1. Introduction

Industry executives are becoming increasingly concerned about the efficacy of novel assembly technologies and the contexts in which they are employed. In the automative sector, some ergonomic issues arise due to conventional assembly methods and settings [

1]. These consequences may have significant financial and societal repercussions. Quality requirements and productivity objectives have taken precedence over concerns about human considerations [

2]. Fatigue, musculoskeletal disorders (MSDs) due to repetitive strain and injuries, and accidents, are quite comment among workers [

3]. The activities like heavy lifting, awkward postures, intense exertions, repetitive motions, and prolonged standing, in the automotive sector, frequently strain the musculoskeletal system. These compel us to search for sound ergonomics interventions. Primary and secondary interventions are the two categories into which ergonomics interventions fall [

4]. The primary intervention involves ergonomic assessment and redesign of the workspace based on ergonomic principles and easily assimilated ergonomic twists while keeping track of work and hours is a secondary intervention. Ergonomics evaluation, training, workstation redesign, and adjustment, professional advice on equipment and procedures, and software to enhance human performance on ergonomic suggestions are the key elements of ergonomics interventions. To accomplish an efficient and seamless operation, ergonomics interventions train the worker to manage tools, machines, and the surrounding environment with proficiency. Most people believe that the cost of ergonomics is a burden rather than an investment. However, excellent production requires well-optimized ergonomics. The growing incidence of work-related musculoskeletal disorders (MSDs), disabilities, compensations, and medical costs in developed nations has made ergonomics a critical component [

5]. An increasingly critical area of concern for automakers is the ergonomic design of workstations, tools, and equipment as they seek to maximize worker productivity and optimize assembly line operations [

6]. Sound ergonomic practices help to keep the frequency of accidents low and productivity high.

Figure 1 shows a summary of ergonomic benefits applicable to various industries. There are few important previous examples reported on successful implementation of ergonomics alone and combined with other industrial engineering tools in the automotive sector [

7,

8,

9,

10,

11].

The present study was performed in a manufacturing company XYZ that performs different operations for the automotive industry. For a long time, the company dominated the market for manufacturing the automotive components that they produce or manufacture. However, things have changed, and the company is experiencing low productivity in one of its operations, the tailgate component. The whole tailgate operation within the company workstation was being run into the ground, and lots of money was being lost. Furthermore, the company hired more workers intending to cover the problem of assembling the tailgate. Workers were underperforming due to a lack of knowledge. As a result, the quality of the tailgate products assembled by operators was compromised. With the use of a modern automotive assembly line, this study seeks to confirm the effects of numerous ergonomics interfaces on workers’ performance and well-being. Our primary focus is on the intervention of ergonomics in worker’s performance and visual interfaces.

The scope and significance of this research is classified by the following:

Workplace Ergonomics Assessment: The study will include a thorough analysis of the workplaces of the organization, encompassing office spaces, manufacturing facilities, and various workstations. The purpose of this analysis is to pinpoint ergonomic risk factors that are linked to low productivity and the occurrence of musculoskeletal disorders (MSDs).

Workers’ Performance and Well-Being: Analysis of employee health data, injury reports, and absenteeism records will be included in the scope to determine the precise effect that ergonomic concerns have on the health and well-being of workers. This will entail looking at the kinds and numbers of MSDs that are reported as well as figuring out which ergonomic risks are most common and cause injuries at work.

Increased Productivity and Efficiency: Notable increases in productivity and efficiency can result from better workplace ergonomics. The objective of this research is to improve organizational performance and competitiveness by limiting downtime caused by injuries or pain, lowering physical strain on personnel, and streamlining work procedures.

