Abstract

This manuscript investigates the effect of MWCNT addition on the morphological and water absorption properties of bio-based polyester nanocomposites made from PLA and PBS. The nanocomposites were produced by the melt-mixing method using a twin-screw extruder. An analysis of the percentage by mass of water absorbed was used to determine the absorption properties of polyesters. The addition of MWCNTs to the polyester matrix is a big challenge because agglomerated MWCNTs can introduce micro-voids and defects that act as a channel for water permeation. The SEM images show that the polyester fracture surface becomes rough with several voids after the addition of MWCNTs. The water absorption properties of bio-based polyesters such as PBS show significant changes (an increase of 185%) compared to pure PBS. These findings reveal that the addition of MWCNTs in a small amount (1 wt%) affects the morphology and water absorption capacity of bio-based polyesters.

1. Introduction

Bio-polyesters have emerged as a biodegradable polymer class of materials aimed at slowing down the continual worsening of global white pollution. Polylactic acid (PLA) and polybutylene succinate (PBS) have enormous potential, such as outstanding processability, high thermal stability, low carbon footprint, and good chemical resistance [1,2,3]. The MWCNTs (multi-walled carbon nanotubes) show great potential in improving the performance of polyester matrix nanocomposites due to their high aspect ratio, good mechanical strength, and high thermal stability [4,5,6]. Despite the enormous advantages of MWCNTs, there is a big concern about the mixing of MWCNTs in polyester matrices. MWCNTs tend to form agglomerates in nanocomposites due to their high aspect ratio and low Van der Waals bonding energies, that limit the homogeneity and increase the roughness of the fractured surface. The melt-mixing method can effectively disentangle and disperse the MWCNTs in the polyester matrix [7,8,9]. The swelling behavior of polyester nanocomposites is a critical factor influencing their performance in various applications, particularly in drug delivery systems, hydrogels, and other biomedical devices [10,11].

The morphology of nanocomposites, encompassing the orientation, dispersion, and interfacial interaction of MWCNT within the matrix, strongly influences their overall properties [12,13,14]. Water absorption is another key property that dictates the suitability of nanocomposites in various environments, especially in applications involving moisture or aqueous exposure [15]. Water ingress in polyester matrices leads to swelling, hydrolytic degradation, and loss of mechanical strength, emphasizing the need to enhance their moisture resistance [16,17]. The morphology of a nanocomposite, particularly the interfacial bonding and dispersion of MWCNT within the polyester matrices (PLA, PBS), is a critical factor that determines the effectiveness of reinforcement [18]. Uniform dispersion of MWCNTs with strong interfacial adhesion can significantly reduce the diffusion routes of water molecules and improve water resistance capabilities of nanocomposites. Additionally, the presence of MWCNT agglomerates provides a pathway for water molecules through micro-voids [19,20].

This work aims to investigate the morphology and water absorption behavior of PLA and PBS nanocomposites containing 1 wt% MWCNTs, an optimal amount according to the literature and preliminary experiments [21,22]. The novelty of the present work lies in analyzing the water absorption properties of PLA- and PBS-based MWCNT nanocomposites and correlating the relationship between morphology and water absorption capabilities.

2. Materials and Methods

2.1. Materials

PBS, under the trade name Bio-PBSTM (FZ91PM), was purchased from PTT MCC Biochem Co., Ltd. (Rayong, Thailand), and PLA, under the trade name Ingeo™ Biopolymer 3100HP, from Natureworks LLC (Saint Paul, MN, USA). MWCNTs were from NANOCYL® (Sambreville, Belgium), series NC7000™, thin MWCNTs produced via the Catalytic Chemical Vapor Deposition (CCVD) process. The surface area of MWCNTs was 250–300 m2/g, with an average diameter and length of about 9.5 nm and 1.5 µm, respectively.

