Abstract

This study aims to optimize the variables of the gas metal arc welding (GMAW)-based wire arc additive manufacturing (WAAM) process namely, wire feed speed (WFS), voltage (V), and travel speed (TS), to achieve the desired bead geometries, specifically bead width (BW), and bead height (BH) on a mild steel substrate. The selection of WAAM parameters significantly influences the characteristics of multi-layer structures in terms of bead geometry. By optimizing these variables, the research seeks to enhance bead geometry properties, thereby improving the overall performance of the WAAM process. Single-layer depositions were performed using TM-B6 metallic wire using Box–Behnken design methodology. Multivariable regression equations were formulated to establish relationships between design variables and their corresponding responses, with their validity assessed through ANOVA. For both BW and BH responses, the R2 and adjusted R2 values were found to be close to unity, indicating excellent model fitness. The results demonstrate the high accuracy of the models, enabling effective analysis of the influence of process parameters on weld bead geometry and accurate prediction of bead dimensions across the design space. The main effects plot illustrates how WFS, V, and TS affect bead width and bead height. Atomic Search Optimization (ASO) was employed to determine optimal parameter combinations. An objective function with equal weightage (0.5) for BH and BW was formulated, resulting in optimized values of BW and BH (4.01 mm and 5.86 mm, respectively) at WFS: 13 m/min, TS: 10 mm/s, and V: 20 V. The obtained findings confirm the high accuracy of the models and their effectiveness in analyzing and optimizing WAAM process parameters.

1. Introduction

Additive manufacturing (AM), formerly known as rapid prototyping, has evolved far beyond its original role of quickly creating prototypes [1,2]. Unlike traditional manufacturing methods, AM constructs objects layer by layer directly from digital model data, greatly simplifying the production of complex 3D geometries [3,4]. AM is considered a game-changer in modern product development and manufacturing, having revolutionized the design and fabrication landscape [5,6].

Various AM techniques serve different industrial needs. Vat photopolymerization methods, such as stereolithography (SL), utilize UV or visible light to precisely and rapidly solidify liquid resins [7]. Powder bed fusion processes, including selective laser sintering (SLS), use lasers to fuse powder layers, enabling the creation of parts with complex geometries using a wide range of materials. Binder jetting (BJ) involves the deposition of a binder onto a powder bed, allowing for the production of both colorful models and functional metal components [8]. Sheet lamination, exemplified by laminated object manufacturing (LOM), cuts and bonds sheets of material, offering cost-effective solutions for large components. Directed energy deposition (DED) techniques, such as laser-assisted net shaping, fabricate parts by melting and depositing materials simultaneously, making them suitable for various applications in electronics and freeform design [9]. Direct wire techniques within DED are particularly advantageous for small-scale structures, offering precise material placement [10,11]. Unlike powder bed fusion, DED processes directly melt metal powder or wire without requiring a powder bed, improving speed and reducing system complexity [12]. Recent advancements in DED include the use of welding and plasma as alternative heat sources, contributing to progress in Wire Arc Additive Manufacturing (WAAM).

WAAM employs an electric arc to melt metal wire, which is then deposited layer by layer onto a substrate to form a 3D structure, distinguishing it from other AM techniques [13,14]. The process is controlled by computer-aided design (CAD) software to achieve complex geometries. WAAM is compatible with various metal alloys and, due to its high deposition rate, is well-suited for large-scale metal fabrication in industries such as aerospace and automotive [15,16,17]. WAAM produces minimal material waste and requires no additional tooling or design modifications, making it highly efficient for producing intricate metal components at scale [18,19]. WAAM offers impressive deposition rates, typically ranging from 3 kg/h to 7 kg/h depending on material type and processing parameters [20,21]. Compared to conventional manufacturing methods, it can reduce costs by 30% to 50%, largely due to the affordability of wire-based feedstock [22]. GMAW-based WAAM demonstrates excellent material adaptability, accommodating metals like aluminum, steel, and titanium, and is capable of fabricating large size components [23,24]. These features make WAAM essential for critical industries such as aerospace and automotive [25].

The integration of Gas Metal Arc Welding (GMAW) with WAAM, particularly using TM-B6 (E81T1-B6C) wire, offers a comprehensive solution for welding 5% Chromium–0.5% Molybdenum steels, which are commonly used in high-temperature and high-pressure environments such as power generation and petroleum industries. The 5Cr–0.5Mo composition in both the base metal and the TM-B6 wire enhances material properties, including corrosion resistance, hardness, and high-temperature performance. Chromium provides protection against corrosion, while molybdenum adds resistance to pitting, crevice corrosion, and thermal degradation. These attributes ensure superior weld integrity and strength, meeting the demands of critical applications. GMAW-WAAM using TM-B6 wire proves to be a reliable and robust solution for high-performance industrial applications. TM-B6 wire is recognized for its rapid-freezing slag, which facilitates welding in various positions with minimal spatter, contributing to a cleaner workspace. Additionally, it consistently produces welds of X-ray quality, satisfying stringent industry standards. These properties make TM-B6 an excellent choice for achieving high-quality welds in demanding environments, particularly in the power and energy sectors [26].