2. Methodology

An understanding was developed about various ergonomics techniques available to address problems occurring in various areas [

12,

13,

14]. A discussion with workers and operators about their working information in an automotive manufacturing facility was conducted. Body Parts Symptoms Survey (BPSS) was conducted to observe the workers posture during specific operations and their analysis. To rank the body parts receiving maximum discomfort, Pareto analysis was conducted. Rapid Upper Limb Assessment (RULA) was applied to analyze the postures of operators assembling the tailgate component in their workstations. The operators reported high levels of discomfort in various body parts, such as the upper back, neck, lower back, arms, and wrists, based on the outcome of BPSS, and prompted by the use of the RULA tools.

In this study, only the employees or workers belonging to assembly and manual material handling in the automatic manufacturing division were considered for the discussion to understand the ergonomics issues related to them. The selected workers were doing double shifts with a total of eight hours in a day. Worker selection was based on the results of the body parts symptoms (BPSS) and the Rapid Upper Limb Assessment (RULA). Select individuals were kept under observation if they felt “extremely uncomfortable” in certain body areas. According to this study, the neck, upper shoulder, hip, arm, wrist, thigh, and calf are the body parts that people report feeling most unpleasant. The environmental factor, personnel, equipment, workstation design, and ergonomics integration in the car manufacturing company were observed to have an impact on the worker’s actions, particularly their ergonomics posture and manual material handling MMH motions. The workstation’s adaptability for manual material handling (MMH) and ergonomics activities were the main emphasis of the environmental factor.

Most of the products produced by the selected manufacturing company XYZ were being assembled on the workstation table. The processing (assembly/welding, etc.) of the product required a long time on the workstation. However, operators have been complaining about MSDs since they have not been performing to their best capabilities in that workstation. An ergonomics analysis was required to be conducted on this workstation to assess the working conditions of the operators and to observe potential ergonomic risks in the processing and operations. It was also observed that the workstation might need a new design for workers’ comfort and workspace safety.

3. Results and Discussion

Visits to the workstation at the production line in company XYZ allowed us to observe the layout for the entire process. This allowed us to discuss with the operators to gain insight into their attitudes toward their jobs and the various challenges they are experiencing while working.

3.1. Body Parts Symptoms Survey (BPSS)

Observing operators assemble tailgates at the workstation was how information was acquired in this section.

