1. Introduction

The development of epidermal electronic systems through printing techniques and the use of flexible substrates enables the development of ultra-thin and conformable electronics [

1], which can support physiological signal monitoring [

2]. This is a major field of study, especially considering the wide range of applications that such systems can serve in the health and biomedical domains [

3,

4,

5].

Tattoo paper has emerged as a promising temporary transfer medium due to its low cost, ease of use, and flexibility in inkjet-printed electronics [

6]. However, the transferred electrodes present challenges in terms of reliable electrical interfacing [

7]. It would be greatly beneficial for designers to have a facile route for designing and fabricating printed systems which would (a) include a passivation layer, (b) ensure strong and robust coupling between electrodes and active materials, and (c) offer a direct interface with traditional electronics. In the past, we have investigated various interface methods for bridging printed and traditional electronics [

8], highlighting a gap between commercial solutions and state-of-the-art printed electronics.

Other printing techniques such as screen printing and aerosol jet printing have also been explored for epidermal sensor fabrication [

9,

10] but typically require more complex process control or are less compatible with ultra-thin, conformal transfer. Additionally, the printed structures cannot be connected with standard electronics using a facile method, often risking mechanical damage and degraded performance.

In contrast to previous reports, our method enables integration with pre-patterned copper electrodes via a simple tattoo paper water-assisted transfer; this greatly lowers interfacial resistance thus facilitating hybrid printed/conventional system integration. The proposed method addresses a major bottleneck of robust electrical interfacing in epidermal electronics, with more traditional measurement and data transmission systems, batteries, etc.

2. Methods

PEDOT:PSS (OrgaconTM IJ1005, 0.8 wt% solid content in water) electrodes were inkjet-printed on tattoo paper (Temporary Transfer Tattoo Kit 2.1, The Magic Touch Ltd., Dunstable, Bedfordshire, UK). The devices were printed using a custom Drop-On-Demand inkjet printer (FR-DEPOSIT, Athens, Greece) equipped with a Microdrop MD-K-140 head (microdrop Technologies GmbH, Norderstedt, Germany—nozzle diameter, 70 μm). After experimenting with the droplet spacing, an optimum spacing of 55 μm in both directions was set; the samples were printed with eight passes to ensure film uniformity. The design was similar to that of a typical electronic component in a “0603” package (1.6 × 0.8 mm).

After printing, White Light Interferometry (Filmetrics Profilm 3D, KLA, Unterhaching, Germany) was employed to depict the film morphology on the tattoo paper. Initial electrical characterization was then performed using a source-meter Keithley 2612 (Tektronix, Inc., Beaverton, OR, USA), using a probe station with needle probes.

Subsequently, we transferred the samples onto 25 μm-thick Kapton substrates with pre-patterned copper electrodes with 9 μm thickness, aiming to improve mechanical robustness and facilitate integration with existing electronic systems. The copper tracks had the dimensions of a “0603” electronic component, but with somewhat enlarged pads to facilitate the alignment process. The transfer process was performed according to the tattoo paper manufacturer; the tattoo paper was transferred by moistening with water and pressing gently on the Kapton surface after aligning with the electrodes, allowing for the reliable release and adhesion of the conductive layer onto the copper electrodes.

For further electro-thermal evaluation, we used a FLIR A655SC IR camera (FLIR Systems, Inc., Wilsonville, OR, USA) and a custom hotplate to control sample temperature.

