Abstract

Pakistan’s housing sector faces a significant shortfall alongside growing climate risks. This study assesses climate-smart construction options autoclaved aerated concrete (AAC) blocks, interlocking bricks, and rat-trap bond masonry through energy simulations, cost modeling, and expert consultations. A 10-Marla residential unit in Islamabad was used as the reference case. Results indicate AAC reduces cooling energy by 22%, interlocking bricks reduce construction costs by 26.6%, and rat-trap masonry lowers electricity use by 12–16%. Despite technical viability, adoption remains limited due to financing and regulatory barriers. The study proposes a phased policy roadmap to integrate low-carbon materials into Pakistan’s housing and climate adaptation strategies.

1. Introduction

1.1. Climate-Smart Housing Globally

The built environment accounts for nearly 39% of global energy-related carbon dioxide emissions, with residential buildings alone contributing over 20% due to inefficient construction practices, fossil-fuel-based energy use, and poor thermal performance [1]. At the same time, nearly 1.6 billion people globally live in inadequate shelter, particularly in low- and middle-income countries (LMICs), where housing deficits intersect with exposure to climate extremes [2]. As global temperatures continue to rise, the housing sector must urgently transform to meet both mitigation and adaptation goals under the Paris Agreement and the Sustainable Development Goals (SDGs), particularly SDG 11 (sustainable cities) and SDG 13 (climate action) [3].

The concept of climate-smart housing has emerged as a multifaceted solution that addresses these challenges by integrating energy efficiency, disaster resilience, and resource-conscious design. It encompasses both passive and active measures, such as natural ventilation, solar orientation, insulation, efficient appliances, and the use of low-carbon building materials that reduce environmental footprints while enhancing human comfort and safety [4,5]. Globally, countries such as Mexico and Indonesia have begun adopting policy and financing frameworks that promote climate-resilient housing, particularly for low-income communities exposed to heatwaves, floods, and cyclones [6].

However, transitioning toward climate-smart housing requires not only technical innovation but also institutional capacity, regulatory alignment, and affordability. These dimensions remain underdeveloped in many LMICs, including Pakistan.

1.2. The Housing–Climate Nexus in Pakistan

Pakistan faces a dual challenge of chronic housing shortages and high climate vulnerability. With a national housing deficit exceeding 10 million units projected to cross 13 million by 2025, the country struggles to provide adequate, affordable, and resilient housing to its growing urban and rural populations [7]. Informal settlements account for over 40% of the urban housing stock, lacking access to durable materials, basic infrastructure, or climate-adaptive design [8].

Simultaneously, Pakistan is ranked first among the world’s top 10 most climate-vulnerable countries, frequently experiencing floods, droughts, heatwaves, and glacial melt events [9]. The 2022 floods alone displaced over 8 million people and damaged or destroyed more than 2 million homes, highlighting the fragility of conventional construction systems [10].

Despite this urgency, the integration of climate resilience into housing policy remains limited. Although Pakistan has revised its Building Energy Code (initially introduced in 1990 and updated in 2011 and 2021), enforcement remains weak due to limited institutional oversight and lack of local adaptation [11]. Similarly, national housing schemes such as Mera Pakistan Mera Ghar have yet to mainstream sustainability or resilience metrics, with green mortgage instruments and climate-linked housing finance still in nascent stages [12].

1.3. Climate-Smart Solutions: Emerging Evidence and Gaps

Climate-smart housing practices remain underutilized due to limited awareness, high upfront costs, and lack of standardization. Moreover, there is a paucity of empirical research that links such construction methods to measurable outcomes in terms of energy savings, disaster resilience, and social acceptability.

This study aims to examine how climate-smart housing can address Pakistan’s intersecting challenges of climate vulnerability, housing deficits, and policy fragmentation. Specifically, the objectives are as follows: (i) to evaluate the current status of housing vulnerability in Pakistan, particularly in relation to climate risk exposure, urban informality, and policy gaps; (ii) to identify and analyze low-carbon and climate-resilient construction techniques that are technically and economically viable within Pakistan’s socio-economic and climatic context;, (iii) to assess the institutional, financial, and regulatory barriers limiting the mainstream adoption of climate-smart housing models; (iv) to propose context-specific policy recommendations and design pathways to integrate climate resilience into Pakistan’s national housing and urban development agenda.

