Industrial Engineering Needs a Revolution to Become Effective and Sustainable: An Exhaustive Review and Outlook †

Abstract

1. Introduction

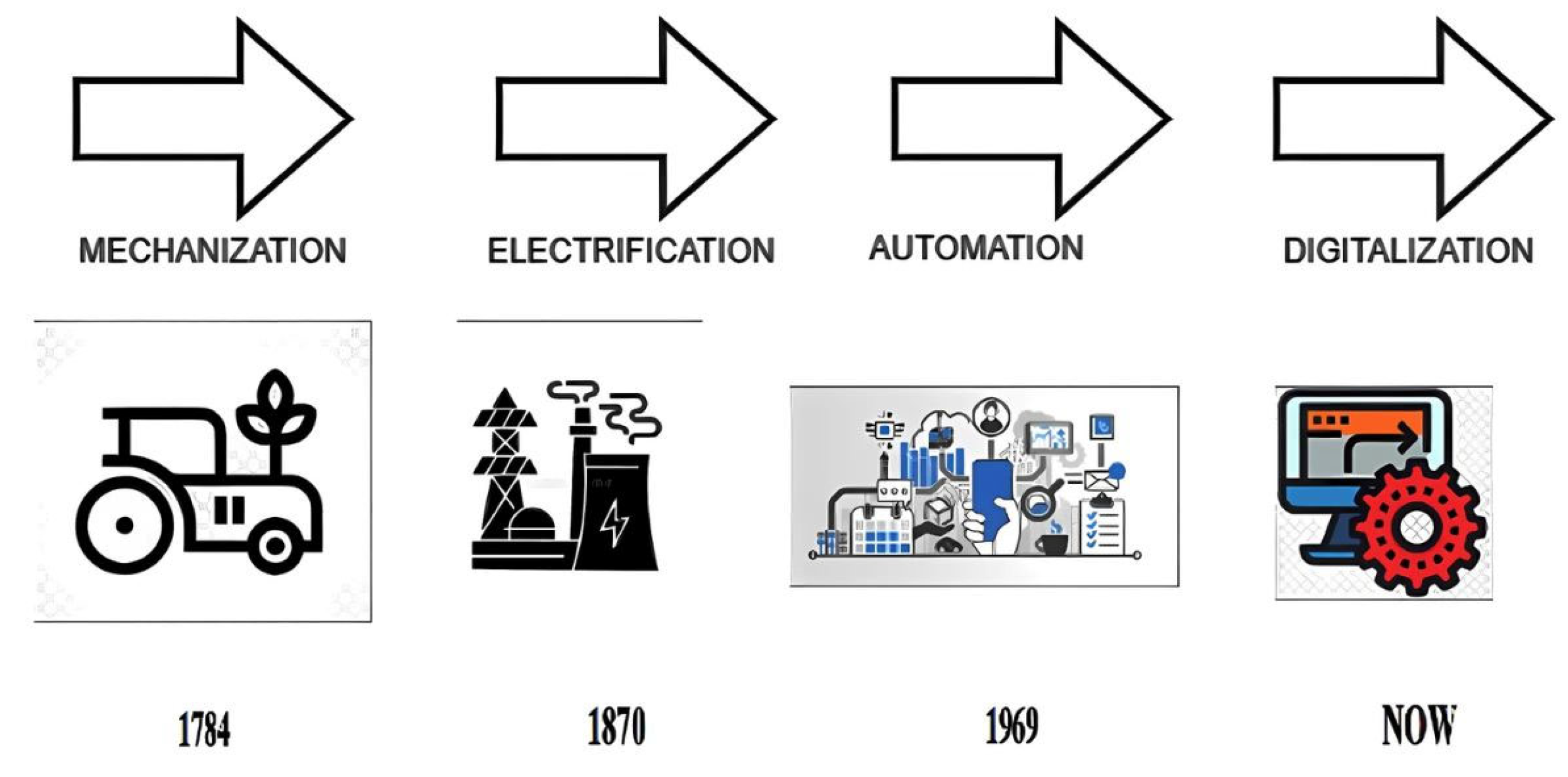

Current State of Industrial Engineering

2. Current Practices in Industrial Engineering

3. Adaptation of New Technologies

4. The Need for Revolution

5. The Challenges the Industry Is Facing Today

6. Strategies for Implementing Revolution in Industrial Engineering

7. Revolutionizing Industrial Engineering

8. Embracing Emerging Technologies

8.1. Fostering Innovation

8.2. Data Analytics and Business Intelligence

8.3. Optimization of Supply Chain

8.4. Integration of Sustainability

8.5. Adopting New Approaches to Problem-Solving

9. Redefining the Role of Industrial Engineers

9.1. Leverage Technology

9.2. Emphasis on Sustainability

9.3. Use System Thinking

9.4. Establish Strong Communication and Collaboration Skills

9.5. Become Proficient in Data Analysis

9.6. Stress Continuous Improvement

10. Benefits of Revolutionizing Industrial Engineering

10.1. Increased Efficiency and Productivity

10.2. Enhanced Quality Control

10.3. Increased Safety

10.4. Less Environmental Impact

10.5. Increased Innovation

10.6. Enhanced Customer Satisfaction

10.7. More Sustainability

11. Collaborating with Stakeholders

12. Conclusions

Current and Future Development

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ourihi, R.; Elhilali, F.Z.; Fihri-Fassi, H. Implementing a Complete Method of Eco-Design, Optimization, and Sustainability in Automotive Mirrors. Recent Pat. Mech. Eng. 2024, 17, 53–64. [Google Scholar] [CrossRef]

- Ji, Y.; Bao, J.; Yin, Y.; Ma, C. Applications of artificial intelligence in tribology. Recent Pat. Mech. Eng. 2016, 9, 193–205. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, Y.; Qi, S.; Fang, X.; Yin, X. Recent patents on RFID-based logistics management systems. Recent Pat. Mech. Eng. 2016, 9, 26–36. [Google Scholar] [CrossRef]