3. Results and Discussion

3.1. Electrical Characterization

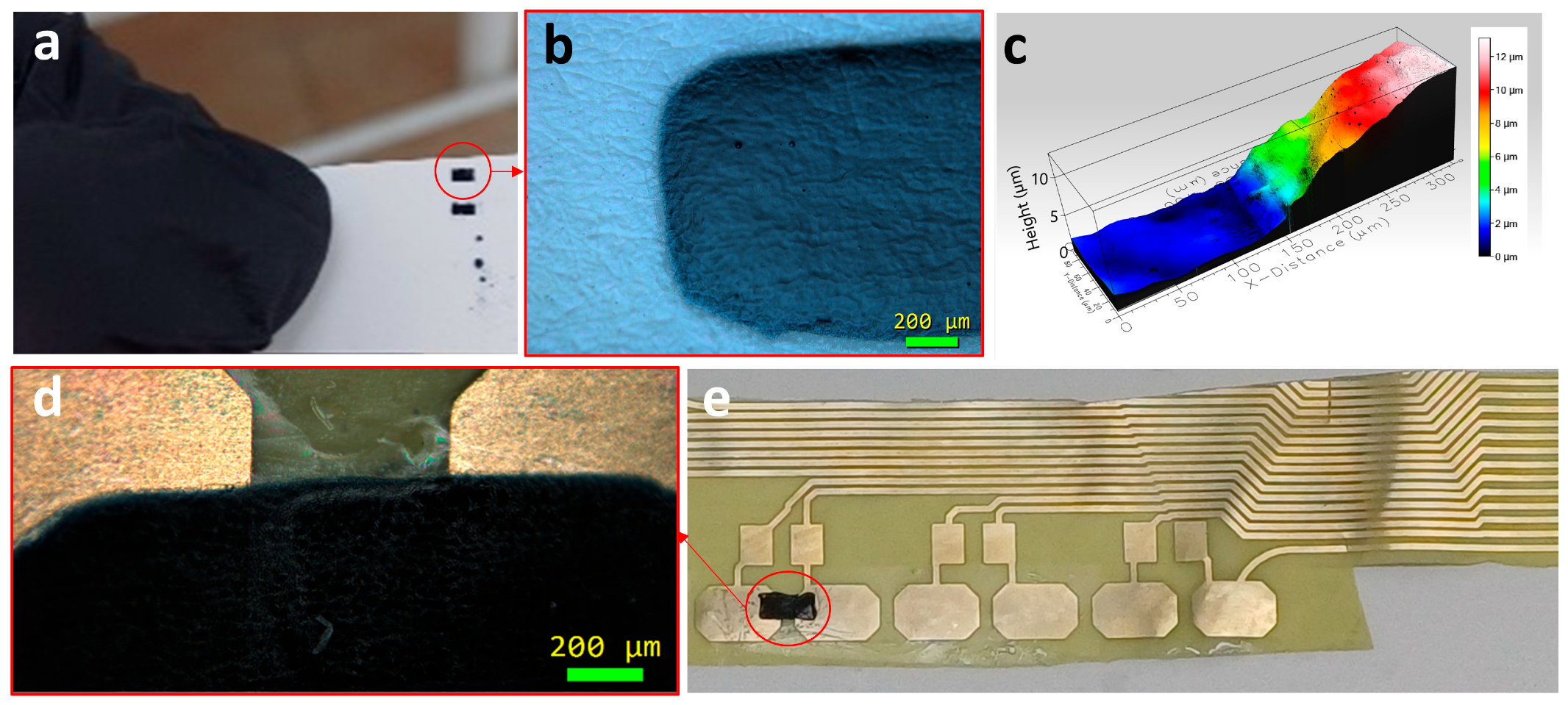

Figure 1a presents an image acquired using a smartphone and

Figure 1b the corresponding optical microscope image of a printed structure. The multi-pass printing strategy ensured that uniform continuous lines were formed and with no observed line breaks, unlike single-pass printing, which resulted in poor line continuity.

Figure 1c presents a White Light Interferometry profile of the printed structure on the tattoo paper which shows a mean height of 10.2 μm. Overall, smooth surfaces were formed at the areas where the ink thickness had reached a steady value (i.e., towards the center of the line).

After transferring the sample onto the Kapton, a visual inspection revealed that the alignment was successfully performed. This is critical given the fact that the actual resistance measurements will be significantly influenced by this interface area, between the Cu tracks and the printed PEDOT:PSS structure.

