Abstract

This study examines initial and repair welds between creep-resistant steels, P22 and P91, using ER90S-B3 and ERNiCrMo-3 steel-based and nickel-based filler materials, respectively. TIG welding with and without PWHT was applied. Microstructural evaluation revealed martensitic transformation in HAZ, decarburization in repairs, and the presence of Laves phase. Ni-based filler welds showed greater inhomogeneity. Hardness profiles confirmed softening in P91 HAZ and improved uniformity with PWHT. Steel-based filler provided better compatibility, especially in repair scenarios. The results support the use of ER90S-B3 with PWHT for enhanced reliability. Our findings align with EPRI guidelines and standards for weld integrity in high-temperature piping applications.

Keywords:

dissimilar welding; P22; P91; TIG repair; ERNiCrMo-3; ER90S-B3; PWHT; Laves phase; decarburization; hardness profile 1. Introduction

The continued drive for higher efficiency and reduced emissions has accelerated the adoption of ultra-supercritical (USC) and advanced ultra-supercritical (AUSC) power plants, which operate at pressures and temperatures often exceeding 600 °C. While such conditions improve thermal efficiency, they place severe demands on structural materials, which must combine creep strength, microstructural stability, oxidation, and corrosion resistance [1,2]. Creep-strength-enhanced ferritic/martensitic (CSEF/M) steels, such as P91 and P92, are widely applied in superheaters, reheaters, and main steam piping due to their tempered martensitic microstructure and precipitation strengthening [1,3]. P92 offers further improvements over P91 through W and B additions, though long-term degradation via carbide coarsening and Laves phase formation reduces hardness and creep resistance [4]. Transition welds between high-Cr steels (P91/P92) and low-alloy steels (P22) are common in boiler headers and piping, but dissimilar welded joints (DWJs) face challenges, including thermal expansion mismatch, residual stress, carbon migration, and the formation of brittle zones such as δ-ferrite, carbon-depleted areas, and Laves phases [5,6,7]. These heterogeneities often lead to Type IV creep cracking in service [7,8]. Several welding processes have been used for P22–P91 joints. Gas tungsten arc welding (GTAW) is conventional but limited by bead size and multi-pass requirements [6], whereas activated TIG (A-TIG) improves penetration and reduces carbon diffusion zones after PWHT [5,9]. Laser beam welding also refines HAZ and microstructure, shifting failures to the weaker P22 base metal [10]. Another key factor is filler metal choice: Ni-based fillers such as ERNiCrMo-3 and IN625 improve ductility and mitigate carbon diffusion [6,11], but also introduce dendritic segregation, secondary phases, and creep-softening effects [11,12,13]. Steel fillers, by contrast, offer greater compatibility, though they may not suppress corrosion as effectively. PWHT plays a critical role by tempering untransformed martensite, reducing hardness mismatch, and relieving residual stresses [8,14]. However, excessive or poorly optimized cycles can accelerate carbon migration and soft zone formation [4,5]. Furthermore, long-term service introduces additional risks such as molten salt corrosion, with degradation strongly dependent on filler and electrode composition [15]. Comparative studies confirm that carbon diffusion, segregation, and secondary phase precipitation remain the main degradation mechanisms across ferritic–ferritic and even Ni–steel welds [7,12,16]. Thus, welding strategies must balance filler selection, process optimization, and sustainable PWHT to mitigate these instabilities. This study investigates the microstructural evolution of dissimilar welds between P22 and P91 steels under as-welded and repair-welded conditions, employing steel- and Ni-based fillers. The objective is to assess repair welding as a means of restoring weld integrity and to clarify the influence of filler type on microstructural stability and degradation mechanisms.

2. Materials and Methods

2.1. Base and Filler Materials

The base materials used in this study were ASTM A335 Grade P22 and P91 steels (Table 1), supplied in the form of tubes with an external diameter of 58 mm and a wall thickness of 7 mm. Importantly, these tubes were extracted from service-exposed piping in a power plant, which had been operating for between 20,000 and 30,000 h at an elevated temperature. P22 is a 2.25Cr–1Mo ferritic steel, while P91 is a 9Cr–1Mo–V–Nb creep-strength-enhanced ferritic steel. Two types of filler materials were employed: ER90S-B3, a Cr–Mo steel filler typically used for creep-resistant steels, and ERNiCrMo-3, a nickel-based austenitic filler.

Table 1.

Nominal chemical composition (wt.%) of P22 and P91 steels (ASTM A335).

2.2. Welding Process

All welds were fabricated using the gas tungsten arc welding (GTAW/TIG) process (Table 2). The welding torch was fitted with an EWTh-2 tungsten electrode and pure argon shielding gas. The welds were performed as multi-pass butt joints on tubes with controlled preheat (~150 °C) and interpass temperature (~250 °C). The current ranged between 100 and 130 A with a voltage of 12–14 V. Initial weldments were produced using both ER90S-B3 (steel-based filler) and ERNiCrMo-3 (nickel-based filler).

Table 2.

Initial welding parameters.