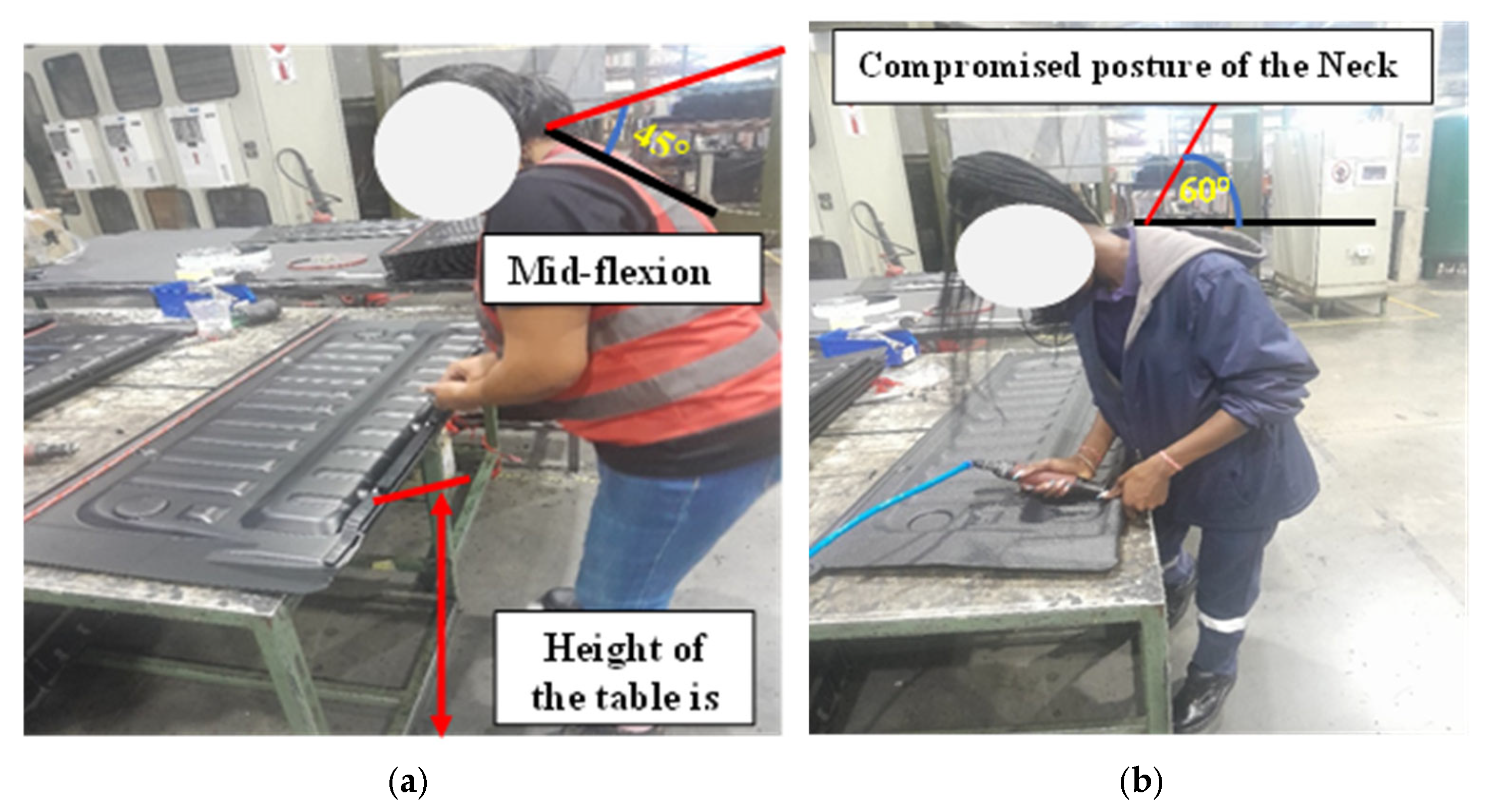

Figure 2 below shows the employees’ body posture while working. Images were collected to monitor the workers’ postures while they were working.

The images were examined to identify potentially dangerous postures and working environments. A few factors were considered, including neck, shoulder, upper back, elbow, lower back, arm, wrist, thigh, and including the time range, the awkward state, and the repetition of the postures from the list of body parts to explain the discomfort that employees experience. The workers’ usage of the Body Parts Symptoms Survey (BPSS) allowed for the identification of body posture and MMH system problems.

During image examination, the focused key areas to identify potentially hazardous postures include the following:

Neck: Check for extreme neck flexion or rotation.

Shoulder: Look for raised or forward-leaning shoulders.

Upper Back: Note any signs of hunched or rounded back.

Elbow: Observe for elbow flexion or extension beyond comfortable limits.

Lower Back: Identify any excessive lumbar flexion or twisting.

Arm: Assess arm positioning and movements.

Wrist: Watch for awkward wrist angles or repetitive strain.

To measure discomfort in different body parts, workers’ BPSS data was gathered.

A discussion with the workers was conducted to analyze which body part was facing ‘extreme discomfort’ and ‘discomfort’.

The total number of workers reporting “Very Uncomfortable” and “Uncomfortable” was added to the total number of respondents for each body part, which is shown in

Table 1.

The percentage of employees experiencing various degrees of discomfort in each body part was calculated using the following equation and is summarized

Table 2.

Mean discomfort = [(% of extreme discomfort × weight for extreme discomfort) + (% of discomfort × weight for discomfort)/(total weight)].

In ergonomics studies, extreme discomfort is more serious than mild discomfort. Therefore, assigning a higher weight to it leads to the following:

This means extreme discomfort counts twice as much as regular discomfort when calculating the average.

