A Fatigue Life Calculation Procedure Implementing Surface and Depth-Graded Mechanical Properties †

Abstract

1. Introduction

2. Methodology Overview

- Geometry: This includes identifying the failure critical location on the component and considering any relevant geometric features or discontinuities that influence stress levels under operational loading.

- Local parameters: The component’s cross-section is discretized into layers from the surface to the core. For each layer, local mechanical characteristics such as local ultimate tensile strength, stress gradient and roughness (only for the outer layer) are assigned based on measured microhardness profile, residual stress profile and surface roughness profile, respectively. These parameters capture the influence of surface treatments and gradation of material properties on fatigue behavior.

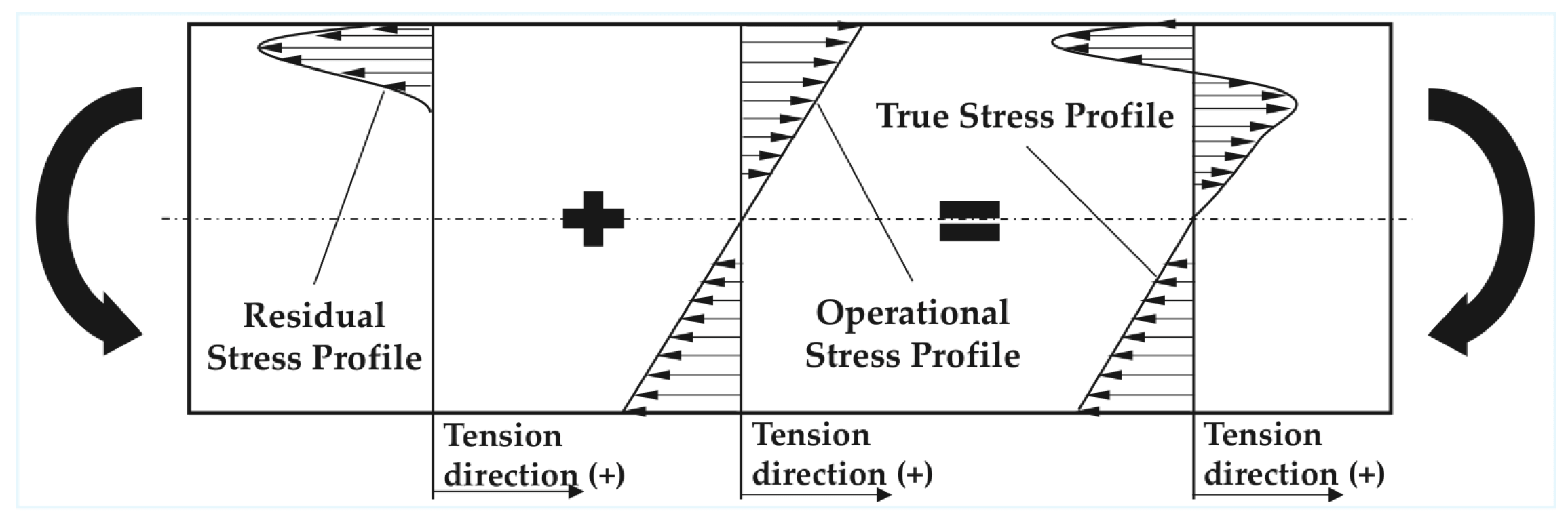

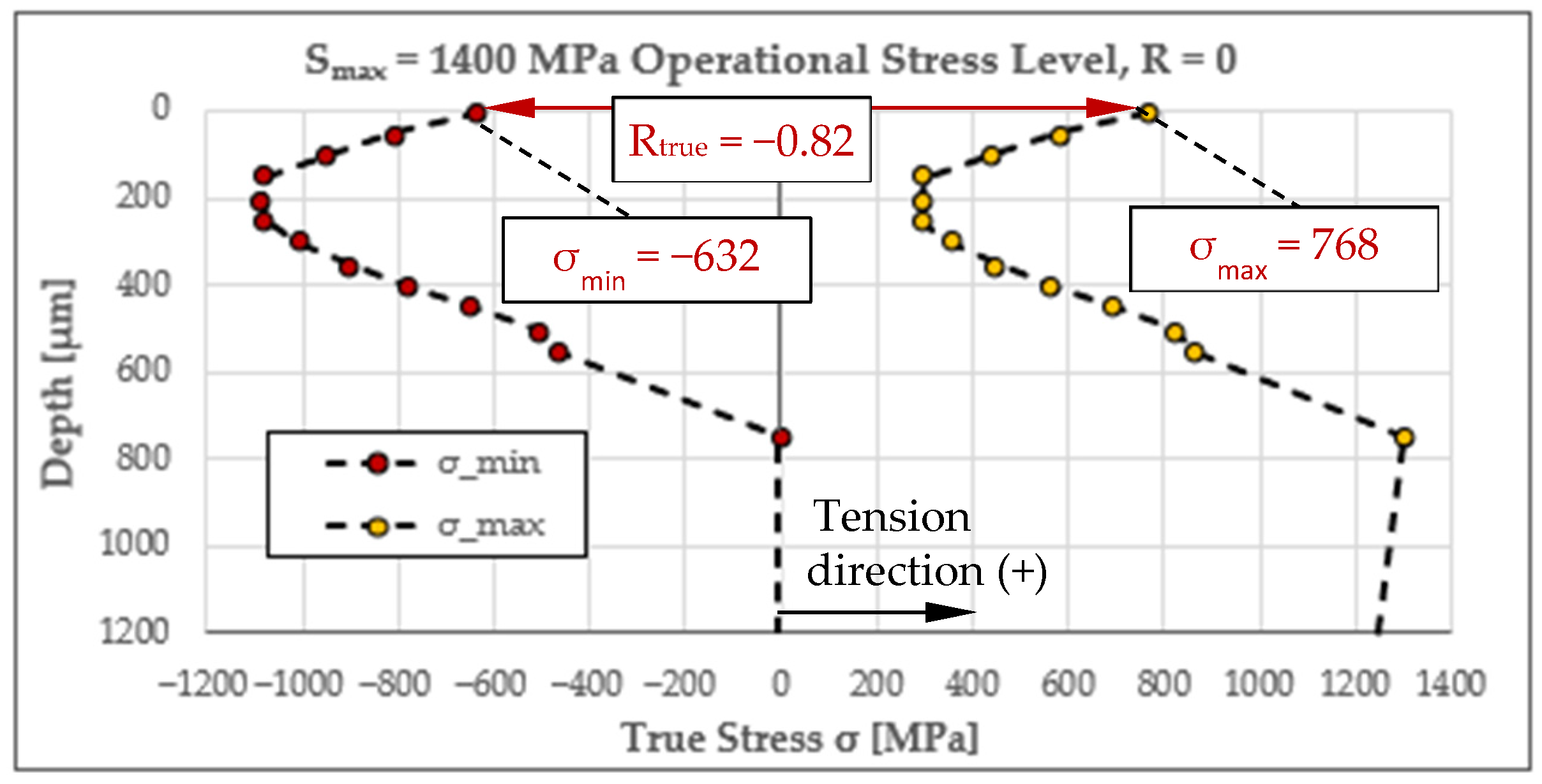

- Loading parameters: Once the aforementioned mechanical characteristics are defined, the local stress of each layer due to the operational loading is calculated. This is done by superimposing the stresses developed by the externally applied loads and the residual stresses, allowing for an accurate assessment of the true stress acting at each layer.

