1. Introduction

Computer-aided design (CAD) and computer-aided manufacturing (CAM) are among the key technologies in the development of the modern metalworking industry. For the first time, CAD/CAM systems were used in the 1960s in the development and production of aircraft wings using the computing power of the IBM 360/44 [

1]. Since then, they have evolved from specialized computing systems to widely applicable digital tools for industrial design and manufacturing.

Nowadays, CAD systems are used to create two-dimensional and three-dimensional digital models, various simulations and analyses of engineering problems. They reduce design time and errors, providing reliable documentation that supports the product life cycle [

2]. CAM systems convert these models into control instructions for computer numerical control (CNC) machines, lathes, mills and lasers. Through them, the production process is accelerated, a higher accuracy is achieved and the consumption of materials is reduced [

3].

Industry 4.0 revolution combines CAD/CAM systems with digital systems, such as IoT (Internet of Things), cyber-physical systems (CPS), and manufacturing execution systems (MES), ensuring seamless connections between design, planning, and production [

4].

Simulations, optimizations, and predictive maintenance in real time are made possible by virtual models of various machines and processes [

5]. According to a systematic review by da Silva et al. (2025), the application of these innovations in metalworking leads to significant increases in process efficiency and reliability [

6]. In recent years, artificial intelligence (AI) and machine learning have also been applied to CAD/CAM. Using HyperGraph convolutional neural networks (HGCNN), hybrid manufacturing allows for the automation of manufacturing processes by classifying manufacturing characteristics with an accuracy of over 97% [

7]. In a CNC environment, machine learning algorithms predict machining times more accurately than small CAM methods [

8]. A key CAD/CAM development trend is hybrid manufacturing, a method of combining 3D printing and subsequent machining, which offers a variety of complex shapes and customized products [

9]. In addition to automatic unwrapping and path optimization, CAM strategies for laser, plasma, and waterjet cutting can reduce waste and energy consumption [

10].

The development of cloud-based CAD/CAM solutions and their integration with Product Lifecycle Management systems facilitate collaboration in global production chains [

11], which is important for the metal-cutting industry, which is highly dependent on international cooperation and quick adaptation to market changes. The implementation of CAD/CAM faces challenges such as high investment costs, cybersecurity, personnel qualifications, and others [

12]. The Industry 5.0 concept emphasizes sustainable and human-centered production, where machines and artificial intelligence support, not replace, human creativity [

13].

The aim of this study is to analyze the application and development of CAD/CAM technologies in the modern metalworking industry, and to evaluate the impact of automatic nesting algorithms on production efficiency, material utilization, and economic performance.

3. Results and Discussion

The present study aims to evaluate the impact of automatic nesting in CAD/CAM systems on the production efficiency of laser cutting of stainless steel. The simulations were performed using AutoCAD 2025 (

https://www.autodesk.com/, accessed on 14 November 2025), applying identical cutting parameters and material properties to ensure consistent evaluation of both manual and automated cutting approaches.

The analysis was performed by simulating real production scenarios involving manual and automatic placement of parts on a sheet of raw material, then comparing the quantitative indicators: number of parts, cutting time, material utilization and economic effect.

For the purposes of the analysis, standard AISI 304 (Austenitic Chromium-Nickel Stainless Steel, EN 1.4301) stainless steel sheets with dimensions of 1000 × 2000 × 10 mm and a density of 7.9 g/cm

3 were used [

15].

The calculated mass of one sheet is:

The price of the raw material is determined based on public databases and market indices, MEPS International (2025) [

16] and MetalMiner Index (2025) [

17] report an average price for AISI 304 10 mm sheet between 8.5 and 9.5 EUR/kg [

1,

2]. Thyssenkrupp Materials Trading GmbH and Tata Steel Europe (catalog 2024) indicate prices between 1350 and 1500 EUR/tonne at wholesale [

18,

19].

The presented price calculations are based on a real European market assessment for the first quarter of 2025.

