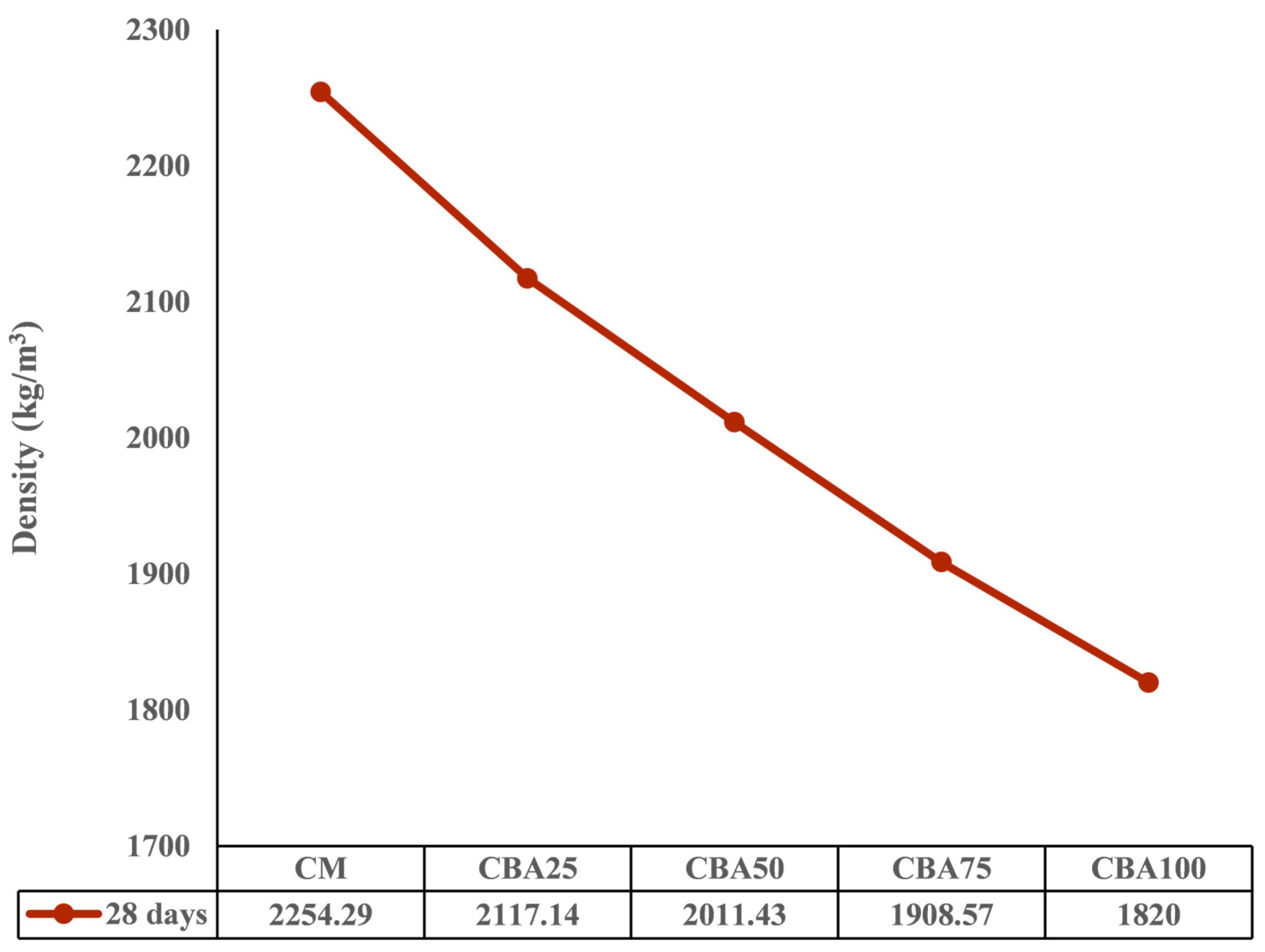

3.2.1. Dry Density and Unit Weight

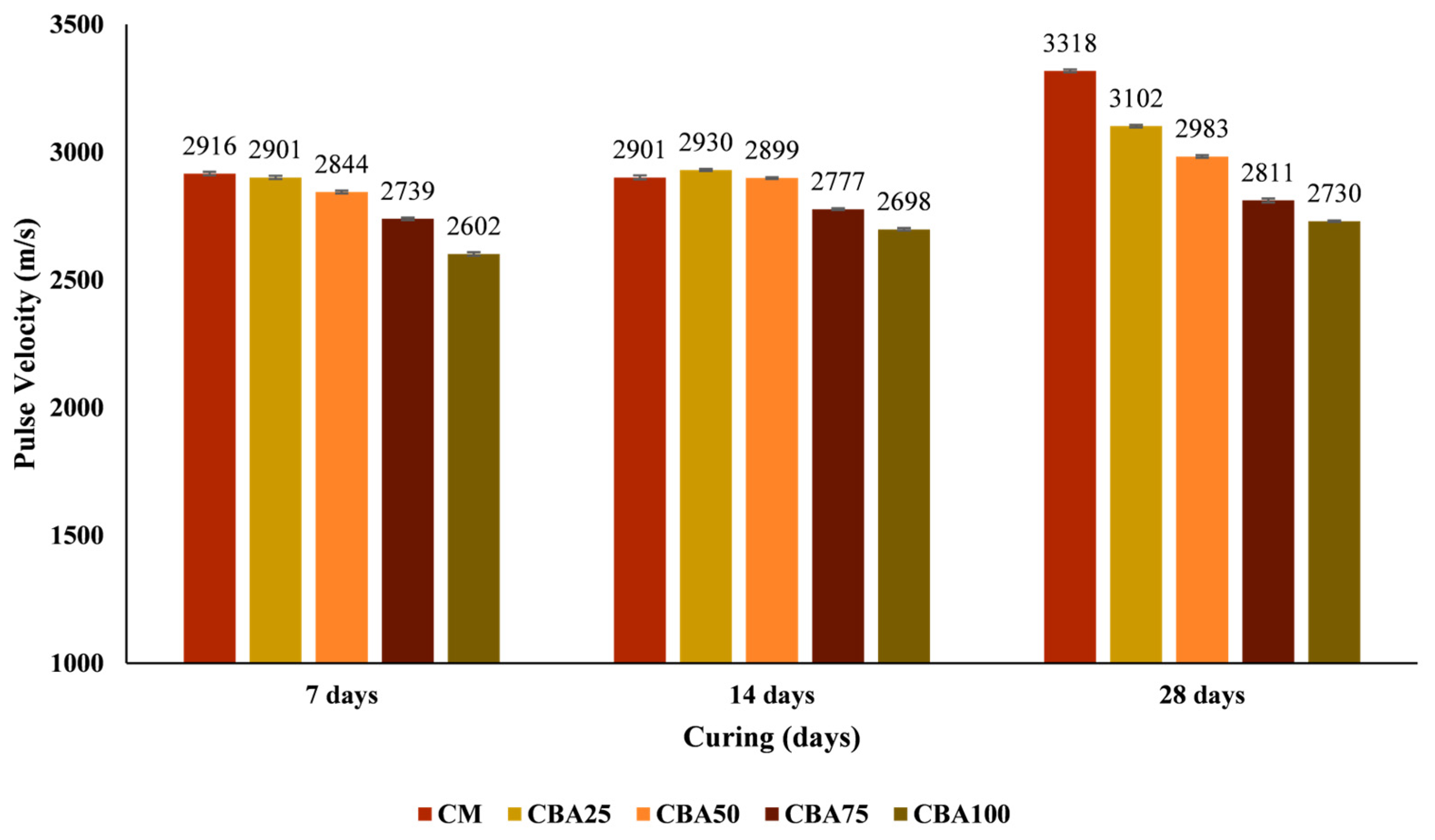

3.2.2. UPV

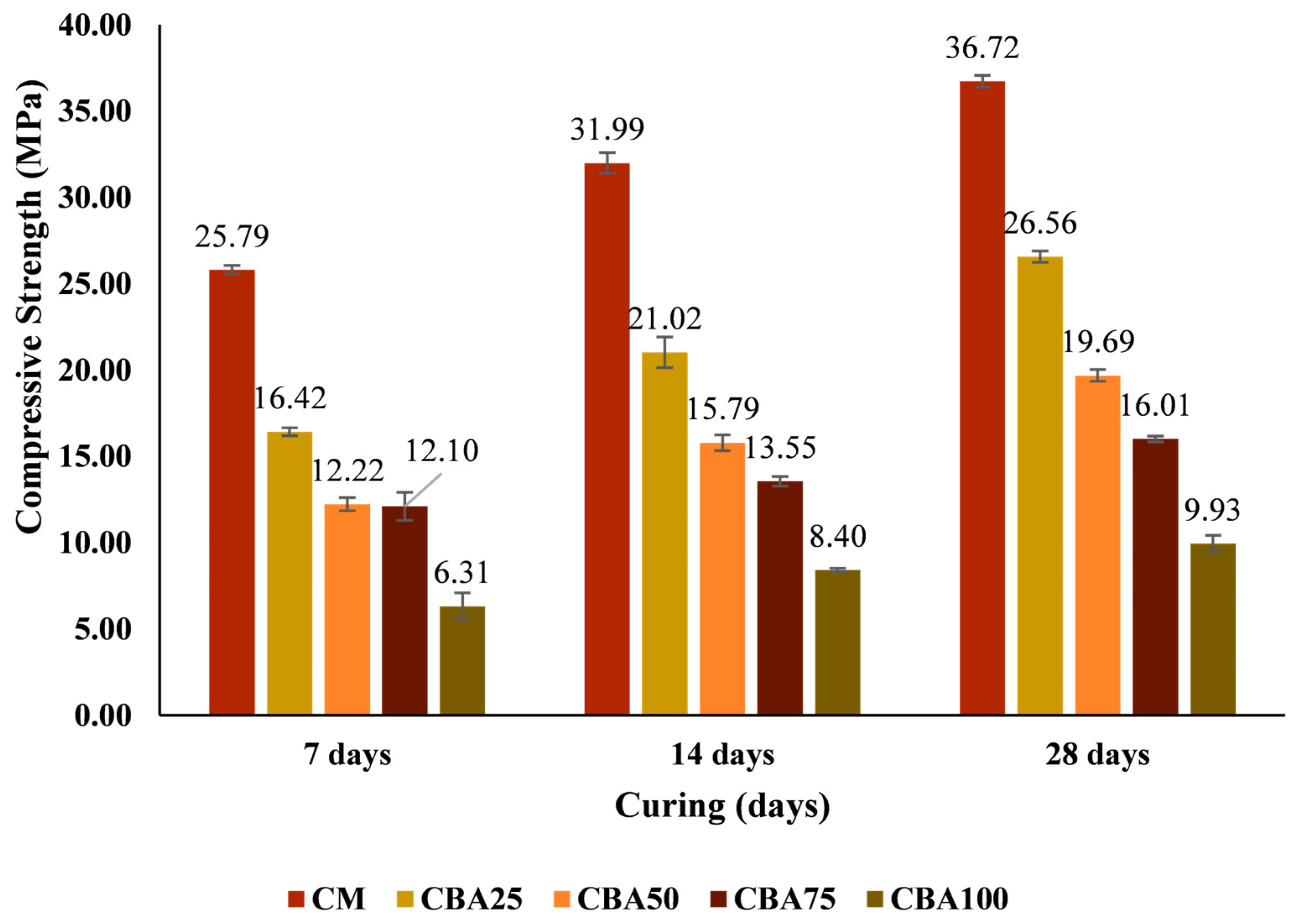

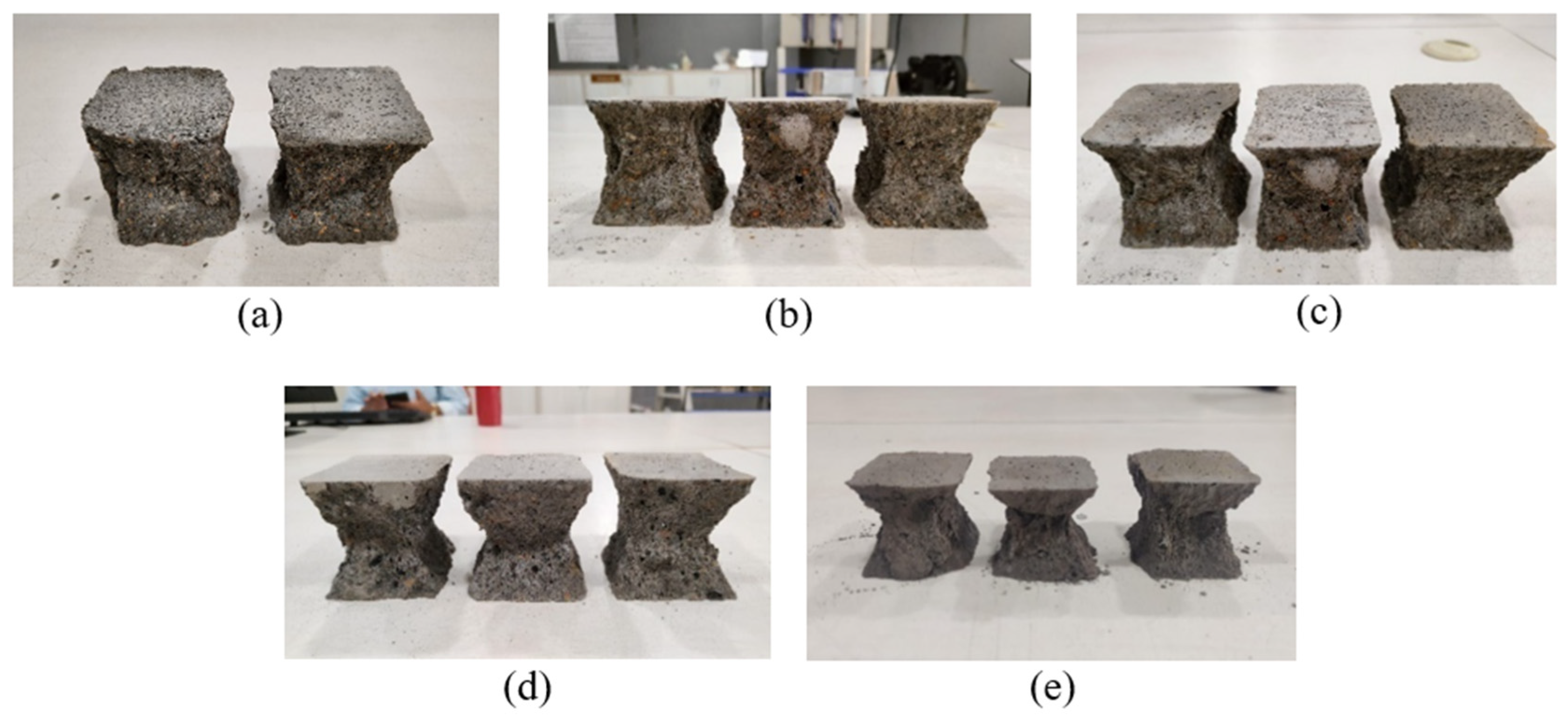

3.2.3. Compressive Strength (CS)

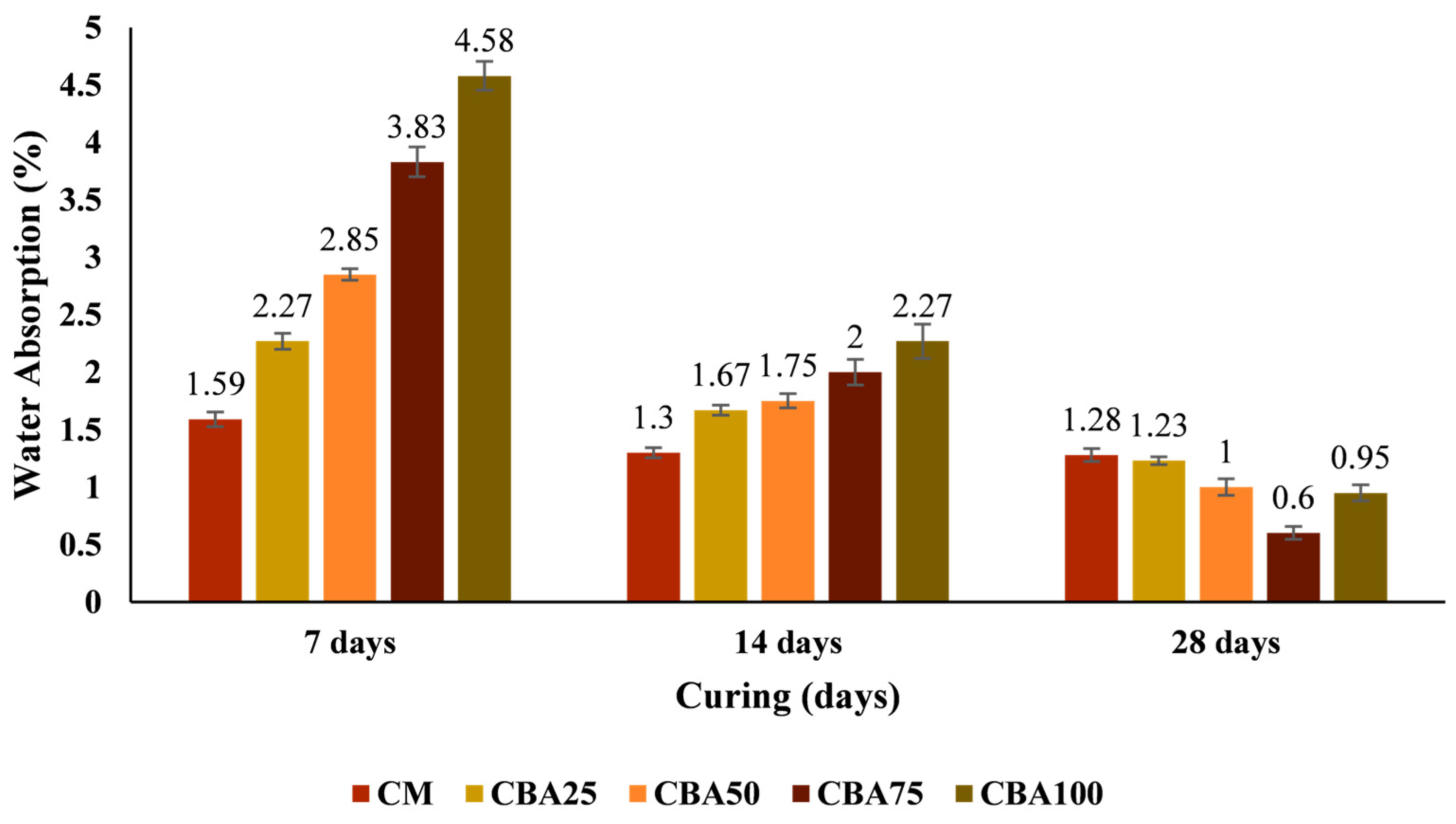

3.2.4. Water Absorption

3.3. Strength Correlations

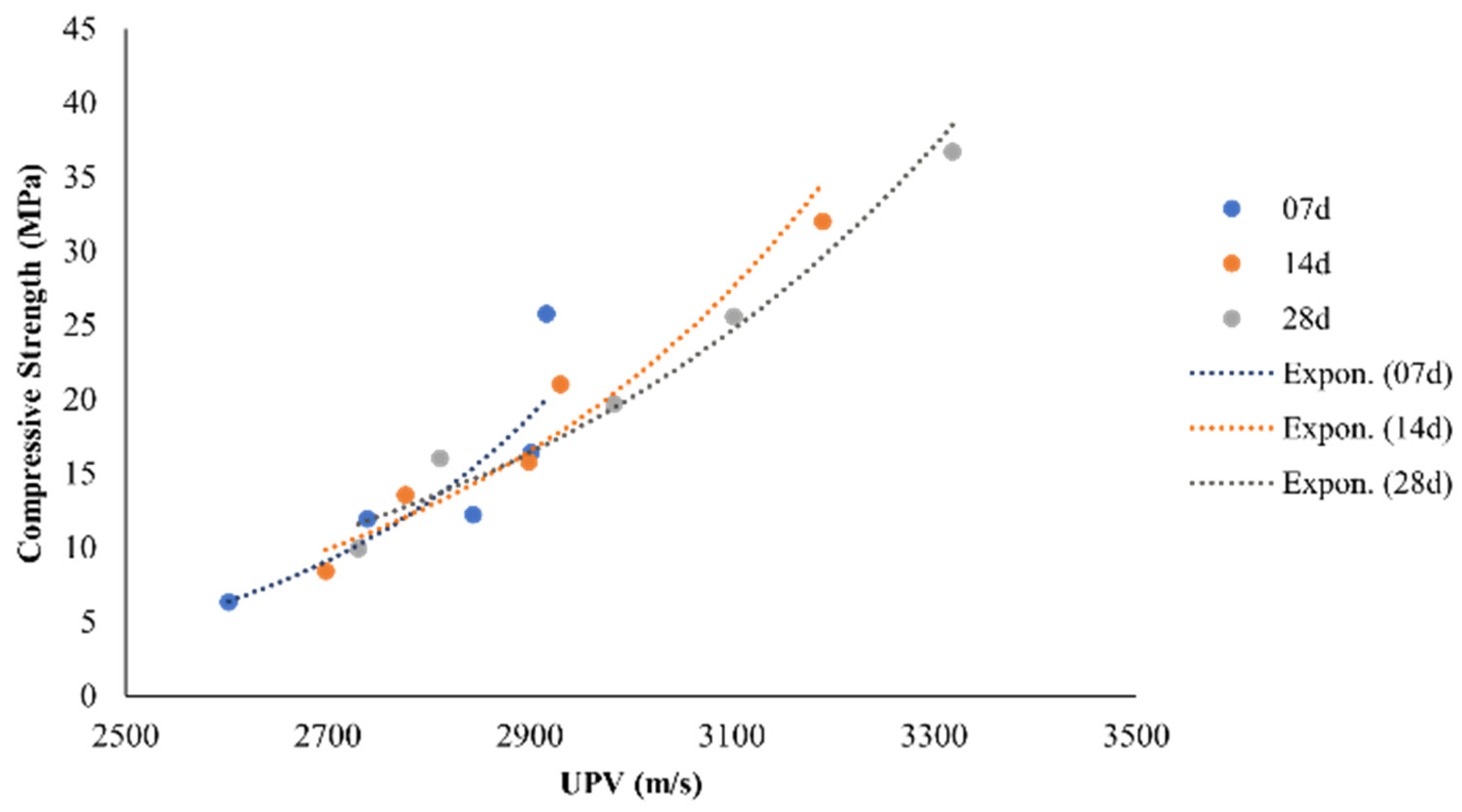

3.3.1. Relationship Between UPV and CS

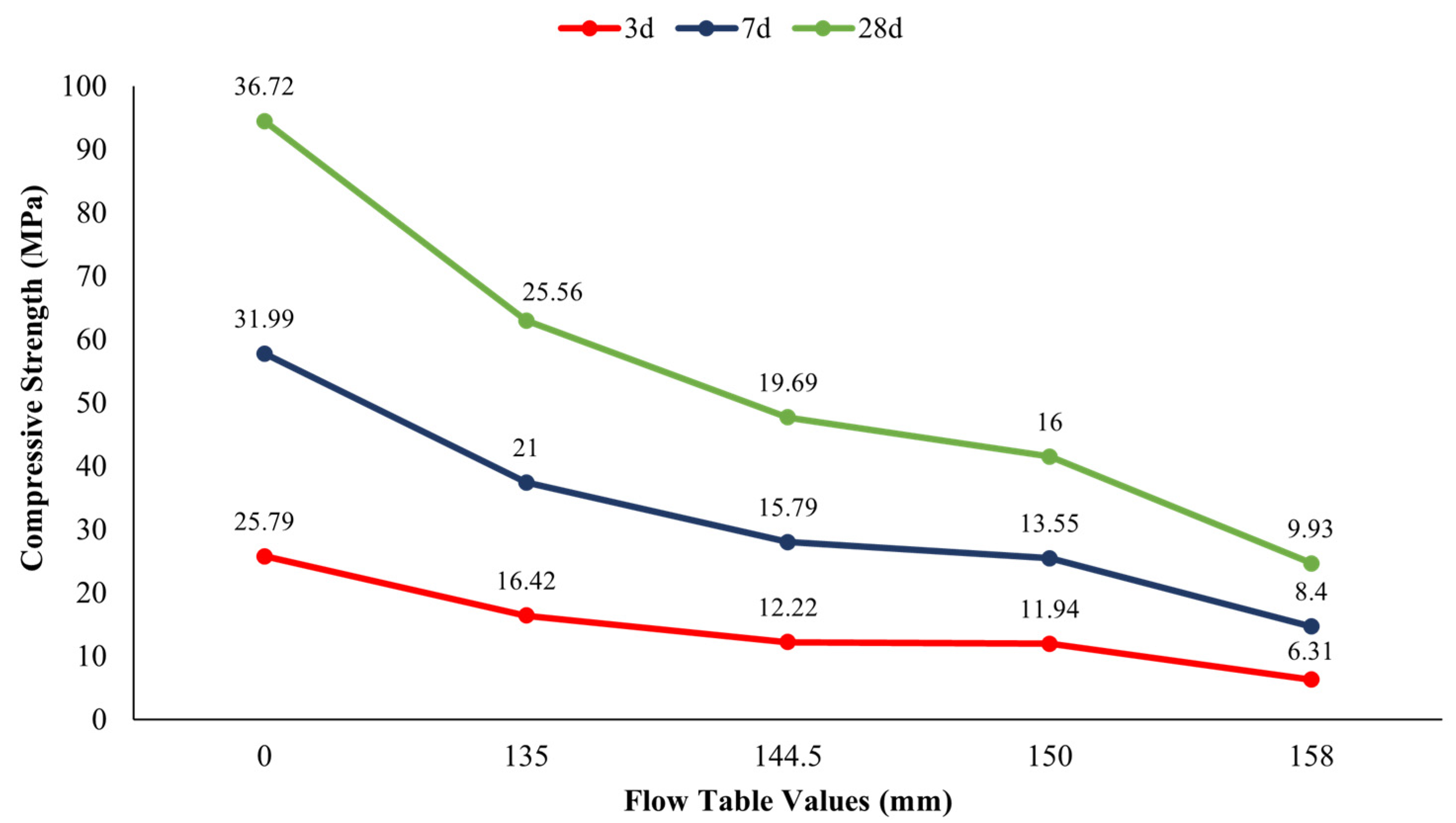

3.3.2. Relationship Between CS and Flowability

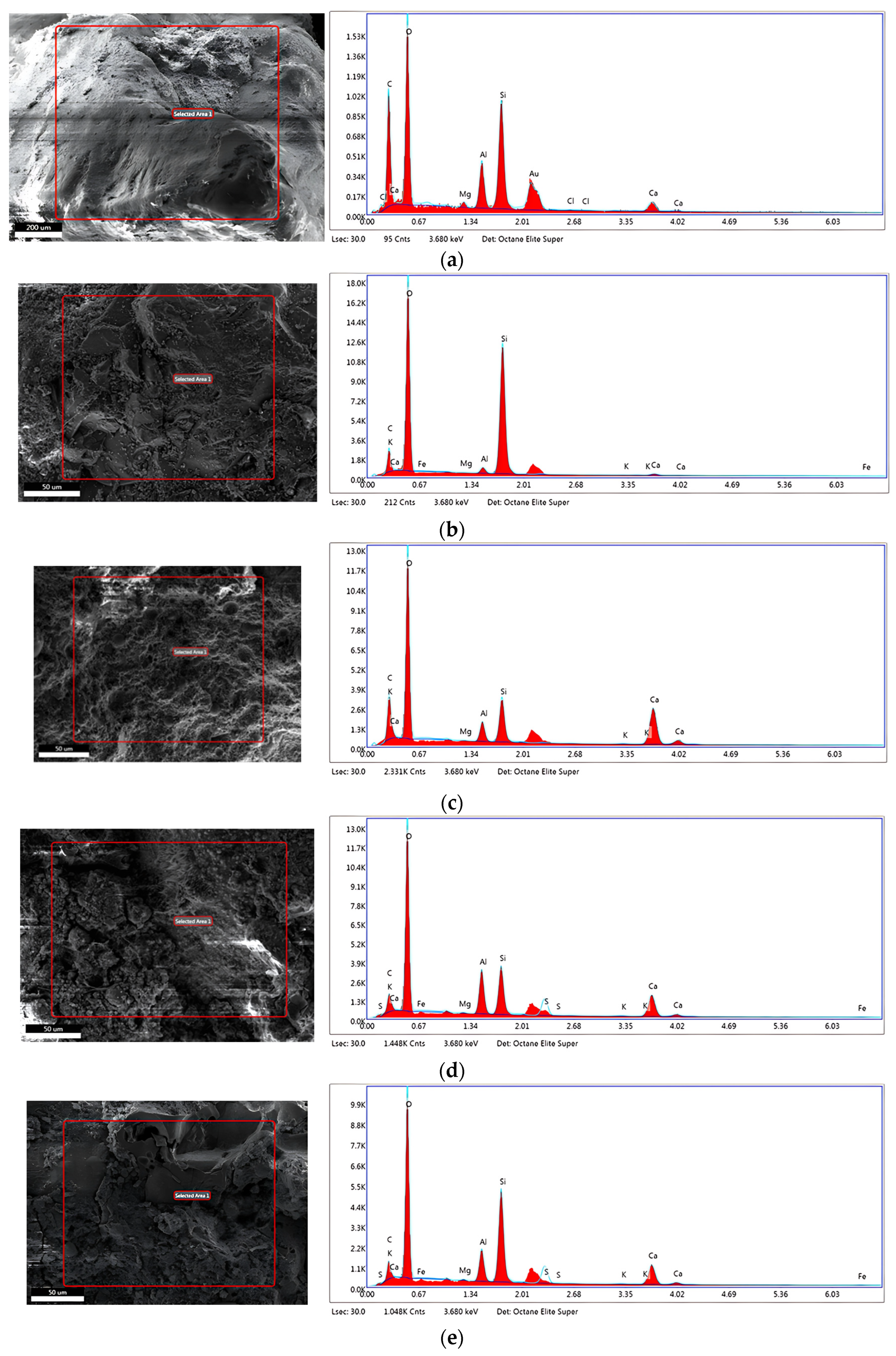

3.4. Morphology and Microstructural Analysis

