Processing Optimization of the New Steel Grade 45SiCrV9Ni for Modern Leaf Springs in Battery Electric Vehicles †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Tensile Tests

2.2.2. Dilatometer

2.2.3. Microscopy

2.2.4. Hardness Measurement

3. Results

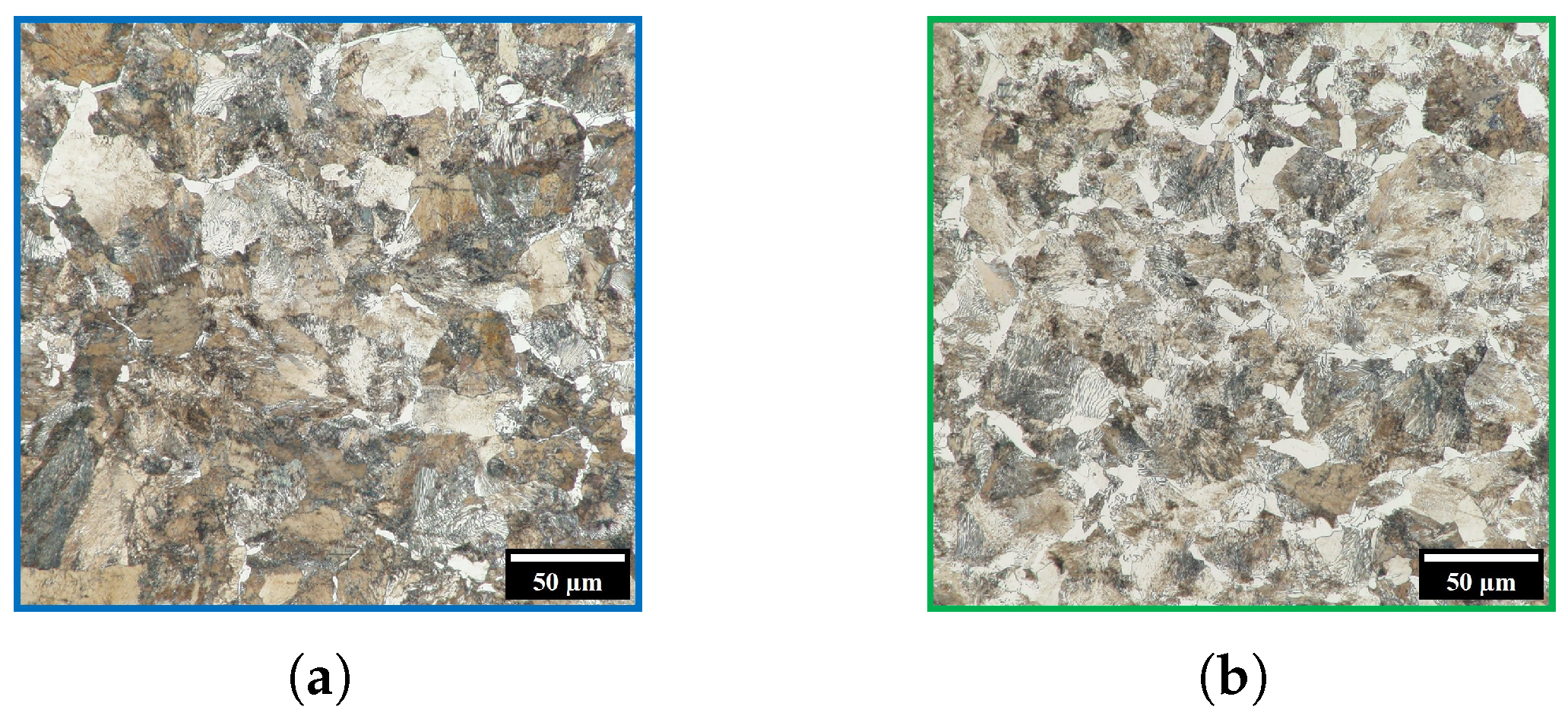

3.1. As-Supplied State

3.1.1. Microstructural Properties

3.1.2. Hot Strength Properties

3.2. Heat Treatment Optimization

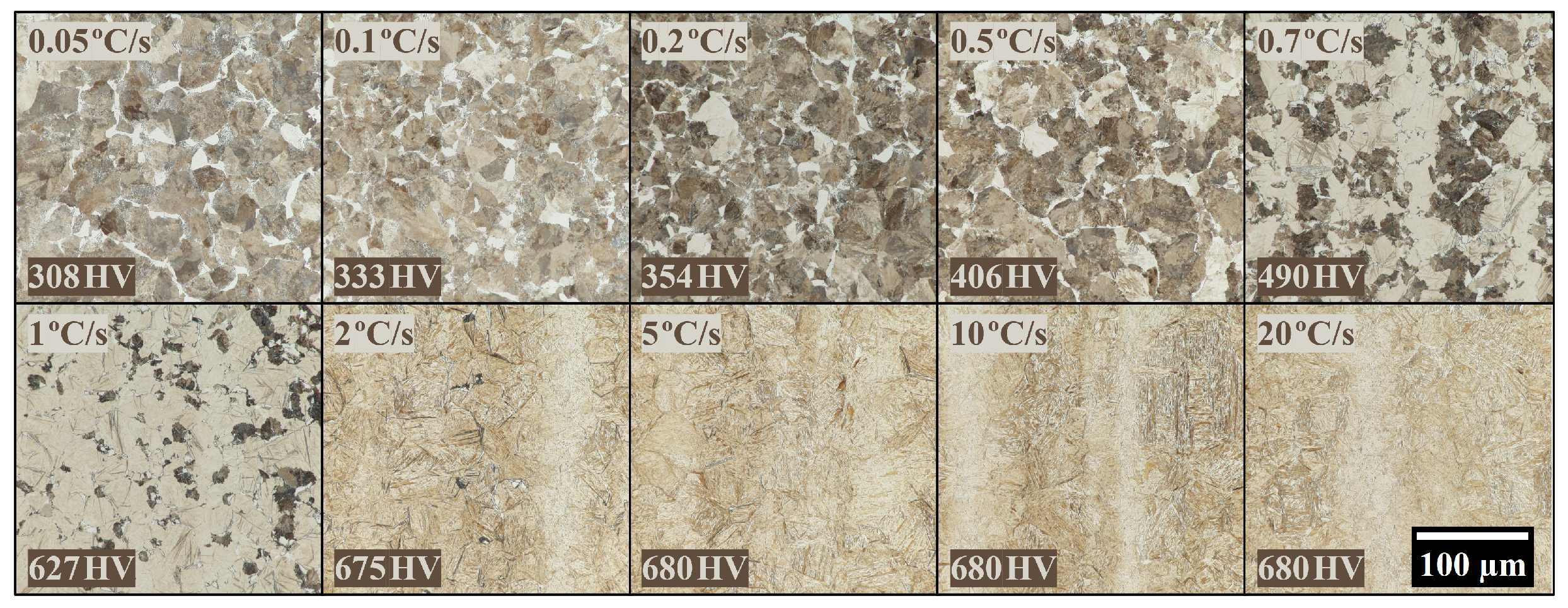