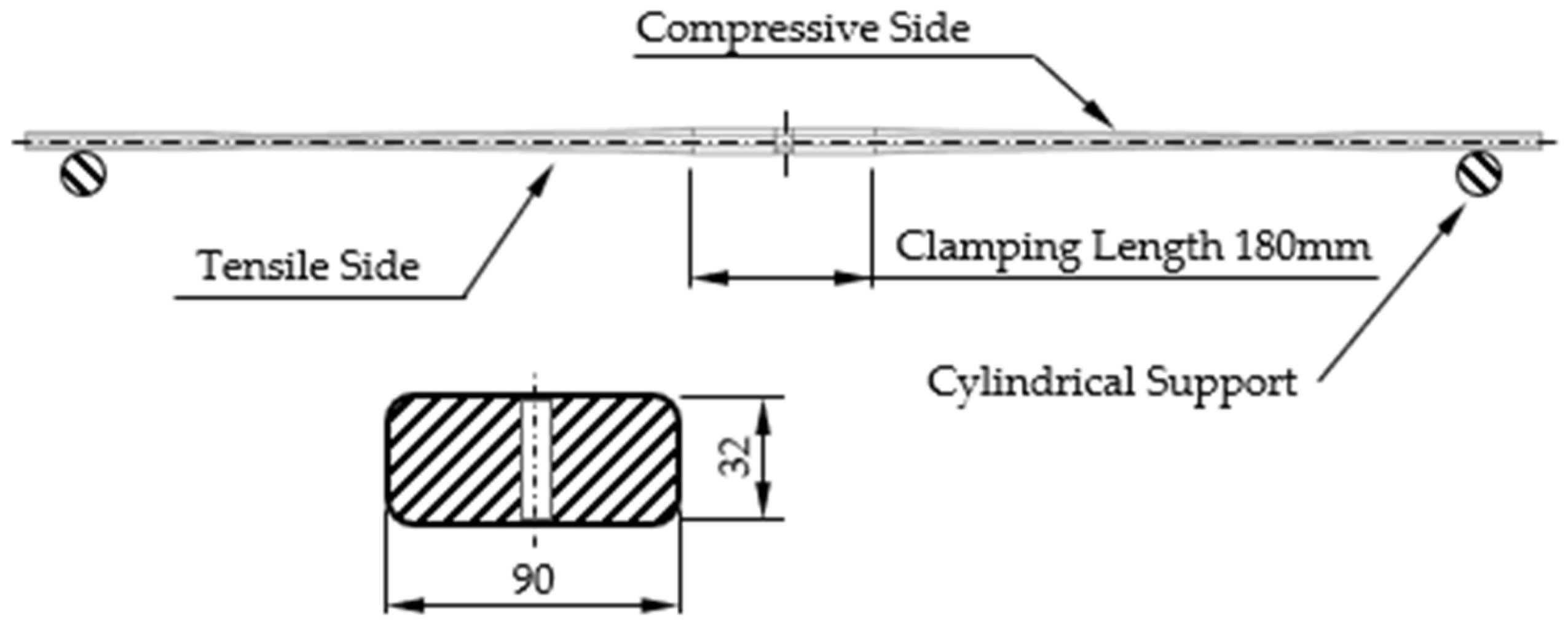

3. Case Study: Monoleaf Spring

3.1. Determination of Point of Interest

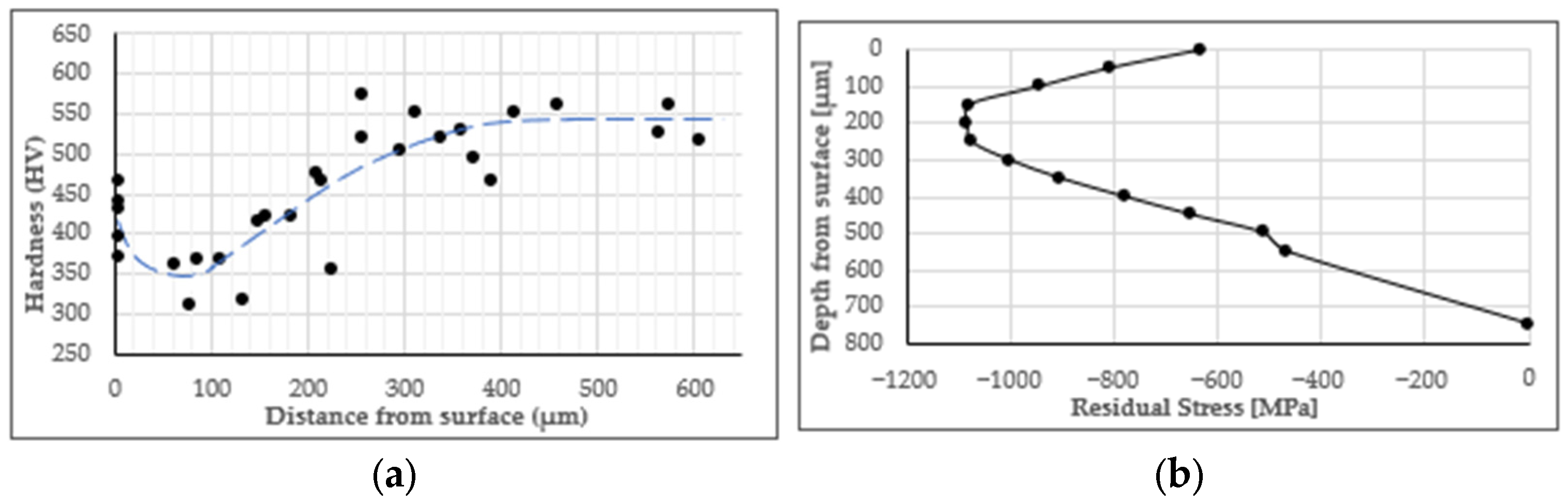

3.2. Examination of Local Properties