2.3. Repair Welds and PWHT

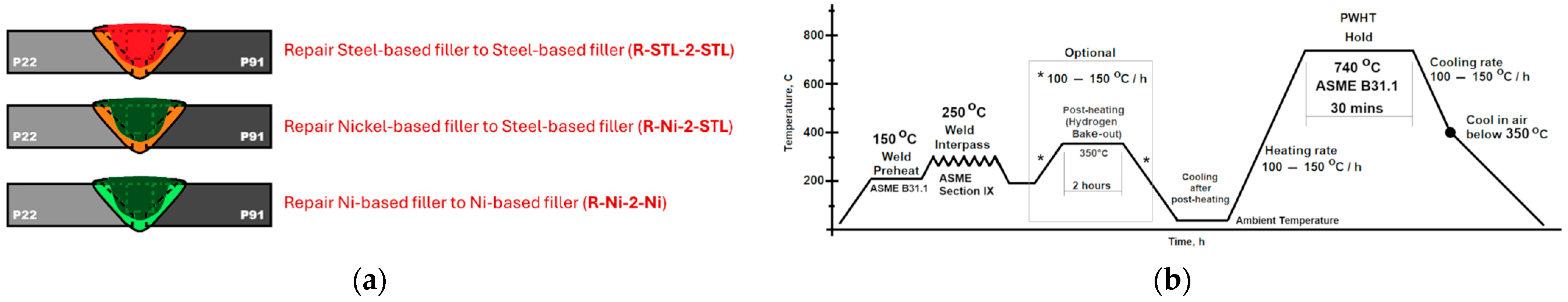

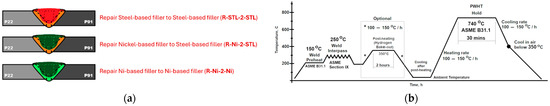

Repair welds were carried out on the initial joints using three different filler strategies: Repair Steel-based filler to Steel-based filler (R-STL-2-STL), Repair Nickel-based filler to Steel-based filler (R-Ni-2-STL) and Repair Ni-based filler to Ni-based filler (R-Ni-2-Ni), as described in the scheme of Figure 1a.

Figure 1.

(a) Scheme describing repair strategies; (b) thermal cycle/post weld heat treatment (PWHT) of initial welds (ASME B31.1).

Each repair configuration was examined both with and without post-weld heat treatment (PWHT). PWHT was applied according to ASME B31.1, consisting of heating to 760–780 °C, soaking for 2 h, followed by furnace cooling (Figure 1b). Multi-pass repair layers were deposited using the respective filler materials (Table 3).

Table 3.

Repair welding strategies and PWHT conditions applied in this study.

2.4. Characterization Techniques

A thorough metallographic and microhardness analysis was performed on the welded and repair-welded joints. Cross-sectional samples were prepared following standard metallographic procedures, including mechanically grinding, polishing, and subsequent chemical etching. Samples were etched with 2% Nital solution (2% HNO3 in C2H5OH) and Vilella’s reagent (1 g of picric acid, 5 mL HCl and 100 mL CH3OH). Macrostructural observations were conducted using an Olympus SZX10 stereoscope (Olympus Corporation, Tokyo, Japan). For microstructural analysis, an optical microscope (ZEISS Axiotech, Carl Zeiss Microscopy GmbH, Jena, Germany) coupled with an Image Analysis tool was utilized. Additionally, a Scanning Electron Microscope (Thermo Scientific Phenom XL, Thermo Fisher Scientific, Eindhoven, The Netherlands) equipped with an Energy Dispersive Spectrometer (EDS) was employed for more detailed microstructural analyses and possible phase chemical composition microanalyses. Vickers microhardness measurements were conducted on cross-sections of the samples using a Qness 60 A+EVO tester with an imposed load of 1.0 kgf (HV1). Special attention was given to transitional areas such as partially mixed zones, decarburized bands, and regions prone to Laves phase formation.

3. Results

3.1. Microstructural Observations

The welded joints exhibited distinct microstructural features depending on the filler material used and the repair strategy applied.