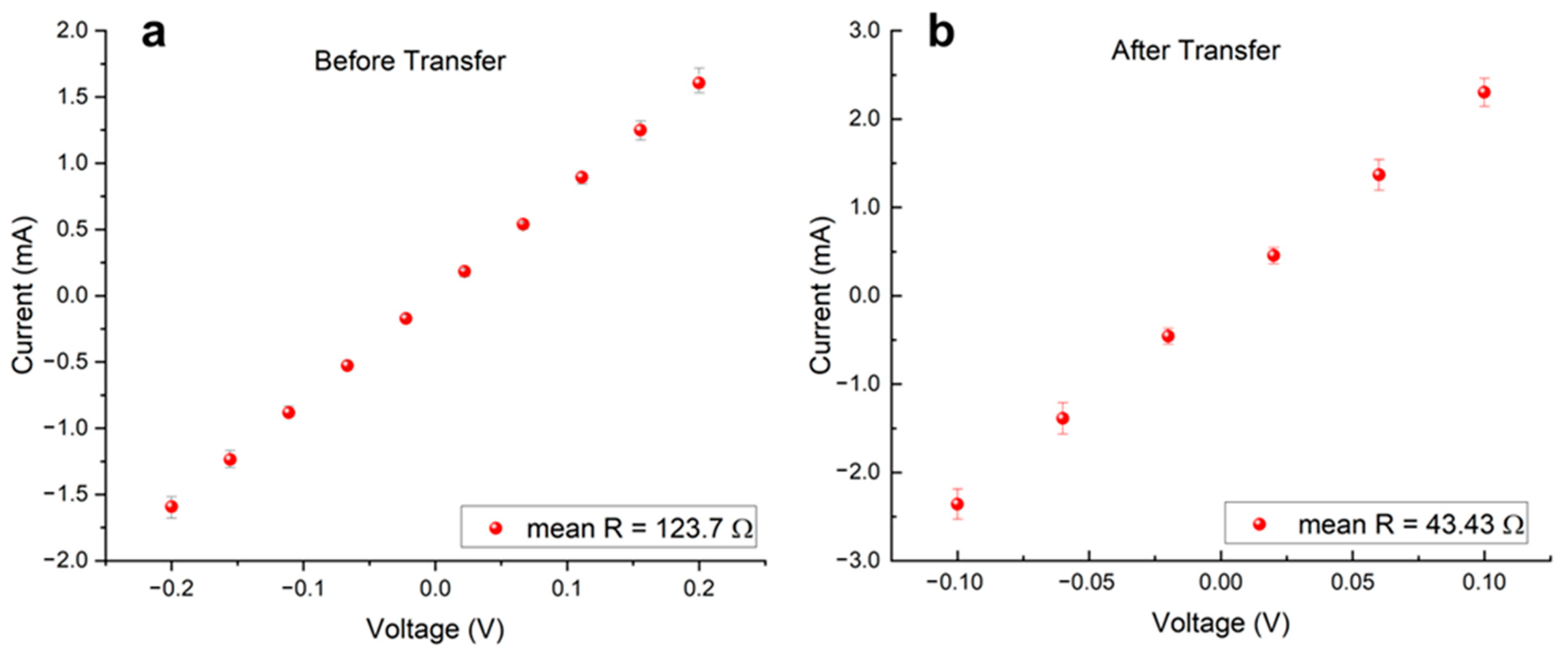

By measuring the resistance before and after transferring the device, we can obtain an estimation of the impact that the process had on the actual device performance. We performed an I-V scan with low voltages so as to ensure that self-heating due to current flow did not occur. It was observed (

Figure 2) that the same device exhibited lower resistance after being transferred to the Kapton substrate. This interesting result can be attributed to improved electrical contact and reduced interfacial resistance between the device and the Cu electrodes after transferring it onto the Kapton substrate. The conformal nature of the tattoo paper greatly helps the sample to bond closely with a large electrode area.