Within the GMAW-WAAM framework, optimization techniques such as the response surface methodology play crucial roles in improving process efficiency and structural quality [27]. The RSM reduces variability in process parameters, leading to robust and economical designs, and to identify significant interactions and effects [28,29]. Atomic Search Optimization (ASO) offers valuable contributions to WAAM by refining surface quality, minimizing porosity, and optimizing key parameters such as travel speed (TS), wire feed speed (WFS), and voltage (V). ASO also aids in the design of efficient support structures and the sequencing of materials in multi-material printing to ensure optimal properties and minimal interfacial defects [30,31]. Overall, ASO enhances the quality, efficiency, and material utilization of the WAAM process [32].

The present study aims to optimize GMAW-based WAAM process parameters to achieve desired bead geometries—specifically, bead width (BW) and bead height (BH) on low-alloy steels deposited onto mild steel substrates. By optimizing these variables, the study seeks to improve bead characteristics and enhance overall WAAM process performance. Single-layer depositions were carried out using TM-B6 metallic wire, based on a Box–Behnken experimental design. Statistical analysis was performed using ANOVA, and high R2 values indicated strong model fit. ASO was employed to identify optimal parameter combinations. This study provides valuable insights for industrial applications involving the fabrication of multi-layer structures using WAAM.

2. GMAW-Based WAAM Process Parameter

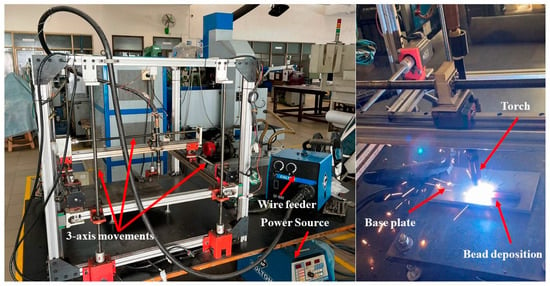

Bead-on-plate trials were conducted using low alloy steel TM-B6 wire (sourced from Hobart Brothers, TRI-MARK) via Gas Metal Arc Welding (GMAW)-based Wire Arc Additive Manufacturing (WAAM) on a 5Cr-0.5Mo steel substrate. The 1.2 mm diameter TM-B6 wire was selected for its suitability in both single-pass and multi-pass welding of low alloy steels. A shielding gas mixture of Argon and CO2 was employed during the process. The chemical composition of the wire is detailed in Table 1. Figure 1 illustrates the experimental WAAM setup used in this study, which includes key components such as a shielding gas supply, wire feeder (WF), GMAW torch, and motion controllers. The WAAM system offers a build volume of 220 × 220 × 500 mm, with the torch responsible for depositing wall structures onto the substrate plate. The GMAW torch is capable of three-axis movement for material deposition, governed by G-code programming integrated into the COLTON IFLEX 350 power source. This programming interfaces directly with the automated controller, managing nozzle motion along the X, Y, and Z axes. Before initiating the deposition process, shielding gas is circulated to prevent atmospheric contamination of the molten material. The base metal is securely clamped, and the torch performs the deposition, allowing precise and flexible movement in multiple directions.

Table 1.

Chemical composition of low alloy steel TM-B6 wire.

Figure 1.

Experimental Setup of GMAW process.

Utilizing a Box–Behnken Design (BBD), single bead depositions were conducted on the base plate. Input parameters, including Wire Feed Speed (WFS), TS, and V, were selected based on equipment capabilities and insights from recent literature. Each bead was maintained at a consistent length of 150 mm, with a steady gas flow rate (GFR) of 15 L/min and an arc length of 3 mm. By conducting bead-on-plate trials using the GMAW-based WAAM process with E81T1-B6C components, a range of parameters was determined, as presented in Table 2. The input variables and their ranges were chosen based on preliminary experimental runs, prior studies, and machine limitations. RSM design minimizes the number of experiments, thereby reducing material usage and time costs [33,34]. Furthermore, the BBD technique establishes correlations between machining variables and their corresponding responses [35]. Fifteen trials were carried out, with variations in the three machining variables across three levels in each trial. The study identified the relationship between input parameters and the geometry of the weld bead through the application of the RSM method. Through structured experimentation and defined optimization objectives, this method effectively modeled a multi-factor response problem, capturing nonlinear relationships between input and response variables [36]. The study established the relationship between input parameters and the geometry of the weld bead utilizing the RSM method. Through structured experiments and optimization objectives, this method effectively modeled, evaluated, and optimized a multi-factor response problem, capturing nonlinear relationships between intake and response variables.

Table 2.

GMAW-based WAAM Process Parameters.