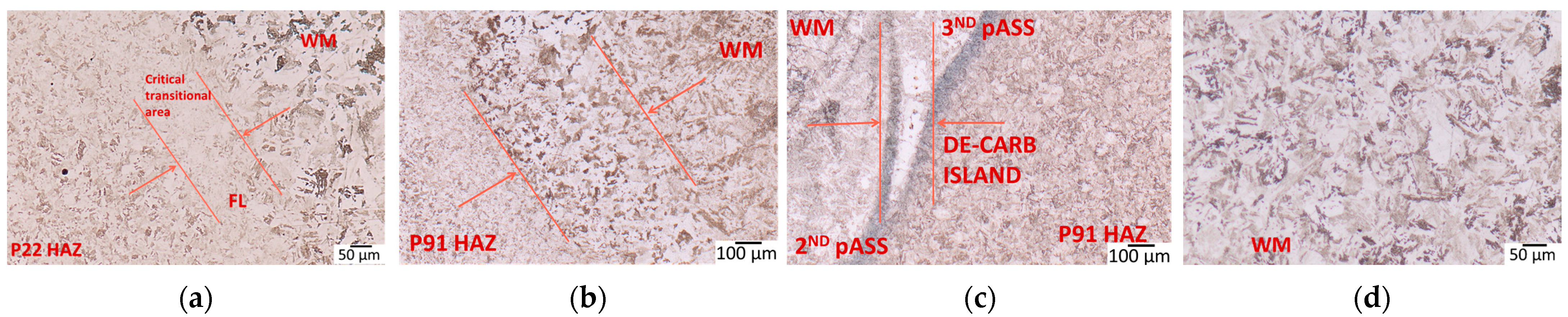

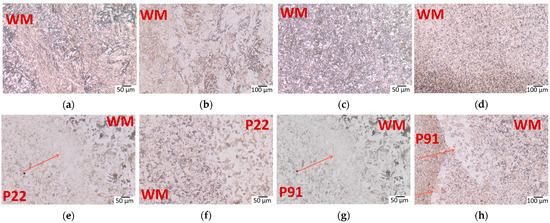

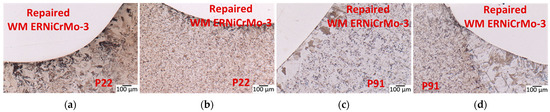

For initial welds fabricated with the steel-based filler ER90S-B3, the weld metal adjacent to the fusion line in P22 and P91 exhibited coarse tempered martensite with dispersed M23C6 carbides, while the HAZ showed over-tempered martensite. No δ-ferrite or segregation-related phases were detected. Occasional carbon-depleted regions were found in multi-pass zones, likely due to reheating during subsequent passes, but in general, the weld metal remained martensitic and free of secondary phases (Figure 2). In contrast, initial welds with the Ni-based filler ERNiCrMo-3 showed fully austenitic weld metal with columnar dendritic growth, δ-ferrite islands, and interdendritic segregation. Secondary phases such as Nb/Ti-rich particles and incipient Laves phase were observed. The P22 HAZ contained tempered martensite with evidence of over-tempering, while P22 and P91 HAZ near the fusion line exhibited white bands and local carbon depletion, indicating diffusion across the fusion boundary (Figure 3).

Figure 2.

Micrographs of initial welds with steel-based filler. (a) Cross-section of P22 welding; (b) cross-section of P91 welding (arrows indicate the coarse-grained heat-affected zone); (c) de-carb island between second and third pass; (d) P91 welding metal.

Figure 3.

Micrographs of initial welds with Ni-based filler: (a) cross-section of P22 welding, 1st pass; (b) cross-section of P22 welding, 2nd and 3rd passes; (c) cross-section of P91 welding, 1st pass; (d) cross-section of P91 welding, 2nd and 3rd passes. The arrows in (b,c) indicate light-etched white bands in the heat-affected zone (HAZ) adjacent to the fusion line, associated with local carbon depletion due to carbon diffusion across the fusion boundary.

