Abstract

In recent years, there has been a significant increase in the number of shipping containers lost at sea. Such incidents result in environmental pollution and economic costs. Given that the underlying causes of container loss are not yet fully understood, it is reasonable to assume that further incidents will occur in the future. The research in the ConTAD project aims to automatically detect multi-container loss with the use of advanced container tracking technology. This paper presents the concept behind the targeted container tracking device, which will be designed to reduce the environmental and economic impact of container loss in the future. A container loss accident phase model is proposed to visualize the impact of the new container tracking technology.

1. Introduction

The loss of containers on ultra-large container vessels (ULCV) can be attributed to a multitude of factors that are frequently associated with adverse weather conditions, inadequate container securing equipment, instability of the containers themselves, and the navigation of the ship. The increase in ship sizes and the increase in extreme weather conditions caused by climate change have led to the loss of approximately 7000 containers at sea over the past three years [1]. It is estimated that a significantly higher number of incidents remain unreported. To address this issue, researchers are investigating the causes of container loss [2] and developing intelligent container securing gear, weather routing technology [3], and roll-sensing equipment. Nevertheless, it is crucial to acknowledge that, from a navigational standpoint, it may not be feasible to entirely prevent container losses through these approaches.

The Container Tracking and Accident Detection (ConTAD) project has the objective of enhancing navigational safety, improving container salvage, and strengthening supply chains by advancing container tracking technology to detect container loss at sea. The project will employ industry standards in communication and navigation technology, including global navigation satellite systems (GNSS), automatic identification system (AIS), and electronic chart display and information systems (ECDIS). The purpose of this paper is to present the baseline for the advanced container tracking technology to be developed based on a real-world container loss incident.

This paper reviews the incident of the container ship MSC Zoe, which lost 342 containers on the night of 1 to 2 January 2019 off the Dutch coast. It then identifies potential opportunities for further development of container tracking technology. The following section provides an overview of current container tracking technology and monitoring systems, identifying current technological gaps. Finally, this discussion considers which technologies need to be advanced to enhance navigational safety, improve container salvage, and strengthen supply chains based on the findings.

2. Review of the MSC Zoe Accident

2.1. Description of the Event

The information pertaining to the MSC Zoe accident is derived from the investigation report [4], unless otherwise specified. On the night of January 1 to 2, 2019, the containership MSC Zoe lost a total of 342 containers in the North Sea. The incident occurred in the vicinity of the Dutch and German coastlines, resulting in a significant pollution with debris being dispersed along the coastline.

The meteorological conditions during the night of the incident were characterized by strong winds and a significant wave height of 5.5 m. The wind approached approximately from north–northwest and reached 35 knots (equivalent to 8 Beaufort scale units, Bft). Gusts reached probably 10 Bft, two Bft over the mean wind. These conditions are met or exceeded on one or two occasions per year and thus cannot be considered as extreme or exceptional [4] (p. 60).

The wave direction was from abeam. The investigation following the accident revealed, that this was the least favorable direction under the prevailing conditions, resulting in extreme ship motions and accelerations [4] (pp. 74–76). Other potential contributing factors to the loss of containers included contact with the seabed, green water, and slamming.

The investigation revealed that the initial loss of containers occurred at approximately 8 p.m. local time, during the storm, and in darkness. Most of the containers on the MSC Zoe were stowed behind the bridge, as the accommodation on large containerships is typically situated closer to the bow. Until 1 a.m., the following day, several container stacks collapsed and were lost overboard. At this juncture, it was observed that several containers were missing. Another container loss was witnessed by the navigation crew 34 min later. Subsequently, the decision was made to alter the ship’s course upwind, and the vessel traffic service (VTS) was duly informed. Approximately 12 h later, the ship continued its voyage to Bremerhaven, where most of the damaged containers were discharged. Subsequently, the MSC Zoe sailed to Gdansk for the complete discharge of its cargo and underwent repairs in a shipyard.

2.2. Relevant Findings

The following findings are deemed pertinent to the development of a container tracking device (CTD) with automatic accident detection capabilities.