By aligning technical feasibility with institutional and financial strategies, the study contributes to the growing discourse on localized climate adaptation and sustainable urban development in Pakistan.

2. Methodology

This study adopts a multi-tiered qualitative methodology combining building simulation, cost modeling, and stakeholder consultations to assess the viability of climate-smart construction materials in Pakistan’s housing sector. Three alternative walling systems were selected for analysis: autoclaved aerated concrete (AAC) blocks, interlocking bricks, and rat-trap bond masonry. These materials were evaluated against conventional fired clay brick construction in terms of thermal performance, construction cost, labor efficiency, and embodied emissions.

A standard 10-Marla (approx. 2722 sq. ft.) single-story residential unit in Islamabad was used as the reference structure. The city’s humid subtropical climate (Zone 4A) was chosen for its representativeness of northern Pakistan’s urban housing typology. Dynamic energy simulations were conducted to assess indoor thermal performance and cooling energy demand using hourly weather data. Construction cost estimates were based on 2022 market prices for materials and labor sourced from suppliers and contractors operating in the Islamabad–Rawalpindi region.

To validate modeling assumptions and identify practical barriers to adoption, the study incorporated stakeholder consultations conducted between February and June 2022. A total of 25 experts participated, including architects, engineers, urban planners, housing financiers, and public officials. The consultations were conducted through three thematic roundtables and one technical training session. A semi-structured discussion guide was used to collect insights on material availability, labor dynamics, cost structures, policy constraints, and adoption challenges. While not statistically representative, the consultations enabled triangulation of assumptions and highlighted context-specific factors shaping material viability.

This integrated methodology enabled a comparative assessment of each material’s performance across technical, economic, and environmental dimensions. The findings informed a phased policy roadmap to guide the adoption of climate-smart construction practices within Pakistan’s housing and urban development sectors.

3. Results and Discussion

This section presents the outcomes of the modeling analysis and stakeholder consultations conducted to evaluate the technical, economic, and environmental performance of climate-smart housing materials in Pakistan. The findings are organized around the three passive construction techniques assessed—autoclaved aerated concrete (AAC) blocks, interlocking bricks, and rat-trap bond masonry—and highlight their comparative advantages over conventional clay brick construction. Key performance indicators include thermal efficiency, energy savings, construction costs, and greenhouse gas (GHG) emissions. The results also draw attention to implementation challenges and contextual considerations that shape the adoption of these techniques in low-income and climate-vulnerable housing segments.

3.1. Thermal and Energy Performance of Passive Construction Materials

The modeling results demonstrate that passive construction techniques, namely autoclaved aerated concrete (AAC) blocks, hollow bricks, and rat-trap bond masonry, significantly outperform traditional clay bricks in terms of thermal comfort and energy efficiency. Among these, AAC blocks emerged as the most effective material, reducing cooling energy demand by 22% and offering the lowest U-value (0.44 W/m2K) among the materials assessed.

The modeled structure using AAC blocks exhibited a 35% lower operational energy requirement for air conditioning compared to clay brick buildings. Hollow bricks, though slightly less insulating than AAC, also provided notable improvements in cooling efficiency and reduced embodied energy by approximately 55%.

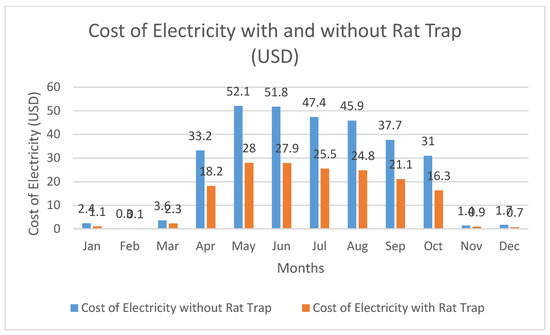

Additionally, Figure 1 illustrates the effect of thermal insulation using rat-trap bond masonry on monthly electricity consumption. Structures with rat-trap insulation consistently consumed 12–16% less electricity, leading to reduced operational costs and improved thermal comfort, especially in hotter months.

Figure 1.

Cost of Electricity with and without Rat Trap.