4. Conclusions

- Flow table results indicated improved workability with increasing CBA content, which can be attributed to CBA’s porous microstructure, which enhances water demand and flowability. Bleeding remained negligible at lower CBA levels (0–25%) but increased significantly at higher replacements, especially in CBA75 and CBA100 mixes, indicating reduced water retention.

- Dry density progressively decreased with increasing CBA content, with a reduction of up to 19.27% observed at full replacement. Mortars exhibited weight gain over time due to continued hydration, but this trend reversed after 14 days in HVCBA mixes, reflecting reduced long-term densification.

- UPV values showed a decline with increasing CBA content, while demonstrating a rise with extended curing age. Based on IS 516 (Part 5): 2018 classifications, only the CM and CBA25 mortars maintained medium quality (Type III), while others were classified as poor quality (Type IV) due to high porosity and weak matrix.

- Strength increased with curing but decreased with higher CBA replacement. At 28 days, the CS dropped by up to 72.96% in the CBA100 mix. Despite these reductions, all mixes exceeded the minimum CS required by IS 2250:1981, thereby validating the high-strength categorisation at all replacement levels.

- A strong exponential correlation (R2 > 0.93) was established between UPV and CS across all curing ages. An inverse relationship was observed between flowability and strength, particularly pronounced in the higher CBA mixes due to increased porosity and weaker particle bonding.

- SEM images revealed extensive formation of hydration products such as C–S–H, ettringite, and portlandite, with improved matrix development in low-CBA mortars. EDS analysis indicated that higher Ca/Si and Al/Si ratios, particularly at 50% CBA replacement, correlated with significant strength reduction, confirming the adverse effect of excessive CBA on microstructural integrity.

- The use of HVCBA in mortar promotes sustainability and contributes to achieving high-strength properties. However, further optimisation of the mix is necessary to ensure suitability for high-strength applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Golewski, G.L. The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete. Materials 2023, 16, 5218. [Google Scholar] [CrossRef]

- Singh, G.; Ram, S. Microstructural and other properties of copper slag–coal bottom ash incorporated concrete using fly ash as cement replacement. Innov. Infrastruct. Solut. 2023, 8, 78. [Google Scholar] [CrossRef]

- Ali, T.; Buller, A.S.; Abro, F.U.R.; Ahmed, Z.; Shabbir, S.; Lashari, A.R.; Hussain, G. Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material. Buildings 2022, 12, 44. [Google Scholar] [CrossRef]

- Central Electricity Authority Annual Report (2022–23), CEA Annual Report, Central Electricity Authority Ministry of Power Government of India. 2023, pp. 1–292. Available online: https://cea.nic.in/annual-report/?lang=en (accessed on 24 February 2024).