- The accident did not occur in extreme weather conditions. The investigation revealed that the current ship size with beams of 60 m is particularly susceptible to heavy rolling in normal sea states. Consequently, it can be anticipated that further losses of containers will occur.

- It took the crew approximately five hours to notice the container loss. Upon realizing that they were losing cargo, the crew turned the ship’s bow against the waves, thus preventing further losses. The accident occurred in darkness and during a storm, conditions that could have contributed to the unnoticed loss of cargo. The implementation of an automatic device for the detection of container loss would allow for prompt action in the event of a loss, thereby reducing the number of containers lost.

- The accident occurred near the coastline, resulting in significant environmental contamination in ecologically sensitive and protected areas. The shallow waters contributed to the occurrence of short wave periods, which were likely a critical factor in this accident. It can be reasonably anticipated that further container losses will occur in similar areas. This underscores the necessity for a fast and effective means of detecting and salvaging lost containers, particularly those containing dangerous goods (DG).

- It took over nine months to locate and salvage 90% of the lost containers. Only 75% of the cargo was recovered [5]. Reducing this time span will result in cost savings and a reduction in pollution following a container loss.

- The precise number of lost containers could only be determined after the ship had been fully unloaded before it went to a shipyard for repairs. Therefore, it took over two weeks to ascertain which containers had been lost at sea. The prompt notification of the loss of containers will serve to reinforce the resilience of supply chains.