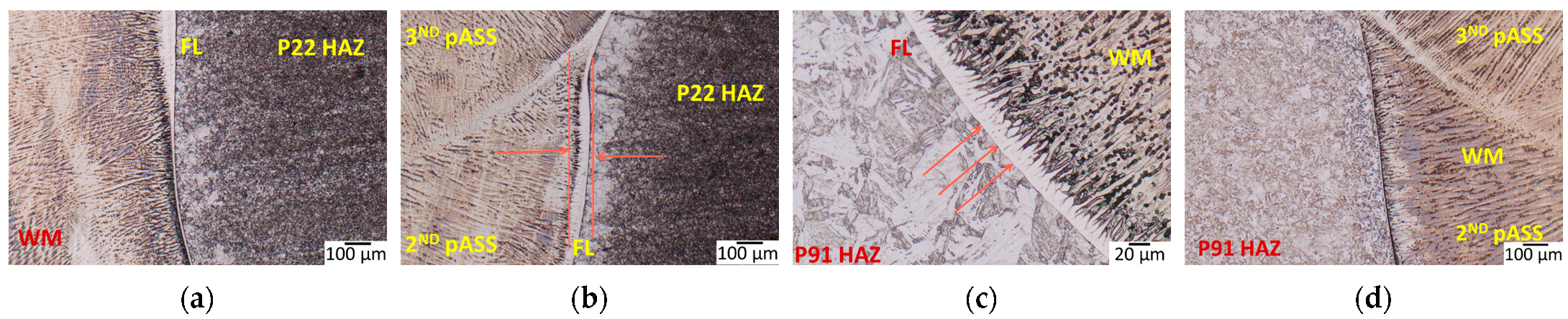

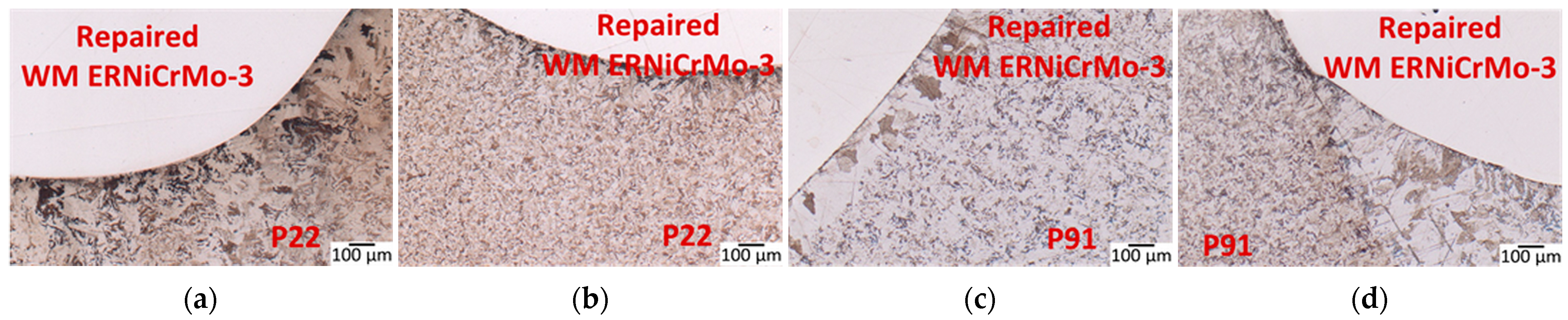

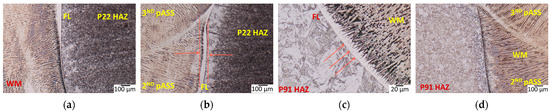

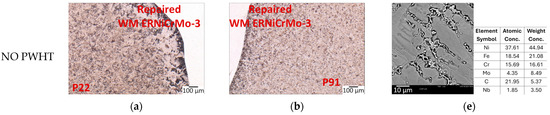

Repair welding introduced further microstructural complexity. In the Steel→Steel (R-STL-2-STL) repairs, the as-deposited repair bead showed coarser martensitic features than the underlying initial bead due to slower cooling and thermal-mass effects (Figure 4a vs. Figure 4c) as well as after PWHT (Figure 4b vs. Figure 4d). PWHT tempered both regions, yet the initial bead retains a finer morphology owing to its rapid solidification/transformation history. This contrast underscores the importance of controlled thermal cycles and stress-relieving in repair welding of creep-resistant steels. A clear fusion boundary, fine tempered martensite and no severe carbon depletion are visible at the P22 fusion line without PWHT (Figure 4e). In contrast, the P91 fusion line without PWHT (Figure 4g) shows signs of carbon depletion. PWHT homogenized and tempered the microstructure near the P22 fusion line with PWHT (Figure 4f). For P91, PWHT improved structural uniformity, although a carbon-depleted zone remains near the fusion line (Figure 4h).

Figure 4.

Micrographs of R-STL-2-STL [with and without PWHT] (arrows indicate zones associated with local carbon depletion). (a) Deposited repair bead without PWHT; (b) deposited repair bead with PWHT; (c) initial bead without PWHT; (d) initial bead with PWHT; (e) fusion line without PWHT for P22; (f) fusion line with PWHT for P22; (g) fusion line without PWHT for P91; (h) fusion line with PWHT for P91.