- Karambelkar, S.; Khaire, R.; Ghule, R.; Hiray, P.; Kulkarni, S.; Somatkar, A. Design and Analysis of Automatic Tripod Style Horizontal Multi Bobbin Wire Winder. In Proceedings of the 6th International Conference on Computing, Communication, Control And Automation, Pune, India, 26–27 August 2022; pp. 1–4. [Google Scholar]

- Tri, N.M.; Hoang, P.D.; Dung, N.T. Impact of the industrial revolution 4.0 on higher education in Vietnam: Challenges and opportunities. Linguist. Cult. Rev. 2021, 5, 1–15. [Google Scholar] [CrossRef]

- Bagade, P.M.; Bagade, P.P.; Chaudhari, A.; Ranjan, P.; Shirke, S.; Sedani, C. Numerical Investigation on Aerodynamic Performance of Helical Savonius Rotor Inspired by Natural Shapes. J. Mines Met. Fuels 2023, 71. [Google Scholar] [CrossRef]

- Devi, M.; Annamalai, M.A.R.; Veeramuthu, S.P. Literature education and industrial revolution 4.0. Univers. J. Educ. Res. 2020, 8, 1027–1036. [Google Scholar] [CrossRef]

- Mayer, C.H.; Oosthuizen, R.M. Positive transformation towards the fourth industrial revolution: Empirical evidence from a technology company. Int. Rev. Psychiatry 2020, 32, 659–672. [Google Scholar] [CrossRef]

- Genkin, E.; Filin, S.; Velikorossov, V.; Kydyrova, Z.; Anufriyev, K. The fourth industrial revolution: Personnel, business and state. E3S Web Conf. 2020, 159, 04012. [Google Scholar] [CrossRef]

- Anshari, M. Workforce mapping of fourth industrial revolution: Optimization to identity. J. Phys. Conf. Ser. 2020, 1477, 072023. [Google Scholar] [CrossRef]

- Pasi, B.N.; Mahajan, S.K.; Rane, S.B. A method for performing forging operation: A perspective of industry 4.0. Recent Pat. Mech. Eng. 2021, 14, 423–435. [Google Scholar] [CrossRef]

