Abstract

By seamlessly integrating the wearing comfortability of textiles with the biomechanical energy harvesting function of a triboelectric nanogenerator (TENG), an emerging and advanced intelligent textile, i.e., smart textile TENG, is developed with remarkable abilities of autonomous power supply and self-powered sensing, which has great development prospects in the next-generation human-oriented wearable electronics. However, due to inadequate interface contact, insufficient electrification of materials, unavoidable air breakdown effect, output capacitance feature, and special textile structure, there are still several bottlenecks in the road towards the practical application of textile TENGs, including low output, high impedance, low integration, poor working durability, and so on. In this review, on the basis of mastering the existing theory of electricity generation mechanism of TENGs, some prospective strategies for improving the mechanical-to-electrical conversion performance of textile TENGs are systematically summarized and comprehensively discussed, including surface/interface physical treatments, atomic-scale chemical modification, structural optimization design, work environmental control, and integrated energy management. The advantages and disadvantages of each approach in output enhancement are further compared at the end of this review. It is hoped that this review can not only provide useful guidance for the research of textile TENGs to select optimization methods but also accelerate their large-scale practical process.

1. Introduction

The rapid consumption of fossil energy and the increasing urgency of environmental security precipitate us to reshape the current energy utilization structures that depend on oil and coal [1]. In addition, ubiquitous wearable electronics and the Internet of Things (IoTs) pose a great challenge to the present energy supply modes in the centralized, fixed, ordered, and high energy density forms, which rely heavily on traditional power plants and cable transmission networks [2]. In general, the power needed to operate millions of wearable sensors is very small, typically at the microwatt to watt level. Although orderly energy supply modes can provide a part of the power for distributed electronic devices, the rest of the power must be provided by random energy sources in our living environment, including solar energy, vibration, motion, wind energy, and other resources [3,4,5,6,7,8,9]. What we expect is to make full use of any available resources in the environment where the device is deployed. Therefore, the idea of a self-powered system is proposed, which is one of the most feasible schemes for low power electronic devices by effectively acquiring environmental energy [10,11,12,13,14,15,16,17,18].

Triboelectrification or contact electrification is a universal phenomenon in which two materials contact each other. A triboelectric nanogenerator (TENG) is a new type of energy collection technology first invented by Wang’s team in 2012. By coupling triboelectric charging and electrostatic induction, various forms of irregular, low-frequency, and distributed mechanical energy, which is common in daily life but usually wasted, can be effectively converted into electric energy, including human movement, vibration, wind, mechanical triggering, water waves, and so on [19,20,21,22,23,24]. With the merits of lightweight, cost-effectiveness, universal availability, abundant materials choice, and especially high conversion efficiency at low frequency, TENGs exhibit a great application prospect in wearable emergency power supply, multifunctional self-powered sensors, healthcare apparatus, and artificial intelligence [25,26,27,28,29,30,31,32,33,34,35]. TENG’s fundamental theory can be traced back to Maxwell’s equations, which shows that the second term in Maxwell’s displacement current has a direct relationship to the output electric current of TENGs [36]. Recently, expanded Maxwell’s equations were also derived by assuming that the medium is moving as a rigid translation in space [37]. The expanded Maxwell’s equations not only largely expand their applications in various fields but also serve as the fundamental theory of the NGs, including output current and associated electromagnetic radiation.

By combining the traditional flexible and wearable textile materials with emerging and advanced TENG science, a new type of intelligent textile technology, namely textile TENG, is developed, which has two outstanding functions: independent energy collection and active self-powered energy-sensing (Figure 1) [38,39,40,41,42]. With the help of wearable intelligent systems with no burden and self-sufficiency, individuals can easily obtain and make efficient use of electric energy, which will help promote the development of people-centered portable electronics and artificial intelligence in the future [43,44,45,46,47]. However, the low power density and high internal impedance are still the two main factors that hinder the effective commercial utilization of textile TENGs. The maximum energy output per cycle has a quadratic relationship with the charge density of the triboelectric surface and is positively correlated with the average output power and energy conversion efficiency of TENGs. According to Paschen’s law, the breakdown effect of high-pressure air has a great influence on the maximum surface charge density [48]. Due to the restriction of high-pressure air breakdown, most of the surface charge densities enhanced by material optimization or external ion implantation are easy to diffuse into the atmosphere and internal triboelectric layer, resulting in charge loss and reduction of surface charge density [49,50]. Breaking through the limitation of air breakdown and prolonging the time of charge decay is especially important for improving the output of TENGs [51]. In order to improve the electromechanical conversion performance of TENGs, people adopted various methods to improve its output performance and expand the applications, such as physical surface modification, chemical surface modification, the embedding of charge trap layer, switching realization, active charge excitation, and so on. Although a large number of reviews summarized these methods to enhance the power output performance of TENGs [52,53,54,55,56,57,58], there is a little comprehensive summary about the improvement of the output performance of textile TENGs. Due to the high aspect ratio, complex curved configuration, and surface micro-to-nano structural defects of 1D fiber structure, it is hard and also unreasonable to directly apply these strategies of improving the power output of the common planar membrane structural TENGs to textile TENGs. In addition, because of the limited effective contact area in textile TENGs, their mechanical-to-electrical conversion efficiency is much lower than that of common planar membrane structures. Therefore, it is extremely necessary to make a comprehensive summary and constructive discussion on the potential strategies to improve the electromechanical conversion output performance of textile TENGs, so as to make their power generation meet the actual use demand.

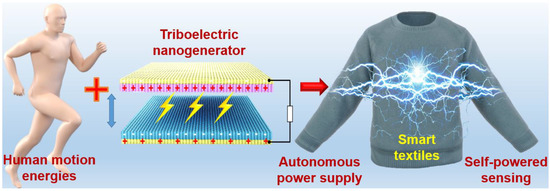

Figure 1.

Schematic illustration of smart textile TENGs by converting human motion energies into electric energy through TENG technology.

This review focuses on textile TENGs, aiming at improving their electrical output performance. The electrification mechanism of TENGs is first interpreted with special attention to the atomic-scale electron-cloud/wave function overlap model. Based on the basic understanding of the charge generation mechanism of TENGs, the potential approaches to enhancing the power output of textile TENGs are systematically investigated, which are mainly divided into five categories on the basis of their respective features, including surface/interface physical treatments, atomic-scale chemical modification, structural optimization design, work environmental control, and integrated energy management. Among them, surface/interface physical treatments consist of two schemes, i.e., micro-/nanostructure patterning and soft contacted interface designing. The atomic-scale chemical modification includes surface modification, ion irradiation/implantation, and charge trapping/storage. As for structural optimization design, it can be further classified into intermediate layer adding, charge shuttling/pumping, and direct-current mode designing. In any case, each strategy has its special advantages in improving the triboelectric output performance but meanwhile exists unavoidable issues. The combination of these methods based on the selected structural characteristics and application directions may be a more preferred scheme. This review is not only a timely retrospection of the emerging smart textiles based on advanced TENG technology but also a key process to break through its existing bottlenecks and promote its real application.

2. Electrification Mechanism

Contact electrification (CE) or triboelectrification means that two different materials or materials of the same chemical type will be charged after physical contact. However, the underlying mechanism was debated for a long time, but no conclusion was reached. Recently, some researchers used a variety of experimental methods to explore the atomic-scale contact or friction behaviors as well as their induced electrification phenomena. For example, the combination of in situ high-resolution transmission electron microscope (TEM) and atomic force microscope (AFM) measurements can provide direct real-time observation of atomic-level interface structure in the processes of friction and the formation of a loosely stacked interface layer between two metal asperities can result in low friction under tensile stress (Figure 2a) [59]. In addition, using Kelvin probe force microscope (KPFM) technology and properly functionalized probes, carbon monoxide molecules can be imaged in σ-real space with anisotropic holes and quadrupole charges (Figure 2b) [60]. This method is expected to expand the possibility of characterizing complex molecular systems and surface charge distribution. The atomic-scale motion of nanotubes on a graphene substrate are also investigated based on DFT simulations to explore their atomic-scale rolling friction behavior and induced charge-transfer mechanism [61]. As shown in Figure 2c, a simplified physical model is established to the theoretical basis on atomic-scale rolling and sliding friction behaviors. The typical maximum and minimum energy positions during the rolling and sliding process are selected to characterize its corresponding charge-transfer morphology (Figure 2d). It can be found that the charge interaction is mainly concentrated in the contact area of the moving object, and there is no charge redistribution beyond the contact area. The charge is completely accumulated at the bottom of the carbon nanotube and depleted at the top of the flat graphene substrate, which indicates that selecting the rod rather than the flat structure as a strategy can effectively increase the induced charge density of the triboelectric interface.

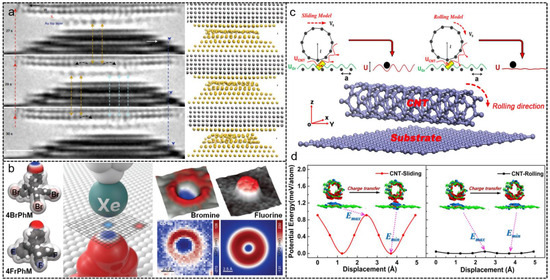

Figure 2.