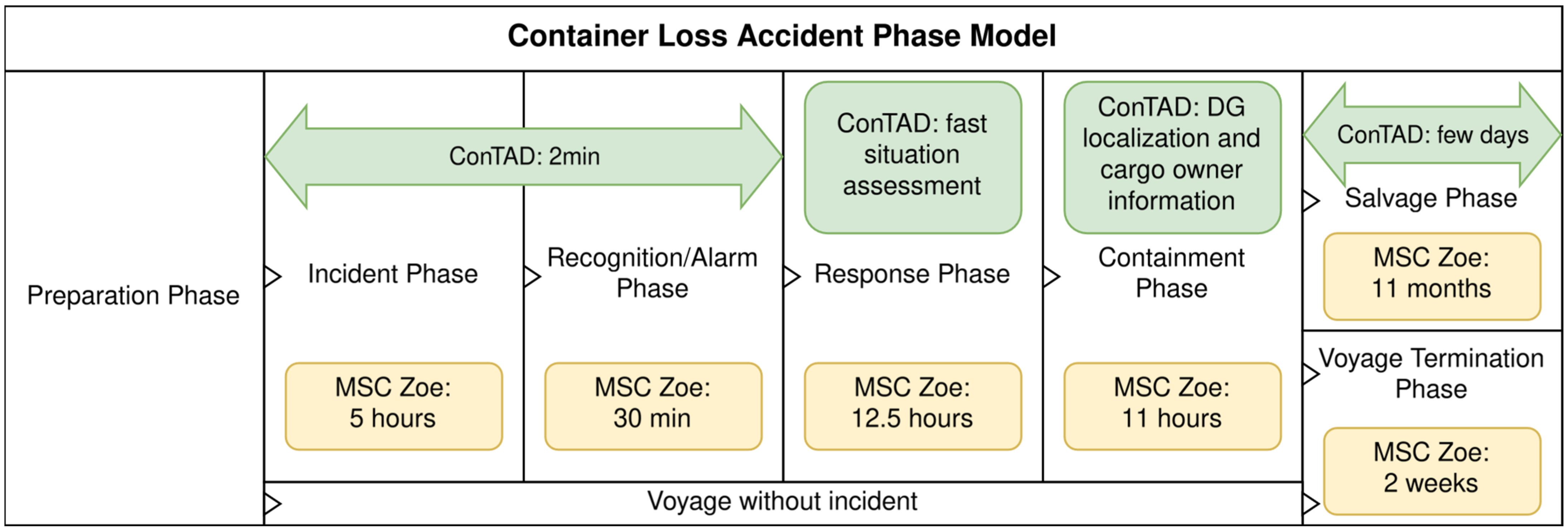

2.3. Phase Model for the Description of Container Loss Accidents

In this section, a phase model for the analysis of the MSC Zoe accident is proposed. The main elements are a preparation phase, where precautions are taken to avoid any incidents at sea. This includes the process of passage planning, e.g., choosing a deep water route, as well as the proper stowage and securing of the cargo with appropriate stowing gear. Additional advice can be found in “5.3 General loss prevention advice” [6] (p. 25). If the voyage is performed without any accident it is terminated in the port of destination. Should an incident happen, the incident phase begins. In case of the MSC Zoe, this was the loss of the first containers. This phase continues until the incident is recognized and the decision to act is made. This phase is called recognition/alarm phase. In case of the MSC Zoe, it took another 30 min from the recognition that containers have been lost to the decision to turn the ship upwind, which only was made because another container stack was observed collapsing. In the response phase, the crew immediately takes measures to control the situation, such as stabilize the ship and inform relevant authorities. For example, on the MSC Zoe a course change was performed to stabilize the ship and avoid further container losses. Additionally, checklists like “5.4 What to do if a container is lost” [6] (p. 25) are followed to take proper actions. After stabilization of the situation and the prevention of additional container losses, the containment phase begins. The main goal is here to bring the ship safely to port with no further container losses. Also, a thorough assessment of the situation is performed, and the damage is estimated. An additional focus is on the reduction in the environmental and economic impact of the accident. As soon as the ship reaches port, it enters the voyage termination phase, and a final assessment of the accident is performed. For the MSC Zoe, it took over two weeks and required the complete discharging of all cargo in the port of Gdansk to determine how many containers were lost. Additionally, there is a salvage phase involving other companies and ships to clean up as much of the lost cargo and containers as possible. In case of MSC Zoe, the cleanup was suspended after 11 months though there was still a quarter of the lost cargo floating in the North Sea [5].