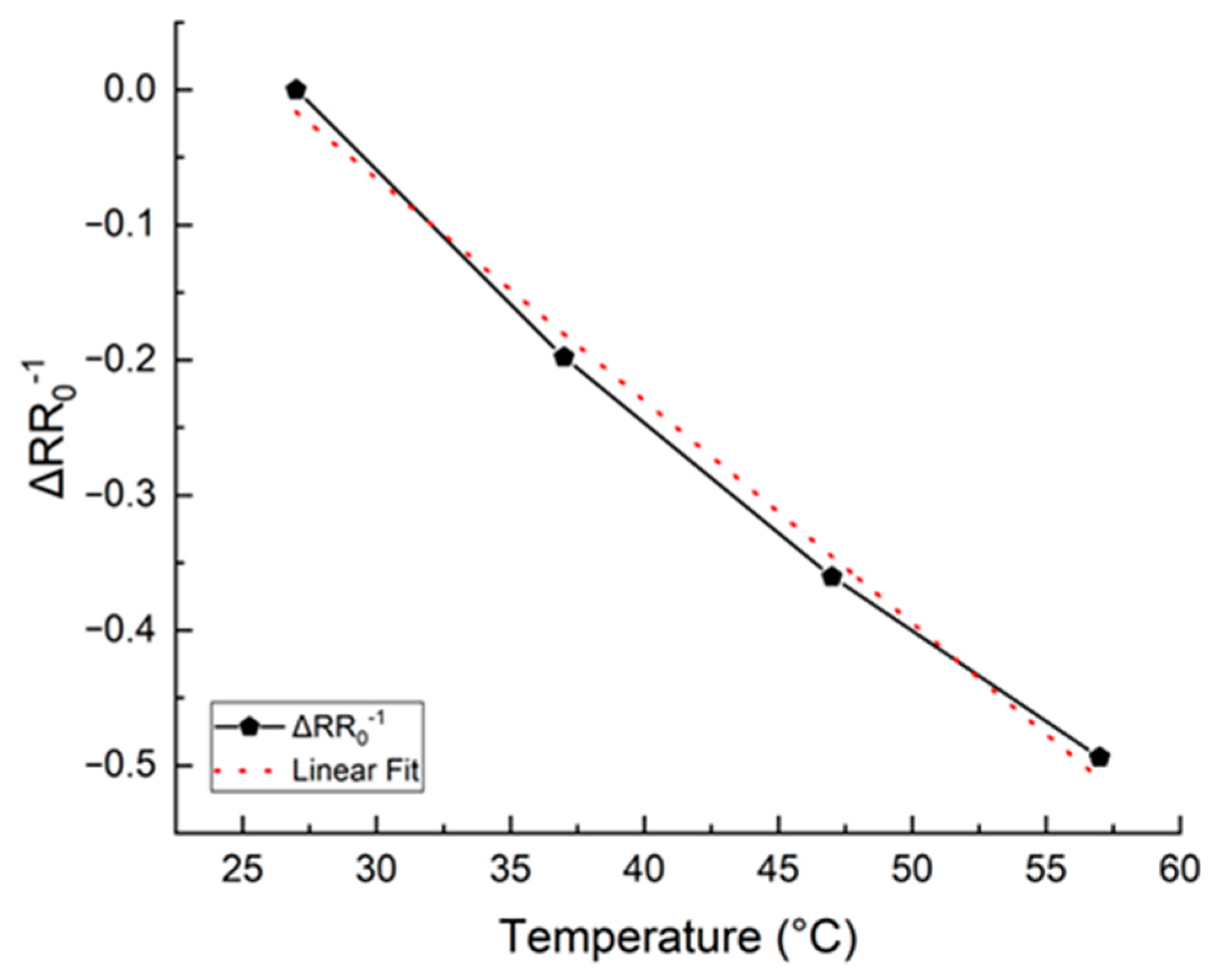

3.2. Evaluation as Temperature Sensor

After transferring the device to Kapton substrate with the Cu electrodes, we performed an external temperature sweep, i.e., the device was placed on a hotplate and the temperature was increase while resistance was measured. The Temperature Coefficient of Resistance (TCR) was subsequently determined to be −0.0164 °C

−1 (

Figure 3). Simultaneously, it was demonstrated that the device can be applied to the skin and exhibits sensitivity to temperature variations within the physiological range as well as to elevated temperatures, up to 57 °C.