Experimental characterization of atomic-scale contact or friction behaviors as well as their induced electrification phenomena. (a) The atomic-scale interface structure in the friction process was observed directly and in real-time. Through in situ high-resolution transmission electron microscopy (TEM) and atomic force microscopy (AFM) measurements, it was found that a loosely stacked interface layer was formed between the two metal micro bumps. Reproduced with the permission of [59], copyright 2021, Springer Nature. (b) Real-space images of the anisotropic charge distribution of the σ-hole and the quadrupolar charge of a carbon monoxide molecule obtained by KPFM. Adapted with the permission of [60], copyright 2021, AAAS. (c) Atomic-scale rolling and sliding friction behaviors between CNT and graphene substrate. (d) The corresponding potential energy distribution during the rolling and sliding process. (c,d) Reproduced with the permission of [61], copyright 2020, American Chemical Society.

Contact electrification or triboelectrification mechanism is particularly important for TENGs. As usual, a macro-scale electron or charge transfer model during two friction layers in a complete contact and separation cycle is used to reveal the electrification mechanism (Figure 3a). Taking the typical vertical contact-separation model as an example, when the two friction materials A and B make contact with each other, the same amount of charges are generated on their interface with opposite polarities (Figure 3a(i)). When the two friction materials begin to separate, static charges are induced in the electrodes, generating an instantaneous electrical current (Figure 3a(ii)). When the two friction layers are completely separated, the charges on the friction layers are fully equilibrated by the electrostatic induced charges on their attached electrodes (Figure 3a(iii)). In the reverse case, if the two frictional materials gradually approach each other, the electrons or charges will be transferred in the reverse trend (Figure 3a(iv)). After the whole system returns to the initial state, the charges on the electrodes will be offset by the frictional layers. The contact and separation process in Figure 3a will form an alternative potential or current signal. In addition to the widely used macro-scale charge transfer model, Wang et al. proposed an atomic-scale electron cloud potential well or wave function overlapping model based on the electron-emission-dominated charge transfer mechanism to attempt to describe the CE process between any two materials and even atoms [62,63]. As shown in Figure 3b, once the two atoms approach and make contact with each other, the electron clouds will overlap between the two atoms to form ionic or covalent bonds, resulting in the initial single potential wells becoming an asymmetric double-well potential. Due to the strong overlap of electron clouds, the energy barrier between the two decreases. Then, electrons can then be transferred from one atom to the other, resulting in CE (Figure 3b(ii)). Due to the existence of surface potential barriers that bind the electrons tightly in specific orbits and prevent the charge generated by CE from flowing back, the charges generated in CE can be readily retained by the material as the electrostatic charges for several hours at room temperature (Figure 3b(iii)) [64]. The process presented in Figure 3b is referred to as the Wang transition, which has laid a solid foundation for exploring the meso-scale and macro-scale contact electrification or triboelectrification of textile TENGs.

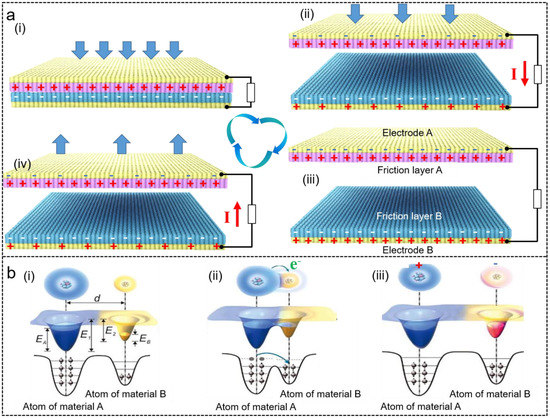

Figure 3.

Electrification mechanism of mechanical-to-electrical conversion during contact or friction process. (a) Classic electron or charge transfer process in a complete contact and separation cycle. (b) An electron-cloud-potential-well model was proposed for explaining CE and Charge transfer between two materials that may not have a well-specified energy band structure. Reproduced with the permission of [65], copyright 2019, Elsevier.

3. Basic Strategies

3.1. Surface/Interface Physical Treatments

3.1.1. Micro-/Nano-Patterned Structures

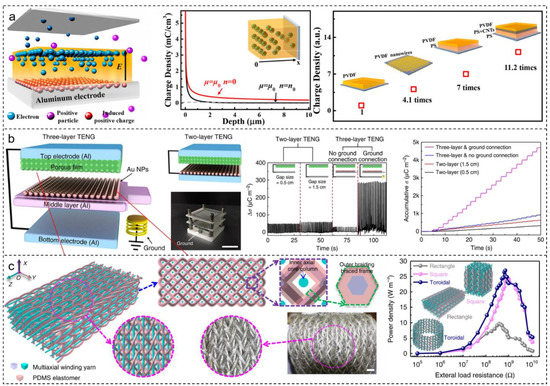

One of the simplest and most common methods to improve the output performance of TENGs is to increase the effective contact area through fabricating micro-/nano-textures at the contact surfaces or interfaces. Multiple micro-/nano- patterned structures with regular and uniform textures can be fabricated based on various processing techniques, such as lithography, etching, self-assembly, laser patterning, and so on [66,67,68,69,70,71]. Various types of nanostructures, including nanoparticles, nanorods, and nanowires, are fabricated into TENGs to increase the contact area, thereby obtaining a high charge transfer density. As shown in Figure 4a, three types of regular and uniform polymer patterned arrays, including line, cube, and pyramid, are fabricated to improve the efficiency of TENGs [72]. The obtained results show that the output efficiency of different TENGs follows film < line < cube < pyramid. The correlation between the contact area and electrical performance of TENG with textured surfaces is revealed to make a quantitative analysis of the effect of the effective contact area of micro-/nano-textures on the power output of TENGs [73]. As illustrated in Figure 4b, both the contact area and open-circuit voltage of TENGs with the pyramid texture increase under lighter loading while remaining stable under heavier loading. In addition, for better understanding the impact of interfacial design on the power generation of TENGs, systematical numerical studies on the adhesive contact at the micro-/nano-structured interfaces are conducted, which confirm that the deformation of interfacial structures is related to the pressure-voltage of TENG [74]. The hysteretic behavior in contact force response of TENG is analyzed, which shows that the counterclockwise hysteresis curve of the contact force versus output power originates from the asymmetric time constant between triboelectric charging and natural discharging [75].

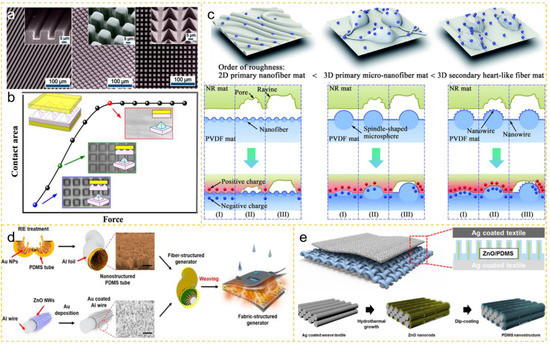

Figure 4.

Construction of micro/nanostructures on the contact interface to improve the working performance of textile TENGs. (a) SEM images of several patterned micro/nanostructures, such as columns, cubes, and pyramids. Reproduced with the permission of [72], copyright 2012, American Chemical Society. (b) Relationship between surface contact area and applied pressure. Reproduced with the permission of [73], copyright 2012, Elsevier. (c) Conceptual illustration showing the contact interface states with 2D primary nanofiber mat, 3D primary micro-nanofiber mat, and 3D secondary heart-like fiber mat. Reproduced with the permission of [76], copyright 2019, The Royal Society of Chemistry. (d) A highly stretchable 2D fabric TENG with the Al wire grown on ZnO nanowires in the core and nanostructural PDMS tube in the shell. Reproduced with the permission of [77], copyright 2015, American Chemical Society. (e) A nanopatterned wearable fabric TENG consisting of an Ag-coated fabric and PDMS nanopatterns based on ZnO nanorod arrays on an Ag-coated textile substrate. Reproduced with the permission of [78], copyright 2015, American Chemical Society.

The 3D secondary heart-like structure is designed on electrospun PVDF nanofibers to improve the output performance of textile TENGs [76]. The high output results from the combined effect between the heart-shaped structure and porous structure expand the effective contact area through its high surface roughness (Figure 4c). Micro-/nano-patterned structures can also be easily applied to the surface of textiles. For example, a fabric-structured TENG is woven from energy harvesting fibers, which is composed of aluminum wire, vertically arranged nanowires and a PDMS tube with a high aspect ratio nanotextured surface (Figure 4d) [77]. Similarly, by using silver-plated fabric and PDMS nano-pattern based on ZnO nanorod array on silver-plated fabric as two kinds of friction materials, a fully flexible and foldable nano-patterned fabric TENGs with high power generation performance and mechanical strength is designed (Figure 4e) [78]. The dramatic increase in the output performance of TENGs with the micro and nanostructures can be attributed to the following reasons: (1) the frictional layers with micro and nanostructures have better electrification to generate more triboelectric charges during the contact; (2) the triboelectric charges are more easily separated to form a larger dipole moment between the electrodes; (3) the micro and nanostructures increase the effective contact area between triboelectric layers, which can increase the capacitance and dielectric constant. It is also worth noting that the interfacial structures of TENGs can be carefully designed with consideration of a special target application based on numerical simulation methods.