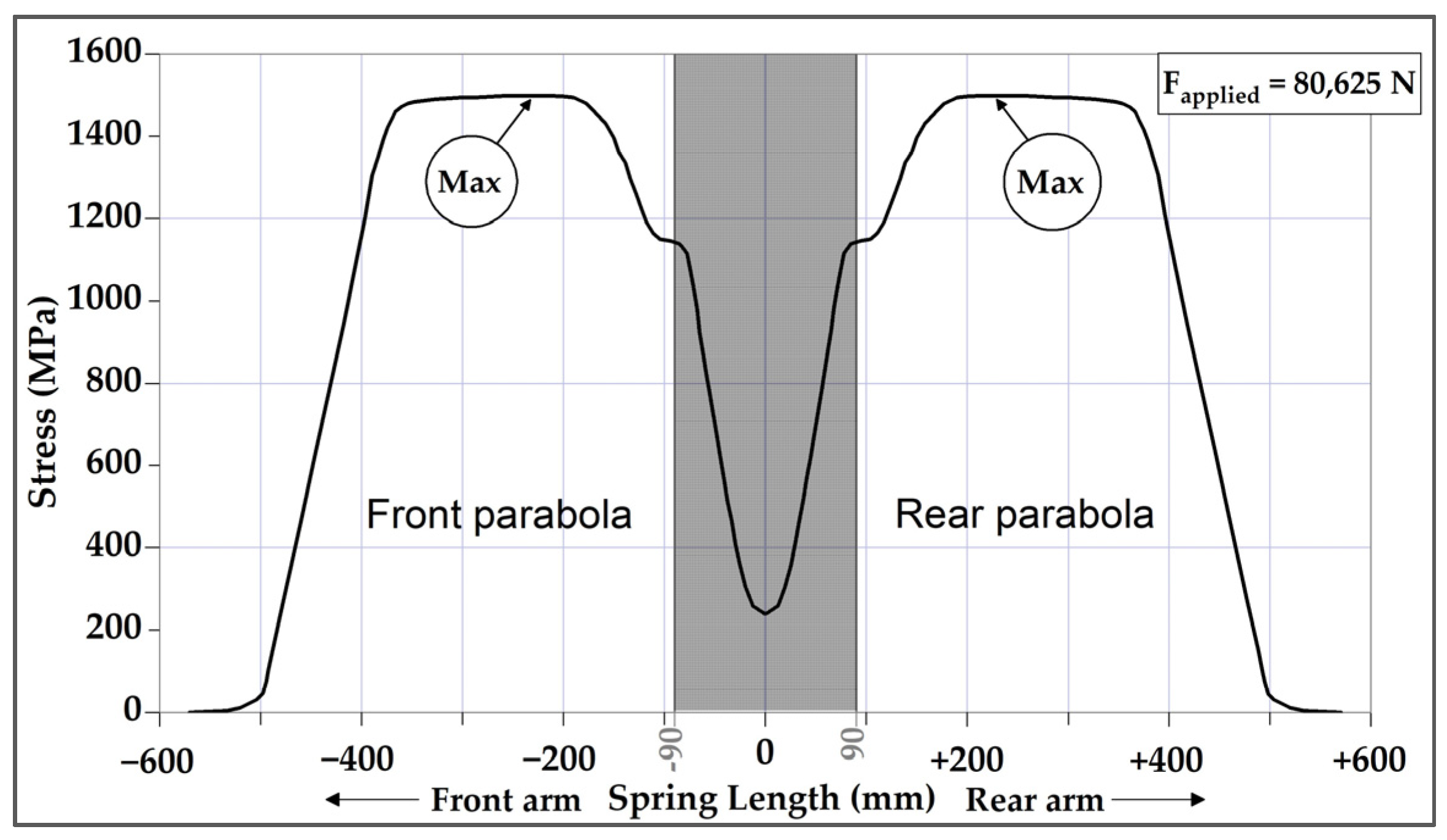

3.3. Loading Parameters

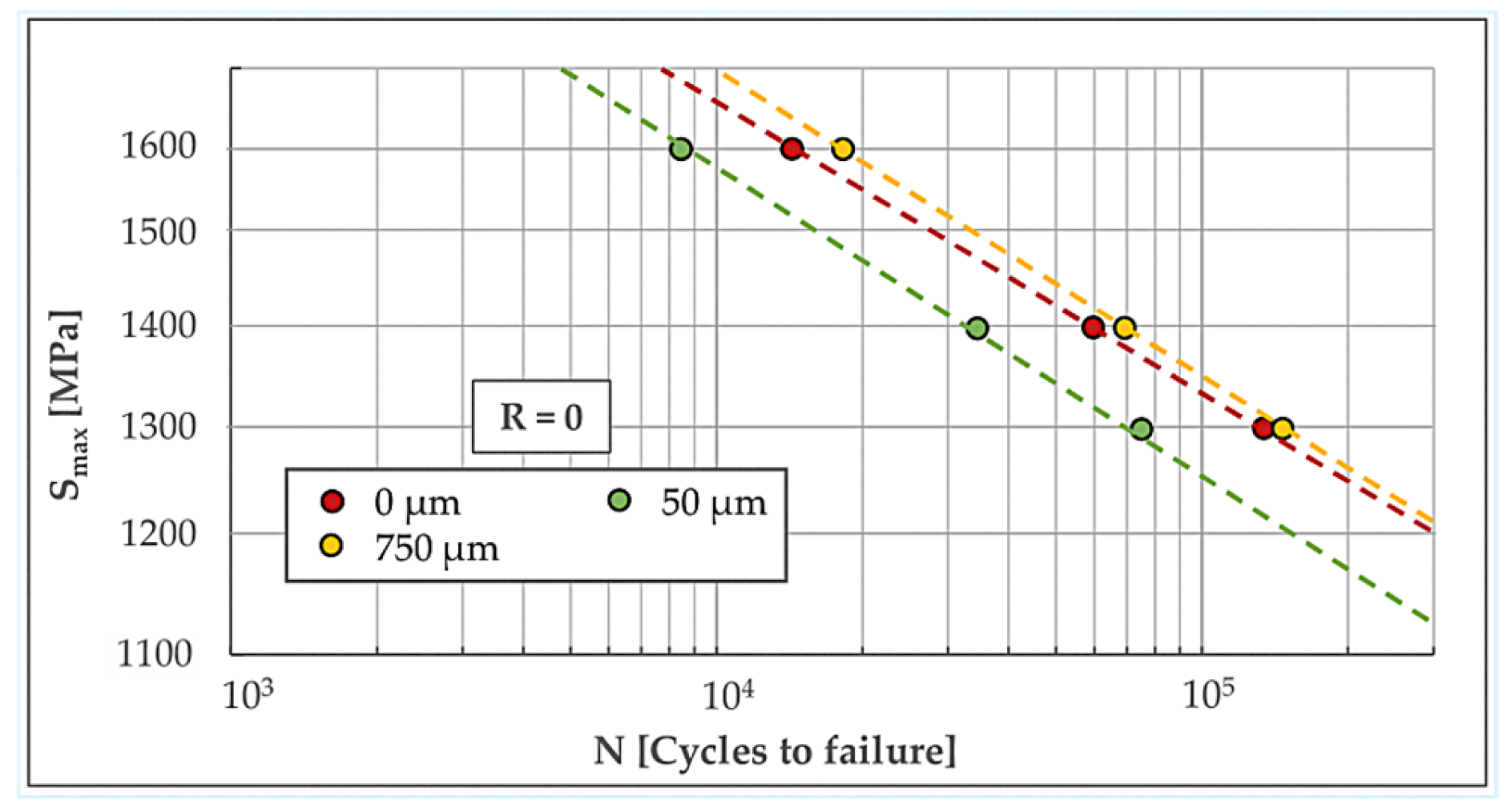

3.4. Fatigue Behavior of Layers

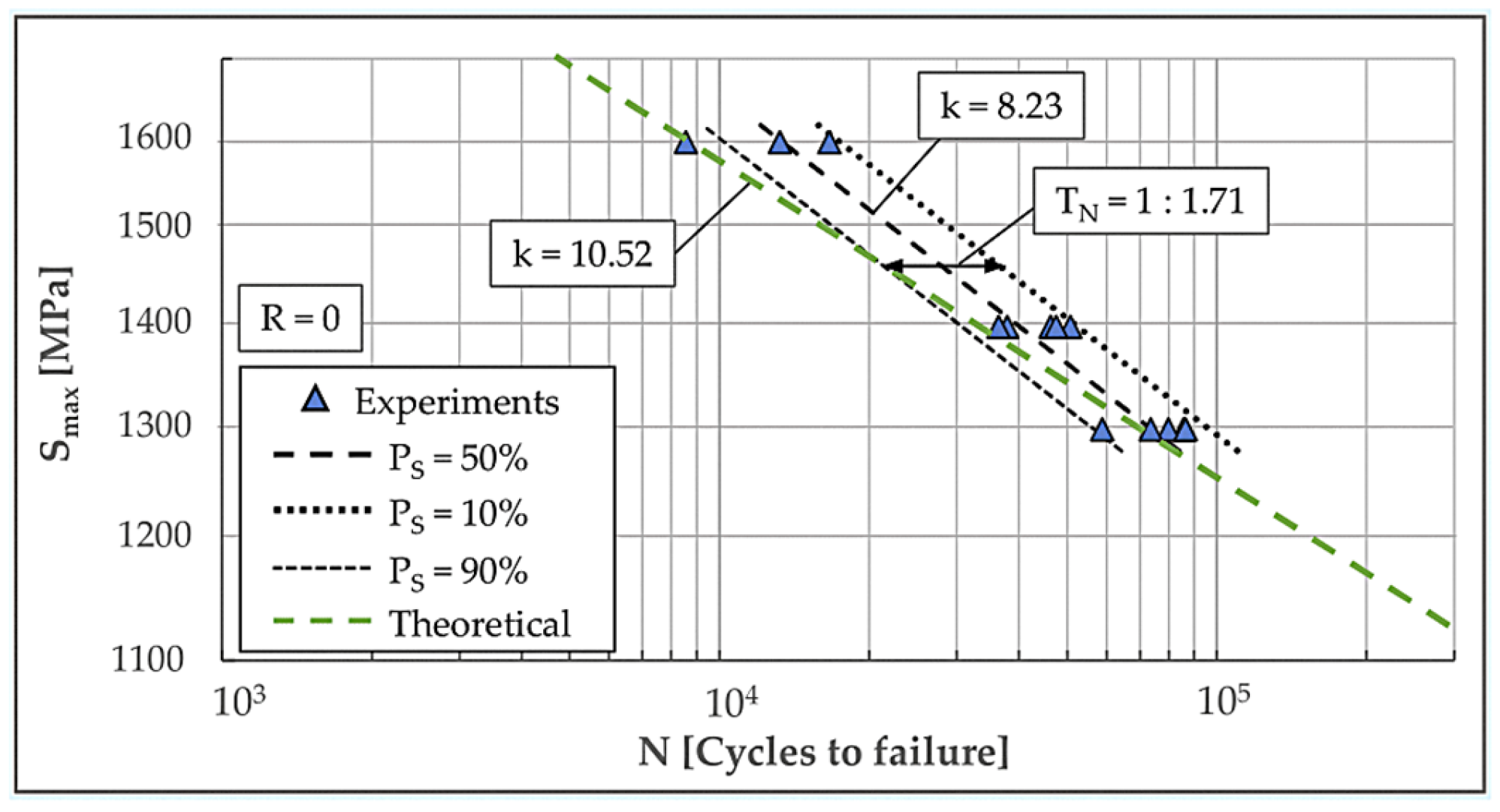