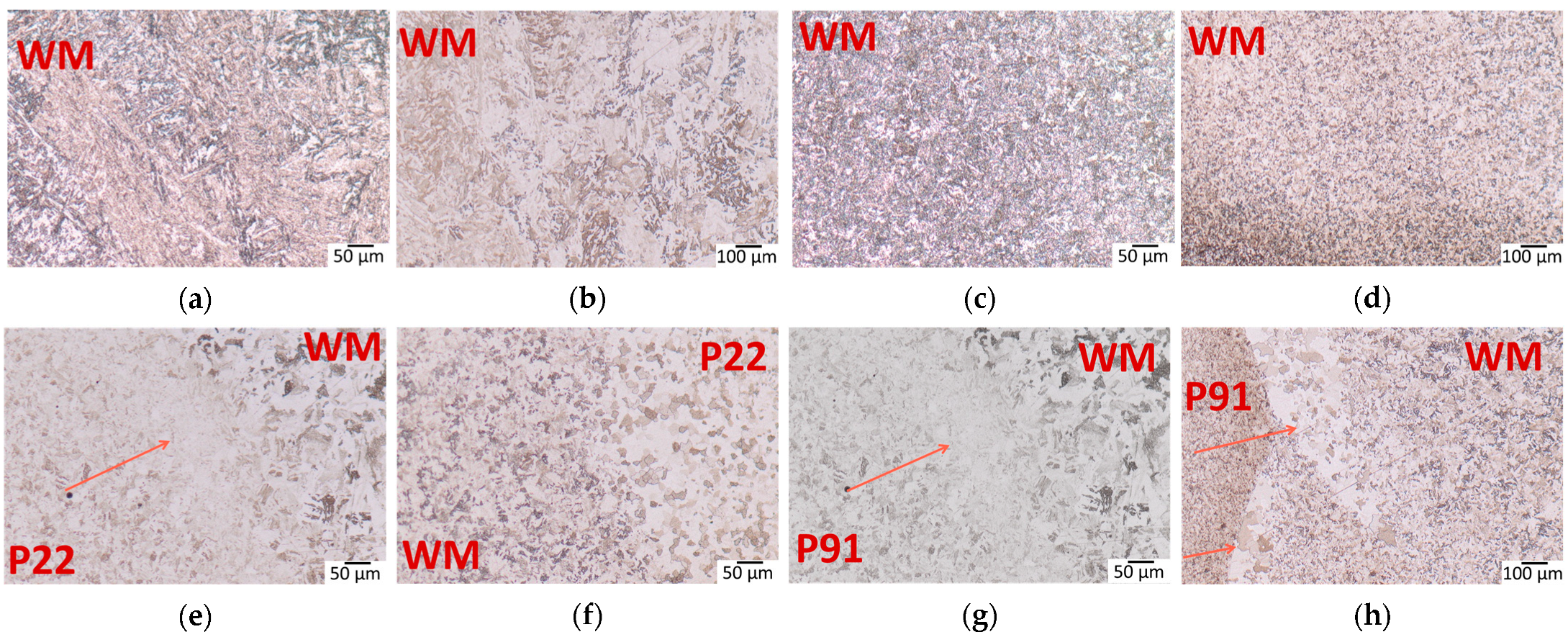

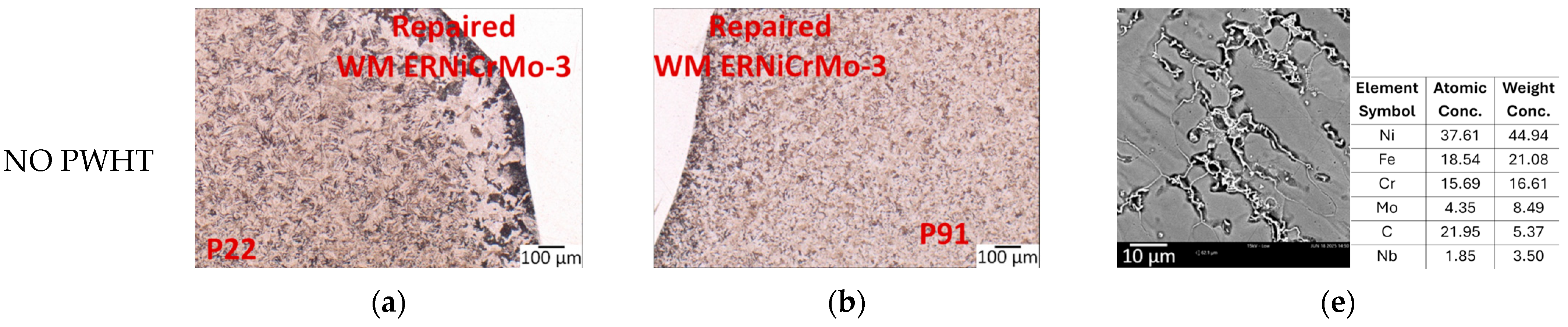

In the Ni→Ni (R-Ni-2-Ni) repair condition (Figure 5), the weld metal displayed similar dendritic austenitic structures as in the initial Ni welds, with pronounced interdendritic segregation and the formation of Laves phases (Figure 5e).

Figure 5.

Micrographs of Repair Ni-Based Filler to Ni-Based Filler [with and without PWHT] (a) without PWHT for P22; (b) without PWHT for P91; (c) with PWHT for P22; and (d) with PWHT for P91. (e) EDS analysis of Laves Phase (Fe,Ni,Cr)_2Nb/(Ni,Fe,Mo)_2Nb Nb-rich (NbC); (f) EDS analysis of Complex MC-type Carbide.