Figure 1 already shows the goals set for the ConTAD approach. First, the incident and recognition phase shall be shortened to a few minutes. This will be achieved by automatic detection of container loss and alarming the ship’s navigation crew. Second, a very fast situation assessment is made possible, since the exact number of lost containers and their cargo, especially DG, is known the moment they are lost overboard. Also, ships in the vicinity are warned of the dangerous floating containers and authorities are automatically informed. Third, by enabling the location of lost containers with DG, the environmental impact of the accident is reduced through fast salvage operations. Also, the immediate and automated information of cargo owners reduces the economic impact in case of time sensitive goods. High-value goods can also be located and salvaged to reduce the overall damage. Finally, the salvage phase following such accidents will be significantly reduced by knowing the precise locations of lost containers and therefore be less costly, depending on the locally available salvage capacity. To achieve these goals, ConTAD will take advantage of existing systems by improving their interactions and expanding their functionality.

Figure 1.

Description of the container loss accident phase model and comparison of the MSC Zoe accident (yellow) with the goals in ConTAD (green).

3. Current Container Tracking Technology and Maritime Monitoring Systems

A central part for the digitalization of the supply chain is knowing the location of cargo at any time. CTDs enable standard freight containers to send position updates multiple times a day. Therefore, more and more containers are equipped with such devices [7]. Their basic functions are tracking a GNSS, sending regular position updates over a mobile network and monitoring the container with shock and acceleration sensors. Often, an additional radio interface for the connection to additional sensors, e.g., via Bluetooth Low Energy (BLE), is also available. Modern and flexible tracking solutions for shipping containers are the focus of some research projects [8,9,10].

Some container tracking use cases have special requirements. For example, in aviation one requirement is to turn off GSM modems during the flight. The tracking device “SocraFlite” already automatically detects if it is loaded on an airplane and is certified for air transport by EASA [11].

This paper also considers a special use case for container tracking during sea transport. While it is commonly accepted that during sea transport the position of the freight containers is equivalent to the ship’s AIS position, a solution should be developed for the event that a container is lost overboard. Certain technologies and concepts are already available. A key element in the concept for e-Navigation by the International Maritime Organization (IMO) is maritime machine-type communication (MTC). This includes the already mentioned AIS as well as the extended functionality of very high frequency (VHF) Data Exchange System (VDES). An overview on frequencies for MTC is given in [12]. Before the approach of ConTAD is introduced in Section 4, a few other ideas to track or localize lost containers are presented.