- Jayaraman, V.; Luo, Y. Industrial engineering research challenges and opportunities for the 21st century. Int. J. Prod. Res. 2019, 57, 2159–2165. [Google Scholar]

- Bagade, P.M.; Bhumkar, Y.G.; Sengupta, T.K. An improved orthogonal grid generation method for solving flows past highly cambered aerofoils with and without roughness elements. Comput. Fluids 2014, 103, 275–289. [Google Scholar] [CrossRef]

- Khan, M.A.; Pohekar, S.D.; Bagade, P.M. Hydrodynamic Analysis of NACA 4415 Hydrofoil for Marine Applications. J. Mines Met. Fuels 2023, 71. [Google Scholar]

- Rahardja, U.; Aini, Q.; Graha, Y.I.; Tangkaw, M.R. Gamification framework design of management education and development in industrial revolution 4.0. J. Phys. Conf. Ser. 2019, 1364, 012035. [Google Scholar] [CrossRef]

- Alves, A.C.; Ferreira, A.; Maia, L.C.; Leão, C.P.; Carneiro, P. A symbiotic relationship between Lean Production and Ergonomics: Insights from Industrial Engineering final year projects. Int. J. Ind. Eng. Manag. 2019, 10, 243–256. [Google Scholar]

- Poór, P.; Ženíšek, D.; Basl, J. Historical overview of maintenance management strategies: Development from breakdown maintenance to predictive maintenance in accordance with four industrial revolutions. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pilsen, Czech Republic, 23–26 July 2019; pp. 23–26. [Google Scholar]

- Jacobs, J.; Pretorius, M.W. The major challenges facing organizations to create technology-enabled value in the fourth industrial revolution: A dynamic capabilities perspective in South Africa. S. Afr. J. Ind. Eng. 2020, 31, 40–61. [Google Scholar]

- Kamaruzamani, F.M.; Hamid, R.; Mutalib, A.A.; Rasul, M.S. Emotional intelligence attributes for engineering graduates of the industrial revolution 4.0. Int. J. Innov. Creat. Change 2019, 7, 326–343. [Google Scholar]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Mokyr, J. Are we living in the middle of an industrial revolution? Econ. Rev.-Fed. Reserve Bank Kans. City 1997, 82, 31–44. [Google Scholar]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Mecerreyes, D. Technologies associated with Industry 4.0 in green supply chains: A systematic literature review. Sustainability 2022, 15, 9784. [Google Scholar] [CrossRef]

- Zareiyan, B.; Korjani, M. Blockchain technology for global decentralized manufacturing: Challenges and solutions for supply chain in fourth industrial revolution. Int. J. Adv. Robot. Autom. 2018, 3, 1–10. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rojas, R.; Carabin, G.; Palomba, I.; Rauch, E.; Vidoni, R.; Matt, D.T. Advanced automation for SMEs in the I4. 0 revolution: Engineering education and employees training in the smart mini factory laboratory. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM) 2018, Bangkok, Thailand, 16–19 December 2018; pp. 1111–1115. [Google Scholar]

- Kusiak, A. Smart manufacturing and industry 4.0: A review of research issues and application examples. Int. J. Prod. Res. 2018, 56, 2924–2937. [Google Scholar]

- Somatkar, A.A. Enhancing Surface Integrity and Quality through Roller Burnishing: A Comprehensive Review of Parameters Optimization, and Applications. Commun. Appl. Nonlinear Anal. 2024, 31, 151–169. [Google Scholar] [CrossRef]

- García Ferrari, T. Design and the Fourth Industrial Revolution. Dangers and opportunities for a mutating discipline. Des. J. 2017, 20, S2625–S2633. [Google Scholar] [CrossRef]

- Mohamed, M.G.; Ahmed Ibrahim, O.; Hamed, H.F.; Abdelnaby, S.F. Engineering’s Next Leap: How Fourth Industrial Revolution is shaping the Future of the Industry. ERU Res. J. 2024, 3, 970–992. [Google Scholar] [CrossRef]