In order to evaluate the effectiveness of CAD/CAM algorithms in optimizing production processes, a comparison between manual and automatic Nesting in laser cutting of sheet metal has been performed. It is a process of arranging parts on a raw sheet in order to minimize waste and maximize the use of available space.

In the manual method, the operator determines the position of each part, striving to maintain minimum technological distances, while in automatic Nesting, built-in optimization algorithms are used that calculate the most appropriate placement based on geometric characteristics and machine constraints [

20]. This comparison aims to quantitatively show the differences in material usage, processing time and number of parts produced, as well as to assess the potential economic and environmental advantages of automated CAD/CAM solutions.

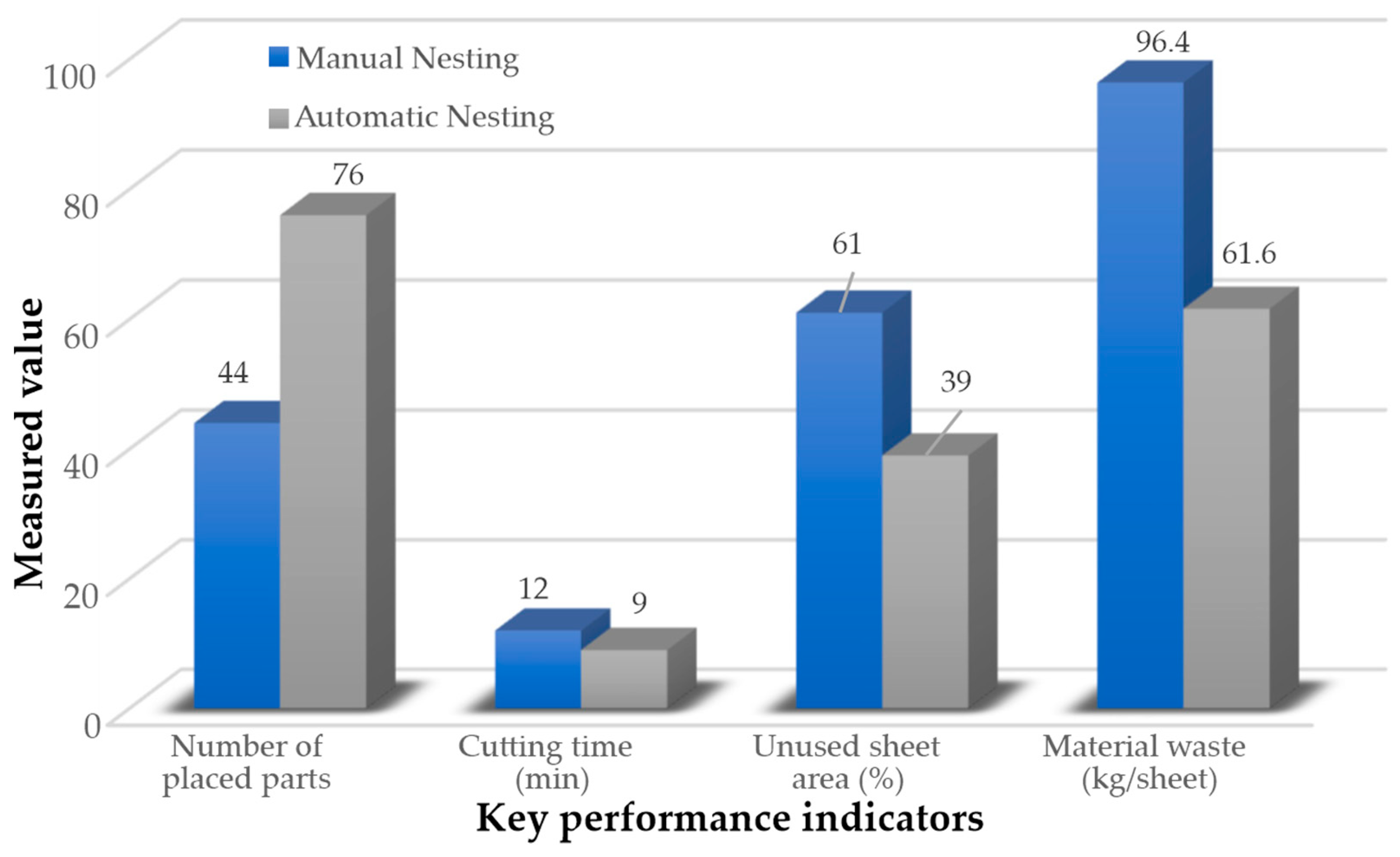

The results of the comparative analysis between the two methods are summarized in

