Abstract

Electric vehicles are now a completely familiar part of the street scene. Their number is determined by many factors, one of the most significant of which is price. With the ever-increasing supply, it is becoming increasingly difficult for buyers to decide between different vehicles, as in many cases, there is a minimal difference between the two vehicles. A parameter influencing such a purchase is the vehicle’s range. Experience shows that in many cases the range given in the catalogue and the real, available range differ significantly. The available range changes dynamically while driving, typically showing a decreasing value. This research describes a range estimation model that takes into account driving habits and temperature conditions.

1. Introduction

The aim of this paper is to determine the energy consumption pattern of an electric vehicle under different speed profiles—urban, suburban, country and motorway use—and to estimate and identify the range-reducing effect of energy-consuming systems in vehicles.

The Introduction Section of the paper presents the general energy challenges of road transport and highlights the importance of environmentally conscious solutions in the transport sector. The Literature Review Section then provides a brief overview of the development of energy-efficient technologies and the role of regenerative systems. The research mentions the currently accepted driving cycles; one such cycle is the WLTP (Worldwide Harmonized Light Vehicles Test Procedure). The Simulation Section presents the obtained simulation results in detail, focusing on the range-reducing effect of other consumers in the vehicle. The paper emphasizes in its Conclusions Section that in order to optimize energy management, a thorough knowledge of the differences between vehicle categories and driving conditions is essential. The research contributes to the development of more efficient energy use strategies and provides valuable information for the development of sustainable transport systems.

2. Literature Review

Road vehicles are typically classified into three categories based on the energy source(s) required to power them. These are conventional (internal combustion engine vehicle—ICEV), hybrid (hybrid electric vehicle—HEV) and purely electric (electric vehicle—EV). The first group includes vehicles powered by gasoline or diesel engines, which have been present in traffic since the 19th century; in contrast, electric vehicles have only achieved significant market penetration in recent years [1]. Hybrid vehicles are classified into several categories based on the energy converter used to power the vehicle (internal combustion engine or electric motor), the energy source (battery, fuel cell or gasoline) and whether they are charged from an external source (charging station or home charger) [2]. Researchers are constantly working to create more accurate predictive models for EVs’ energy consumption [3]. An analytic investigation reported on the range and state of electric vehicles based on different drive cycles [4]. The standardized drive cycle plays a vital role in estimating energy consumption (NEDC, WLTP, etc.). An analytical EV power estimation model to improve EVs’ energy efficiency was proposed [5].

2.1. Energy Management System

In the case of electric vehicles, one of the most important research areas is energy management, particularly battery management. The energy density of batteries fundamentally determines the range and performance of vehicles [6]. There are various solutions in energy management strategies (EMSs) that help increase the range of electric vehicles, reduce energy consumption and improve battery life [7]. These include various battery management systems (BMSs), new energy storage solutions, regenerative braking systems, charging optimization and V2G systems. In terms of estimating the range of electric light commercial vehicles, we deal with battery management and regenerative braking systems.

2.1.1. Battery Management System

Batteries have long been the energy source for electric vehicles. There is currently a lot of research into developing new types of batteries, but there are currently several different types of batteries (e.g., lead–acid, nickel–zinc and nickel–cadmium batteries) [8], but the lithium-ion battery is the most widespread, as it has high energy density, high power density, relatively long life (∼1000 charge–discharge cycles) and environmentally friendly properties.

The task of a BMS is to effectively manage the battery of electric vehicles. This is especially important, since this battery can consist of hundreds or even thousands of individual cells, which individually or in blocks require continuous monitoring of several parameters, the most typical of which are voltage and temperature.

The most important tasks of the BMS include the following:

- Protection of cells and battery: The system prevents damage to batteries, such as overcharging, overheating or the formation of reverse polarity.

- Ensuring safe operation: The BMS ensures that batteries operate within the correct voltage and temperature range, thereby extending their service life.

- Monitoring and optimizing battery health: The system monitors a battery’s state of charge (SOC) or depth of discharge (DOD), state of health (SOH) and state of function (SOF) to ensure that it operates according to the vehicle’s needs.

