Beam Based and Triply Periodic Minimal Surface Lattice Structures in Inconel 718: An In-Depth Comparative Analysis of Manufacturability Through L-Pbf and Metallographic Characterization

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

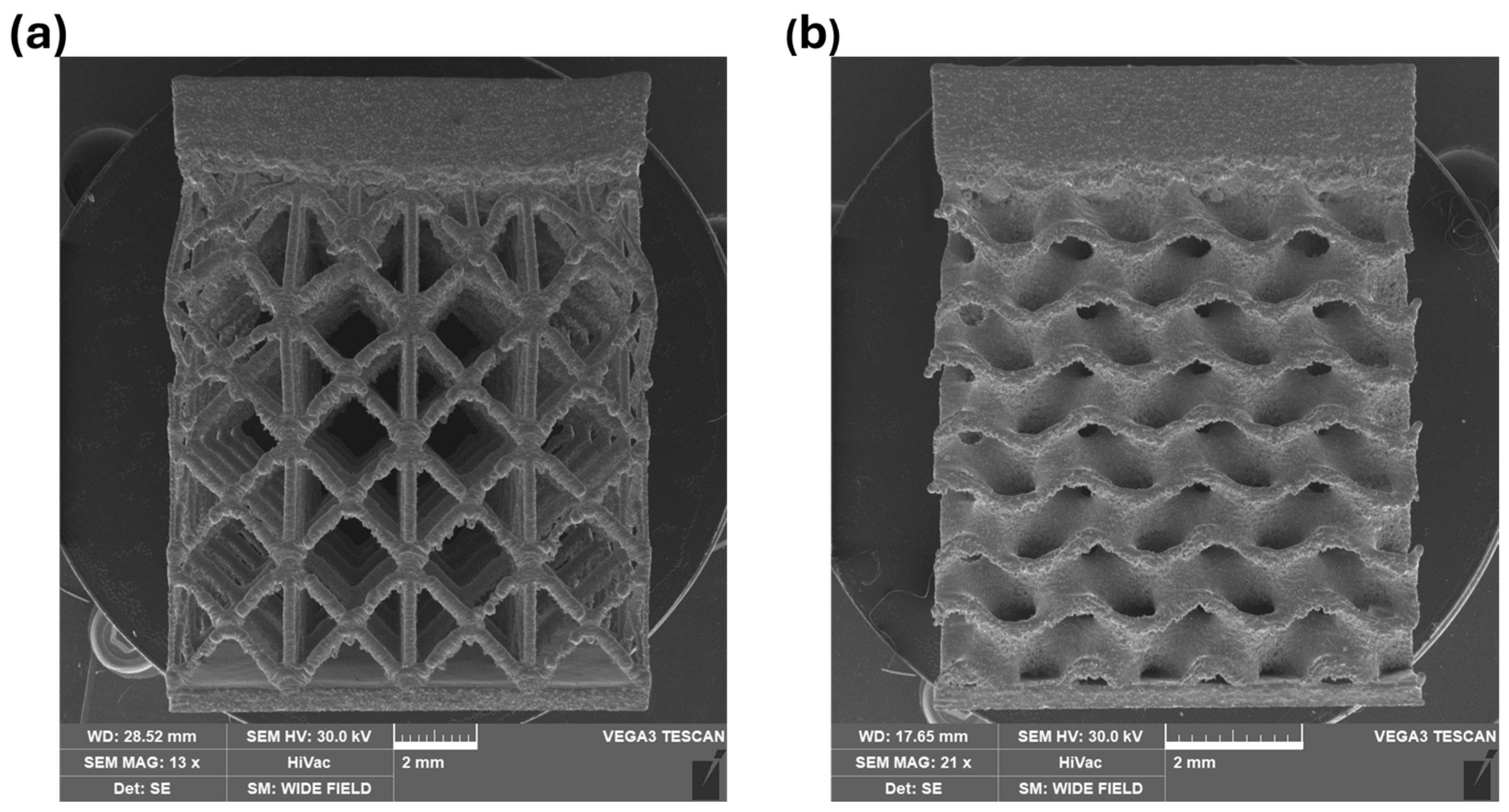