- Kodama, F. Learning mode and strategic concept for the 4th Industrial Revolution. J. Open Innov. Technol. Mark. Complex. 2018, 4, 32. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.; Yang, S. Service innovation and smart analytics for Industry 4.0 and big data environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Ullah, R.; Tamimi, N. Industrial engineering and sustainability: A systematic review. J. Clean. Prod. 2019, 208, 1275–1293. [Google Scholar]

- Shinde, D.; Somatkar, A.; Nangare, S.; Bhambere, V. Revolutionizing Automotive Security with Advanced ADAS Technology. J. Autom. Automob. Eng. 2024, 1–12. [Google Scholar]

- Narkhede, G.B.; Pasi, B.N.; Rajhans, N.; Kulkarni, A. Industry 5.0 and sustainable manufacturing: A systematic literature review. Benchmarking Int. J. 2024, 32, 608–635. [Google Scholar] [CrossRef]

- Narkhede, G.; Dohale, V.; Mahajan, Y. Darker side of industry 4.0 and its impact on triple-bottom-line sustainability. Sustain. Dev. 2023, 32, 5999–6016. [Google Scholar]

- Azmi, A.N.; Kamin, Y.; Noordin, M.K.; Nasir, A.N.M. Towards industrial revolution 4.0: Employers’ expectations on fresh engineering graduates. Int. J. Eng. Technol. 2018, 7, 267–272. [Google Scholar] [CrossRef]

- Du Preez, N.D.; Pintelon, L. The industrial engineer-caught between two revolutions? Prod. Plan. Control 1997, 8, 418–430. [Google Scholar] [CrossRef][Green Version]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J.P. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef]

- Gupta, V.; Kacker, M. Industrial Engineering: Innovative Networks; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Ozer, M.; Bektas, T. The impact of Industry 4.0 on industrial engineering. J. Ind. Eng. Manag. 2019, 12, 297–305. [Google Scholar]

- George, A.S.; George, A.H. Industrial revolution 5.0: The transformation of the modern manufacturing process to enable man and machine to work hand in hand. J. Seybold Rep. 2020, 15, 214–234. [Google Scholar]

- Harahap, N.J.; Rafika, M. Industrial revolution 4.0: And the impact on human resources. Ecobisma (J. Ekon. Bisnis Manaj.) 2020, 7, 89–96. [Google Scholar] [CrossRef]

- Lase, D. Education and industrial revolution 4.0. J. Handayani 2019, 10, 48–62. [Google Scholar] [CrossRef]

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90–95. [Google Scholar] [CrossRef]

- Uygun, Y. Industry 4.0: Principles, Effects and Challenges; Nova Science: Hauppauge, NY, USA, 2020. [Google Scholar]

- Senge, P.M.; Carstedt, G.; Porter, P.L. Next industrial revolution. MIT Sloan Manag. Rev. 2001, 42, 24–38. [Google Scholar]

- Abdin, M.J. Opportunities and Challenges of the New Industrial Revolution. SSRN 2017. [Google Scholar] [CrossRef]

- Halili, S.H.; Sulaiman, S.; Sulaiman, H.; Razak, R. Embracing industrial revolution 4.0 in universities. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1088, 012111. [Google Scholar] [CrossRef]

- Florida, R. The new industrial revolution. Futures 1991, 23, 559–576. [Google Scholar] [CrossRef]

- Von Tunzelmann, G.N. Engineering and innovation in the industrial revolutions. Interdiscip. Sci. Rev. 1997, 22, 67–77. [Google Scholar] [CrossRef]

- Dogaru, L. The main goals of the fourth industrial revolution. Renewable energy perspectives. Procedia Manuf. 2020, 46, 397–401. [Google Scholar] [CrossRef]

- Blinder, A.S. Education for the third industrial revolution. Am. Prospect. 2006, 17, 44–46. [Google Scholar]

