Implementation of the Theory of Constraints (TOC) for a Furniture Manufacturing-Based Organization †

Abstract

1. Introduction

2. Literature Review

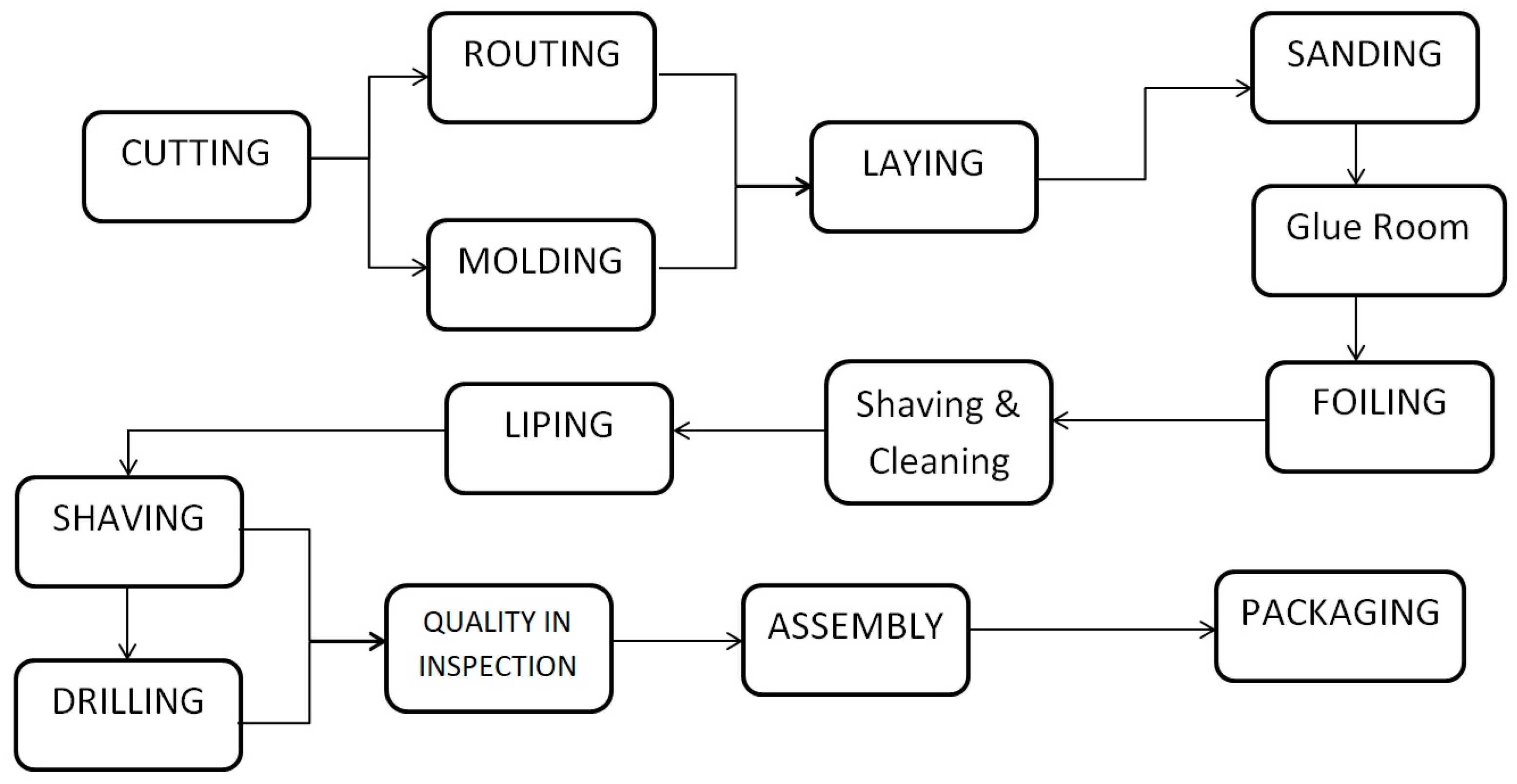

3. TOC in the Furniture Manufacturing

3.1. Introducing the Firm

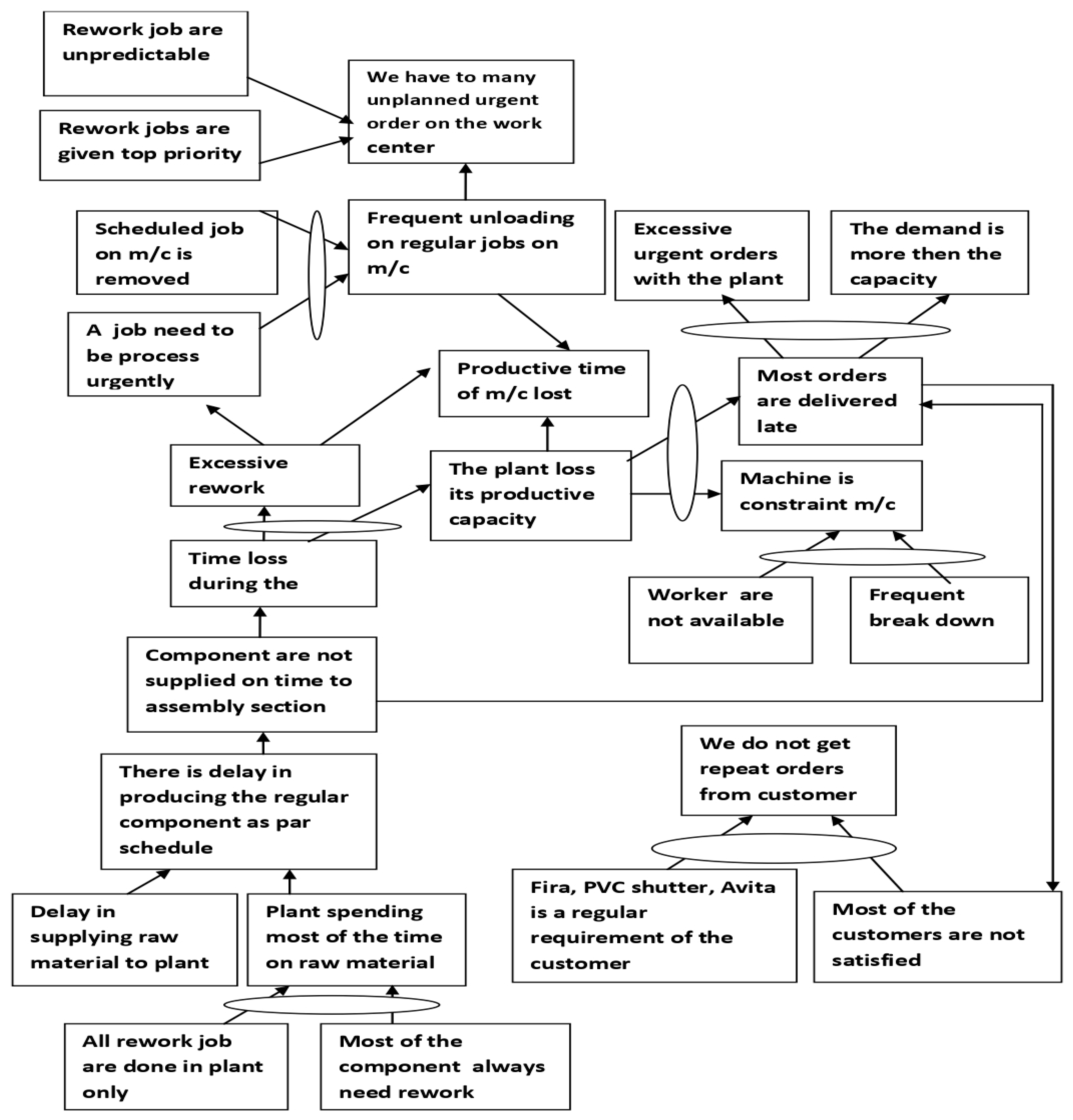

3.2. Identifying the Constraints

3.3. Protecting Constraint Capacity

