Abstract

In recent years, unconventional machine techniques have made the machining process simpler than it was under conventional machining methods. EDM is recognized as one of the leading methods in unconventional machining processes. The need for materials with improved mechanical properties continues to rise due to constant advancements in the mechanical industry. Cryogenic treatment is used for property enhancement and can be useful in an extensive range of metals. This research investigates the performance of a cryogenically treated copper electrode during EDM of Monel 400. The EDM parameters varied during the research are pulse on time, pulse off time, gap voltage, and discharge current. The experiments were designed using Taguchi’s design of experiment. The constraints of the process are fine-tuned for both MRR and surface smoothness, with their proportion impacts assessed through the ANOVA technique. Regression analysis is accomplished, creating an experimental correlation between both MRR and surface smoothness, examined using RSM technique. This comprehensive study demonstrates that cryogenic treatment of electrode provides better MRR and SR.

1. Introduction

Electric discharge machining (EDM) was originally identified in the 1770s by Joseph Priestly, who observed the eroding impact of electrical sparks [1]. The primary benefit of the EDM process is that it does not rely on the stiffness of the material being worked on, and it can machine all conductive materials, including metals, metallic alloys, and certain ceramic substances. The term cryogenic comes from two Greek words: “kryos,” meaning “frost”, and “genic,” meaning “produce”. Cryogenic temperatures typically denote temperatures that fall below −150 °C.

Currently, EDM stands as the most frequently employed method for high precision machining of various conductive metals, regardless of their hardness. It is utilized in the automotive sector, in aerospace, and in agriculture [2]. Although the method is commonly embraced in the manufacturing community, it still presents certain limitations such as a reduced MRR, increased surface roughness, and longer machining times in contrast with other alternative machining methods. Numerous development enhancement methods have been documented in the realm of EDM, such as integrating tool or workpiece movements, utilizing various dielectric fluids and introducing powder postponements, employing dissimilar tool constituents, developments to enhance the tool electrode characteristics [3]. Utilizing cryogenics in EDM is one of the development enhancement methods, as it greatly enhances material characteristics [4]. Numerous scientists have utilized this technique to decrease tool wear, which is nearly unavoidable in EDM. Kumar et al. [5] used cryogenically preserved copper electrodes to conduct experiments aimed at assessing the effectiveness of additive powder-mixed EDM for Inconel 718, noting a considerable decrease in tool wear rate. Abdulkareem et al. [6] implemented cryogenic chilling with liquid nitrogen while machining Ti-6Al-4V to decrease electrode wear. A comparable approach was utilized by Srivastava and Pandey [7,8] with M2-grade high-speed steel; cryogenically treated electrodes exhibited superior profile holding compared to untreated electrodes post-machining. The method has additionally been noted for use in micro EDM, issues such as tool wear are highly damaging [9]. Yildiz et al. [10] explored the influence of cryogenic treatment on beryllium-copper and found a growth in MRR of approximately 20 to 30%. Gill and Singh [11] examined the influence of deep cryogenic preservation on the machinability of a titanium alloy in EDD, demonstrating enhanced hole precision in preserved alloy workpieces.

Our literature review indicates that numerous studies have been published on cryogenic-treated workpieces in EDM, the impact of cryogenic treatment on electrodes and their effects over numerous iterations in EDM. Aim of this paper is to examine the performance of cryogenically preserved tool electrodes and to compare it with that of untreated electrodes.

2. Materials, Experimental Setup and Process Parameters

A Monel 400 plate measuring 100 mm × 50 mm × 3 mm is utilized as the material for the experimental work. The Spark Electro Discharge Machine, Model XPERT-1, manufactured by ELECTRONICA, is used to carry out experiments as shown in Figure 1. Throughout the experiments, EDM parameters such as servo voltage (SV), peak current (IP), spark-on time (TON), and spark-off time (TOFF) are adjusted within the ranges of 30–60 volts, 25–100 amps, 20–50 µs, and 10–25 µs, respectively. The experiments utilize positive polarity and EDM oil as the dielectric fluid. Electrodes made of copper with a diameter of 10 mm are utilized for cutting materials. In the current research, the demonstration of the EDM process is estimated using the material removal rate (MRR) and the roughness of the machined surface (SR). The composition of Monel 400 is shown in Table 1.

Figure 1.

Experimental setup (Spark Electro Discharge Machine, Model XPERT-1).