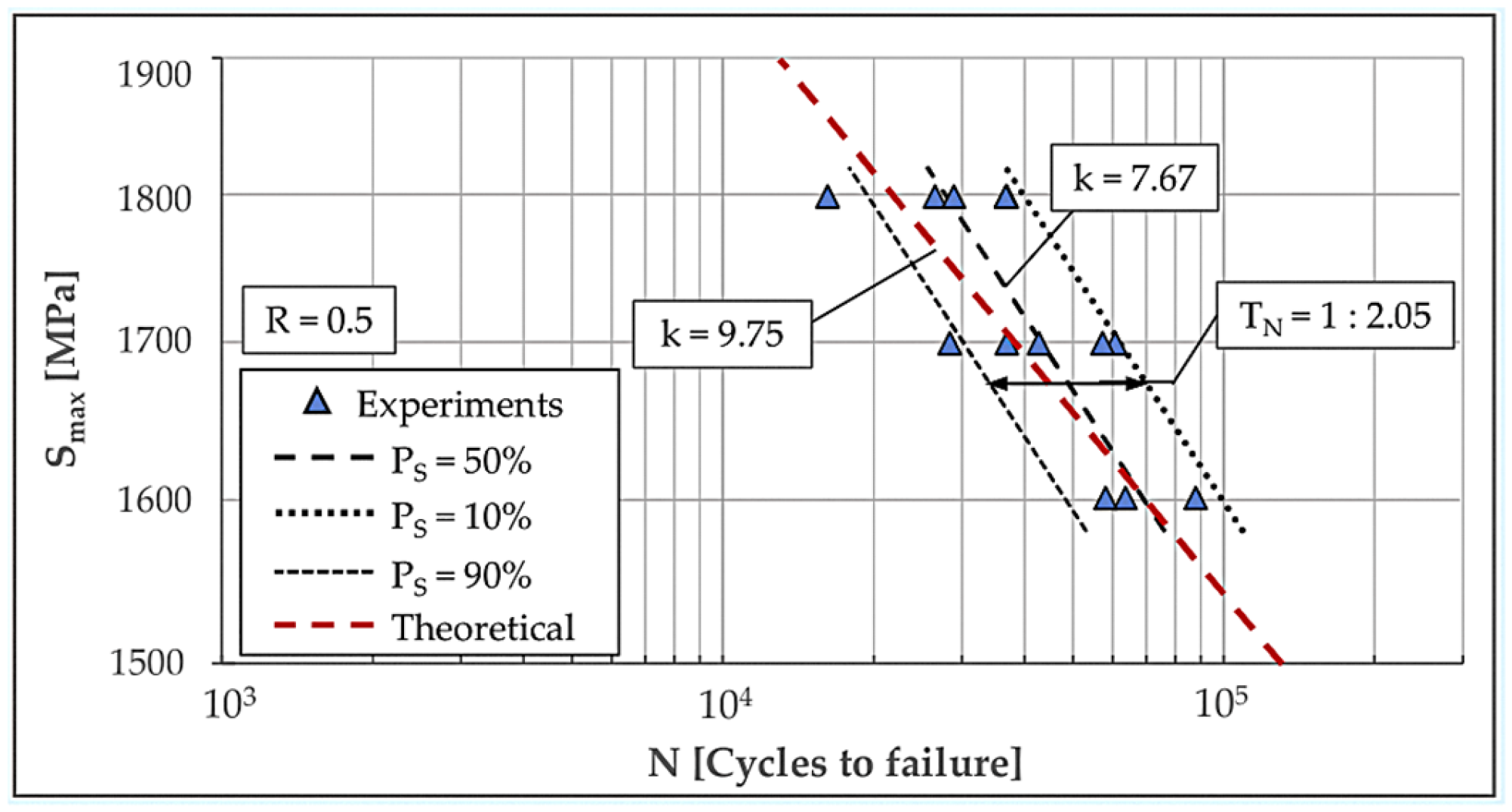

4. Results and Discussion

5. Conclusions

- The fatigue assessment based on discrete material depth layers demonstrates good agreement with experimental fatigue data, providing first validation of the approach, despite the fact that stress relaxation during cyclic loading is ignored.

- Incorporating depth-graded mechanical properties for heat treated and shot-peened components as in the present case study leads to accurate fatigue life predictions based on measurable parameters.