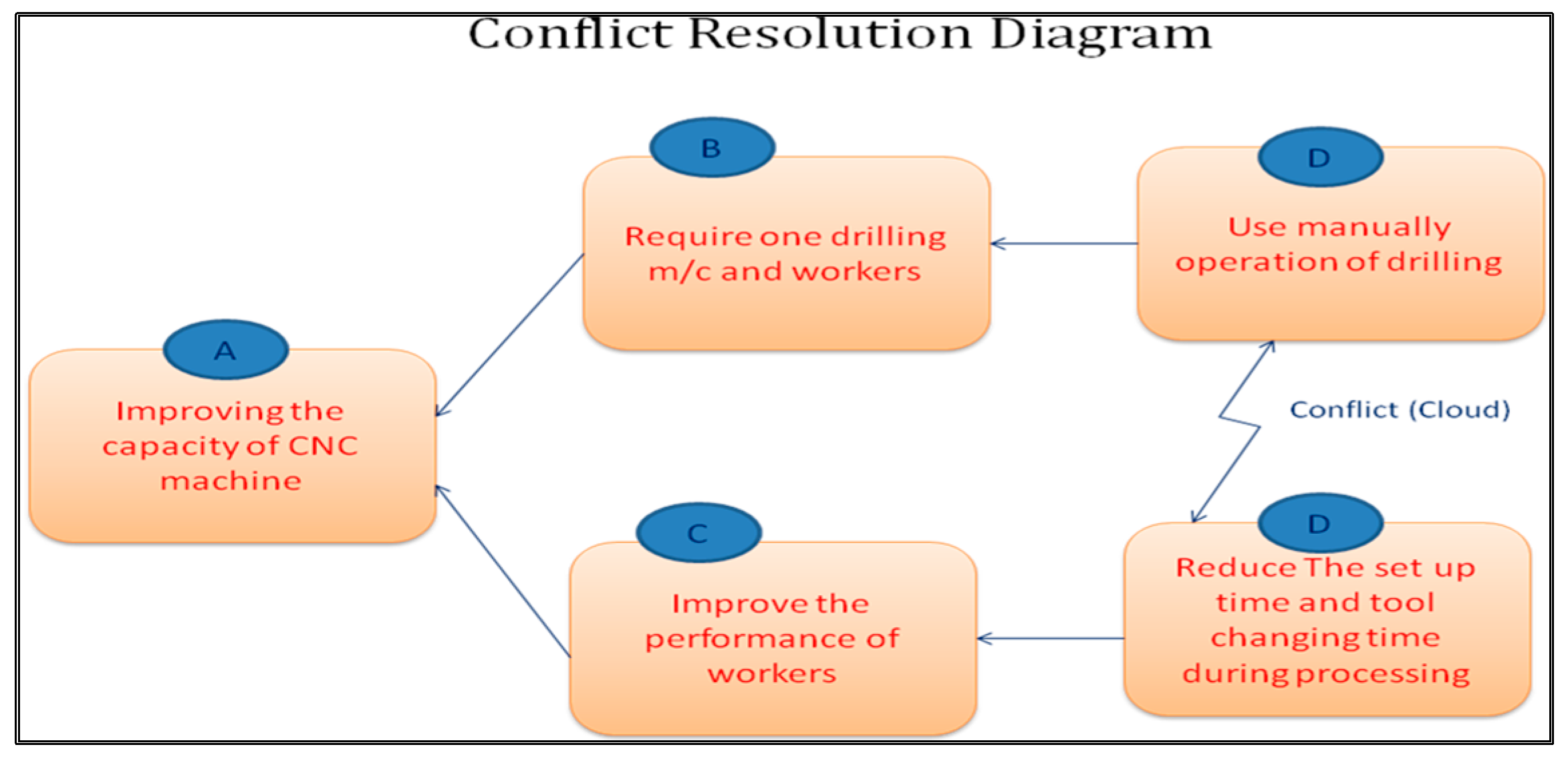

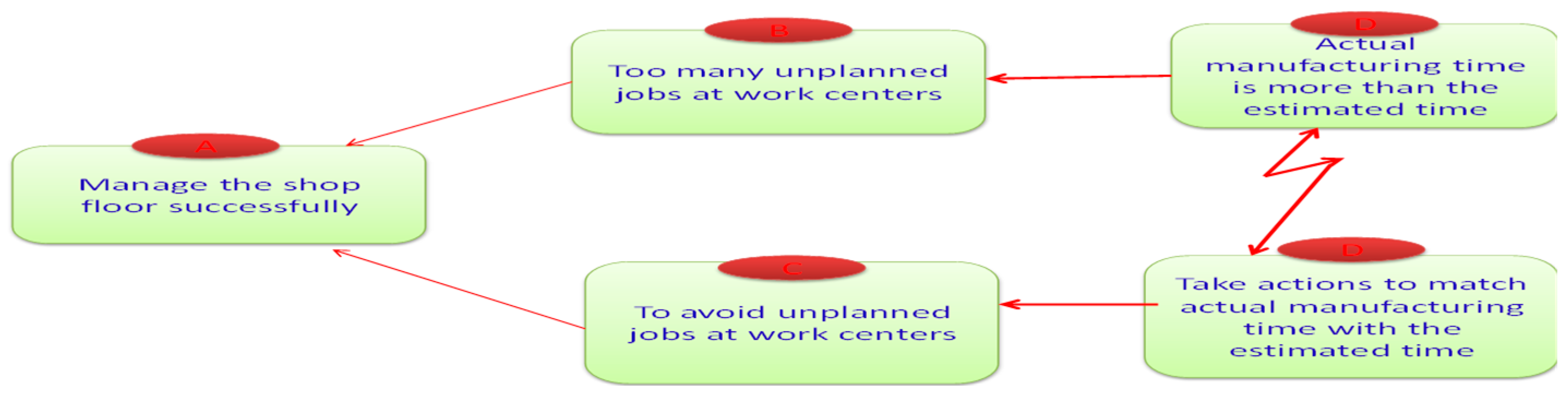

3.3.1. Conflict Resolution Diagram

- View 1: Use the manual operation of drilling

- View 2: Reduce setup time and tool changing time during processing.

- “The other problem exists due to this core problem”.

- “Solving this single problem will reduce the overall time”.