While both AAC blocks and hollow bricks offer considerable improvements over conventional fired clay bricks, the decision to prioritize AAC in thermal performance modeling was based on its superior insulation characteristics. AAC blocks exhibited the lowest thermal transmittance (U-value of 0.44 W/m2K) and resulted in a modeled 22% reduction in cooling energy demand higher than the reduction observed for hollow brick configurations. However, it is acknowledged that hollow bricks outperform AAC in terms of embodied energy reduction, estimated at 55% lower than fired bricks due to their lower raw material intensity and energy requirements during production.

Therefore, while AAC is preferable from an operational energy savings perspective, hollow bricks may be more advantageous from a cradle-to-site emissions standpoint. The optimal material choice would ultimately depend on project priorities, whether minimizing recurring energy costs or reducing initial embodied emissions.

3.2. Cost Saving and Construction Efficiency

In economic terms, climate-smart construction techniques offer considerable long-term savings. Despite AAC blocks costing 10–20% more upfront, they lead to lower lifecycle costs due to reduced energy bills and maintenance requirements. The payback period for AAC-based construction was estimated to be between 3 and 5 years, depending on regional electricity prices and usage intensity.

The interlocking brick system, meanwhile, demonstrated substantial cost and labor efficiency. In the analysis, cost efficiency is defined as the percentage reduction in total construction costs, material, labor, and finishing when using non-conventional materials compared to conventional fired brick construction. This includes direct savings from lower per-unit brick costs, elimination of cement mortar, and reduced reliance on skilled masons.

Labor efficiency refers to the simplification of construction processes, particularly the ability to use semi-skilled labor for wall assembly and the shorter construction time enabled by dry-stacking interlocking systems. This reduces on-site skilled labor costs and speeds up project timelines, especially in single-story or self-build scenarios. As shown in Table 1, interlocking bricks can reduce total construction costs by up to 26%, primarily by eliminating the need for cement mortar and reducing skilled labor dependency. This makes the technique particularly suitable for low-income housing applications and self-built community projects. In terms of structural performance, the interlocking bricks assessed in this study demonstrated compressive strengths ranging from 7.5 to 10 MPa. These values are within the acceptable range for residential applications, particularly for single and double-story structures. Additionally, the modular interlocking design enhances lateral stability and enables load distribution without compromising wall integrity. While structural validation for multistory use would require reinforced systems, the observed strength is compliant with national construction standards for low-rise housing.

Table 1.

Comparative Cost Analysis of Conventional vs. Interlocking Brick Construction for a Standard 10-Marla Residential Unit in Islamabad (Zone 4A).

Both conventional construction and the interlocking brick system involve similar foundational and finishing activities, including earthwork, site clearance, mobilization, sub-structure preparation with excavation, formwork, and concreting, as well as drainage, sewerage, and final site clearance. Conventional construction includes beams, columns, and slabs with traditional brickwork and plastering on both sides. In contrast, the interlocking system replaces conventional brickwork with Interlocking Hollow Block System (IHBS) and mortar and uses ground beams and slabs instead of vertical columns. Both methods involve transportation and machinery use, installation of roof trusses, windows, doors, plumbing, and electrical works, followed by painting and formal design endorsement.

The payback period for AAC-based construction was calculated by comparing the incremental capital cost (10–20% higher than conventional brick walls) with the annual cost savings from reduced electricity consumption. Assuming an average cooling energy saving of 1100–1400 kWh/year and a tariff of PKR 19.5/kWh, annual operational savings range from PKR 21,500 to PKR 27,000. With an upfront material cost differential of PKR 75,000–125,000 (based on wall area), the resulting simple payback period is between 3 and 5 years. This estimation assumes constant energy tariffs and excludes inflation or maintenance factors. The payback period presented in this study is calculated using a simple payback approach, comparing the incremental capital cost of climate-smart materials with the annual energy cost savings achieved through enhanced thermal performance. For the purpose of this analysis, key financial parameters such as interest rates were treated as control variables in order to focus only on how different construction materials affect costs and savings.

All thermal and energy savings results are based on modeled energy consumption for cooling loads in a standard 10-Marla single-story home in Islamabad, under peak summer conditions. Baseline assumptions include an average electricity tariff of PKR 19.5 per kWh (2022), an indoor cooling setpoint of 27 °C, and the use of a split air conditioning system with a coefficient of performance (COP) of 3.2. AAC-based walls reduced cooling load by 22% compared to fired clay bricks, which translated into monthly energy savings of 85–120 kWh during peak summer months. These outputs were derived from hour-by-hour building simulation using local climate data.