3.1.2. Soft Contacted Interface

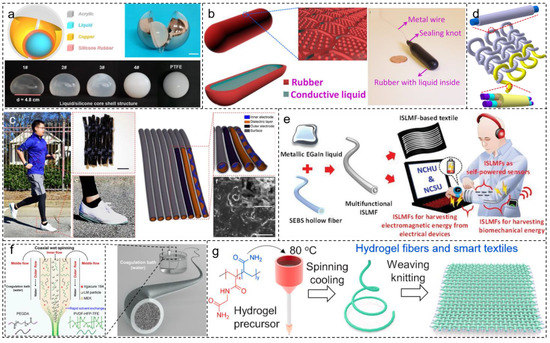

Soft-surface contact is another effective approach that largely improves transferred charges by increasing the contact area. There are several benefits to using the soft contact interface for fabricating TENGs [79,80]. Firstly, more effective energy harvesting and higher sensitivity of soft TENGs can be realized under a tiny external mechanical stimulation. Secondly, the TENGs fabricated with soft materials are easier to adhere to curved surfaces, and more prominently, they can quickly adapt to the deformations caused by complex body movements. Last but not least, compared with the general rigid TENGs, soft-textured TENGs has a wider range of application scopes, especially in implantable medical monitoring. In order to fabricate soft-textured TENGs, supersoft yet tough silicone rubber is often chosen as the elastomeric dielectric, owing to its inherent biocompatibility, superior mechanical properties, excellent flexibility/stretchability, and strong tendency to gain electrons [81,82]. For example, a typical soft-surface-contact TENG is made of an acrylic hollow ball as the shell and a rolling flexible liquid/silicone as the core to effectively collect water wave energy (Figure 5a) [83]. The results show that compared with the traditional PTFE-based hard contact electrode, the maximum output charge of the soft contact spherical TENG is increased by 10 times. In addition to the friction layers, the conductive electrodes can also be made of soft-textured materials. For example, TENG, composed of a conductive liquid electrode and an elastic polymer covering layer, is highly shape-adaptive and stretchable and is designed to effectively collect energy in various working modes [84]. As shown in Figure 5b, TENG can withstand up to 300% strain without lowering the electrical performance due to the unique adaptability of liquid electrodes and the high flexibility of the rubber cover. However, the mechanical stability of TENGs based on liquid electrodes is a great challenge due to the high risk of leakage of liquid electrodes. Therefore, researchers usually take another method by directly mixing with elastic polymer materials with a conductive medium to prepare soft electrodes with better mechanical stability. As exhibited in Figure 5c, a tubular TENG is made of elastic material and spiral inner electrode adhered to the tube with dielectric layer and outer electrode, respectively [85]. These methods to obtain a more fully interface contact state can be used to design high-performance fiber-based TENGs. Among them, the simplest is to directly coat the elastic dielectric material on the surface of the conductive fiber. As shown in Figure 5d, by mixing fiber TENGs and fiber supercapacitor in a fabric, a self-charging electric fabric with biomechanical energy collection capability and energy storage capability based on all yarns is developed [86]. The fiber TENG is obtained by coating silicone rubber on the surface of stainless steel/polyester blended fiber, which can be further knitted into large-scale fabrics. However, the interfacial bonding strength between fiber electrodes and surface coating elastomers is not high, resulting in poor mechanical stability. The poor interface stability can be effectively avoided by directly injecting flowing liquid electrodes into dielectric elastomeric tubes. For example, a triboelectric fiber consists of an elastomeric SEBS hollow fiber filled with metallic EGaIn liquid, fabricated with melt extrusion and injection methods (Figure 5e) [87]. Similarly, a coaxial wet spinning process is used to continuously manufacture inherently stretchable, high conductivity, and stable conductivity liquid metal core microfibers (Figure 5f) [88]. However, the issue of liquid metal-based triboelectric fibers is that liquid electrodes are easy to leak outside. To this end, some researchers use the photo-crosslinking method to solidity the core liquid electrode to obtain triboelectric fibers with more stable mechanical properties. As shown in Figure 5g, a core–shell triboelectric fiber is prepared in silicone hollow fiber by the gel photo-crosslinking method. The fiber has the advantages of softness, flexibility, electrical conductivity, and large-scale production [89].

Figure 5.

Softness interface to maximize the contact area. (a) Soft-contact spherical TENG with a flexible rolling sphere. Reproduced with the permission of [83], copyright 2019, Elsevier. (b) A highly shape-adaptive and stretchable conductive liquid-based TENG. Reproduced with the permission of [84], copyright 2016, AAAS. (c) Tube-like TENG woven into a coat and assembled under shoes. Reproduced with the permission of [85], copyright 2016, Springer Nature. (d) Knitting power textiles fabricated with silicone rubber coated triboelectric fibers. Adapted with the permission of [86], copyright 2017, American Chemical Society. (e) Multifunctional liquid-metal triboelectric fibers with metallic EGaIn liquid filled in SEBS hollow fiber. Reproduced with the permission of [87], copyright 2021, Wiley-VCH. (f) Liquid-metal sheath-core microfibers consisting of double-network fluoroelastomer as the sheath and that percolated EGaIn alloy nanoparticles as the core. Reproduced with the permission of [88], copyright 2021, AAAS. (g) Scalable triboelectric fibers fabricated with an organogel electrode and soft silicone rubber. Reproduced with the permission of [89], copyright 2021, Elsevier.

3.2. Atomic-Level Chemical Modification

3.2.1. Surface Functionalization

The material physicochemical properties of the triboelectric layer are related to its behavior and ability to gain and lose electrons in the process of contact electrification or triboelectrification. In principle, the greater the difference of electron affinity between two triboelectric layers is, the more the triboelectric surface charges will be generated. In addition, the ability of electricity generation of triboelectric layer also depends on their intrinsic material properties, such as dielectric constant, polarity, work function, etc. The triboelectric series for a wide range of polymers is quantified using a universal standard method, which establishes a fundamental materials property of quantitative triboelectrification [90,91,92,93,94]. The normalized triboelectric charge density is defined and deduced to reveal the intrinsic tendency of polymers to gain or lose electrons [62,95]. However, the triboelectric charge density of the material can be changed by adjusting the functional groups on the surface with different electron-withdrawing or electron-donating abilities. Considering that the charge density on polymer surface is closely related to the surface chemical property, surface chemical engineering treatments through appropriate functionalizations, including overall chemical reaction, surface chemical treatment, functional group grafting, and so on, are one of the most fundamental strategies to improve the output performances of TENGs [56,96,97]. For example, the surface charge of polymers can be controlled by carrying their physicochemical properties, such as the strength of macromolecular interactions and surface adhesion. It has been found that polymers with lower modulus show higher surface charge values than those with a higher modulus. In fact, the modulus is directly proportional to the cohesive energy of materials. The effect of polymer cohesion energy on contact electrification is much greater than that of the surface roughness. Polymers showing strong surface adhesion and low cohesion energy in bulk are expected to have higher surface charge [98].

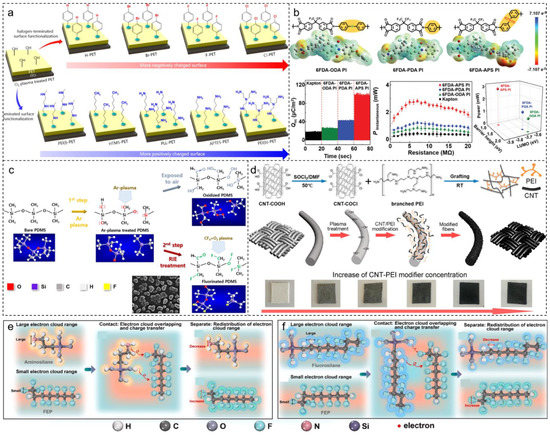

A facile atomic-level chemical functionalization method is proposed to effectively modify the triboelectric property of polymer surfaces by using a series of halogens and amines [99]. As shown in Figure 6a, the negative triboelectric charge on the PET surface is functionalized by arylsilane terminated with electron-accepting elements, halogens, while for the triboelectrically positive side, its surface is functionalized using several aminated molecules. In addition to the PET, the triboelectric properties of other polymers can also be well modulated by chemical modification. The output power of polyimide (PI)-based TENGs is enhanced by introducing electron-withdrawing and electron-donating groups into the main chain [100]. Density functional theory is used to study the relationship between charge retention characteristics and functional groups of the PI films so as to observe the molecular electrostatic potential and the charge distribution (Figure 6b). It is found that the increase of electrical outputs is attributed to the increase of the charge density transferred from the electrode. The chemical functionalization method to improve the electrical output performance of TENGs is also very easy to apply to fibers or fabrics. As shown in Figure 6c, by coating surface interface-engineered PDMS layers on highly conductive Ni-Cu textiles, the electrical performance of the textile TENG is greatly enhanced [101]. The chemical modification of the coated PDMS surface is achieved by one-step Ar-only plasma treatment and a two-step process with consecutive Ar and CF4 + O2 plasma treatment. In addition, by enriching the fiber surface with hierarchical structures and amide bonds through chemical grafting of CNT and PET via a polyamidation reaction, a fabric-based TENG can easily achieve over 10 times improvement in output voltage and current at a low modifier content of less than 1 wt% (Figure 6d) [102]. A relatively systematic and improved mechanism is proposed to clarify the influence of chemically finishing on contact electrification [103]. The electron cloud of the atomic nucleus with electron-donating ability has a large density and occupies a large area, while that with electron-withdrawing ability occupies a small area. As shown in Figure 6e, for the contact between aminosilane and FEP, the overlap of electron cloud leads to the reduction of the energy barrier between them. Afterwards, the electrons are transferred from the low electronegativity atom (N) to the high electronegativity atom (F). Once they are separated, the electron cloud range of N atoms decreases, while the electron cloud range of F atoms increases. As for the contact between fluorosilane and FEP, the electrons of the H atom are transferred to the F atom, due to that the more F atoms in the FEP polymer, the stronger the ability to obtain electrons (Figure 6f). In summary, creating new functional groups through a variety of chemical methods to obtain strong electron-donating or electron-accepting ability on fabric surface is an effective method to greatly and stably improve the output performance of textile TENGs.