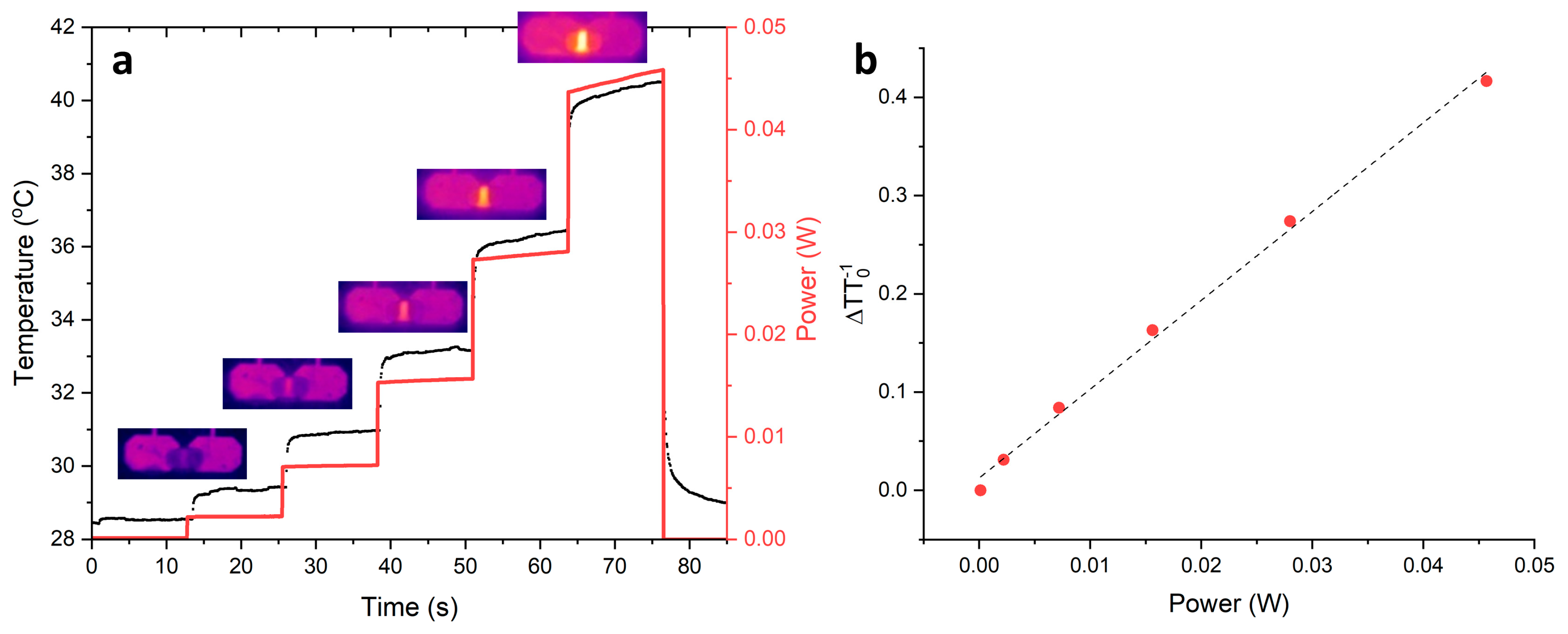

3.3. Evaluation as Microheater

The microheater performance was evaluated by applying gradual input power and monitoring the corresponding temperature increase with the IR camera (

Figure 4a). The device demonstrated rapid temperature increase, achieving up to 40.4 °C with just 45 mW of power. A linear relationship between normalized temperature change (ΔT/T

0−1) and power was observed, indicating high heating efficiency attributed to low-loss ohmic contacts (

Figure 4b). The efficiency was calculated as 6.4 mW/°C. These results confirm the device’s suitability for low-power heating applications on human skin. This efficiency classifies our device as highly efficient compared to similar wearable heaters reported recently [

11,

12,

13].

