1. Introduction

Liquid hydrogen (LH

2) offers high specific energy and zero-emission potential for aviation, but its storage at extremely low temperatures (−253 °C) introduces severe thermomechanical challenges. Thermal gradients, heat ingress, and repeated thermal cycling could induce significant thermal stresses in LH

2 storage tank structures, affecting material performance and structural integrity. As the aviation sector moves toward decarbonization goals (e.g., the European Green Deal), research increasingly focuses on the coupled thermal and mechanical behavior of LH

2 storage tanks, with emphasis on insulation efficiency, stress mitigation, and material durability under extreme thermal loads [

1].

A way to handle the aforementioned issues appearing on storage tanks is to structure them with Functionally Graded Materials (FGM). The proposed use of FGMs was made in Japan (1984) as a preparation of thermal barrier materials [

2]. Initially, FGMs were used in aerospace but there are applications in other fields, like industrial materials, optoelectronics, biomaterials, energy materials, Nuclear Energy, Electronics, Cutting Tools, and Automotive [

3,

4]. The use of FGMs has the following advantages [

5,

6]: (a) smoothing of the thermal stress distribution, (b) mitigated or eliminated interfacial cracking or debonding caused by stress concentration due to abrupt change in material properties between distinct materials, (c) minimization or elimination of stress concentrations and singularities at the free edges, and (d) increase in the bond strength of two materials and improved fracture toughness.

The materials commonly used in applications are as follows [

7]: FGM Alloys: Aluminum, Copper, and Titanium and, as reinforcements, Aluminum oxide, Silicon carbide, Silicon nitride, Silicon dioxide, Titanium nitride, Titanium dioxide, and Aluminum nitride.

In this study, a curved sandwich beam which may be used as a storage tank component, with FGM face sheets and a homogeneous core under thermomechanical loads, is investigated. In particular, we study two cases of core material, the Silicon carbide (SiC) and Titanium carbide (TiC), and in both cases, Aluminum alloy is the metal material. The finite element method (FEM) is used to deal with the problem. Plane isoparametric eight-node elements are used, where the gradient of the material properties is incorporated in the formulation of the element. In our investigation, the Gauss quadrature method is applied, and the material properties are sampled at the Gauss points. The effect of the thickness and volume fraction index (VFI) of the FGM face sheets on the stress and the temperature fields are studied.

2. Thermoelasticity Governing Equations

The equations of motion and energy equation are given below [

8,

9,

10]:

where

is the stress tensor and the

is the heat flux. The kinematic equations are [

9,

11,

12]

where

is the coefficient of thermal expansion,

total strain,

the Kronecker’s delta and

is the temperature difference, and

is the displacement. Furthermore, the constitutive equations are given by [

8,

9,

10,

13]

where

is the fourth order tensor of elastic moduli,

is the thermoelasticity tensor, and

is the thermal conductivity tensor. The equations of thermoelasticity for nonhomogeneous graded materials are [

11]

3. Numerical Implementation

3.1. FEM

In FEM, for a plane element with n nodes, the

and the

fields are approximated by the shape functions

[

8,

9,

14] and take the following form:

Applying the Galerkin method [

8,

9,

10] for Equation (4), it is obtained:

Similarly, the energy equation becomes

3.2. Graded FEM

In the GFEM, the material properties are sampled at the Gauss points, which is referred to as Direct Gaussian integration formulation (DGIF) [

15].

The displacements for the isoparametric elements are given by [

15,

16,

17]:

For the case of the functionally graded materials, the matrices are [

11]

Flux at a boundary due to convection is given by Newton’s law of cooling [

18,

19]:

where

is the heat flux on the boundary [

19]. Temperature in the fluid varies from

to the surface temperature

through the thickness of a boundary layer adjacent to the solid [

18]. The convection matrix and convection vector for

are given by [

18,

19]

where

The local material properties of the element are obtained by substituting the Cartesian coordinates

in terms

[

20]:

Finally, the general matrix has the following form:

where

.

4. The Curved Beam Application

From the problem presented in

Figure 1 [

21], the boundary conditions (BCs) are fixed support at both beam ends, a temperature

at the lower outer surface, and a pressure

and the convection BC

at the upper–outer surface. The radius differences

define the FGM sheets’ thickeness. Moreover, the parameteres are reference temperature

, convection coefficient

, pressure

, height

, free flow temperature

, boundary temperature

, and radius

.