Calculation of mean discomfort of upper back/shoulder, as shown in

Table 2, was conducted as follows:

Extreme weight = 2

Discomfort = 1

Therefore, the average discomfort level (factoring in severity) is 30% for the upper back/shoulder. All the body parts were calculated using the same method to obtain the mean level of discomfort. The discomfort analysis highlights upper body strain, especially in the upper back and neck regions, as a significant ergonomic concern. These findings support the need for targeted ergonomic improvements to enhance worker comfort, reduce injury risk, and improve overall productivity.

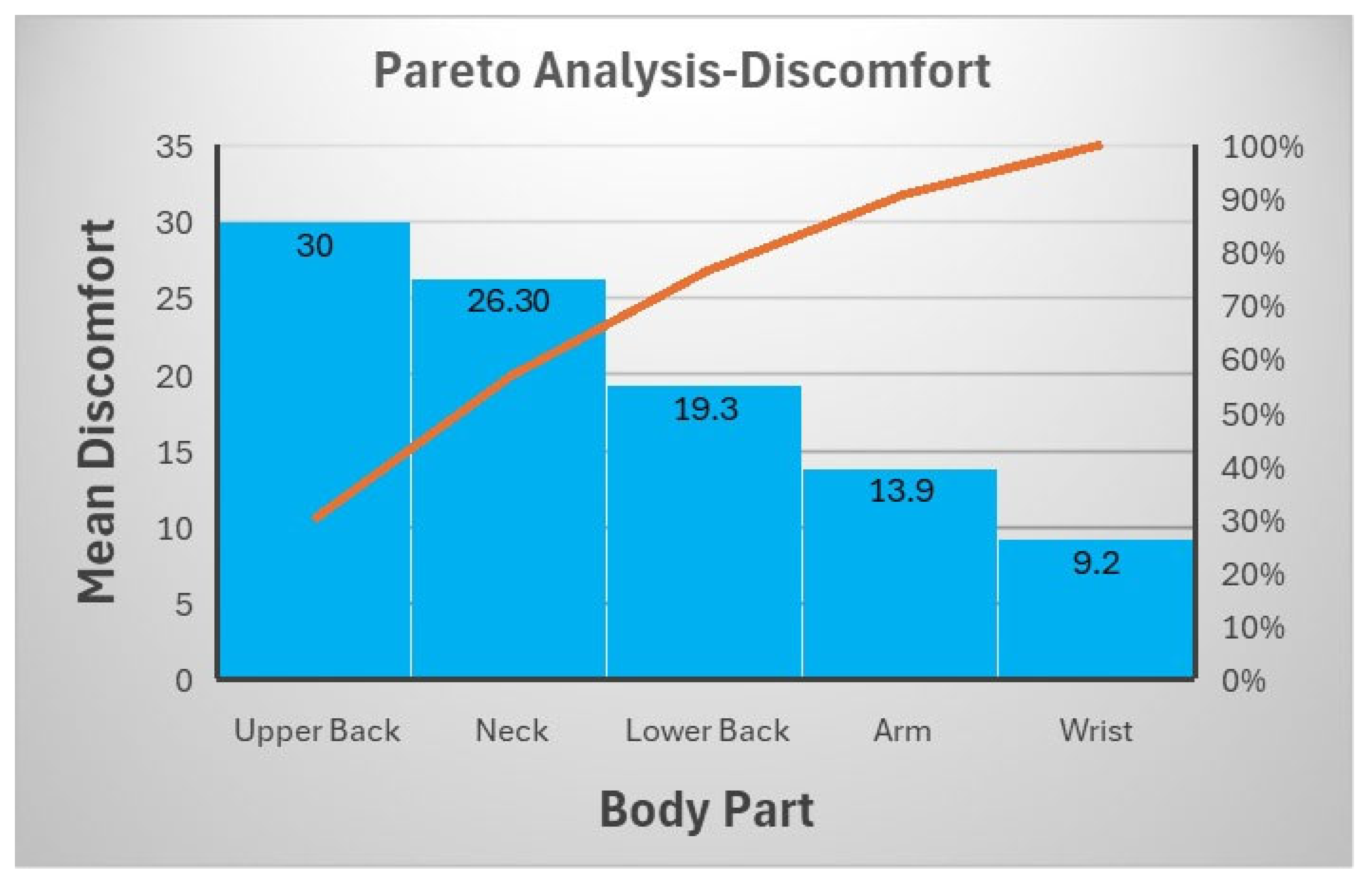

The mean discomfort percentages were compared to identify which body parts are causing the most discomfort on average. This can help prioritize areas for ergonomic improvements. Body parts with the highest mean discomfort should be targeted for interventions to reduce overall pain.

Table 2 shows that the body parts with the highest mean discomfort were upper back, lower back, and neck. These prompt implementing specific ergonomic solutions like improved workstation design, better lifting techniques, or additional support equipment. The strategy involves continuing monitoring discomfort levels to assess the effectiveness of the interventions and make further adjustments as needed.

The Pareto Analysis-Mean Discomfort/Cumulative Percentage, for discomfort level-based ranking of body parts, is shown in

Figure 3. The Pareto chart shows that the upper back accounts for 30.40% of the total discomfort and the neck accounts for 26.64% of the total discomfort, and together, the upper back and neck account for over 57% of the total discomfort. Therefore, the top three areas (upper back, neck, and lower back) account for nearly 77% of the total discomfort. According to the Pareto Principle (80/20 rule), addressing the top 20% of causes (in this case, discomfort in the upper back, neck, and lower back) will significantly reduce the overall discomfort. These areas should be prioritized for ergonomics interventions to achieve the greatest impact.

3.2. Rapid Upper Limb Assessment (RULA)