3.4. Biocompatibility: Future Work

Preliminary manual flexing of the transferred devices revealed stable operation. The devices, after being transferred, were bent by hand and no impact on electrical resistance or visible cracks was observed. However, systematic durability testing—including exposure to sweat and repeated on-skin application—will be addressed in future studies.

Additionally, while biocompatibility tests were not performed in this preliminary work, the tattoo paper substrate, which is commercially available for skin contact, has been employed for epidermal sensors in various recent works [

6,

7]. The PEDOT:PSS layer is encapsulated between the tattoo paper and Kapton, eliminating direct skin exposure; additionally, both PEDOT:PSS [

14,

15] and Kapton [

16,

17] offer great biocompatibility. However, it is in our future plans to perform cytotoxicity and adhesion testing for the clinical translation of the proposed device.

4. Conclusions

In this work, we present a method for transferring printed electronics onto pre-patterned electrodes using a straightforward commercial process. Printing of structures onto tattoo paper as an intermediate step offers the following advantages: (a) compatibility with a wide range of substrates, including flexible and unconventional materials while providing an inherent back-side passivation layer; (b) preservation of device integrity during transfer, as demonstrated by the significant reduction in electrical resistance after transfer; (c) rapid, low-cost, and scalable fabrication of flexible wearable devices; and (d) seamless integration with conventional electrode materials, such as copper, capable of being directly integrated with traditional electronics.

R-T measurements were aligned with recent literature, demonstrating that the proposed method does not adversely affect the printed material for its sensing capabilities. Additionally, when the device was operated as a microheater, the insulating nature of Kapton assisted in maximizing performance, i.e., high-power efficiency.

We believe that this easy-to-implement method offers unique advantages and can be adapted to fabricate high-end flexible electronics for demanding on-body applications.

Author Contributions

Conceptualization, A.A. and D.B.; methodology, G.K.; validation, A.A., D.B. and F.J.; formal analysis, A.A.; resources, G.K.; data curation, D.B.; writing—original draft preparation, A.A.; writing—review and editing, D.B., F.J., K.A. and G.K.; visualization, A.A.; supervision, F.J. and G.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ajman University (grant agreement 2024-IRG-ENIT-12) and by the Special Account for Research Grants—University of West Attica.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, S.; Huang, J.; Wang, M.; Deng, K.; Guo, C.; Li, B.; Cheng, Y.; Sun, H.; Ye, H.; Pan, T.; et al. Structural Electronic Skin for Conformal Tactile Sensing. Adv. Sci. 2023, 10, 2304106. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; He, K.; Li, J.; Chen, X. Conformal Electrodes for On-skin Digitalization. SmartMat 2021, 2, 252–262. [Google Scholar] [CrossRef]

- Liu, X.; Wei, Y.; Qiu, Y. Advanced Flexible Skin-Like Pressure and Strain Sensors for Human Health Monitoring. Micromachines 2021, 12, 695. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, R.G.; Silva, A.P.; Nunes-Pereira, J. Current On-Skin Flexible Sensors, Materials, Manufacturing Approaches, and Study Trends for Health Monitoring: A Review. ACS Sens. 2024, 9, 1104–1133. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ke, K.; Jia, J.; Pu, J.; Zhao, X.; Bao, R.; Liu, Z.; Bai, L.; Zhang, K.; Yang, M.; et al. Recent Advances in Multiresponsive Flexible Sensors towards E-skin: A Delicate Design for Versatile Sensing. Small 2022, 18, 2103734. [Google Scholar] [CrossRef] [PubMed]

