Modeling Tensile Properties in Selective Laser Melting of 316L Stainless Steel Using Statistical Multi-Parameter Analysis and Artificial Neural Networks †

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

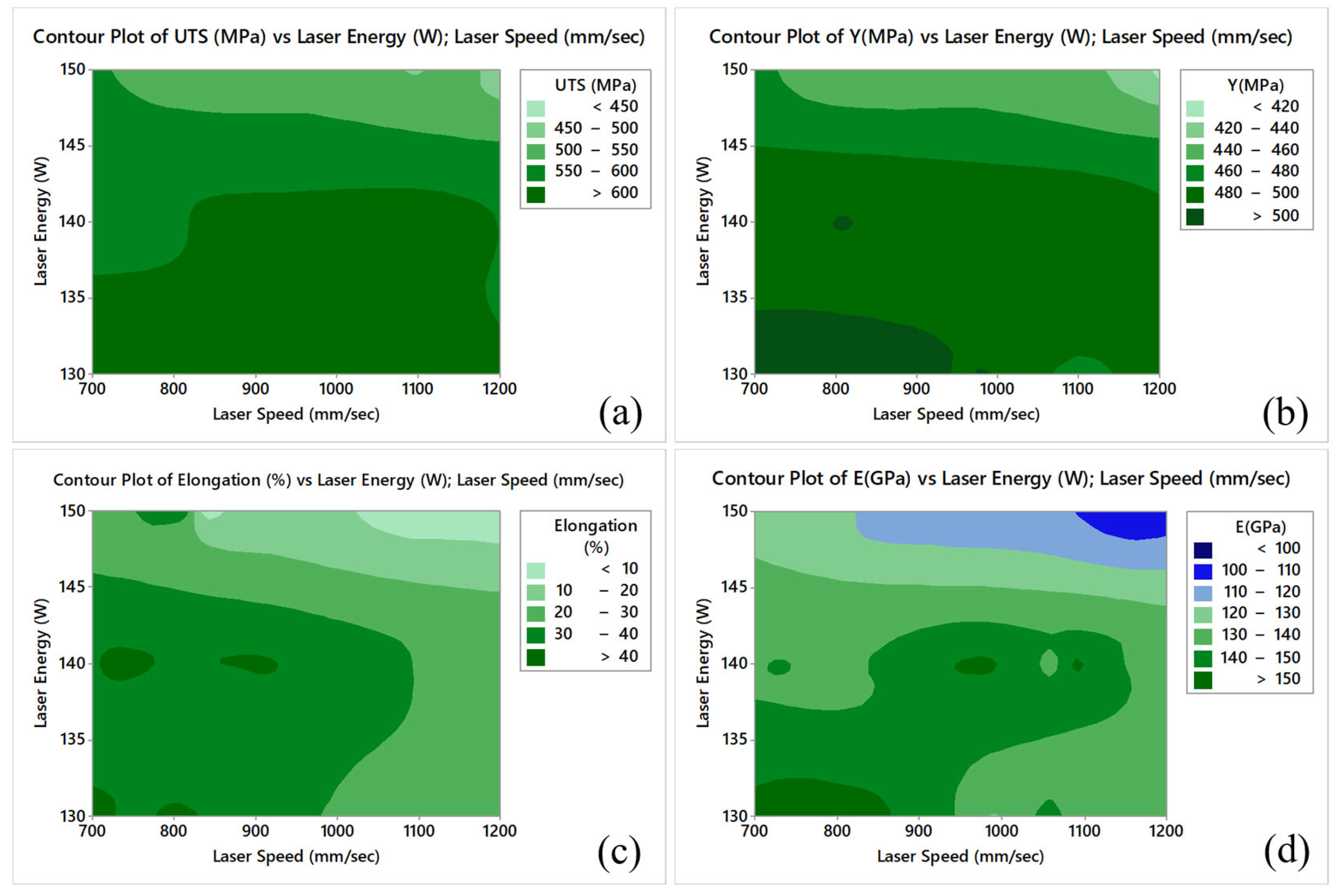

3.1. Mechanical Properties and Influence of SLM Parameters

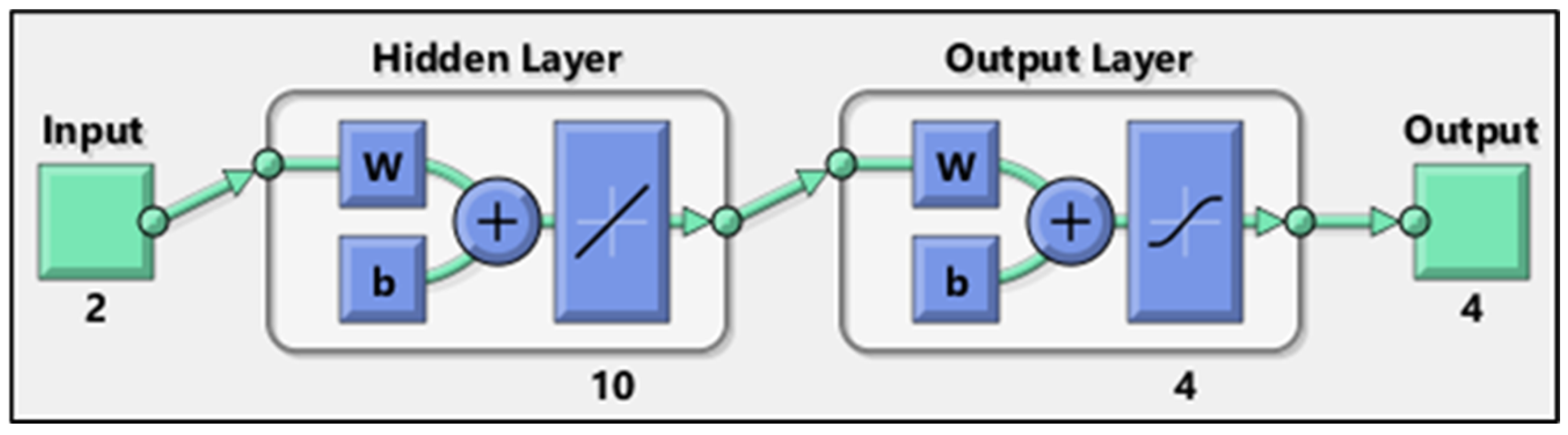

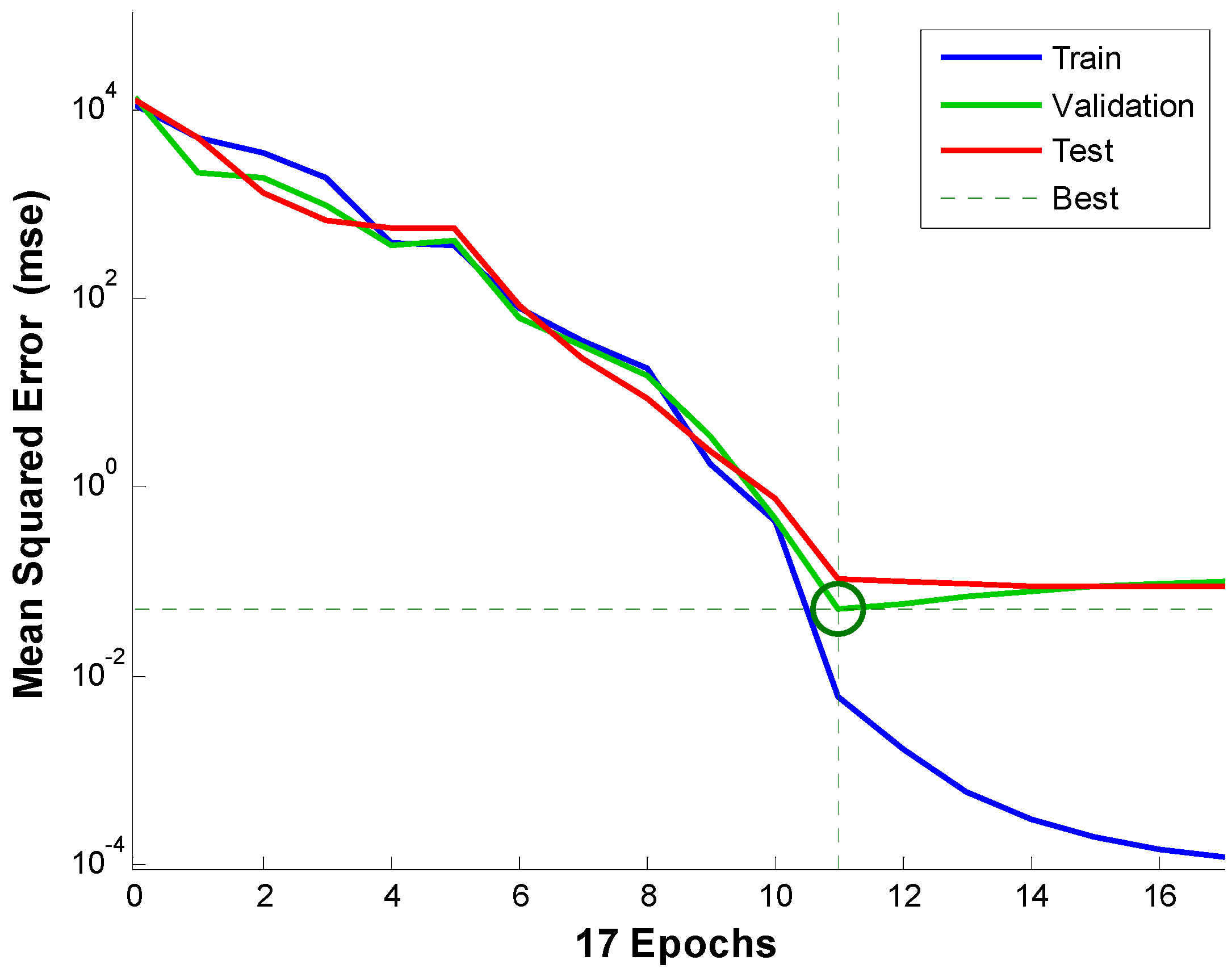