Table 1.

Composition of work piece (percentages).

3. Results and Analysis

A thorough examination of response features in relation to the machining parameters was conducted as shown in Table 2. Variance analysis was conducted to determine the importance of the parameters selected for testing to measure their influence on the response to attributes.

The experimental results are listed below.

Table 2.

Results of experiments.

Table 2.

Results of experiments.

| S. No | Ton | SV (V) | IP (A) | Toff | MRR (Non-Cryo) gm/min | MRR (Cryo) gm/min | SR (Non-Cryo) µm | SR (Cryo) µm |

|---|---|---|---|---|---|---|---|---|

| 1 | 20 | 30 | 25 | 10 | 0.017 | 0.025 | 2.46 | 2.35 |

| 2 | 20 | 40 | 50 | 15 | 0.040 | 0.053 | 3.22 | 3.08 |

| 3 | 20 | 50 | 75 | 20 | 0.077 | 0.068 | 3.07 | 3.63 |

| 4 | 20 | 60 | 100 | 25 | 0.025 | 0.034 | 3.50 | 3.85 |

| 5 | 30 | 30 | 50 | 20 | 0.141 | 0.157 | 3.30 | 3.15 |

| 6 | 30 | 40 | 25 | 25 | 0.045 | 0.062 | 3.34 | 2.79 |

| 7 | 30 | 50 | 100 | 10 | 0.059 | 0.068 | 2.98 | 3.24 |

| 8 | 30 | 60 | 75 | 15 | 0.095 | 0.109 | 5.20 | 4.81 |

| 9 | 40 | 30 | 75 | 25 | 0.154 | 0.164 | 5.87 | 5.65 |

| 10 | 40 | 40 | 100 | 20 | 0.123 | 0.128 | 4.84 | 5.12 |

| 11 | 40 | 50 | 25 | 15 | 0.065 | 0.069 | 3.82 | 3.46 |

| 12 | 40 | 60 | 50 | 10 | 0.088 | 0.122 | 4.31 | 3.44 |

| 13 | 50 | 30 | 100 | 15 | 0.123 | 0.133 | 5.35 | 5.44 |

| 14 | 50 | 40 | 75 | 10 | 0.093 | 0.099 | 5.32 | 5.20 |

| 15 | 50 | 50 | 50 | 25 | 0.123 | 0.141 | 4.33 | 4.03 |

| 16 | 50 | 60 | 25 | 20 | 0.043 | 0.052 | 3.32 | 3.48 |

3.1. Formulation of Mathematical Model

Using the Taguchi design of experiments, the machining act is connected to the different parameters to find the equations. Minitab 19 is used for data fitting and experimental design construction. Regression analysis is used to remove irrelevant terms from mathematical models when creating calculations among the response to parameters (MRR and SR) and method parameters (SV, IP, TON, and TOFF). The resulting mathematical models are displayed below.

| MRR(NC) = 0.0819 − 0.0421 Ton_20 + 0.0030Ton_30 + 0.0255 Ton_40 + 0.0135 Ton_50 + 0.0268 SV_30 − 0.0066 SV_40 − 0.0009 SV_50 − 0.0191 SV_60 − 0.0394 Ip_25 + 0.0160 Ip_50 + 0.0228 Ip_75 + 0.0005 Ip_100 − 0.0176 Toff_10- 0.0011 Toff_15 + 0.0140 Toff_20 + 0.0048 Toff_25 MRR(C) = 0.0927 − 0.0477 Ton_20 + 0.0062 Ton_30 + 0.0280 Ton_40 + 0.0135 Ton_50+ 0.0270 SV_30 − 0.0072 SV_40 − 0.0062 SV_50 − 0.0135 SV_60 − 0.0407 Ip_25 + 0.0255 Ip_50 + 0.0172 Ip_75 − 0.0020 Ip_100 − 0.0142 Toff_10 − 0.0017 Toff_15 + 0.0085 Toff_20 + 0.0075 Toff_25 SR(NC) = 4.135 − 1.020 Ton_20 − 0.375 Ton_30 + 0.662 Ton_40 + 0.732 Ton_50 + 0.41SV_30 + 0.112 SV_40 − 0.553 SV_50 + 0.025 SV_60 − 0.795 Ip_25 − 0.303 Ip_50 + 0.785 Ip_75 + 0.312 Ip_100 − 0.307 Toff_10 + 0.538 Toff_15 − 0.475 Toff_20 + 0.245 Toff_25 SR(C) = 4.0431 − 0.8056 Ton_20 − 0.4906 Ton_30 + 0.5369 Ton_40 + 0.7594 Ton_50 + 0.3994 SV_30+ 0.0594 SV_40 − 0.3606 SV_50 − 0.0981 SV_60 − 0.9856 Ip_25 − 0.6031 Ip_50 + 0.8444 Ip_75 + 0.7444 Ip_100 − 0.3956 Toff_10 + 0.4369 Toff_15 − 0.1381 Toff_20 + 0.0969 Toff_25 |

