Abstract

This study examines a duplex surface treatment combining case-hardening and Physical Vapor Deposition (PVD) techniques, widely used to enhance mechanical strength and surface durability of components under high wear conditions. Despite industrial relevance, understanding of the interaction between case-hardened substrates and Diamond-Like Carbon (DLC) coatings remains limited. Using the Daimler-Benz Rockwell-C adhesion test, this research evaluates duplex-treated system performance, focusing on adhesion characteristics and mutual behavior between the support layer and DLC topcoat. The experimental approach assesses coating adhesion and substrate influence on coating integrity. Through systematic analysis, the study aims to optimize surface engineering practices for enhanced reliability and wear resistance.

1. Introduction

Surface treatment and heat treatment technologies play a vital role in the global economy. These processes are widely utilized across numerous industrial sectors, including the automotive [1], aerospace [2], tool and machine industries [3]. A key objective of such technologies is to enhance surface hardness and wear resistance. A wide range of surface hardening technologies is available [4]. Among the most commonly employed methods include nitriding [5,6] and boriding [7,8,9], both of which form hard surface layers through diffusion-based chemical reactions. Among these methods, case-hardening is a well-established thermochemical process that significantly contributes to improving the mechanical properties and operational lifespan of components [10]. Case-hardening is a surface modification process consisting of two primary stages: the enrichment of the surface layer with carbon (commonly referred to as carburizing), followed by heat treatment through quenching. This dual-step approach produces a significantly hardened outer layer that enhances wear resistance. The resulting hardened case typically extends to a depth of about 2 mm from the surface and can reach hardness levels as high as 55–65 HRC [11]. Due to these characteristics, the case-hardened layer is also suitable for serving as a mechanical support for applied surface coatings. The process is most effective when applied to low-carbon steels—generally with carbon content below 0.2%—which ensures that the core does not undergo transformation during hardening. This preserves the ductility and toughness of the inner layers, which is critical for withstanding mechanical stresses during service [11].

To enhance the tribological performance of surfaces, a variety of coatings and deposition technologies have been developed. Among these, Physical Vapor Deposition (PVD) techniques are widely used, including the application of hard nitride coatings such as TiN and CrN, as well as Diamond-Like Carbon (DLC) coatings [12,13].

DLC layers can be produced using several methods, including ion beam deposition, cathodic arc evaporation, and plasma-assisted ion implantation [14]. Notably, the deposition process can occur at relatively low temperatures, with layer formation observed even at 50 °C [15]. This allows for the preservation of the pre-existing heat-treated condition of the substrate during coating. Furthermore, the DLC layer can be doped with elements such as H, N, Al, Cu, Zr, Ti. The presence and concentration of these dopants can significantly influence the mechanical and tribological properties of the coating, making it possible to optimize it for specific application requirements [16,17,18]. DLC coatings are often used due to their exceptional hardness and superior tribological behavior, including low friction coefficients and high wear resistance, even in the absence of lubricants. These favorable characteristics have led to their widespread adoption in both medical devices and various mechanical applications, such as in racing engines, bearing assemblies, and transmission gears in the automotive industry [19].

The aim of this study is to explore how the thickness of the case-hardened layer influences the adhesion and failure modes of DLC coatings. In order to achieve the best results, the Daimler-Benz Rockwell-C adhesion test is employed as a standardized evaluation method. The study seeks to identify correlations between the depth of the hardened substrate layer and the observed coating behavior, providing insights into the interfacial mechanics of duplex-treated surfaces and contributing to the design of more reliable coated components.

2. Materials and Methods

2.1. The Base Material

The material selected for the experimental series is 16MnCr5 (EN 1.7131, also known as BC3), a low-carbon alloy steel commonly used in the manufacturing of gears and shafts in industrial applications, it is also used for engine valve tappets and crankpins. Due to its chemical composition, this steel is particularly well-suited for case-hardening processes. The detailed chemical composition of the material is presented in Table 1 [20,21,22].

Table 1.

Chemical composition of 16MnCr5.

Following case-hardening, 16MnCr5 develops a surface layer characterized by high hardness and excellent wear resistance. These properties make it an ideal substrate for further surface enhancement through PVD coatings, such as Diamond-Like Carbon (DLC), which can significantly improve its tribological performance.