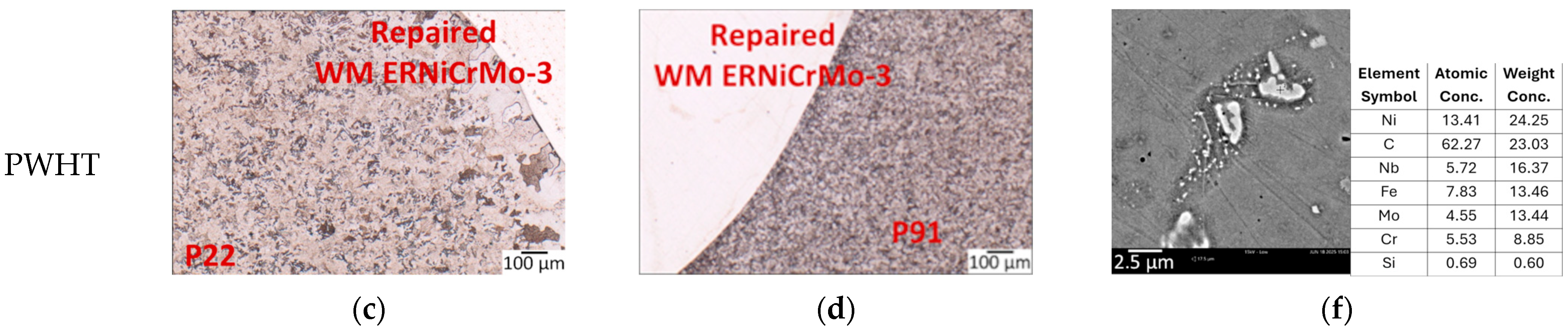

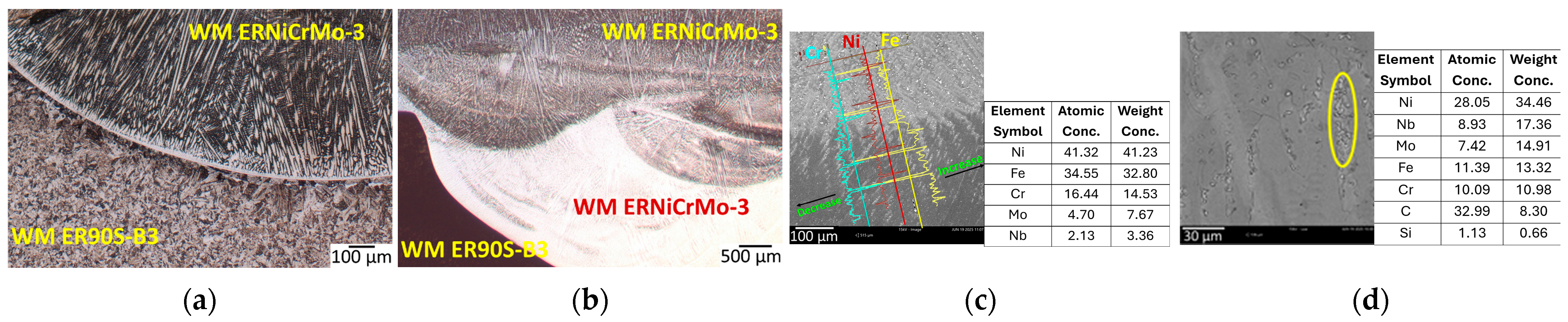

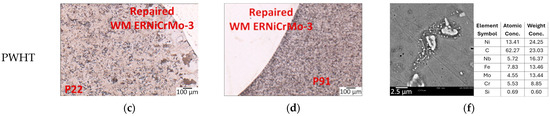

EDS spot analyses of the Laves phase (Figure 5e) revealed Nb enrichment of approximately 18–22 at.% together with Fe, Cr and Ni as a balance. The measured composition is consistent with the expected Nb-rich stoichiometry ((Fe,Ni,Cr)2Nb/(Ni,Fe,Mo)2Nb) reported in the literature [11,12,13], thereby confirming the identification of the phase, although such Nb-rich Laves phases are generally considered detrimental to the long-term creep performance of ferritic steels. PWHT reduced residual stresses and hardness but did not eliminate segregation-related phases. The Ni→Steel (R-Ni-2-STL) repairs revealed the strongest metallurgical gradients, with a sharp transition between tempered martensite (ER90S-B3) and columnar dendritic austenite (ERNiCrMo-3) (Figure 6). Dilution effects at the interface resulted in a mixed microstructure containing Laves phase and decarburized ferritic bands near the P91 fusion line. Even after PWHT, these features persisted, posing risks for creep damage (Figure 7).

Figure 6.

Micrographs of Repair Ni-Based Filler to Steel-Based Filler [with and without PWHT] (a) without PWHT for P22; (b) with PWHT for P22; (c) EDS analysis of Laves Phase; (d) EDS analysis of Complex MC-type Carbide (yellow circled area).

Figure 7.

Micrographs of Repair Ni-Based Filler to Steel-Based Filler Fusion Line [with and without PWHT] (a) without PWHT for P22; (b) with PWHT for P22; (c) without PWHT for P91; (d) with PWHT for P91.

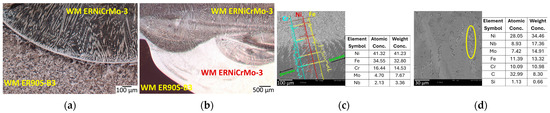

3.2. Hardness Measurements

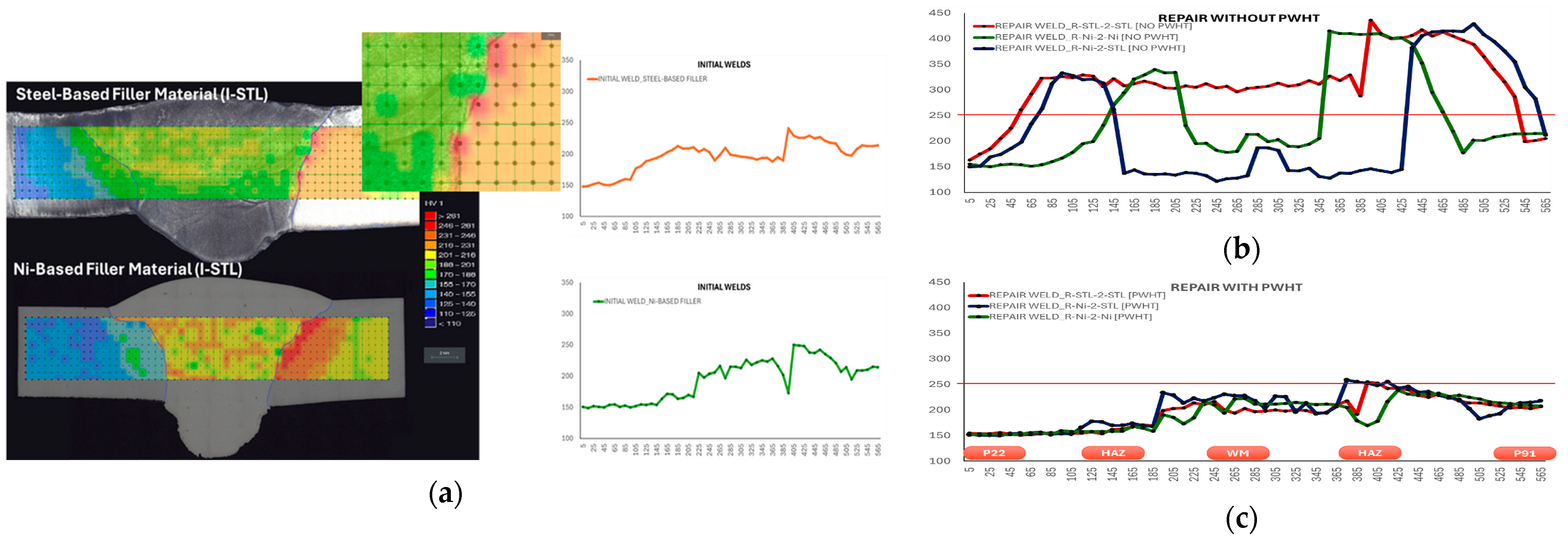

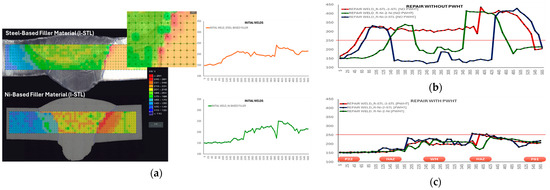

Microhardness mapping (HV1) across the P22–WM–P91 cross-sections provided insights into the influence of filler selection and PWHT on mechanical performance. For the initial welds, the ER90S-B3 filler produced relatively uniform hardness values, with weld metal hardness ranging between 220 and 260 HV and consistent profiles across both HAZ regions. The ERNiCrMo-3 welds showed slightly higher but more scattered hardness values, although they remained within acceptable post-PWHT ranges (Figure 8).

Figure 8.

(a) Microhardness measurements of the initial welds; (b) microhardness measurements of the repair welds without PWHT; and (c) microhardness measurements of the repair welds with PWHT.