Table 1 and

Figure 1, where the main technological indicators are presented: number of parts placed on a sheet, cutting time, percentage of unused space and amount of waste material. As can be seen from the data, automatic Nesting achieves significantly better results in all considered parameters.

The analysis of the results in

Table 1 shows the advantage of automated nesting. Over 70% more parts were produced and 36% less waste was generated as a result of CAM algorithms optimizing production processes. Generally, cutting time reductions of up to 25% lead to both machine time savings and a reduction in energy consumption, which directly influences production costs and the environmental footprint.

In order to quantify the economic benefits of deployment optimization, a comparative cost analysis was performed between manual and automatic deployment methods. The evaluation includes the cost of lost material, energy consumption and process efficiency. In all calculations, a stainless-steel price of €9/kg is assumed, which corresponds to the current market value of AISI 304 sheets in Europe [

16,

17] shown above.

A comparison of the economic advantages of automatic placement versus manual placement is presented in

Table 2. As can be seen, waste is reduced by 34.8 kg per sheet, resulting in an average savings of approximately €314 per sheet processed. By using an automatic method, sheet utilization rates are 61% compared to 39% using the manual method due to a better distribution of parts and minimal residual areas [

14]. Due to the material savings, the reduction in cutting time by about 3 min per sheet and the reduction in energy consumption by approximately 0.7 kWh per sheet, additional savings were realized in production costs. The combined effect of these factors leads to higher operational efficiency, reduced resource use and increased sustainability of the production process.

To provide a more comprehensive assessment of the economic efficiency of automatic nesting, calculations of the expected outcomes for various production scales were performed. The estimates are based on the observed average material saving of 34.8 kg per sheet and the average market price of stainless steel of 9 EUR/kg [

16,

21]. This corresponds to an approximate cost reduction of 314 EUR per processed sheet. To analyze the impact on total production costs, a production range of 50 to 500 sheets per month was considered, encompassing the typical manufacturing capacities of small-, medium-, and large-sized enterprises in the metal cutting industry. The obtained values are summarized in

Table 3, which illustrates the relationship between the number of processed sheets, the amount of material saved, and the corresponding financial savings.

The calculations in the table are based on an average material saving of 34.8 kg per sheet and a unit price of stainless steel of 9 EUR/kg according to AISI 304 [

22,

23,

24].

It should be emphasized that the economic estimates in

Table 3 are obtained by linearly scaling the savings per sheet with the number of processed sheets. This simplified model does not account for production variability, machine downtime, setup changes, or additional costs related to software implementation and process integration. Therefore, the calculated values should be interpreted as indicative potential savings under stable operating conditions rather than precise forecasts. Developing a more detailed economic model that incorporates stochastic demand, maintenance schedules and integration costs is a relevant direction for future work.