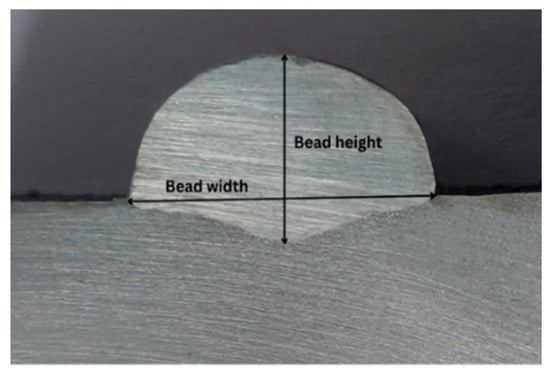

BH and BW response values were analyzed using optical microscopy. For each single-layer deposition, three measurements were taken at different locations across the cross-section. The mean of these readings was used in the analysis to ensure greater accuracy. Metallographic samples were sectioned using wire-cut EDM, then ground with sandpaper and polished using a metallographic polisher. Subsequently, the samples were etched with a 2% Nital reagent. The cross-sectional morphology was captured using an optical microscope, and the bead width and height of the single-pass deposition layers were measured individually, as shown in Figure 2.

Figure 2.

Cross-sectional views of single bead deposition specimens for BH and BW.

3. Results and Discussion

A Box–Behnken design was adopted as the design matrix, with the experimental design conducted using the DOE tool of Minitab 17. A total of 15 experiments were conducted, involving three factors and a center point of three. Table 3 presents the test parameters used in RSM.

Table 3.

Results of Bead morphologies as per BBD.

3.1. Regression Equations for BW and BH

Multivariable nonlinear regressions were used to establish relationships between process parameters and responses. The Box–Behnken Design (BBD) in Minitab v17 generated equations linking WAAM variables with bead height (BH) and bead width (BW). These equations enable evaluation beyond the experimental matrix. In the present study, stepwise regression was employed to develop the regression equations. The validity of these models was determined through ANOVA and residual plot analysis. The regression equations for bead width (BW) and bead height (BH) were derived using the stepwise method and are presented as Equations (1) and (2), respectively.

The signs and magnitudes of the coefficients in the regression equations reflect the physical influence of process parameters on bead geometry. The negative linear coefficients of WFS, TS, and V in both equations indicate that an increase in these parameters generally leads to a decrease in BH and BW, likely due to increased arc energy causing a wider and flatter bead profile with reduced height. The positive quadratic terms (e.g., WFS2, V2) suggest nonlinear behavior, where extreme values of input variables begin to reverse the initial trend due to changes in arc stability and heat input. The interaction terms (e.g., TS × V, WFS × TS) show the combined effects of simultaneous parameter changes, which influence bead shape through complex metallurgical and thermal mechanisms. For example, higher TS at elevated voltage may result in increased arc energy density, affecting bead penetration and morphology. These interpretations are consistent with established GMAW-WAAM behavior and support the reliability of the derived models.

3.2. ANOVA Analysis for BW and BH

The proficiency and validity of the derived regression equations were confirmed through the results of the ANOVA test. Utilizing Minitab v17, a computed F-value of 95.15 was obtained, indicating the model’s high level of significance. ANOVA results were employed to evaluate the importance of both significant and non-significant model terms at a 5% confidence level. A probability value (P) less than 0.05 was interpreted as statistically significant, indicating the influence of the respective term on the response variables [37,38]. Specifically, the probability value of 0.000, being lower than 0.05, confirmed the model’s statistical significance, as outlined in Table 4 and Table 5 for BW and BH, respectively. The statistical significance of the quadratic model for bead width underscores the critical roles of the regression, linear interaction, and squared terms in the analysis. At the 5% confidence level, all terms (WFS, TS, and V), along with the squared terms of WFS and V, were found to be statistically significant. Furthermore, the model’s lack of fit was evaluated with value of 2.88 and a p-value of 0.28, indicating that the lack of fit was not statistically significant. This confirms the model’s adequacy and reliability for prediction purposes. Among the input variables, Voltage (V) was found to exert the most significant influence on the BW response, as evidenced by the highest F-value, followed by WFS and TS. This statistical analysis provides valuable insights into the key process factors influencing BW and BH responses within the scope of the conducted experiments.

Table 4.

ANOVA results: BW Vs V, WFS, TS.

Table 5.

ANOVA results: BH Vs V, WFS, TS.

The BW exhibited an R2 value of 0.9662 and adjusted R2 value of 0.9758, while the BH displayed an R2 value of 0.9914 and an adjusted R2 value of 0.9827. These values, nearing unity, suggest the model’s suitability for the current data and its capability to predict new observations for both BW and BH responses [39,40]. Hence, the models for BW and BW are validated across the entire Design domain, enabling their utilization in predicting optimized processing parameters.