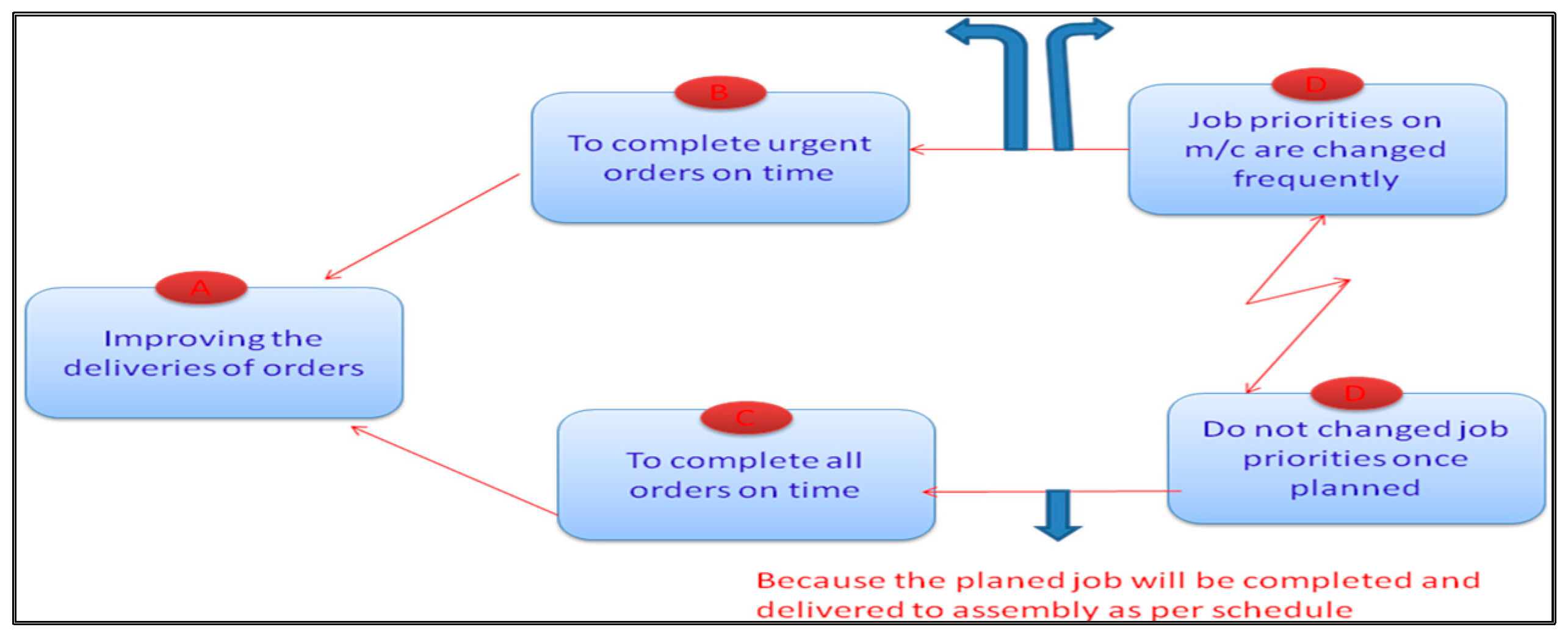

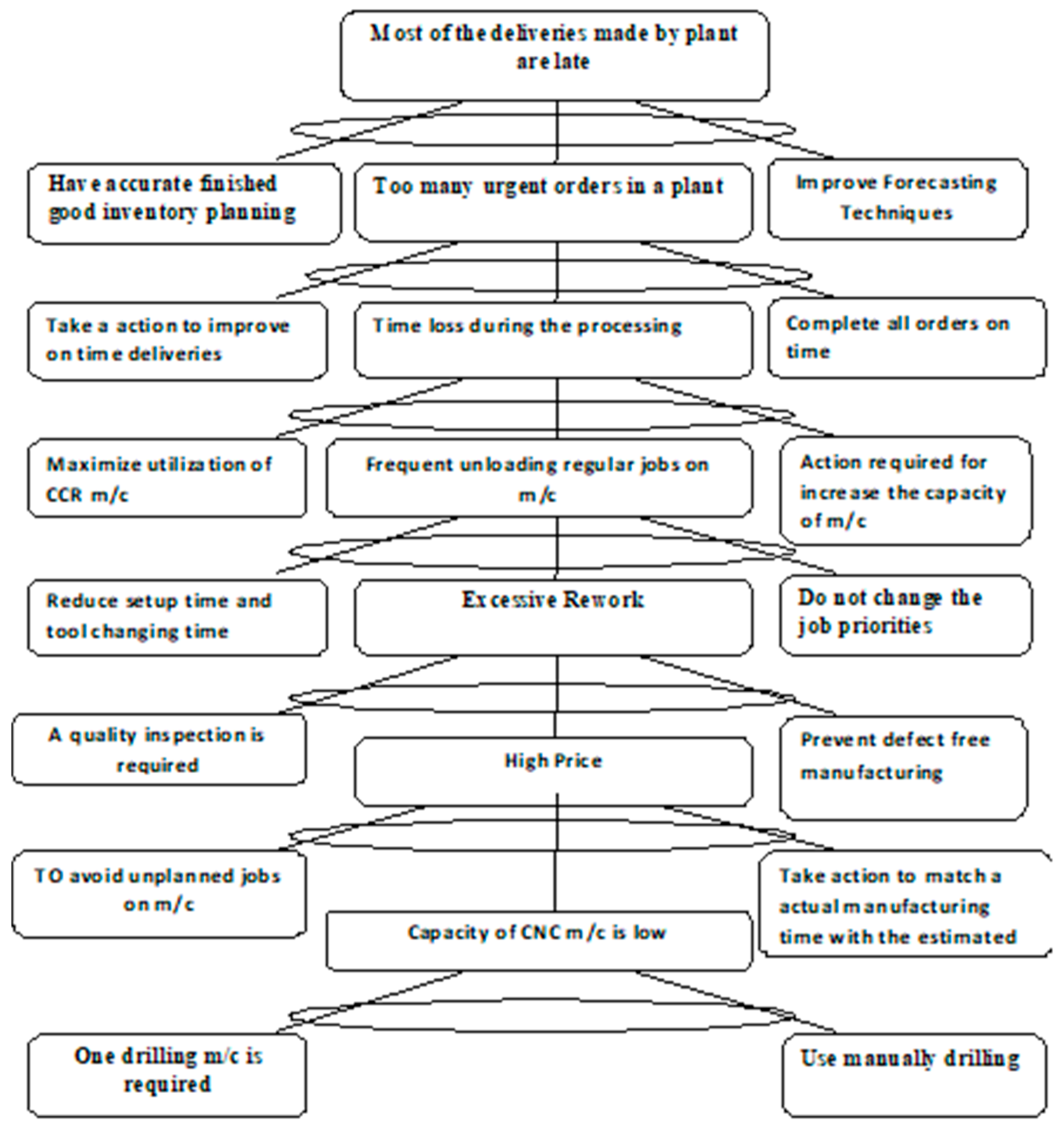

3.3.2. Cloud for the UDEs: Late Deliveries of Most Orders

3.3.3. Cloud for the UDEs: High Price

3.4. Subordinating Every Related Decision to the Constraints

- Subordination required aligning all other CNCs with the optimized speed of CNC-3, even if it meant inefficiencies in non-constraints. Staff reallocation and priority access to shared resources were implemented to support this alignment.

- Rearranging the work sequence may increase setup for non-constraint processes but help reduce or simplify setup for the constraint.

- Staff can be away from non-constraint areas to support the constraint when required, such as during setup. Additionally, certain tasks of the constraint—like material handling, quality checks, or parts calculating—can be delegated to employees working in preceding or subsequent processes.

