Abstract

Friction stir processing (FSP) is a solid-state processing technique used to refine the microstructures of metallic alloys. It involves inserting a rotating tool into the material, which generates heat and plastic deformation, leading to the recrystallization and refinement of the microstructure. The aluminium alloy 7050 is a high-strength alloy possessing good corrosion resistance, and is commonly used in aerospace applications. By incorporating SiC particles into the alloy with different percentiles of 0 to 1%, the resulting composite can have improved mechanical properties, such as higher strength and stiffness, as well as increased wear resistance. Mechanical testing and optical metallographic characterization were conducted. The test results showed that weldments have improved mechanical properties compared to the base material, making them suitable for high-strength and low-weight applications.

1. Introduction

Aluminium AA7050 is a high-strength aluminium alloy that is commonly used in aerospace and defence applications. It is a precipitation-hardened alloy that is created by adding copper as the primary alloying element, along with other elements such as magnesium, zinc, and zirconium. AA7050 has excellent mechanical properties, including a high strength, good toughness, and resistance to fatigue and stress corrosion cracking. It also has good resistance to corrosion and can be easily welded and machined [1]. SiC powder is a versatile material that has a wide range of potential applications in a variety of industries, and ongoing research and development are expected to uncover new and exciting ways to utilize its unique properties [2]. FSP can be used to refine the grain structure, reduce the porosity, increase the hardness, and enhance the strength of metals [3,4]. In those experiments, the reinforcement was inserted into a 1:5 mm square groove that had been cut into the surface. In recent years, there has been a growing interest in the development of aluminium matrix composites (AMCs) reinforced with ceramic particles to improve their mechanical properties [5,6,7,8,9,10,11]. One such composite is AA7050 reinforced with silicon carbide (SiC) particles [12]. SiC is a high-strength ceramic material with excellent wear resistance and thermal stability, making it an ideal reinforcement material for AMCs. The additions of SiC particles to AA7050 results in a composite material with improved mechanical properties and wear resistance [13]. The fracture toughness, fatigue behaviour, and mechanical properties of the composite have been studied as well [14,15]. In this study, the mechanical properties and metallographic characterization of varying proportions of SiC-reinforced AA7050 were studied using friction-stir-processing techniques.

2. Materials and Methods

AA7050 is an aluminium alloy that belongs to the 7000 series of aluminium alloys, which are known for their high strength-to-weight ratios. AA7050 is a high-strength alloy with excellent corrosion resistance and toughness. The mechanical properties of AA7050 can be improved through heat treatment. Silicon carbide (SiC) nanoparticles are tiny particles of SiC that have at least one dimension measuring less than 100 nm. SiC nanoparticles have high thermal conductivity, excellent mechanical strength, and good chemical stability, making them useful in a variety of applications. In this study, a friction stir process was conducted on 200 × 100 × 15 mm plates at Welding Research Institute, BHEL Trichy.

The slot was prepared for the AA7050 in the centre, with a depth of about 7 mm and a diameter of 25 mm where the FSP tool ran the work. The volume was calculated with reference to the specific density of the SiC particles. Then, the AA7050 plate was clamped, and the tool ran on the slot imposed with the SiC particles of a proportional weight of 0 to 1%. This caused the material to be stirred and mixed, resulting in a refined and homogenised grain structure.

3. Results and Discussion

3.1. Mechanical Properties

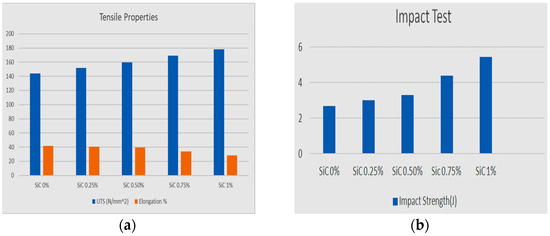

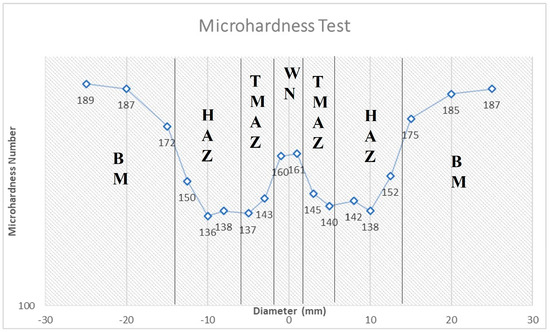

A room-temperature tensile test was conducted on a computerized universal tensile testing machine. Test specimens were prepared according to the ASTM B557M [16] standard. Similarly, an impact test was carried out in a Charpy impact tester. Test specimens were prepared according to the ASTM E23 standard [17]. Three samples of each composition were tested, and the averages of the results were reported. Figure 1 represents the tensile and impact results of the base material, which varied (0–1%) among the SiC-reinforced AA7050 weldments. Microhardness measurements were recorded on the mid-cross section of the weldments, with a load of 0.1 kg and a dwell period of 3 s. Figure 2 represents the microhardness of the weldment profile.