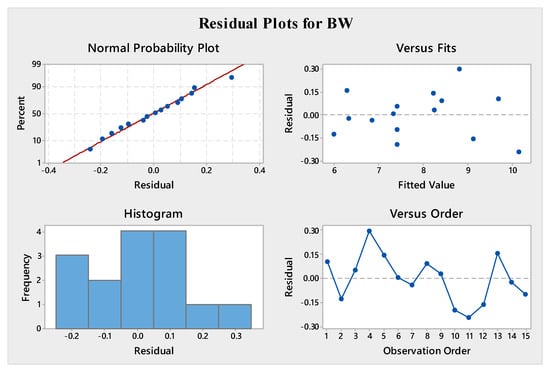

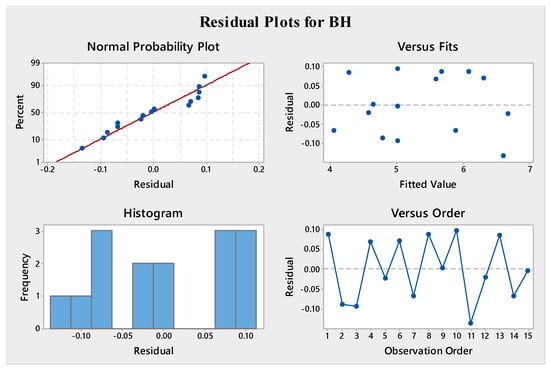

Residual plots were analyzed to validate the assumptions of the regression models and to verify the accuracy and adequacy of the ANOVA results [41]. ANOVA is considered an effective tool for model evaluation when its underlying assumptions are met, and residual analysis plays a crucial role in confirming this [42]. Figure 3 illustrates the residual analysis for BW, including a normal probability plot, a fitted versus predicted values plot, a histogram, and a residual versus observation order plot. The normal probability plot shows that the residuals closely follow a straight line, indicating that the model is appropriate [43]. The random scatter of points in the fitted versus predicted plot suggests the absence of systematic bias. The bell-shaped distribution in the histogram supports the normality assumption of the residuals [44]. Additionally, the residuals versus observation order plot displays no visible trend, reinforcing the statistical reliability of the ANOVA results. Collectively, these diagnostics confirm that the model satisfies all essential residual assumptions. Comparable results shown in Figure 4 for bead height (BH) further validate the strength and applicability of the regression models and the ANOVA outcomes.

Figure 3.

Residual plot for BW.

Figure 4.

Residual plot for BH.

3.3. Impact of Processing Parameters on BW and BH

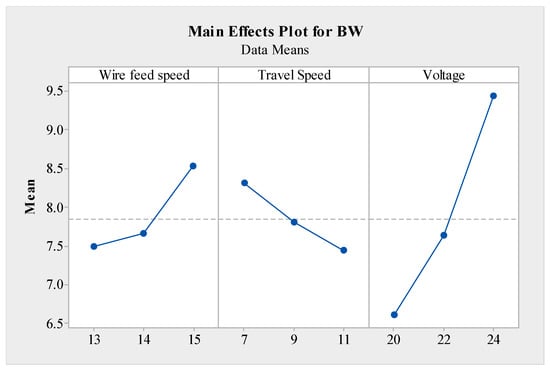

In Figure 5, the main effects plot illustrates the influence of wire feed speed (WFS), travel speed (TS), and voltage (V) on bead width (BW). An increase in WFS from 13 to 15 mm/min correlates with a rise in BW, consistent with the higher deposition rates typically observed at elevated WFS levels [45]. Conversely, an increase in TS from 7 to 11 mm/s results in a reduction in BW, attributed to the higher torch speed allowing less time for molten metal deposition, thereby decreasing bead width [46]. Furthermore, increasing the voltage from 20 to 24 V shows a significant positive effect on BW, likely due to arc widening, which produces larger droplets and increases bead width [47]. In general, increasing WFS has a positive influence on BW, while increasing TS has a negative effect. However, excessive voltage may eventually have a negative impact on BW due to arc instability or excessive dispersion of molten metal [48]. These trends align with expectations regarding the variation in deposition rates and bead geometry in response to changes in process parameters.

Figure 5.

The plot illustrates the main effect of BW.