The RULA scoring method involves levels ranging from 1 to 7 that are assigned to each body part. To determine the urgency of intervention, the scores are classified into Action Levels, with lower levels indicating normal conditions and higher levels indicating greater urgency. Using RULA, the postures were evaluated for their ergonomic risks. The ergonomic assessment identified multiple issues with the workstation setup, especially in terms of the operators’ body postures. Using RULA, the postures were evaluated for their ergonomic risks.

Neck: When assembling parts on tables that were too low, many operators were seen bending their necks forward. Because of the length and angle of flexion, this posture received a high grade.

Shoulders: To access components or materials, operators frequently had to extend their arms above shoulder height, which led to high shoulder muscle strain and fatigue.

Lower Back: The lower back received a high RULA score due to the frequent strain from having to bend forward at the waist while working on the tailgate assembly.

Arms and Wrists: During assembly, bad arm postures and repetitive wrist movements raised the risk of upper limb problems.

The percentage discomfort levels as per RULA are neck discomfort—26.3%, shoulder/upper back discomfort—30%, and lower back discomfort—19.3%.

These scores fall within the medium- to high-risk range on the RULA scale, indicating the need for immediate ergonomics interventions to improve postures, reduce muscle strain, and prevent long-term injuries.

3.3. Design Improvement and Implementation

There were a few ergonomic design interventions to be used to address the ergonomic problems as identified, specifically the high degrees of discomfort in the neck, lower back, and shoulder. The suggested major steps for an ergonomic workstation and equipment at company XYZ are depicted in the process flow in

Figure 4.

The new workstation design incorporates several key ergonomic improvements aimed at reducing discomfort and preventing injuries. Adjustable workstation heights allow operators to modify the work surface to suit their individual needs, minimizing bending and reaching. Seated workstations are set to allow operators to keep their elbows at a 90-degree angle, while standing workstations are positioned at elbow height to reduce back and shoulder strain. Proper seating with adjustable lumbar support promotes a neutral spine position, preventing lower back discomfort. For standing tasks, anti-fatigue mats and footrests help reduce pressure on the back and legs.