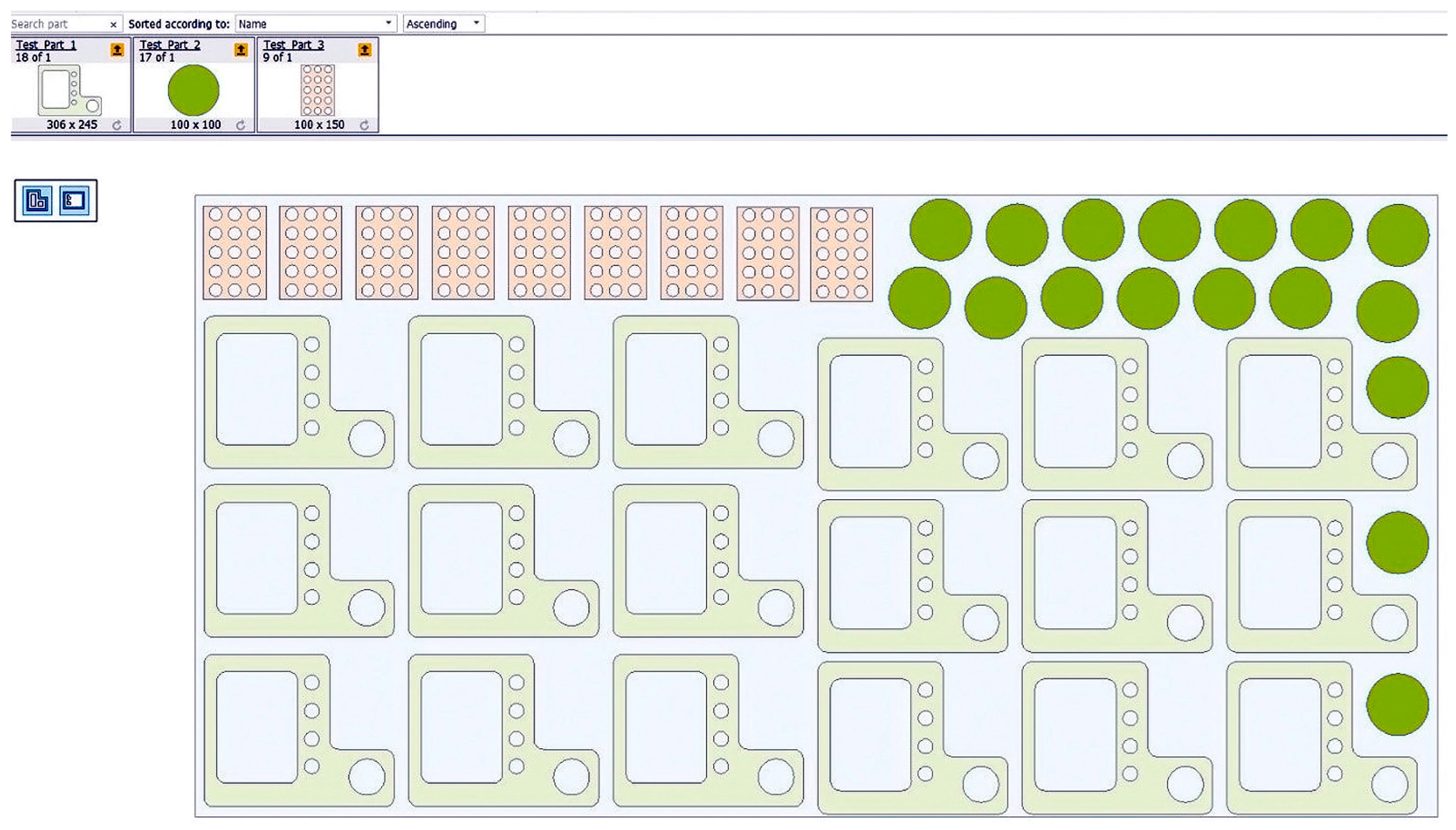

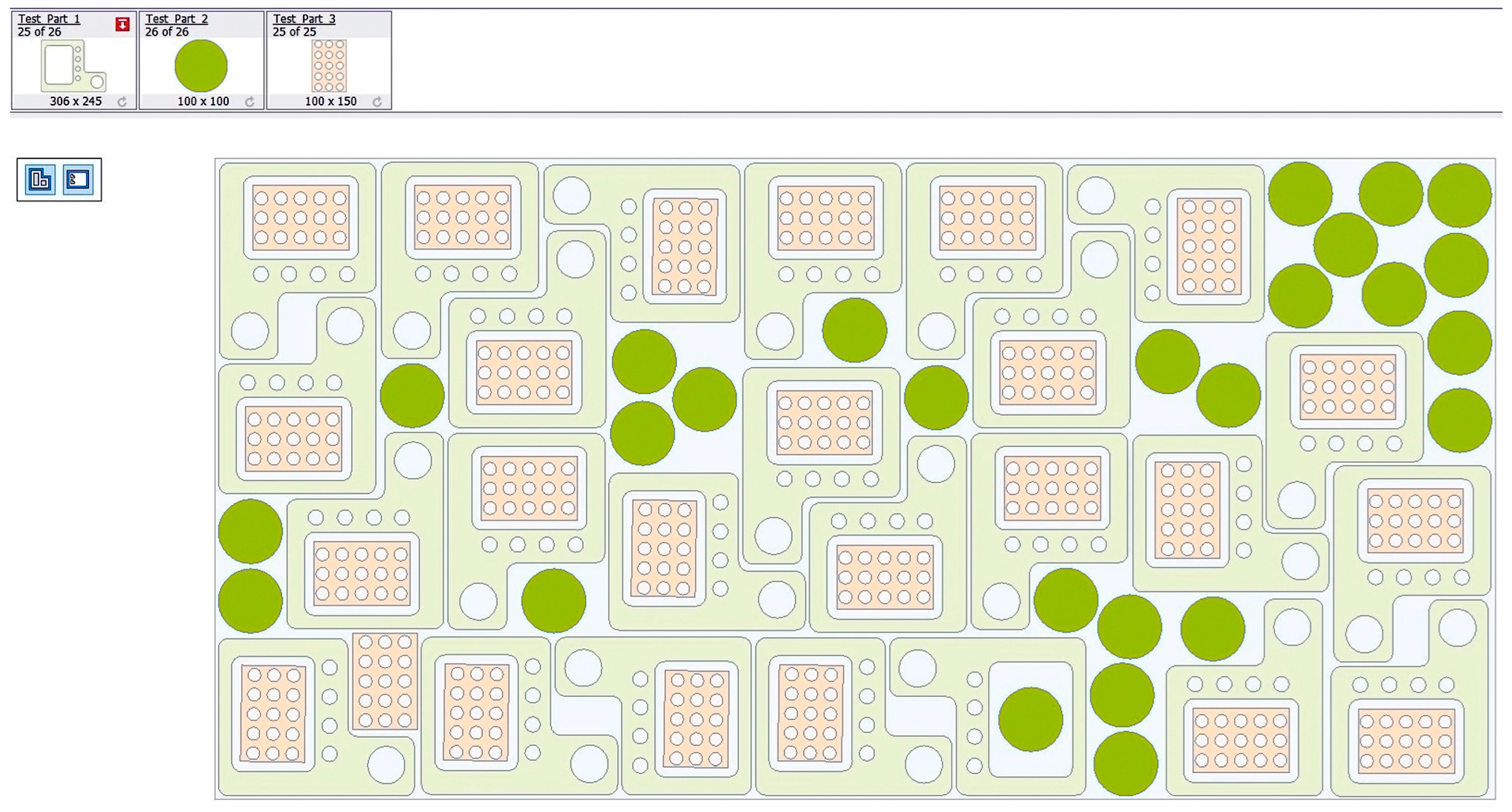

Figure 2 and

Figure 3 illustrate, respectively, the manual and automatic nesting layouts for the same set of parts on an AISI 304 sheet under identical technological constraints. In the manual nesting case (

Figure 2), the operator arranges the contours one by one, respecting minimum safety distances between parts (e.g., 14 mm) and from the sheet edge (10 mm).

Although this approach is acceptable for simple geometries or small production runs, it inevitably leads to larger “islands” of unused material and a less compact packing of the parts. In contrast, the automatic nesting shown in

Figure 3 is generated by the CAD/CAM system using an internal optimization algorithm that explores many feasible placements and orientations. The resulting layout is visibly denser, with reduced gaps and improved contour adjacency, which directly contributes to the higher material utilization, the increased number of parts per sheet, and the shorter cutting path reported in the quantitative section. Thus,

Figure 2 and

Figure 3 provide a visual explanation of the numerical results: the algorithmic search performed by the nesting module systematically outperforms the operator’s intuitive arrangement, especially as the geometry becomes more complex or the batch size grows.