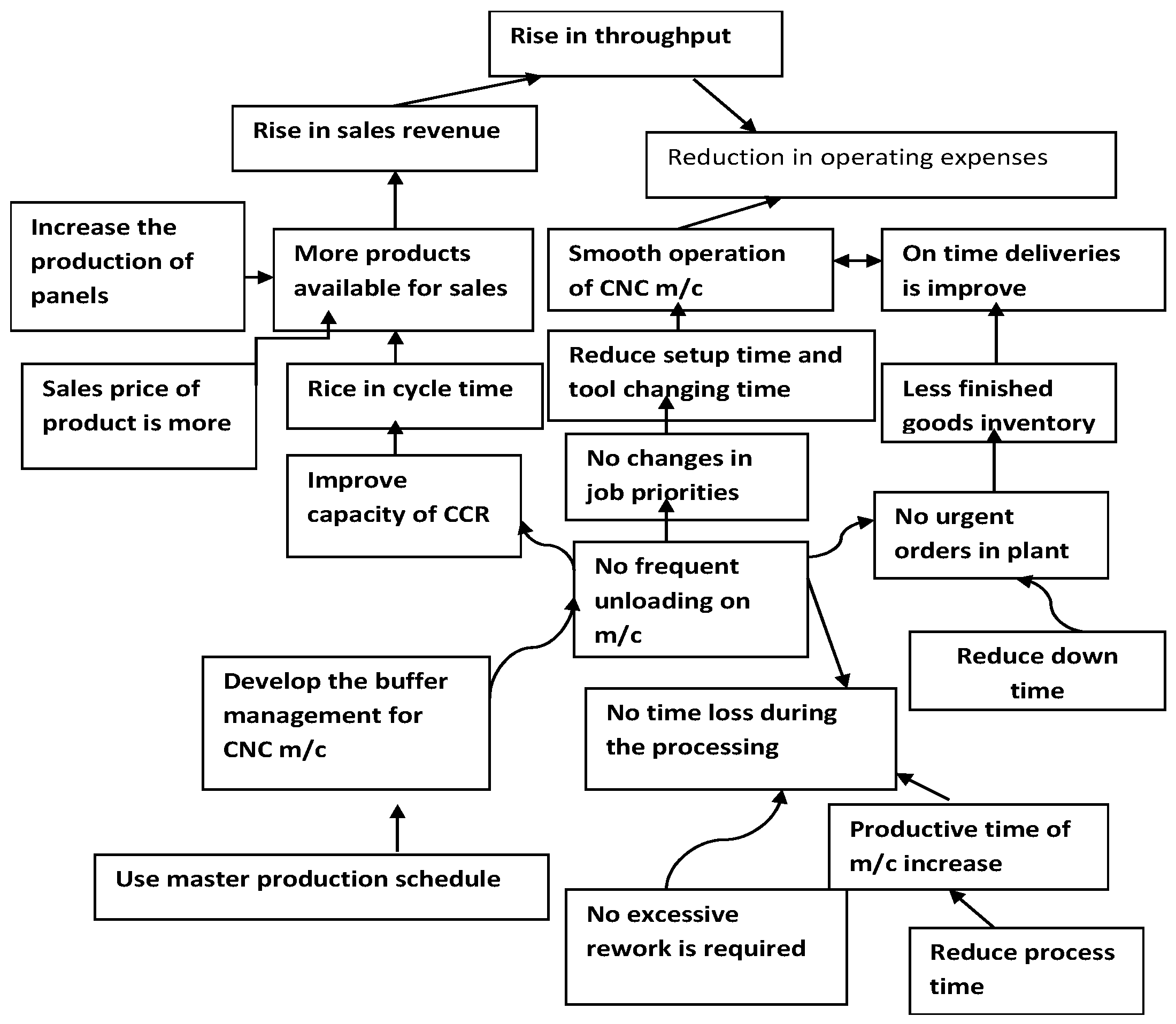

3.5. Future Reality Tree

3.5.1. Negative Branches

- If By installing manual drilling, operating expenses are increased.

- For developing a master production schedule, buffer management is required for each recourse.

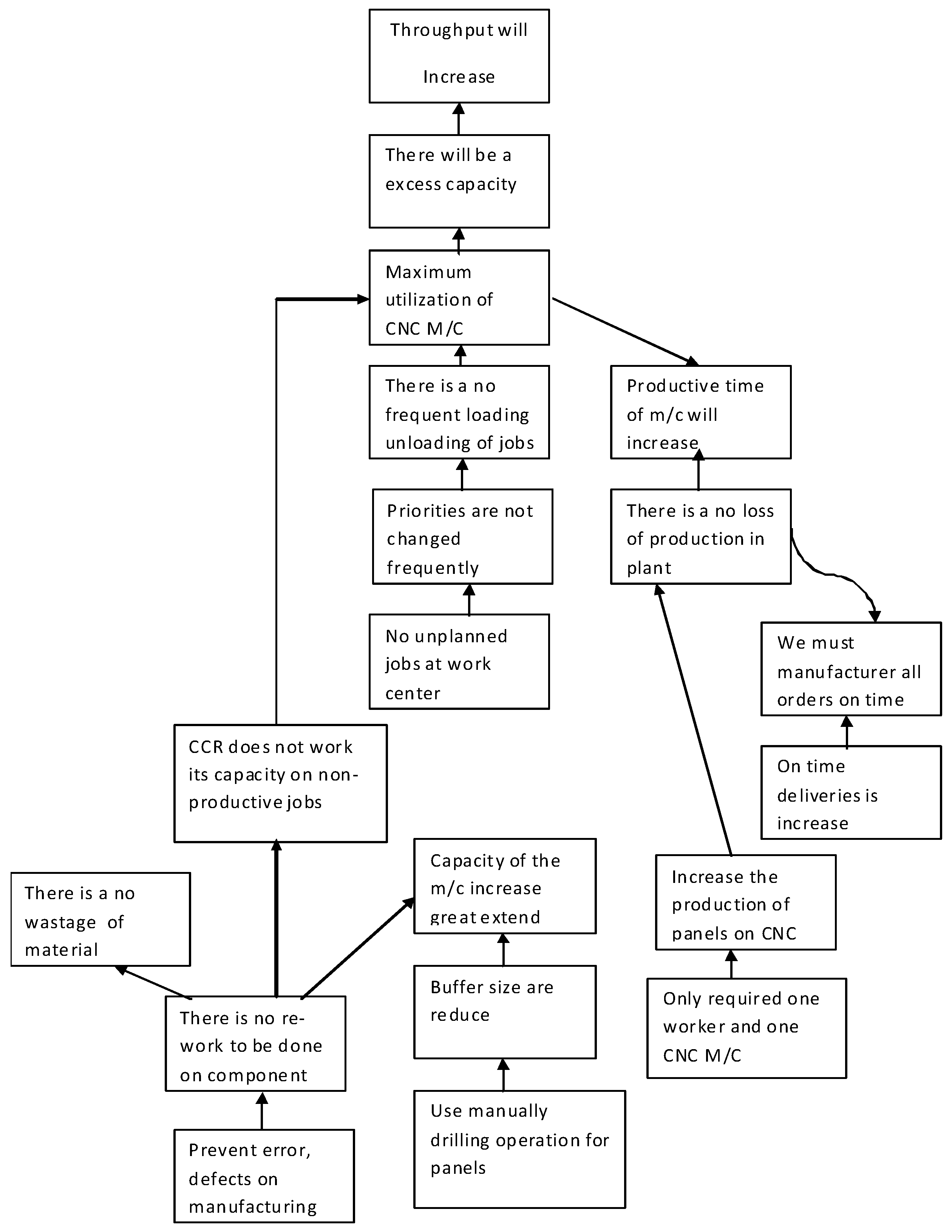

3.5.2. Prerequisite Tree

- To identify the obstacles that may come in the way of implementing the proposed solution.

- To find ways to overcome the obstacles.

- To develop a plan of action for the execution of the new solution.

