1. Introduction

Nowadays, the development of vehicle simulation models is becoming more and more important due to the need for virtual validation of new vehicle functions. The application of artificial intelligence methods can accelerate product development processes, so companies should consider the applicability of these methods [

1,

2].

Implementing vehicle simulation means cost, time, and energy savings [

3]. This article examines the possibilities of using neural network-based technology to create a replacement model for the transmission of a vehicle simulation model, rather than traditional modeling methods.

An artificial neural network is able to reproduce the operation of the transmission by learning from real measurement data [

4]. The aim of this article is to demonstrate the use of neural networks and to support the reliability of their applicability in vehicle simulation models.

One of the most important aspects in the development of vehicle simulation models is the accuracy of the transmission modeling. The number of gear ratios determined by the simulation directly affects the vehicle speed, which significantly affects various dynamic characteristics [

5].

Artificial neural networks are increasingly widely used in various fields today, creating new opportunities in many scientific areas. For example, they are also used in the automotive industry to predict battery performance [

6,

7,

8]. These networks are able to identify complex patterns as well as simple ones and create measurement-based models, thereby facilitating fine-tuning of processes and control strategies [

9]. The popularity of artificial intelligence (AI) has led to novel, sophisticated, and adaptive solutions that can revolutionize modeling processes of vehicles. Virt and Zöldy write about the use of predictive capabilities of artificial intelligence-based models, where AI methods were used to predict internal combustion engine parameters. This highlights that AI can be used with sufficient accuracy to replace traditional solutions [

10].

The Neural Fitting tool in MATLAB R2020a [

11] is extremely useful for training and optimizing neural networks, especially for solving regression problems. Its goal is to find the best fit between input data and output values related to the vehicle’s driving behavior. Integrating appropriate control mechanisms is essential during model development, which significantly affects the reliability and accuracy of the results. Generating the number of gear ratios using a neural network can bring significant benefits to vehicle simulation model building, as it can replace the time- and data-intensive programming work traditionally associated with creating transmission models.

Al-Ajmi et al. have published an article on physics-based transmission modeling [

12], detailing the construction of the model in Matlab R2020a Simulink. In contrast, the huge advantage of the neural network-based gearbox model is that it does not require any auxiliary data other than the input data or programming logic from the manufacturer. When creating an NN, it learns the operation and behavior of the transmission based on the measured data.