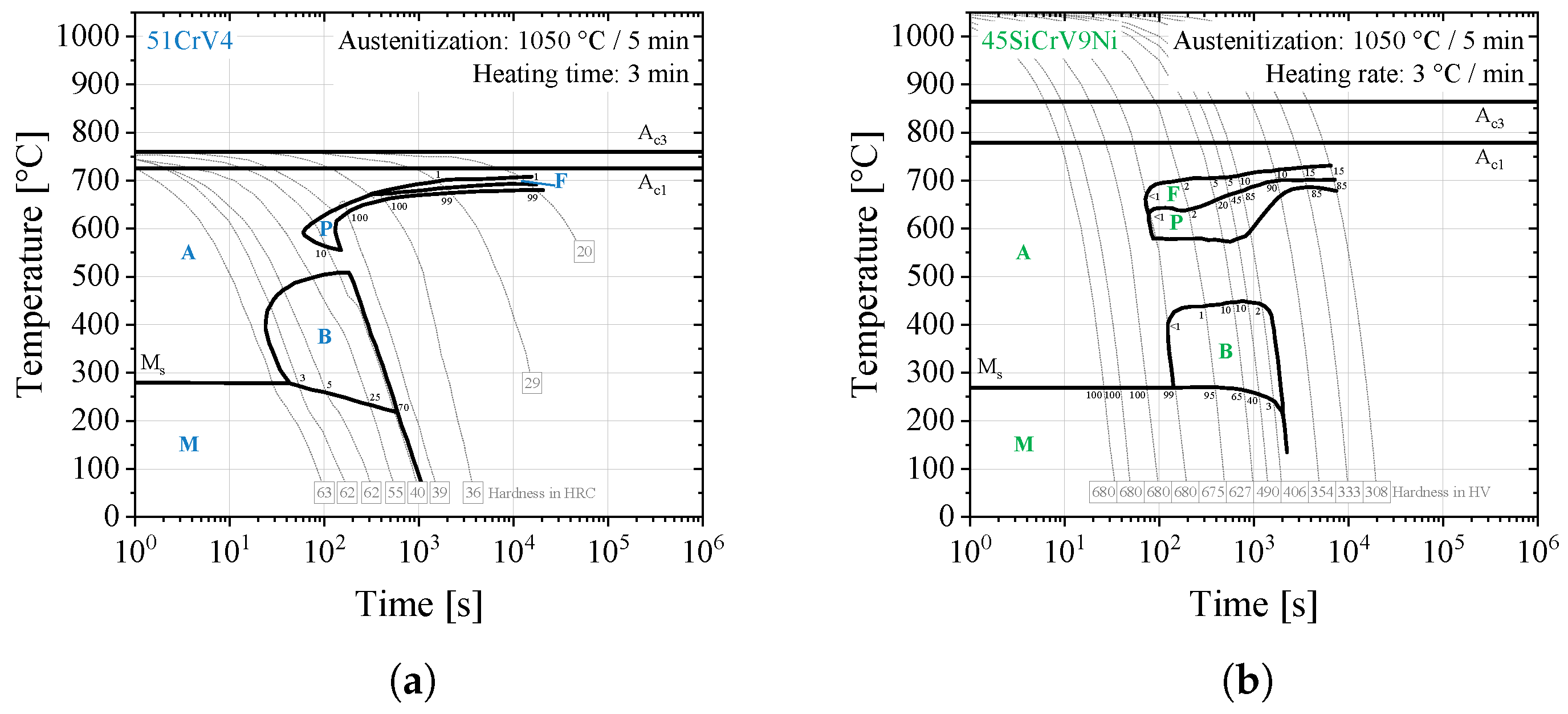

3.2.1. Continuous Cooling Transformation (CCT) Diagram

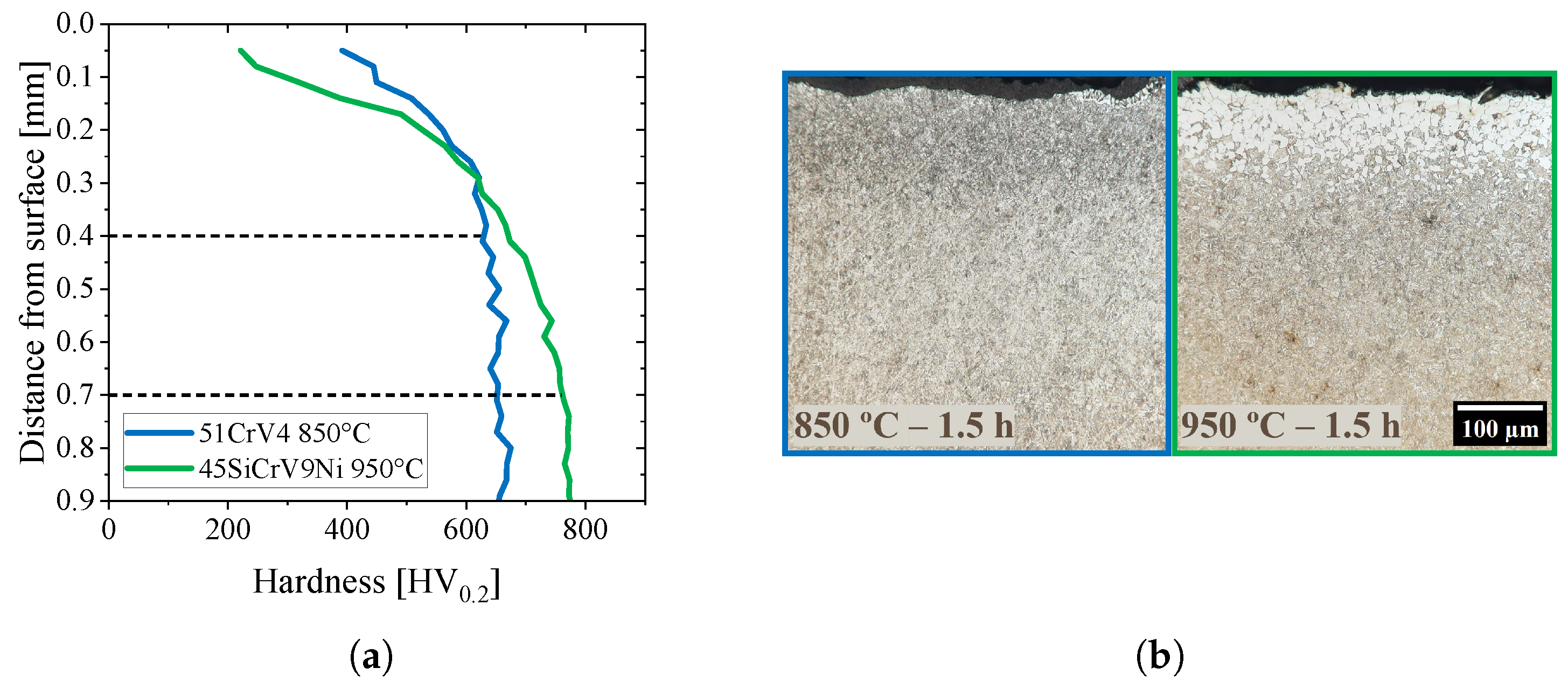

3.2.2. Austenitization and Decarburization

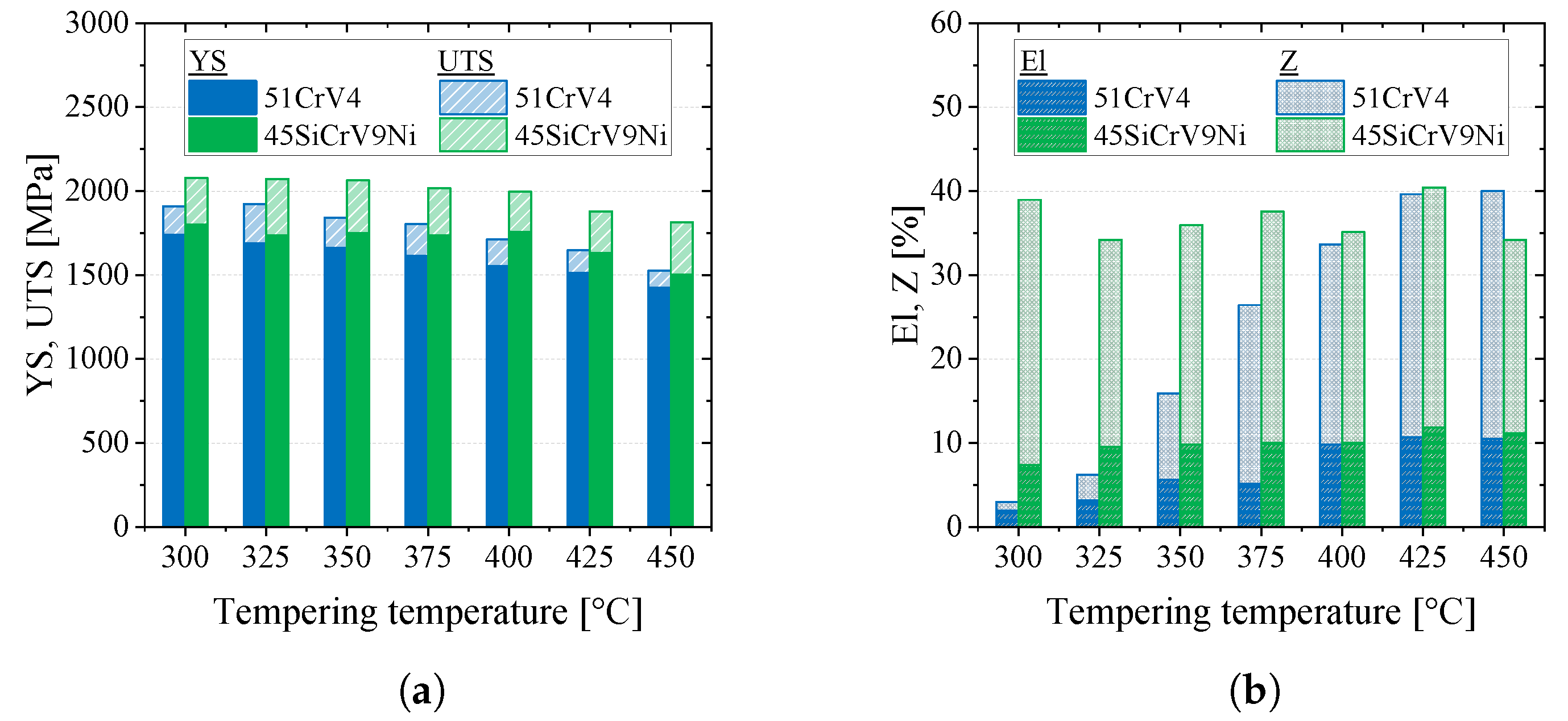

3.2.3. Influence of Tempering

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Podgornik, B.; Tehovnik, F.; Burja, J.; Senčič, B. Effect of Modifying the Chemical Composition on the Properties of Spring Steel. Metall. Mater. Trans. A 2018, 49, 3283–3292. [Google Scholar] [CrossRef]

