Abstract

The construction industry is increasingly adopting digital technologies to enhance productivity and efficiency, in alignment with the principles of Construction 4.0 (C4). The progress and advances recorded thus far are largely due to advancements in cyber-physical systems (CPS), computational processing power, deep learning solutions, robotics, and other related technologies. However, a major challenge in this research space is the lack of an integrated solution for both the interior and exterior construction environments, which has led to fragmented data, hindering efficiency. Several researchers have proposed frameworks in recent years that focused on either indoor or outdoor construction environments; this approach has resulted in the creation of siloed information, to the detriment of the C4 ideals and principles. In this study, a comprehensive system architecture for raw data captured using sensors and other inputs to provide useful insight for the construction team and stakeholders was mapped out. This study presents an integrated framework of various technologies for both indoor and outdoor construction environments. The solution provided for localisation algorithms and technologies such as Simultaneous Localisation and Mapping (SLAM), odometry, and inertial measurement unit (IMU) devices. The unified 5-level Cyber-Physical Systems (CPS) architecture was used as the primary architecture, and it was compared with the IoT Architecture layers in terms of data analytics and management perspectives. The Digital Twin (DT), which sits at the cyber level of the architecture, warehouses and tracks in real-time the dynamic complexities of the construction site throughout the project life cycle, serving as the single source of truth for the project. This system architecture and framework presented in this research contributed towards advancing the field of construction automation by offering a scalable solution for efficient construction in project management.

1. Introduction

The planning and implementation of large and complex construction and installation projects are often rife with cost overruns due to schedule delays and rework [1]. This is often a result of improper constructability considerations at the design phase of the project and inaccurate schedule and cost estimates at the planning phase. This can also be a result of the inability to properly capture, access, and respond correctly to the variabilities that arise from the dynamic nature of the construction and installation site [2]. This study focuses on creating an integrated framework for capturing construction activity data and variations from project baselines during the construction and installation phase of the project lifecycle, utilising emerging technologies.

Traditionally, construction activities are captured in logbooks and photographic images, which are later transferred into project report templates and fed into the construction management software manually. This workflow leaves a lot of room for error due to mistakes as a result of human fatigue and other factors. The data and information collected are also often siloed within each discipline, department, and subcontractor’s repository/databases [3]. This creates friction in the flow of information, impacting the ability of the project management team to make data-driven decisions based on the current state of the construction and installation project. The data/information captured is also sometimes subjective [2], and often lacks positional context, as similar geometry and aesthetics can be found at different locations within the construction site.

To bridge the gap highlighted, information technology systems are used to bridge the physical and digital aspects of the construction industry. While the use of technology is not new to construction, the level of connectedness, speed of execution, and cost of execution are rapidly making it ideal for the construction engineering and execution phase, as well as for the entire project lifecycle. Embedded cyber-physical systems are enabling this integration towards the goal of C4 [4].

The technology adoption rate in the construction industry lags behind that of other sectors, such as manufacturing [5]. This has resulted in low productivity, cost overruns, and safety issues, among others [6]. However, there has been an increase in the adoption rate of technology in the fourth industrial revolution (4IR) era.

There are several emerging technologies—Cyber-Physical Systems (CPS), Internet of Things (IoT), Big Data, Cloud Computing, Wireless Sensor Networks (WSN), and Radio Frequency Identification—that are now being adopted to reduce mistakes and provide objects (data and visual images) with the metadata that provides the context that previously lacked. These IT systems come as standalone or integrated embedded systems, which include physical environment, embedded computing devices, and smart objects that indicate real-time data that are processed into the workflow and then provide insights that are used by the construction project management team for making project decisions.

Construction 4.0 (C4), inspired by Industry 4.0, has emerged as a paradigm shift emphasising the integration of cyber-physical systems (CPS), automation, and data-driven decision-making to enhance efficiency and sustainability to eventually achieve autonomous intelligent systems in the construction industry. The key enablers include Internet of Things (IoT) sensors, robotics, building information modelling (BIM), and artificial intelligence (AI), which facilitate real-time monitoring and predictive analytics [5]. It is important to note that the goal of C4 is not to digitalise our current construction approaches and workflow, but to re-imagine an autonomous, self-adapting intelligent system that dynamically responds to variation and trends outside the established project baseline [7].

The outdoor construction industry exhibits far more complexity, variability and uncertainty compared to manufacturing, which is mostly characterised by repeated operations to produce a specific product in a controlled environment. This means directly adopting the Industry 4.0 principle (the foundation for C4) is not recommended [4].

There are several data collection points in a project’s construction activities. The data is typically siloed in separate repositories and databases across different disciplines. There is therefore a need to create a framework that synchronises and coordinates data from various cyber-physical data sources into an operable and optimisable data storage that can be turned into insight for all technical teams and other stakeholders [4].

1.1. Problem Statement

Despite these advancements in the adoption of IT in construction, a significant gap persists: the existing frameworks for construction progress monitoring focus either on indoor or outdoor environments. The two environments employ different systems due to the distinct nature of lightning, occlusions, and satellite access, among other variables that vary between the two environments. For instance, outdoor monitoring often relies on drones and GPS-based systems, while indoor solutions utilise fixed cameras and RFID tags. This fragmentation results in inefficient data management, delayed decision-making, and increased project risks. It is therefore imperative to develop an integrated framework that highlights the differences, limitations, and mitigating/bridging approaches. A major challenge faced in this research space is the lack of an integrated solution for both the interior and exterior construction environments has led to fragmented data, hindering efficiency.

The outdoor–indoor paradigm is basically that of a difference in the efficiency of the sensors used. It is important to ensure that the dichotomy is grounded in an integrated workflow for implementation. Therefore, a systems architecture that showcases the overall flow of data and information, highlighting the systems and technologies involved from data collection to insight and from perception to cognition, is included.

Recent studies have explored partial solutions that focus on the combination of different technologies. For example, automated progress monitoring models using lidar scan capture, as well as a photogrammetry approach, a computer vision (CV) technique that utilises convolutional neural networks (CNNs), reconstruct site images to form a 3D model of the site. Several combinations have been proposed for the indoor and outdoor site environment, based on cost, internet access, satellite access, and lightning conditions, among other limiting factors. Other researchers embedded IoTs into the workflow to achieve a digital twin (DT). Digital Twins (DTs) have gained traction for lifecycle management, offering virtual replicas that synchronise with physical assets via IoT and BIM integration. However, only a few frameworks address the integration of indoor and outdoor monitoring within a unified DT ecosystem.

1.2. Research Objectives

The objectives of this research are to develop an integrated framework for automated construction progress sensing, monitoring, and evaluation. This was carried out at two levels. These include:

- Highlight the system architecture that highlights the connectivity of different data collection, process and executing layers of the construction management operation in the Construction 4.0 context. Many segmentation perspectives will be considered within the framework.

- The study also highlights an integrated framework that highlights the complementary use of sensors in an indoor and outdoor construction environment.

1.3. Research Contributions

There is an increasing need for civil and construction workers to not only understand the art of construction, but also IT skills, especially sensing technologies and data analytics knowledge, to function in the current data-driven construction practices. While many researchers have discussed the different aspects of technological use in construction, it is important to present a big-picture, top-down, systems approach in order to see how they are all connected.

This study addresses the gap highlighted by first presenting a system architecture of a construction site management using the unified 5-level Cyber-Physical Systems (CPS) architecture [8], and the broad architecture was delineated to focus on the integrated framework for construction progress sensing, monitoring, and evaluation. The integrated framework combines sensors, the fundamental building block for perception. It combines them to achieve localisation technologies (e.g., Simultaneous Localisation and Mapping (SLAM), odometry, Inertial Measurement Units (IMUs), cameras, CPS, and IoT sensors); deep learning (computer vision (CV)); and BIM within a DT platform. The objective is to enable automated, real-time progress sensing, monitoring, and evaluation for both indoor and outdoor environments, promoting scalable C4 adoption. This research contributed towards advancing the field of construction automation by offering a scalable solution for efficient construction in project management through the use of an integrated framework.

2. Related Works

Ref. [9] posited that a huge amount of live data is being collected when Internet of Things (IoT), CPS smart devices, and construction management software (such as BIM and Construction Intelligence (CI)) are deployed on a construction project. The data being collected is often siloed in heterogeneous repositories; therefore, there is a need to create an integrated framework that takes a system-driven perspective, which is what the integrated framework being worked on aims to achieve. They developed a Service-Oriented-Architecture (SOA) that combines software and other services. Their architecture improved on the traditional, static, one-way interactive 3D-BIM approach that focuses on the semantic, geometry, function and feature information of a construction project, and fails to provide information about the current state of the outdoor or indoor conditions of the construction site, to a more dynamic, two-way interactive, cognitive model that indicates all the aforementioned information. The SOA integrates high-fidelity BIM and real-time IoT devices that are used by other construction management applications to provide construction insight for the CPT. They also discuss the challenges, limitations, and barriers that face BIM–IoT integration, such as interoperability issues and Cloud computing. The focus on their integrated framework is on the operational construction and facility management domain in the construction lifecycle.