3.1.1. Material Removal Rate

It is evident that regardless of the cryogenic behavior applied to the tool electrode, the MRR rises with an increase in current and pulse on time. The actual energy available at the tool–workpiece boundary rises with an upsurge in current, which raises the MRR. Additionally, Table 3 and Table 4 show that, according to analysis of variance, the most significant influences on MRR are current and pulse on time.

Table 3.

ANOVA for MRR of non-treated electrode.

Table 4.

ANOVA for MRR of cryo-electrode.

The correctness of the advanced predictive models is then examined using analysis of variance (ANOVA). If the model’s obtained p-value is less than 0.05, it is considered significantly accurate using this technique. Based on the tables, both models have p-values that are significantly acceptable because they are less than 0.05.

Later, determining the corresponding coefficients of determination (R2) provides additional evidence of the accuracy of the developed models. For non-treated individuals, the calculated R2 and adjusted R2 for the MRR model are 98.18 percent and 90.91 percent, respectively, while for cryo-treated individuals, they are 97.87 percent and 89.35 percent. The mathematical models that have been created are incredibly accurate.

Confirmatory tests are conducted for both cases, and the results found are satisfactory: MRR (optimum) = 2.40 gm/min (non-treated) and 1.41 gm/min (cryo-treated).

3.1.2. Surface Roughness

Because the molten metal re-solidifies during machining and material is removed, the surface produced by the EDM process is continuously likely to be rough. The rougher the surface, the greater the energy discharge. Both current and pulse on time have a statistically important role according to the ANOVA results (Table 5 and Table 6).

Table 5.

ANOVA for SR of non-treated electrode.

Table 6.

ANOVA for SR of cryo-electrode.

Based on the tables, both models have p-values that are significantly acceptable because they are less than 0.05.

Later, the corresponding coefficients of determination (R2) are found to further demonstrate the accuracy of the developed models. The R2 and adjusted R2 for the SR model are 99.49 percent and 97.43 percent for cryo-treated and 97.18 percent and 85.88 percent for non-treated, respectively. High-accuracy mathematical models have been developed.

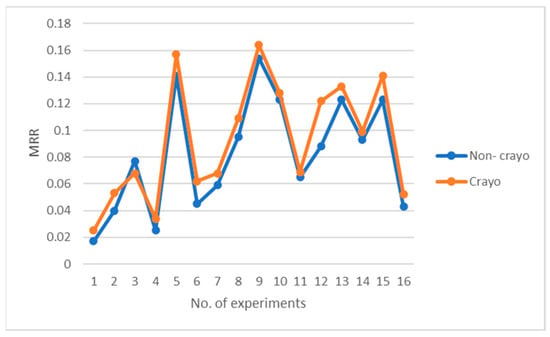

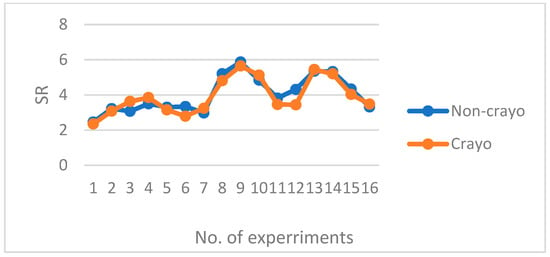

Confirmatory tests are conducted for both cases, and the results found are satisfactory: SR (optimum) = 2.40 µm (non-treated) and 2.05 µm (cryo-treated). The comparison of MRR and SR for cryogenically treated and non-cryo electrode as shown in Figure 2 and Figure 3, respectively.

Figure 2.

Comparison of MRR cryogenically treated and non-cryo electrode.

Figure 3.