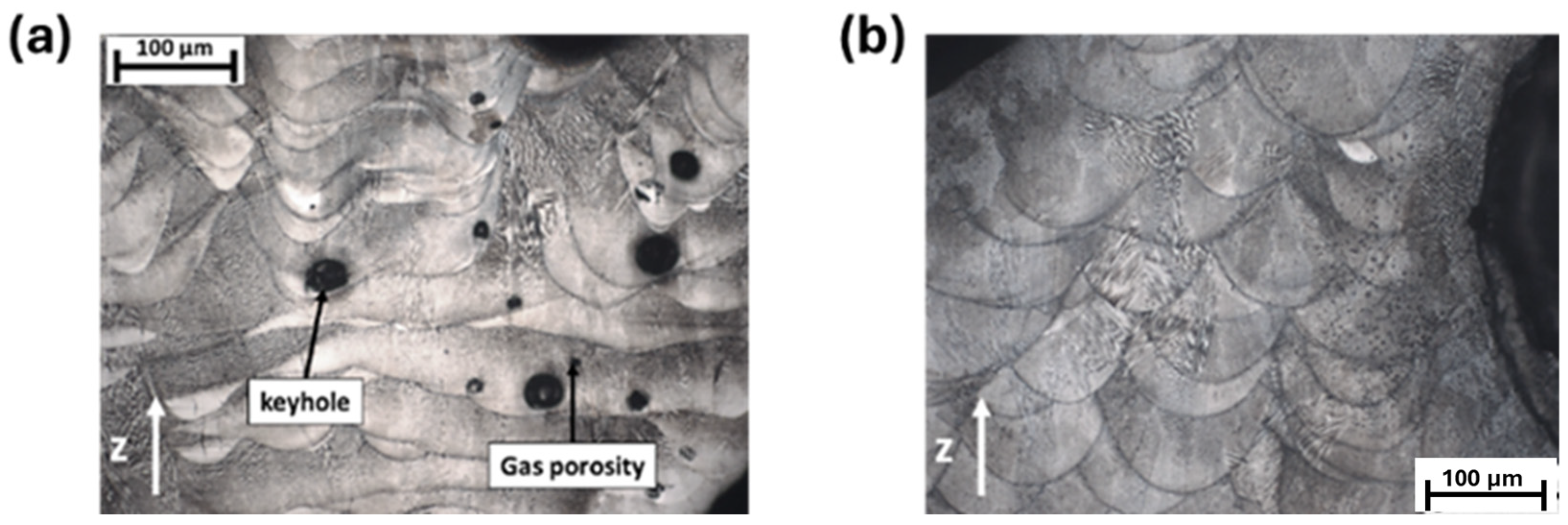

3.1. Preliminary Defect Detection and Failure Analysis

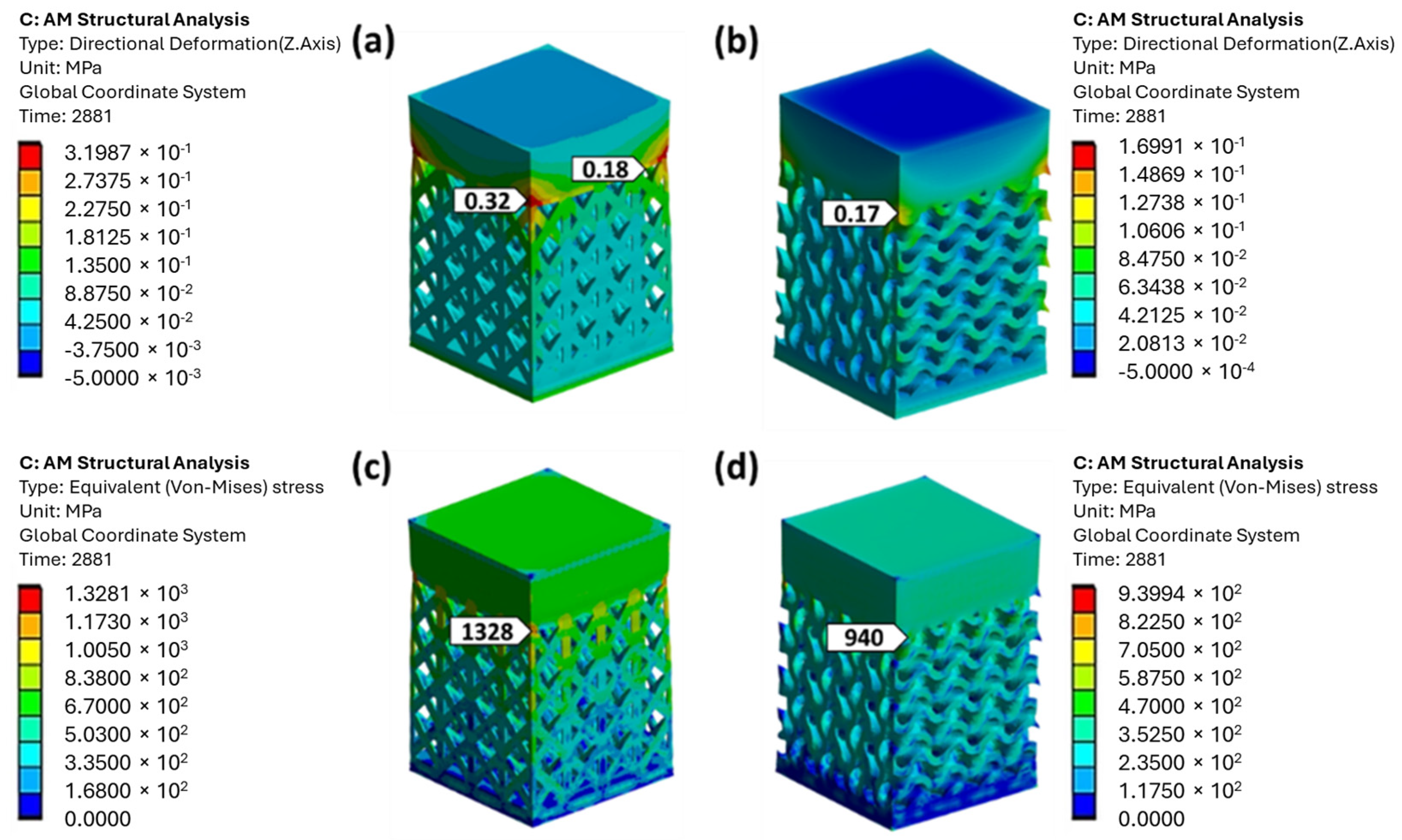

3.2. FEM Analysis

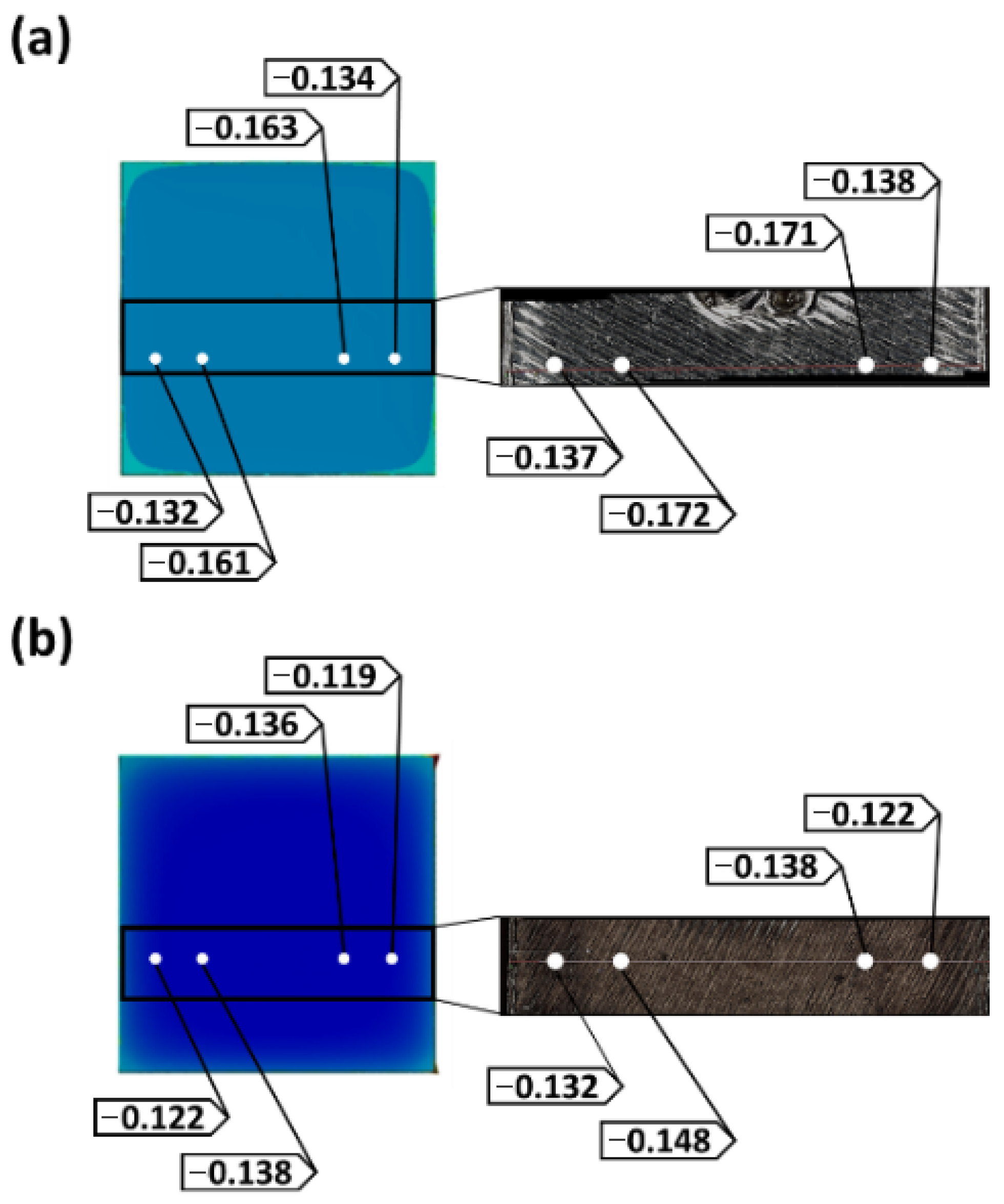

3.3. FEM Analysis vs. Experimental Results

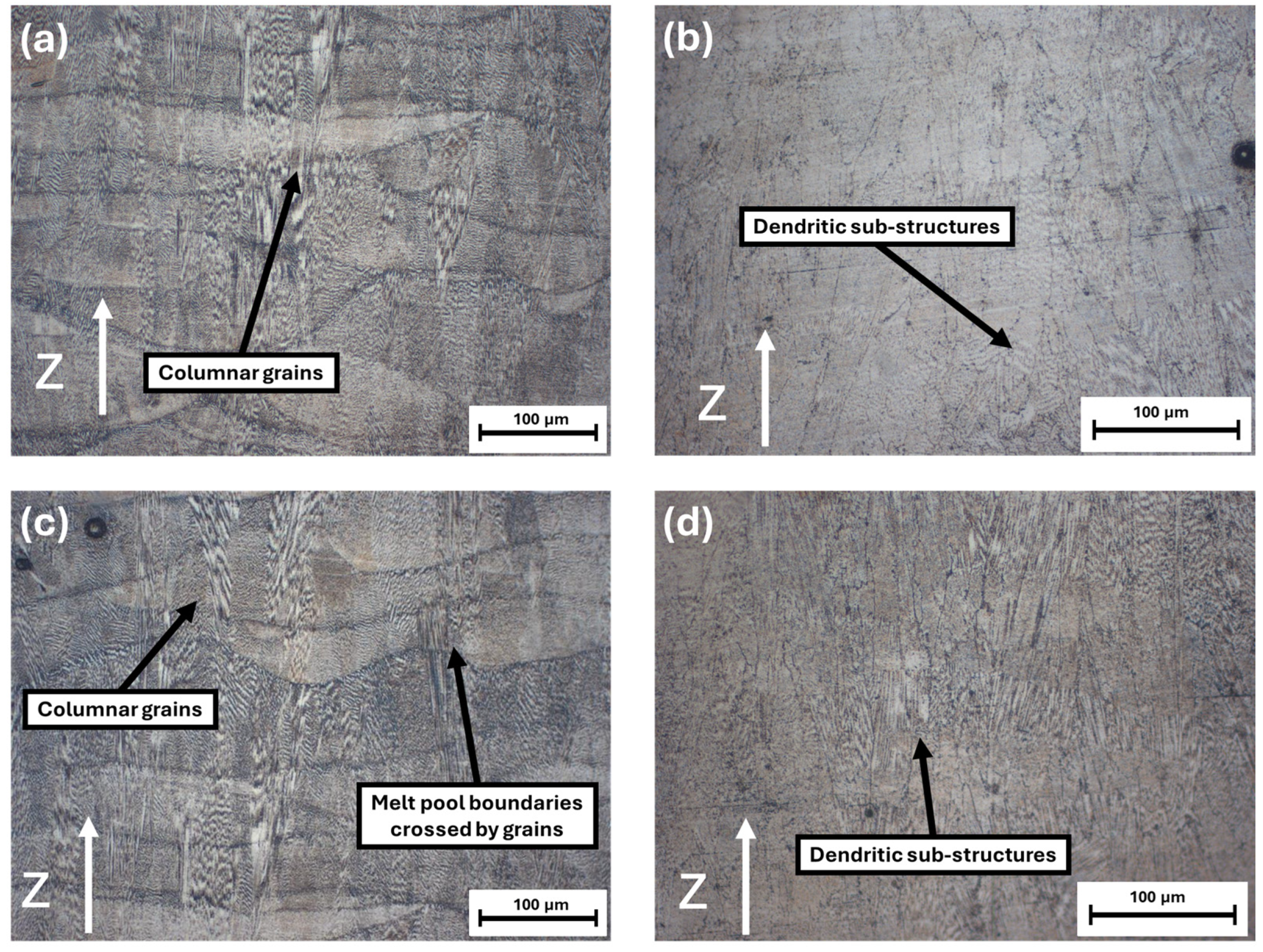

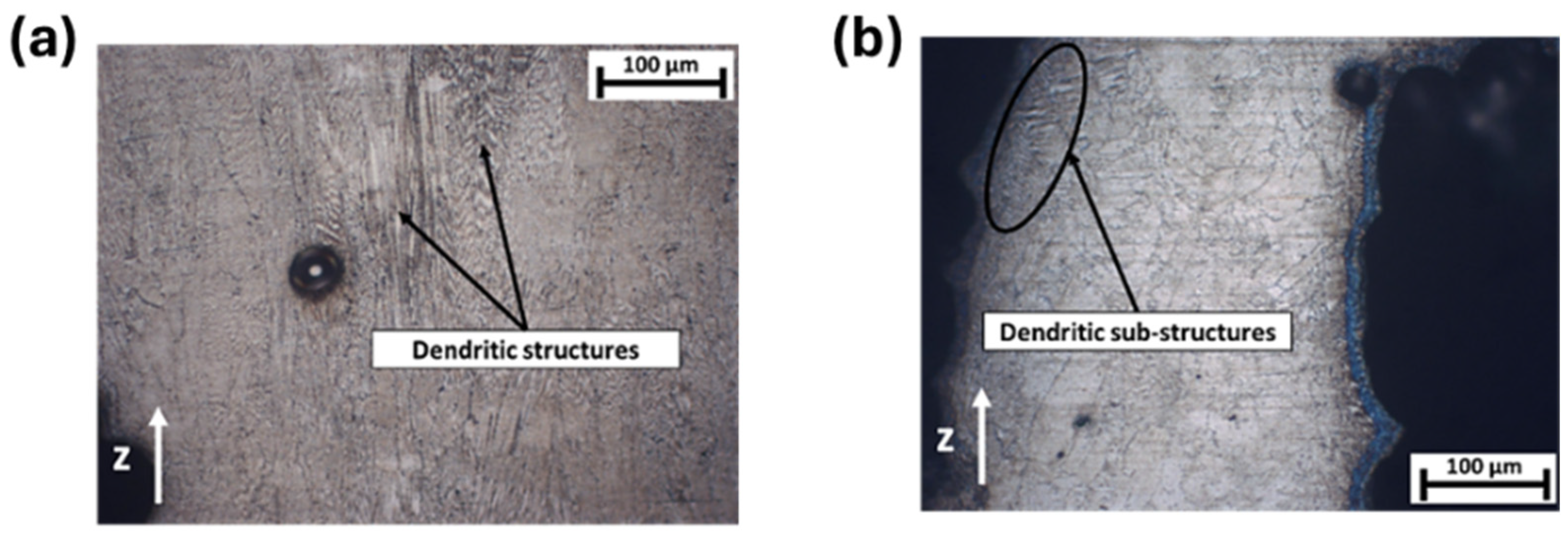

3.4. Assessment of Microstructural and Mechanical Behaviour in As-Built and Heat-Treated Conditions

4. Conclusions

- Defect formation and porosity: Quantitative metallographic analysis revealed that the Gyroid lattice exhibited approximately 40% lower porosity than the FCCZ structure in the lattice region (approximately 1.2% vs. 1.7%, Table 4), with complete suppression of keyhole type defects observed in the beam-node architecture. This demonstrates that the Gyroid’s smooth curvature effectively mitigates local overheating and recoil-pressure instabilities during laser melting.