Figure 1.

Mechanical properties of SiC-reinforced AA7050. (a) Tensile properties and (b) impact toughness.

Figure 2.

Microhardness plot.

Figure 1 clearly indicates that the ultimate tensile and impact toughness of the weldments gradually increased with an increase in the SiC reinforcement compositions when compared to the base material. This is due to the uniform distribution of the nanoparticles with refined grain structures. However, the ductility of the weldments decreased upon increasing the SiC proportions. The inclusion of SiC drastically improved the brittle nature of the weldments, which also improved the surface hardness properties.

The microhardness values of the indentations can be used to figure out how the SiC particles are distributed in an AA7050 matrix. The presence of SiC particles was expected to increase the hardness of the material. Figure 2 depicts the microhardness results obtained, with the help of graphs, from the different zones of the weldments (i.e., WN, TMAZ, HAZ, and BM). The results from the sample are quite remarkable, which show the hardnesses at different zones of SiC reinforcement in AA7050.

3.2. Metallurgical Characterization

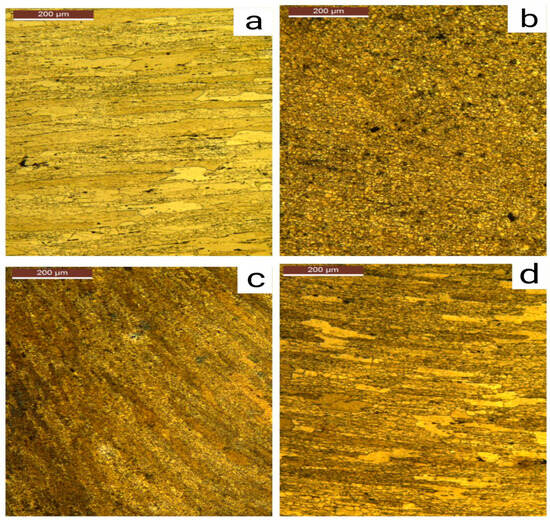

The analysis of the microstructure of silicon carbide (SiC) reinforcement on the friction stir processing (FSP) of AA7050 entails examining the alterations in the microstructural composition that arise when the aluminium alloy 7050 is reinforced with particles of silicon carbide is shown in Figure 3. The microstructure of the friction-stir-processed (FSP) zone was examined through the utilization of optical microscopy in order to observe the distribution of SiC particles and their interaction with the aluminium at the micrometre scale. The microstructure of the heat-affected zone (HAZ) and the thermo-mechanically affected zone (TMAZ) can be influenced by the presence of SiC reinforcement particles in FSP AA7050-SiC composites. The inclusion of SiC particles can serve as nucleation sites for the process of recrystallization or precipitation of other phases, hence leading to the development of a more intricate microstructure. The weld nugget’s microstructure in the FSP AA7050-SiC composites exhibited a homogeneous and finely dispersed arrangement of SiC particles, with a significant dislocation density resulting from the intense plastic deformation encountered during the FSP procedure. In general, the weld nugget’s favourable microstructure can lead to enhanced mechanical characteristics, including increased strength and stiffness, in comparison to the underlying material. Nonetheless, the integrity of the weld nugget may be compromised by various imperfections, including voids, cracks, and inclusions, thereby diminishing the mechanical characteristics of the composite material.

Figure 3.

Micrographs of different zones of FSP sample: (a) BM, (b) WN, (c) TMAZ, and (d) HAZ.

4. Conclusions

- The FSP of AA7050 with SiC reinforcement at 0–1% resulted in an increase in the strength and hardness of the alloy due to the uniform distribution of SiC particles in the aluminium matrix;

- However, the ductility and impact toughness of the alloy decreased with an increase in the SiC content;

- The microstructure analysis showed that the SiC particles made the grains in the FSP zone smoother, which led to a finer grain structure;

- Therefore, the FSP of AA7050 with SiC reinforcement can be used in applications where high strength and hardness are required, but impact toughness and ductility are not critical.