The variation of material properties for the ceramic core configuration is given by [

21,

22]

where

is the material property,

is the ceramic material property,

is the metal material property,

is the volume fraction of the ceramic phase, and

is the volume fraction index (VFI) [

21,

22]. In particular, we have

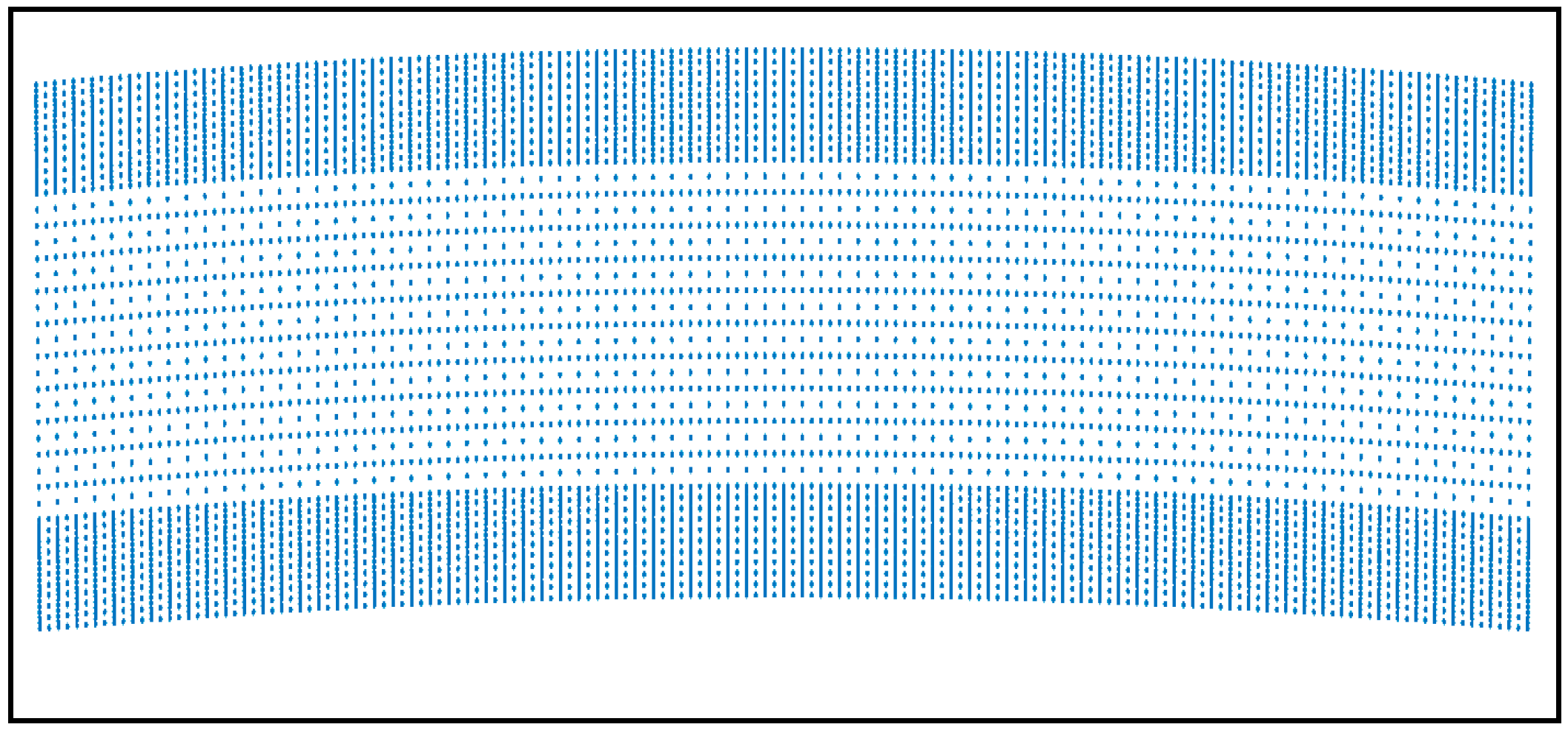

We study two cases of core material, SiC and TiC, with Aluminum as the metal material (

Table 1).The solution of the problems conducted with plane isoparametric quadratic eight-node elements, where the gradient of the material properties is incorporated into the formulation of the element. For the integration, the Gauss quadrature method is used and the material properties are sampled at the Gauss points. The number of elements is 1800 in each layer (FGM sheets and core) and, in total, 5400 (

Figure 2).