Ref. [4] proposed a strategic roadmap for synchronised construction management that coordinates and maintains relationships between construction activities in a spatial-temporal scope. Their framework integrates CPS into the digital twin. They emphasised the achievement of a human-centred, sustainable, and resilient C4. Ref. [10] developed a pilot indoor/enclosed navigation project using mobile phone standard 5G as the orientation signal and without additional infrastructure for navigation in indoor environments managed by a pedestrian site worker.

Ref. [11] used the integration of Point Cloud Data and IoTs (real-time sensor data) to monitor the concrete strength and the concrete curing process, and worker safety. They presented an integrated smart construction monitoring system that combines point cloud data (PCD) from a 3D laser scanner with real-time IoT sensors and ultrawideband (UWB) indoor positioning technology to enhance construction site safety and quality management. Their system mitigates the limitation of the traditional Building Information Management (BIM)-based methods by leveraging high-precision PCD that accurately reflects actual site conditions.

2.1. Construction Management Data

During construction management activities, data is being used to plan, execute, monitor, evaluate, and optimise the construction of the project to prevent schedule and cost overruns. The generated data drives data-driven decisions, enhances efficiency, improves safety, and mitigates risks. Traditionally, the data is collected manually and recorded in logbooks or stored in databases. It can either be real-time and historical data on process efficiency, resource utilisation, site conditions, progress status and performance metrics. In the C4 era, digital technologies are used to collect data through various sensors, integrated cyber-physical systems and are then stored/warehoused in the enterprise data infrastructure.

The construct management data includes:

- Project management data integrates into BIM, which includes project schedules, costs, timelines, progress monitoring, safety metrics, and workflows (e.g., integrated via Building Information Modelling or BIM).

- Project resource data, these are materials, equipment, and labour information captured from the staff clock-in database, RFID and sensors data.

- Site environmental data, which includes weather or terrain conditions. These are captured from drones or IoT sensors.

- Simulation and visualisation data captured from digital models for design, reconstruction, and virtual simulations.

Construction 4.0—representing the digitisation and automation of the industry—employs advanced technologies for real-time, data-driven approaches, integrating cyber-physical systems for seamless collaboration and decision-making.

2.2. Construction Progress Sensing, Monitoring and Evaluation

Construction Progress Sensing, Monitoring and Evaluation (CPSME) is an important aspect of construction management that allows visibility into the current state of work at the construction site. This information enables the construction management team (CMT) to adequately respond to the complex and dynamic nature of construction sites.

The adoption of digital technologies such as sensors on construction sites affords the CMT with the data and visibility required to make data-driven and context-aware decisions, as opposed to the traditional approach that is riddled with human error from data collection and transfer. This has led to increased productivity and project success. Making traditional evaluation methods based on manual data collection and direct observation less effective [12].

Construction 4.0 is based on the principle of integrated information between the people, process, and the product (built environment assets). It adopts emerging technologies and algorithms to improve efficiency and productivity in the way construction assets are managed through their lifecycles [13].

2.3. Description of Key Technologies in the Integrated Framework

Before the proposed integration is discussed, the core technologies in the framework must be discussed. Due to space constraints, only the major technologies will be discussed below.

2.3.1. Sensors

Sensors are devices that detect and measure physical properties or environmental conditions and convert this data into electrical signals for processing. In the construction management context, sensor-enabled technologies like GPS, LiDAR, and IoTs are used to monitor progress, ensure safety, and optimise resource use. These are the foundational elements of the integrated framework proposed. Sensors include tilt sensors, vibration sensors, strain sensors, moisture sensors, gas sensors, and thermal sensors.

2.3.2. Embedded Systems

Embedded systems are the integrated computing systems within devices that process sensor data locally, enabling smart functionality in tools like drones or machinery. They include microcontroller or microprocessor and software designed for a specific task.

2.3.3. Internet of Things (IoT)

IoTs are networked embedded systems that connect sensors and devices for data sharing and remote monitoring over the internet. In IoTs, a Microcontroller Unit (MCU) acts as the “brain” of an IoT device, a small, self-contained computer on a single chip that collects sensor data runs the device’s software, makes decisions, and controls operations. MCUs are ideal for IoT because they are simple, cost-effective, and have integrated memory and I/O peripherals. They enable devices to be portable, battery-powered, and communicate wirelessly with gateways and the cloud to collect, process, and transmit data for monitoring and control purposes.

IoT is an architecture of interconnected IoT devices that send information into and from a digital environment, such as BIM, to create a common operating environment. IoT devices are composed of advanced hardware (sensors and actuators), software, and cloud platforms. IoT sensor devices can sense, identify, and recognise changes in environmental conditions, construction elements and people’s activities on the construction site.

IoT extends the capabilities of embedded systems by adding internet connectivity. IoT devices can collect, share, and analyse data from their environment through networks, enabling remote monitoring and control. Think of smart homes, connected cars, and industrial IoT applications that rely on cloud-based analysis and real-time data sharing. In summary:

Embedded Systems = Hardware + Software for specific tasks, while

IoT = Embedded Systems + Internet Connectivity for smarter interactions.

2.3.4. Cyber-Physical Systems (CPS)

CPS integrates physical processes with computational and networking capabilities, using IoT to bridge real-world assets and digital controls for automated responses. Ref. [14] defined CPS as “a system composed of collaborative entities, equipped with calculation capabilities and actors of an intensive connection with the surrounding physical world and phenomena, using and providing together services of treatment and communication of data available on the network.”

CPS is a vital enabler of C4, which is used to sense and collect data concerning the physical state of construction elements and resources, and then used to gain insights into their integrated and simulated digital equivalent state. According to [8], CPS are composed of two broad sub-systems: (1) advanced connectivity, and (2) intelligent data management, analytics and computational capability [15]. In addition to CPS, Cyber-Physical Production System (CPPS) is another component of Industry 4.0 that provides data anywhere and anytime, enabling a strong connection between the cyber world and the physical world and its ongoing processes.

2.3.5. Building Information Modelling (BIM)

BIM is the digital representation of building characteristics, serving as a collaborative platform for design and data management. Ref. [16] defines BIM as “a model-based process of generating and managing coordinated and consistent building data that facilitates the accomplishment of established sustainability goals.”

BIM is a visualisation and collaboration tool that warehouses and displays the geometric interaction of construction elements, as well as the functional and semantic information about the elements, being carried out by the different architectural, engineering and construction (AEC) disciplines in the achievement of a construction project’s objectives [17]. BIM is a data-rich, intelligent, and object-oriented parametric building modelling tool. They warehouse outputs from different software programmes and database contents for the management of construction visualisation and management of construction activities. BIM integrates a digital archive of geometric, semantic, and topological data, which can be performed in various formats and contents within parametric objects.

While many software packages are used to create BIM models. Most of the popular software has not adopted the open data formats, like the most widely used formats—the Industry Foundation Classes (IFC) from buildingSmart. To achieve the goal of C4, data interoperability must be encouraged.

2.3.6. Virtual Design and Construction (VDC)

VDC uses BIM and simulation tools for virtual planning, testing, and optimisation of construction and installation processes before physical implementation.

2.3.7. Digital Twin (DT)

DT is a dynamic virtual replica of physical assets, synced in real-time with sensor data via IoT and CPS, for predictive simulation and lifecycle management. DT is ideally a high-fidelity, fully automated, closed-loop system which creates a bidirectional flow of data between the construction site and virtual digital construction software applications. It is used to simulate, monitor, and predict the performance of a construction site, and can also be used for decision-making and control of construction management variables. DT warehouses several site monitoring technologies such as sensing technologies, BIM, AI algorithms, etc. [18].

Ref. [6] posited that the concept of Digital Twin is associated with Cyber-Physical integration. The developed framework incorporated a project construction site Digital Twin (DT) that tracked the dynamic nature of the construction site throughout the project life cycle from conceptualisation to end-of-life, as a single source of truth for the project. The dynamic aspects incorporated improve situational awareness for the CMT.

2.3.8. Construction 4.0 (C4)

C4 is the overarching concept that brings together all the above-listed elements to achieve an advanced digitisation, automation, and connectivity of the AEC industry [19,20]. C4 uses centralised data warehousing to achieve data-centric construction engineering and management. The warehoused data is often used for applications such as Computer Aided Engineering (CAE), BIM, VDC, etc. To achieve this, several sensing devices are used for data capture, and data analytics algorithms are data processing.

The use of information and communication technologies (ICTs) in the construction industry has evolved from the use of Computer Aided Engineering (e.g., Computer Aided Design (CAD) and Drafting (CADD), structural analysis programmes) to BIM, often described as Construction 3.0 (C3). In C3, human agency is the connection between the physical construction site and the digital construction information systems [7]. However, with the proliferation of sensors and controllers used in IoTs and CPS, the construction workflow is gradually reaching a stage where human intervention is being reduced and is often limited to that of an accessor and decision-maker at the insight stage, rather than the connection stage. The new workflow is often called digital transformation or Construction 4.0 [5].

To achieve a real-time and dynamic visualisation, perspective, and situation awareness of the construction site, various streaming sensors are deployed.