3.6. Elevating the Constraints

Transition Tree

4. Results & Discussion

4.1. Identification of the Constraint

4.2. Analysis of CNC Performance

4.3. Improvements After TOC Implementation

4.4. Managerial Implications and Discussion

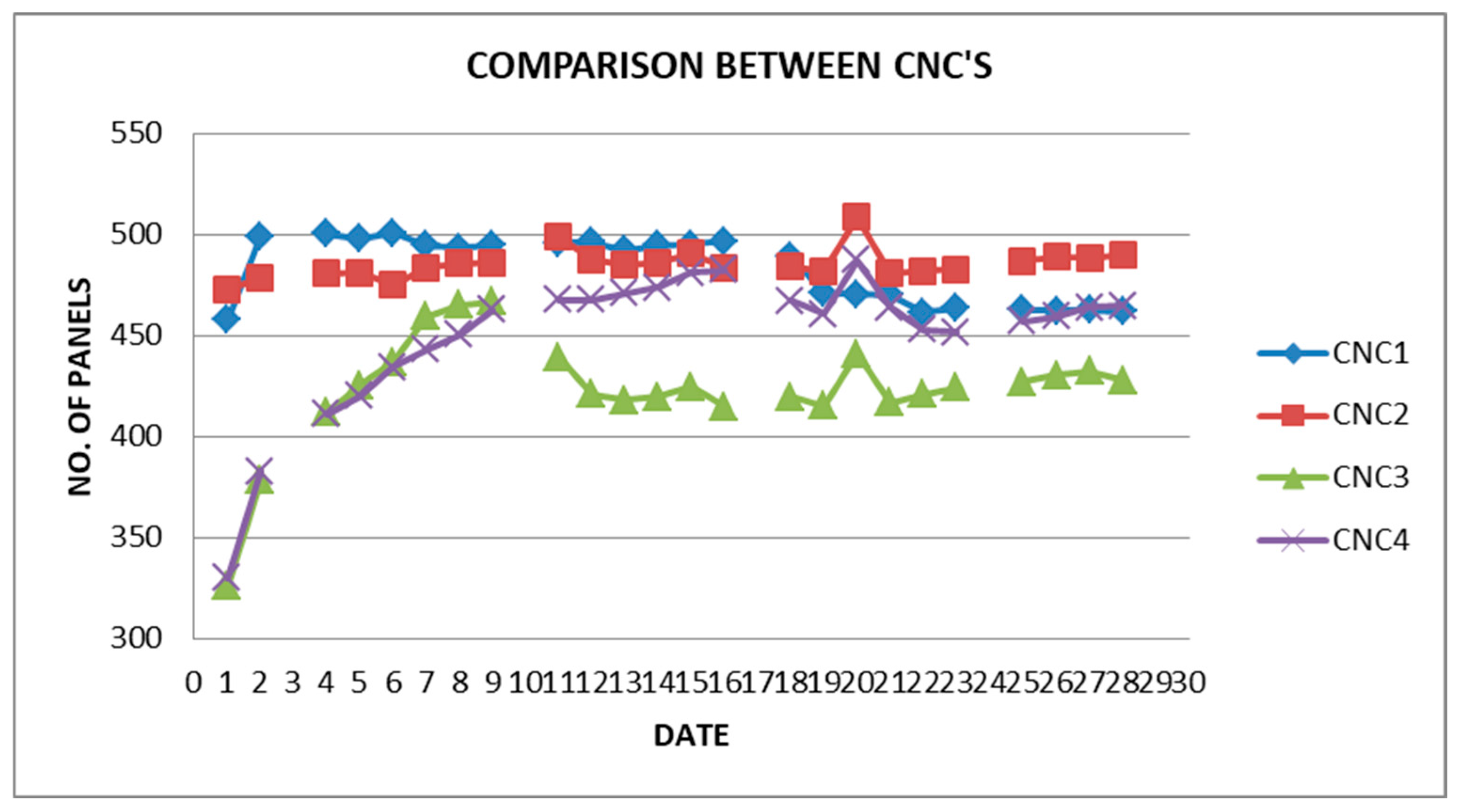

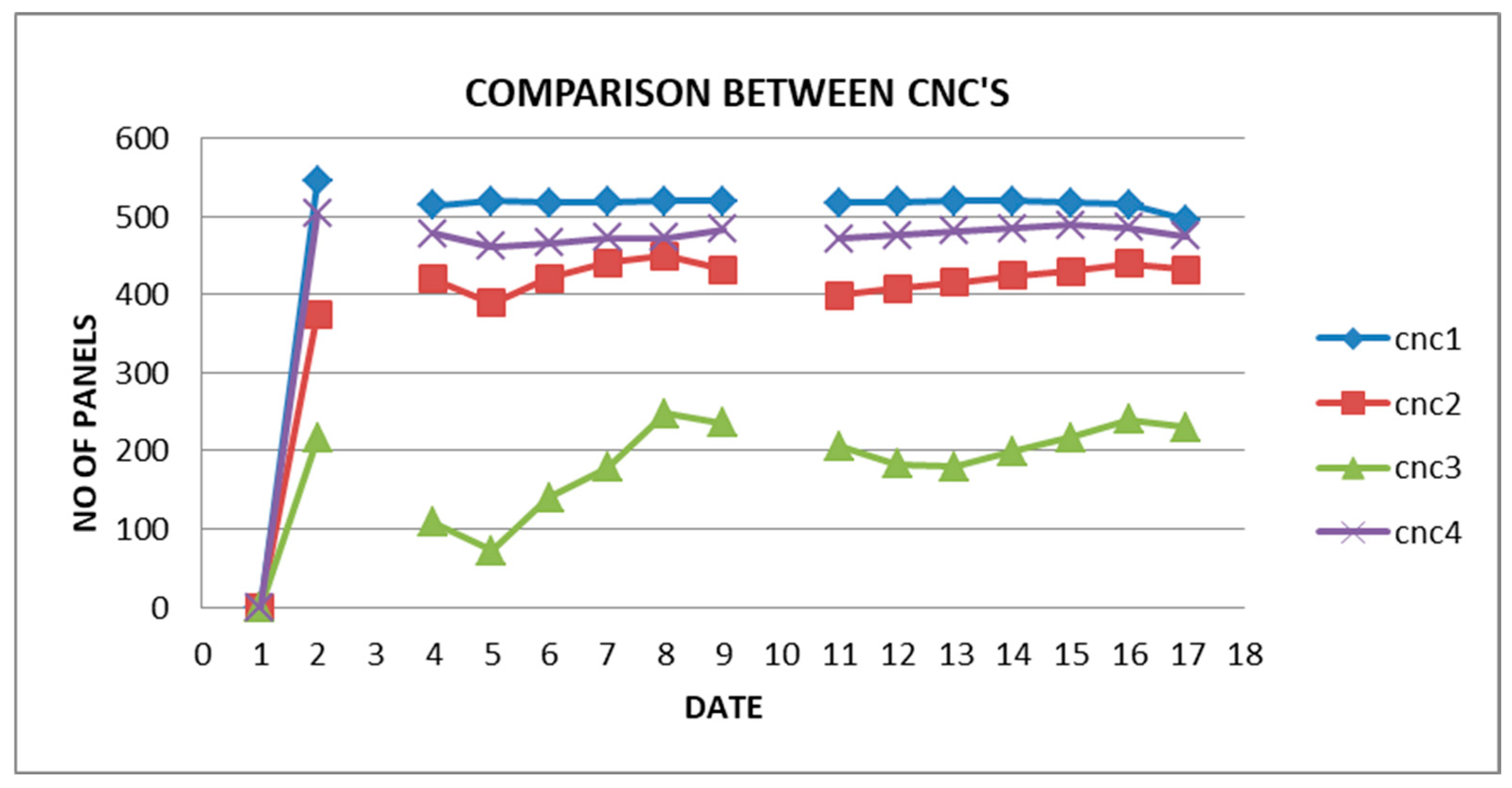

4.5. Comparison Between CNC’s

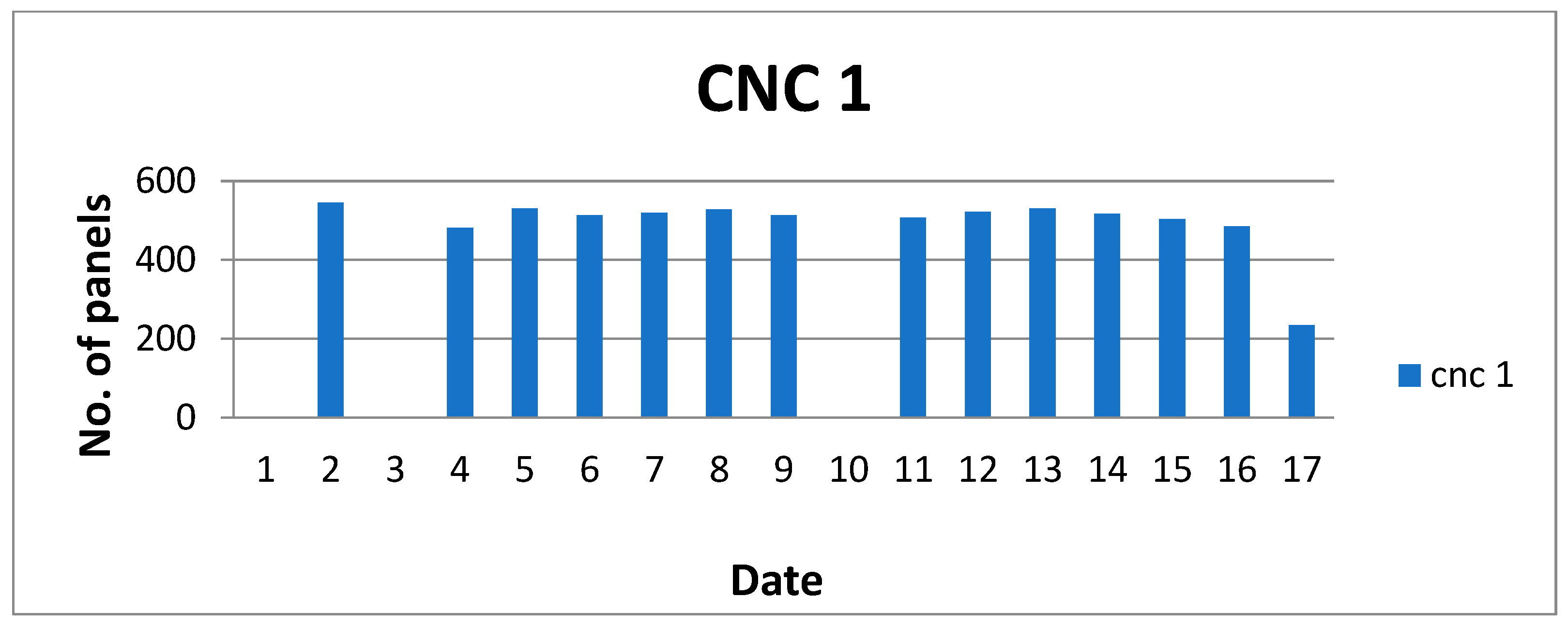

- Production of CNC-1

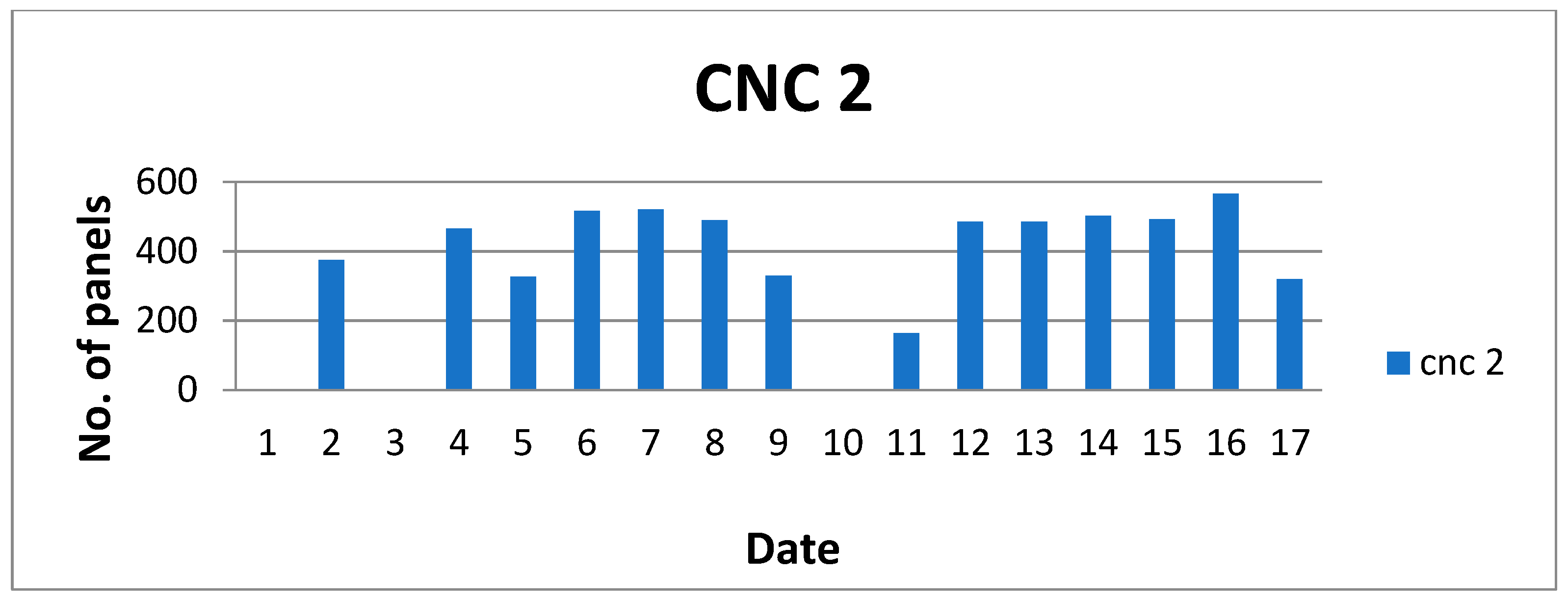

- Production of CNC-2

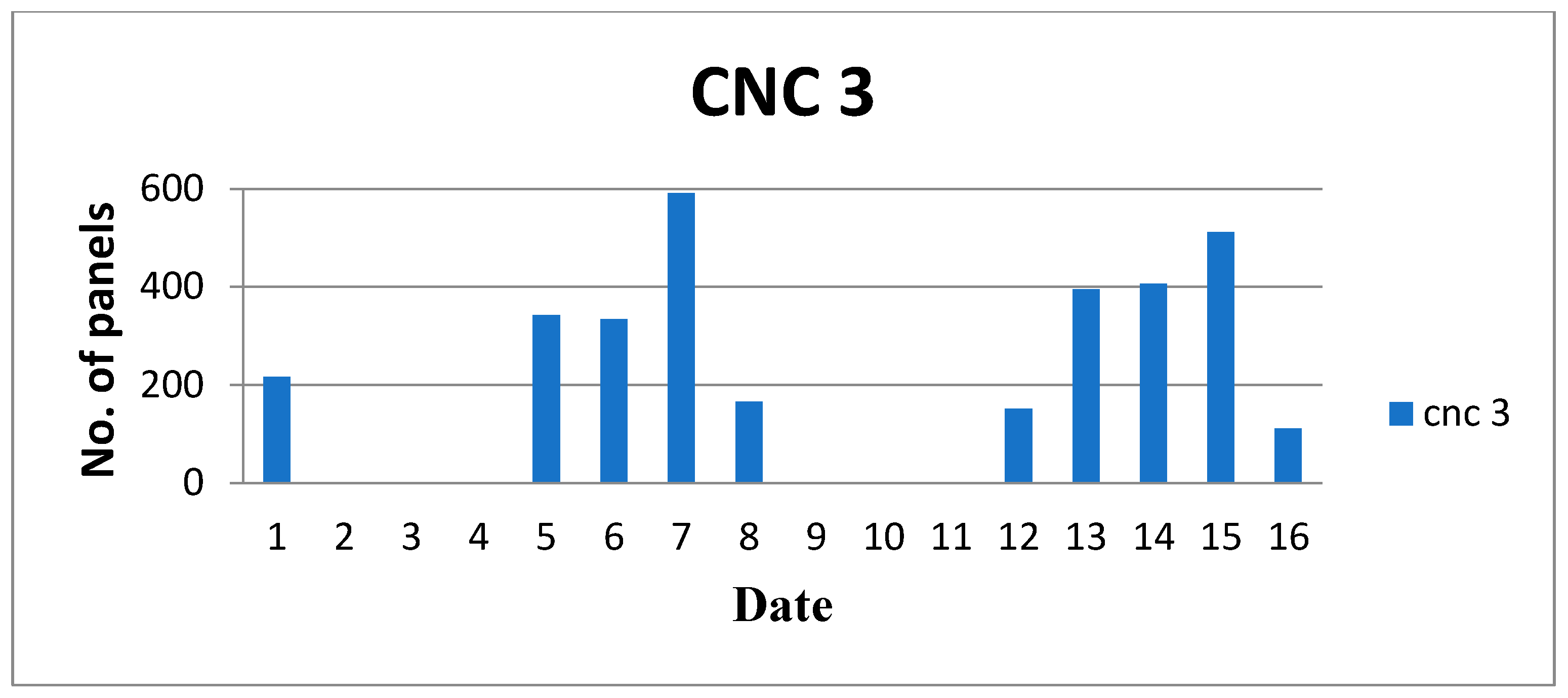

- Production of CNC-3

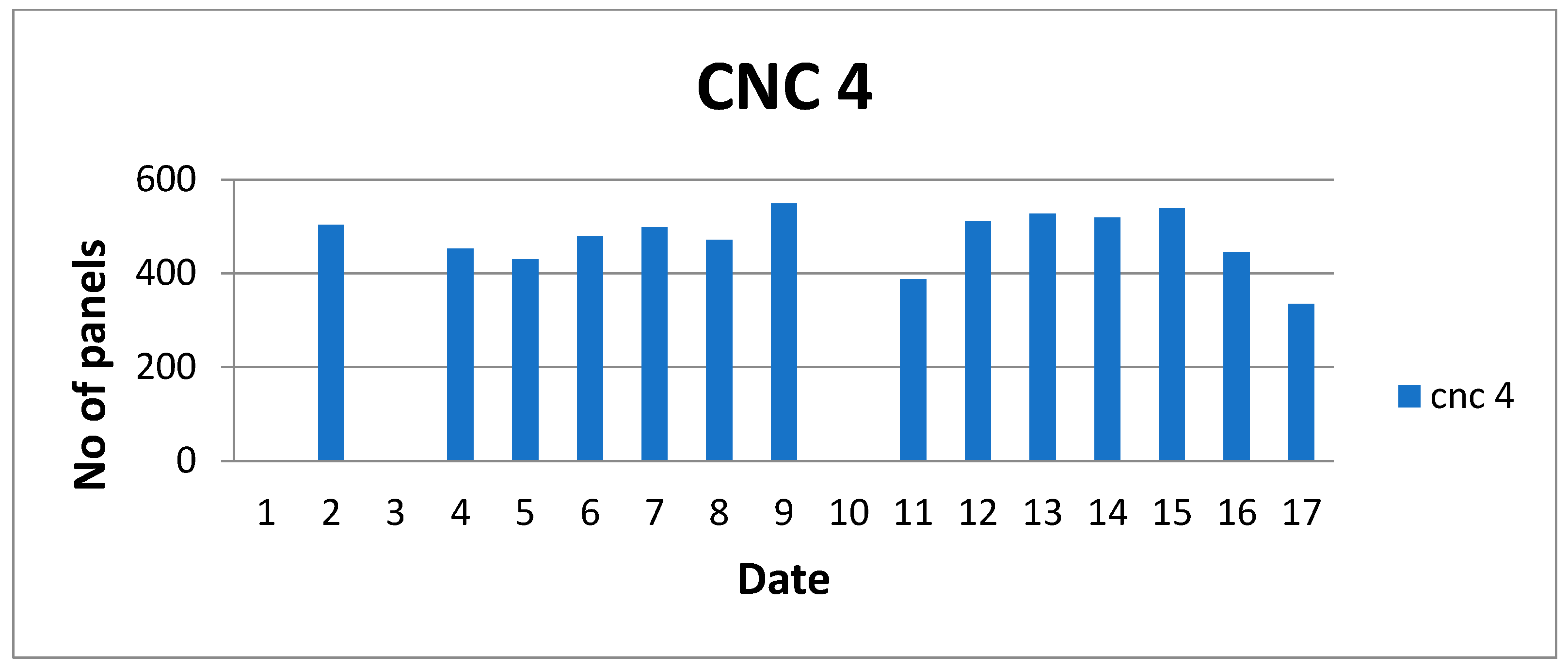

- Production of CNC-4

4.6. Comparison with Actual Data

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azaria, S.; Ronen, B.; Shamir, N. Justice in Time: A theory of constraints approach. J. Oper. Manag. 2023, 69, 1202–1208. [Google Scholar] [CrossRef]

- Tarte, N.; Suryawanshi, Y.; Batule, R. Implementation of Theory of Constraints for Cost Reduction in Manufacturing Industries: A Case Study. Online J. Distance Educ. e-Learn. 2023, 11, 2. [Google Scholar]

- Stopka, O.; Zitrický, V.; Ľupták, V.; Stopková, M. Application of specific tools of the Theory of Constraints—A case study. Cogn. Sustain. 2023, 2, 1. [Google Scholar] [CrossRef]