2.2. Sample Preparation

The nanocomposites were prepared by melt blending pure polyester pellets and MWCNTs by using a (LTE 26-48, Labtech scientific, Samutprakarn 10280, Thailand) twin-screw extruder with a screw diameter of 26 mm and an L/D ratio of 48. The indirect technique was applied for mixing: polyester and MWCNTs (weight ratio 95/5) were stirred manually before they were blended in the extruder to prepare 5 wt% masterbatches. All materials were previously dried at 60 °C for 5 h. To prepare PLA 1 wt% MWCNT nanocomposite, pure PLA and the PLA 5 wt% MWCNT masterbatch were mixed in a weight ratio of 80/20. The extruder temperature and screw speed were 190–200 °C and 55 rpm, respectively. Similarly, PBS nanocomposites were fabricated under an extruder temperature and screw speed of 150–160 °C and 55 rpm, respectively [23]. For ease, final products were indicated as PLA/1%MWCNT and PBS/1%MWCNT.

2.3. Characterization Methods

A Scanning Electron Microscope (SEM) (EVO MA 10, Zeiss, Oberkochen 73447, Germany) was used to examine the fractured surface of neat polyesters and polyester/MWCNT nanocomposites. Before examinations, all fractured surface cross-sections were coated with a 6 nm thin gold layer. The accelerating voltage was 15 kV.

Water absorption was determined according to ISO 62:2008 [24], and the analysis was based on the percentage by mass of water absorbed. All the samples were previously dried at 60 °C for 24 h. After drying, all the samples were weighed; this weight was termed as Wd. Furthermore, all the samples were put in demineralized water for 24 h at room temperature (23 °C). Then, all the samples were taken out from water and the excess water from the surface of the samples was removed by soaking paper. Once more, all the samples were weighed; this weight was termed as WS.

The following equations were used for the calculations.

where Wd = dry weight and WS = wet weight.

Swelling ratio = WS/Wd

Water content (%) = ((WS − Wd)/WS) ∗ 100

3. Results and Discussions

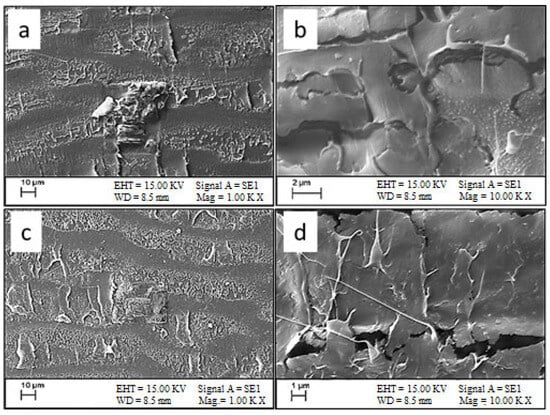

SEM micrographs of pure PLA and PLA/1%MWCNT nanocomposites are presented in Figure 1. The surface of pure PLA displays a smooth surface with a typical brittle fracture (Figure 1a,b). For the PLA/1%MWCNT nanocomposite, MWCNTs were found to disperse uniformly in the PLA matrix with no obvious agglomerates in the SEM images, but the roughened surface of nanocomposite contains micro-void channels, which are predominantly associated with the crystallization of the PLA phase. The presence of MWCNTs serves as a nucleating agent, changing the crystallization rate of PLA. The morphology of the PLA/1%MWCNT nanocomposite highly depends on the processing method [25,26]. In particular, with the melt-mixing method that we used in processing, the MWCNTs show a certain level of alignment during processing and appear as more ordered structures [27]. Furthermore, the dispersion of MWCNTs in PLA profoundly influences the microstructure of the polyester and hence the water absorption behavior of the nanocomposite (Figure 1c,d).

Figure 1.

SEM micrographs of (a,b) neat PLA, and (c,d) PLA/1%MWCNT nanocomposites at different magnifications.