2.3.9. Intelligent Systems

This is the pinnacle of the systems. At this stage, the system is autonomous and closed-loop. It is AI-driven systems that leverage data from the entire chain for autonomous decision-making, optimisation, and predictive analytics in construction. This is equivalent to the configuration layer of the Unified 5-level CPS implementation architecture (5C Architecture) by [8].

2.4. Indoor–Outdoor Sensor

Unlike exterior maps of a construction site, which can be managed using drones and static cameras, the indoor areas cannot be universally mapped due to partitions, walls (mainly x-z or y-z oriented), floors (mainly x-y oriented), obstructions, and occlusions that make data capture extremely complex. Therefore, 3D site reconstruction is relatively easier for outdoor environments, as there are fewer obstructions and partitions [7]. Unique challenges arise when sensors are deployed in indoor and outdoor environments for construction progress sensing, monitoring, and evaluation. These challenges are environmental, technological, and operational in nature.

2.4.1. Indoor Sensors Limitation

In indoor environments, issues include: (1) satellite signal blockage caused by walls, roofs, and other structures, which severely weaken or obstruct signals indoors. As an alternative to GPS, technologies like UWB, BLE, Wi-Fi, and IR can be used; however, they are affected by (2) multi-path interference resulting from reflections of signals off walls, furniture, and equipment, which reduces the accuracy of positioning and localisation. These alternative technologies also have (3) a limited operational range, typically around 100 metres or less. Other limitations involve (4) environmental factors such as dust, humidity, and temperature fluctuations common on construction sites, which can impact sensor performance—particularly optical sensors in RGB cameras and environmental sensors measuring temperature and humidity. (5) The constant movement of machinery and personnel can cause line-of-sight issues, with some IR and UWB applications requiring direct line-of-sight that may be blocked by construction materials or machinery indoors.

2.4.2. Outdoor Sensors Limitation

The challenges of the sensors operating in an outdoor environment include: (1) weather conditions such as rain, fog, snow, or extreme sunlight, affecting visibility and signal quality, thereby impacting the behaviour of sensors like LiDAR, RGB cameras, and GPS. (2) The presence of tall buildings, trees, or terrain can block or weaken satellite signals, leading to reduced accuracy or dropout zones. (3) Due to the remote nature of some construction sites, long-range signals like LoRa, SigFox, and GSM can degrade due to poor network coverage or interference from natural obstacles. (4) Outdoor sensors, such as IoT devices and GPS trackers, may suffer from battery life limitations, leaving the sensors non-functional. (5) The exposure of the sensors to harsh climate conditions (such as UV radiation, moisture) can cause physical damage to sensors like RFID tags, cameras, and IMUs over time.

2.4.3. Indoor–Outdoor Sensors Corrective Measures

To address the issues in indoor systems, it is crucial to use hybrid systems (e.g., UWB with IMU) and install repeaters or anchors to extend range and enhance signal reliability. For outdoor sensors, weather-resistant casings should be employed, and redundancy should be incorporated into the sensor network. For example, in a terrestrial system, LoRa can be used alongside GSM. Additionally, regular calibration, robust data filtering (e.g., Kalman filters), and strategic sensor placement are vital.

2.5. Positioning, Localisation, and Navigation (PLN)

When using an integrated and embedded sensor device, such as those in hand-held capture devices (like cameras, robots, and drones), it is crucial that they can determine their position and localise themselves within their environment before navigating to their destination, if necessary. Positioning refers to establishing the precise spatial reference (e.g., latitude and longitude) in global coordinates of the sensor, whether in a device, machine, or person, while localisation involves tracking the sensor’s location, movement, and orientation within its environment. Positioning typically employs technologies like Global Positioning System (GPS), Global Navigation Satellite System (GLONASS), or inertial sensors, whereas localisation depends on data from maps, sensors, or real-time location systems (RTLS).

Navigation involves moving a sensor from point A to point B. The sensor, drone, or robot first determines its position through ‘localisation’ and then navigates to its destination. The need to identify precise locations for various applications is unavoidable; these include surveying, navigation (automobile, aviation, maritime), tracking, mapping, earth observation, mobile phone technology, rescue operations, and more [21].

For outdoor environments (land, sea, and air), satellite-based positioning, navigation, and timing via Global Navigation Satellite Systems (GNSS) such as the US’s GPS, Russia’s GLONASS, Europe’s Galileo, and China’s BeiDou, offer users accurate location, speed, and time information through signals transmitted by these satellites. This is possible because of their open-space access to satellites, which enhances signal reception for devices. However, indoor environments and enclosed spaces require specialised solutions that serve limited buildings or users, as GNSS does not function in such environments. Large building complexes and connected facilities may also necessitate navigation aids [10,21].

2.6. Implementation Approaches, Algorithm, and Technology Deployed in Positioning, Localisation and Navigation in Indoor and Outdoor Environments

To achieve the best PLN result for both indoor and outdoor environments, Table 1 presents the implementation approaches, the algorithm and the technology to be deployed in each of the approaches.

Table 1.

PLN implementation approaches, algorithms, and technology for indoor and outdoor environments.

2.7. Deep Learning and Computer Vision

For automated construction progress sensing, monitoring and Evaluation purposes, computer vision in construction utilises Convolutional Neural Networks (CNNs) like YOLOv8 and Mask R-CNN to perform tasks such as object detection and progress estimation with an acceptable level of accuracy [22]. They are often used to identify structural elements like columns, beams and slabs, as well as construction elements wet and dry wall, at different levels of completion (from framing to paint). Images captured from a 360-degree camera are also often 3D-reconstructed and compared with the BIM geometry and metadata [23]. The two are used to detect deviation, evaluate the progress of work against the baseline project schedule. Training these models requires annotated construction site images, often leveraging transfer learning from pre-trained models on datasets like COCO, with fine-tuning to address domain-specific challenges such as diverse lighting or limited dataset availability.

Vision-Based Progress Monitoring

Different techniques are used to monitor and estimate construction progress using computer vision using imaging sensors. They are explained below [24].

- Occupancy-based progress monitoring: This technique compares the elements present in the 3D-BIM models with the presence or occupancy of construction elements in the 3D-reconstructed. The 3D reconstruction from point clouds from photogrammetry and laser scans focuses on geometric and spatial accuracy.

- Appearance-based progress monitoring: This technique uses machine learning (ML)-assisted construction material classification using the textures, colours, or patterns of the construction elements in the images or videos captured by the 360-degree cameras.

- Deep learning-based progress monitoring: This technique employs deep learning models, such as Convolutional Neural Networks (CNNs) like YOLOv8 or Mask R-CNN, to detect and classify construction elements present in the images and videos captured by the 360-degree camera.

Other approaches include photogrammetry-based progress monitoring, augmented Reality (AR)-based, thermal imaging-based progress monitoring, and stereo vision-based Progress Monitoring

3. System Architecture and Integrated Framework

To fully deploy C4, it is important that business executives, engineers and decision-makers in the Architectural, Engineering and Construction (AEC) space understand what the system architecture of an integrated construction operations system that caters for the entire project lifecycle is like. It is therefore important to present the system perspective for clarity of execution. The presented system architecture will advance the field of construction automation by offering a scalable solution for efficient construction project management operations.

3.1. Review of the Previous Framework

Construction sites are highly dynamic environments characterised by continuous changes in workers, machinery, and equipment, making prediction challenging [11]. Preventing construction site accidents requires systematic management and continuous monitoring across various dimensions.

Ref. [25] posit that IoT and communication technologies, such as Cellular Communications (LTE, 5G), Bluetooth Low-Energy (BLE), Wi-Fi, and UWB, enhance safety by enabling real-time data collection and alert notifications. Individual sensing technologies are suitable tools for monitoring construction sites. However, most existing research focuses on specific technologies and limited scopes, with insufficient studies addressing comprehensive monitoring for areas such as worker safety management and quality control [11]. Ref. [6] conducted an extensive literature review of C4 and developed a four-layer implementation plan for adoption throughout the project’s lifecycle, using a case study approach. Their work presented an integration framework for nine C4 technologies. These are BIM, augmented reality (AR), and virtual reality (VR). Ref. [8] proposed an architecture that leverages CPS to bridge physical and digital realms. With sensors as the core for real-time data collection, the unified 5-level architecture can guide the deployment of CPS. The proposed architecture expanded the traditional two functional components of CPS, which they described as “the advanced connectivity that ensures real-time data acquisition from the physical world and information feedback from the cyber space; and intelligent data management, analytics and computational capability that constructs the cyber space.”

3.2. Framework Overview

The proposed integrated framework is structured as a multi-layer system inspired by C4 implementation models, comprising data acquisition, processing, integration, and visualisation layers. The unified 5-level CPS implementation architecture, as proposed by [8], is adopted as the base architecture. The architecture is analysed from the perspective of data extraction and acquisition, data analysis, data engineering, and data management.