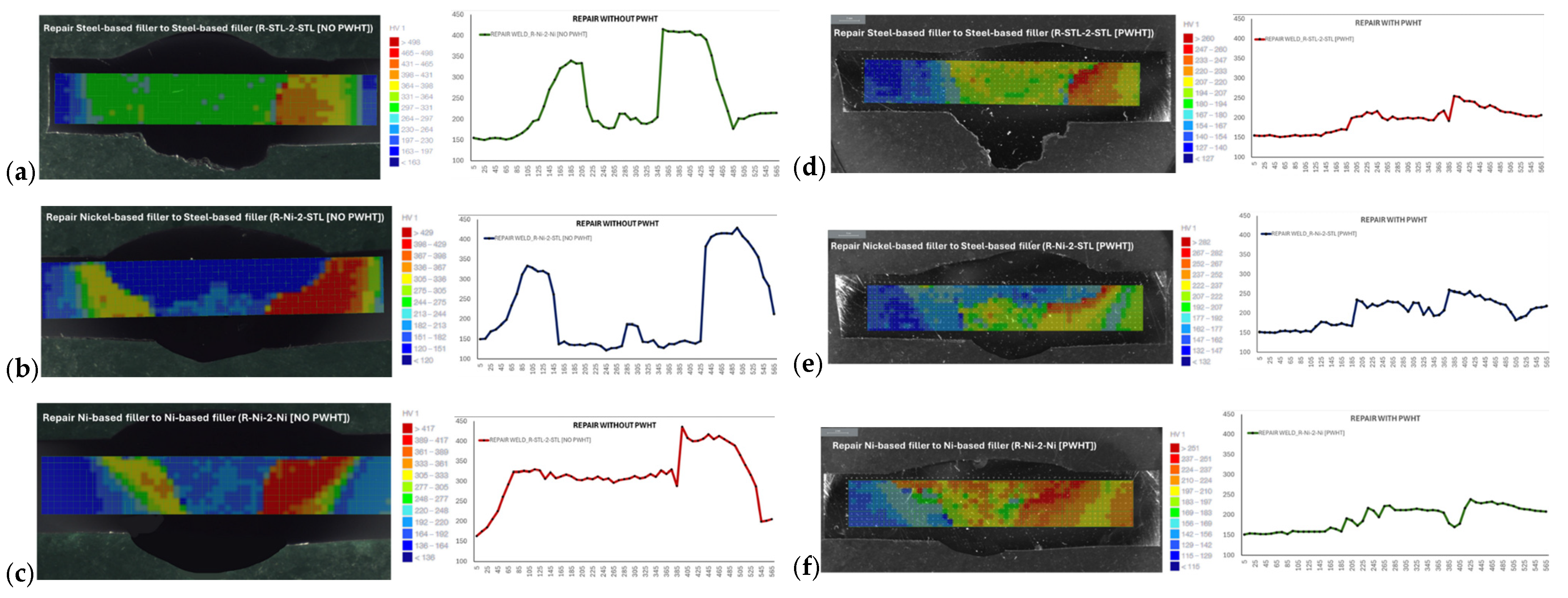

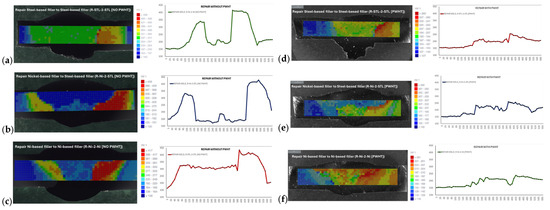

Repair welds without PWHT exhibited severe hardness fluctuations (Figure 9b). Steel→Steel and Ni→Steel repairs showed localized hardness peaks exceeding 400 HV, raising concerns of brittleness and cracking. The Ni→Ni repair displayed soft zones at the weld interfaces, with hardness values as low as 130–150 HV, leading to strength mismatch (Figure 9a–c). These extremes were effectively mitigated by PWHT, which produced homogenized hardness distributions between 180 and 260 HV in all repair scenarios (Figure 9c). Nevertheless, a notable drop in hardness was consistently recorded on the P91 side due to localized decarburization, particularly in Ni-containing repairs (Figure 9d–f).

Figure 9.

Microhardness mapping of the repair welds without PWHT. (a) R-STL-2-STL; (b) R-Ni-2-STL; (c) R-Ni-2-Ni. Microhardness mapping of the repair welds with PWHT; (d) R-STL-2-STL; (e) R-Ni-2-STL; (f) R-Ni-2-Ni.

4. Conclusions

Filler metal selection and post-weld heat treatment (PWHT) proved decisive for the performance of P22–P91 dissimilar welds. Welds with the steel-based filler ER90S-B3 developed tempered martensite with fine carbides, no δ-ferrite, and uniform hardness, confirming its superior metallurgical compatibility and creep resistance [1,2,3]. In contrast, Ni-based ERNiCrMo-3 welds exhibited dendritic structures with δ-ferrite, Nb/Mo segregation, and Laves phases, leading to localized soft zones in agreement with earlier studies [4,5,6]. Repair welds further increased heterogeneity: Steel→Steel repairs were the most stable after PWHT, while Ni→Ni retained segregation and Laves phase, and Ni→Steel showed the sharpest gradients with decarburization and mixed microstructures, consistent with literature on repair-related Type IV cracking and dilution effects [7,8,9,10]. PWHT was critical in homogenizing microstructure and hardness by lowering >400 HV peaks in Steel→Steel and Ni→Steel repairs and eliminating excessively soft zones (130–150 HV) in Ni→Ni welds, yielding values between 180 and 260 HV. However, Ni-containing welds retained persistent soft zones near the P91 fusion line that may initiate creep cracking. These observations corroborate reports that PWHT enhances reliability by tempering martensite and reducing residual stresses [11,12,13], though excessive tempering in P91 can promote soft-zone formation and compromise creep strength [14]. Overall, ER90S-B3 combined with proper PWHT provided the most reliable balance of microstructural stability and mechanical integrity, while Ni-based fillers, despite their corrosion resistance, introduced segregation and soft zones that may limit long-term creep performance. These findings align with service-exposed component studies linking failures to Laves phases and soft zones in P91 HAZ regions [15,16]. Thus, for both fabrication and repair welding of P22–P91 joints in USC/AUSC power plant applications, steel-based fillers with optimized PWHT remain the most suitable choice.