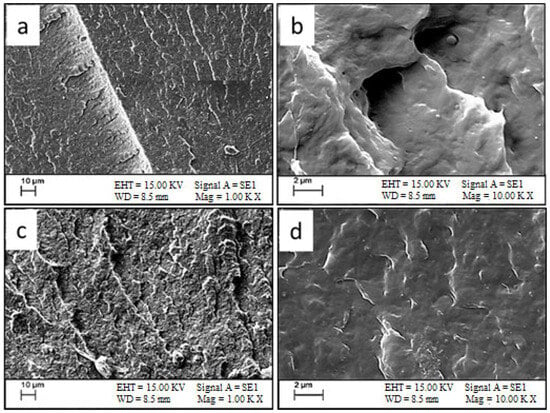

Additionally, pristine PBS showed a smooth and uniform surface in the SEM micrograph (Figure 2a,b). The incorporation of a small amount of MWCNTs (1 wt%) into the PBS matrix significantly changed the microstructure of the nanocomposite, such as by increasing roughness and producing small clusters of MWCNT agglomerates compared to PLA. Figure 2c shows that after MWCNT addition, the fracture surface becomes uneven with large number of micro-voids. The SEM micrograph of the PBS nanocomposite showed that the dispersion of MWCNTs in the PBS matrix was homogeneous but not uniform; some entangled clusters of MWCNT were found due to the direct mixing (without functionalization) of MWCNTs (Figure 2c,d). However, the homogeneous dispersion of MWCNTs in the PBS matrix is very hard to achieve due to their insolubility and inherently poor compatibility. Better dispersion of MWCNTs in the PBS matrix without using any compatibilizers was achieved through multiple extrusions as well as optimizing extrusion parameters such as temperature, screw speed, and die diameter.

Figure 2.

SEM micrographs of (a,b) neat PBS, and (c,d) PBS/1%MWCNT nanocomposites at different magnifications.

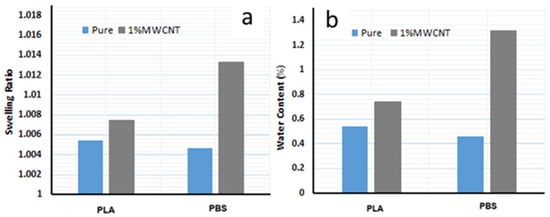

Figure 3 shows the swelling ratio and water content of PLA, PBS, and their nanocomposites. Pure PLA and PBS contain ester groups that are polar in nature and weakly hydrophilic, but in the case of large molecules like polymers, they often contribute to an overall hydrophobic behavior [28]. This is why they absorb water slowly and degrade hydrolytically over time. Both nanocomposites show an increase in water absorption after 24 h in comparison to pure polyesters, i.e., the increment in water absorption could be related to the existence of MWCNT agglomerates and micro-voids, which provide channels to absorb more water (Figure 3a,b). However, the increment in water content in the PLA nanocomposite (36%) is lower than the PBS nanocomposite (185%), which shows the compatibility of MWCNTs with the matrix materials. PLA shows better mixing and dispersion, with good interfacial adhesion of MWCNTs, than the PBS matrix and hence exhibits a lower swelling ratio and water content. Moreover, the addition of MWCNTs can reduce the water absorption capacity [29]. This phenomenon is attributed to the formation of a more compact structure within the polymer matrix, which is more likely to occur with the PLA matrix. Furthermore, biodegradable polymers such as PLA and PBS incorporated with MWCNTs can alter the hydrophilicity of nanocomposites [30]. The PBS/1%MWCNT nanocomposite shows significantly higher water content and swelling ratio compared to pure PBS because PBS undergoes hydrolysis in the presence of water, and MWCNTs maximizes water absorption due to the presence of agglomeration and microstructural features in the PBS nanocomposite matrix.

Figure 3.

Pure polyesters and their nanocomposites: (a) swelling ratio and (b) water content (%).

4. Conclusions

The results reported in this paper showed that the incorporation of 1 wt% MWCNTs into the PLA matrix was uniform and homogeneous, without the presence of agglomeration, achieved by the melt-mixing method with multiple extrusions. In contrast, the PBS nanocomposites show a number of MWCNT agglomerates and several micro-voids. Moreover, the incorporation of MWCNTs into the PLA and PBS matrices significantly increased their water absorption capacity. Notably, the PBS/1%MWCNT nanocomposite showed a high water content (185%) compared to pure PBS. By optimizing MWCNT loading and surface functionalization, it is possible to tailor the water uptake behavior to meet the specific requirements of various applications.