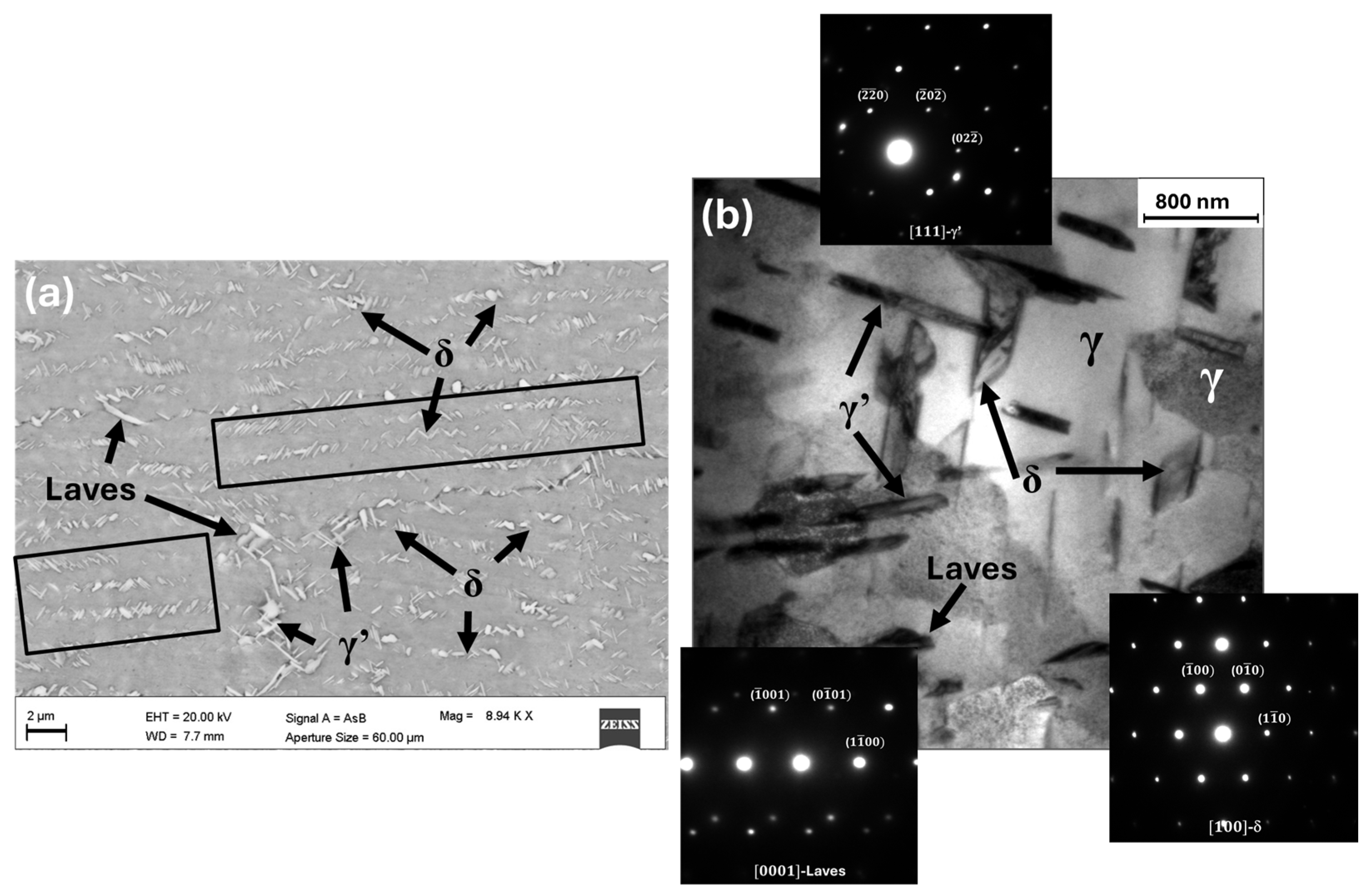

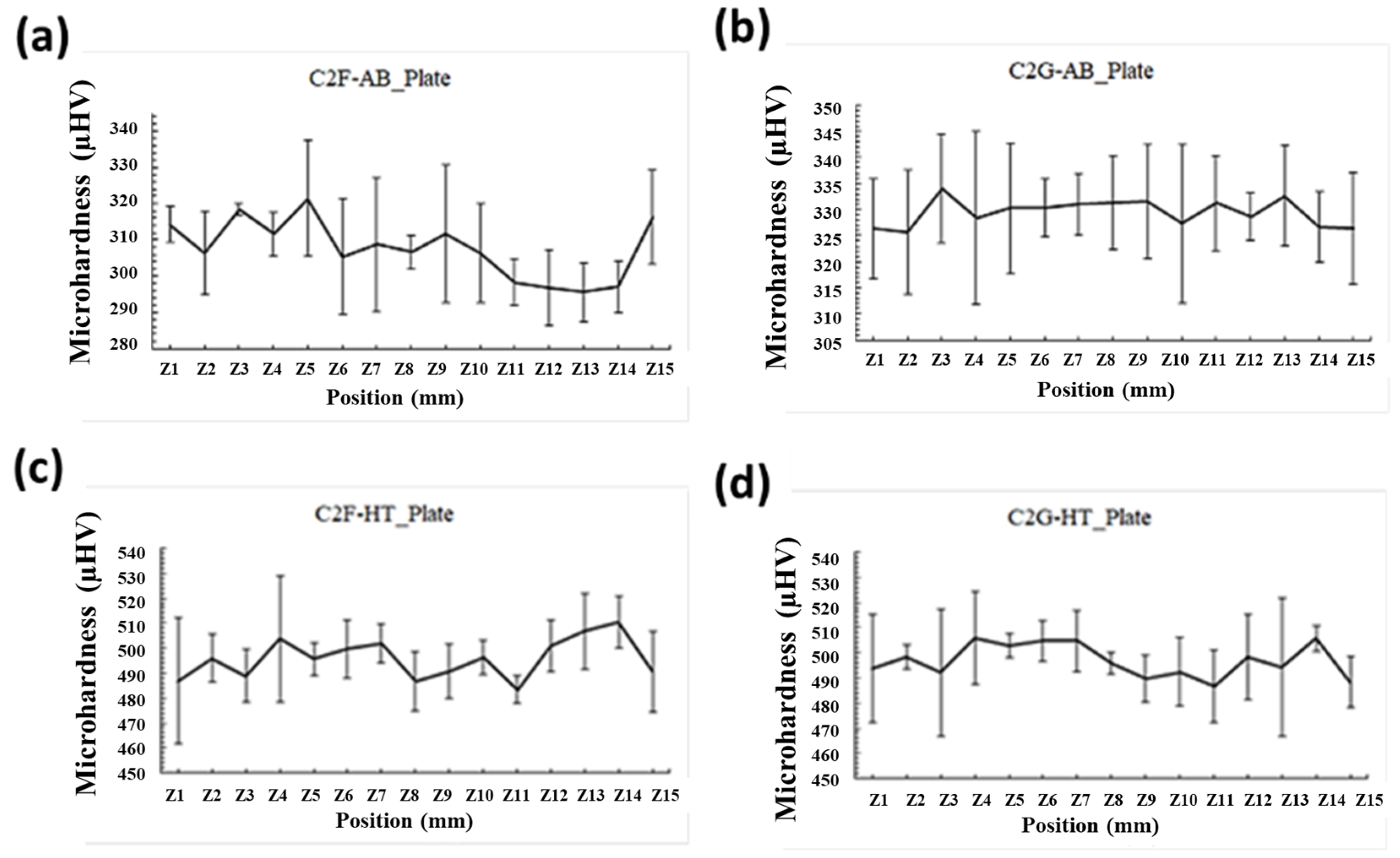

- Microstructural evolution: Heat treatment according to AMS 2774 + 5662 induced partial recrystallization and precipitation of γ’ and δ phases in both lattices, increasing Vickers microhardness from 308 ± 16 HV for C2F-AB sample and 329 ± 12 HV for C2G-AB sample to microhardness values of approximately 497 ± 10 HV on average corresponding to an increase of about 55–60% compared to the as-built condition. These results confirm that the Gyroid topology exhibits a more uniform hardness distribution and improved microstructural consistency compared to the FCCZ structure, reflecting a greater thermal stability of melt pool solidification and heat treatment response, factors that are critical for ensuring reliable mechanical performance in service.