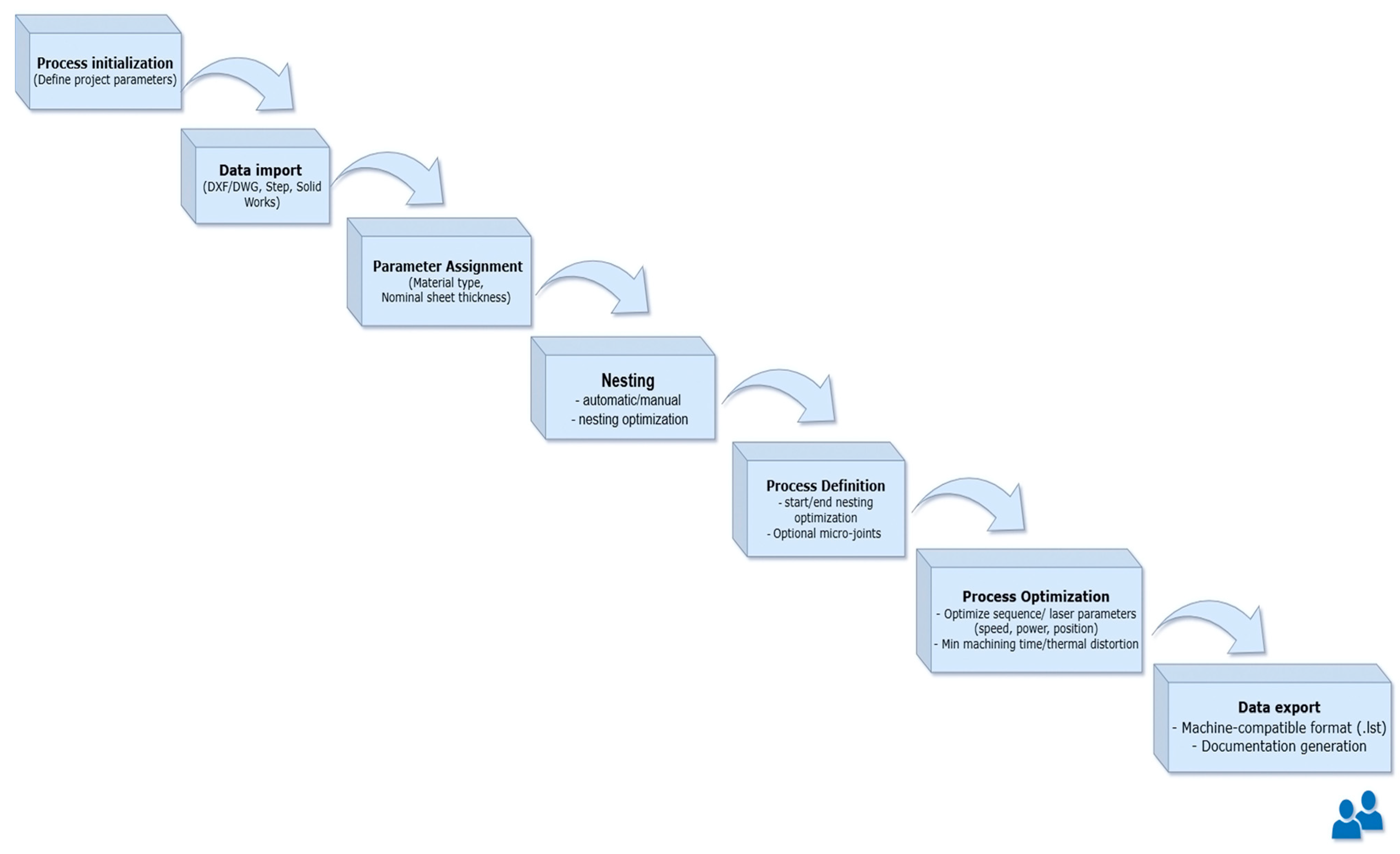

After the nesting process is complete, the CAM software creates NC code (Numerical Control Code) instructions for the machine. The code contains information about start and end points, cutting speed, sequence of operations, and depth of cut.