- Rico-Cortez, M.; Andersson, N.E.; Johansen, K. Exploring the Indus-trial Engineering Competences in the Changing Landscape of the New Industrial Revolution. In Sustainable Production Through Advanced Manufacturing, Intelligent Automation and Work Integrated Learning; IOS Press: Amsterdam, The Netherlands, 2024; pp. 672–686. [Google Scholar]

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boer, C.R.; Westkamper, E.; Williams, D.; Paci, A.M. The incoming global technological and industrial revolution to-wards competitive sustainable manufacturing. CIRP Ann. 2008, 57, 641–659. [Google Scholar] [CrossRef]

- Hidayat, H.; Tasrif, E.; Jaya, P.; Anwar, M.; Hadi, A.; Budayawan, K.; Asmara, D. The Empirical Analysis of Industrial Work Challenges in the Industrial Revolution 5.0 Towards a Grade Point Average (GPA) for Electronic Engineering Education Students. Int. J. Online Biomed. Eng. 2021, 17, 21–34. [Google Scholar] [CrossRef]

- Radziwill, N.M. Quality 4.0: Let’s Get Digital-The many ways the fourth industrial revolution is reshaping the way we think about quality. arXiv 2018, arXiv:1810.07829. [Google Scholar]

- Rymarczyk, J. Technologies, opportunities and challenges of the industrial revolution 4.0: Theoretical considerations. Entrep. Bus. Econ. Rev. 2020, 8, 185–198. [Google Scholar] [CrossRef]

- Sorooshian, S.; Panigrahi, S. Impacts of the 4th Industrial Revolution on Industries. Walailak J. Sci. Technol. (WJST) 2020, 17, 903–991. [Google Scholar] [CrossRef]

- Hyun Park, S.; Seon Shin, W.; Hyun Park, Y.; Lee, Y. Building a new culture for quality management in the era of the Fourth Industrial Revolution. Total Qual. Manag. Bus. Excell. 2017, 28, 934–945. [Google Scholar] [CrossRef]

- Arcidiacono, G.; Pieroni, A. The revolution lean six sigma 4.0. Int. J. Adv. Sci. Eng. Inf. Technol. 2018, 8, 141–149. [Google Scholar] [CrossRef]

- Taher, G. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities. Manag. Stud. Econ. Syst. 2021, 6, 109–127. [Google Scholar] [CrossRef]

- Yao, X.; Lin, Y. Emerging manufacturing paradigm shifts for the in-coming industrial revolution. Int. J. Adv. Manuf. Technol. 2016, 85, 1665–1676. [Google Scholar] [CrossRef]

- Rotatori, D.; Lee, E.J.; Sleeva, S. The evolution of the workforce during the fourth industrial revolution. Hum. Resour. Dev. Int. 2021, 24, 92–103. [Google Scholar] [CrossRef]

- Koh, L.; Orzes, G.; Jia, F.J. The fourth industrial revolution (Industry 4.0): Technologies disruption on operations and supply chain management. Int. J. Oper. Prod. Manag. 2019, 39, 817–828. [Google Scholar] [CrossRef]

- Sharma, A.; Singh, B.J. Evolution of industrial revolutions: A review. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 66–73. [Google Scholar] [CrossRef]

- Putra, F.A.; Suseno, B.D. Industrial Revolution 4.0 as a Strategic Issue of Higher Education. Int. J. Sci. Res. Manag. 2022, 10, 3045–3051. [Google Scholar] [CrossRef]

- Fernandez, G.C.; Gutierrez, S.M.; Ruiz, E.S.; Perez, F.M.; Gil, M.C. Robotics, the new industrial revolution. IEEE Technol. Soc. Mag. 2012, 31, 51–58. [Google Scholar] [CrossRef]

- Darwish, H.; Van Dyk, L. Bottom of Pyramid 4.0: Modularizing and assimilating industrial revolution cognition into a 4-tiered social entrepreneurship upliftment model for previously disconnected communities. J. Ind. Integr. Manag. 2018, 3, 1850010. [Google Scholar] [CrossRef]