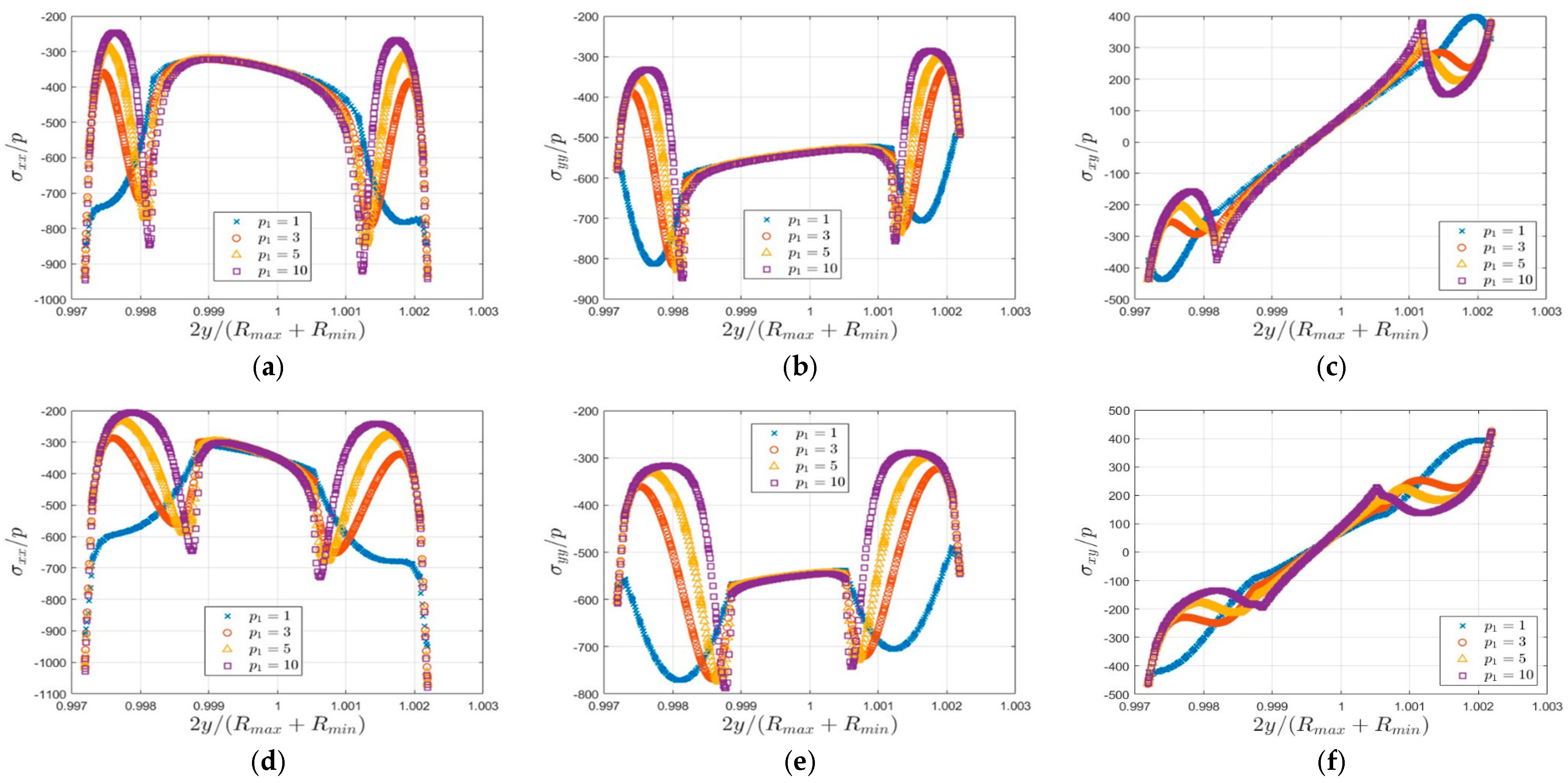

5. Results and Discussion

In this section, the stress distributions

,

,

and the temperature through the height of the beam section are presented for the left fixed end.

Figure 2 and

Figure 3 referred to the SiC core and

Figure 4 and

Figure 5 to TiC.

Figure 3.

SiC’s stress distributions (i) , (a–c) and (ii) , (d–f).

Figure 3.

SiC’s stress distributions (i) , (a–c) and (ii) , (d–f).

Figure 4.

SiC’s temperature distributions (a) , (b) and (c) a comparison for the two different FGM sheets’ thickness in the case of = 1.