Other tasks include thermal management, balancing the charge levels between individual cells, diagnosing faults and sending appropriate signals based on data collected by temperature sensors and other sensors. It also manages battery charging and ensures the electromagnetic compatibility of the system. Overall, a well-functioning BMS plays a key role in the safe and efficient operation of batteries and is essential for increasing a vehicle’s range [9].

2.1.2. Regenerative Brake System

One of the biggest advantages of electric vehicles is kinetic energy recovery, also known as regenerative braking, which is a braking method that uses the kinetic energy of a vehicle to convert it into electric energy, which is recovered into a battery. In theory, a regenerative braking system can recover a significant portion of the vehicle’s kinetic energy and use it to charge the battery. It is particularly effective in urban driving, where braking and acceleration are frequent, as a certain amount of energy can be recovered with each deceleration [10].

The integration of regenerative braking systems offers several advantages, as it significantly improves energy efficiency by maximizing the amount of energy that can be reused and reducing the energy loss due to heat generated by conventional brakes. In addition, it improves the performance and sustainability of electric cars and positively affects the driving experience. With the help of these braking systems, we can recover up to 5–8% of the wasted energy [10]. Engine efficiency plays a significant role in the overall efficiency of a vehicle. Nowadays, researchers are working on a new electric motor design and torque control that ensure the motor operates with excellent efficiency across the entire speed and torque range [11].