- Okwu, M.O.; Tartibu, L.; Machesa, M. Fourth industrial revolution and sustainable impact in autonomous fleets for effective supply chain network in manufacturing systems. In Proceedings of the 31st Annual Conference of Southern African Institute for Industrial Engineering, Virtual, 5–7 October 2020; pp. 5–7. [Google Scholar]

- Irwanto, I. Characteristics of effective vocational education in the industrial revolution 4.0. Vanos J. Mech. Eng. Educ. 2019, 4. [Google Scholar] [CrossRef]

- Puhovichova, D.; Jankelova, N. Changes of human resource management in the context of impact of the fourth industrial revolution. Industry 4.0 2020, 5, 138–141. [Google Scholar]

- Fu, G.; Zhou, S.; Qi, L. A size-dependent Bernoulli-Euler beam model based on strain gradient elasticity theory incorporating surface effects. ZAMM J. Appl. Math. Mech. Z. Für Angew. Math. Und Mechanik 2019, 99, e201800048. [Google Scholar]

- Rothwell, R.; Zegveld, W. Reindustrialization and technology. Creat. Educ. 2023, 14, 83–104. [Google Scholar]

- Öztayşi, B.; Sevim, U. Industry 4.0: Challenges, opportunities, and the future of industrial engineering. J. Ind. Eng. Int. 2021, 17, 1–20. [Google Scholar]

- Bora, N.P.; Parmar, P.L.; Avinash, S.; Somatkar, A.; Kumar, M.H.; Bagale, G. Blockchain Applications in Supply Chain Management: Enhancing Transparency, Efficiency, and Risk Management. Libr. Prog.-Libr. Sci. Inf. Technol. Comput. 2024, 44, 9511–9520. [Google Scholar]

- Shi, J.; Liu, Z.; Zhang, H.; Jiang, Q.; Li, T. Life Cycle Assessment: State of the Art and Future Perspectives. Recent Pat. Mech. Eng. 2015, 8, 211–221. [Google Scholar] [CrossRef]

- Hocking, C. The relationship between objects and identity in occupational therapy: A dynamic balance of rationalism and romanticism. N. Z. J. Occup. Ther. 2004, 52, 38. [Google Scholar]

- Magenuka, T.K.; Sibanda, M. Developing a Curriculum for the Fourth Industrial Revolution in Electrical Engineering Education. In Proceedings of the 10th Focus Conference (TFC 2023), Durban, South Africa, 23–25 August 2023; Volume 788, p. 284. [Google Scholar]

- Jarosz, S.; Soltysik, M.; Zakrzewska, M. The fourth industrial revolution in the light of social and competence changes. Eur. Res. Stud. 2020, 23, 530–548. [Google Scholar] [CrossRef]

- Matondang, Z.; Sitompul, H. Evaluation of implementation practices of industrial field on revitalization of the vocational educational institution in the industrial revolution 4.0. J. Phys. Conf. Ser. 2020, 1511, 012045. [Google Scholar] [CrossRef]

- Andrișan, G.; Modreanu, A. An Overview of the Fourth Industrial Revolution through the Business Lens. Bus. Ethics Leadersh. 2022, 6, 39–46. [Google Scholar] [CrossRef]

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. agriculture in a future development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef]

- Motzer, P.L.H.; Armellini, F.; Pelletier, L.S. Change management in the context of the Fourth Industrial Revolution: An exploratory research using qualitative methods. J. Mod. Proj. Manag. 2020, 7, 154–175. [Google Scholar]

- Mokyr, J. Entrepreneurship and the industrial revolution in Britain. Invent. Enterp. Entrep. Anc. Mesop. Mod. Times 2010, 10, 183. [Google Scholar]

- Ajah, I.A.; Chigozie-Okwum, C.C. Exploring the benefits of the 4th industrial revolution: The Nigerian experience. AFRREV STECH Int. J. Sci. Technol. 2019, 8, 22–32. [Google Scholar] [CrossRef][Green Version]

- Bryner, M. Smart manufacturing: The next revolution. Chem. Eng. Prog. 2012, 108, 4–12. [Google Scholar][Green Version]