Comparison of SR cryogenically treated and non-cryo electrode.

4. Conclusions

The Monel 400 alloy was used as the work piece, and untreated and cryogenically treated copper as the electrode, in an EDM experiment. Cryogenic treatment was reported to improve the material removal rate (MRR). Cryogenic treatment improved thermal and electrical properties, leading to lower coefficient friction and easier machining; hence, the surface quality also improved.

The elementary conclusions are stated below:

- ➢

- All the parameters SV, IP, Ton, and Toff, impacted MRR and SR meaningfully in the EDM of Monel 400.

- ➢

- Substantial growth in MRR and surface finish was detected for the cryogenically treated electrodes.

- ➢

- ANOVA confirms that the current and pulse on time play protruding role in MRR and SR for both the electrodes.

Author Contributions

Conceptualization, A.M. and A.S.; methodology, A.M.; software, M.P.U.; validation, A.M., J.D.B. and M.P.U.; formal analysis, M.P.U.; investigation, A.S.; resources, A.S.; data curation, A.M.; writing—original draft preparation, A.S.; writing—review and editing, A.M.; visualization, M.P.U.; supervision, J.D.B.; project administration, A.M.; funding acquisition, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

No specific grant from a public, private, or nonprofit funding organization was obtained for this study.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are not available in this manuscript.

Conflicts of Interest

No conflicts of interest are disclosed by the authors.

References

- Chowdary, R.; Kumar, H.; Garg, R. Analysis and evaluation of heat affected zones in electric discharge machining of EN-31 DIE Steel. Indian J. Eng. Mater. Sci. 2010, 17, 91–98. [Google Scholar]

- Shamsudin, S.; Mohamed, S.; Yusoff, M.; Ismail, N. Electrical Discharge Machining (EDM) of beryllium copper alloys using Design of Experiment (DOE) approach. In Proceedings of the 3rd International Engineering Convention 2009, Singapore, 22–26 April 2009; pp. 257–268. [Google Scholar]

- Pandey, A.; Singh, S. Current research Trends in Variants of Electrical Discharge Machining: A review. Int. J. Eng. Sci. Technol. 2010, 2, 2172–2191. [Google Scholar]

- Kalsi, N.; Sehgal, R.; Sharma, V.S. Cryogenic Treatment of Tool Materials: A Review. Mater. Manuf. Process. 2010, 25, 1077–1100. [Google Scholar] [CrossRef]

- Kumar, A.; Maheshwari, S.; Sharma, C.; Beri, N. Machining Efficiency Evaluation of cryogenically treated copper electrode in additive mixed EDM. Mater. Manuf. Process. 2012, 27, 1051–1058. [Google Scholar] [CrossRef]

- Yildiz, Y.; Sundaram, M.M.; Rajurkar, K.P.; Nalbant, M. The effects of Cold and Cryogenic Treatments on the Machinability of Beryllium-Copper Alloy in Electro Discharge Machining. In Proceedings of the 44th CIRP Conference on Manufacturing Systems, Madison, WI, USA, 1–3 June 2011. [Google Scholar]

- Abdulkareem, S.; Khan, A.A.; Konneh, M. Reducing electrode wear ratio using cryogenic cooling during electrical discharge machining. Int. J. Adv. Manuf. Technol. 2009, 45, 1146–1151. [Google Scholar] [CrossRef]

- Srivastava, V.; Pandey, P.M. Study of the Cryogenically Cooled Electrode Shape in Electric Discharge Machining Process. World Acad. Sci. Eng. Technol. 2011, 60, 1017–1021. [Google Scholar]

- Srivastava, V.; Pandey, P.M. Performance Evaluation of Electrical Discharge Machining (EDM) Process Using Cryogenically Cooled Electrode. Mater. Manuf. Process. 2012, 27, 683–688. [Google Scholar] [CrossRef]

- Jefferson, M.; Hariharan, P. Experimental Investigation on Machining Performance of Cryogenically treated Electrodes in μEDM. In Proceedings of the 4th International and 25th National AIMTDR Conference, Jadavpur University, Kolkata, India, 16 December 2012; pp. 1069–1072. [Google Scholar]

- Gill, S.S.; Singh, J. Effect of Deep Cryogenic Treatment on Machinability of Titanium Alloy (Ti-6246) in Electric Discharge Drilling. Mater. Manuf. Process. 2010, 25, 378–385. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).