Figure 4.

SiC’s temperature distributions (a) , (b) and (c) a comparison for the two different FGM sheets’ thickness in the case of = 1.

Figure 5.

TiC’s stress distributions (i) , (a–c) and (ii) , (d–f).

Figure 5.

TiC’s stress distributions (i) , (a–c) and (ii) , (d–f).

The temperature

is quite similar both for SiC and TiC materials for the different values of VFIs (

Figure 4 and

Figure 6). For the case of the TiC with

and

, there is a distinguished difference in the upper face sheet (

Figure 6b,c).

Figure 6.

TiC’s temperature distributions (a) , (b) and (c) a comparison for the two different FGM sheets’ thickness in the case of = 1.

Figure 6.

TiC’s temperature distributions (a) , (b) and (c) a comparison for the two different FGM sheets’ thickness in the case of = 1.

In the cases of the SiC and TiC, the stress distributions

,

,

are almost identical for all values of

along the core (

Figure 3 and

Figure 5). For the cases of

the stress distributions at the face sheets are quite similar. However, a significant difference between the stresses distributions of

and the stresses distributions of

is appeared (

Figure 3 and

Figure 5).

In addition, for both materials (SiC and TiC) and for the different values of

, the stresses

have the maximum values at the outer surfaces of the beam. The stresses

have the maximum values at the interfaces between the face sheets and the core of the beam. There is an exception regarding the TiC material, in the case of

where the maximum value of

is located on the inner part of the face sheets.Finally, the stresses

have the maximum values at the outer surfaces of the beam (

Figure 3 and

Figure 5).

The FGM face sheets’ thickness affectsneither the maximum (or the minimum) of the stress distributions nor the quality form of them (

Figure 3 and

Figure 5), except for the case of

distributions of SiC (

Figure 3c,f).

6. Conclusions and Perspectives

In the present study, an aircraft/aerospace LH2 storage component is investigated for its structural response under thermomechanical loadings. The component is simulated as a curved sandwich beam comprising FGM face sheets and a homogeneous core. The numerical study is performed by the FEM, utilizing eight-node, plane, isoparametric elements. The computational analysis is based on the incorporation of the spatial variation of material properties directly into the element formulation, thereby enabling an accurate representation of the gradient effects within the FGM layers. The influence of both the thickness and the VFI of the FGM face sheets on the resulting stress and temperature fields is examined. As in our best knowledge, this is the first time that the aforementioned problem has been attempted to be handled.

The numerical results indicate that, for all configurations considered, the maximum stress values occur at the outer FGM surfaces or at the interface between the core and the face sheets of the curved beam for both SiC and TiC materials, regardless of the face-sheet thickness. Furthermore, the stress distributions corresponding to exhibit smoother gradients compared with those of . The temperature field is found to be nearly linear across the FGM thickness for SiC, whereas for TiC it exhibits a linear variation with a different slope across the distinct material regions.

The scope of our study highlights the necessity for a detailed and rigorous design methodology in the development of LH2 storage components to mitigate the risk of fracture and failure under severe thermomechanical BCs.

The present results provide preliminary valuable insights toward the identification and optimization of suitable advanced materials for reliable LH2 containment in engineering applications.

Author Contributions

Methodology, software, investigation, writing—original draft preparation, D.A.M.; Conceptualization, validation, investigation, writing—original draft, visualization, C.C.K.; Formal analysis, writing—review and editing, supervision, project administration, E.E.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mantzaroudis, V.K.; Theotokoglou, E.E. Computational Analysis of Liquid Hydrogen Storage Tanks for Aircraft Applications. Materials 2023, 16, 22–45. [Google Scholar] [CrossRef] [PubMed]

- Swaminathan, K.; Naveen, D.T.; Zenkour, A.M.; Carrera, E. Stress, vibration and buckling analyses of FGM plates-A state-of-the-art review. Compos. Struct. 2015, 120, 10–31. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Gupta, A.; Talha, M. Recent development in modeling and analysis of functionally graded materials and structures. Prog. Aerosp. Sci. 2015, 79, 1–14. [Google Scholar] [CrossRef]

- Pitakthapanaphong, S.; Busso, E.P. Self-consistent elastoplastic stress solutions for functionally graded material systems subjected to thermal transients. J. Mech. Phys. Solids 2002, 50, 695–716. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, Z.; Yang, Z.; Ke, L.; Kitipornchai, S.; Yang, J. Functionally graded graphene reinforced composite structures: A review. Eng. Struct. 2020, 210, 110339. [Google Scholar] [CrossRef]