A tracking device utilizing radar reflections and their detection was proposed at ICMET [13]. Some advantages are the simplicity and the low cost of this solution. The disadvantage is that a radar reflection does not include any information on the object it is reflected from. It is useful to avoid a collision with the floating, stranded, or sunk container; however, during night or in restricted visibility, the navigator cannot tell if the object is a container or something else. Therefore, it still requires a search for the container if the precise position of the container loss is unknown. Also, the passive radar reflection does not inform anyone in the supply chain about the loss of containers.

Another solution exploiting AIS was proposed by Archie Shering [14]. He suggested a floating device, connected with a cable to the container. The device can transmit its position to ships nearby via AIS and therefore has a GPS position sensor, too. Its sole purpose is to warn other ships of floating containers and does not fulfill any of the tracking needs for a digital supply chain.

4. Closing the Technological Gap: The ConTAD Approach

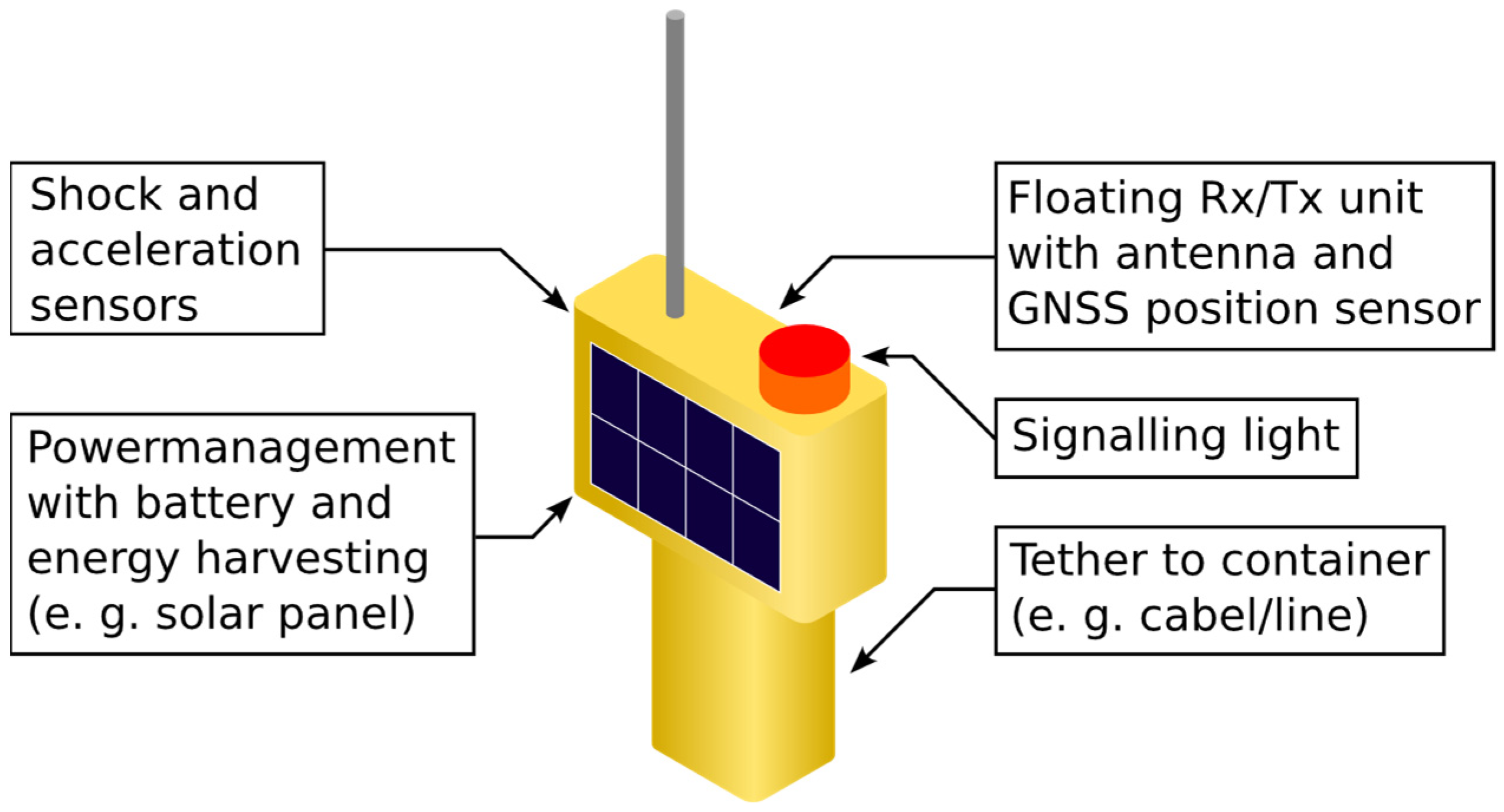

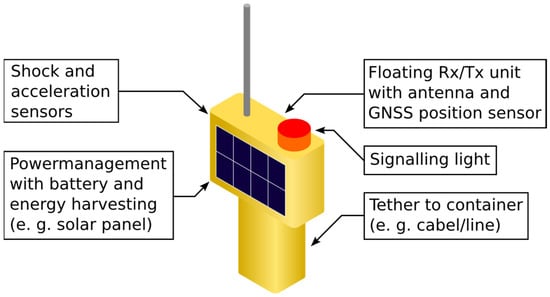

Losing containers is a problem that cannot be easily mitigated. Even if future ships are built to keep all containers safe, current ships will continue sailing for another few decades. A ship constructed for keeping all containers safe, which probably involves all containers being structurally enclosed, would lead to much higher transport costs and, probably, not prove to be economically feasible. Another option, to just sail ships when the weather is favorable, would make shipping unreliable, and even then, ships can still be surprised by sudden weather changes and unpredicted wave systems. Therefore, the ConTAD project follows a reactive approach to the problem of lost shipping containers. The following sections cover the main challenges identified for this kind of approach. Figure 2 gives an overview of the main components of the CTD that will be developed in the project.

Figure 2.

Main Elements of the ConTAD tracking unit.

4.1. Detection of Container Loss

The first challenge is detecting container loss at sea. Since common tracking units are already equipped with acceleration or shock sensors, these can be utilized by a detection algorithm. Methods to avoid wrong alerts need to be implemented.