Author Contributions

K.U.K.: Investigation. Conceptualization, Visualization, Methodology, and Writing—Original Draft; A.Á.M.: Writing—Review and Editing, Resources, and Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available upon request from corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rostami, A.; Nazockdast, H.; Karimi, M. Graphene Induced Microstructural Changes of PLA/MWCNT Biodegradable Nanocomposites: Rheological, Morphological, Thermal and Electrical Properties. RSC Adv. 2016, 6, 49747–49759. [Google Scholar] [CrossRef]

- Gumede, T.P.; Luyt, A.S.; Pérez-Camargo, R.A.; Tercjak, A.; Müller, A.J. Morphology, Nucleation, and Isothermal Crystallization Kinetics of Poly(Butylene Succinate) Mixed with a Polycarbonate/MWCNT Masterbatch. Polymers 2018, 10, 424. [Google Scholar] [CrossRef] [PubMed]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review Article: Polymer-Matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Zeng, R.T.; Hu, W.; Wang, M.; Zhang, S.D.; Zeng, J.B. Morphology, Rheological and Crystallization Behavior in Non-Covalently Functionalized Carbon Nanotube Reinforced Poly(Butylene Succinate) Nanocomposites with Low Percolation Threshold. Polym. Test. 2016, 50, 182–190. [Google Scholar] [CrossRef]

- Khan, K.U. Effects of CNT on Polymer Matrix: A Focused Review with Lasers. Gradus 2024, 11, 1–8. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review from Preparation to Processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Alruwaili, B.M.; Saeed, U.; Ahmad, I.; Al-Turaif, H.; Aboalkhair, H.; Alsaiari, A.O. Development of Multiwalled Carbon Nanotube-Reinforced Biodegradable Polylactic Acid/Polybutylene Succinate Blend Membrane. Membranes 2021, 11, 760. [Google Scholar] [CrossRef]

- Bleija, M.; Platnieks, O.; Macutkevič, J.; Banys, J.; Starkova, O.; Grase, L.; Gaidukovs, S. Poly(Butylene Succinate) Hybrid Multi-Walled Carbon Nanotube/Iron Oxide Nanocomposites: Electromagnetic Shielding and Thermal Properties. Polymers 2023, 15, 515. [Google Scholar] [CrossRef] [PubMed]

- Huang, A.; Lin, J.; Chen, S.; Fang, H.; Wang, H.; Peng, X. Facile Preparation of Poly(Butylene Succinate)/Carbon Nanotubes/Polytetrafluoroethylene Ternary Nanocomposite Foams with Superior Electrical Conductivity by Synergistic Effect of “Ball Milling” and Supercritical Fluid-Assisted Processing. Compos. Sci. Technol. 2021, 201, 108519. [Google Scholar] [CrossRef]

- Chopra, S.; Batthula, S.; Deshmukh, K.; Peshwe, D. Tribological Behaviour of Multi-Walled Carbon Nanotubes (MWCNT) Filled Polybutylene Terephthalate (PBT) Nanocomposites. Trans. Indian Inst. Met. 2017, 70, 801–807. [Google Scholar] [CrossRef]

- Saif, B.M.; Tazwar, H.T.; Antora, M.F.; Bhadra, D. Influence of Carboxyl Functionalized MWCNT Loading on the Thermal Stability and Long-Term Water Uptake Behavior in Tri-Layered Jute FRCs. Results Eng. 2024, 24, 103287. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer Nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- Norazlina, H.; Hadi, A.A.; Qurni, A.U.; Amri, M.; Mashelmie, S.; Kamal, Y. Effects of Multi-Walled Carbon Nanotubes (MWCNTs) on the Degradation Behavior of Plasticized PLA Nanocomposites. Polym. Bull. 2019, 76, 1453–1469. [Google Scholar] [CrossRef]