3.2. ANN Modeling

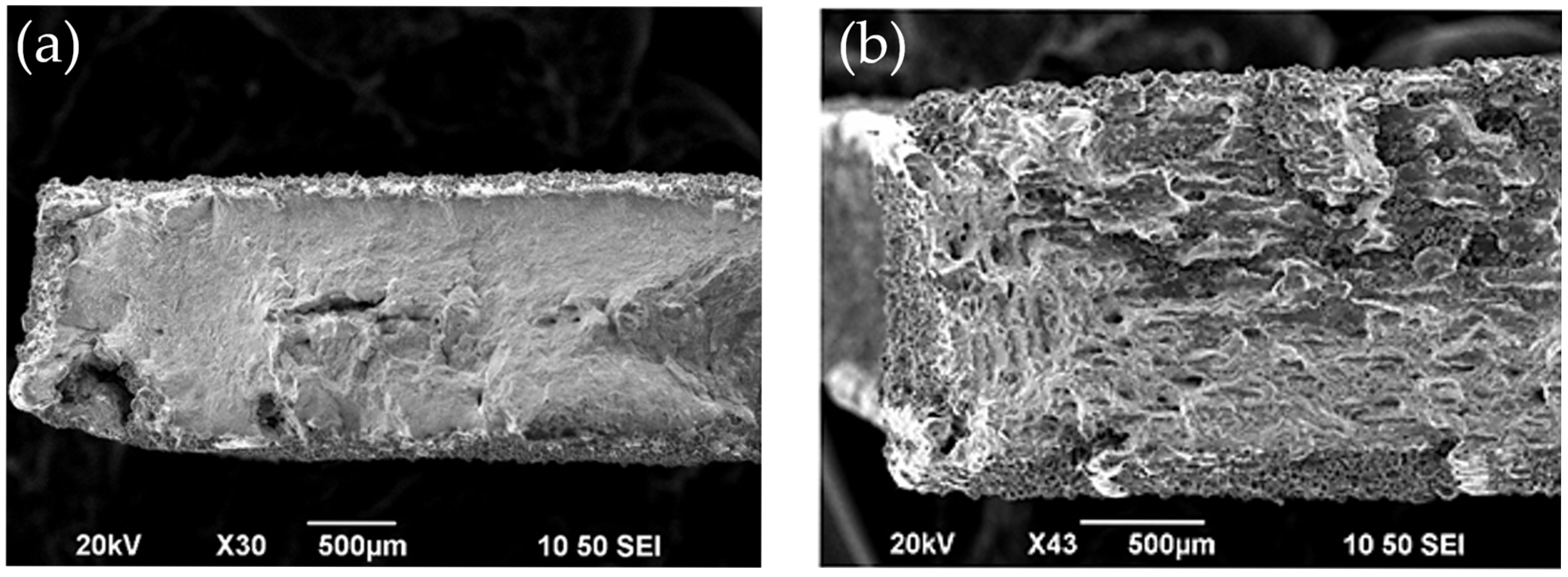

3.3. Fractography (Validation)

4. Conclusions

- Process–property relationships: Mechanical performance was highly sensitive to scan speed and energy input. Optimal properties such as yield stress above 500 MPa, ultimate tensile strength above 600 MPa, elongation exceeding 40%, and modulus of elasticity up to 158 GPa were achieved at low scan speeds (700–850 mm/s) and moderate power (130–140 W).

- Statistical and ANN modeling: Full quadratic regression models and ANN predictions consistently identified the same optimal parameter window. The ANN achieved excellent predictive accuracy (R2 > 0.998), confirming its ability to capture nonlinear interactions beyond conventional regression approaches.