3. Simulation

3.1. Standard Driving Cycles

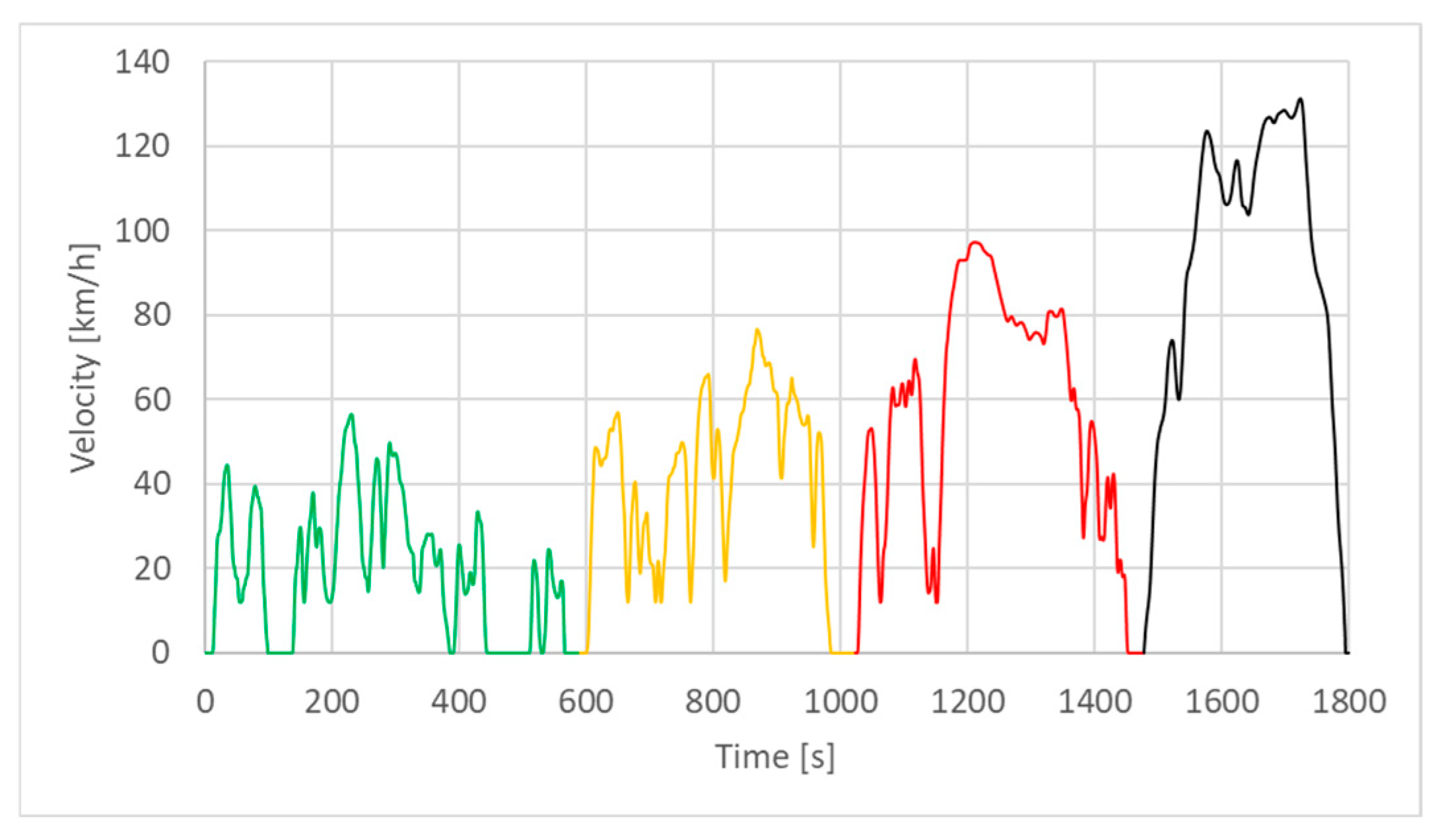

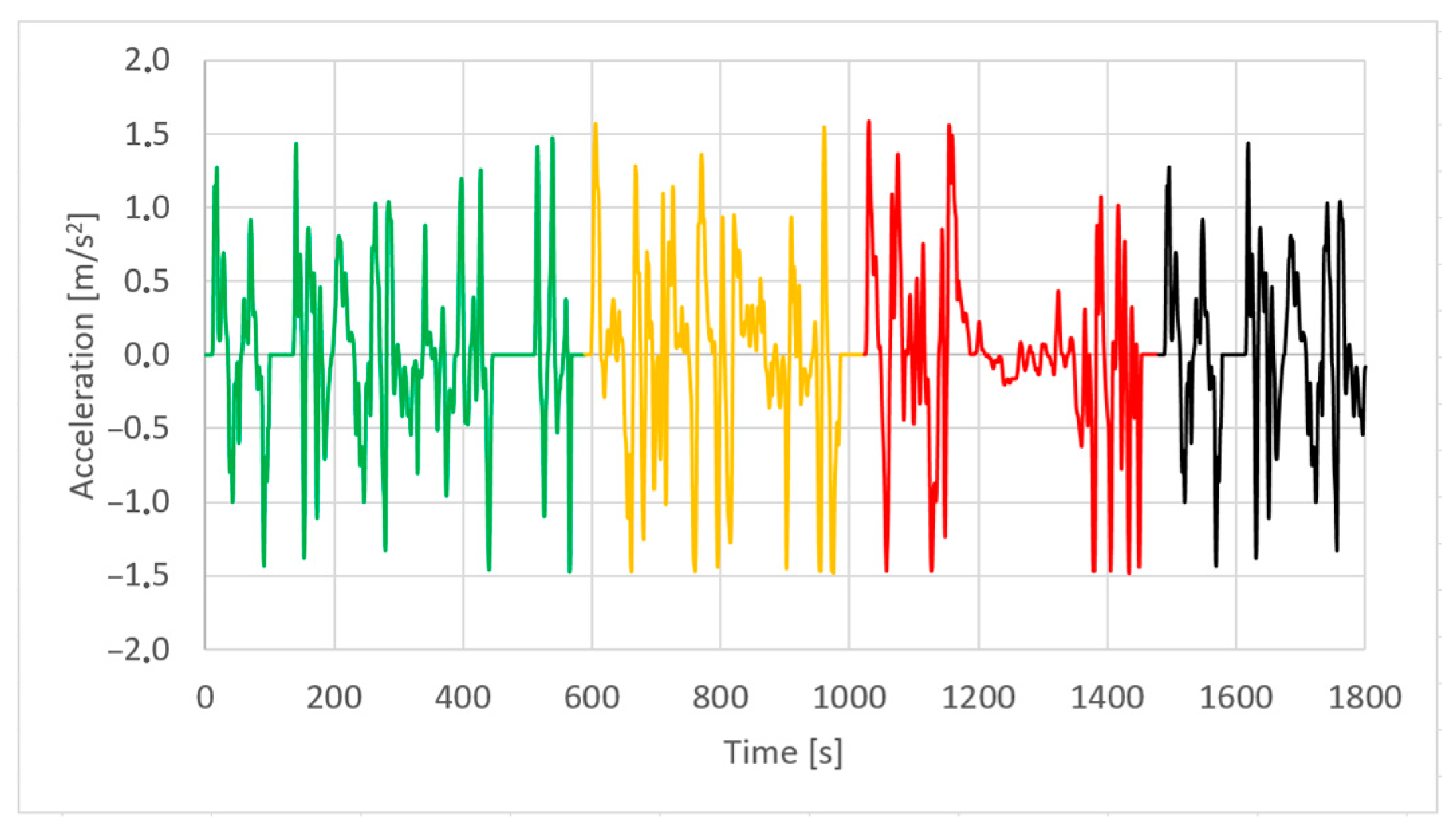

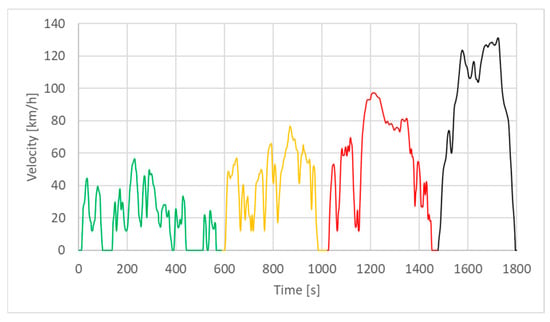

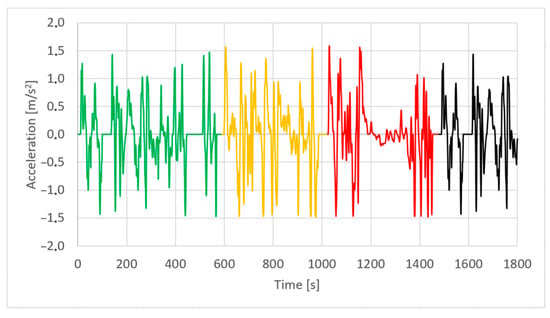

In general, vehicles, and especially electric vehicles, typically use a standardized driving cycle to determine emissions (typically in the case of ICEVs) and range. Previously, the New European Driving Cycle (NEDC) was adopted in the European Union, but today it has lost its validity, and manufacturers have turned to the WLTP driving cycle. WLTP stands for Worldwide Harmonized Light Vehicles Test Procedure. It is a global standard that also measures the fuel efficiency, emissions and electric range of vehicles. It was introduced in the European Union in 2017 to replace its predecessor, the NEDC, because it modelled simplified driving conditions and thus gave overly optimistic fuel consumption and emission results. In contrast, the WLTP was intended to provide real driving conditions. The WLTP test cycle consists of four different driving phases, as illustrated in Figure 1 and Figure 2. The four different phases are shown by four colours: green is low, yellow is medium, red is high and black is the very high phase.

Figure 1.

Speed profile of WLTP class 3b.

Figure 2.

Acceleration profile of WLTP class 3b.

The temperature specified by the WLTP cycle is 23 °C. The cycle reflects the real consumption values well for urban and suburban driving at pleasant outside temperatures. However, in the case of long-term motorway use or winter cold, the range given by the cycle can be 10–25% lower than the originally given value. The aim of the simulation is to estimate how the consumption value given by the WLTP changes with changes in the outside temperature. The simulation examines two separate cases. The first is a cold day corresponding to winter weather, where much more lighting and heating are needed. And similarly, we examined how much the vehicle’s electricity consumption increases on a hot summer day, where less lighting but much more AC use is needed. The simulation was performed for the summer and winter cases. In the first case, a cold January day was taken, where the temperature was −10 °C. In the second case, a hot summer day was considered, when the temperature was 35 °C.

In order to simulate the vehicle’s additional electrical energy consumption, the power of the lighting, driving support and comfort electronics of an average electric vehicle were mapped. These are shown in the tables below, Table 1 and Table 2. The main parameters of the simulated vehicle can be found in Table 3.

Table 1.