- This procedure supports early-stage fatigue design, applicable in early stages of development, when components are not yet available.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Malikoutsakis, M.; Gakias, C.; Makris, I.; Kinzel, P.; Müller, E.; Pappa, M.; Michailidis, N.; Savaidis, G. On the Effects of Heat and Surface Treatment on the Fatigue Performance of High-Strength Leaf Springs. MATEC Web Conf. 2021, 349, 04007. [Google Scholar] [CrossRef]

- Fragoudakis, R.; Karditsas, S.; Savaidis, G.; Michailidis, N. The Effect of Heat and Surface Treatment on the Fatigue Behaviour of 56SiCr7 Spring Steel. Procedia Eng. 2014, 74, 309–312. [Google Scholar] [CrossRef]

- Farrahi, G.H.; Lebrijn, J.L.; Couratin, D. Effect of Shot Peening on Residual Stress and Fatigue Life of a Spring Steel. Fatigue Fract. Eng. Mat. Struct. 1995, 18, 211–220. [Google Scholar] [CrossRef]

- Analytical Strength Assessment of Components in Mechanical Engineering: FKM-Guideline. In FKM-Guideline, 5th ed.; Forschungskuratorium, M., Ed.; VDMA Verl: Frankfurt am Main, Germany, 2003; ISBN 978-3-8163-0425-8. [Google Scholar]

- Kloos, K.H.; Velten, E. Berechnung der Dauerschwingfestigkeit von plasmanitrierten bauteilähnlichen Proben unter Berücksichtigung des Härte-und Eigenspannungsverlaufs. Konstruktion 1984, 36, 181–188. [Google Scholar]

- Hassani-Gangaraj, S.M.; Moridi, A.; Guagliano, M.; Ghidini, A.; Boniardi, M. The Effect of Nitriding, Severe Shot Peening and Their Combination on the Fatigue Behavior and Micro-Structure of a Low-Alloy Steel. Int. J. Fatigue 2014, 62, 67–76. [Google Scholar] [CrossRef]

- De La Cruz, P.; Odén, M.; Ericsson, T. Effect of Laser Hardening on the Fatigue Strength and Fracture of a B–Mn Steel. Int. J. Fatigue 1998, 20, 389–398. [Google Scholar] [CrossRef]

- DIN EN ISO 4288:1998; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. Beuth Verlag: Berlin, Germany, 1998.

- ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 18265:2013(E); Metallic Materials—Conversion of Hardness Values. International Organization for Standardization: Geneva, Switzerland, 2013.

- Dalaei, K.; Karlsson, B.; Svensson, L.-E. Stability of Shot Peening Induced Residual Stresses and Their Influence on Fatigue Lifetime. Mater. Sci. Eng. A 2011, 528, 1008–1015. [Google Scholar] [CrossRef]

| Property | Before HTT and SSP | After HTT and SSP |

|---|---|---|

| HRC hardness | 31.8 | 48.2 |

| Ultimate tensile strength Rm [MPa] | 999 | 1644 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamidis, P.; Gakias, C.; Giannakis, E.; Savaidis, G. A Fatigue Life Calculation Procedure Implementing Surface and Depth-Graded Mechanical Properties. Eng. Proc. 2025, 119, 25. https://doi.org/10.3390/engproc2025119025

Adamidis P, Gakias C, Giannakis E, Savaidis G. A Fatigue Life Calculation Procedure Implementing Surface and Depth-Graded Mechanical Properties. Engineering Proceedings. 2025; 119(1):25. https://doi.org/10.3390/engproc2025119025

Chicago/Turabian StyleAdamidis, Paschalis, Christos Gakias, Efstratios Giannakis, and Georgios Savaidis. 2025. "A Fatigue Life Calculation Procedure Implementing Surface and Depth-Graded Mechanical Properties" Engineering Proceedings 119, no. 1: 25. https://doi.org/10.3390/engproc2025119025

APA StyleAdamidis, P., Gakias, C., Giannakis, E., & Savaidis, G. (2025). A Fatigue Life Calculation Procedure Implementing Surface and Depth-Graded Mechanical Properties. Engineering Proceedings, 119(1), 25. https://doi.org/10.3390/engproc2025119025