3.3. Unified 5-Level CPS Implementation Architecture (5C Architecture)

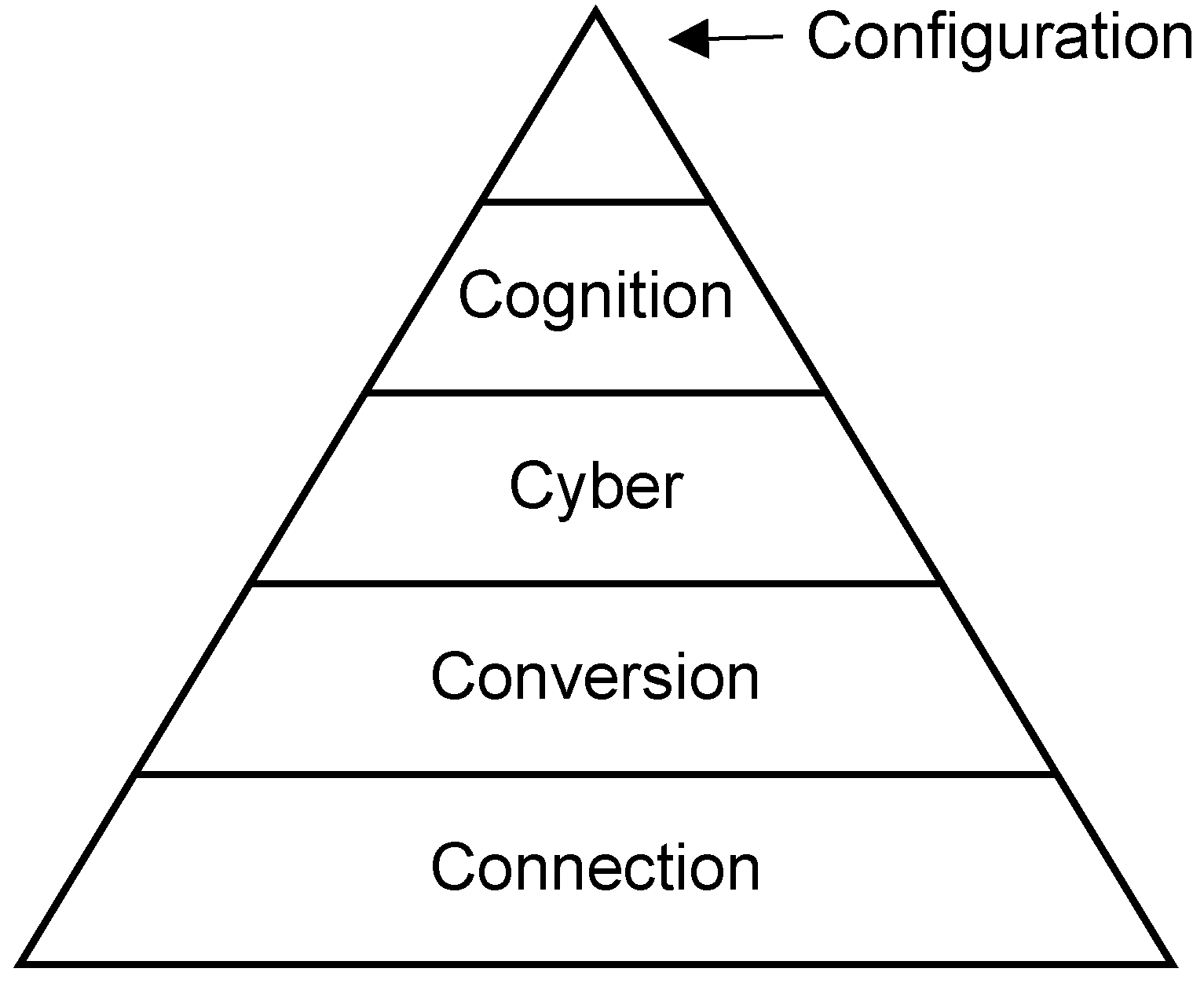

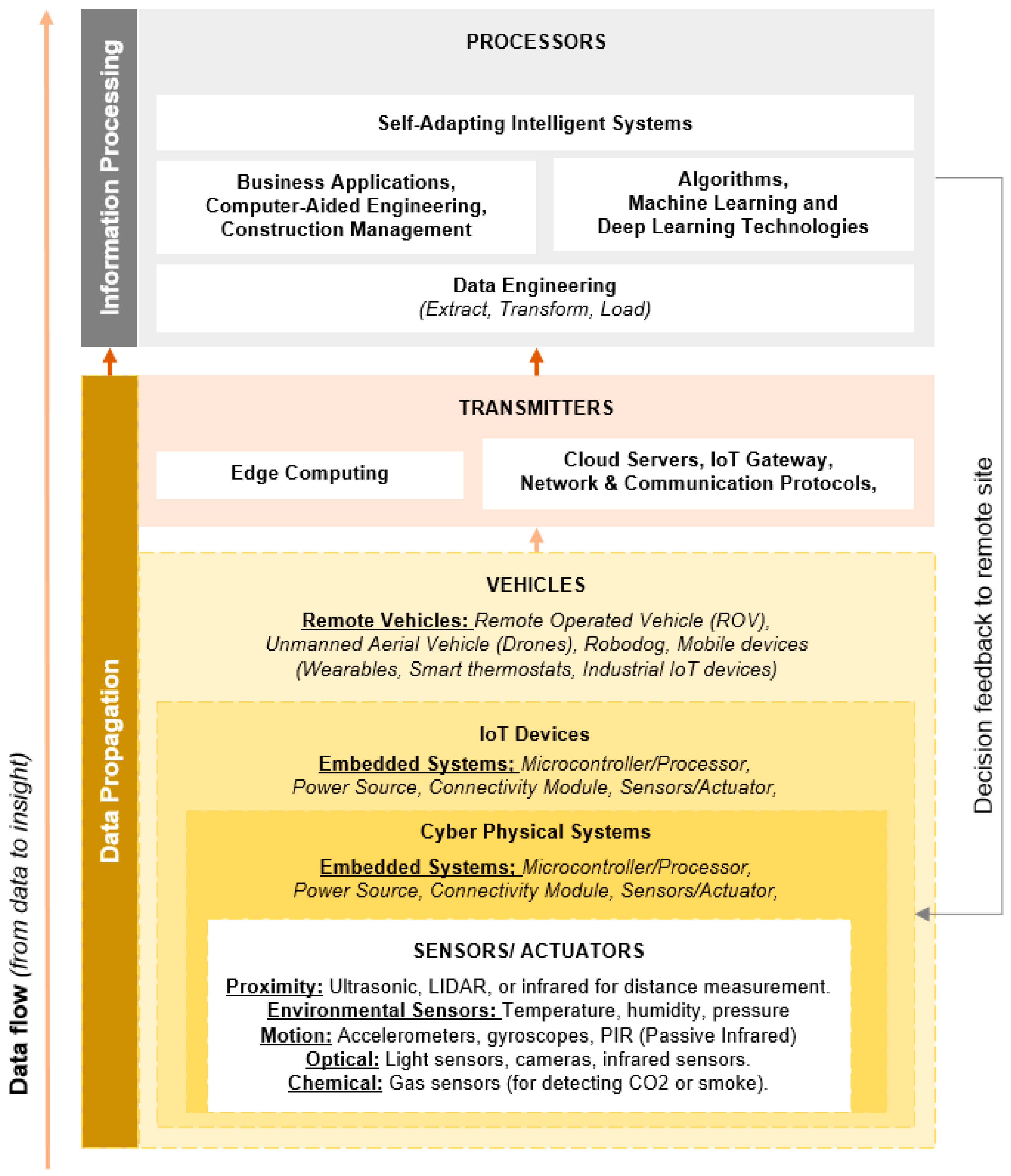

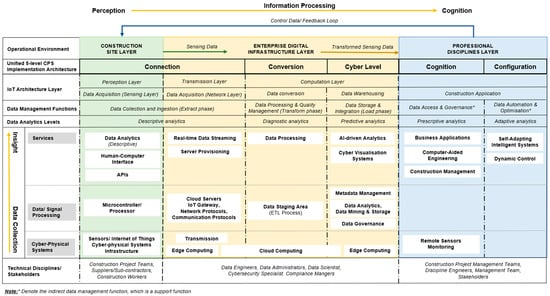

The unified 5-level Cyber-Physical Systems (CPS) architecture, commonly known as the 5C architecture, serves as a guideline for implementing CPS in Industry 4.0 (I4) manufacturing environments. 5C structures the progression from raw data acquisition to advanced system adaptation. Levels of data analysis (or analytics maturity) align closely with these 5C levels, evolving from basic descriptive processing to sophisticated adaptive decision-making. Figure 1 below shows the breakdown of the 5C architecture.

Figure 1.

Unified 5-level CPS implementation architecture.

Though the architecture was originally proposed for manufacturing systems, this study has adapted it for the construction project monitoring and management systems. The implications of the [8] are discussed below:

- Smart Connection Level (Connection): Here, devices or sensors and other Internet of Things (IoT) technology are used to collect construction-related data. The data includes environmental data (temperature, humidity, lightness, atmospheric pressure), state of work, surveillance information, images and videos [8]. The focus is on the collection and extraction of accurate, reliable raw data from physical assets via sensors and networks.