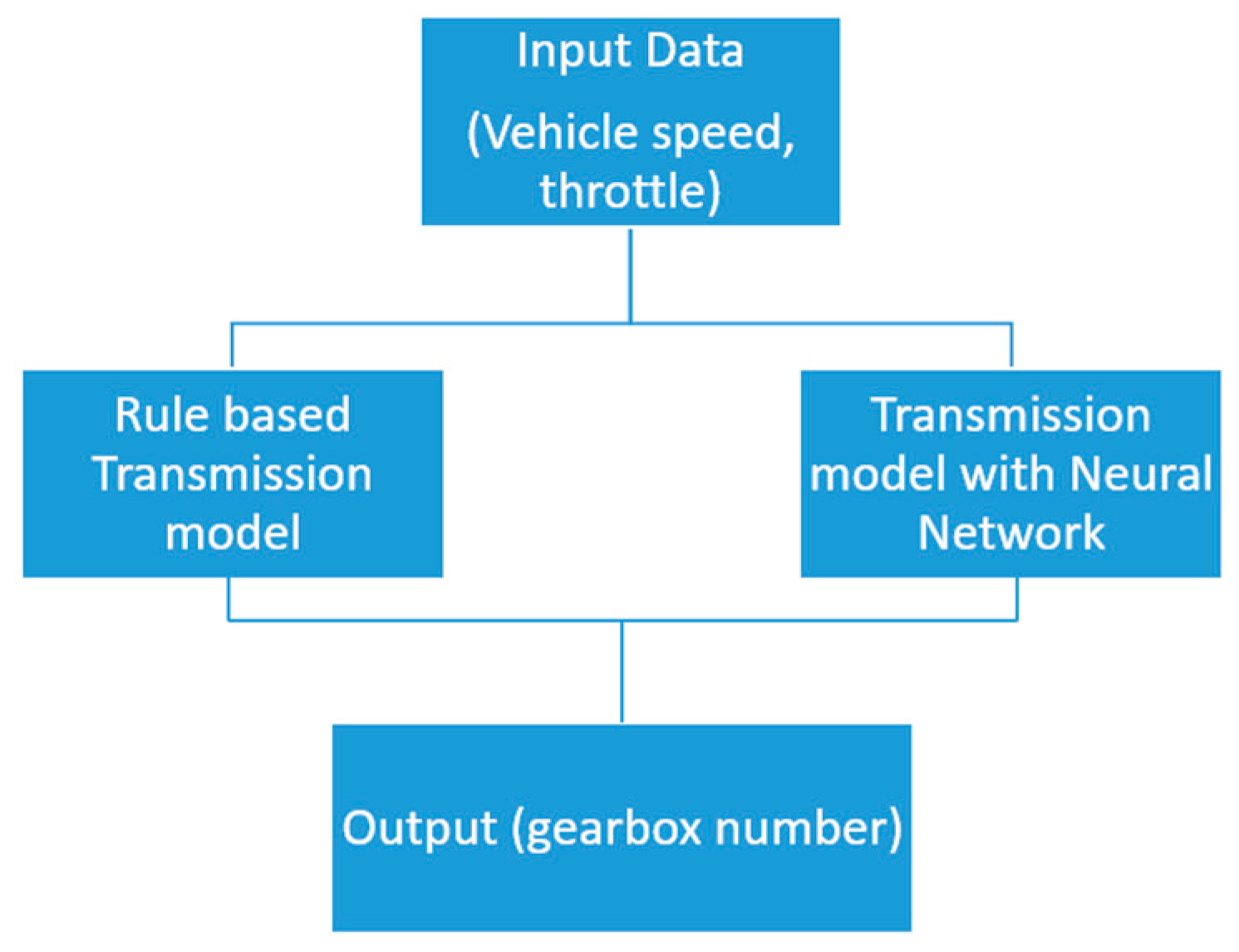

Figure 1 shows the methodology for using a neural network in a vehicle simulation model test environment in a Simulink model. First, we need real measurement data, which is needed for training the neural network. Once the neural network is ready, it can be used directly in a complex vehicle simulation model. The input parameters must be given to the neural network, and then a gear ratio numerical value is generated based on them [

4].

The MATLAB Simulink environment is a highly flexible tool that helps model complex systems, thereby supporting the development and implementation of simulational models.

The current research presents a simulational model, in which the transmission operation is performed by artificial intelligence, intending to replace the traditional transmission model with an artificial neural network-based transmission model.

2. Methodology

To conduct the experiment, real vehicle measurement data was primarily required. The vehicle measurements were taken in downtown Győr, using a four-cylinder 2 L turbocharged engine with a parallel hybrid configuration. The measurement period was 16 min. The ambient temperature was 23 degrees Celsius at the start of the measurement and 23.4 degrees Celsius at the end. The internal combustion engine has a power output of 110 kW, while the electric motor has a power output of 75 kW. The vehicle weighs 1950 kg without the driver. Prior to the measurement, the error reading was performed from the engine control unit using software called DiagRA D Version 7. Diagra is the most widely used diagnostic software in the automotive industry, which communicates with the vehicle’s control unit to collect diagnostic data. There are several options for reading data from the engine control unit, either directly from the On-Board Diagnostics (OBD) port or using a special engine control unit that can communicate with ETAS hardware. The huge advantage of this is that it can handle large amounts of data with higher sampling rates than the OBD reading. With the help of the Diagra software, the data was recorded via the OBD connector while driving. The measurement data obtained in this way was used to train the neural network. Data on the speed and torque of the internal combustion engine and electric motor, the speed of the vehicle, and the position of the accelerator and brake pedals were used. The values were recorded with a sampling rate of 10 Hz.

Neural networks are able to recognize complex patterns, hence making accurate predictions that can be particularly useful in modeling dynamic vehicular systems. An artificial neural network transmission model in vehicle simulation is effectively able to automatically determine the gear ratio, replacing the traditional rule-based transmission models. This approach allows the simulation to give life-like responses to different driving situations under changing conditions. The vehicle simulation model was created in Matlab Simulink R2020a, an efficient method for simulating the dynamics of complex vehicular systems. This method is particularly suitable for treating the behavior of different mechanical and electrical components of the vehicle separately but simultaneously. Thus, the real-time interaction of the engine, transmission, final drive train, and other powertrain components can be modeled.