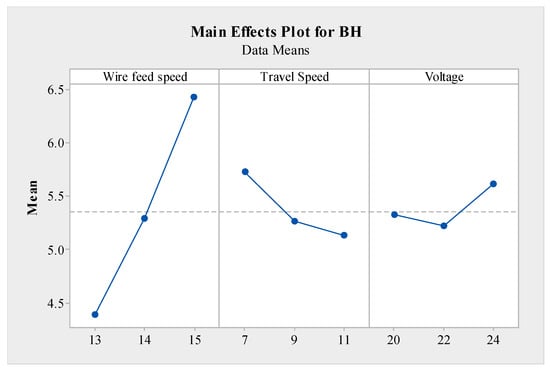

The influence of WAAM design parameters—specifically WFS, TS, and V on the height of the deposited bead was investigated, as illustrated in Figure 6. A notable increase in BH was observed with rising WFS, attributed to intensified material deposition resulting from the higher wire feed rate. Conversely, increasing TS from 7 to 11 mm/s led to a reduction in BH, as the faster torch movement restricted the amount of material deposited, thereby lowering the bead height [49,50]. The effect of V on BH was comparatively minimal, with fluctuations occurring within a narrow range. However, a slight increase in BH was noted at higher voltage settings. In contrast, a general decline in BH was observed with increasing TS and V. Elevated TS reduced the deposition time per unit length, resulting in decreased BH. Similarly, higher V values led to reduced BH due to increased arc length and a spreading effect of the molten material, which caused the bead to flatten rather than grow in height [51]. On the other hand, increasing WFS had a consistently positive effect on BH by enhancing the rate of material deposition. These trends highlight the complex and varying impacts of process parameters on BH.

Figure 6.

Plot illustrating the main effect of BH.

3.4. Optimization by ASO Algorithm

Optimization of BH and BW responses using the Atomic Search Optimization (ASO) Algorithm talks the differing levels of Wire-Arc Additive Manufacturing (WAAM) variables observed in the ASO algorithm. The ASO algorithm, known for its efficacy in navigating complex search spaces, was chosen to achieve optimal levels of both BH and BW while considering the interplay of design variables. Throughout the ASO execution, stringent bounds were set for the design variables: WFS: 13 to 15 m/min, TS: 7 to 11 mm/s, and V: 20 to 24 V. The ASO algorithm used in the present study has different parameters like: Population Size = 25, No. of iteration = 200, Atomic Radius Coefficient = 0.3, Damping Coefficient = 0.9, Collision Coefficient = 0.5, Attraction-Repulsion Coefficient = 1, Mutation Probability = 0.01. All the output variables were considered as positive integers during the optimization.

Table 6 presents the results of single-response optimization, polished using the Atomic Search Optimization (ASO) algorithm. The ASO algorithm minimizes discrepancies between predicted and validated results, securing a strong alignment between WAAM variables and bead geometry. This underlines ASO’s efficacy in optimizing WAAM processes with precision.

Table 6.

Single response optimization.

Addition to single-response optimization, multi-objective optimization was vital to establish ideal integration of design parameters. Variables that can optimize BW and BH simultaneously. This was vital for achieving the sought-after quality in both outcomes.

where w1 and w2 characterize the weights given during the ASO execution.

To achieve simultaneous enhancement of both BW and BH, multi-objective optimization was vital. In the present study, BH and BW were given equal importance as the optimal process conditions were derived to fabricate a thin-walled structure. The aim of optimization was to minimize BW (for better precision and dimensional control) and maximize BH (to build taller structures with fewer layers). Thus, equal weightage for both BW and BH were considered during the simultaneous optimization. An objective function considering equal weightage (0.5) for BH and BW was formulated, leading to optimized values of BW and BH (4.01 mm and 5.86 mm, respectively) at WFS: 13 m/min, TS: 10 mm/s, and V: 20 V.

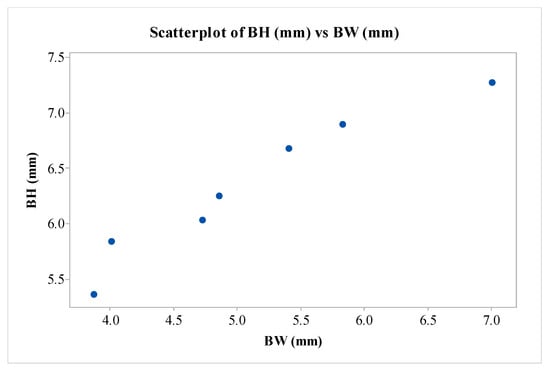

In the domain of WAAM, the multi-objective Atomic Search Optimization (ASO) algorithm was employed to address the conflicting objectives associated with bead height (BH) and bead width (BW). In addition to the optimization analysis, Pareto fronts were developed, revealing distinct non-dominated solutions. A total of seven optimal solutions were identified, each offering unique and continuous values of WAAM process parameters tailored to meet diverse industrial application requirements, as presented in Table 7. Figure 7 illustrates the Pareto graph of these seven optimal points. These solutions provide manufacturers with optimal process settings for simultaneously achieving the desired BH and BW values. To validate the ASO findings, verification trials were conducted for all the Pareto-optimal points listed in Table 7. The experimental results showed an acceptable deviation of less than 4%, indicating the adequacy of the developed linear models combined with ASO. The validation experiments confirmed the accuracy and reliability of the ASO-based multi-objective optimization results, demonstrating the algorithm’s effectiveness in enhancing WAAM performance. The successful optimization achieved through the ASO algorithm highlights its capability to precisely recommend process parameters for WAAM, enabling the fabrication of high-quality multi-layer structures with minimal discrepancies between predicted and measured values.