- Persistent secondary phases: TEM observations confirmed the presence of residual Nb-rich Laves phases after the AMS cycle, potentially limiting complete precipitation hardening and long-term creep or fatigue performance. These findings highlight the need for optimized homogenization or HIP + aging treatments to fully dissolve interdendritic phases in additively manufactured Inconel 718 lattices.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TPMS | Triply Periodic Minimal Surface |

| FCCZ | Face Centered Cubic with Z Struts |

| PBF | Powder Bed Fusion |

| DED | Direct Energy Deposition |

| L-PBF | Laser Powder Bed Fusion |

| OM | Optical Microscopy |

| SEM | Scanning Electron Microscopy |

| TEM | Transmission Electron Microscopy |

| BF | Bright-Field |

| FEM | Finite Element Method |

| DoE | Design of Experiment |

| AB | As-Built |

| HT | Heat Treated |

| HIP | Hot Isostatic Pressure |

References

- ASTM F2792-12a; Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- ISO/TC 261; Additive Manufacturing. International Organization for Standardization: Geneva, Switzerland, 2025.

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular Solids. MRS Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The Design Process of Additively Manufactured Mesoscale Lattice Structures: A Review. J. Comput. Inf. Sci. Eng. 2018, 18, 040801. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Insights into the Mechanical Properties of Several Triply Periodic Minimal Surface Lattice Structures Made by Polymer Additive Manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of Light-Weight AlSi10Mg Periodic Cellular Lattice Structures Fabricated via Direct Metal Laser Sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Beyer, C.; Figueroa, D. Design and Analysis of Lattice Structures for Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2016, 138, 121014. [Google Scholar] [CrossRef]

- Catchpole-Smith, S.; Sélo, R.R.J.; Davis, A.W.; Ashcroft, I.A.; Tuck, C.J.; Clare, A. Thermal Conductivity of TPMS Lattice Structures Manufactured via Laser Powder Bed Fusion. Addit. Manuf. 2019, 30, 100846. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and Mechanical Behavior of Inconel 718 Fabricated by Selective Laser Melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Calandri, M.; Yin, S.; Aldwell, B.; Calignano, F.; Lupoi, R.; Ugues, D. Texture and Microstructural Features at Different Length Scales in Inconel 718 Produced by Selective Laser Melting. Materials 2019, 12, 1293. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Inconel 718 Processed by Selective Laser Melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Kirka, M.M.; Unocic, K.A.; Raghavan, N.; Medina, F.; Dehoff, R.R.; Babu, S.S. Microstructure Development in Electron Beam-Melted Inconel 718 and Associated Tensile Properties. JOM 2016, 68, 1012–1020. [Google Scholar] [CrossRef]

- Wang, C.; Li, R. Effect of Double Aging Treatment on Structure in Inconel 718 Alloy. J. Mater. Sci. 2004, 39, 2593–2595. [Google Scholar] [CrossRef]

- Santoni, A.; Cabibbo, M.; Mandolini, M.; Palladino, M.; Spigarelli, S.; Santecchia, E. Laser Powder Bed Fusion Inconel 718 Lattice Structures: From Process Simulation to Microstructural and Mechanical Characterizations. Met. Mater. Int. 2025, 31. [Google Scholar] [CrossRef]

- Chen, Q.; Liang, X.; Hayduke, D.; Liu, J.; Cheng, L.; Oskin, J.; Whitmore, R.; To, A.C. An Inherent Strain Based Multiscale Modeling Framework for Simulating Part-Scale Residual Deformation for Direct Metal Laser Sintering. Addit. Manuf. 2019, 28, 406–418. [Google Scholar] [CrossRef]

- Additive Manufacturing Test Cases, VM-AM-MECH-001, Additive Manufacture of Five-Post Beam Using Inconel 718. Available online: https://ansyshelp.ansys.com/public/account/secured?returnurl=/Views/Secured/corp/v251/en/wb_vm/vm-am-mech-001.html (accessed on 4 January 2025).

- EOS. EOS NickelAlloy IN718—Material Data Sheet Metal Solutions; EOS: Krailling, Germany, 2020. [Google Scholar]

- AMS 2774G; Heat Treatment of Wrought Nickel and Cobalt Alloy Parts. SAE International: Warrendale, PA, USA, 2020.

- AMS 5562F; Steel, Corrosion and Heat Resistant, Seamless Tubing (9.0 Mn, 20 Cr, 6.5 Ni, 0.28 N). SAE International: Warrendale, PA, USA, 2021.

- ImageJ (2024). Available online: https://imagej.net/ij/ (accessed on 8 October 2025).