Figure 4 presents a block diagram of the complete digital workflow, from CAD modelling to the generation of NC code for the CNC laser cutting machine. The process begins with importing the CAD geometry, where the system supports multiple neutral and native formats with extensions such as .dxf/dwg, step, ensuring compatibility with different design environments. The next step is the definition of the technological context: selection of the material (e.g., stainless steel 1.4301) and thickness (10 mm), which determines the appropriate cutting speed, laser power and assist gas parameters. The nesting stage follows, where either manual or automatic placement of the parts on the sheet is performed. Afterwards, the CAM environment generates the cutting technology—lead-ins, lead-outs, pierce points, micro-joints and contour sequence—taking into account collision avoidance and thermal distortion. In the final stages, optimization routines minimize the total cutting time by refining the toolpath order and feed rates, and the system exports the corresponding NC program together with an operator report. This diagram emphasizes that the nesting task is not an isolated operation but an integral part of a fully digital CAD/CAM–CNC chain, where decisions at each stage (material selection, nesting strategy, path optimization) cumulatively affect productivity, material efficiency and overall process sustainability.

To begin with, analysis shows that adopting automatic nesting not only reduces production costs, but also supports sustainable manufacturing practices by minimizing material waste and energy consumption.

A closer examination of the mechanisms behind the observed gains suggests that the benefits of automatic nesting arise not only from higher packing density but also from secondary effects in toolpath planning—namely reduced non-productive head travel, fewer long traverses across thermally affected zones, and a more consistent heat load that stabilizes cut quality. In practical terms, the simultaneous improvements reported in

Table 1 (up to 36% less scrap, 25% shorter cutting time, and >22% higher material utilization) and

Table 2 (≈314 EUR saved per sheet at 9 EUR/kg) indicate that automated placement interacts favorably with contour sequencing and micro-feature ordering, thereby compounding savings across material usage, cycle time, and rework risk. Industrially, these gains translate into higher throughput per shift and lower variability in yield—two levers that strengthen production scheduling and capacity planning for small-, medium-, and large-batch contexts alike.

At the same time, several boundary conditions temper generalization. The present evaluation is based on AISI 304 sheets of a single size and thickness (1000 × 2000 × 10 mm) and assumes unrestricted part orientation and uniform kerf/thermal behavior; in settings that require grain-direction or cosmetic constraints, common-line cutting policies, or strict part-to-edge offsets, the magnitude of improvement may differ. The economic advantage is also sensitive to input prices: using the study’s mean saving of 34.8 kg per sheet, the plausible market range of 8.5–9.5 EUR/kg implies ≈€296–€331 saved per sheet, with energy savings remaining comparatively minor against material costs. Moreover, linear scaling to monthly totals (

Table 3) may overstate benefits at very high volumes if remnant-library policies, batch-mix variability, setup interleaving, or downstream operations (deburring, micro-joint removal, inspection) become rate-limiting. Future replications should therefore include multi-objective nesting (material, path length, pierce county), explicit thermal/kerf constraints, and cross-material/thickness validation, ideally within a digital-twin loop to capture run-to-run variability and shop-floor scheduling effects.

To formalize the computational workflow, two algorithms were developed to process post-cutting data and quantify the economic benefits.