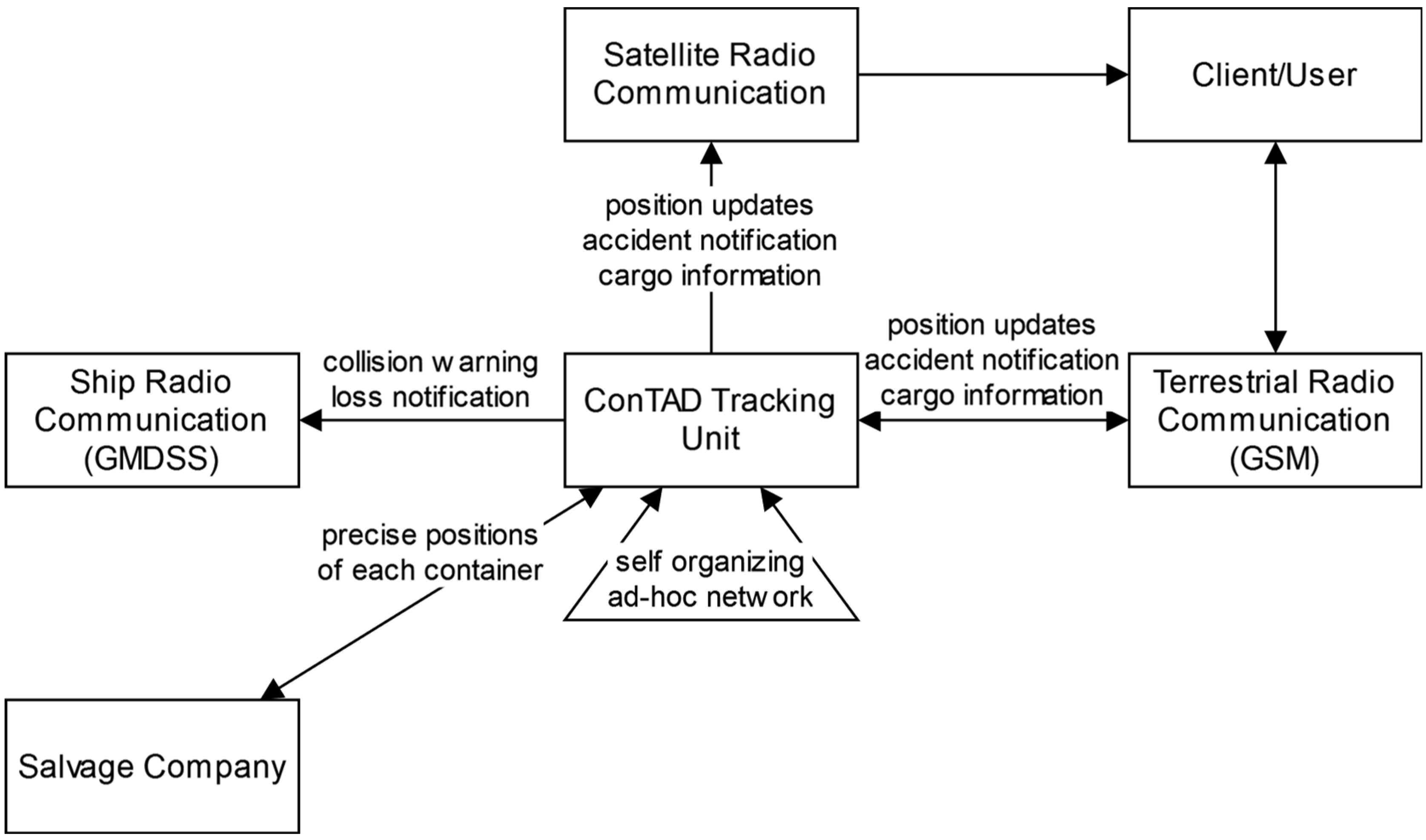

4.2. Obtaining Information on Ships

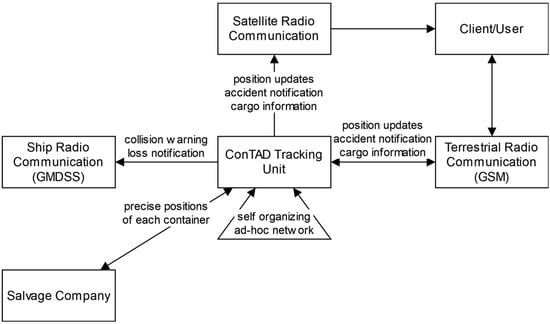

If the loss of containers can be automatically detected, it is mandatory to inform the ship losing cargo about the accidents. Therefore, a ConTAD tracking unit needs a method to communicate with the ship, preferably on already existing means of communication. Since every commercial vessel is equipped with VHF and AIS, these are possible options to be considered. The advantage of these systems is that also other ships in the area can be warned and avoid collisions with floating containers.

4.3. Obtaining Information on Land

In case of lost containers overboard, a quick reaction by salvage companies is important to recover most of the cargo while it is still floating, therefore reducing pollution and the cost of the salvage operation. Immediately informing the recipient about the lost cargo is also important, since they can take quick action to replace necessary deliveries. To obtain the information about the loss of containers ashore, methods like GSM or satellite communication are available. It is also possible to analyze AIS signals received by land stations or satellites to detect containers in case the tracking unit is equipped with an AIS transceiver, as suggested in Section 4.2.

4.4. Ensuring Communication with a Floating Device

When a container is lost at sea, there are several possible outcomes. It may end up floating on the surface and be destroyed on impact or sink to the sea floor. The container might float upside down or be partially submerged. This needs to be considered in the development process of a tracking unit that works on lost containers. Since radio communications will not work underwater, it is important to ensure that the antenna can float on the surface. Therefore, the tracking unit, or at least a communication part, needs to be able to disconnect from the container. The disadvantage is that the tracking unit’s position is no longer the position of the container. Hence, a type of line connection or an underwater acoustic connection between the container and the tracking unit needs to be considered.