- Conversion Level (Conversion): At this level, the data collected at the connection layer is converted to insight/information through statistical tools and machine learning for prediction, forecasting, and decision-making in construction operations and responding to the variations from the initially set baselines [8].

- Cyber Level: At this level, the information collected is warehoused. In the C4 context, the information is collected in the same structured database to prevent information silos. This is the central data hub for the construction company/enterprise. The data collected across all is used to update the BIM, digital twin of the physical asset, Enterprise Resource Planning (ERP), project and construction management software. The data collected is used for predictive and prescriptive purposes [8].

- Cognition Level: At this level, the data gathered is converted to information that guides the engineering, project, and construction team, as well as the necessary project stakeholders. The CMT uses the information to make decisions [8].

- Configuration Level: At this level, feedback from the cyber level is used to adjust, improve, and correct the physical assets and the construct team activities dynamically and autonomously. In the context of construction project management, machine learning and deep learning algorithms are used to suggest preventive and corrective actions to the CPMT [8].

The goal and the core of the proposed integrated framework is the collection and management of construction data. If the collected data is not integrated, then the goal of C4 cannot be achieved. While the 5C architecture and others like it govern the systems’ connection to the people and project outcome, the implementation is governed by data management. It is therefore important to consider the data analysis and data management perspective.

3.4. Data Analysis Levels

Insights from collected and warehoused data are mined at different levels, ranging from basic data processing to advanced, autonomous decision-making. The levels are briefly described below.

- Descriptive analytics answers the what question; it focuses on describing, summarising, and providing real-time insights into what is happening in the raw data collected. This level is used for monitoring the performance or status of a construction site.

- Diagnostic analytics answers the why question; it provides deeper insight that helps to determine why something is happening. Here, the root causes of issues or anomalies are identified through data correlation and analysis.

- Predictive analytics forecasts what will happen by using historical and current data to predict future events, like construction delay, cost overrun, or any other construction trends.

- Prescriptive analytics recommends what should be performed to cause-correct any anomalies and variations. This level of analysis supports decision-makers with actionable insights needed to optimise construction processes or mitigate risks.

- Adaptive/Autonomous analytics uses autonomous, self-optimising actions where systems dynamically adjust based on real-time insights, ensuring resilience and efficiency. AI/ML/DL technologies are used to imitate human decision-making. The systems continuously learn from new data to improve their ability to analyse and make decisions over time.

Each of the levels above corresponds to the levels in 5C Architecture.

3.5. Data Management

Data management is the structured process, policy, and tools used for organising, storing, and governing data to ensure its quality, accessibility, and security throughout its lifecycle. Data management ensures that the data being collected and the metadata are well integrated and interoperable across all applicable systems and devices in the workflow. This is achieved by stating the acceptable data formats, connectivity protocols, and initial quality checks. In the 5C architecture context, data management ensures that, from the raw data acquisition to autonomous system optimisation, data management defines the foundational infrastructure and governance to support this progression.

Stages of Data Management

Data management from raw construction data collected onsite to advanced, automated systems in the 5C architecture can be explained in five stages, described below:

- Data Collection and Ingestion: Focuses on gathering raw data from various sources, such as sensors, IoTs, CPS, databases, or manual inputs, ensuring accurate and secure capture. Here, data sources are configured, establishing connectivity protocols, defining metadata, and performing basic validation. This is equivalent to the ‘Extract’ level of the data engineering ETL (Extract, Transform, and Load) process.

- Data Processing and Quality Management: The goal here is to clean, transform, and normalise raw construction data extracted into data that is consistent, accurate, and usable for analysis. Data quality for reliable insights is the focus here. This level is equivalent to the ‘Transform’ level of the data engineering process.

- Data Storage and Integration: Focuses on organising and storing data in scalable repositories, such as databases or data lakes, while integrating data from multiple sources for comprehensive analysis. This level ensures data is structured and accessible. This level is equivalent to the ‘Load’ level of the data engineering process.

- Data Access and Governance: Ensures data is discoverable, secure, and compliant with regulations, enabling effective use in analytics and decision-making. This level focuses on governance policies and tools to manage data access and usage.

- Data Automation and Optimisation: Enables real-time, automated data management to support dynamic, self-optimising applications. This level focuses on streaming data pipelines and automated governance to facilitate advanced, autonomous systems.

Each of the levels above corresponds to the levels in 5C Architecture.

