Abstract

The exponential growth in artificial intelligence (AI) and automation technologies is changing industries, creating a niche for a digitally competent workforce. Technical and vocational education (TVET) and training institutions are at the center of this transformational wave, with their role of equipping individuals with the competencies required for the digital era. The integration of AI and automation into the TVET curriculum and practice was explored as a game-changer for vocational education and training. AI-powered tools are used for personalized learning, intelligent tutoring systems, and virtual simulation of hands-on skills acquisition. The challenges and opportunities in using the technologies were explored to mitigate the digital divide, update instructor capabilities, and ensure inclusive access to modern training resources. Based on the results, TVET institutions can educate students, aligning with the need for Industry 4.0/5.0. Strategic frameworks for policy, curriculum design, and industry partnerships must be established to ensure that TVET continues to play a pivotal role in sustainable and equitable digital transformation.

1. Introduction

The emergence of artificial intelligence (AI) and automation is reshaping industries across the globe, creating an urgent demand for workforces equipped with digital and technical skills [1]. In this dynamic environment, technical and vocational education and training (TVET) institutions are uniquely positioned to bridge the skills gap by delivering industry-relevant training and fostering lifelong learning [2]. In this study, the transformative role of AI and automation in TVET was explored to demonstrate how these technologies enhance the quality and accessibility of vocational education.

AI-driven tools such as adaptive learning platforms and intelligent tutoring systems enable education to meet individual learning requirements, thus enabling TVET to effectively train students [3]. Automation technologies such as robotics and process control provide ample opportunities for hands-on training even in simulated environments. Figure 1 shows the vocational students operating automated machinery. With the development of advanced technologies, integration within TVET presents challenges such as the digital divide, inadequately trained instructors, and a lack of industry alignment. These challenges also provide opportunities in curriculum redesign, innovation, and inclusivity [4]. TVET institutions must adapt to stay relevant in a rapidly evolving technological landscape. This requires collaboration with industries, policymakers, and technology providers to create dynamic ecosystems for skill development [5].

Figure 1.

Integration of AI tools into TVET (AI-driven virtual classrooms and robotics labs).

Table 1 highlights how AI-enabled TVET addresses the limitations of traditional approaches by improving flexibility, relevance, and efficiency. It ensures that learners are better equipped to adapt to the demands of modern workplaces, particularly in industries undergoing rapid technological transformation.

Table 1.

Comparison of traditional and AI-enabled TVET.

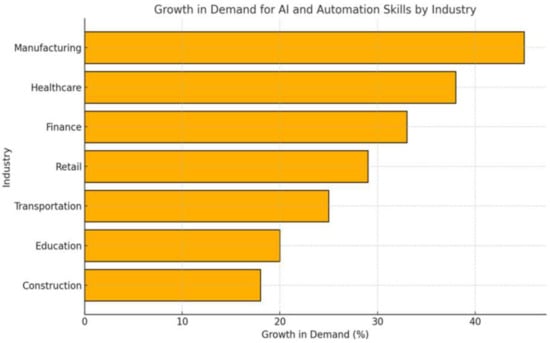

Figure 2 represents the growth in demand for AI and automation skills across industries. The graph highlights the sectors where automation and AI are being adopted most rapidly, showcasing the need for a workforce equipped with these skills [6]. Manufacturing shows 45% growth in skill demand, due to high adoption of robotics, AI-driven quality control, and automated production lines. Industries like automotive and electronics lead in leveraging automation for efficiency and precision.

Figure 2.

Growth in demand for AI and automation skills by industry.