4.5. Managing the Loss of Multiple Hundreds of Containers

Past accidents demonstrate that containers can become lost in big numbers all at once. If all these containers start sending out messages in an unorganized way, the capacity of the used frequency spectrum can easily be exceeded. This is especially critical when using a safety-related system, such as AIS, to transmit messages. Therefore, the tracking units need to organize themselves after the accident. This can be achieved by integrating the activated tracking units into a mobile ad hoc network and sending out the accident information in compressed messages by a designated unit. An overview of the means of communication proposed in Section 4.2, Section 4.3, Section 4.4 and Section 4.5 is given in Figure 3.

Figure 3.

Communications overview for the ConTAD project.

4.6. Power Management

Regular tracking units send position updates once or twice a day. Their energy efficiency allows for multiple years of operation without battery changes. It can be assumed that a tracking unit with container loss detection must possess similar properties to be accepted on the market while still being able to perform the previously described operations in the event of container loss. To achieve this, it is necessary to consider resource sharing in the mobile ad hoc network, as outlined in Section 4.5. Tracking units with sufficient remaining battery capacity should perform power-intensive tasks, such as external communication. Moreover, the potential use of energy-harvesting methods, such as solar cells, should be explored.

4.7. No Hardware Installation on Board of Ships

For quick adaptation of the proposed tracking unit, no further requirements, such as additional hardware on board ships, should be needed. This will keep the market entry costs low and increase the acceptance of the proposed tracking unit.

5. Discussion

The accident on the MSC Zoe in the North Sea showed that there are several ways to reduce the environmental and economic impact of container losses. This paper proposes the development of a CTD that can automatically detect the loss of containers overboard, inform the carrying ship that and which containers were lost, warn ships in the vicinity to avoid collisions with floating containers, and inform authorities and cargo owners of the accident. The benefits of such a device are as follows:

- An immediate alarm at the time of the accident allows for a fast reaction of the crew to avoid further container losses.

- Ships in the vicinity of the accident are immediately notified. Ship owners benefit from increased safety at sea, since collisions with floating containers and debris can easily be avoided.

- With the information on which containers were lost, authorities can quickly assess the situation and take appropriate action. Especially, the tracking of containers with DG allows for targeted salvage operations. Salvage costs are reduced, since complicated localization operations can be avoided. A fast cleanup will also be beneficial for the reputation of the shipping companies, as their names are in focus in the event of an accident.

- Cargo owners are immediately notified about the loss of their containers and can take appropriate measures to replace important goods. This is especially important for just-in-time deliveries and strengthens the supply chain.

Table 1 lists the specific problems in the MSC Zoe accident and explains how they are addressed in the ConTAD project.

Table 1.

Problems identified in the MSC accident and how they are addressed in ConTAD.

Economic feasibility of CTDs like these is difficult to achieve. Only a very small fraction of all containers transported at sea each year is lost. Therefore, hardware costs need to be low and comparable to existing devices. The success of the proposed tracking unit relies also on legislation aspects. Coastal states might want to keep their coasts clean and their nature reserves undamaged. Therefore, they could enforce the use of a mandatory tracking unit with accident detection, especially on cargos carrying DG.

6. Conclusions

The article reviews the MSC Zoe accident and proposes a container loss accident phase model (CAPM). The CAPM has been used to visualize the time spent responding to the incident and to demonstrate the ambition of the ConTAD project. The challenges derived from the accident investigation and the P&I clubs’ recommendations have been addressed through the ConTAD approach, as outlined in Section 4. As the discussion shows, there is a high chance for strengthening future supply chains and increasing the sustainability of shipping, which is contingent upon economic and legislative considerations. Future research within the project will address technical solutions from an economic perspective.