The specimens used in the study were machined from Ø36 mm cylindrical bar stock. Disc-shaped samples with a final diameter of Ø30 mm and a thickness of 8 mm were produced. The front (flat) surfaces of the samples were precision-ground to ensure a smooth finish, while the cylindrical surfaces were prepared via turning.

2.2. Evaluation Methods for the Adhesion Behavior of DLC Coatings

One of the most frequently observed failure mechanisms in Diamond-Like Carbon (DLC) and other hard coatings includes cracking, spallation, and delamination often resulting from insufficient adhesion between the coating and the substrate. To assess coating adhesion strength, the Daimler-Benz indentation test is commonly used, particularly in industrial quality assurance contexts. This test employs a Rockwell-C type indenter with a standard loading force of 150 kg (approximately 1470 N), making it suitable for qualitative evaluation of coating-substrate interface integrity [9].

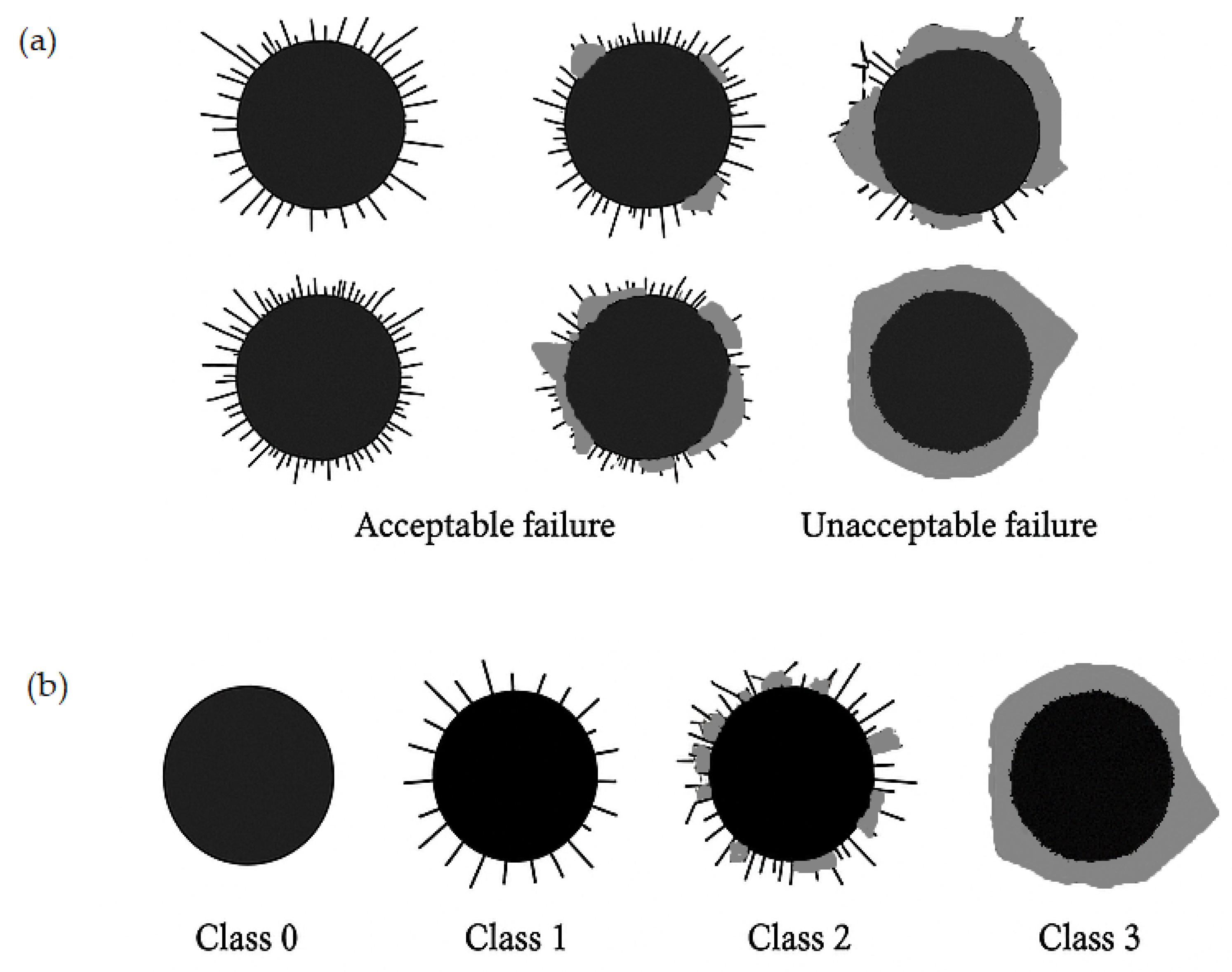

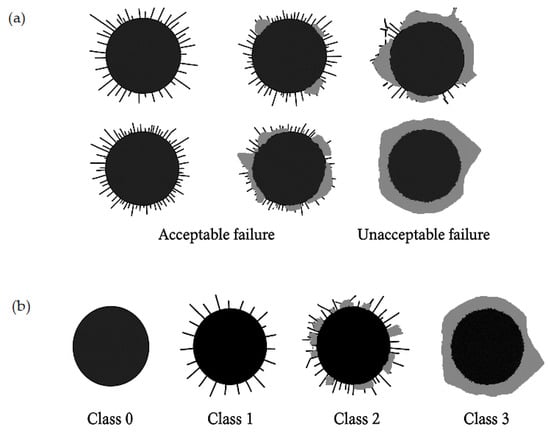

Adhesion assessment is typically conducted by visually inspecting the indentation area according to standardized classification systems. One widely recognized approach is based on the VDI 3198 [23] guideline, illustrated in Figure 1a. This classification table distinguishes between acceptable and unacceptable coating damage: the two columns on the left represent acceptable levels of failure (e.g., minor cracking or localized chipping), while the columns on the right identify severe delamination or widespread failure deemed unacceptable.

Figure 1.

Different evaluation methods for the Daimler-Benz adhesion test: (a) Adhesion assessment according to VDI 3198 (based on [23]); (b) adhesion assessment according to ISO 26443:2023 (based on [24]); (c) adhesion assessment according to DIN 4856 (based on [25]).

In addition to VDI 3198 [23], several other international standards are also utilized for interpreting test results. For instance, ISO 26443:2023 [24] (Figure 1b) categorizes coating failures into four distinct damage levels, providing a more nuanced differentiation of failure modes. Another standard, DIN 4856 [25] (Figure 1c), uses an HF-scale system where HF1 through HF4 are considered acceptable levels of adhesion, while HF5 and HF6 indicate inadequate bonding and thus failure of the coating in terms of industrial requirements.

These classification systems offer a reliable framework for comparing adhesion quality across different coatings, substrates, and processing conditions, and they play a vital role in both R&D and quality control processes involving hard coatings such as DLC.