Figure 6.

Chemical modification of polymer materials to alter the electron-withdrawing or electron-donating abilities. (a) Atomic-level chemical functionalization on PET polymer surface. Reproduced with the permission of [99], copyright 2017, American Chemical Society. (b) High-output TENGs based on PI-based polymers by introducing functionalities into the backbone. Adapted with the permission of [100], copyright 2019, Wiley-VCH. (c) Improvement of output performance of TENGs by a simple plasma treatment approach. Reproduced with the permission of [101], copyright 2019, Elsevier. (d) Enhancing the performance of fabric TENGs by structural and chemical modification. Reproduced with the permission of [102], copyright 2021, American Chemical Society. (e) Schematic diagram of the electron cloud overlap model between aminosilane and FEP, in which aminosilane has a large electron cloud range with orange color and FEP has a small electron cloud range with green color. (e) Schematic diagram of the electron cloud overlap model between fluorosilane and FEP, where fluorosilane has a large electron cloud range with blue color and FEP has a small electron cloud range with green color. (e,f) Reproduced with the permission of [103], copyright 2021, Elsevier.

3.2.2. Ion Injection/Irradiation/Implantation/Decoration

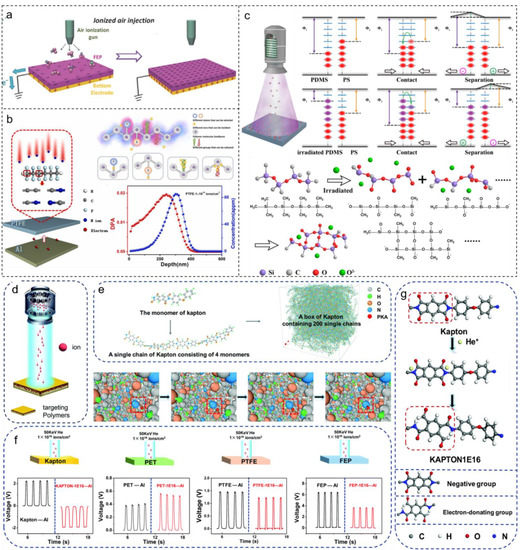

The above surface functionalization methods to alter the original electro-donating and electron-withdrawing ability are limited by their low accuracy and poor stability. Due to this, the surface triboelectric charges only come from two surfaces with the difference in surface potentials; the compensation of surface potential difference by injecting or implanting additional electrons or ions is also an effective method. Therefore, by directly adding ions or single-polarity charged particles on or inside the triboelectric materials, the charge density of triboelectric surfaces can be greatly increased. Ionized-air injection is the simplest method to implant polarized charges into polymers. With the assistance of an air-ionization gun, the ions with negative or positive polarities are generated and subsequently implanted onto the material surfaces [96]. The polarity of the ions injected from the outlet of the gun can be manually controlled by pressing or releasing the trigger bar. As shown in Figure 7a, the negative ions reaching the surface of FEP film transfer the same number of electrons from the bottom electrode to the ground by electrostatic induction so that the bottom electrode has positive charges of the same charge density [104]. As a result, the charge density on the FEP surface from the ion-injection process can reach a much higher level than that on an electrode-free FEP layer. In order to further improve the stability and retention rate of implanted ions, a modification strategy based on ion implantation technology is proposed to precisely control the distribution and concentration of dopant atoms in the polymers. As shown in Figure 7b, under the accelerated fields, polar groups and unsaturated bonds containing N element can not only break the symmetry of the spatial structural of PTFE, but also combine with the free radicals on the chain to form new chemical bonds and chemical groups [105]. The electronegativity and the increase of electron cloud density of the group lead to the improvement of the electron-withdrawing ability. As a result, the ion implantation modified PTFE and FEP films exhibit the most negative triboelectricity in the triboelectric series. Besides nitrogen ion implantation, other ions are also gradually used to change the charging properties of polymer materials. Atomic oxygen irradiation is used to manipulate the surface structure and chemical components to adjust their electrical properties [106]. As seen in the mechanism illustrated in Figure 7c, atomic oxygen infrared radiation can increase the electron-donating groups and enhance electropositivity of PDMS films, which leads to an increase in the work function of PDMS, thus enhancing its surface states to be charged. In addition, a Kapton film modified by low-energy helium ion irradiation also shows several unprecedented characteristics, such as high surface charge density, excellent stability, and ultrahigh electro-donating capability, which makes it lose electrons during the contact electrification process (Figure 7d,e) [107]. The electrification properties of other ion irradiated polymers, such as PET, PTFE, and FEP, are also systematically studied (Figure 7f), which suggests that the same ion irradiation can lead to different performance changes for different polymers. Argon ion implantation is carried out on Kapton to make it serve as a positive triboelectric layer, while pure Kapton behaves as a negative triboelectric layer [108]. The effect of argon plasma treatment (including plasma power and treatment time) on the output performance of TENG is also investigated [109]. Neutral beam is also an advanced plasma-based etching and surface treatment technology of polymers. Kim et al. modified the surfaces of PDMS and TPU using N2 and O2 gas-based neutral beam process, which showed the remarkable output performance of TENGs [110].

Figure 7.

Ion injection or ion irradiation/implantation. (a) Ionized-air injection to maximum surface charge density of TENG. Reproduced with the permission of [104], copyright 2014, Wiley-VCH. (b) Implanting ions into the polymers to change their chemical structure by ion implanter. Reproduced with the permission of [105], copyright 2021, Elsevier. (c) Manipulating electrical properties of silica-based materials via atomic oxygen irradiation. Adapted with the permission of [106], copyright 2021, American Chemical Society. (d–g) Manipulating triboelectric surface charge density of polymers by low-energy helium ion irradiation or implantation. Adapted with the permission of [107], copyright 2020, The Royal Society of Chemistry.

The approach of ion injection or implantation technology to the study of triboelectric polymers is helpful to further clarify the internal mechanism between molecular composition/structure and contact electrification/triboelectrification ability, which provides useful guidance for developing high-performance triboelectric polymers.

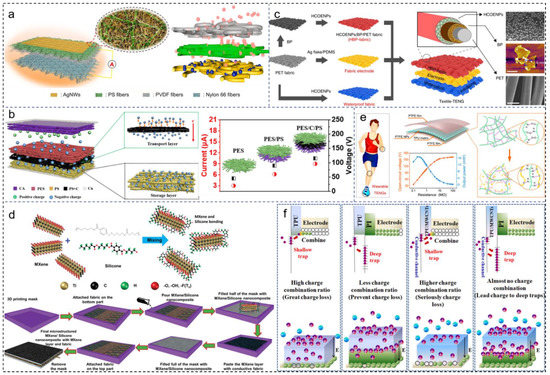

3.2.3. Charge Trapping/Storage

Triboelectric charges will delay the surface friction of materials and transfer to the interface between the friction layer and electrode, which will decrease triboelectric charge density [111,112,113,114]. Interfacial modifications made by mixing charge trapping or storage elements are considered a suitable method to increase the retention of triboelectric charges for output enhancement [115]. For instance, the ferroelectric polymer-metallic nanowire composite nanofibers are described for use in high-performance TENGs. For example, an improved fiber-based TENG with a breathable-antibacterial Ag NWs electrode and electrostatic induction enhancement electrospun polystyrene (PS) nanofibers as charge storage layer is proposed in order to improve the output performance of TENGs and meanwhile maintain good flexibility and breathability (Figure 8a) [116]. The result shows that the samples with PS film as the intermediate charge storage layer have an obvious higher output than others without one. Similarly, a multilayered nanofiber TENG is proposed to greatly enhance the triboelectric charge density by introducing a charge-transport layer (polystyrene and carbon black) and a charge-storage layer (polystyrene) (Figure 8b) [117]. The short-circuit current and open-circuit voltage of the multilayered TENG are distinctively 3 times and 2.5 times larger compared with the single-layer structured TENG, respectively. Another example is a high-performance TENG which is designed utilizing the electrospun PVDF-Ag NW composite and nylon fibers as the top and bottom triboelectric layers, respectively. The enhanced surface charge potential and the charge trapping capabilities of the PVDF-Ag NW composite nanofibers significantly enhance the output performance of TENG [118].

Figure 8.