- Erraoui, Y.; Charkaoui, A. Analysis of Buffer techniques in Lean distribution and theory of constraints in a distribution context. J. Oper. Manag. Optim. Decis. Support 2023, 3, 11–15. [Google Scholar]

- Shashi, M. Sustainable Digitalization in Pharmaceutical Supply Chains Using Theory of Constraints: A Qualitative Study. Sustainability 2023, 15, 8752. [Google Scholar] [CrossRef]

- Mason-Jones, R.; Davies, P.G.; Thomas, A. Applying the Theory of Constraints to Explore the UK Renewable-Energy Supply Chain. Sustainability 2022, 14, 13307. [Google Scholar] [CrossRef]

- Zhao, X.; Hou, J. Applying the Theory of Constraints Principles to Tourism Supply Chain Management. J. Hosp. Tour. Res. 2022, 46, 400–411. [Google Scholar] [CrossRef]

- Urban, W.; Rogowska, P. Systematic Literature Review of Theory of Constraints. In Springer Reference Medizin; Springer: Berlin/Heidelberg, Germany, 2019; pp. 129–138. [Google Scholar] [CrossRef]

- Okutmuş, E.; Kahveci, A.; Kartasova, J. Using theory of constraints for reaching optimal product mix: An application in the furniture sector. Intellect. Econ. 2016, 9, 138–149. [Google Scholar] [CrossRef]

- Aramyan, L.H.; Oude Lansink, A.G.J.M.; van der Vorst, J.G.A.J.; van Kooten, O. Performance measurement in agri--food supply chains: A case study. Supply Chain. Manag. 2007, 12, 304–315. [Google Scholar] [CrossRef]