3. Results

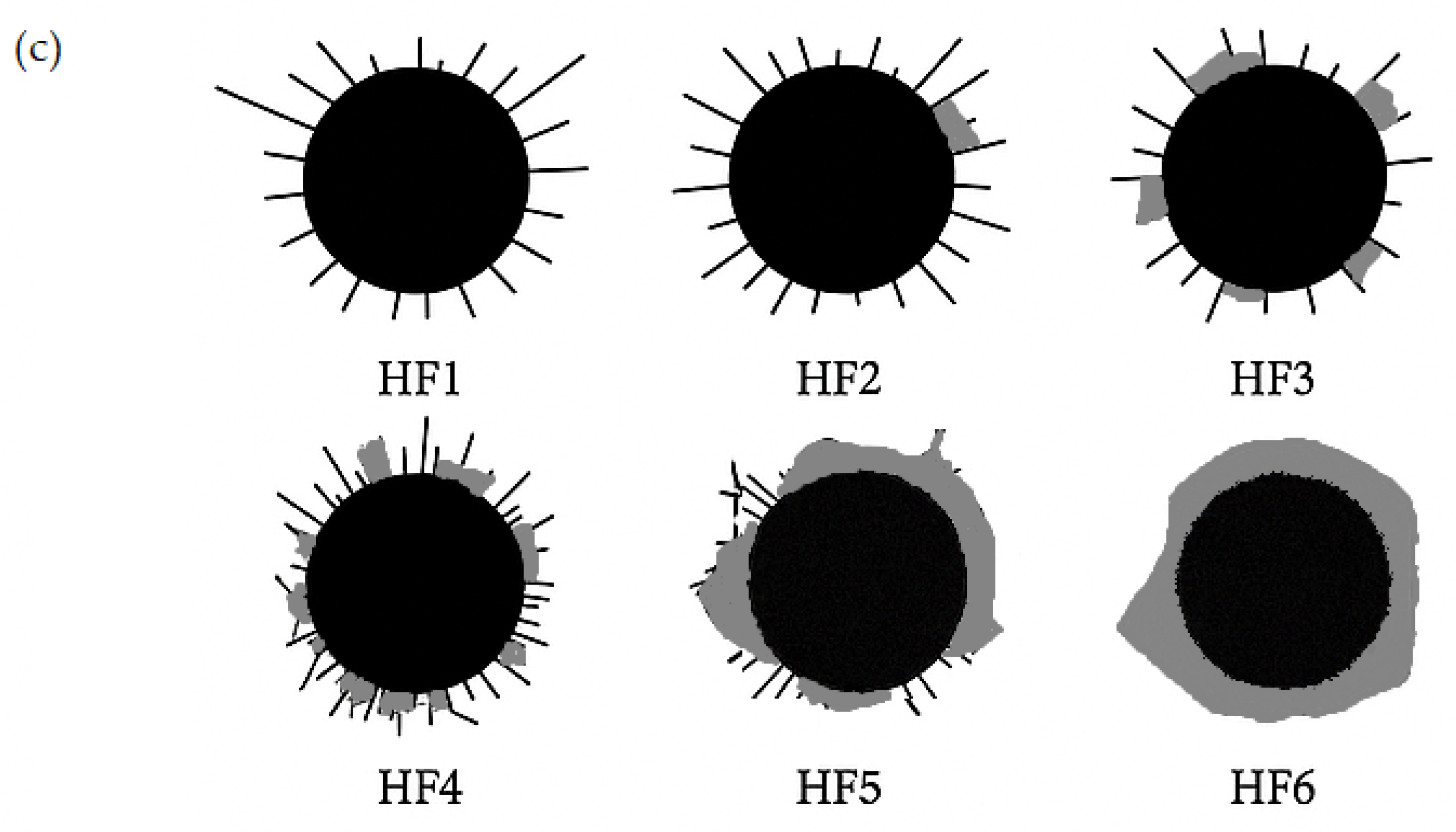

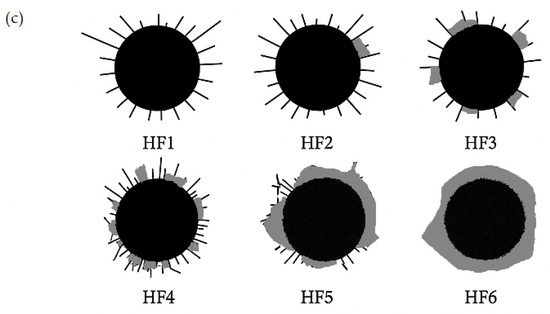

Prior to the Daimler-Benz adhesion test, metallographic specimens prepared from the case-hardened test samples were examined under a microscope to determine the case depth. The microscopic images obtained from this examination are shown in Figure 2.

Figure 2.

Microscopic images obtained during metallographic examinations: (a) 0.5 mm case depth; (b) 1.0 mm case depth.

Based on the results of the microscopic examinations, it can be stated that the case depths predetermined according to the technological parameters approximately correspond to the values obtained through optical measurement.

In the present study, a loading force of 150 kgf was applied during the Daimler-Benz adhesion tests, deviating from the 100 kg load specified in ISO 26443:2023 [24]. This increased load was intentionally selected to induce more pronounced coating damage, thereby enhancing the clarity and contrast in adhesion behavior among the tested samples and surface layer thicknesses.