- Fractographic validation: SEM analysis supported the mechanical findings, showing ductile fracture with well-developed dimples at low scan speeds and brittle morphologies with unmelted particles at higher scan speeds, linking processing conditions to failure mechanisms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| ANN | Artificial Neural Network |

| SLM | Selective Laser Melting |

| RSM | Response Surface Methodology |

References

- DebRoy, T.; Wei, H.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A. Laser powder bed fusion additive manufacturing of metals: Physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective laser melting technology: From the single laser melted track stability to 3D parts of complex shape. Phys. Procedia 2010, 5, 551–560. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Li, H.; Zhang, J. The fracture behavior of 316L stainless steel with defects fabricated by SLM additive manufacturing. Crystals 2021, 11, 1542. [Google Scholar] [CrossRef]

- Hodroj, A.; Bouglia, R.; Ding, Y.; Zghal, M. Machine learning for density prediction and process optimization of 316L stainless steel fabricated by selective laser melting. J. Intell. Manuf. 2025. [Google Scholar] [CrossRef]

- Röttger, A.; Boes, J.; Theisen, W.; Thiele, M.; Esen, C.; Edelmann, A.; Hellmann, R. Microstructure and mechanical properties of 316L austenitic stainless steel processed by different SLM devices. Int. J. Adv. Manuf. Technol. 2020, 108, 769–783. [Google Scholar] [CrossRef]

| Specimen No. | Laser Power (W) | Laser Speed (mm/s) | YS (MPa) | UTS (MPa) | E (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| A1 | 150 | 800 | 446.3 | 531.3 | 126.7 | 38 |

| A2 | 850 | 451.9 | 533.9 | 110.7 | 2 | |

| A3 | 900 | 443.9 | 519.1 | 116.1 | 19 | |

| A4 | 950 | 457.9 | 549.2 | 113.3 | 16 | |

| A5 | 1000 | 451.5 | 529.3 | 114.4 | 10 | |

| A6 | 1050 | 450.7 | 520.4 | 117.5 | 7 | |

| A7 | 1100 | 442.7 | 493.2 | 109.0 | 3 | |

| A8 | 1150 | 437.0 | 519.9 | 98.5 | 8 | |

| A9 | 1200 | 413.3 | 449.8 | 106.9 | 3 | |

| B1 | 140 | 750 | 494.8 | 591.1 | 140.8 | 43 |

| B2 | 800 | 501.5 | 596.7 | 132.3 | 38 | |

| B3 | 850 | 498.2 | 609.3 | 141.0 | 40 | |

| B4 | 900 | 501.8 | 612.8 | 144.2 | 43 | |

| B5 | 950 | 488.2 | 605.9 | 150.9 | 37 | |

| B6 | 1000 | 498.2 | 617.0 | 153.2 | 34 | |

| B7 | 1050 | 491.6 | 613.4 | 136.9 | 33 | |

| B8 | 1100 | 499.1 | 623.0 | 152.1 | 30 | |

| B9 | 1150 | 494.8 | 591.1 | 140.8 | 43 | |

| C1 | 130 | 700 | 512.3 | 620.2 | 151.1 | 44 |

| C2 | 750 | 510.2 | 617.0 | 158.2 | 39 | |

| C3 | 800 | 510.1 | 626.2 | 154.9 | 42 | |

| C4 | 850 | 505.6 | 626.3 | 155.8 | 39 | |

| C5 | 900 | 514.2 | 629.0 | 143.5 | 33 | |

| C6 | 950 | 498.2 | 622.6 | 139.1 | 33 | |

| C7 | 1000 | 502.3 | 623.2 | 126.0 | 29 | |

| C8 | 1050 | 483.5 | 609.1 | 145.2 | 26 | |

| C9 | 1100 | 473.8 | 601.4 | 132.4 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papantoniou, I.; Fountas, N.A.; Manolakos, D.E.; Vaxevanidis, N.M. Modeling Tensile Properties in Selective Laser Melting of 316L Stainless Steel Using Statistical Multi-Parameter Analysis and Artificial Neural Networks. Eng. Proc. 2025, 119, 23. https://doi.org/10.3390/engproc2025119023

Papantoniou I, Fountas NA, Manolakos DE, Vaxevanidis NM. Modeling Tensile Properties in Selective Laser Melting of 316L Stainless Steel Using Statistical Multi-Parameter Analysis and Artificial Neural Networks. Engineering Proceedings. 2025; 119(1):23. https://doi.org/10.3390/engproc2025119023

Chicago/Turabian StylePapantoniou, Ioannis, Nikolaos A. Fountas, Dimitrios E. Manolakos, and Nikolaos M. Vaxevanidis. 2025. "Modeling Tensile Properties in Selective Laser Melting of 316L Stainless Steel Using Statistical Multi-Parameter Analysis and Artificial Neural Networks" Engineering Proceedings 119, no. 1: 23. https://doi.org/10.3390/engproc2025119023

APA StylePapantoniou, I., Fountas, N. A., Manolakos, D. E., & Vaxevanidis, N. M. (2025). Modeling Tensile Properties in Selective Laser Melting of 316L Stainless Steel Using Statistical Multi-Parameter Analysis and Artificial Neural Networks. Engineering Proceedings, 119(1), 23. https://doi.org/10.3390/engproc2025119023