Improving output performance of TENGs by adding charge trapping layers. (a) An all-fibrous TENG with enhanced outputs depended on the PS charge storage layer. Adapted with the permission of [116], copyright 2021, Elsevier. (b) Enhancement of charge density by introducing a charge-transport layer and a charge-storage layer. Reproduced with the permission of [117], copyright 2018, Elsevier. (c) Textile TENGs with black phosphorous as the synergetic electron-trapping coating. Reproduced with the permission of [119], copyright 2018, Springer Nature. (d) A double-side-contact fabric-assisted TENG by using 2D MXene as the charge trapping layer. Reproduced with the permission of [120], copyright 2021, Wiley-VCH. (e) Boosting the power and lowering the impedance of TENGs through manipulating the permittivity. Reproduced with the permission of [121], copyright 2021, American Chemical Society. (f) Schematic illustration of charging trapping mechanisms. Reproduced with the permission of [122], copyright 2021, American Chemical Society.

In addition to adding charge trapping material into nanofibers by electrospinning, it can also be realized on fabrics. As shown in Figure 8c, an all-fabric TENG with excellent durability and high triboelectricity was developed using black phosphorus (BP) encapsulated with hydrophobic cellulose oleoyl ester nanoparticles (HCOENPs) as a synergetic electron-trapping layer [119]. The HCOENPs/BP mixed layer provides a charge storage layer to reduce the dissipation of triboelectric electrons to increase the electricity outputs. With a novel, scalable surface modification method of fabric-assisted micropatterning techniques, a highly negative MXene/silicone nanocomposite surface with 2D MXene as the charge trapping layer was adopted to boost the output performance of double-side-contact fabric-assisted TENG (Figure 8d) [120]. The obtained output voltage and current are appropriately 1.6 and 1.5 times higher than those of the sandpaper-assisted microstructures. In order to decrease the high intrinsic impedance of TENGs, which often range from dozens to hundreds of megohms, a high-performance TENG with boosted electrical output and lower internal impedance is reported, which consisted of a thermoplastic TPU matrix with polyethylene glycol additives and PTFE nanoparticle inclusions (Figure 8e) [121]. The increment of permittivity improves the injected charge density and internal capacitance of the TENG, thus resulting in the enhancement of output power and the reduction of matching impedance, respectively. The charge trapping mechanism combined with increased conductivity for improving the output performance of TENGs is illustrated in Figure 8f [122]. When there is no PI layer and MWCNTs, the triboelectric charges with purple dots generated by TPU are generally trapped in shallow traps, which is easy to combine with the induced charges with green dots on the electrode and charged ions or particles with blue dots from the air, resulting in obvious charge loss and low output. If the PI layer is attached with the TPU, partial triboelectric charges will be trapped in the TPU/PI double layer, resulting in less charge loss. In addition, the volume conductivity of TPU can be improved by adding MWCNTs, which will make the newly generated charge easily move to the PI layer, thus allowing more charges in shallow traps to enter the deep traps.

3.3. Structural Optimization Design

3.3.1. Intermediate Layer Embedding

Embedding a superior intermediate layer into TENGs was also proved as an efficient strategy to enhance the surface charge density and power output performance that are attributed to the enhancement of the dielectric permittivity [6,51,123]. The research shows that the triboelectric charge in the friction dielectric layer will decay with time. The intermediate layer between the triboelectric layer and electrode can capture and accumulate more electrons, which reduces the drift and diffusion of electrons and thus prolongs the charge decay process. When there is no intermediate layer, the electrons on the surface may drift inward under the driving force of the electric field and eventually combine with the opposite charge induced on the electrode, thus reducing the surface charge density. Therefore, it is of great significance to add an intermediate layer between the triboelectric layer and the electrode to reduce the mutual shielding of charges.

The method of adding an intermediate layer to the triboelectric layer is put forward as a novel strategy to prolong the charge decay time and enhance induced charge so as to improve the output performance of TENGs. For example, Cui et al. investigated the relationship between the thickness of the friction layer and the transport process of triboelectric charges in a PVDF film. The results showed that when the thickness of the friction layer was greater than the storage depth, the stored charge could reach a maximum. In addition, with the excess increase of storage depth, the charge did not accumulate further (Figure 9a) [124]. Moreover, by further adding a dielectric layer and a transport layer between the PVDF and the electrode, the output performance of TENG will be more significantly improved. Similarly, by adjusting the content of MXene flakes and the balance between the dielectric property and the percolation effect, the oriented MXene-doped PVDF composite film with highly enhanced triboelectric output performance is developed [125]. MXenes are an emerging class of 2D transition metal carbides, which possess outstanding metallic electronic conductivity and a high electronegative surface [126,127]. It is found that the surface charge density of the MXene-modified TENG obtained 350% enhancement compared to that with the pure PVDF. In order to overcome the limitation of traditional TENG’s output performance in the actual environment, an electric double layer made of Al film coated by Au nanoparticles is inserted between a top layer made of Al/PDMS and a bottom layer made of Al to develop sustainable and enhanced output performance of TENG, whose energy conversion efficiency can reach 22.4% (Figure 9b) [128]. When the force is loaded to the top layer and then withdrawn, the positive and negative charges are spatially separated in the middle layer through the sequential contact structure and the direct electrical connection between the middle layer and the ground, forming an electric double layer. It can be found that the power output of the three-layer TENG is much higher than that two-layer TENG [129]. In addition, in order to prevent the problem of poor interface strength caused by simple, intermediate layer stacking, an interlaminar fiber winding structure is adopted. For instance, a 3D braided TENG with shape adaptability and high resilience is developed through a four-step braiding technology, which is easy to implement and can be expanded industrially for power supply and pressure sensing (Figure 9c) [130]. The output of the 3D braided TENG is about twice that of the multilayered 2D TENG fabric, which is due to the special 3D braided structure with more contact and separation areas that can effectively enhance the total power output.

Figure 9.

Improvement of output performance of TENGs by embedding superior intermediate layer. (a) Improvement of output performance of TENGs by adjusting the depth distribution of the triboelectric charges. Reproduced with the permission of [124], copyright 2016, American Chemical Society. (b) Output performance of TENGs enhanced by electric double layer effect. Reproduced with the permission of [128], copyright 2016, Springer Nature. (c) Shape adaptable and highly resilient 3D braided TENGs. Reproduced with the permission of [130], copyright 2020, Springer Nature.

3.3.2. Charge Shuttling/Pumping

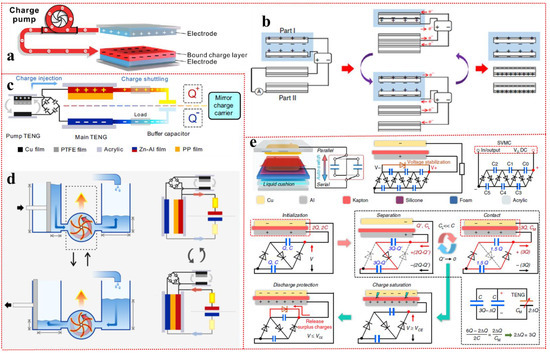

The surface charge density of tribomaterial, which is highly correlated with the current, voltage and charge transfer of TENG, is considered to be the most important parameter of electrical output. However, the surface charge density of dielectric materials is limited by air breakdown and the number of stored charges in surface energy states. Inspired by the excitation strategy of the electromagnetic generator, In 2018, Cheng et al. [131] and Xu et al. [132] independently discovered the external charge excitation strategy to improve the surface charge density of the tribomaterials of TENG. As shown in Figure 10a, they both choose metal materials that can store high-density charge rather than dielectric materials as the tribomaterials, and charges can be pumped from one of the electrodes to the another one in the main TENG by a pump TENG [132]. In detail, part 1 and part 2 act as the pump and main TENG, respectively. The contact and separation of the pump TENG will drive the positive and negative charges to the two electrodes of the main TENG in one direction through the high-voltage rectifier bridges, which causes the surface charge density of the tribomaterials in the main TENG to increase gradually until it reaches a saturation value (Figure 10b). Therefore, the electrical output of the main TENG can be greatly increased (the surface charge density can reach 1003 μC cm−2). Recently, Bai et al. successfully achieved an ultrahigh average power density of 1.66 kW m−3 under a low drive frequency of 2 Hz and high transferred charges of about 4.5 μC with 15 times improvement by charge pumping strategy [133]. Wang et al. added a buffer capacitor based on this strategy (Figure 10c) [134]. The charges pumped into the main TENG will shuttle between it and ceramic capacitors as its capacitance value varies during the contact-separation process, which will introduce two power sources (Figure 10d). The charge density of 1.85 mC m−2 proves the success of this strategy. Furthermore, this TENG was successfully applied to efficiently harvest ocean wave energy. Liu et al. also obtained an ultra-high surface charge density of 2.38 mC m−2 by a half-wave rectifier bridge [135].

Figure 10.

Strategies for direct-current textile TENGs. (a) Basic methods to obtain direct-current output from TENGs. (b) Schematic illustration of the basic structure of direct-current TENG. Reproduced with the permission of [138], copyright 2020, Wiley-VCH. (c) A direct-current fabric TENG by tactfully taking advantage of the electrostatic breakdown phenomenon of clothes. Reproduced with the permission of [139], copyright 2020, American Chemical Society. (d,e) A high output direct-current power fabric based on the air breakdown effect by alternately coating two electrodes on the top surface and bottom surface of polyester fabric. Reproduced with the permission of [140], copyright 2021, The Royal Society of Chemistry. (f,g) Direct-current textile TENGs based on the tribovoltaic effect at dynamic metal-semiconducting polymer interfaces. Reproduced with the permission of [141], copyright 2021, American Chemical Society.