- Huang, Y.; Fleming, T.G.; Clark, S.J.; Marussi, S.; Fezzaa, K.; Thiyagalingam, J.; Leung, C.L.A.; Lee, P.D. Keyhole Fluctuation and Pore Formation Mechanisms during Laser Powder Bed Fusion Additive Manufacturing. Nat. Commun. 2022, 13, 1170. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Shukla, M. Keyhole induced porosity evolution for inconel 718 alloy in laser powder bed fusion: A computational fluid dynamics approach. In Recent Advances in Additive Manufacturing; Mallaiah, M., Thapliyal, S., Bose, S.C., Eds.; Springer: Singapore, 2025; Volume 2, pp. 191–202. [Google Scholar]

- Snow, Z.; Nassar, A.R.; Reutzel, E.W. Invited Review Article: Review of the Formation and Impact of Flaws in Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2020, 36, 101457. [Google Scholar] [CrossRef]

- Fritsch, T.; Sprengel, M.; Evans, A.; Farahbod-Sternahl, L.; Saliwan-Neumann, R.; Hofmann, M.; Brunoa, G. On the Determination of Residual Stresses in Additively Manufactured Lattice Structures. J. Appl. Crystallogr. 2021, 54, 228–236. [Google Scholar] [CrossRef]

- Dassi, L.; Chatterton, S.; Parenti, P.; Pennacchi, P. Gyroid Lattice Heat Exchangers: Comparative Analysis on Thermo-Fluid Dynamic Performances. Machines 2024, 12, 922. [Google Scholar] [CrossRef]

- Hu, J.; Xu, W.; Liang, H.; Shi, J.; Tang, W.; Guo, B.; Yang, J.; Zhu, L. Flow and Heat Transfer Characteristics of 3D Printed Sheet and Solid Triply Periodic Minimal Surfaces Porous Structures. Sci. Rep. 2025, 15, 29255. [Google Scholar] [CrossRef]

- Chouhan, G.; Namdeo, A.K.; Guner, A.; Essa, K.; Bidare, P. Heat Transfer Performance of Compact TPMS Lattice Heat Sinks via Metal Additive Manufacturing. Prog. Addit. Manuf. 2025, 10. [Google Scholar] [CrossRef]

- Lai, W.H.; Samad, A. Development and Flow Optimization of “Gyroid” Based Additive Manufacturing Heat Exchanger: Both Computational and Experimental Analyses. Int. J. Therm. Sci. 2025, 213, 109835. [Google Scholar] [CrossRef]

- Yu, X.; Moreira, T.A.; Chen, B.; Rankouhi, B.; Thoma, D.J.; Anderson, M.H.; Qian, X. Data-Driven Optimization, Additive Manufacturing and Thermohydraulic Testing of a High-Temperature Gyroid-Based TPMS Heat Exchanger. Appl. Therm. Eng. 2025, 280, 128422. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding Melt Pool Characteristics in Laser Powder Bed Fusion: An Overview of Single- and Multi-Track Melt Pools for Process Optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Alphonso, W.E.; Baier, M.; Carmignato, S.; Hattel, J.H.; Bayat, M. On the Possibility of Doing Reduced Order, Thermo-Fluid Modelling of Laser Powder Bed Fusion (L-PBF)—Assessment of the Importance of Recoil Pressure and Surface Tension. J. Manuf. Process. 2023, 94, 564–577. [Google Scholar] [CrossRef]

- Salem, H.; Carter, L.N.; Attallah, M.M.; Salem, H.G. Influence of Processing Parameters on Internal Porosity and Types of Defects Formed in Ti6Al4V Lattice Structure Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2019, 767, 138387. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and Mechanical Properties of Inconel 718 Produced by Selective Laser Melting: Sample Orientation Dependence and Effects of Post Heat Treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Li, X.; Shi, J.J.; Wang, C.H.; Cao, G.H.; Russell, A.M.; Zhou, Z.J.; Li, C.P.; Chen, G.F. Effect of Heat Treatment on Microstructure Evolution of Inconel 718 Alloy Fabricated by Selective Laser Melting. J. Alloys. Compd. 2018, 764, 639–649. [Google Scholar] [CrossRef]

- Chamanfar, A.; Sarrat, L.; Jahazi, M.; Asadi, M.; Weck, A.; Koul, A.K. Microstructural Characteristics of Forged and Heat Treated Inconel-718 Disks. Mater. Des. 2013, 52, 791–800. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of Standard Heat Treatment on the Microstructure and Mechanical Properties of Selective Laser Melting Manufactured Inconel 718 Superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Feng, K.; Liu, P.; Li, H.; Sun, S.; Xu, S.; Li, J. Microstructure and Phase Transformation on the Surface of Inconel 718 Alloys Fabricated by SLM under 1050 °C Solid Solution + Double Ageing. Vacuum 2017, 145, 112–115. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Z.; Bai, P.; Qu, H.; Liu, B.; Li, L.; Wu, L.; Guan, R.; Liu, H.; Guo, Z. Microstructural Evolution and Mechanical Properties of IN718 Alloy Fabricated by Selective Laser Melting Following Different Heat Treatments. J. Alloys Compd. 2019, 772, 861–870. [Google Scholar] [CrossRef]