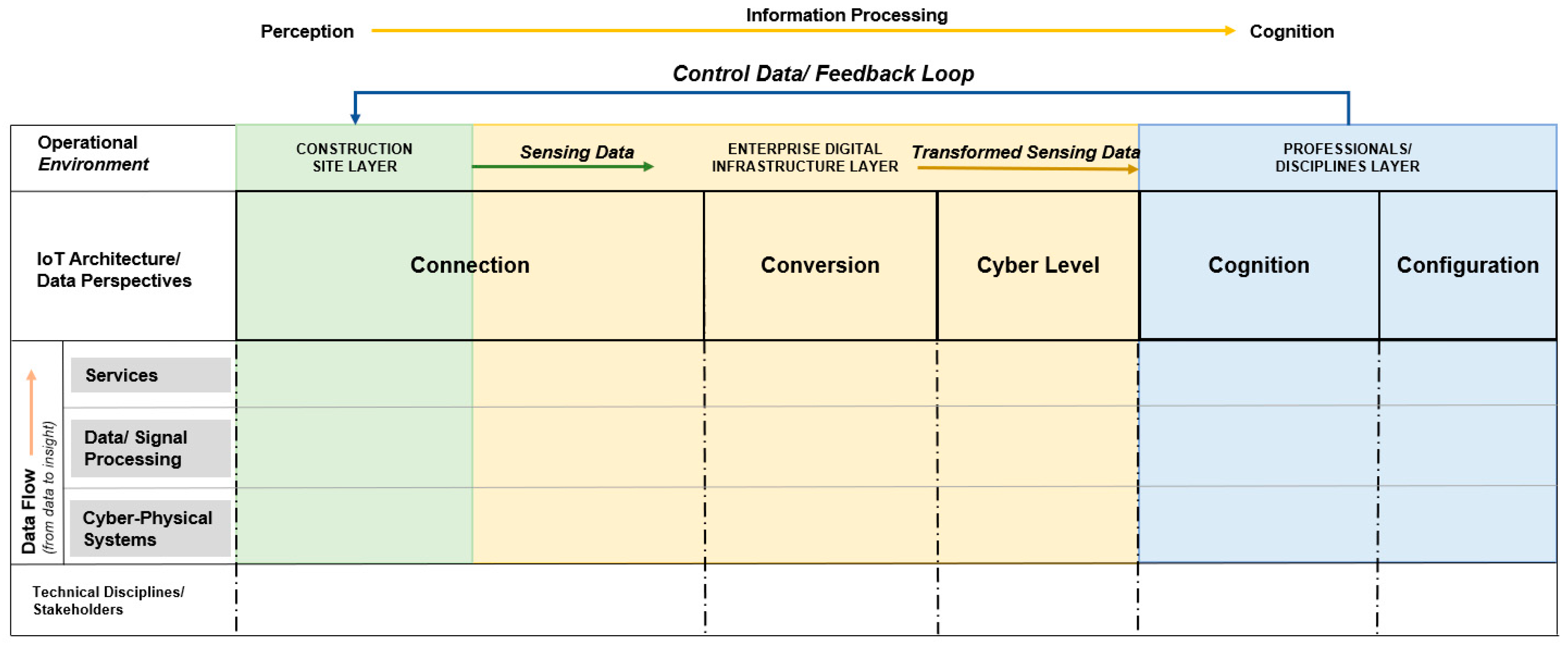

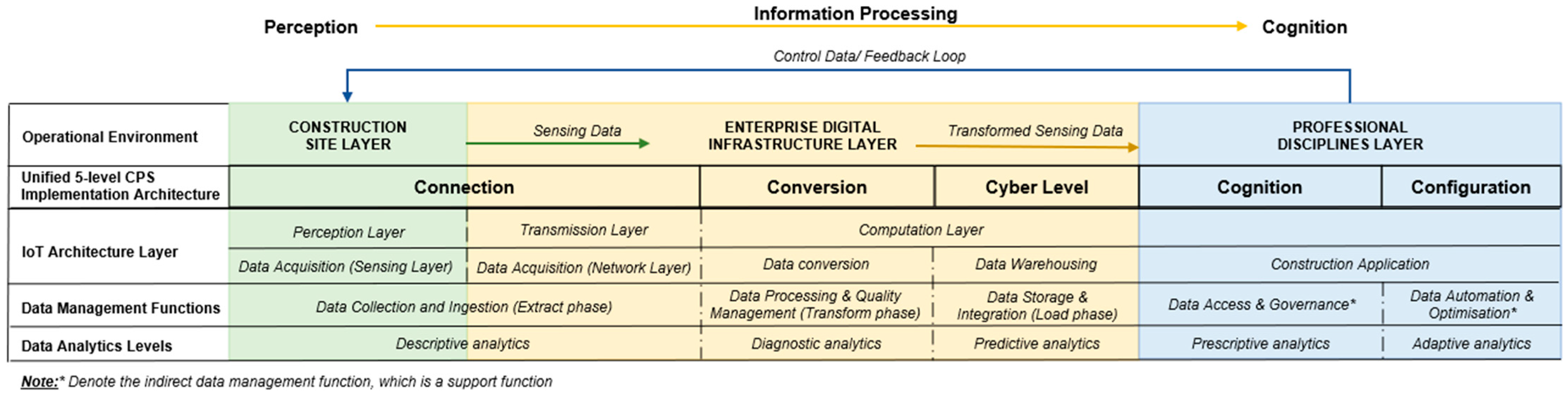

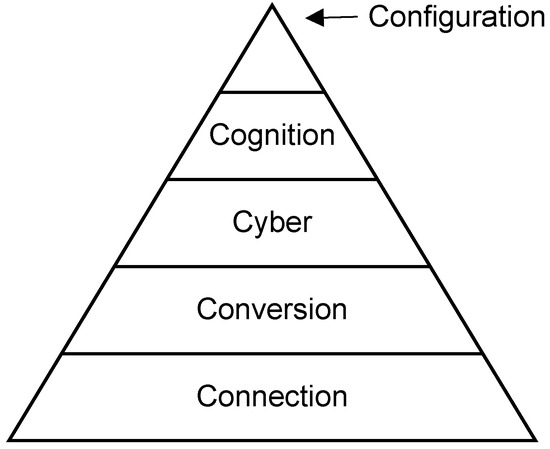

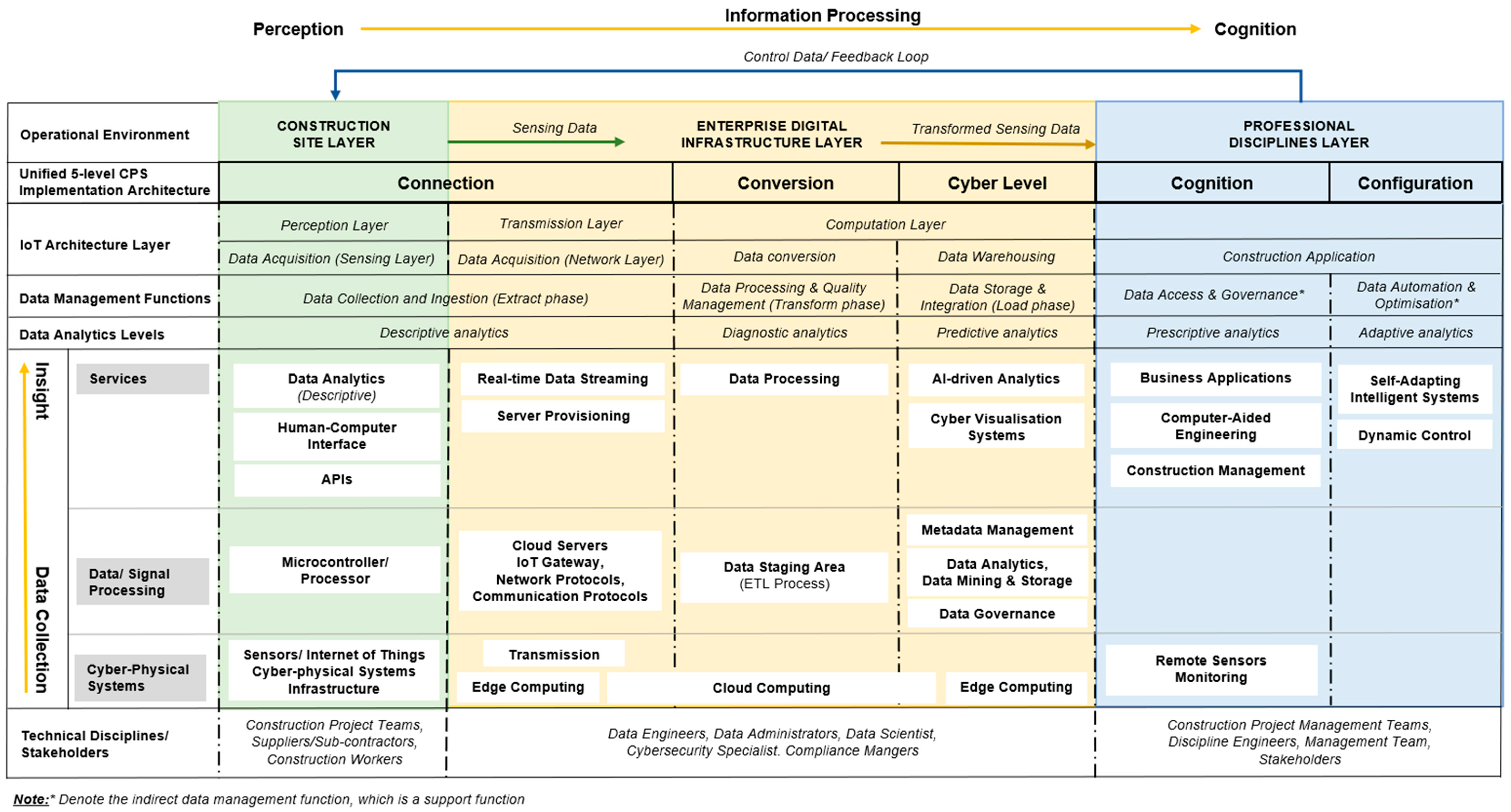

3.6. Architecture Interpretation Methodology/Approach

The proposed system architecture adopts the 5C IoT architecture paradigm, a 5-layer architecture proposed by [8] as its base architecture. The 5C architecture (connection, conversion, cyber level, cognition, and configuration level) is then compared with similar IoT architectures with varying numbers of architecture levels/layers and nomenclature. IoT layers are also compared with data analysis and management perspectives. Figure 2 below provides an overview of the architecture.

Figure 2.

Architecture Methodology/Approach Schema.

From a broad data flow perspective, data flows vertically from the bottom up in each layer of the architecture; data is collected at the bottom using CPS to capture data, it then goes through the data/signal processing stage, and then to the services stage at the top, where services are rendered. The level of insight achieved at each level of the IoT architecture corresponds to its respective stage in data analytics.

In the horizontal direction, tagged ‘information processing’, data/information flows from left to right across the IoT architecture layers. The horizontal direction is a spectrum from perception to cognition; the left is the perception region, and the right is the cognition region. The level of information increases to the right to achieve a higher level of useful decision-making data/information. This corresponds to the level of data analytics, until it reaches the cognition stage/level on the right side of the architecture.

In the vertical, there are four main groups for the rows, these are as follows: the operational environment, IoT architecture/data perspectives, data flow, and the technical disciplines/stakeholders. This is shown in Figure 2 below.

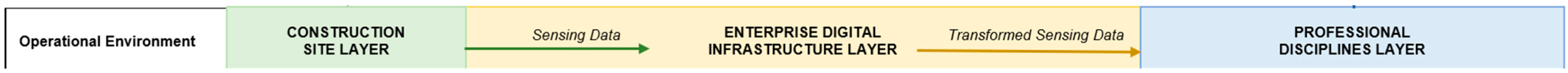

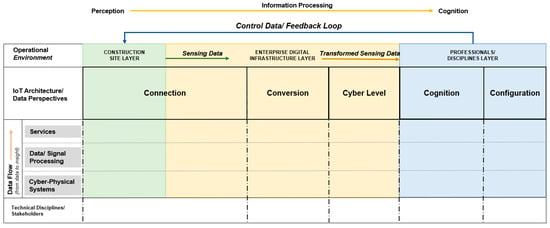

On the horizontal, there are three (3) operation environments these are the construction site layer, the enterprise digital infrastructure layer, and the professional discipline layer. These layers are colour-coded for easy delineation, as shown in Figure 3 below. The technical disciplines responsible for each of the layers are discussed below, and are listed in Figure 5.

Figure 3.

Operational Environment Layers.

Some of these main rows have sub-groups, which are indicated and explained below:

- Operational environment: This group indicates the environment where the operation is being carried out. There are three operational environments in this framework, they are as follows: the construction site layer, the enterprise digital infrastructure layer, and the professional disciplines layer. These layers are explained below.

- ▪

- Construction site layer: This is the outdoor brownfield or greenfield construction site where the construction activities are taking place. The sensors, actuators, and CPS are deployed in this environment. As indicated in the schema, sensing data collected in the Perception layer of the Connection level of the 5C architecture is the output of this layer and is then transmitted through the Transmission layer, still at the Connection layer of the 5C architecture, through to the enterprise digital infrastructure layer. The disciplines that interact directly or indirectly with this operational environment include the construction project teams, suppliers/subcontractors, construction workers, etc.