Author Contributions

Conceptualization, funding acquisition, and methodology, M.O. and C.D.; project administration and supervision, H.-C.W., C.D. and M.S.; resources and software, M.S., H.-C.W. and M.O.; writing—original draft and visualization, M.O.; writing—review and editing, M.O., C.D., H.-C.W. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry for Economic Affairs and Climate Action, grant number 03SX602C.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

We are grateful for the support of our associated partners: Hapag-Lloyd AG, EUROGATE Container Terminal Bremerhaven GmbH, Neue Schleppdampfschiffsreederei Louis Meyer GmbH & Co. KG, m2m Germany GmbH, and Maritimes Cluster Norddeutschland e. V.

Conflicts of Interest

Author Hanns-Christian Wüstner was employed by the company Socratec Telematic GmbH. Author Moritz Schmidt was employed by the company Brehmer GmbH & Co. KG. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- World Shipping Council. Containers Lost at Sea—2023 Update; World Shipping Council: Washington, DC, USA, 2023. [Google Scholar]

- Koning, J.; Grin, R.; Pauw, W. TopTier, seakeeping and container cargo securing safety. In Proceedings of the 18th International Ship Stability Workshop, Gdansk, Poland, 12–14 September 2022. [Google Scholar]

- Walther, L.; Rizvanolli, A.; Wendebourg, M.; Jahn, C. Modeling and Optimization Algorithms in Ship Weather Routing. Int. J. e-Navig. Marit. Econ. 2016, 4, 31–45. [Google Scholar] [CrossRef]

- Dutch Safety Board. Loss of Containers Overboard from MSC ZOE; Dutch Safety Board: The Hague, The Netherlands, 2020. [Google Scholar]

- Buitendijk, M. Quarter of Cargo Lost by Container Ship MSC Zoe Still in the North Sea. SWZ Maritime [Online]. 4 January 2021. Available online: https://swzmaritime.nl/news/2021/01/04/quarter-of-cargo-lost-by-container-ship-msc-zoe-still-in-the-north-sea/ (accessed on 8 May 2024).

- The Swedish Club. Container Focus 2020; The Swedish Club: Gothenburg, Sweden, 2021. [Google Scholar]

- Hapag-Lloyd. Hapag-Lloyd First Mover in Equipping all Containers with Real-Time Tracking Devices. Available online: https://www.hafen-hamburg.de/en/press/news/hapag-lloyd-first-mover-in-equipping-all-containers-with-real-time-tracking-devices/ (accessed on 3 May 2022).

- Falcitelli, M.; Misal; Noto, S.; Pagano, P. Development of a Multi-Radio Device for Dry Container Monitoring and Tracking. IoT 2024, 5, 187–211. [Google Scholar] [CrossRef]

- Bauk, S.; Radulović, A.; Džankić, R. Physical Computing in a Freight Container Tracking: An Experiment. In Proceedings of the 2023 12th Mediterranean Conference on Embedded Computing, Budva, Montenegro, 6–10 June 2023. [Google Scholar]

- Salah, K.; Alfalasi, A.; Alfalasi, M.; Alharmoudi, M.; Alzaabi, M.; Alzyeodi, A.; Ahmad, R.W. IoT-Enabled Shipping Container with Environmental Monitoring and Location Tracking. In Proceedings of the CCNC 2020: 2020 17th IEEE Annual Consumer Communications & Networking Conference (CCNC), Las Vegas, NV, USA, 10–13 January 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6, ISBN 978-1-7281-3893-0. [Google Scholar]

- Socratec Telematic GmbH. SocraFlite: GPS-Positioning, Temperature and Shock Monitoring, Theft Alert. Available online: https://www.socratec.de/en/solutions/socraflite/ (accessed on 8 May 2024).

- Zhang, J.; Wang, M.M.; Xia, T.; Wang, L. Maritime IoT: An Architectural and Radio Spectrum Perspective. IEEE Access 2020, 8, 93109–93122. [Google Scholar] [CrossRef]

- Behforouzi, M. Tracking Device for Detecting the Containers Lost Over Board. In Proceedings of the Conference Proceedings of ICMET Oman. International Conference on Marine Engineering and Technology Oman, Muscat, Oman, 5–7 November 2019; IMarEST: London, UK, 2019. [Google Scholar]

- Shering, A. STAT Deep Blue Project; Richmond, 2020. Available online: https://www.stjohns.tas.edu.au/newsletter/65178 (accessed on 8 May 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).