It is well known that self-excitation is also an efficient way to obtain high-output electromagnetic generators. Similarly, the self-charge excitation strategy can also be used to develop a high surface charge density of TENG except for the external charge excitation strategy. Liu et al. realized self-charge excitation through a voltage multiplier circuit, thereby obtaining a high charge density of 1.25 mC m−2 [136]. As shown in Figure 10e, three diodes and two capacitors are taken as an example to illustrate the working mechanism of the self-charge excitation strategy. The TENG can be regarded as a tiny capacitor with high voltage when it is in a separated state thus most of the charges in TENG will be pumped into the two ceramic capacitors connected in series. However, when the TENG is in a separated state, the reverse current direction will cause the connection state of the ceramic capacitor to change from parallel to series, which will result in more charges to transfer from the ceramic capacitor to the TENG with almost zero voltage. The surface charge density of the TENG will be saturated to a super high value after several cycles. In addition, a Zener diode is connected to the voltage multiplier circuit to avoid the impact of air breakdown on the output stability. Long et al. further designed the sliding mode TENG using the self-charge excitation strategy [137].

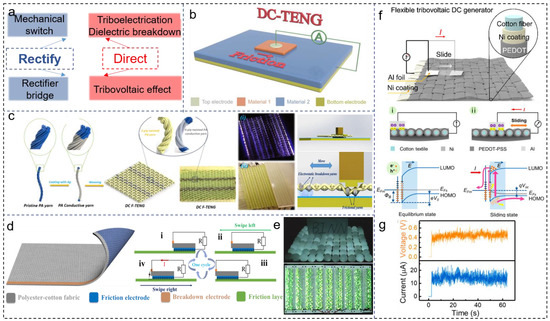

3.3.3. Direct-Current Mode

It is well known that almost all electronic products need a direct-current (DC) power source. Therefore, the alternating current (AC) output of traditional TENG cannot directly meet their power demands. Researchers developed various methods to obtain DC from TENG (Figure 11a) [138,142,143,144,145]. In general, these strategies can be broadly divided into two categories, including direct output DC through other physical effects (tribovoltaic effect and dielectric breakdown effect) and various rectifier devices (rectifier bridge and mechanical switch). Choosing commercial electronic rectifier bridges, including full-wave and half-wave rectification, is the most widely used method of converting AC signals into DC output, which is undoubtedly the most convenient and low-cost method [130,146,147,148]. However, as a member of electronic devices, the electronic rectifier bridge will inevitably consume extra energy when it is working, which cannot be underestimated for the TENG with low energy output. The high voltage (~kV) of TENGs may also cause fatal damage to the rectifier bridge [144,149,150]. Moreover, the rigid electronic rectifier bridge seems to be unfriendly for fabric-based TENG, which is one of the promising solutions for wearable energy harvesters. A reasonable mechanical rectifier bridge can ensure that the two electrodes in the external circuit are periodically and alternately connected to the two electrodes in the TENG, which is usually realized by a disc structure. However, this periodic contact seems difficult to be guaranteed for the fabric TENG, which requires high flexibility. There is no related report of this method for fabric-based TENG.

Figure 11.

Charging shuttling/pumping approach towards the high and stable output of TENGs. (a) Schematic diagram of the charge pumping principle. Reproduced with the permission of [132], copyright 2018, Elsevier. (b) Working mechanism of the charge pumping strategy. Adapted with the permission of [131], copyright 2018, Springer Nature. (c,d) Increasing the charge density of a TENG by charge-shuttling. Reproduced with the permission of [134], copyright 2020, Springer Nature. (e) A self-charge excitation TENG system using part of the energy output from TENG to improve its working charge density. Reproduced with the permission of [136], copyright 2019, Springer Nature.

Dielectric breakdown will reduce the surface charge density of dielectric materials, which was always regarded as an unfavorable factor for TENGs. Yang et al. first designed a DC-TENG based on the coupling effect of dielectric breakdown and triboelectrification in 2014 [151]. Researchers understand that air breakdown can also be beneficial to TENG. Liu et al. simplified the structure in 2019, in which the simplest DC-TENG only needs two kinds of electrodes (Figure 11b) [152]. The friction electrode generates charges on the surface of the friction layer based on the triboelectrification, while the breakdown electrode harvests the surface charges based on the air breakdown effect. However, there is still few works on the flexible DC-TENG for wearable electronics. Chen et al. prepared fabric-based DC-TENG by weaving conductive yarns into the fabric [139]. The electrical output can be scaled up by connecting multiple conductive yarns in series (Figure 11c). Moreover, yarn supercapacitors are integrated into another piece of fabric to form a self-powered system. This is a good attempt. However, to obtain a stable air breakdown gap, the fabric-based DC-TENG must be attached to the hard acrylic board, and almost no flexibility exists. Cheng et al. utilizes the tiny height of the fabric to build an air gap, which shows no obvious effect on the flexibility of the textile (Figure 11d) [140]. This structural design is suitable for any thin and/or flexible material. Benefiting from the high electrical output performance of the fabric-based DC-TENG, various wearable electronics, such as watches, calculators, 1053 LEDs, and 99 bulbs, can be directly powered by a finger-sized fabric-based DC-TENG without rectifier bridge and storage devices (Figure 11e).

Similar to the photovoltaic effect, the friction energy will result in electron-hole pairs between the semiconductor-semiconductor/metal interface, and they will be separated under the built-in electric field, thereby generating a unidirectional current in the external circuit (defined as the tribovoltaic effect). Based on this effect, Meng et al. developed FDC-TENG by utilizing the Schottky contact between poly(3,4-ethylenedioxythiophene) (PEDOT) and nickel (Ni) as well as the ohmic contact between PEDOT and aluminum (Al) [141]. Ni and PEDOT are coated on the cotton fabric successively. DC output can be obtained by sliding Al on the surface of the treated cotton fabric (Figure 11f). Moreover, constant DC can be achieved by sliding the Al slider at a uniform speed (Figure 11g). However, the voltage of DC-TENG based on the tribovoltaic effect is not high owing to the limitation of the built-in electric field.

4. Work Environmental Control

The electricity output performance of TENG largely depends on its external working environments, which mainly includes humidity, temperature, and pressure. Ngugen and Yang studied the effects of humidity and pressure on the output performance of TENGs since 2013, i.e., the second year of its first invention. They found that the generated charge increased more than 20% when the relative humidity decreased from 90% to 10% at the ambient pressure and decreased as the air pressure decreased from atmospheric pressure to 50 Torr at the relative humidity close to 0% [153,154]. In addition, Wen et al. conducted experiments to specifically investigate the influence of temperature on the output performance of TENGs over a wide range of temperatures from 300 K to 500 K in a high-temperature range and from 77 K to 300 K in a low-temperature range [155]. The results found that the performance of TENGs is maximized at around 260 K and degrades at both higher and lower temperatures. Lin et al. studied the contact electrification and triboelectric charging process for a metal-dielectric case under different thermal conditions with the help of AFM and KPFM [156]. It was found that the hotter solids tend to have positive triboelectric charges, while colder solids tend to acquire negative charges. Electrons are excited by heat and transferred from the hot surface to the cold surface. Therefore, a thermionic emission band structure model is put forward to describe the electron transfer phenomenon between two solids at different temperatures.

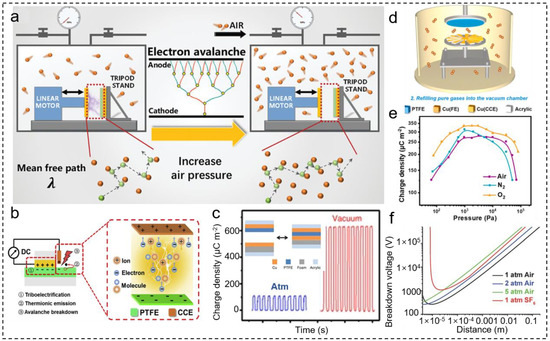

Electrostatic breakdown is a ubiquitous phenomenon existing in electrostatic discharge for numerous devices. The surface charge density of TENG is limited by triboelectrification charge density, air breakdown, and dielectric breakdown [157,158]. When the voltage exceeds the threshold breakdown voltage, or the electric field exceeds the threshold breakdown electric field, the electrons emitted from the cathode will be accelerated to high kinetic energy, which will continue to collide with the gas molecules and cause collision ionization. Then, during the collision, the secondary electrons will be formed, causing the chain reaction, which is called electron avalanche (Figure 12a) [159]. However, the increase of gas pressure can cause a shorter mean free path and thereby inhibit the gas breakdown. With the increase of temperature, the mean free path of electrons and collide possibility increase. Electrons will gain more energy under an electrostatic field, making the avalanche breakdown more likely to occur (Figure 12b) [160]. Considering the limitation of dielectric breakdown effect in air, Wang et al. reported an optimization method to increase the triboelectric charge density by coupling surface polarization, triboelectrification and hysteretic dielectric polarization of vacuum ferroelectric materials (~10−6 torr) [157]. As exhibited in Figure 12c, when the TENG is operated in vacuum (~10−6 torr), the air breakdown described by Paschen’s law is avoided, and the triboelectric charge density increases from 120 to 660 μC m−2. A high vacuum environment can not only ensure better performance of TENGs but also avoid the performance degradation of TENGs caused by the natural accumulation of dust and moisture. In addition, Yi et al. also proposed a strategy to improve the output performance of TENG in a wide range of atmosphere pressure of oxygen [161]. As shown in Figure 12d, a high vacuum system was built to accurately measure the output performance of TENGs in different environments. The chamber was firstly pumped to a high vacuum environment and then the pure gases was injected into the vacuum chamber to minimize the interference of other environmental factors, such as temperature and humidity. The output charge density of the TENG under different gas environments first increases and then decreases with the increasing of gas pressure (Figure 12e). In addition, the output charge density in oxygen gas is higher than that in air or nitrogen gas, the reason of which can be attributed to the lower threshold voltage and easier breakdown characteristics of oxygen gas compared with air and nitrogen gas.