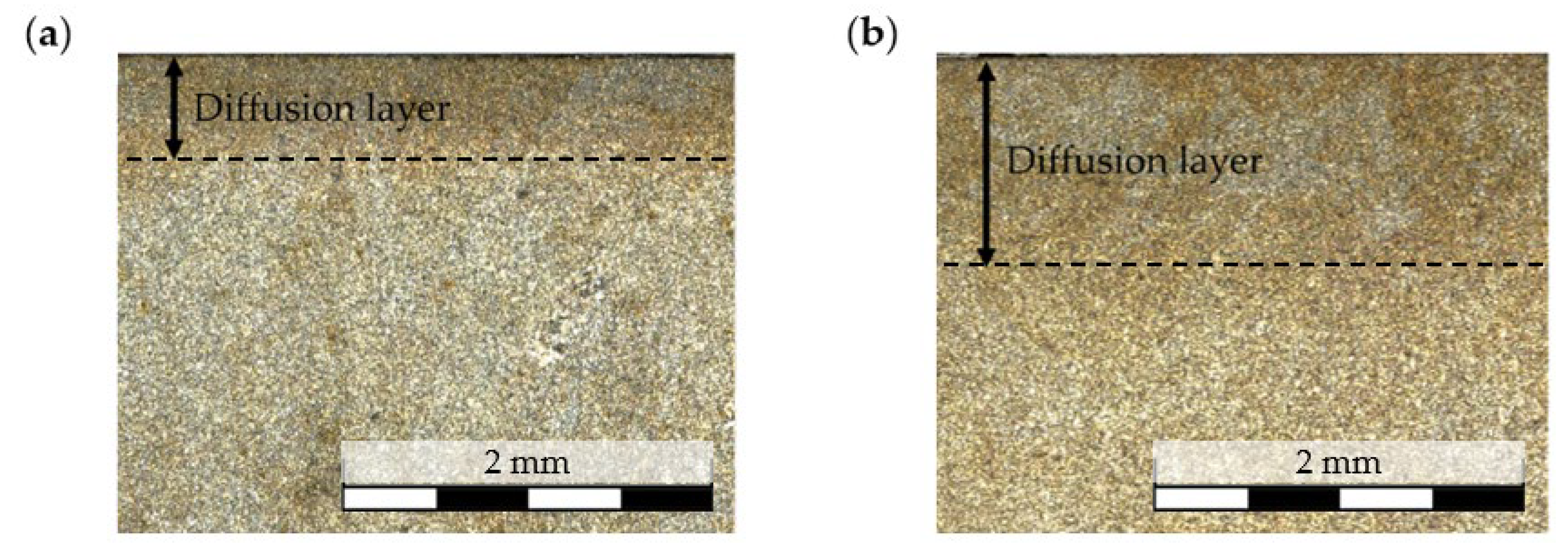

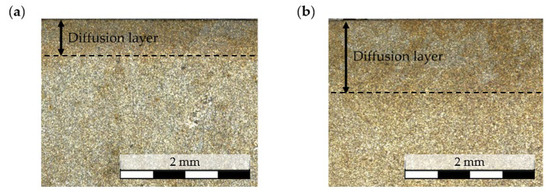

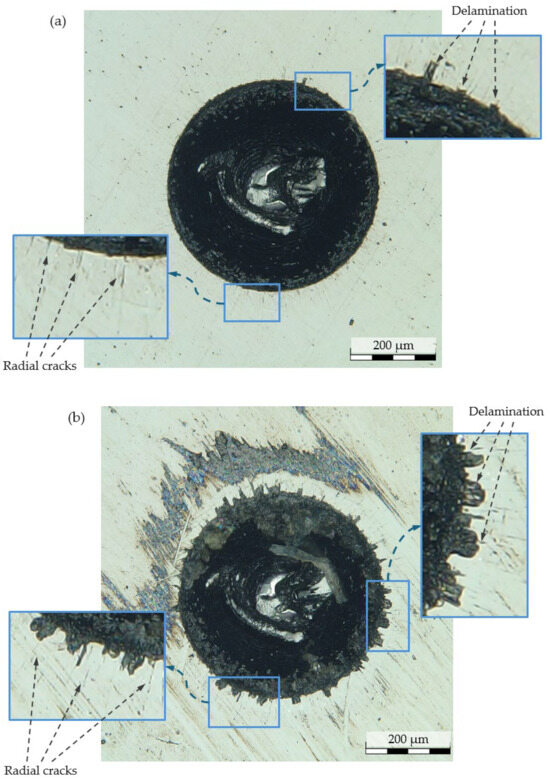

The outcomes of the adhesion tests, conducted under the adjusted loading conditions, are presented in Figure 3. This figure compiles representative images of the indentations, visually documenting the characteristic damage patterns observed on each specimen and allowing for a comparative analysis of adhesion performance across the test conditions.

Figure 3.

Microscopic images obtained during the Daimler-Benz adhesion test: (a) specimen with 0.5 mm case depth; (b) specimen with 1.0 mm case depth.

The comparison of samples with two different case-hardened layer thicknesses revealed substantial differences in coating failure behavior. In the case of the 0.5 mm hardened layer, radial cracking was observed around the indentation site, accompanied by minor delamination.