- Goudar, S.K.; Shivaprasad, K.N.; Das, B.B. Mechanical properties of fiber-reinforced concrete using coal-bottom ash as replacement of fine aggregate. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2019; Volume 25, pp. 863–872. [Google Scholar] [CrossRef]

- Mohammed, S.A.; Koting, S.; Katman, H.Y.B.; Babalghaith, A.M.; Patah, M.F.A.; Ibrahim, M.R.; Karim, M.R. A review of the utilization of coal bottom ash (CBA) in the construction industry. Sustainability 2021, 13, 8031. [Google Scholar] [CrossRef]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Coal bottom ash as supplementary material for sustainable construction: A comprehensive review. Constr. Build. Mater. 2023, 389, 131679. [Google Scholar] [CrossRef]

- Sutcu, M.; Erdogmus, E.; Gencel, O.; Gholampour, A.; Atan, E.; Ozbakkaloglu, T. Recycling of bottom ash and fly ash wastes in eco-friendly clay brick production. J. Clean. Prod. 2019, 233, 753–764. [Google Scholar] [CrossRef]

- Putilova, I.V. Current state of the coal ash handling problem in Russia and abroad, aspects of the coal ash applications in hydrogen economy. Int. J. Hydrog. Energy 2023, 48, 31040–31048. [Google Scholar] [CrossRef]

- Savadogo, N.; Messan, A.; Hannawi, K.; Agbodjan, W.P.; Tsobnang, F. Durability of mortar containing coal bottom ash as a partial cementitious resource. Sustainability 2020, 12, 8089. [Google Scholar] [CrossRef]

- Zhou, H.; Bhattarai, R.; Li, Y.; Si, B.; Dong, X.; Wang, T.; Yao, Z. Towards sustainable coal industry: Turning coal bottom ash into wealth. Sci. Total Environ. 2022, 804, 149985. [Google Scholar] [CrossRef]

- Gooi, S.; Mousa, A.A.; Kong, D. A critical review and gap analysis on the use of coal bottom ash as a substitute constituent in concrete. J. Clean. Prod. 2020, 268, 121752. [Google Scholar] [CrossRef]

- Kim, H.-K. Utilization of sieved and ground coal bottom ash powders as a coarse binder in high-strength mortar to improve workability. Constr. Build. Mater. 2015, 91, 57–64. [Google Scholar] [CrossRef]

- Singh, N.; Mithulraj, M.; Arya, S. Influence of coal bottom ash as fine aggregates replacement on various properties of concretes: A review. Resour. Conserv. Recycl. 2018, 138, 257–271. [Google Scholar] [CrossRef]

- Aydin, E. Novel coal bottom ash waste composites for sustainable construction. Constr. Build. Mater. 2016, 124, 582–588. [Google Scholar] [CrossRef]

- Debasree; Amrin, A.; Biswal, D.R.; Sahoo, K.K.; Dhir, P.K. Utilization of Bottom Ash and Pond Ash as a Partial Replacement for Sand in Cement Mortar and Concrete: A Critical Review. Pract. Period. Struct. Des. Constr. 2023, 28, 03123004. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H. Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete. Constr. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Shenoy, D.; Sugandhini, H.K.; Kudva, P.L. Towards a New Approach in Designing High-Strength Concrete: Challenges in Replacing Three-Fourth of Natural Fine Aggregate with Coal Bottom Ash. Civ. Eng. Archit. 2025, 13, 522–542. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour. Conserv. Recycl. 2013, 72, 20–32. [Google Scholar] [CrossRef]

- Yang, I.-H.; Park, J.; Le, N.D.; Jung, S.; Stevulova, N. Strength Properties of High-Strength Concrete Containing Coal Bottom Ash as a Replacement of Aggregates. Adv. Mater. Sci. Eng. 2020, 2020, 4246396. [Google Scholar] [CrossRef]

- IS 3812 (Part 1); Pulverized Fuel Ash—Specification; Part 1: For Use as Pozzolana in Cement, Cement Mortar and Concrete. Bureau of Indian Standards: New Delhi, India, 2013; pp. 1–18.

- IS 15388; Silica Fume—Specification. Bureau of Indian Standards: New Delhi, India, 2003; pp. 1–13.

- IS 4031 (Part 1); Method of Physical Tests for Hydraulic Cement, Part 1: Determination of Fineness by Dry Sieving; Reaffirmed 2016. Bureau of Indian Standards: New Delhi, India, 1996; pp. 1–7.

- IS 4031 (Part 4); Methods of Physical Tests for Hydraulic Cement, Part 4: Determination of Consistency of Standard Cement Paste. Reaffirmed 2019. Bureau of Indian Standards: New Delhi, India, 1988; pp. 1–4.

- IS 4031 (Part 2); Methods of Physical Tests for Hydraulic Cement, Part 2: Determination of Fineness by Blaine Air Permeability Method. Reaffirmed 2004. Bureau of Indian Standards: New Delhi, India, 1999; pp. 1–13.

- IS 4031 (Part 11); Methods of Physical Tests for Hydraulic Cement, Part 11: Determination of Density. Bureau of Indian Standards: New Delhi, India, 1988; pp. 1–6.

- IS 4031 (Part 5); Methods of Physical Tests for Hydraulic Cement, Part 5: Determination of Initial and Final Setting Times. Bureau of Indian Standards: New Delhi, India, 1988; pp. 1–5.

- IS 4031 (Part 3); Methods of Physical Tests for Hydraulic Cement, Part 3: Determination of Soundness. Bureau of Indian Standards: New Delhi, India, 1988.

- IS 4031 (Part 6); Methods of Physical Tests for Hydraulic Cement, Part 6: Determination of Initial and Final Setting Times; Reaffirmed 2019. Bureau of Indian Standards: New Delhi, India, 1988; pp. 1–9.

- IS 1727; Methods of Test for Pozzolanic Materials. Bureau of Indian Standards: New Delhi, India, 1967; pp. 1–55.

- IS 2386 (Part 3); Methods of Test for Aggregates for Concrete, Part 3: Specific Gravity, Density, Voids, Absorption and Bulking; Reaffirmed 2016. Bureau of Indian Standards: New Delhi, India, 1963; pp. 1–22.

- IS 2386 (Part 1); Methods of Test for Aggregates for Concrete, Part 1: Particle Size and Shape; Reaffirmed 2016. Bureau of Indian Standards: New Delhi, India, 1963; pp. 1–23.