The power of the electric vehicle’s lighting systems.

Table 2.

The power of the electric vehicle’s comfort and driver-assist systems.

Table 3.

Main parameters of the simulated electric vehicle.

3.2. Longitudinal Vehicle Model

To estimate the electricity consumption, a simple longitudinal vehicle dynamics model was defined that meets the speed and acceleration requirements of the WLTP cycle. The following equation is used to determine the vehicle traction force [12]:

where λ: coefficient of rotational inertia; m: vehicle mass; vveh: vehicle speed; aveh: vehicle acceleration; Mmotor: torque of the electric motor; kgb: ratio of the gearbox; ηt: total efficiency of the powertrain; kd: ratio of the differential gear (kt = kgb×kd); α: angle of slope; RW: dynamic radius of the tire.

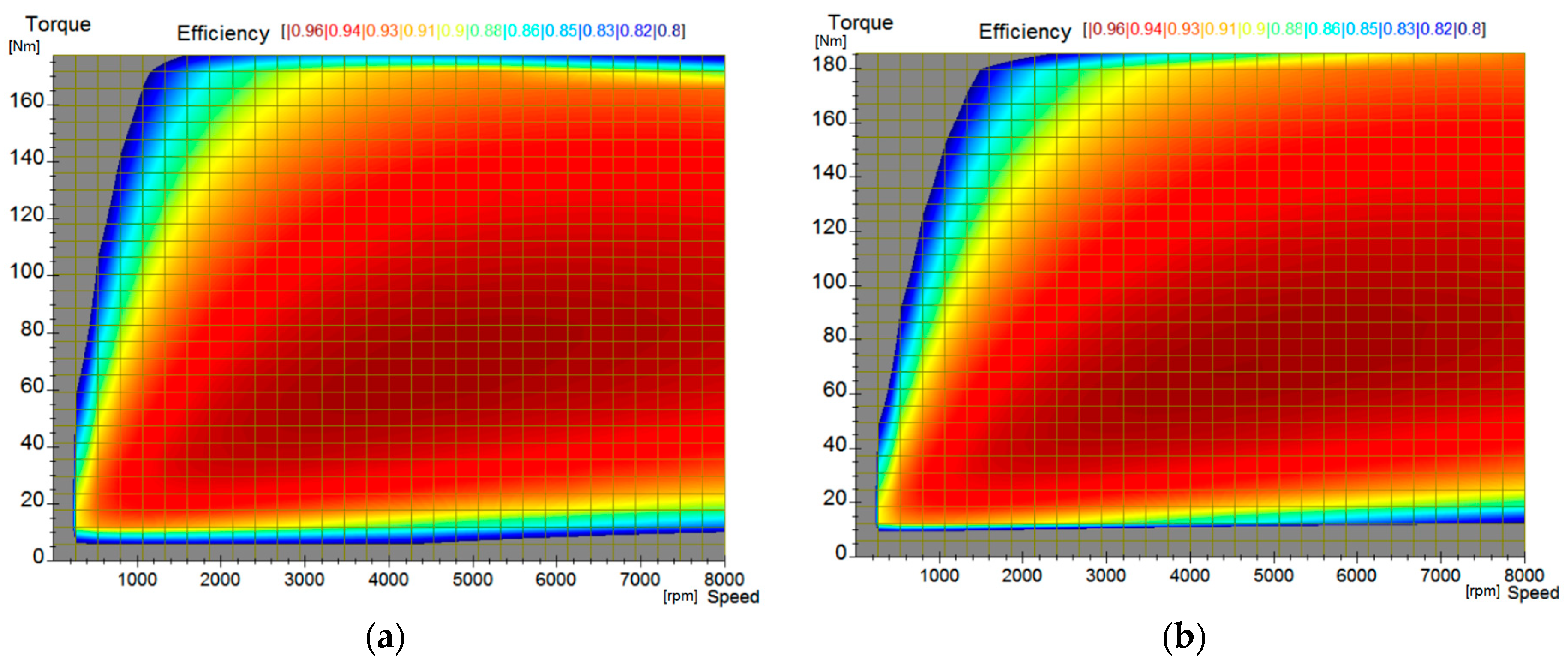

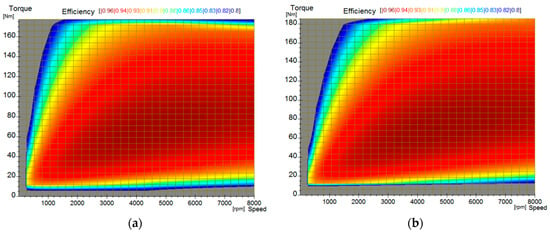

The efficiency map used for the simulation of motor/generator operation can be seen in Figure 3.