- Podgornik, B.; Leskovšek, V.; Godec, M.; Senčič, B. Microstructure refinement and its effect on properties of spring steel. Mater. Sci. Eng. A 2014, 599, 81–86. [Google Scholar] [CrossRef]

- Podgornik, B.; Torkar, M.; Burja, J.; Godec, M.; Senčič, B. Improving properties of spring steel through nano-particles alloying. Mater. Sci. Eng. A 2015, 638, 183–189. [Google Scholar] [CrossRef]

- Zhang, L.; Gong, D.; Li, Y.; Wang, X.; Ren, X.; Wang, E. Effect of Quenching Conditions on the Microstructure and Mechanical Properties of 51CrV4 Spring Steel. Metals 2018, 8, 1056. [Google Scholar] [CrossRef]

- Gonçalves, V.R.M.; Podgornik, B.; Leskovšek, V.; Totten, G.E.; Canale, L.D.C.F. Influence of Deep Cryogenic Treatment on the Mechanical Properties of Spring Steels. J. Mater. Eng. Perform. 2019, 28, 769–775. [Google Scholar] [CrossRef]

- Klumpp, A.; Elvira, R.; Dapprich, S.; Dietrich, S.; Schulze, V. Effects of Shot Peening on Surface Layer States and Fatigue Behavior in Experimental Casts of Enhanced Leaf Spring Steels. In Proceedings of the 14th International Conference on Shot Peening (ICSP14), Milan, Italy, 4–7 September 2022. [Google Scholar]

- DIN EN ISO 6892-1; Metallische Werkstoffe-Zugversuch. DIN Media GmbH: Berlin, Germany, 2020. [CrossRef]

- DIN EN ISO 6507-1; Metallische Werkstoffe-Härteprüfung nach Vickers. DIN Media GmbH: Berlin, Germany, 2018. [CrossRef]