Monitor and component placement ensures materials and screens are positioned at eye level, reducing neck strain. Tools are placed within easy reach to avoid unnecessary bending or stretching. Ergonomic tools with cushioned grips are introduced to reduce wrist strain, and adjustable tool holders bring tools into a neutral position.

Task rotation and regular breaks are implemented to reduce repetitive strain injuries (RSIs), with workers alternating between tasks and taking micro-breaks every 30–60 min. Adequate lighting ensures work areas are well lit, reducing the need for awkward head positions. Finally, footrests and adjustable work surfaces accommodate varying worker heights, ensuring that all operators can work in a neutral, comfortable posture. These improvements promote better health, comfort, and productivity.

The current workstation that is being used to assemble the tailgate is a table that is 550 mm in height (see

Figure 5). Based on our data analysis, it was observed that operators bent at an angle 45 degrees mild flexion when using this table to assemble tailgates.

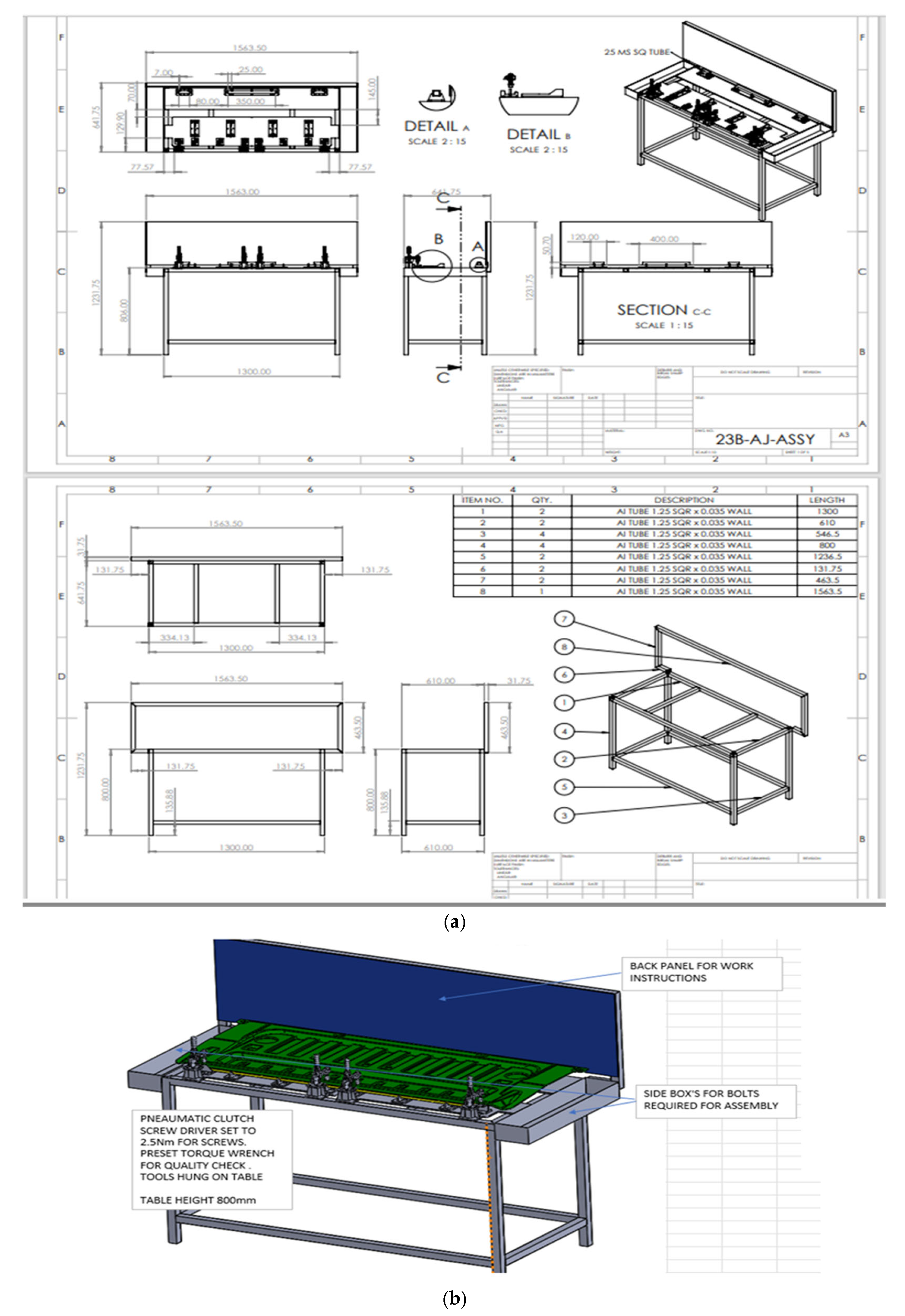

Considering the ergonomics element, Step 1 suggested in

Figure 4 (Design and Adjustable Workstation Height) was implemented to improve ergonomics. Firstly, a drawing for the improved ergonomics workstation/jigs was proposed as shown in

Figure 6.

The aim of this proposed design was to make an adjustable workstation that accommodates all employees assembling tailgates at company XYZ to reduce the incidence of musculoskeletal disorders (MSDs) caused by bending, as well as neck and shoulder strain. This design also positions materials needed for tailgate assembly closer to the operator, minimizing movement and reducing manual material handling (MMH). This ergonomic improvement was considered to have the potential to increase productivity at company XYZ.

Company XYZ authorized the maintenance department to receive the drawing for the construction of the jig/workstation. This provided an opportunity to instruct the welding department on the specific requirements for the workstation/jig, ensuring that key design features were implemented for the operators. The work surface was positioned at an ergonomic height to prevent bending, with frequently used tools placed within easy reach to minimize unnecessary movements.