The artificial neural network models used in the present simulational modelling study were able to adapt to new data that continuously improved the accuracy and reliability of the model. This is a significant advantage in the development process over traditional rule-based models, for the system can continuously learn from different driving conditions and errors. Matlab Simulink allows for visually building and testing dynamic systems without requiring in-depth programming knowledge. The predefined functions and blocks in Simulink accelerate the development process significantly through the many pre-built components available that can be easily used in the simulational models. The graphical interface allows users to visually model a system, modify parameters, and immediately see their impact on the behavior of the system. This speeds up the iteration steps between different solutions, optimizing vehicle performance and efficiency. MATLAB Simulink also supports real-time simulation and hardware in-cycle testing, which is key to shortening the development cycle.

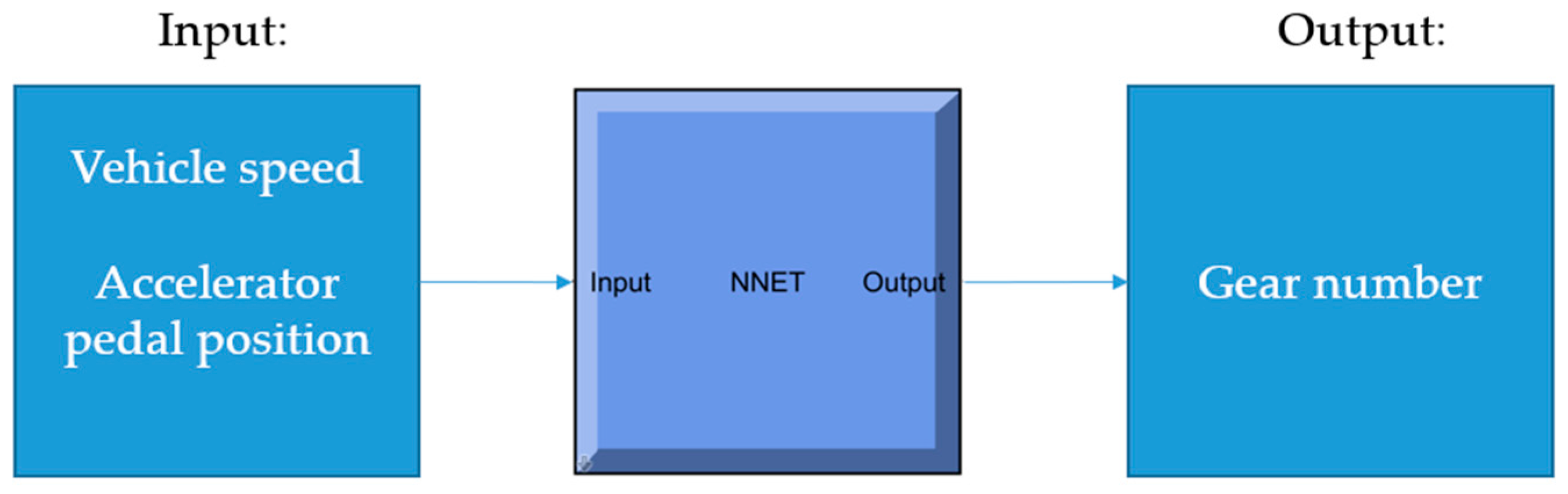

Figure 2 shows the conceptual diagram for gearbox modeling in Simulink, where the neural network was created and its performance was compared with real data. For the AI-based modeling of the transmission, the vehicle speed and the accelerator pedal position were given as input data, and the gear number of a transmission was given based on the two input data.