- ▪

- Enterprise digital infrastructure layer: This layer is the digital infrastructure layer of the construction company (enterprise). The infrastructure here helps with the transmission and processing of the sensing data and the creation of a single source of truth for all enterprise systems. The layer is not created and maintained by civil/construction project teams but by the data engineering team. The data engineering team ensures the appropriate data is extracted, transformed and loaded, guided by the enterprise data governance policies, and is made available to each team/discipline for decision-making. The IoT layers (transmission layer and computation layers), as well as the data management and analytics layers, were previously discussed in Section 3.3, Section 3.4 and Section 3.5.

- ▪

- Professional disciplines layer: This layer is where business, engineering, construction, and other management teams carry out analysis, simulation, visualisations and decision-making. There is a feedback mechanism tagged ‘control data/feedback loop’ to pass signal/information to the sensors and actuators on site, as well as the construction project team on the construction site. The disciplines that interact directly or indirectly with this operational environment include the construction project management teams, discipline engineers, management team, and other stakeholders.

- IoT architecture/data perspectives: This group deals with the IoT architecture, data analytics, and data management aspects of the processing of perceived data obtained from sensors to a higher level of cognition across the architecture levels. The 5C architecture serves as the baseline, and the various IoT architectures with varying numbers of architecture levels/layers and nomenclature, as well as the data analytics and data management levels equivalence, are indicated in Figure 4 below.

Figure 4. IoT architectures and data perspectives.

Figure 4. IoT architectures and data perspectives.

- Data Flow: Data flows vertically from the bottom up in each layer of the architecture; data is collected at the bottom using CPS to capture data and then processed in the data/signal processing stage, and then used at the services stage at the top, where services are rendered.

- Technical disciplines/stakeholders: The disciplines that interact directly or indirectly with each of the operational environments were listed in the operational environment section above and listed in Figure 5.

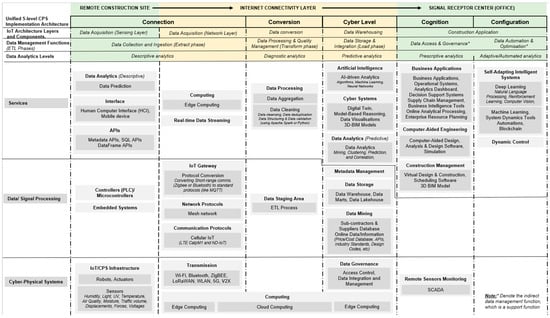

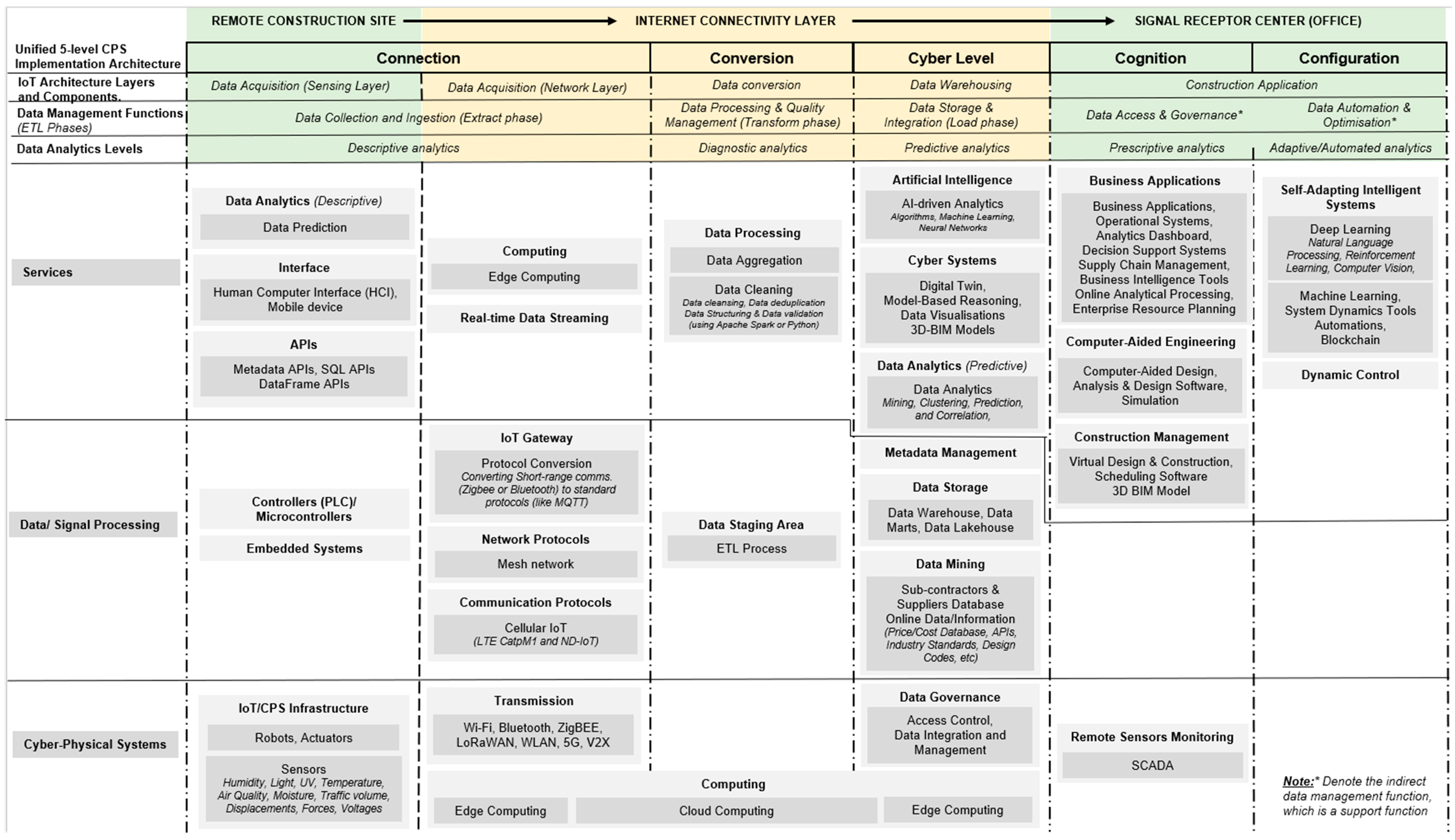

3.7. Systems Architecture for Integrated IoT/CPS for Digital Construction Site Management

The system architecture is further expanded in two steps: Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation—block view (Figure 5), and Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation—expanded view (Figure 6). Figure 5, the block view, provides the group names of each of the sections in the architecture, while Figure 6, the expanded view, the expanded view provides more details about each of the groupings. Each detail in the expanded view includes activities, technologies, and broad business operations as may apply to the section in concern.

Figure 5.

Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation—Block View.

Figure 5.

Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation—Block View.

Figure 6.

Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation—expanded view.

Figure 6.

Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation—expanded view.

3.8. Integrated Framework for IoT/CPS in Construction Progress Sensing, Monitoring and Evaluation

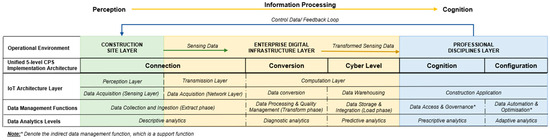

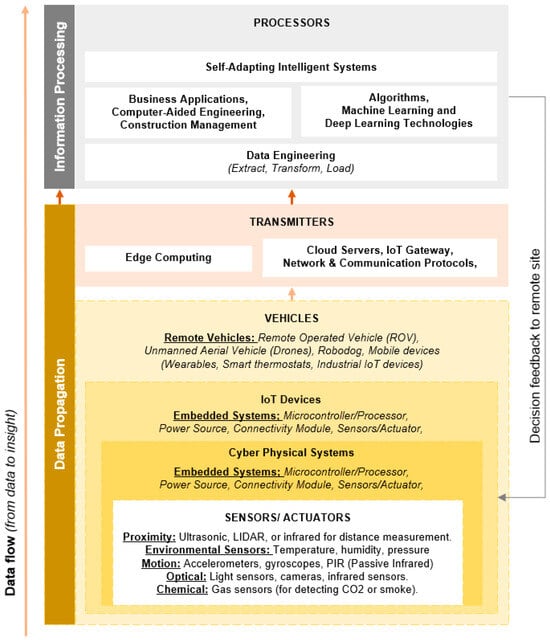

As shown in Figure 7 below, the integrated framework for IoT/CPS being developed is divided into four segments: The vehicles, the sensors, the transmitters, and the processors. The vehicles, which serve as a medium of carriage for other sensors, include robots, unmanned aerial vehicles (UAVs)/drones. The sensors, which are used to detect, measure and capture information about human activities, material movement, and the utilisation of equipment/machine operations, as well as construction progress. This includes IoT devices, laser scanners, cameras, and GPS. Also, the transmitters used to send information include the internet, cables, protocols, etc. And lastly, the processors, which extract, transform and load the CPS data into the data infrastructure (data lake, data warehouse). The data is then filtered and made available to the relevant enterprise system from the data mart of the particular system. Tools and technologies used include algorithms, machine learning, and deep learning technologies (computer vision, natural language processing). The segments can then be grouped into (1) The Information Propagation, which includes the vehicles, sensors, and transmitters, and (2) The Information Processing, which includes the processor [12,26].