- Bonacchini, G.E.; Bossio, C.; Greco, F.; Mattoli, V.; Kim, Y.; Lanzani, G.; Caironi, M. Tattoo-Paper Transfer as a Versatile Platform for All-Printed Organic Edible Electronics. Adv. Mater. 2018, 30, 1706091. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, J.; Chen, D.; Ge, S.; Liu, Y.; Wang, Z.; Zhang, X.; Guo, Q.; Yang, J. Robust Tattoo Electrode Prepared by Paper-Assisted Water Transfer Printing for Wearable Health Monitoring. IEEE Sens. J. 2022, 22, 3817–3827. [Google Scholar] [CrossRef]

- Apostolakis, A.; Barmpakos, D.; Pilatis, A.; Patsis, G.; Pagonis, D.-N.; Belessi, V.; Kaltsas, G. Resistivity Study of Inkjet-Printed Structures and Electrical Interfacing on Flexible Substrates. Micro Nano Eng. 2022, 15, 100129. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, Y.; Gu, S.; Cao, S.; Wang, J.; Zhang, M.; Wu, Y.; Kong, D. Fully Screen-Printed, Multicolor, and Stretchable Electroluminescent Displays for Epidermal Electronics. ACS Appl. Mater. Interfaces 2020, 12, 47902–47910. [Google Scholar] [CrossRef] [PubMed]

- Cooper, C.; Hughes, B. Aerosol Jet Printing of Electronics: An Enabling Technology for Wearable Devices. In Proceedings of the 2020 Pan Pacific Microelectronics Symposium (Pan Pacific), Big Island, HI, USA, 10–13 February 2020; pp. 1–11. [Google Scholar]

- Pattanarat, K.; Petchsang, N.; Osotchan, T.; Kim, Y.-H.; Jaisutti, R. Wash-Durable Conductive Yarn with Ethylene Glycol-Treated PEDOT:PSS for Wearable Electric Heaters|ACS Applied Materials & Interfaces. ACS Appl. Mater. Interfaces 2021, 13, 48053–48060. [Google Scholar] [CrossRef]

- Deng, C.; Zhao, S.; Su, E.; Li, Y.; Wu, F. Trilayer MXene Fabric for Integrated Ultrasensitive Pressure Sensor and Wearable Heater. Adv. Mater. Technol. 2021, 6, 2100574. [Google Scholar] [CrossRef]

- Liu, Q.; Tian, B.; Liang, J.; Wu, W. Recent Advances in Printed Flexible Heaters for Portable and Wearable Thermal Management. Mater. Horiz. 2021, 8, 1634–1656. [Google Scholar] [CrossRef] [PubMed]

- Stříteský, S.; Marková, A.; Víteček, J.; Šafaříková, E.; Hrabal, M.; Kubáč, L.; Kubala, L.; Weiter, M.; Vala, M. Printing Inks of Electroactive Polymer PEDOT:PSS: The Study of Biocompatibility, Stability, and Electrical Properties. J. Biomed. Mater. Res. A 2018, 106, 1121–1128. [Google Scholar] [CrossRef]

- Yang, T.; Yang, M.; Xu, C.; Yang, K.; Su, Y.; Ye, Y.; Dou, L.; Yang, Q.; Ke, W.; Wang, B.; et al. PEDOT:PSS Hydrogels with High Conductivity and Biocompatibility for in Situ Cell Sensing. J. Mater. Chem. B 2023, 11, 3226–3235. [Google Scholar] [CrossRef] [PubMed]

- Andrani, M.; Borghetti, P.; Saleri, R.; Simonazzi, B.; Cavalli, V.; D’Onofrio, I.; Tarabella, G.; Botti, M.; D’Angelo, P.; Martini, F.M. In Vitro Evaluation of the Biocompatibility and Chondro-Inductive Potential of Kapton® for Cartilage Tissue Engineering. Res. Vet. Sci. 2025, 193, 105755. [Google Scholar] [CrossRef] [PubMed]

- Brăileanu, P.I.; Pascu, N.E. Influence of Surface Texture in Additively Manufactured Biocompatible Materials and Triboelectric Behavior. Materials 2025, 18, 3366. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).