- IS 383; Coarse and Fine Aggregate for Concrete. Bureau of Indian Standards: New Delhi, India, 2016; pp. 1–24.

- IS 2250; Code of Practice for Preparation and Use of Masonry Mortars. Bureau of Indian Standards: New Delhi, India, 1981.

- ASTM C232-07; Standard Test Methods for Bleeding of Concrete. ASTM International: West Conshohocken, PA, USA, 2007. Available online: www.astm.org (accessed on 24 February 2024).

- IS 516; Methods of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 1959; pp. 1–25.

- IS 516 (Part 5)-; Hardened Concrete —Methods of Test Part 5 Non-destructive Testing of Concrete. Bureau of Indian Standards: New Delhi, India, 2018. Available online: www.standardsbis.in (accessed on 24 February 2024).

- Srivastava, A.; Singh, S.K.; Sharma, C.S. Correlation Between Ultrasonic Pulse Velocity (UPV) and Compressive Strength of Coal Bottom Ash Mortar. J. Inst. Eng. 2021, 102, 421–433. [Google Scholar] [CrossRef]

- Ankur, N.; Singh, N. Performance of cement mortars and concretes containing coal bottom ash: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 149, 111361. [Google Scholar] [CrossRef]

- Singh, M. Coal bottom ash. In Waste and Supplementary Cementitious Materials in Concrete: Characterisation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–50. [Google Scholar] [CrossRef]

- Huynh, T.-P.; Ngo, S.-H. Waste incineration bottom ash as a fine aggregate in mortar: An assessment of engineering properties, durability, and microstructure. J. Build. Eng. 2022, 52, 104446. [Google Scholar] [CrossRef]

- Kumar, P.K. Workability Strength and Elastic Properties of Cement Mortar with Pond Ash as Fine Aggregates. 2020. Available online: https://www.sciencedirect.com/science/article/pii/S2214785320331060 (accessed on 24 February 2024).

- Hashemi, S.S.G.; Bin Mahmud, H.; Djobo, J.N.Y.; Tan, C.G.; Ang, B.C.; Ranjbar, N. Microstructural characterization and mechanical properties of bottom ash mortar. J. Clean. Prod. 2018, 170, 797–804. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Properties of concrete containing high volumes of coal bottom ash as fine aggregate. J. Clean. Prod. 2015, 91, 269–278. [Google Scholar] [CrossRef]

| Mix Designation | CBA Replacement% | w/b | OPC | FA | Microsilica | NFA (SSD) | CBA (SSD) | Water | PCE |

|---|---|---|---|---|---|---|---|---|---|

| CM | 0 | 0.29 | 810 | 900 | 90 | 1800 | 0 | 523.8 | 7.2 |

| CBA25 | 25 | 0.29 | 810 | 900 | 90 | 1350 | 450 | 264.6 | 7.2 |

| CBA50 | 50 | 0.29 | 810 | 900 | 90 | 900 | 900 | 354.6 | 7.2 |

| CBA75 | 75 | 0.29 | 810 | 900 | 90 | 450 | 1350 | 444.6 | 7.2 |

| CBA100 | 100 | 0.29 | 810 | 900 | 90 | 0 | 1800 | 534.6 | 7.2 |

| Curing Age (Days) | Regression Coefficient (fc = A·eB·V) | Correlation Coefficient, R2 | |

|---|---|---|---|

| A | B | ||

| 7 | 0.044 | 0.002 | 0.9757 |

| 14 | 0.01 | 0.0026 | 0.9454 |

| 28 | 0.0005 | 0.0036 | 0.9305 |

| Mix | Si | Al | Ca | Mg | Ca/Si | Ca/Al | Al/Si |

|---|---|---|---|---|---|---|---|

| CM | 18.64 | 7.64 | 4.88 | 0.83 | 0.26 | 0.64 | 0.41 |

| CBA25 | 34.54 | 1.41 | 1.48 | 0.05 | 0.04 | 1.05 | 0.04 |

| CBA50 | 9.38 | 3.99 | 24.98 | 0.10 | 2.66 | 6.26 | 0.43 |

| CBA75 | 11.23 | 9.82 | 16.25 | 0.22 | 1.45 | 1.65 | 0.87 |

| CBA100 | 20.08 | 6.57 | 13.80 | 0.25 | 0.69 | 2.10 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, S.; Shenoy, D.; Vardhan, V.; Choudhary, K.; Kudva, L.P.; Sugandhini, H.K. Re-Imagining Waste: CBA-Modified High-Strength Mortar as a Blueprint for Greener Construction. Constr. Mater. 2025, 5, 76. https://doi.org/10.3390/constrmater5040076

Kumar S, Shenoy D, Vardhan V, Choudhary K, Kudva LP, Sugandhini HK. Re-Imagining Waste: CBA-Modified High-Strength Mortar as a Blueprint for Greener Construction. Construction Materials. 2025; 5(4):76. https://doi.org/10.3390/constrmater5040076

Chicago/Turabian StyleKumar, Shivam, Deepthi Shenoy, Vansh Vardhan, Kiran Choudhary, Laxman P. Kudva, and H. K. Sugandhini. 2025. "Re-Imagining Waste: CBA-Modified High-Strength Mortar as a Blueprint for Greener Construction" Construction Materials 5, no. 4: 76. https://doi.org/10.3390/constrmater5040076

APA StyleKumar, S., Shenoy, D., Vardhan, V., Choudhary, K., Kudva, L. P., & Sugandhini, H. K. (2025). Re-Imagining Waste: CBA-Modified High-Strength Mortar as a Blueprint for Greener Construction. Construction Materials, 5(4), 76. https://doi.org/10.3390/constrmater5040076