- Sam, M.; Jojith, R.; Radhika, N. Progression in manufacturing of functionally graded materials and impact of thermal treatment-A critical review. J. Manuf. Process. 2021, 68, 1339–1377. [Google Scholar] [CrossRef]

- Balla, M. Formulation of coupled problems of thermoelasticity by finite elements. Period. Polytech. Mech. Eng. 1989, 33, 59–70. [Google Scholar]

- Hetnarski, R.B.; Eslami, M.R. Thermal Stresses―Advanced Theory and Applications, 2nd ed.; Solid Mechanics and Its Applications; Springer: Cham, Switzerland, 2019; Volume 158, p. 668. [Google Scholar] [CrossRef]

- Gao, Z.-W.; Zhou, Y.-H.; Lee, K.Y. Graded finite element simulation of thermal stress in inhomogeneous high-Tc superconductor. Phys. C Supercond. 2010, 470, 2010–2015. [Google Scholar] [CrossRef]

- Burlayenko, V.N.; Altenbach, H.; Sadowski, T.; Dimitrova, S.D.; Bhaskar, A. Modeling functionally graded materials in heat transfer and thermal stress analysis by means of graded finite elements. Appl. Math. Model. 2017, 45, 422–438. [Google Scholar] [CrossRef]

- Mallios, D.A.; Theotokoglou, E.E.; Koutsoumaris, C.C. Thermomechanical analysis of FGM sandwich beams through graded FEM. J. Therm. Stress. 2025, 1–19. [Google Scholar] [CrossRef]

- Carter, J.P.; Booker, J.R. Finite element analysis of coupled thermoelasticity. Comput. Struct. 1989, 31, 73–80. [Google Scholar] [CrossRef]

- Nicholson, D.W. Finite Element Analysis: Thermomechanics of Solids, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008; 480p. [Google Scholar] [CrossRef]

- Paulino, G.H.; Kim, J.-H. The Weak Patch Test for Nonhomogeneous Materials Modeled with Graded Finite Elements. J. Braz. Soc. Mech. Sci. Eng. 2007, 29, 63–81. [Google Scholar] [CrossRef]

- Santare, M.H.; Thamburaj, P.; Gazonas, G.A. The use of graded finite elements in the study of elastic wave propagation in continuously nonhomogeneous materials. Int. J. Solids Struct. 2003, 40, 5621–5634. [Google Scholar] [CrossRef]

- Li, C.; Zou, Z.; Duan, Z. Multiple isoparametric finite element method for nonhomogeneous media. Mech. Res. Commun. 2000, 27, 137–142. [Google Scholar] [CrossRef]

- Cook, R.D.; Malkus, D.S.; Plesha, M.E.; Witt, R.J. Concepts and Applications of Finite Element Analysis, 4th ed.; Wiley: Hoboken, NJ, USA, 2001; 736p. [Google Scholar]

- Muftu, S. Finite Element Method: Physics and Solution Methods, 1st ed.; Academic Press: Cambridge, MA, USA, 2022; 540p. [Google Scholar]

- Xiong, T.; Guo, Y.-K.; Li, Y.-D.; Zhang, H.-C. Improved graded finite elements with applications in simulating non-homogeneous elastic, piezoelectric and magneto-electro-elastic materials. Int. J. Comput. Mater. Sci. Eng. 2017, 6, 1750012. [Google Scholar] [CrossRef]

- Belarbi, M.-O.; Houari, M.S.A.; Hirane, H.; Daikh, A.A.; Bordas, S.P.A. On the finite element analysis of functionally graded sandwich curved beams via a new refined higher order shear deformation theory. Compos. Struct. 2022, 279, 114715. [Google Scholar] [CrossRef]

- Swaminathan, K.; Sangeetha, D.M. Thermal analysis of FGM plates—A critical review of various modeling techniques and solution methods. Compos. Struct. 2017, 160, 43–60. [Google Scholar] [CrossRef]

- Available online: https://www.acapublishing.com/dosyalar/baski/BEN_2020_79.pdf (accessed on 15 September 2025).

- Available online: https://accuratus.com/silicar.html (accessed on 15 September 2025).

- Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=b8d536e0b9b54bd7b69e4124d8f1d20a&ckck=1 (accessed on 15 September 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https:/ /creativecommons.org/licenses/by/4.0/).