Figure 12.

External environmental control to suppress the gas breakdown. (a) The threshold output energy density of TENGs is enhanced by suppressing the breakdown effects in a high-pressure environment. Reproduced with the permission of [159], copyright 2020, Wiley-VCH. (b) Physical model and the avalanche breakdown of DC-TENG. Reproduced with the permission of [160], copyright 2020, Wiley-VCH. (c) Increasing the triboelectric charge density under vacuum working conditions. Reproduced with the permission of [157], copyright 2017, Springer Nature. (d) Schematic illustration of the measurement system. (e) The charge density of TENG in different gas environments. (d,e) Reproduced with the permission of [161], copyright 2021, Elsevier. (f) Diagram of Paschen’s law and the maximum effective energy output of each cycle in different environments. Reproduced with the permission of [159], copyright 2017, Wiley-VCH.

However, the above performance improvement methods only work at ultrahigh vacuum. In fact, the output performance of TENGs is still limited when the vacuum is lower than the ultrahigh level due to the unavoidable air breakdown effect. By suppressing the breakdown effects under a high-pressure gas environment [159], Zi et al. investigated the air breakdown limits of TENGs in different air pressure and gas atmosphere [48]. As shown in Figure 12f, with the increase of air pressure, the Paschen’s curve moves to the left, and the threshold breakdown voltage increases, which is due to lower mean-free-path and less accumulated kinetic energy in electrons. In other words, air breakdown will be easier under a lower vacuum level. In the low-pressure range, the density of air molecules is relatively low, which makes it difficult to cause air breakdown.

5. Integrated Power Management

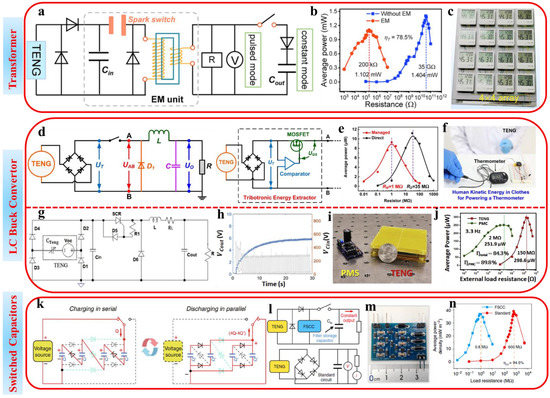

The capacitive TENG shows the high voltage (~kV) and low current (~μA) output characteristics, which endow it with extremely high internal resistances (~hundreds of MΩ). However, the internal actual resistance of most electronics is several hundred to several thousand ohms. The great mismatched internal impedance results in low energy utilization efficiency. Therefore, many studies focused on decreasing the voltage and increasing the current through the energy management module (EMM). Transformers, the voltage conversion devices widely used in power grids, are successfully applied to increase the current of TENGs [150,162,163,164,165,166,167]. In general, transformers exhibit high energy conversion efficiency under high-frequency electrical signals thus many researchers utilize transformers to manage the power of turntable mode TENGs. After the management of the transformer, Zhu et al. successfully charge the mobile phone by the TENG at 3000 r min−1 [165]. Pu et al. obtained an energy conversion efficiency of 72.4% after optimizing the transformer [167]. Except for the turntable mode TENGs, transient discharge can also be utilized to achieve a high energy conversion efficiency of the transformer for low-frequency TENGs. Niu et al. used an electronic switch to control the charge and discharge of the capacitor charged by TENGs to obtain a rapidly changing electrical signal, and the conversion efficiency reached 60% [164]. Wang et al. combined the spark switch with the transformer and designed an efficient EMM with 78.5% energy conversion efficiency (Figure 13a,b) [150]. The spark switch will be turned on when the voltage of Cin reaches its breakdown voltage, and the energy stored in Cin will be released to the load or stored in Cout through the transformer. Peak current density of 2010 A m−2 and a constant power density of 291 mW m−2 can be achieved at 3 Hz. After optimizing the spark switch and transformer, 16 series hygrothermographs are continuously powered at 1 Hz (Figure 13c).

Figure 13.

Power management strategies for TENGs. (a–c) Circuit diagram (a), conversion efficiency (b), and application (c) of EMM based on transformer and spark switch. Reproduced with the permission of [150], copyright 2020, Elsevier. (d–f) Circuit diagram (d), conversion efficiency (e), and application (f) of EMM based on buck circuit and MOSFET. Reproduced with the permission of [170], copyright 2017, Elsevier. (g–j) Circuit diagram (g), output (h), actual photos (i), and conversion efficiency (j) of EMM based on buck circuit and silicon-controlled rectifier. Reproduced with the permission of [169], copyright 2020, Elsevier. (k–n) Working Mechanism (k), circuit diagram (l), actual photos (m), and conversion efficiency (n) of EMM based on switched capacitors and silicon-controlled rectifier. Reproduced with the permission of [173], copyright 2020, Springer Nature.

The buck circuit, which is widely used in the design of microelectronic circuits, was also successfully developed to reduce the internal impedance of TENGs [168,169,170,171]. The advantages of non-magnetic, miniaturization and light weight make buck circuits seem more suitable for flexible electronics. The key to obtaining an effective LC buck circuit is to design a suitable switch. In 2017, Xi et al. achieved an energy conversion efficiency of 80.4% by choosing a MOSFET and a voltage comparator as the switch (Figure 13d,e) [170]. The working process of the circuit can be roughly divided into three stages. Firstly, when the voltage of TENG reaches its optimal value, the switch will be turned on, and the energy of TENG will be transferred to inductor L, capacitor C, and resistor R. Secondly, the energy in the inductor L will move to the capacitor C and the resistor R when the switch is turned off. Finally, the energy stored in capacitor C will power the resistor R. After optimizing the EMM, the human body motion energy can be harvested through the FTENG to drive the thermometer (Figure 13f). However, as an active switch, MOSFET will consume a lot of energy from TENG. Harmon et al. selected a passive switch silicon-controlled rectifier (SCR) in the buck circuit (Figure 13g) [169]. The working cycle of the circuit is similar to the above paper. Therefore, the voltage of Cout increases while that of Cin decreases (Figure 13h). As for the switch, when the voltage of Cin exceeds the regulated value of D5, the triggered SCR will be turned on. Additionally, the SCR will be turned off when the voltage across the SCR is 0. The whole module can be very small (Figure 13i). The energy conversion efficiency is 89.8%, which is higher than that of MOSFET for the lower loss of passive switch (Figure 13j). Moreover, other switches are also cleverly designed, such as mechanical switches [168] and air breakdown switches [171].

Besides the above energy management strategies, using the switched capacitors is another effective way of decreasing the intrinsic resistance of the TENG. In general, switched capacitors means utilizing switches and capacitors to design a circuit that capacitors are charged in series and discharged in parallel. Tang et al. first designed a switched capacitor EMM with mechanical switches, and the output energy can be enhanced 2200 times after management [172]. However, the mechanical switches will complicate the system. To overcome this problem, Liu et al. used the diodes as electronic switches and successfully designed an EMM (Figure 13k–n) [173]. As shown in Figure 13k, the dotted diodes are turned off when TENG is charging the EMM, and the capacitor is connected in series. When the capacitor in the EMM supplies energy to the external circuit, another part of the turned-off diodes will result in the capacitors connected in parallel, thereby increasing the output current and reducing the output voltage. Furthermore, the filter storage capacitor will provide a constant output for the load. Compared with full-wave rectification, half-wave rectification can provide a higher voltage (Figure 13l) [174]. The photograph of EMM on a printing circuit board demonstrates its high integration (Figure 13m). After optimization, a power density of 954 W m−2 was achieved (Figure 13n). Additionally, the matched load resistance can be reduced from 600 MΩ to 0.8 MΩ with a high conversion efficiency of 94.5%.