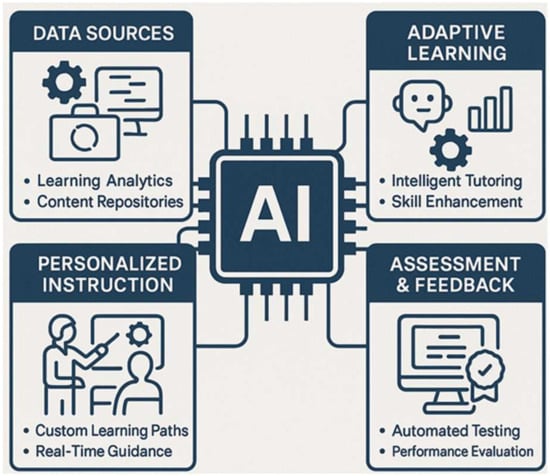

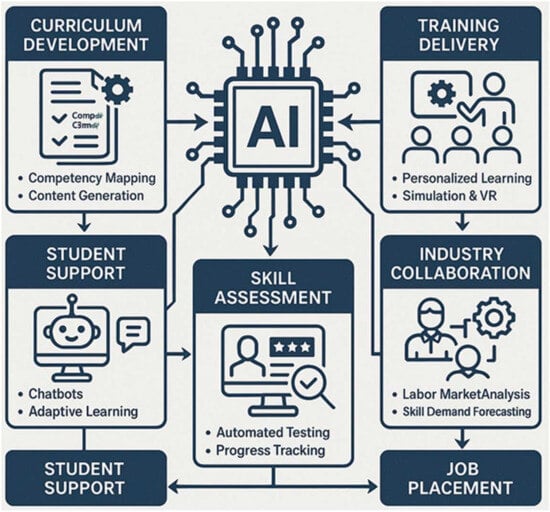

The AI-powered training ecosystem integrates multiple components to create a dynamic, interactive learning environment that enhances training outcomes [5]. Figure 3 presents how AI-driven tools, industry collaboration, and student feedback systems work together to support personalized learning, curriculum alignment, and continuous improvement. Studies of TVET institutions integrating AI indicated a 20% improvement in student engagement and a 15% reduction in training costs through automation and personalized learning systems [7]. Students trained with AI-powered tools showed a 30% higher employment rate in AI-driven industries compared with those trained using traditional methods [5].

Figure 3.

AI-powered training ecosystem.

2. Literature Review

The concept of integrating AI and automation into education dates back to the mid-20th century, when the first computer-assisted instruction systems, such as programmed logic for automated teaching operations (PLATO), were developed in the 1960s [7]. These systems formed the basis for personalized learning by adapting content according to user inputs. By the 1990s, a stream of educational software had become available, and by the 2010s, AI-powered platforms such as adaptive learning systems and virtual assistants started to be adopted [5].

Automation has influenced industrial training in vocational training at the advent of Industry 3.0 during the 1970s and 1980s, using programmable logic controllers and industrial robots [7]. In Industry 4.0 in the 2010s, AI-driven tools such as robotic process automation (RPA) and machine learning (ML) transformed hands-on training in robotics, mechatronics, and other technical areas [8]. TVET acquired manual and practical skills traditionally. However, with the emergence of Industry 4.0 and 5.0, there is increased interest in the need to equip students with digital competencies. Previous studies also identified the integration of AI into the TVET curriculum as a game-changer.

McKinsey’s 2022 report [9] illustrated how AI-powered platforms facilitated personalized learning pathways, enabling students to progress at their own paces. According to UNESCO [2], immersive technologies such as virtual reality (VR) and augmented reality (AR) enhance students’ industrial skills in a simulated environment with minimal risks [6]. The World Economic Forum highlighted benefits such as improved learning outcomes and personalized skill acquisition. Based on cost efficiency, automation reduces dependence on physical resources. Despite the benefits, challenges persist, including a lack of trained instructors, limited access to technology in low-income regions, and the need for substantial initial investments [10].

Traditional TVET applies standardized content and paces, which do not meet the needs of individual learners (Table 2). AI-driven TVET adopts adaptive technologies in learning, which modify content based on the progress of a student, their strengths, and areas that need improvement.

Table 2.

Comparison of traditional and AI-driven TVET.