3.3. Environmental Impact and Embodied Emissions

The environmental performance of construction materials is increasingly central to climate mitigation efforts, particularly in rapidly urbanizing countries like Pakistan. In this context, climate-smart housing materials such as autoclaved aerated concrete (AAC) blocks, hollow bricks, and rat-trap bond masonry are gaining traction due to their potential to reduce embodied carbon emissions and improve lifecycle performance.

These materials offer tangible reductions in embodied emissions primarily through lower raw material intensity, energy-efficient manufacturing processes, and reduced transportation loads. AAC blocks, for instance, are significantly lighter than conventional bricks, which not only reduces the structural load and associated material use in foundations but also minimizes emissions during transport. Hollow bricks, by design, consume less raw material per unit area and offer improved insulation performance, thereby supporting both embodied and operational emission reductions.

Rat-trap bond masonry achieves material efficiency by incorporating vertical air cavities within wall structures. This design significantly reduces the total number of bricks required per square meter of wall surface. For a standard 9-inch wall, this technique can reduce brick usage by approximately 25% compared to traditional English or Flemish bond patterns, where bricks are laid flat [13]. The reduced volume results in lower material costs and contributes to lighter wall loads, without compromising structural stability for low-rise applications.

While precise emissions data for these materials in the Pakistani context remains limited, international studies and comparative lifecycle assessments consistently show that low-density, thermally efficient materials can reduce embodied carbon footprints by 30–60% relative to traditional fired clay bricks. These benefits are further amplified when combined with reductions in operational energy demand.

Comparative Performance for Double-Storey Housing

To assess the broader applicability of climate-smart materials, a double-storey 10-Marla house (approximately 5444 sq. ft.) in Islamabad was modeled under two scenarios: conventional fired clay brick construction and a hybrid climate-smart design using AAC blocks, interlocking bricks, and rat-trap bond masonry.

- Construction Cost: The total construction cost for the conventional design was estimated at PKR 15.0 million, while the climate-smart alternative was estimated at PKR 10.9 million, reflecting approximately 27% savings in material and labor.

- Energy Efficiency: Annual cooling energy savings ranged from 2200 to 2600 kWh, equivalent to PKR 50,000 in avoided electricity bills (based on 2022 tariffs). This was driven by improved thermal insulation from AAC and optimized wall geometry from rat-trap masonry.

- Embodied GHG Emissions: The conventional structure emitted an estimated 38–42 tons of CO2 over its lifecycle. The climate-smart design reduced emissions by 30–35%, saving 13–15 tons of CO2, primarily through lower cement usage and reduced brick volume.

3.4. Global Case Studies

3.4.1. India: Autoclaved Aerated Concrete in Rajkot Smart City Housing

Under India’s Smart Ghar III initiative in Rajkot, part of the Pradhan Mantri Awas Yojana, AAC block construction was deployed in affordable housing projects to enhance thermal performance and resource efficiency. Based on a report by the Energy Transition Preparedness Initiative (ETPI), buildings utilizing AAC blocks with cavity wall systems achieved a >5 °C reduction in peak summer indoor temperatures and extended the number of comfortable hours (below 30 °C) from about 2600 to 6300 h annually [14].

3.4.2. Sri Lanka: Compressed Stabilized Earth Blocks for Post-Conflict Reconstruction

In Sri Lanka’s Kurunegala region, UN-Habitat’s “Returning Home” project used Compressed Stabilized Earth Blocks (CSEBs) as an alternative to fired bricks in rebuilding homes affected by conflict. Beneficiaries reported that CSEB-based walls were “cooler than others,” required no plaster, and used less cement mortar during bonding. The project emphasized local production, reducing transport emissions and supporting community livelihoods, while delivering more thermally comfortable housing under climatically challenging conditions [15].

4. Policy Recommendations

To accelerate the uptake of climate-smart housing in Pakistan (Table 2), a phased policy roadmap is essential one that bridges regulatory gaps, incentivizes market adoption, and embeds low-carbon materials into mainstream housing delivery systems. The following recommendations outline targeted short-, medium-, and long-term actions to enable systemic transformation across public, private, and informal housing segments.

Table 2.

Phased Policy Roadmap for Smart Housing in Pakistan.