Figure 3.

Efficiency maps of e-motor in two modes: (a) motor mode; (b) generator mode [13].

The following two equations were used to simulate electric energy transformation from the battery pack during motor mode and to the battery pack during recuperation. The electric power consumption from the battery pack (in motor mode) is calculated using the following equation:

The electric power recuperation to the battery pack (in generator mode) is calculated using the following equation:

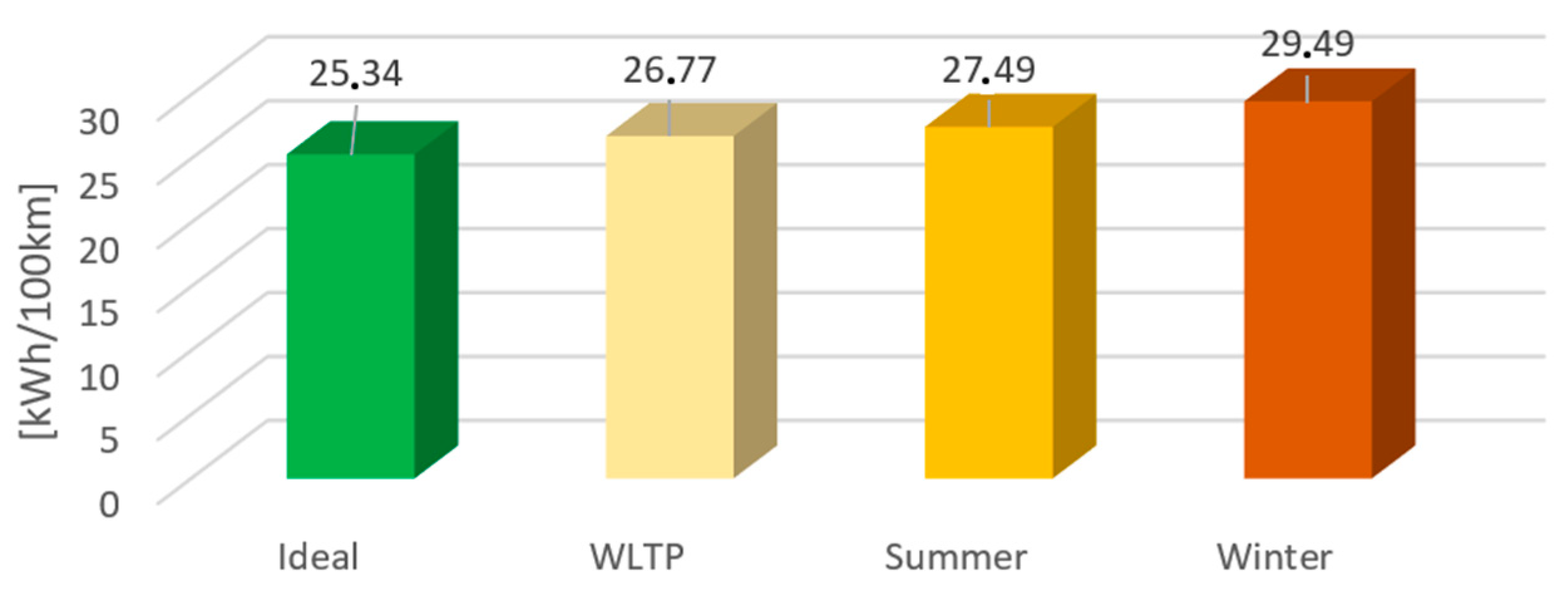

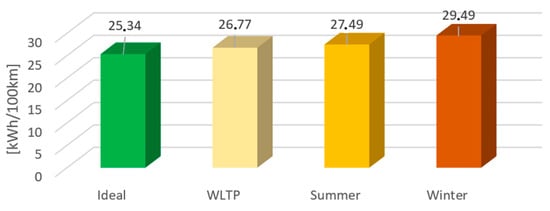

The consumption was determined for the entire cycle, and the consumption per 100 km was determined from this. The total length of the cycle was 23,266 m. This is shown in the following Figure 4.