- Rose, A.; Peter, W.; Strassburg, W.; Rademacher, L. Atlas zur Wärmebehandlung der Stähle-Band 1-Teil 2; Max—Planck-Institut für Eisenforschung in Zusammenarbeit mit dem Werkstoffausschuß des Vereins Deutscher Eisenhüttenleute: Düsseldorf, Germany, 1954. [Google Scholar]

- Zhang, G.; Zhou, Y.; Yang, J.; Yang, H.; Wang, M.; Jing, K.; Xie, Z.; Zhang, L.; Liu, R.; Li, G.; et al. Effect of Si content on the microstructure and mechanical properties of 9Cr-ferritic/martensitic steels. Nucl. Mater. Energy 2023, 35, 101428. [Google Scholar] [CrossRef]

- Anya, C.; Baker, T. The effect of silicon on the grain size and the tensile properties of low carbon steels. Mater. Sci. Eng. A 1989, 118, 197–206. [Google Scholar] [CrossRef]

- Yu, Q.; Zhao, Y.; Zhao, F. Influence of Nickel on Microstructure and Mechanical Properties in Medium-Carbon Spring Steel. Materials 2024, 17, 2423. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Borgenstam, A.; Stark, A.; Hedström, P. Effect of Si on bainitic transformation kinetics in steels explained by carbon partitioning, carbide formation, dislocation densities, and thermodynamic conditions. Mater. Charact. 2022, 185, 111774. [Google Scholar] [CrossRef]

- Zheng, H.; Ye, X.; Li, J.; Jiang, L.; Liu, Z.; Wang, G.; Wang, B. Effect of carbon content on microstructure and mechanical properties of hot-rolled low carbon 12Cr–Ni stainless steel. Mater. Sci. Eng. A 2010, 527, 7407–7412. [Google Scholar] [CrossRef]

- Savaidis, A. Surface Properties and Fatigue Life of Stress Peened Leaves. Mater. Test. 2012, 54, 529–534. [Google Scholar] [CrossRef]

| Element [wt-%] | C | Mn | Si | Cr | Ni | Mo | V | Cu |

|---|---|---|---|---|---|---|---|---|

| 51CrV4 | 0.53 | 0.99 | 0.36 | 0.93 | 0.11 | 0.02 | 0.15 | 0.12 |

| 45SiCrV9Ni | 0.43–0.51 | ≤1.0 | 2.0–3.0 | 0.8–1.2 | 0.5–1.0 | ≤0.1 | 0.1–0.3 | ≤0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Nouri, N.; Escauriaza, B.; Gakias, C.; Savaidis, G.; Elvira, R.; Dietrich, S.; Schulze, V. Processing Optimization of the New Steel Grade 45SiCrV9Ni for Modern Leaf Springs in Battery Electric Vehicles. Eng. Proc. 2025, 119, 52. https://doi.org/10.3390/engproc2025119052

Nouri N, Escauriaza B, Gakias C, Savaidis G, Elvira R, Dietrich S, Schulze V. Processing Optimization of the New Steel Grade 45SiCrV9Ni for Modern Leaf Springs in Battery Electric Vehicles. Engineering Proceedings. 2025; 119(1):52. https://doi.org/10.3390/engproc2025119052

Chicago/Turabian StyleNouri, Niki, Borja Escauriaza, Christos Gakias, Georgios Savaidis, Roberto Elvira, Stefan Dietrich, and Volker Schulze. 2025. "Processing Optimization of the New Steel Grade 45SiCrV9Ni for Modern Leaf Springs in Battery Electric Vehicles" Engineering Proceedings 119, no. 1: 52. https://doi.org/10.3390/engproc2025119052

APA StyleNouri, N., Escauriaza, B., Gakias, C., Savaidis, G., Elvira, R., Dietrich, S., & Schulze, V. (2025). Processing Optimization of the New Steel Grade 45SiCrV9Ni for Modern Leaf Springs in Battery Electric Vehicles. Engineering Proceedings, 119(1), 52. https://doi.org/10.3390/engproc2025119052