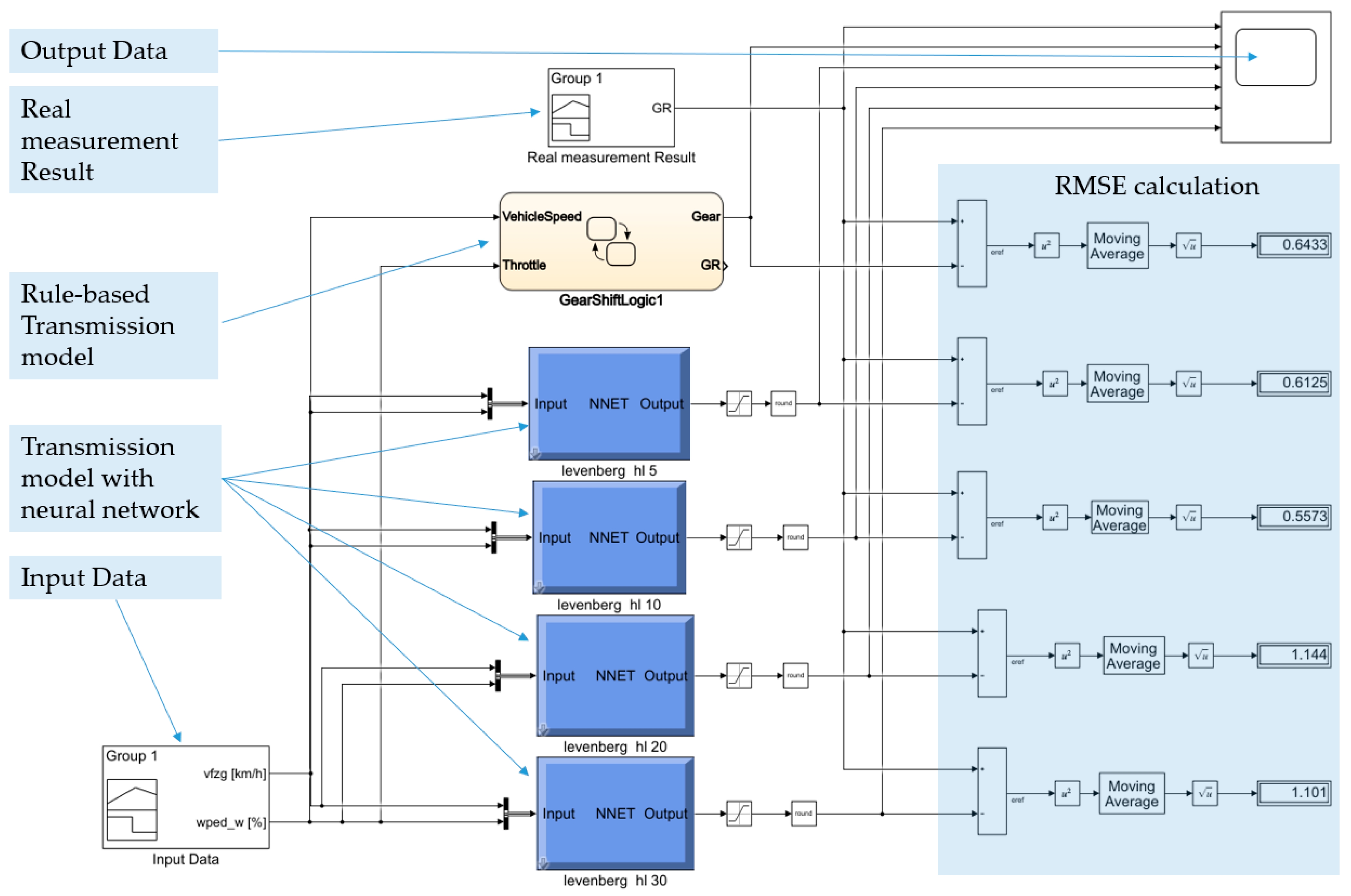

To train the neural network, 70% of the input data from vehicle measurements was set for NN training, 15% for validation, and 15% for testing on the Matlab programming interface. In our own test environment (

Figure 3), the same input data was used for verification (vehicle speed and accelerator pedal position).

For the RMSE calculation, the values of the vehicle speed gear number and the predicted speed gear number were compared in the simulation running in the test environment.