- Penprase, B.E. The fourth industrial revolution and higher education. High. Educ. Era Fourth Ind. Revolut. 2018, 10, 978–981. [Google Scholar][Green Version]

- Koren, Y. The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar][Green Version]

- Mohajan, H. Third industrial revolution brings global development. J. Soc. Sci. Humanit. 2021, 7, b239–b251. [Google Scholar][Green Version]

- Lipsey, R.G.; Bekar, C. Science, institutions, and the Industrial Revolution. J. Eur. Econ. Hist. 2004, 33, 709–753. [Google Scholar][Green Version]

- Yao, X.; Huang, G.Q. Industrial big data analytics for Industry 4.0: Opportunities and challenges. J. Ind. Inf. Integr. 2020, 17, 100116. [Google Scholar][Green Version]

- Chowdhury, T.M.; Murzi, H. The evolution of teamwork in the engineering workplace from the first industrial revolution to industry 4.0: A literature review. In Proceedings of the 2020 ASEE Virtual Annual Conference Content Access, Montréal, QC, Canada, 21–24 June 2020. [Google Scholar][Green Version]

- Baynes, K. The Role of Modelling in the Industrial Revolution. In Modelling: The Language of Designing, 1st ed.; The Design Education Unit: London, UK, 1992; pp. 18–31. [Google Scholar][Green Version]

- Görçün, Ö.F. The rise of smart factories in the fourth industrial revolution and its impacts on the textile industry. Int. J. Mater. Mech. Manuf. 2018, 6, 136–141. [Google Scholar] [CrossRef][Green Version]

- Alhosani, H.M.M.G.; Ahamat, A.; Ismail, N. Industrial revolution 4.0 (IR 4.0) competencies: A literature review of manufacturing industry. Part 2 J. Leg. Ethical Regul. Issues 2021, 24, 1. [Google Scholar][Green Version]

- Sharma, P. Digital revolution of education 4.0. Int. J. Eng. Adv. Technol. 2019, 9, 3558–3564. [Google Scholar] [CrossRef]

- Eberhard, B.; Podio, M.; Alonso, A.P.; Radovica, E.; Avotina, L.; Peiseniece, L.; Solé-Pla, J. Smart work: The transformation of the labour market due to the fourth industrial revolution (I4. 0). Int. J. Bus. Econ. Sci. Appl. Res. 2017, 10, 47–66. [Google Scholar]

- Goh, P.S.C.; Abdul-Wahab, N. Paradigms to drive higher education 4.0. Int. J. Learn. Teach. Educ. Res. 2020, 19, 159–171. [Google Scholar] [CrossRef]

- Mohamed, B.; Ismail, S.; Abdullah, D. Industrial Revolution (IR4.0) Impact on Management. In Proceedings of the International Conference on Creative Economics, Tourism and Information Management, Pulau Pinang, Malaysia, 20–21 November 2019; pp. 104–109. [Google Scholar] [CrossRef]

- Satpathy, S.; Dash, K.K.; Mohapatra, M. A study on the new design thinking for industrial revolution 4.0, requirements and graduate readiness. Rupkatha J. Interdiscip. Stud. Humanit. 2020, 12, 1–10. [Google Scholar] [CrossRef]

| Ref. No. | Author(s) and Year | Focus Area | Key Contributions | Identified Gaps | How Current Review Addresses the Gap |

|---|---|---|---|---|---|

| [5] | Tri et al. (2021) | Higher Education in 4IR | Examines challenges/opportunities in Vietnamese HEIs adapting to 4IR | Limited focus on industrial engineering-specific curriculum changes | Proposes redefining engineering education to embrace innovation, creativity, and universal applicability beyond traditional domains |

| [6] | Bagade et al. (2023) | Technological Innovation | Simulation study on rotor performance inspired by nature, highlighting optimization in design | Focuses narrowly on product design, not the systemic shift required in industrial engineering | Advocates for optimization as an attitude and universal principle across industries, not just product-specific |

| [7] | Devi et al. (2020) | Education and Digital Literacy | Discusses the integration of literature education and digital tools | Lack of cross-disciplinary integration in engineering contexts | Calls for cross-domain creativity and innovation within industrial engineering for transformative impact |