Figure 4.

Estimation of electricity consumption under different circumstances in kWh/100 km.

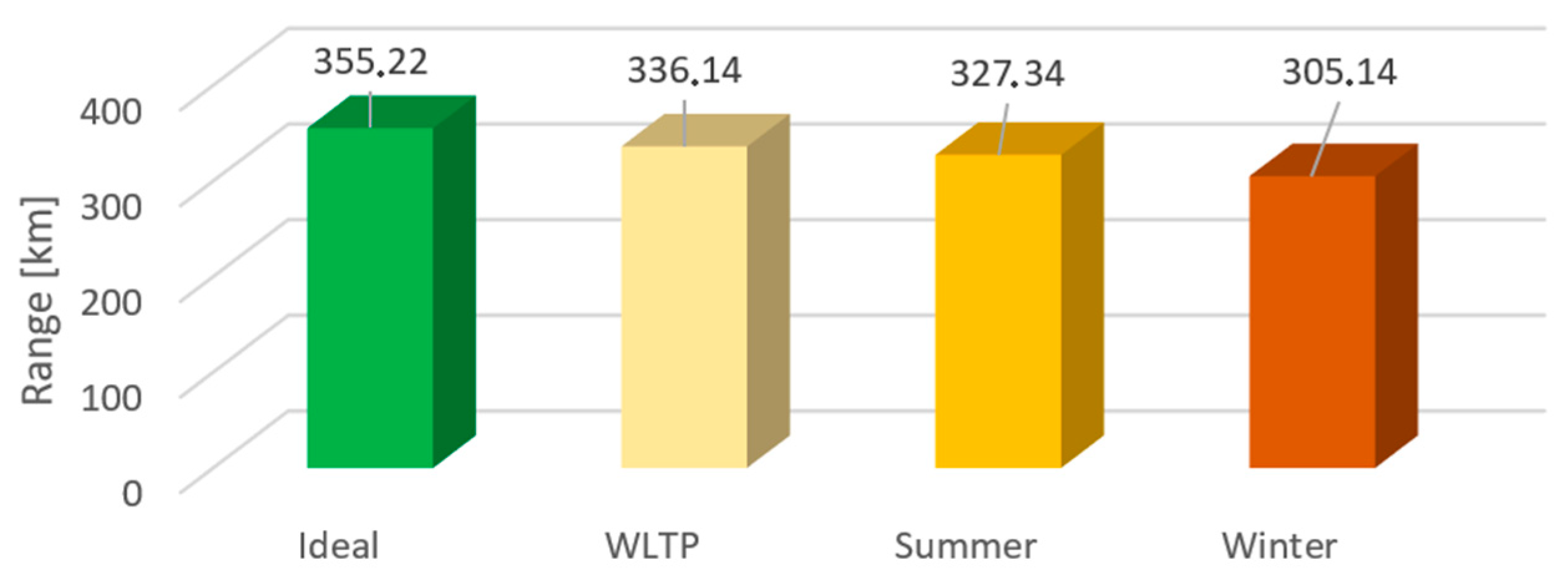

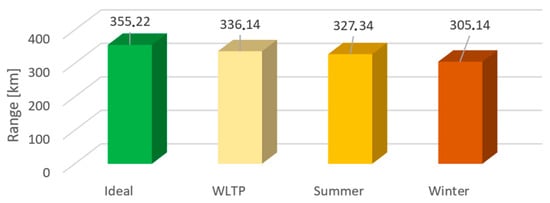

The range estimation is shown in Figure 5. The simulation was performed with a battery capacity of 100 kWh and with its SoC at 90%. The range calculated according to the WLTP cycle decreases further during summer operation and decreases further in winter when heating is required.

Figure 5.