Table 7.

Pareto optimal points.

Figure 7.

Pareto graph for BH vs. BW response.

4. Conclusions

In the present study, a parametric investigation of GMAW-based WAAM process variables using TM-B6 wire on a mild steel substrate was conducted to enhance the bead morphology of single-layer deposition structures. Voltage, wire feed speed (WFS), and travel speed (TS) were considered the major process parameters influencing the achievable values of bead width (BW) and bead height (BH). The authors implemented the Box–Behnken Design (BBD) and Atomic Search Optimization (ASO) within the framework of Response Surface Methodology (RSM) to generate predictive models, which were validated through ANOVA with significant accuracy. Voltage was found to have the strongest effect on BW, followed by WFS as the second most influential parameter among all experimental factors. Both single-objective and multi-objective optimizations of BH and BW were carried out using the ASO algorithm. An objective function with equal weightage (0.5) for BH and BW was formulated, resulting in optimized values of BW and BH (4.01 mm and 5.86 mm, respectively) at WFS: 13 m/min, TS: 10 mm/s, and V: 20 V. Pareto fronts were developed, showing distinct non-dominated solutions. Subsequently, a multi-layer structure will be fabricated in future work using these optimized parameters: voltage of 20 V, wire feed speed of 13 m/min, and travel speed of 10 mm/s. This study offers valuable insights for industrial applications involving the fabrication of multi-layer structures. The research team plans to evaluate these structures through tensile testing, impact testing, microhardness assessment, and radiographic analysis. Further refinement of WAAM processing is expected to yield improvements suitable for manufacturing applications in industry.

Author Contributions

Conceptualization, K.P., R.C., V.V., V.P. and J.V.; methodology, K.P., R.C. and J.V.; software, V.P.; validation, K.P., R.C., V.V., V.P. and J.V.; formal analysis, K.P.; investigation, K.P., R.C., V.V., V.P. and J.V.; resources, K.P., R.C., V.V., V.P. and J.V.; data curation, K.P., V.V., R.C. and J.V.; writing—original draft preparation, K.P., R.C. and J.V.; writing—review and editing, R.C. and J.V.; visualization, K.P., R.C., V.V., V.P. and J.V.; supervision, R.C. and J.V.; project administration, R.C. and J.V.; funding acquisition, R.C. and J.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tareq, S.; Rahman, T.; Poudel, B.; Chung, H.; Kwon, P. Heat treatment protocol for additively manufactured nitinol shape memory alloys in biomedical applications. Mater. Sci. Eng. A 2024, 897, 146274. [Google Scholar] [CrossRef]

- Tang, P.; Zhao, X.; Shi, H.; Hu, B.; Ding, J.; Yang, B.; Xu, W. A review of multi-axis additive manufacturing: Potential, opportunity and challenge. Addit. Manuf. 2024, 83, 104075. [Google Scholar] [CrossRef]

- Meng, X.; Gardner, L. Hybrid construction featuring wire arc additive manufacturing: Review, concepts, challenges and opportunities. Eng. Struct. 2025, 326, 119337. [Google Scholar] [CrossRef]

- Hiremath, S.; Sahu, A.R.; Majumder, H. Modeling and analysis of fused deposition modeling (FDM) process parameters on the mechanical properties of thermoplastic parts. AIP Conf. Proc. 2023, 2427, 020063. [Google Scholar] [CrossRef]

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive Manufacturing of Metals: The Technology, Materials, Design and Production; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Majumder, H.; Gajghate, S.S.; Sahu, A.R.; Behera, A.K.; Limbadri, C.; Ukey, K. Finite element analysis of wheel rim by additive manufacturing materials. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Yang, H.; Shan, Z.; Yan, D.; Shi, J.; Shi, H.; Huang, J. Advances in digital multi-material composite sand-mold binder-jetting forming technology and equipment. Addit. Manuf. Front. 2024, 3, 200138. [Google Scholar] [CrossRef]

- Vora, J.; Parmar, H.; Chaudhari, R.; Khanna, S.; Doshi, M.; Patel, V. Experimental investigations on mechanical properties of multi-layered structure fabricated by GMAW-based WAAM of SS316L. J. Mater. Res. Technol. 2022, 20, 2748–2757. [Google Scholar] [CrossRef]

- Vaghasia, V.; Chaudhari, R.; Patel, V.K.; Vora, J. Parametric Study on Investigations of GMAW-Based WAAM Process Parameters and Effect on Microstructure and Mechanical Properties of NiTi SMA. J. Manuf. Mater. Process. 2025, 9, 58. [Google Scholar] [CrossRef]