| [8] | Mayer & Oosthuizen (2020) | Organizational Transformation | Case study of tech firm adapting positively to 4IR | Focus on organizational change, less on engineering methods | Encourages a mindset shift in industrial engineering across all sectors, not limited to individual companies |

| [9] | Genkin et al. (2020) | Workforce and HR in 4IR | Explores personnel management, business, and governance in 4IR | Lacks a framework for engineering-driven workforce transformation | Suggests redefining engineering roles to align with AI, automation, and dynamic skillsets |

| [10] | Anshari (2020) | Workforce Mapping | Proposes optimization techniques for identity in workforce planning | Abstract application without detailed engineering focus | Links workforce evolution directly to engineering practice and design transformation |

| [11] | Pasi et al. (2021) | Smart Manufacturing | Explores forging operations through Industry 4.0 perspectives | Focus on one process, lacks a broader industrial engineering lens | Promotes application of optimization across all sectors, not just process-specific |

| [12] | Jayaraman & Luo (2019) | Future Research Agenda | Identifies challenges and opportunities in industrial engineering | Provides a foundation but lacks urgency or call for paradigm shift | Introduces a revolutionary perspective demanding immediate change, novelty, and patentable solutions |

| Technology/Method | Role in Industrial Engineering Revolution | Primary Areas of Application |

|---|---|---|

| Artificial Intelligence (AI) | Automates decision-making, predictive maintenance, process optimization | Manufacturing, supply chain management, robotics |

| Internet of Things (IoT) | Real-time data collection and analysis, smart manufacturing, monitoring | Smart factories, production monitoring |

| Robotics and Automation | Enhances productivity, reduces human error, increases safety | Assembly lines, material handling, packaging |

| Digital Twins | Virtual modeling for real-time simulation and optimization of systems | Product development, system optimization |

| Big Data Analytics | Optimizes decision-making through data-driven insights, improves forecasting | Supply chain, production planning |

| Machine Learning (ML) | Improves process efficiency and quality control through predictive algorithms | Quality control, predictive maintenance |

| Cyber-Physical Systems | Integrates physical and digital processes, enabling smart factories | Automation, real-time process control |

| Cloud Computing | Enhances collaboration, data storage, and accessibility | Manufacturing, supply chain management |

| Augmented/Virtual Reality (AR/VR) | Assists in training, maintenance, and process visualization | Worker training, design visualization |

| Blockchain | Increases transparency and traceability in supply chains | Supply chain management, logistics |

| Sustainability Technologies | Focuses on reducing waste, energy usage, and carbon footprint | Sustainable manufacturing, energy management |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Somatkar, A.; Gaikwad, M.U.; Bagade, P.; Kharde, M.R.; Dhede, V.M. Industrial Engineering Needs a Revolution to Become Effective and Sustainable: An Exhaustive Review and Outlook. Eng. Proc. 2025, 114, 8. https://doi.org/10.3390/engproc2025114008

Somatkar A, Gaikwad MU, Bagade P, Kharde MR, Dhede VM. Industrial Engineering Needs a Revolution to Become Effective and Sustainable: An Exhaustive Review and Outlook. Engineering Proceedings. 2025; 114(1):8. https://doi.org/10.3390/engproc2025114008

Chicago/Turabian StyleSomatkar, Avinash, Mahendra U. Gaikwad, Pramodkumar Bagade, Mukund R. Kharde, and Vaishali M. Dhede. 2025. "Industrial Engineering Needs a Revolution to Become Effective and Sustainable: An Exhaustive Review and Outlook" Engineering Proceedings 114, no. 1: 8. https://doi.org/10.3390/engproc2025114008

APA StyleSomatkar, A., Gaikwad, M. U., Bagade, P., Kharde, M. R., & Dhede, V. M. (2025). Industrial Engineering Needs a Revolution to Become Effective and Sustainable: An Exhaustive Review and Outlook. Engineering Proceedings, 114(1), 8. https://doi.org/10.3390/engproc2025114008