In contrast, the sample with a 1.0 mm case-hardened depth exhibited more severe coating degradation. As shown in Figure 2b, this specimen demonstrated extensive delamination, along with the presence of radial cracks similar to those seen in the thinner-hardened layer sample.

Based on the observed damage patterns, it can be concluded that increasing the thickness of the case-hardened layer resulted in a greater degree of coating failure under the same test conditions. According to the DIN 4856 [25] classification system, the 1.0 mm sample corresponds to damage category HF3, while the 0.5 mm sample aligns with the less severe HF2 classification.

4. Conclusions

In this study, the influence of varying case-hardened layer thicknesses on the adhesion performance of Diamond-Like Carbon (DLC) coatings was investigated using the Daimler-Benz Rockwell-C indentation method. Specimens with two different case depths (0.5 mm and 1.0 mm) were analyzed to identify coating damage patterns and classify them according to established standards. The results highlighted that the thickness of the hardened substrate has a notable effect on coating integrity, especially in terms of crack propagation and delamination.

Key findings from the investigation are:

- Increased case-hardened layer thickness resulted in more severe coating damage, including pronounced delamination and radial cracking.

- According to DIN 4856 classification, the sample with a 1.0 mm hardened layer was rated HF3, indicating poorer adhesion, while the 0.5 mm sample achieved a better HF2 rating.

- The findings suggest that excessive case depth may reduce the adhesion quality of DLC coatings under similar test conditions.

- For improved adhesion performance, optimization of the case-hardening depth should be considered in the design of duplex surface treatment systems.

Further investigations involving a broader range of case depths and substrate conditions are recommended to refine these observations and support more robust design guidelines for industrial applications.

Author Contributions

Conceptualization, G.P. and R.H.; methodology, G.P. and R.H.; software, G.P. and F.O.; validation, G.P. and R.H.; formal analysis, M.R.; investigation, G.P.; resources, G.P.; data curation, G.P. and R.H.; writing—original draft preparation, G.P. and R.H.; writing—review and editing, G.P. and R.H.; visualization, G.P.; supervision, M.R. All authors have read and agreed to the published version of the manuscript.

Funding

Project no. 2025-2.1.1-EKÖP-2025-00019-D-171 and 2024-2.1.1 were implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the 2025-2.1.1-EKÖP University Research Scholarship Programme (EKÖP) funding scheme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank Attila Széll for his help with heat treatments and DLC coating process.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| DLC | Diamond-Like Carbon |

| PVD | Physical Vapor Deposition (PVD) |

References

- Łach, Ł. Recent Advances in Laser Surface Hardening: Techniques, Modeling Approaches, and Industrial Applications. Crystals 2024, 14, 726. [Google Scholar] [CrossRef]

- Barshilia, H.C. Surface Modification Technologies for Aerospace and Engineering Applications: Current Trends, Challenges and Future Prospects. Trans. Indian Natl. Acad. Eng. 2021, 6, 173–188. [Google Scholar] [CrossRef]

- Labidi, C.; Collet, R.; Nouveau, C.; Beer, P.; Nicosia, S.; Djouadi, M. Surface treatments of tools used in industrial wood machining. Surf. Coatings Technol. 2005, 200, 118–122. [Google Scholar] [CrossRef]

- Yildiz, U.T.; Varol, T.; Pürçek, G.; Akçay, S.B. A Review on the Surface Treatments Used to Create Wear and Corrosion Resistant Steel Surfaces. J. Polytech. 2024, 27, 227–236. [Google Scholar] [CrossRef]

- Akhtar, S.S.; Arif, A.F.M.; Yilbas, B.S. Evaluation of gas nitriding process with in-process variation of nitriding potential for AISI H13 tool steel. Int. J. Adv. Manuf. Technol. 2009, 47, 687–698. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, L.; Shiozawa, K.; Zhou, W.; Zhang, W. Effect of nitrocarburizing and post-oxidation on fatigue behavior of 35CrMo alloy steel in very high cycle fatigue regime. Int. J. Fatigue 2011, 33, 880–886. [Google Scholar] [CrossRef]

- Campos-Silva, I. The Boriding Process: Growth Kinetics and Mechanical Characterization of Boride Layers. JESTECH 2012, 15, 53–61. [Google Scholar]

- Kara, R.; Çolak, F.; Kayali, Y. Investigation of Wear and Adhesion Behaviors of Borided Steels. Trans. Indian Inst. Met. 2015, 69, 1169–1177. [Google Scholar] [CrossRef]