Algorithm 1 describes the analysis and interpretation of post-cutting data exported from the CAD/CAM system, while Algorithm 2 estimates economic impact based on material savings and market prices. These formulations make the data processing workflow clear and reproducible across different CAD/CAM environments.

| Algorithm 1: ParseNestingData(filePath) |

| 1. | Input: Nesting data file exported from CAD/CAM system |

| 2. | Output: Summary metrics of nested parts |

| 3. | procedure ParseNestingData () |

| 4. | schema ← extractAttributes(“MM,AT” lines) |

| 5. | data ← extractRecords(“DA,” lines) |

| 6. | for each record in data do |

| 7. | if record is valid then |

| 8. | extract part parameters (id, posX, posY, sizeX, sizeY, angle, mirror) |

| 9. | add part to Parts |

| 10. | end if |

| 11. | end for |

| 12. | validate (Parts) |

| 13. | metrics ← {count(Parts), ∑(sizeX × sizeY), mean(angle), share(mirror)} |

| 14. | output metrics |

| 15. | end procedure |

| Algorithm 2: CalculateEconomicEffect(materialSaved_kg,price_EUR_per_kg, sheetsPerMonth) |

| 1. | Input: Average material saving per sheet, market price kg, number of processed sheets |

| 2. | Output: Estimated cost reduction per sheet and total monthly savings |

| 3. | procedure CalculateEconomicEffect(materialSaved_kg, price_EUR_per_kg, sheetsPerMonth) |

| 4. | if materialSaved_kg > 0 and price_EUR_per_kg > 0 then |

| 5. | costPerSheet ← materialSaved_kg x price_EUR_per_kg |

| 6. | totalSaving ← costPerSheet x sheetsPerMonth |

| 7. | else |

| 8. | costPerSheet ← 0 |

| 9. | totalSaving ← 0 |

| 10. | end if |

| 11. | Output Material saved:, materialSaved_kg, kg |

| 12. | Output Cost per sheet:, costPerSheet, EUR |

| 13. | Output Monthly saving:, totalSaving, EUR |

| 14. | end procedure |

Algorithm 2 estimates the respective economic impact. By taking the average material saving per sheet, the current stainless-steel market prices, and production volume, the algorithm is able to determine both the per sheet cost reduction and the total monthly savings.

The results shown in this study indicate that automatic nesting implemented in CAD/CAM systems results in improved laser cutting efficiency for stainless steel. Based on algorithm analysis, optimization through computational methods leads to a greater degree of material utilization, a shorter processing time, and a measurable economic effect. In addition to being a design tool, CAD/CAM technologies are also an essential element of smart and sustainable manufacturing.

4. Conclusions

In summary, CAD/CAM systems have transformed from a design and manufacturing tool into a strategic factor for digital transformation, innovation, and competitiveness in the metalworking industry. Their integration with artificial intelligence, digital twins, cloud platforms, and hybrid manufacturing technologies opens up new opportunities for increasing efficiency, quality, and sustainability.

The scientific novelty of this work lies in the systematic integration of geometric, technological, and economic criteria into a unified framework for evaluating nesting strategies in an actual industrial environment. Unlike purely theoretical or software-oriented studies, the proposed approach quantifies the impact of automatic nesting in a CAD/CAM system through directly measurable indicators—number of parts per sheet, utilization coefficient, cutting time, scrap mass, and cost per sheet—under strictly identical production conditions. This enables an objective assessment of algorithmic nesting performance and provides reproducible evidence of its contribution to sustainable manufacturing, thereby offering a practical methodological template that can be transferred to other materials, cutting technologies, and Industry 5.0-oriented production systems.

The conducted analysis demonstrates that the integration of CAD/CAM systems with automatic nesting algorithms significantly enhances both the technological and economic performance indicators of metalworking production. Automatic nesting provides measurable improvements across all key performance metrics—reducing material waste by up to 36%, decreasing cutting time by 25%, and improving material utilization by more than 22%. The resulting cost savings reach approximately 314 EUR per sheet, increasing linearly with production volume, thereby confirming the strong economic potential of this approach.

Furthermore, the reduction in energy consumption and waste generation supports the broader objectives of sustainable and resource-efficient manufacturing. These findings are consistent with current research emphasizing the importance of algorithmic optimization, digital integration, and AI-based process control in achieving the next generation of intelligent manufacturing systems.

Future research should focus on the integration of machine learning algorithms and digital twin technologies within CAD/CAM environments to enable real-time process monitoring, predictive maintenance, and autonomous optimization in metalworking applications.