- Li, H.; Shi, X.; Wu, B.; Corradi, D.R.; Pan, Z.; Li, H. Wire arc additive manufacturing: A review on digital twinning and visualization process. J. Manuf. Process. 2024, 116, 293–305. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parikh, N.; Khanna, S.; Vora, J.; Patel, V. Effect of multi-walled structure on microstructure and mechanical properties of 1.25 Cr-1.0 Mo steel fabricated by GMAW-based WAAM using metal-cored wire. J. Mater. Res. Technol. 2022, 21, 3386–3396. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, C.; Li, C.; Wu, S. Advances in Ultrasonic-Assisted Directed Energy Deposition (DED) for Metal Additive Manufacturing. Crystals 2024, 14, 114. [Google Scholar] [CrossRef]

- Raspall, F.; Araya, S.; Pazols, M.; Valenzuela, E.; Castillo, M.; Benavides, P. Wire Arc Additive Manufacturing for Widespread Architectural Application: A Review Informed by Large-Scale Prototypes. Buildings 2025, 15, 906. [Google Scholar] [CrossRef]

- Kumar, P.; Ghangas, G.; Dhull, S. Effects of WAAM Process Parameters on Mechanical and Surface Integrity: A Comprehensive Review. In Manufacturing Strategies and Systems; CRC Press: Boca Raton, FL, USA, 2025; pp. 62–84. [Google Scholar]

- Dhinakaran, V.; Ajith, J.; Fahmidha, A.F.Y.; Jagadeesha, T.; Sathish, T.; Stalin, B. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys—A review. Mater. Today Proc. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A review of WAAM for steel construction–Manufacturing, material and geometric properties, design, and future directions. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1506–1522. [Google Scholar]

- Srivastava, M.; Rathee, S.; Tiwari, A.; Dongre, M. Wire arc additive manufacturing of metals: A review on processes, materials and their behaviour. Mater. Chem. Phys. 2023, 294, 126988. [Google Scholar] [CrossRef]

- Wang, C.; Suder, W.; Ding, J.; Williams, S. The effect of wire size on high deposition rate wire and plasma arc additive manufacture of Ti-6Al-4V. J. Mater. Process. Technol. 2021, 288, 116842. [Google Scholar] [CrossRef]

- Ke, W.; Oliveira, J.; Cong, B.; Ao, S.; Qi, Z.; Peng, B.; Zeng, Z. Multi-layer deposition mechanism in ultra high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102513. [Google Scholar] [CrossRef]

- Kokare, S.; Shen, J.; Fonseca, P.P.; Lopes, J.G.; Machado, C.M.; Santos, T.G.; Oliveira, J.P.; Godina, R. Wire arc additive manufacturing of a high-strength low-alloy steel part: Environmental impacts, costs, and mechanical properties. Int. J. Adv. Manuf. Technol. 2024, 134, 453–475. [Google Scholar] [CrossRef]

- Pattanayak, S.; Sahoo, S.K. Gas metal arc welding based additive manufacturing—A review. CIRP J. Manuf. Sci. Technol. 2021, 33, 398–442. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A review of the recent developments and challenges in wire arc additive manufacturing (WAAM) process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Prahl, U.; Schleser, M.; Reisgen, U.; Bleck, W. Micro–macro-characterisation and modelling of mechanical properties of gas metal arc welded (GMAW) DP600 steel. Mater. Sci. Eng. A 2014, 589, 1–14. [Google Scholar] [CrossRef]

- Schmitt-Harsh, M.; Sweeney, S.P.; Evans, T.P. Classification of coffee-forest landscapes using Landsat TM imagery and spectral mixture analysis. Photogramm. Eng. Remote Sens. 2013, 79, 457–468. [Google Scholar] [CrossRef]

- Baghel, P.K.; Gupta, T. Optimization of parameters of pulse current gas tungsten arc welding using non conventional techniques. J. Adv. Join. Process. 2022, 6, 100124. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Mani Prabu, S.; Palani, I.; Patel, V.K.; Parikh, D.; de Lacalle, L.N.L. Multi-response optimization of WEDM process parameters for machining of superelastic nitinol shape-memory alloy using a heat-transfer search algorithm. Materials 2019, 12, 1277. [Google Scholar] [CrossRef]

- Chen, W.-H.; Uribe, M.C.; Kwon, E.E.; Lin, K.-Y.A.; Park, Y.-K.; Ding, L.; Saw, L.H. A comprehensive review of thermoelectric generation optimization by statistical approach: Taguchi method, analysis of variance (ANOVA), and response surface methodology (RSM). Renew. Sustain. Energy Rev. 2022, 169, 112917. [Google Scholar] [CrossRef]

- Mossa, M.A.; Kamel, O.M.; Sultan, H.M.; Diab, A.A.Z. Parameter estimation of PEMFC model based on Harris Hawks’ optimization and atom search optimization algorithms. Neural Comput. Appl. 2021, 33, 5555–5570. [Google Scholar] [CrossRef]