Provincial and municipal authorities should align building approval processes and public housing schemes with the updated Energy Conservation Building Code (ECBC 2023) introduced by the National Energy Efficiency and Conservation Authority (NEECA). The code mandates energy efficiency benchmarks such as minimum thermal insulation, solar reflectivity standards, and passive ventilation design. Integrating ECBC compliance into urban planning frameworks can mainstream thermal-efficient construction across formal and low-income housing segments [16].

Effective implementation of these policy measures requires clearly defined institutional roles and cross-agency coordination. The Ministry of Housing and Works (MoH&UA) and the Ministry of Climate Change (MoCC) should take the lead in mainstreaming climate-smart construction practices into national housing strategies and climate policy instruments (e.g., NDCs, LT-LEDS). The Pakistan Standards and Quality Control Authority (PSQCA) and Pakistan Council of Scientific and Industrial Research (PCSIR) should oversee material standardization and testing protocols, while NAPHDA and provincial housing authorities are best positioned to integrate these materials into public housing schemes.

Additionally, the State Bank of Pakistan (SBP) and Ministry of Finance can enable financial incentives through green refinancing, while vocational training bodies (TEVTA, NAVTTC) should be mobilized to build the skilled workforce necessary for scaling up non-conventional building techniques. To ensure coherence and oversight, a National Taskforce on Climate-Resilient Housing, co-chaired by MoH&UA and MoCC, should be established to monitor progress, facilitate knowledge exchange, and coordinate donor and private sector engagement.

5. Conclusions

This study demonstrates the tangible potential of climate-smart construction materials, particularly AAC blocks, interlocking bricks, and rat-trap bond masonry to improve affordability, energy efficiency, and climate resilience in Pakistan’s housing sector. Compared to conventional brick-based construction, these materials can reduce cooling energy use by up to 22%, cut construction costs by approximately 26.6%, and lower embodied carbon emissions by 30–35%.

For a standard 10-Marla home in Islamabad, the modeled savings equate to PKR 4–5 million in construction cost reductions and annual electricity savings exceeding PKR 45,000. These performance gains are further enhanced by reduced material volumes and shorter construction timelines.

However, uptake remains limited due to regulatory inertia, financing barriers, and lack of workforce familiarity. A coordinated national roadmap anchored in updated building codes, green financing tools, and skill development is needed to scale these alternatives. Climate-smart housing represents a practical entry point for low-carbon urban development and can serve as a core pillar of Pakistan’s Nationally Determined Contributions (NDCs) and disaster resilience agenda, particularly in flood- and heat-vulnerable regions.

While this study offers valuable insights into the comparative benefits of climate-smart construction materials, it is limited by its primarily qualitative methodology, which draws on secondary literature and stakeholder consultations. The absence of large-scale, longitudinal field data such as real-time energy performance monitoring across diverse climatic zones restricts the ability to generalize findings across all housing contexts in Pakistan. Future research should incorporate experimental validations, cost–benefit analyses, and household-level adoption studies to strengthen the empirical evidence base and guide more granular policy interventions.

Author Contributions

Conceptualization, S.A.A.M. and S.Q., methodology, S.A.A.M.; writing—original draft preparation, S.A.A.M.; writing—review and editing, S.Q.; supervision, S.Q., U.-U.R.Z. and M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors acknowledge the support provided by the Ministry of Commerce and the Ministry of Energy, Government of Pakistan, during the course of this research. We also extend our sincere appreciation to all stakeholders and experts who participated in consultations and shared valuable insights into sustainable construction practices in Pakistan.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AAC | Autoclaved Aerated Concrete |

| SDGs | Sustainable Development Goals |

| IHBS | Interlocking Hollow Block System |

| CSEBs | Compressed Stabilized Earth Blocks |

| PCSIR | Pakistan Council of Scientific and Industrial Research |

| UETs | University of Engineering and Technology |

| TEVTA | Technical Education and Vocational Training Authority |

| PSQCA | Pakistan Standards and Quality Control Authority |

| PEC | Pakistan Engineering Council |

| LMICs | Low- and Middle-Income Countries |

| GHG | Greenhouse Gas |

| ETPI | Energy Transition Preparedness Initiative |

| PGBC | Pakistan Green Building Council |

| NUST | National University of Sciences and Technology |

| MoH&UA | Ministry of Housing and Urban Affairs |

| NAVTTC | National Vocational and Technical Training Commission |

| SBP | State Bank of Pakistan |

| NDCs | Nationally Determined Contributions |

References

- Hamilton, I.; Kennard, H. 2022 Global Status Report for Buildings and Construction. 2022. Available online: https://globalabc.org/sites/default/files/2022-11/FULL%20REPORT_2022%20Buildings-GSR_1.pdf (accessed on 23 July 2025).