6. Summary and Perspectives

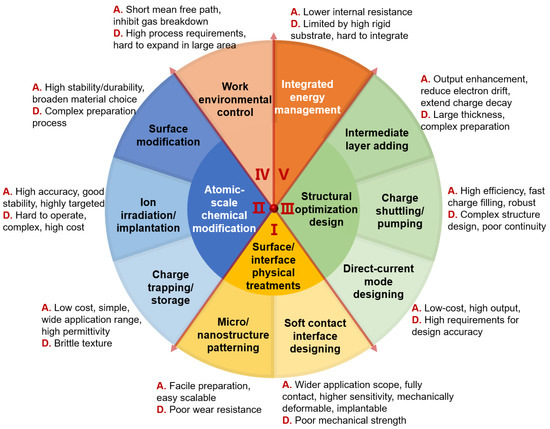

In this review, the current feasible strategies to enhance the mechanical-to-electrical conversion performance of textile TENGs are systematically summarized. The electricity generation mechanism of TENGs is firstly introduced based on an atomic-scale electron-cloud potential well or wave function overlapping model. Afterwards, five major strategies, including surface/interface physical treatments, atomic-scale chemical modification, structural optimization design, external environmental control, and integrated energy management, to enhance the power output of textile TENGs are put forward, each of which was analyzed and discussed in detail. Based on the comprehensive understanding of these approaches, a targeted comparison highlights the superiorities and the potential deficiencies in improving the electricity output of textile TENGs (Figure 14). For example, the intermediate layer structural design can greatly increase the power output by reducing the electron drift and extending charge decay. As for the surface physical modification, the soft contacted interface can enable TENGs to fully contact with the external loading to generate high mechanical deformability, which endows them with high sensitivity and wide application scope. However, the soft texture of the selected materials also leads to their poor mechanical strength. On balance, each method has its advantages and disadvantages. Appropriate material selections and structural designs are required according to the actual requirements. In addition, in order to improve the output performance of textile TENGs to truly meet their large-scale commercial application, the following issues are also worth full consideration.

Figure 14.

Comparison of the five major strategies to enhance the electricity output performance of textile TENGs. The abbreviations of “A.” and “D.” represent the advantages and disadvantages, respectively.

- (1)

- The charge transferring and electricity generation mechanism of textile TENGs, particularly for fibers with special structural effects, is still very confusing. Although the electron-cloud potential well or wave function overlapping model can well explain the electron transport behavior between single atoms, there is still a lack of effective exploration on the collision charge generation process between molecules or atomic clusters with multiple atoms. In addition, although a large number of researches reported the effect of micro/nanostructures on the electrical output of planar membrane structural TENGs, few studies explore the impact of the special structural effect on the surface of high-aspect-ratio curved fiber TENGs on their electrical output performance. Therefore, it is necessary to investigate the physical structure effect and chemical electricity generation mechanism of fiber/textile TENGs by means of macro measurement or micro analysis in more detail.

- (2)

- Most of the above output improvement methods are applicable when the electricity output of textile TENGs is small. However, when the open-circuit voltage reaches the level of air or dielectric breakdown, most of the above methods will lose their function. In this case, direct-current mode structural design and external environment control may be feasible methods. However, the implementation of external environment control is very difficult and can hardly be applied in practice. The direct-current power generation mode depends on the construction of a narrow air breakdown channel and a certain sliding distance, which has high structural and motion mode limitations. Therefore, it is still necessary to explore a better way to improve the triboelectric output performance beyond the air breakdown effect.

- (3)

- It is also a great challenge to effectively and orderly connect the electrodes from different units in textile TENGs and with other energy management or storage devices. Most smart textiles will extend to all parts of the human body, which makes the circuit design across the whole body network more difficult. In fact, most of the current circuit components are rigid and relatively high weight, which will add extra burden to the actual wearing. Therefore, the whole body flexible electrode network design is also urgent for the actual application of textile TENGs.

- (4)

- At present, there is still a lack of comprehensive performance evaluation standards for textile TENGs. Although the structural figure-of-merit and performance figure-of-merit of TENG are proposed to evaluate the effects of structure and material on its output performance, respectively, the impact of other factors is ignored, such as surface condition, working environment, and so on. In addition, the performance evaluation criterion of textile TENGs should still consider the special structural effect and wearing performance of textiles.

- (5)

- The application terminal of textile TENGs is the human body, which not only needs to have a high degree of fitness to meet the diverse and complex human motion and external environment variations but should also bring certain comfort and satisfaction to the daily wearing of the human body. Therefore, for the material selection of textile TENGs, it is best to choose materials with good affinity to human skin to avoid toxic materials or materials that will cause itching to human skin.

- (6)

- During the operation of textile TENGs, frequent, direct and long-term mechanical impacts, as well as negative environmental factors, pose serious challenges to their robustness and reliability [175]. Therefore, improving the robustness and reliability of textile TENGs is an important issue that needs to be addressed urgently. Textile TENGs for wearable use will constantly be subject to abrasion, pressure, and other complex mechanical deformations, which will cause wear and defects. In addition, machine washability is also a great challenge for textile TENGs, which requires appropriate packaging technology to avoid structural or circuit damage.

We hope that this review can not only burst out more inspiration and ideas for the researchers who are focusing on the study of textile TENGs, but also bring a new dawn to industrial designers who are committed to developing commercial products of textile TENGs. We believe that through the persistent efforts of researchers and the continuous follow-up of relevant technical means, textile TENGs will be bound to play an irreplaceable role in the future intelligent wearable market and artificial intelligence field.

Author Contributions

K.D. planned and supervised the whole process. X.P. and R.C. assisted in literature collation and part of chapter writing. Z.L.W. supervised the whole process of this manuscript. All authors revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the support received from the National Key R&D Project from the Minister of Science and Technology (Grant No. 2021YFA1201601), National Natural Science Foundation of China (Grant No. 22109012), Natural Science Foundation of the Beijing Municipality (Grant No. 2212052), and the Fundamental Research Funds for the Central Universities (Grant No. E1E46805).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Davis, S.J.; Lewis, N.S.; Shaner, M.; Aggarwal, S.; Arent, D.; Azevedo, I.L.; Benson, S.M.; Bradley, T.; Brouwer, J.; Chiang, Y.-M.; et al. Net-zero emissions energy systems. Science 2018, 360, eaas9793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hittinger, E.; Jaramillo, P. Internet of Things: Energy boon or bane? Science 2019, 364, 326–328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, L.; Guo, X.; Lee, C. Promoting smart cities into the 5G era with multi-field Internet of Things (IoT) applications powered with advanced mechanical energy harvesters. Nano Energy 2021, 88, 106304. [Google Scholar] [CrossRef]

- Dharmasena, R.D.I.G.; Jayawardena, K.D.G.I.; Mills, C.A.; Deane, J.H.B.; Anguita, J.V.; Dorey, R.A.; Silva, S.R.P. Triboelectric nanogenerators: Providing a fundamental framework. Energy Environ. Sci. 2017, 10, 1801–1811. [Google Scholar] [CrossRef]

- Ryu, H.; Park, H.-M.; Kim, M.-K.; Kim, B.; Myoung, H.S.; Kim, T.Y.; Yoon, H.-J.; Kwak, S.S.; Kim, J.; Hwang, T.H.; et al. Self-rechargeable cardiac pacemaker system with triboelectric nanogenerators. Nat. Commun. 2021, 12, 4374. [Google Scholar] [CrossRef]

- Wang, H.; Han, M.; Song, Y.; Zhang, H. Design, manufacturing and applications of wearable triboelectric nanogenerators. Nano Energy 2021, 81, 105627. [Google Scholar] [CrossRef]

- He, W.; Fu, X.; Zhang, D.; Zhang, Q.; Zhuo, K.; Yuan, Z.; Ma, R. Recent progress of flexible/wearable self-charging power units based on triboelectric nanogenerators. Nano Energy 2021, 84, 105880. [Google Scholar] [CrossRef]

- Feng, H.; Bai, Y.; Qiao, L.; Li, Z.; Wang, E.; Chao, S.; Qu, X.; Cao, Y.; Liu, Z.; Han, X.; et al. An Ultra-Simple Charge Supplementary Strategy for High Performance Rotary Triboelectric Nanogenerators. Small 2021, 17, 2101430. [Google Scholar] [CrossRef]

- Huang, L.-B.; Dai, X.; Sun, Z.; Wong, M.-C.; Pang, S.-Y.; Han, J.; Zheng, Q.; Zhao, C.-H.; Kong, J.; Hao, J. Environment-resisted flexible high performance triboelectric nanogenerators based on ultrafast self-healing non-drying conductive organohydrogel. Nano Energy 2021, 82, 105724. [Google Scholar] [CrossRef]

- Yin, L.; Kim, K.N.; Trifonov, A.; Podhajny, T.; Wang, J. Designing wearable microgrids: Towards autonomous sustainable on-body energy management. Energy Environ. Sci. 2022, 15, 82–101. [Google Scholar] [CrossRef]

- Karan, S.K.; Maiti, S.; Lee, J.H.; Mishra, Y.K.; Khatua, B.B.; Kim, J.K. Recent Advances in Self-Powered Tribo-/Piezoelectric Energy Harvesters: All-In-One Package for Future Smart Technologies. Adv. Funct. Mater. 2020, 30, 2004446. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric Materials for Energy Harvesting and Sensing Applications: Roadmap for Future Smart Materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef] [PubMed]

- Sahu, M.; Hajra, S.; Kim, H.-G.; Rubahn, H.-G.; Kumar Mishra, Y.; Kim, H.J. Additive manufacturing-based recycling of laboratory waste into energy harvesting device for self-powered applications. Nano Energy 2021, 88, 106255. [Google Scholar] [CrossRef]