- Izci, D. A novel improved atom search optimization algorithm for designing power system stabilizer. Evol. Intell. 2022, 15, 2089–2103. [Google Scholar] [CrossRef]

- Bi, J.; Zhang, Y. An improved atom search optimization for optimization tasks. Multimed. Tools Appl. 2023, 82, 6375–6429. [Google Scholar] [CrossRef]

- Veza, I.; Spraggon, M.; Fattah, I.R.; Idris, M. Response surface methodology (RSM) for optimizing engine performance and emissions fueled with biofuel: Review of RSM for sustainability energy transition. Results Eng. 2023, 18, 101213. [Google Scholar] [CrossRef]

- Majumder, H.; Paul, T.; Dey, V.; Dutta, P.; Saha, A. Use of PCA-grey analysis and RSM to model cutting time and surface finish of Inconel 800 during wire electro discharge cutting. Measurement 2017, 107, 19–30. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Prabu, S.; Palani, I.; Patel, V.K.; Parikh, D. Pareto optimization of WEDM process parameters for machining a NiTi shape memory alloy using a combined approach of RSM and heat transfer search algorithm. Adv. Manuf. 2021, 9, 64–80. [Google Scholar] [CrossRef]

- Kumari, B.; Tiwary, R.; Yadav, M. Non linear regression analysis and RSM modeling for removal of Cr (VI) from aqueous solution using PANI@ WH composites. Mater. Chem. Phys. 2022, 290, 126457. [Google Scholar] [CrossRef]

- Rahardja, U.; Aini, Q. Evaluating the effectiveness of digital marketing campaigns through conversion rates and engagement levels using anova and chi-square tests. J. Digit. Mark. Digit. Curr. 2025, 2, 26–45. [Google Scholar] [CrossRef]

- Ukey, K.; Sahu, A.R.; Majumder, H. Influence of process parameters on the machinability features of shape memory alloy kovar during WEDM. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2025. [Google Scholar] [CrossRef]

- Bouloumpasi, E.; Skendi, A.; Christaki, S.; Biliaderis, C.G.; Irakli, M. Optimizing conditions for the recovery of lignans from sesame cake using three green extraction methods: Microwave-, ultrasound-and accelerated-assisted solvent extraction. Ind. Crops Prod. 2024, 207, 117770. [Google Scholar] [CrossRef]

- Wani, K.M.; Uppaluri, R.V. Efficacy of ultrasound-assisted extraction of bioactive constituents from Psidium guajava leaves. Appl. Food Res. 2022, 2, 100096. [Google Scholar] [CrossRef]

- Bansal, S.; Singh, G. Multiple linear regression based analysis of weather data: Assumptions and limitations. In Proceedings of the International Conference on Advanced Communication and Intelligent Systems, Warsaw, Poland, 16–17 June 2023; pp. 221–238. [Google Scholar]

- Magabe, R.; Sharma, N.; Gupta, K.; Paulo Davim, J. Modeling and optimization of Wire-EDM parameters for machining of Ni 55.8 Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Chantarangsi, W.; Liu, W.; Bretz, F.; Kiatsupaibul, S.; Hayter, A.J. Normal probability plots with confidence for the residuals in linear regression. Commun. Stat.-Simul. Comput. 2018, 47, 367–379. [Google Scholar] [CrossRef]

- Boylan, G.L.; Cho, B.R. The normal probability plot as a tool for understanding data: A shape analysis from the perspective of skewness, kurtosis, and variability. Qual. Reliab. Eng. Int. 2012, 28, 249–264. [Google Scholar] [CrossRef]

- Vora, J.; Pandey, R.; Dodiya, P.; Patel, V.; Khanna, S.; Vaghasia, V.; Chaudhari, R. Fabrication of Multi-Walled Structure through Parametric Study of Bead Geometries of GMAW-Based WAAM Process of SS309L. Materials 2023, 16, 5147. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire arc additive manufacturing: Review on recent findings and challenges in industrial applications and materials characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, A.; Das, A.K.; Kumar, S. Parametric study and characterization of wire arc additive manufactured steel structures. Int. J. Adv. Manuf. Technol. 2021, 115, 1723–1733. [Google Scholar] [CrossRef]

- Vora, J.; Parikh, N.; Chaudhari, R.; Patel, V.K.; Paramar, H.; Pimenov, D.Y.; Giasin, K. Optimization of bead morphology for GMAW-based wire-arc additive manufacturing of 2.25 Cr-1.0 Mo steel using metal-cored wires. Appl. Sci. 2022, 12, 5060. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc welding processes for additive manufacturing: A review. In Transactions on Intelligent Welding Manufacturing: Volume I; Springer: Singapore, 2018; pp. 3–24. [Google Scholar]

- Giarollo, D.F.; Mazzaferro, C.C.P.; Mazzaferro, J.A.E. Comparison between two heat source models for wire-arc additive manufacturing using GMAW process. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).