Author Contributions

Conceptualization, S.C.; methodology, S.C. and A.Z.; validation, S.C. and M.M.; investigation, S.C., A.Z. and M.M.; resources, S.C.; data curation, S.C. and A.Z.; writing—original draft preparation, S.C.; writing—review and editing, S.C.; visualization, A.Z. and M.M.; supervision, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

No funding was received for this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated for this study are available upon request to the corresponding author.

Conflicts of Interest

Author Aimilianos Zervas and Author Michail Mathioudakis were employed by the company PPC Inspectra. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Saini, N.; Mulik, R.S.; Mahapatra, M.M. Influence of filler metals and PWHT regime on the microstructure and mechanical property relationships of CSEF steels dissimilar welded joints. Int. J. Press. Vessel. Pip. 2019, 170, 1–9. [Google Scholar] [CrossRef]

- Dak, G.; Pandey, C. A critical review on dissimilar welds joint between martensitic and austenitic steel for power plant application. J. Manuf. Process. 2020, 58, 377–406. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, C.; Goyal, A. A microstructural and mechanical behavior study of heterogeneous P91 welded joint. Int. J. Press. Vessels Pip. 2020, 185, 104128. [Google Scholar] [CrossRef]

- Sun, X.; Che, C.; Qian, G.; Wang, X. Microstructure, hardness and creep properties for P91 steel after long-term service in an ultra-supercritical power plant. Int. J. Press. Vessels Pip. 2024, 212, 105330. [Google Scholar] [CrossRef]

- Kulkarni, A.; Dwivedi, D.K.; Vasudevan, M. Study of mechanism, microstructure and mechanical properties of activated flux TIG welded P91–P22 joint. Mater. Sci. Eng. A 2018, 731, 309–323. [Google Scholar] [CrossRef]

- Sauraw, A.; Sharma, A.K.; Fydrych, D.; Sirohi, S.; Gupta, A.; Świerczyńska, A.; Pandey, C.; Rogalski, G. Study on microstructural characterization, mechanical properties and residual stress of GTAW dissimilar joints of P91 and P22 steels. Materials 2021, 14, 6591. [Google Scholar] [CrossRef] [PubMed]

- Mayr, P.; Schlacher, C.; Siefert, J.A.; Parker, J.D. Microstructural features, mechanical properties and high temperature failures of ferritic to ferritic dissimilar welds. Int. Mater. Rev. 2018, 63, 227–250. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.M.; Kumar, P. Fracture behaviour of crept P91 welded sample for different post weld heat treatments condition. Eng. Fail. Anal. 2019, 95, 18–29. [Google Scholar] [CrossRef]

- Arivazhagan, B.; Vasudevan, M. Studies on A-TIG welding of 2.25Cr-1Mo (P22) steel. J. Manuf. Process. 2015, 18, 55–59. [Google Scholar] [CrossRef]

- Sirohi, S.; Gupta, A.; Pandey, C.; Vidyarthy, R.S.; Guguloth, K.; Natu, H. Investigation of the microstructure and mechanical properties of the laser welded joint of P22 and P91 steel. Opt. Laser Technol. 2022, 147, 107610. [Google Scholar] [CrossRef]

- Kumar, S.; Yadav, V.K.; Sharma, S.K.; Pandey, C.; Singh, R.; Gupta, A. Role of dissimilar Ni-based ERNiCrMo-3 filler on microstructure, mechanical properties and residual stresses of P91 welds. Int. J. Press. Vessels Pip. 2021, 193, 104443. [Google Scholar] [CrossRef]

- Srikanth, A.; Subramani, P.; Kannan, V.; Shanmugam, N.S. Investigation on microstructure, micro-segregation and mechanical properties of GTA weldment of Alloy 600. Mater. Today Proc. 2018, 5, 13244–13250. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, M.; Xu, L.; Chu, Y. Effect of dendritic structure and secondary phases on the fatigue behavior of ERNiCrMo-3 weld metal. Int. J. Fatigue 2024, 180, 108113. [Google Scholar] [CrossRef]

- Singh, B.J.; Kumar, P. TIG Welding P22 and P91 Steels: Behavior Analysis and Sustainable PWHT. Master’s Thesis, MM University, Ambala, India, CIPET, Jaipur, India, 2020. [Google Scholar]

- Mahajan, S.; Chhibber, R. High temperature molten salt corrosion investigations on P22/P91 power plant dissimilar welds. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2020, 234, 123–132. [Google Scholar] [CrossRef]

- Ioannidou, D.; Foinikaridis, M.; Deligiannis, S.; Tsakiridis, P.E. Microstructural evaluation of Inconel 718 and AISI 304L dissimilar TIG joints. Metals 2024, 14, 54. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).