Estimation of range in different circumstances in km.

4. Conclusions

Determining the electrical energy consumption of a vehicle is a difficult task. The instantaneous consumption is, of course, available from the vehicle control unit (ECU), which is a calculated value in most cases, but determining the average consumption in advance is difficult. After all, this depends on many things: the vehicle, driver behaviour, habits, road conditions, outside temperature, etc. That is why the so-called standard driving cycles are used, such as the WLTP cycle, which prescribes the predefined conditions for determining electrical energy consumption. Of course, a vehicle and its driver will not only use their vehicle under idealized measurement conditions, but also in winter cold and summer heat, uphill and downhill. This research aims to show that a significant difference in electrical energy consumption compared to the standard cycle conditions can be expected, typically in winter operation, where the vehicle and battery pack need to be heated. This can reach a 10% reduction in range and at the same time a specific increase in consumption of kWh/100 km relating to the WLTP.

Author Contributions

Conceptualization, P.H. and A.N.; methodology, P.H. and A.N.; formal analysis, P.H.; investigation, A.N.; writing—original draft preparation, P.H.; writing—review and editing, P.H. All authors have read and agreed to the published version of the manuscript.

Funding

This study was prepared with the professional support of the doctoral student scholarship programme of the co-operative doctoral programme of the Ministry for Innovation and Technology from the source of the national research, development and innovation fund. The research was supported by the European Union within the framework of the National Laboratory for Autonomous Systems (RRF-2.3.1-21-2022-00002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Simulation results are available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Veza, I.; Asy’ari, M.Z.; Idris, M.; Epin, V.; Fattah, I.M.R.; Spraggon, M. Electric vehicle (EV) and driving towards sustainability: Comparison between EV, HEV, PHEV, and ICE vehicles to achieve net zero emissions by 2050. Alex. Eng. J. 2023, 82, 459–467. [Google Scholar] [CrossRef]

- Nour, M.; Chaves-Ávila, J.P.; Magdy, G.; Sánchez-Miralles, Á. Review of positive and negative impacts of electric vehicles charging on electric power systems. Energy 2020, 13, 4675. [Google Scholar] [CrossRef]

- Choi, M.; Cha, J.; Song, J. Impact of lightweighting and driving conditions on electric vehicle energy consumption: In-depth analysis using real-world testing and simulation. Energy 2025, 323, 129728. [Google Scholar] [CrossRef]

- Prasad, S.L.; Gudipalli, A. An effective range estimation and state-of-charge to mitigate range anxiety in electric vehicles. Heliyon 2025, 11, e18340. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Freese, D.; Cabrera, A.; Kitch, W.A. Electric vehicles’ energy consumption measurement and estimation. Transp. Res. Part D Transp. Environ. 2015, 34, 52–67. [Google Scholar] [CrossRef]

- Burke, A.F. Batteries and ultracapacitors for electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 806–820. [Google Scholar] [CrossRef]

- Bishop, J.D.K.; Axon, C.J.; Bonilla, D.; Tran, M.; Banister, D.; McCulloch, M.D. Evaluating the impact of V2G services on the degradation of batteries in PHEV and EV. Appl. Energy. 2013, 111, 206–218. [Google Scholar] [CrossRef]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development. Energies. 2017, 10, 1217. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Nigam, P. Review on regenerative braking methodology in electric vehicle. SSRN Electron. J. 2015. [Google Scholar] [CrossRef]

- Szászi, I.; Paiss, V.; Kovács, R.C.; Horváth, C.; Vajsz, T. A new type of motor topology for reducing the torque ripples in synchronous reluctance motor drives of electric vehicles. In Proceedings of the 3rd Cognitive Mobility Conference (COGMOB 2024), Győr, Hungary, 10–12 April 2024; pp. 528–540. [Google Scholar]

- Nyerges, Á.; Zöldy, M. Longitudinal vehicle model development for range estimation in electric vehicles. Tech. Rev. Elektrotech. Mérést. 2019, 74, 13–22. [Google Scholar]

- GVM310 Global Vehicle Motor. Catalogue Parker GVM Global Vehicle Motor; Parker Hannifin Corporation: Cleveland, OH, USA, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).