To address continuous bending during tasks, the design incorporated a height-adjustable workstation with lumbar support and tiltable work surfaces, allowing operators to position themselves without the need for awkward bending. Additionally, to reduce repetitive movements and awkward hand positions, ergonomic tools with cushioned grips were provided, supporting a neutral wrist posture. Adjustable tool holders were also introduced to allow operators to bring the tools into the correct position, rather than by extending their arms.

Once the fabrication of the workstation was completed, it was moved to the tailgate assembly area, where operators began using it. The pictures presented in

Figure 7 show the completed workstation and its implementation by the operators.

The proposed design of a jig/workstation is recommended to be used as follows:

Place the lower bracket into the fixture, making sure the edges align to the fixture LH and RH are seated correctly in the fixture.

Make sure clips are facing forward.

Further, make sure holes are aligned. If holes are misaligned, tailgate needs to be put aside, and the workstation needs to be adjusted correctly.

All the clamps shown must be closed when the tailgate is on top of the jig before moving on to the next step. Work instructions (WI) will be in front of the workstation as indicated, and all the bolts will be on the side of the fixture for easy reach.

Figure 7.

The new, developed workstation and its use by the operators. (a) Ergonomically improved workstation. (b) Operators working at new station.

Figure 7.

The new, developed workstation and its use by the operators. (a) Ergonomically improved workstation. (b) Operators working at new station.

The following improved ergonomical aspects can be observed in the newly designed workstation.

Adaptable to height desks and adaptable to work requiring standing.

Work surface angle: some surfaces are slanted to lessen bending and make it easier to reach components.

Materials for surfaces that come into contact with the body use ergonomic cushioning or sturdy materials like stainless steel.

Eye-level monitors: screens can be kept at or marginally below eye level using adjustable monitor supports.

Tool racks and component trays are positioned 14–18 inches away from the user to minimize reaching.