Figure 3 shows the test environment created in Simulink, where the generated neural network was validated based on real data. The traditional transmission model was compared with the transmission data measured during vehicle testing. The results obtained provide a reference basis for comparing the models generated by the neural network. Levenberg–Marquardt (LM), Scaled Conjugate Gradient (SCG), and Bayesian Neural Networks (BNN) are the three most common methods for creating neural networks. Since all three methods are different from each other, we examined which method proved to be the most effective in our case. The Levenberg–Marquardt (LM) algorithm is a hybrid optimization method that combines gradient descent and the Newton method. This method is often used for small and medium-sized problems because it offers fast convergence and efficient solutions for nonlinear fitting tasks.

Since it requires the LM Hessian matrix or its approximation, a computer with high memory requirements is needed. The method is sensitive to the initial weights, which affects the convergence speed and the probability of getting stuck in a local optimum, so its use may prove to be a disadvantage [

13].

The scaled conjugate gradient (SCG) algorithm is a conjugate gradient technique that eliminates the need for Hessian matrix calculations, as nonlinear transformations result in gradient reduction, which is particularly common when using sigmoid and tanh activation functions. Methods such as ReLU activation and batch normalization fundamentally improve the quality of neural networks. These approaches simplify the process and contribute to more stable, efficient learning. The present body of scholarly research provides ample evidence of their advantages for model performance and reliability. This feature enhances SCG’s performance on larger-scale challenges and increases its adaptability. In general, it can be said that SCG converges more slowly than LM [

14].

In the use of BNN, every weight is considered as a probability distribution, which makes this method very useful in cases where the reliability of the answer is crucial. Since the evaluation of the model is often slower than with standard methods. The disadvantage of BNN is the high processing requirements and complexity [

15].

While Levenberg–Marquardt and Scaled Conjugate Gradient belong to deterministic optimization techniques, Bayesian neural networks focus on handling uncertainties and modeling ambiguities, which enables more reliable predictions.

To test the methods, the neural adapter library of the MATLAB Simulink toolkit was used, which allows the hidden neural layers to be modified while specifying the input data. The inaccuracy of the model created in this way is given by the root-mean-square error (RMSE) metric. This is calculated automatically by the testing environment at each simulation time point until the end of the test, where the difference between the measured data and the predicted data is squared, averaged, and then the square root is taken. Thus, during experimentation, the smallest RMSE value is considered the best result.