- Lin, C.S.; Shih, Y.F.; Jeng, R.J.; Dai, S.A.; Lin, J.J.; Lee, C.C. Nanocomposites with Enhanced Electrical Properties Based on Biodegradable Poly(Butylene Succinate) and Polyetheramine Modified Carbon Nanotube. J. Taiwan Inst. Chem. Eng. 2012, 43, 322–328. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of Water Absorption on the Mechanical Properties of Hemp Fibre Reinforced Unsaturated Polyester Composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Hsu, Y.W.; Wu, C.C.; Wu, S.M.; Su, C.C. Synthesis and Properties of Carbon Nanotube-Grafted Silica Nanoarchitecture-Reinforced Poly(Lactic Acid). Materials 2017, 10, 829. [Google Scholar] [CrossRef]

- Tamayo-vegas, S.; Muhsan, A.; Liu, C.; Tarfaoui, M.; Lafdi, K. The Effect of Agglomeration on the Electrical and Mechanical Properties of Polymer Matrix Nanocomposites Reinforced with Carbon Nanotubes. Polymers 2022, 14, 1842. [Google Scholar] [CrossRef] [PubMed]

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Lagazzo, A.; Moliner, C.; Finocchio, E.; Caputo, S.; Arato, E. Hydrolytic Degradation and Assessment of Performance of PLA and PBS-Based Plastics Designed for Packaging Applications. Int. J. Polym. Sci. 2025, 2025, 5602847. [Google Scholar] [CrossRef]

- Shih, Y.F.; Chen, L.S.; Jeng, R.J. Preparation and Properties of Biodegradable PBS/Multi-Walled Carbon Nanotube Nanocomposites. Polymer 2008, 49, 4602–4611. [Google Scholar] [CrossRef]

- Wu, C.S.; Liao, H.T. Study on the Preparation and Characterization of Biodegradable Polylactide/Multi-Walled Carbon Nanotubes Nanocomposites. Polymer 2007, 48, 4449–4458. [Google Scholar] [CrossRef]

- Taha, Z.T.; Bata, A.; Molnár, B.; Ronkay, F. Impact of Montmorillonite Reinforcement on the Physical Recyclability of Biobased and Petroleum-Based Polyesters. Heliyon 2025, 11, e43022. [Google Scholar] [CrossRef] [PubMed]

- MSZ EN ISO 62:2008; Plastics: Determination of Water Absorption. Hungarian Standards Institution: Budapest, Hungary, 2008.

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer Nanocomposites Based on Functionalized Carbon Nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Guan, L.Z.; Zhao, L.; Wan, Y.J.; Tang, L.C. Three-Dimensional Graphene-Based Polymer Nanocomposites: Preparation, Properties and Applications. Nanoscale 2018, 10, 14788–14811. [Google Scholar] [CrossRef]

- Nayini, M.M.R.; Ranjbar, Z. Carbon Nanotubes: Dispersion Challenge and How to Overcome It. In Handbook of Carbon Nanotubes; Springer: Cham, Switzerland, 2022; pp. 341–392. [Google Scholar] [CrossRef]

- Shikata, T.; Okuzono, M. Are All Polar Molecules Hydrophilic? Hydration Numbers of Ketones and Esters in Aqueous Solution. J. Phys. Chem. B 2013, 117, 7718–7723. [Google Scholar] [CrossRef]

- Diaz Varela, J.Y.; Burciaga Jurado, L.G.; Olivas Armendáriz, I.; Martínez Pérez, C.A.; Chapa González, C. The Role of Multi-Walled Carbon Nanotubes in Enhancing the Hydrolysis and Thermal Stability of PLA. Sci. Rep. 2024, 14, 8405. [Google Scholar] [CrossRef] [PubMed]

- Sorrentino, A.; Gorrasi, G.; Vittoria, V. Potential Perspectives of Bio-Nanocomposites for Food Packaging Applications. Trends Food Sci. Technol. 2007, 18, 84–95. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).