- Zivaljevic, A. Theory of constraints—Application in land transportation systems. Manag. Environ. Qual. Int. J. 2015, 26, 505–517. [Google Scholar] [CrossRef]

- Ukey, K.; Sawaitul, P.B. Organization planning using theory of constraints. J. Mech. Civ. Eng. 2021, 7, 1–5. [Google Scholar]

- Knop, K. Managing constraints in a machinery company using theory of constraints’ thinking process tools. case study. Prod. Eng. 2025, 33, 401–413. [Google Scholar] [CrossRef]

- Vanomy, A.E.; Engellika, G.; Jeffrey, J.; Vanessa, J.; Liliana, L.; Te, R.; Zhang, S.; Stendy, S.; Vina, V.; Viorensa, V. The Implementation of the Theory of Constraints (TOC) to Increase Production Cost Efficiency and Productivity: VAF Case Study. Profit J. Adminsitrasi Bisnis 2025, 19, 143–162. [Google Scholar]

- Pereira, G.B.; Soardi, G.; Attanasio, A.; Frazzon, E.M. Applying Theory of Constraints (TOC) to digital twins: Simulation and managerial outputs. Procedia CIRP 2025, 134, 717–722. [Google Scholar] [CrossRef]

- Mabin, V.J.; Cavana, R.Y. A framework for using Theory of Constraints thinking processes and tools to complement qualitative system dynamics modelling. Syst. Dyn. Rev. 2024, 40, e1768. [Google Scholar] [CrossRef]