3. Result and Discussion

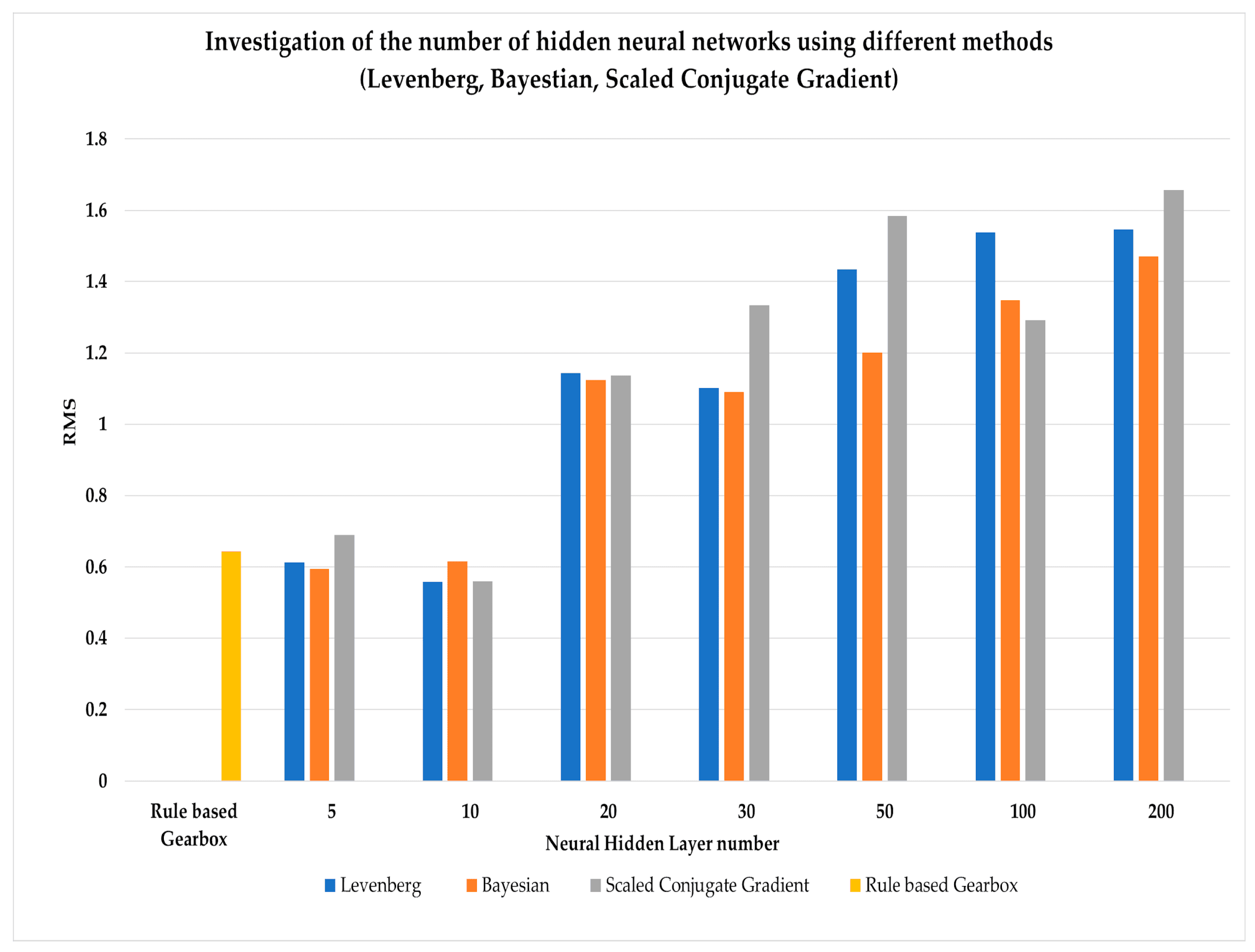

Based on the results, the Bayesian method is the most suitable method for solving the problem among the three methods presented. When defining the hidden neural layers, it best imitates the operation of the vehicle transmission using 10 hidden layer neurons.

Figure 4 shows how the root mean square error (RMSE) values change by modifying the number of neurons in the hidden layer of the network. We compared the obtained RMSE values and observed that using too many hidden neural layers leads to a decrease in the performance of the neural network.

In general, using too many hidden layers in a neural network can lead to overfitting, which results in the memorization of training data instead of model generalization. This complexity makes the network vulnerable as the gradients become very small, which hinders the effective learning of previous layers. The problem of vanishing gradients can occur in machine learning when the gradient value becomes too small, making it difficult to train early layers in deep neural networks. In addition, deeper networks require more computational resources, which does not necessarily justify the improvement in accuracy. Optimizing more parameters in deeper architectures complicates the training process and can result in longer convergence times. In summary, replacing the gearbox model with neural networks in the vehicle simulation test environment resulted in an RMSE of 0.5573. In contrast, the rule-based gearbox model resulted in an RMSE of 0.6433.

4. Conclusions

This vehicle simulation example demonstrates the potential of applying AI-based simulation techniques. Such simulation techniques offer the opportunity to optimize vehicle performance while reducing development costs and time. Operating a transmission with neural networks could revolutionize vehicle simulation modeling.

The use of neural networks can bring significant benefits to vehicle modeling, as demonstrated in our case study. These benefits can extend to various development areas, including vehicle architecture optimization, control strategy development, and improvements in performance, fuel consumption, and emissions. In addition, this approach offers opportunities for future developments, such as more accurate and safe control of autonomous vehicles. Further research should explore the potential of neural networks in the automotive industry throughout the vehicle development process, with the aim of utilizing their capabilities more effectively.

The modeling of a transmission driven by a neural network is a practical example in the development of vehicle simulation systems that goes beyond the development of dynamic and intelligent control strategies. This approach can not only improve vehicle modeling, but also contribute to the development of more sustainable and innovative transportation systems.

Creating vehicle dynamics simulations raises many questions for developers, even if the direction of development changes. The proposed solution can be applied in any vehicle technology environment; therefore, the application of artificial networks is an exciting and rapidly developing area that offers many research opportunities.

In our future work, the classified neural network will be tested, which can help to achieve more accurate results, since its main advantage is the ability to identify complex nonlinear patterns.