- UN-Habitat. Envisaging the Future of Cities. 2022. Available online: https://unhabitat.org/sites/default/files/2022/06/wcr_2022.pdf (accessed on 23 July 2025).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/publications/transforming-our-world-2030-agenda-sustainable-development-17981 (accessed on 23 July 2025).

- International Energy Agency (IEA). The Future of Cooling: Opportunities for Energy Efficient Air Conditioning. 2018. Available online: https://iea.blob.core.windows.net/assets/0bb45525-277f-4c9c-8d0c-9c0cb5e7d525/The_Future_of_Cooling.pdf (accessed on 23 July 2025).

- Woetzel, J.; Ram, S.; Peloquin, S.; Limam, M.; Mischke, J. Housing Affordability: A Supply-Side Toolkit for Cities. 2017. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/operations/our%20insights/housing%20affordability%20a%20supply%20side%20tool%20kit%20for%20cities/housing-affordability-mgi-briefing-note-oct-2017.pdf (accessed on 23 July 2025).

- World Bank. Global Program for Resilient Housing. 2022. Available online: https://www.worldbank.org/en/topic/disasterriskmanagement/brief/global-program-for-resilient-housing (accessed on 23 July 2025).

- Qureshi, S.; Aslam, H.; Zia, U.U.R. Climate Smart Housing in Pakistan, 1st ed.; Sustainable Development Policy Institute (SDPI): Islamabad, Pakistan, 2022; Available online: https://sdpi.org/assets/lib/uploads/Working%20Paper%20194-08-2022.pdf (accessed on 24 July 2025).

- UN-Habitat. Pakistan UN-Habitat Country Report 2023. 2023. Available online: https://unhabitat.org/sites/default/files/2023/06/4._pakistan_country_report_2023_b5_final_compressed.pdf (accessed on 24 July 2025).

- Adil, L.; Eckstein, D.; Kunzel, V.; Schafer, L. Climate Risk Index 2025. 2025. Available online: https://www.germanwatch.org/sites/default/files/2025-02/Climate%20Risk%20Index%202025.pdf (accessed on 24 July 2025).

- Government of Pakistan. Pakistan Floods 2022: Post-Disaster Needs Assessment. 2022. Available online: https://www.undp.org/pakistan/publications/pakistan-floods-2022-post-disaster-needs-assessment-pdna (accessed on 24 July 2025).

- Pakistan Engineering Council (PEC). Building Code of Pakistan. 2021. Available online: https://www.pec.org.pk/wp-content/uploads/2024/09/BCP2021-Final-Draft-dated-26.10.2021.pdf (accessed on 24 July 2025).

- State Bank of Pakistan (SBP). Mera Pakistan Mera Ghar (MPMG). 2020. Available online: https://www.sbp.org.pk/MPMG/index.html (accessed on 24 July 2025).

- Santhakumar, A.R.; Sivakumar, A.; Ashok, S. Validation of Rat-Trap Bond for Cost-Effective Housing, 9th Canadian Masonry Symposium. 2001. Available online: https://www.canadamasonrydesigncentre.com/research/validation-of-rat-trap-bond-for-cost-effective-housing/ (accessed on 29 July 2025).

- Malaviya, S.; Soni, R.; Tagotra, N. Rajkot Smart GHAR III Project: Addressing Thermal Comfort in Affordable Housing. 2024. Available online: https://www.etpi.in/sites/default/files/publications/RajkotSmartGHARIII_Case%20study_ETPI.pdf (accessed on 24 July 2025).

- UN-Habitat. UN-Habitat Promotes Eco-Friendly, Compressed Stabilised Earth Blocks for Construction. UN-Habitat 2015, February. Available online: https://unhabitat.lk/news/un-habitat-promotes-eco-friendly-compressed-stabilised-earth-blocks-for-construction// (accessed on 24 July 2025).

- National Energy Efficiency and Conservation Authority (NEECA). Energy Conservation Building Code–2023; NEECA: Islamabad, Pakistan, 2024. Available online: https://neeca.pk/neecagov/homepage/ecbc23.pdf (accessed on 31 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).