Author Contributions

Investigation, R.A.; Writing, S.A.; Conceptualization, P.R.; Methodology, Review and editing, R.P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data and materials are available upon request, please contact corresponding author email for access, in compliance with ethical and privacy standards.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sathish, T.; Karthick, S. Wear behaviour analysis on aluminium alloy 7050 with reinforced SiC through taguchi approach. J. Mater. Res. Technol. 2020, 9, 3481–3487. [Google Scholar] [CrossRef]

- Cai, Y.; Lang, Y.; Cao, L.; Zhang, J. Enhanced grain refinement in AA7050 Al alloy by deformation-induced precipitation. Mater. Sci. Eng. A 2012, 549, 100–104. [Google Scholar] [CrossRef]

- Song, F.; Zhang, X.; Liu, S.; Tan, Q.; Li, D. The effect of quench rate and overageing temper on the corrosion behaviour of AA7050. Corros. Sci. 2014, 78, 276–286. [Google Scholar] [CrossRef]

- Venkatesan, S.; Anthony Xavior, M. Tensile behavior of aluminum alloy (AA7050) metal matrix composite reinforced with graphene fabricated by stir and squeeze cast processes. Sci. Technol. Mater. 2018, 30, 74–85. [Google Scholar] [CrossRef]

- Sharma, A.; Dwivedi, V.K.; Singh, Y.P. Effect on ultimate tensile strength on varying rotational speed, plunge depth and welding speed during friction stir welding process of aluminium alloy AA7075. Mater. Today Proc. 2020, 26, 2055–2057. [Google Scholar] [CrossRef]

- White, B.C.; White, R.E.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. The effect of tensile pre-straining on fatigue crack initiation mechanisms and mechanical behavior of AA7050 friction stir welds. Mater. Sci. Eng. A 2018, 736, 228–238. [Google Scholar] [CrossRef]

- Subroto, T.; Miroux, A.; Eskin, D.G.; Katgerman, L. Tensile mechanical properties, constitutive parameters and fracture characteristics of an as-cast AA7050 alloy in the near-solidus temperature regime. Mater. Sci. Eng. A 2017, 679, 28–35. [Google Scholar] [CrossRef]

- Ranjith, R.; Karthick, B.; Sindhu Kavi, M.; Somu, C.; Pravin, T. Impact of various reinforcement particles on the density of AA7050 graded aluminium fabricated through stir casting. Mater. Today Proc. 2020, 26, 1465–1468. [Google Scholar] [CrossRef]

- Li, W.; Liu, W.; Qian, F.; Mao, P.; Wang, J. Microstructural evolution of AA7050 alloy wires during tandem hot rolling (THR) and cold-drawing process. Mater. Sci. Eng. A 2022, 849, 143512. [Google Scholar] [CrossRef]

- Cavalcante, T.R.F.; Pereira, G.S.; Koga, G.Y.; Bolfarini, C.; Bose Filho, W.W.; Avila, J.A. Fatigue crack propagation of aeronautic AA7050-T7451 and AA2050-T84 aluminum alloys in air and saline environments. Int. J. Fatigue 2022, 154, 106519. [Google Scholar] [CrossRef]

- Li, D.; Li, M.; Liu, Y.; Wang, Q.; Li, C. Effects of SiC particles on the microstructure and mechanical properties of AA7050/SiC composites. Mater. Sci. Eng. A 2020, 775, 139231. [Google Scholar] [CrossRef]

- Hasanpour, R.; Zabihi, O.; Abbasi, M. The effect of SiC particles on the microstructure, mechanical properties, and fracture behavior of AA7050 aluminum matrix composites. J. Mater. Res. Technol. 2021, 10, 88–98. [Google Scholar]

- Hong, S.G.; Han, J.G.; Kim, J.S. The effect of SiC particles on the fatigue behavior of AA7050/SiC composites. Compos. Struct. 2018, 187, 81–89. [Google Scholar] [CrossRef]

- Ali, M.Y.; Heidarzadeh, A.; Jahazi, M. Effect of friction stir processing on microstructure, mechanical and corrosion properties of AA7050-T7451. J. Mater. Eng. Perform. 2017, 26, 1053–1065. [Google Scholar]

- Park, H.J.; Jang, D.K.; Kim, J.H. Microstructure and mechanical properties of AA7050 aluminum alloy friction stir processed at different temperatures. Mater. Sci. Eng. A 2019, 748, 180–189. [Google Scholar] [CrossRef]

- ASTM B 557M–02A 2010; Standard Test Methods of Tension Testing Wrought and Cast Aluminum and Magnesium Alloys Products ASTM B557-10. ASTM International: West Conshohocken, PA, USA, 2010; Volume 2, pp. 1–15.

- ASTM E 23–12C 2013; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–25.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).