Figure 7.

Integrated Framework IoT/CPS in Construction Progress Sensing, Monitoring, and Evaluation.

In the integrated framework presented above, data flows from the sensors in the embedded system and is empowered for local signal processing by the CPS, which accesses the other systems through IoT. It can be observed that data flows from the base, at the sensor level, to the processor level. Feedback can then be sent back to the construction site in the form of a project parameter update, project schedule updates, and remote access of sensors and actuators, etc. It should be noted that the integrated framework is a high-level expanded sensor segment of the previously discussed system architecture for digital construction site management. The usage of the sensors to be used in indoor and outdoor environments was discussed in Section 2.6—Implementation Approaches, Algorithm, and Technology deployed in Positioning, Localisation and Navigation in Indoor and Outdoor Environments. (Note: This framework can be better interpreted when viewed through the overall system architecture.) This can be adopted in the construction operations management, such as project management.

4. Discussion

The integrated framework will be used to visualise the physical and digital infrastructure architecture, as well as the data management practice required to prevent data silo and achieve a single source of truth for the construction project throughout its lifecycle. The presented framework also fosters communication and collaboration among the multiple disciplines in a construction project. It also enhances stakeholder engagement [27].

The integrated framework overcomes siloed monitoring by unifying indoor and outdoor data streams, aligning with C4 four-layer models. Compared to CV-only approaches, it enhances scalability through DT integration. The challenges in the presented framework include high initial sensor costs and data privacy concerns.

The integrated framework provides a system overview—from the base data capture component to the configuration level, which is more of a futuristic level. The prevailing C4 use cases are currently at the cognition level, where, at best, the AI and other related systems might suggest preventive and corrective actions, which are still subject to human subjective decision for implementation. Therefore, while the 5C Architecture adopted in this research work has five levels, the implementation or setting up of the systems in the framework is not in the civil engineering and construction project management disciplines/domain, as shown in the discipline layer of the integrated framework. That said, it is important for civil engineers, construction project management professionals, policy makers, and researchers to have a high-level overview of how to achieve higher productivity through the deployment of C4 systems.

4.1. Research Limitations

The presented framework has not been tested in simulations; real-world deployments may face environmental interferences. Future work could incorporate edge computing for faster processing. While an effort was made to include the relevant elements, there are some that may not have been included in the framework. Also, while a hypothetical use case was analysed, the presented integrated framework was not validated in a real-life project/use case.

4.2. Future Recommendation

It is important to implement the presented integrated framework in order to gain relevant insights and the necessary updates required from feedback. Future studies will thus focus on extending and bridging the gaps highlighted. It is also imperative to dive deeper into the Configuration layer to achieve the autonomous, self-adapting, and intelligent goal by investigating the feasibility of adopting agentic AI technologies.

4.3. Conclusions

This study presents a sensor-driven framework for automated construction progress monitoring, integrating SLAM, IoT, CV, BIM, and DT for indoor–outdoor unity. It advances C4 by enabling efficient, scalable project management, with potential for widespread industry adoption. This research has contributed towards advancing the field of construction automation by offering a scalable solution for efficient construction in project management through the use of an integrated DT framework.

Author Contributions

Conceptualisation, M.T.O.; methodology, M.T.O. and M.A.; validation, M.T.O. and M.A.; writing—original draft preparation, M.T.O.; writing—review and editing, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mukuka, M.; Aigbavboa, C.; Thwala, W. Effects of Construction Projects Schedule Overruns: A Case of the Gauteng Province, South Africa. Procedia Manuf. 2015, 3, 1690–1695. [Google Scholar] [CrossRef]

- Golnaraghi, S.; Zangenehmadar, Z.; Moselhi, O.; Alkass, S. Application of Artificial Neural Network(s) in Predicting Formwork Labour Productivity. Adv. Civ. Eng. 2019, 2019, 5972620. [Google Scholar] [CrossRef]

- Mirahadi, F.; Zayed, T. Simulation-Based Construction Productivity Forecast Using Neural-Network-Driven Fuzzy Reasoning. Autom. Constr. 2016, 65, 102–115. [Google Scholar] [CrossRef]

- Jiang, Y.; Su, S.; Zhao, S.; Zhong, R.Y.; Qiu, W.; Skibniewski, M.J.; Brilakis, I.; Huang, G.Q. Digital Twin-Enabled Synchronized Construction Management: A Roadmap from Construction 4.0 towards Future Prospect. Dev. Built Environ. 2024, 19, 100512. [Google Scholar] [CrossRef]

- Klinc, R.; Turk, Ž. Construction 4.0—Digital Transformation of One of the Oldest Industries. Econ. Bus. Rev. 2019, 21, 4. [Google Scholar] [CrossRef]

- El Jazzar, M.; Schranz, C.; Urban, H.; Nassereddine, H. Integrating Construction 4.0 Technologies: A Four-Layer Implementation Plan. Front. Built Environ. 2021, 7, 671408. [Google Scholar] [CrossRef]

- Van Der Heijden, J. Construction 4.0 in a Narrow and Broad Sense: A Systematic and Comprehensive Literature Review. Build. Environ. 2023, 244, 110788. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Altohami, A.B.A.; Haron, N.A.; Ales@Alias, A.H.; Law, T.H. Investigating Approaches of Integrating BIM, IoT, and Facility Management for Renovating Existing Buildings: A Review. Sustainability 2021, 13, 3930. [Google Scholar] [CrossRef]

- Schuldt, C.; Shoushtari, H.; Hellweg, N.; Sternberg, H. L5IN: Overview of an Indoor Navigation Pilot Project. Remote Sens. 2021, 13, 624. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Kang, S.; Cho, J.; Jeong, S.; Kim, S.; Sung, Y.; Lee, B.; Kim, G.-H. Implementation of Integrated Smart Construction Monitoring System Based on Point Cloud Data and IoT Technique. Sensors 2025, 25, 3997. [Google Scholar] [CrossRef]

- Kempecova, D.; Kozlovska, M. Sensing Technologies for Construction Productivity Monitoring. MATEC Web Conf. 2023, 385, 01032. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. (Eds.) Construction 4.0: An Innovation Platform for the Built Environment; Routledge: Abingdon, UK; New York, NY, USA, 2020; ISBN 978-0-367-02730-8. [Google Scholar]

- Lee, E.A. Cyber-Physical Systems—Are Computing Foundations Adequate? Available online: https://ptolemy.berkeley.edu/projects/chess/pubs/329.html (accessed on 4 June 2025).

- Vogel-Heuser, B.; Hess, D. Guest Editorial Industry 4.0–Prerequisites and Visions. IEEE Trans. Automat. Sci. Eng. 2016, 13, 411–413. [Google Scholar] [CrossRef]

- Xu, X.; Mumford, T.; Zou, P.X.W. Life-Cycle Building Information Modelling (BIM) Engaged Framework for Improving Building Energy Performance. Energy Build. 2021, 231, 110496. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a Semantic Construction Digital Twin: Directions for Future Research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Pal, A.; Lin, J.J.; Hsieh, S.-H.; Golparvar-Fard, M. Automated Vision-Based Construction Progress Monitoring in Built Environment through Digital Twin. Dev. Built Environ. 2023, 16, 100247. [Google Scholar] [CrossRef]

- Ammar, A.; Nassereddine, H. Blueprint for Construction 4.0 Technologies: A Bibliometric Analysis. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1218, 012011. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive Manufacturing as an Enabling Technology for Digital Construction: A Perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Bhatta, B. Global Navigation Satellite Systems: New Technologies and Applications, 2nd ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2021; ISBN 978-0-367-47408-9. [Google Scholar]

- Wei, W.; Lu, Y.; Zhong, T.; Li, P.; Liu, B. Integrated Vision-Based Automated Progress Monitoring of Indoor Construction Using Mask Region-Based Convolutional Neural Networks and BIM. Autom. Constr. 2022, 140, 104327. [Google Scholar] [CrossRef]

- Lin, J.J.; Golparvar-Fard, M. Visual and Virtual Progress Monitoring in Construction 4.0. In Construction 4.0; Routledge: London, UK, 2020; ISBN 978-0-429-39810-0. [Google Scholar]

- Reja, V.K.; Varghese, K.; Ha, Q.P. Computer Vision-Based Construction Progress Monitoring. Autom. Constr. 2022, 138, 104245. [Google Scholar] [CrossRef]

- Cho, J.; Jeong, S.; Lee, B. A Study on Anchor Placement and 3D Positioning Algorithm for UWB Application in Small Sites. KSCE J. Civ. Eng. 2024, 28, 4575–4587. [Google Scholar] [CrossRef]

- Kropp, C.; Koch, C.; König, M. Interior Construction State Recognition with 4D BIM Registered Image Sequences. Autom. Constr. 2018, 86, 11–32. [Google Scholar] [CrossRef]

- Elia, G.; Margherita, A.; Secundo, G. Project Management Canvas: A Systems Thinking Framework to Address Project Complexity. IJMPB 2021, 14, 809–835. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).