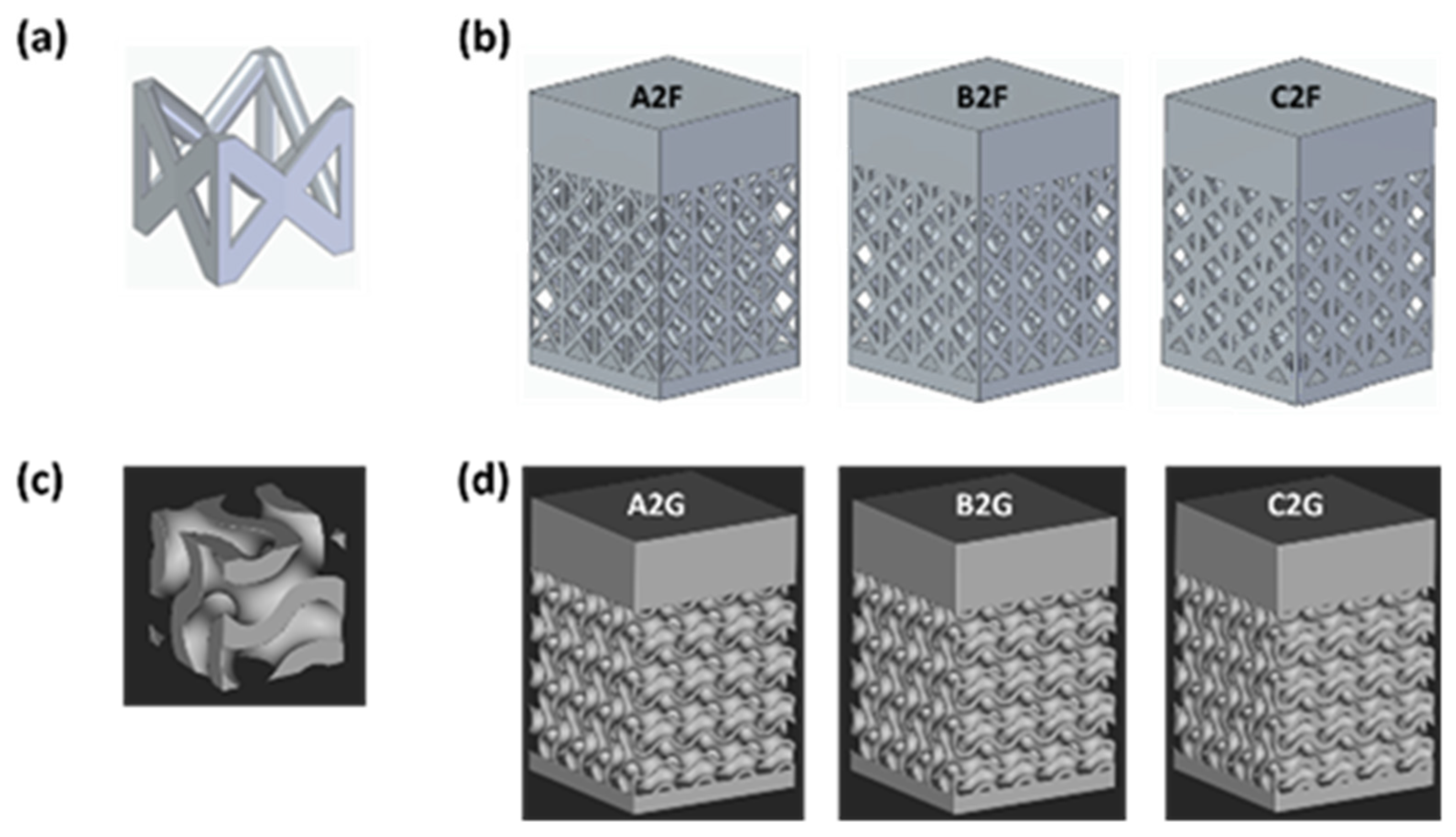

| Unit Cell Topology | Sample ID Code | Cell Size (mm) | Strut Diameter (mm) |

|---|---|---|---|

| FCCZ | A2F | 2 | 0.3 |

| B2F | 2 | 0.4 | |

| C2F | 2 | 0.5 | |

| Gyroid | A2G | 2 | 0.3 |

| B2G | 2 | 0.4 | |

| C2G | 2 | 0.5 |

| Material | Inconel 718 |

| Layer thickness | 40 µm |

| Laser power | 285 W |

| Scanning speed | 960 mm/s |

| Hatch distance | 100 µm |

| Build plate preheating temperature | 80 °C |

| Powder temperature | 80 °C |

| Gas temperature | 22 °C |

| Layered tetrahedron size for lattice structures | 0.2 mm |

| Layered tetrahedron size for base plate | 4 mm |

| Fe | Ni | Cr | Nb | Mo | Ti | Al | Other |

|---|---|---|---|---|---|---|---|

| Balance | 50–55 | 17–21 | 4.75–5.50 | 2.80–3.30 | 0.65–1.15 | 0.20–0.80 | <1.0 |

| Porosity (%) | ||

|---|---|---|

| Upper Plate | Lattice | |

| C2F–AB | 0.1309 ± 0.0003 | 1.688 ± 0.003 |

| C2G–AB | 0.078 ± 0.004 | 1.287 ± 0.002 |

| C2F–HT | 0.1316 ± 0.0005 | 1.923 ± 0.005 |

| C2G–HT | 0.071 ± 0.003 | 1.186 ± 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santoni, A.; Cabibbo, M.; Virgili, G.; Santecchia, E.; Sleem, K.; Grima, G. Beam Based and Triply Periodic Minimal Surface Lattice Structures in Inconel 718: An In-Depth Comparative Analysis of Manufacturability Through L-Pbf and Metallographic Characterization. Compounds 2025, 5, 52. https://doi.org/10.3390/compounds5040052

Santoni A, Cabibbo M, Virgili G, Santecchia E, Sleem K, Grima G. Beam Based and Triply Periodic Minimal Surface Lattice Structures in Inconel 718: An In-Depth Comparative Analysis of Manufacturability Through L-Pbf and Metallographic Characterization. Compounds. 2025; 5(4):52. https://doi.org/10.3390/compounds5040052

Chicago/Turabian StyleSantoni, Alberto, Marcello Cabibbo, Gianni Virgili, Eleonora Santecchia, Kamal Sleem, and Gabriele Grima. 2025. "Beam Based and Triply Periodic Minimal Surface Lattice Structures in Inconel 718: An In-Depth Comparative Analysis of Manufacturability Through L-Pbf and Metallographic Characterization" Compounds 5, no. 4: 52. https://doi.org/10.3390/compounds5040052

APA StyleSantoni, A., Cabibbo, M., Virgili, G., Santecchia, E., Sleem, K., & Grima, G. (2025). Beam Based and Triply Periodic Minimal Surface Lattice Structures in Inconel 718: An In-Depth Comparative Analysis of Manufacturability Through L-Pbf and Metallographic Characterization. Compounds, 5(4), 52. https://doi.org/10.3390/compounds5040052