- Rodríguez-Castro, G.A.; Jiménez-Tinoco, L.F.; Méndez-Méndez, J.V.; Arzate-Vázquez, I.; Meneses-Amador, A.; Martínez-Gutiérrez, H.; Campos-Silva, I. Damage Mechanisms in AISI 304 Borided Steel: Scratch and Daimler-Benz Adhesion Tests. Mater. Res. 2015, 18, 1346–1353. [Google Scholar] [CrossRef]

- Wołowiec-Korecka, E. Case hardening development review (2001–2020). Arch. Mater. Sci. Eng. 2023, 120, 70–85. [Google Scholar] [CrossRef]

- Tóth, L.; Nyikes, Z.; Umesh, M. Increasing Tool Steel Surface Wear Resistance by Surface Treatment. Műszaki Tudományos Közlemények 2020, 13, 170–173. [Google Scholar] [CrossRef]

- Gupta, G.; Tyagi, R.; Rajput, S.; Saxena, P.; Vashisth, A.; Mehndiratta, S. PVD based thin film deposition methods and characterization/property of different compositional coatings—A critical analysis. Mater. Today Proc. 2021, 38, 259–264. [Google Scholar] [CrossRef]

- Aisenberg, S.; Chabot, R. Ion-Beam Deposition of Thin Films of Diamondlike Carbon. J. Appl. Phys. 1971, 42, 2953–2958. [Google Scholar] [CrossRef]

- Feldiorean, D.I.; Tierean, M.H. Overview on DLC Layers Used to Increase the Tribological Properties. Bull. Transilv. Univ. Braşov 2015, 8, 43–50. [Google Scholar]

- Yang, L.; Li, T.; Shang, B.; Guo, L.; Zhang, T.; Han, W. The Influence of Deposition Temperature on the Microscopic Process of Diamond-like Carbon (DLC) Film Deposition on a 2024 Aluminum Alloy Surface. Crystals 2024, 14, 950. [Google Scholar] [CrossRef]

- Owens, A.G.; Brühl, S.; Simison, S.; Forsich, C.; Heim, D. Comparison of Tribological Properties of Stainless Steel with Hard and Soft DLC Coatings. Procedia Mater. Sci. 2015, 9, 246–253. [Google Scholar] [CrossRef]

- Inkin, V.; Kirpilenko, G.; Dementjev, A.; Maslakov, K. A superhard diamond-like carbon film. Diam. Relat. Mater. 2000, 9, 715–721. [Google Scholar] [CrossRef]

- Nakahigashi, T. Usage of Extending Carbon Films Including DLC. Hyomen Kagaku 2004, 25, 110–114. [Google Scholar] [CrossRef][Green Version]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Cai, S.; Sun, J.; He, Q.; Shi, T.; Wang, D.; Si, J.; Yang, J.; Li, F.; Xie, K.; Li, M. 16MnCr5 gear shaft fracture caused by inclusions and heat treatment process. Eng. Fail. Anal. 2021, 126, 105458. [Google Scholar] [CrossRef]

- Li, Y.; Li, R.; Li, J.; Han, G. Development and Production of 16MnCr5 Cold Heading Steel Wire Rod for Automobile Engine Valve Tappet. Spec. Steel 2020, 41, 24–27. (In Chinese) [Google Scholar]

- Baskar, S.; Megaraj, M.; Manjunathan, K.; Chandrasekaran, M.; Anish, M.; Umamaheswarrao, P.; Giri, J.; Samhan, A.A.A. Hardening Characteristics of 16MnCr5 Metals for Engine Block. In Proceedings of the 2024 2nd International Conference on Emerging Trends in Engineering and Medical Sciences (ICETEMS), Nagpur, India, 22–23 November 2024; pp. 710–715. [Google Scholar]

- VDI 3198; Beschichten von Werkzeugen der Kaltmassivumformung; CVD- und PVD-Verfahren. Verein Deutscher Ingenieure: Düsseldorf, Germany, 1992.

- ISO 26443:2023; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Rockwell Indentation Test for Evaluation of Adhesion of Ceramic Coatings. International Organization for Standardization: Geneva, Switzerland, 2023.

- DIN 4856; Carbon-Based Films and Other Hard Coatings—Rockwell Penetration Test to Evaluate the Adhesion. Deutsches Institut für Normung: Berlin, Germany, 2018.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).