- Gupta, M.; Digalwar, A.; Gupta, A.; Goyal, A. Integrating Theory of Constraints, Lean and Six Sigma: A framework development and its application. Prod. Plan. Control. 2024, 35, 238–261. [Google Scholar] [CrossRef]

| Sr. No. | Date | No of Panels | Total Panels | Avg. No of Panels | Total Avg. Panels | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CNC-1 | CNC-2 | CNC-3 | CNC-4 | CNC-1 | CNC-2 | CNC-3 | CNC-4 | ||||

| 1 | 01/02/10 | 458 | 473 | 326 | 330 | 1587 | 458 | 473 | 326 | 330 | 1587 |

| 2 | 02/02/10 | 541 | 484 | 431 | 436 | 1892 | 500 | 478.5 | 378.5 | 383 | 1740 |

| 3 | 03/02/10 | 0 | |||||||||

| 4 | 04/02/10 | 503 | 485 | 479 | 468 | 1935 | 501 | 480.7 | 412 | 411 | 1805 |

| 5 | 05/02/10 | 490 | 483 | 466 | 447 | 1886 | 498 | 481.3 | 425.5 | 420 | 1825 |

| 6 | 06/02/10 | 513 | 450 | 483 | 492 | 1938 | 501 | 475 | 437 | 435 | 1848 |

| 7 | 07/02/10 | 463 | 527 | 573 | 486 | 2049 | 495 | 483.7 | 459.7 | 443 | 1881 |

| 8 | 08/02/10 | 487 | 497 | 498 | 495 | 1977 | 494 | 485.6 | 465.1 | 451 | 1895 |

| 9 | 09/02/10 | 504 | 491 | 478 | 548 | 2021 | 495 | 486.3 | 466.8 | 463 | 1911 |

| 10 | 10/02/10 | 0 | |||||||||

| 11 | 11/02/10 | 505 | 600 | 222 | 508 | 1835 | 496 | 498.9 | 439.6 | 468 | 1902 |

| 12 | 12/02/10 | 502 | 390 | 255 | 468 | 1615 | 497 | 488 | 421.1 | 468 | 1874 |

| 13 | 13/2/10 | 448 | 456 | 387 | 504 | 1795 | 492 | 485.1 | 418 | 471 | 1866 |

| 14 | 14/2/10 | 522 | 499 | 439 | 504 | 1964 | 495 | 486.3 | 419.8 | 474 | 1875 |

| 15 | 15/2/10 | 503 | 544 | 482 | 568 | 2097 | 495 | 490.7 | 424.5 | 481 | 1892 |

| 16 | 16/2/10 | 518 | 394 | 288 | 503 | 1703 | 497 | 483.8 | 414.8 | 483 | 1878 |

| 17 | 17/2/10 | 0 | |||||||||

| 18 | 18/2/10 | 387 | 491 | 490 | 253 | 1621 | 490 | 484.3 | 419.8 | 467 | 1861 |

| 19 | 19/2/10 | 190 | 450 | 348 | 365 | 1353 | 471 | 482.1 | 415.3 | 461 | 1829 |

| 20 | 20/2/10 | 465 | 450 | 391 | 467 | 1773 | 471 | 508.6 | 441.3 | 488 | 1937 |

| 21 | 21/2/10 | 464 | 493 | 468 | 512 | 1937 | 470 | 480.9 | 416.9 | 464 | 1832 |

| 22 | 22/2/10 | 308 | 501 | 494 | 255 | 1558 | 462 | 482 | 420.9 | 453 | 1818 |

| 23 | 23/2/10 | 501 | 504 | 484 | 425 | 1914 | 464 | 483.1 | 424.1 | 452 | 1823 |

| 24 | 24/2/10 | 0 | |||||||||

| 25 | 25/2/10 | 449 | 569 | 491 | 568 | 2077 | 463 | 487.2 | 427.3 | 457 | 1835 |

| 26 | 26/2/10 | 452 | 531 | 493 | 509 | 1985 | 462 | 489.2 | 430.3 | 460 | 1841 |

| 27 | 27/2/10 | 475 | 481 | 484 | 560 | 2000 | 463 | 488.8 | 432.6 | 464 | 1848 |

| 28 | 28/2/10 | 445 | 510 | 320 | 486 | 1761 | 462 | 489.7 | 427.9 | 465 | 1845 |

| Sr. no | Date | No of Panels | Total Panels | Avg. No of Panels | Total Avg. Panels | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CNC 1 | CNC 2 | CNC 3 | CNC 4 | CNC 1 | CNC 2 | CNC 3 | CNC 4 | ||||

| 1 | 01/03/10 | 0 | 0 | 0 | 0 | 0 | 0 | ||||

| 2 | 02/03/10 | 545 | 375 | 216 | 503 | 1639 | 545 | 375 | 216 | 503 | 1639 |

| 3 | 03/03/10 | 0 | |||||||||

| 4 | 04/03/10 | 482 | 465 | 0 | 452 | 1399 | 513.5 | 420 | 108 | 478 | 1519 |

| 5 | 05/03/10 | 530 | 327 | 0 | 430 | 1287 | 519 | 389 | 72 | 462 | 1442 |

| 6 | 06/03/10 | 513 | 516 | 343 | 478 | 1850 | 517.5 | 420.8 | 139.8 | 466 | 1544 |

| 7 | 07/03/10 | 520 | 521 | 334 | 498 | 1873 | 518 | 440.8 | 178.6 | 472 | 1610 |

| 8 | 08/03/10 | 528 | 489 | 591 | 471 | 2079 | 519.7 | 448.8 | 247.3 | 472 | 1688 |

| 9 | 09/03/10 | 514 | 329 | 166 | 549 | 1558 | 518.9 | 431.7 | 235.7 | 483 | 1669 |

| 10 | 10/03/10 | 0 | |||||||||

| 11 | 11/03/10 | 507 | 164 | 0 | 387 | 1058 | 517.4 | 398.3 | 206.3 | 471 | 1593 |

| 12 | 12/03/10 | 522 | 485 | 0 | 510 | 1517 | 517.9 | 407.9 | 183.3 | 475 | 1584 |

| 13 | 13/03/10 | 530 | 486 | 151 | 527 | 1694 | 519.1 | 415.7 | 180.1 | 481 | 1595 |

| 14 | 14/03/10 | 517 | 502 | 395 | 519 | 1933 | 518.9 | 423.5 | 199.6 | 484 | 1626 |

| 15 | 15/03/10 | 503 | 492 | 406 | 538 | 1939 | 517.6 | 429.3 | 216.8 | 489 | 1652 |

| 16 | 16/03/10 | 485 | 566 | 512 | 445 | 2008 | 515.1 | 439.8 | 239.5 | 485 | 1680 |

| 17 | 17/03/10 | 235 | 319 | 111 | 334 | 999 | 495.1 | 431.1 | 230.4 | 474 | 1631 |

| Part No. | Req. | Before | After |

|---|---|---|---|

| Total Time Req. (min) | Total Time Req. (min) | ||

| P-1 | 120 | 31,320 | 29,760 |

| P-2 | 90 | 18,405 | 17,595 |

| P-3 | 82 | 16,072 | 15,416 |

| P-4 | 70 | 11,515 | 11,095 |

| P-5 | 110 | 24,915 | 23,815 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ukey, K.; Chinta, L.; Majumder, H.; Patil, D.S.; Mitkari, S.; Sahu, A.R.; Dhutekar, P.K. Implementation of the Theory of Constraints (TOC) for a Furniture Manufacturing-Based Organization. Eng. Proc. 2025, 114, 17. https://doi.org/10.3390/engproc2025114017

Ukey K, Chinta L, Majumder H, Patil DS, Mitkari S, Sahu AR, Dhutekar PK. Implementation of the Theory of Constraints (TOC) for a Furniture Manufacturing-Based Organization. Engineering Proceedings. 2025; 114(1):17. https://doi.org/10.3390/engproc2025114017

Chicago/Turabian StyleUkey, Kamal, Limbadri Chinta, Himadri Majumder, Dipak S. Patil, Sanjay Mitkari, Anil R. Sahu, and Prashant K. Dhutekar. 2025. "Implementation of the Theory of Constraints (TOC) for a Furniture Manufacturing-Based Organization" Engineering Proceedings 114, no. 1: 17. https://doi.org/10.3390/engproc2025114017

APA StyleUkey, K., Chinta, L., Majumder, H., Patil, D. S., Mitkari, S., Sahu, A. R., & Dhutekar, P. K. (2025). Implementation of the Theory of Constraints (TOC) for a Furniture Manufacturing-Based Organization. Engineering Proceedings, 114(1), 17. https://doi.org/10.3390/engproc2025114017