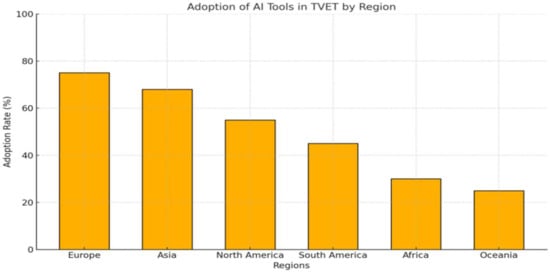

Figure 4 illustrates the adoption rates of AI tools in TVET institutions across various global regions. The data highlights disparities in adoption, with Europe and Asia leading in implementing AI-driven solutions. Europe shows a 75% adoption rate, driven by substantial investment in education technology and partnerships between governments and industries. Examples include AI-powered learning platforms, VR/AR simulations, and industry-aligned curricula [6]. Asia presents a 68% adoption rate due to its focus on digital transformation and skill development in emerging markets such as India and China [3]. Rapid industrial growth in the region necessitates skilled workforces trained with cutting-edge tools.

Figure 4.

Adoption of AI tools in TVET.

AI integration into the dual education system in mechatronics training has increased by 30% in the employment rate of graduates majoring in robotics in Germany [8]. The implementation of AI tutoring systems in TVET institutions in Southeast Asia reduced dropout rates by 20%. Introduction of AR-based learning modules in African TVET centers experienced a 35% boost in technical skill accuracy. AI and automation are not merely supplementary tools but transformative forces reshaping the landscape of TVET. By addressing implementation challenges and fostering international collaboration, TVET plays a pivotal role in preparing a digitally skilled workforce [10].

3. Methodology

The integration of AI and automation into TVET programs and its implications were analyzed in this study for skill acquisition and workforce readiness. The methodology included qualitative and quantitative research methods. Research design targeted case studies, policy reviews, and industry reports, which were reviewed to understand the level of AI integration and automation in TVET globally. The survey responses from TVET institutions, instructors, and students were analyzed to assess learning outcomes, adoption rates, and readiness in the industry. Sources included peer-reviewed articles, government reports, and publications from UNESCO, ILO, and the World Economic Forum [2]. Global and regional examples of the dual system in Germany and the SkillFuture initiative in Singapore were explored. Thirty educators and policymakers were interviewed in this study.

Kirkpatrick’s four levels of training evaluation were used to assess learning outcomes, engagement, and industry impact. AI-driven survey analysis platforms and data visualization tools were compared using a graphical representation to compare the outcomes of traditional TVET and AI-driven initiatives programs. Regression and correlation analyses were conducted to identify trends and outcomes.

Germany’s dual education system integrates on-the-job training with classroom learning. AI and automation technologies have been introduced to align with Industry 4.0 demands, particularly in robotics, automotive, and manufacturing [8]. Adaptive learning platforms for theoretical knowledge and robotics labs for practical training in industrial automation were included in the analysis [8]. VR and AR simulations were conducted for hazardous tasks. The collaborations and partnerships with companies, including Siemens and Bosch, enabled the development of AI curricula. Students trained in AI tools demonstrated a 35% higher proficiency in programming robotic systems than those in traditional settings [8]. A 20% increase in job placement rates was observed within 6 months of graduation. The cost efficiency and training costs were reduced by 15% due to the use of virtual simulations. Figure 5 shows components such as virtual classrooms, robotics labs, and industry partnerships interconnected within the AI-driven TVET ecosystem [8].

Figure 5.

AI-driven TVET ecosystem.

AI-driven TVET significantly outperforms traditional methods in terms of proficiency, engagement, and scalability (Table 3). The use of digital tools and real-time data ensures alignment with industry demands, increasing job placement rates and reducing costs. While traditional TVET has been effective for specific areas, its limitations highlight the need for transformation in Industry 4.0 and 5.0. The integration of AI and automation in TVET is revolutionizing vocational training, ensuring students are prepared for Industry 4.0 and beyond. The German case study exemplifies the potential of AI-driven tools to enhance learning outcomes, job readiness, and cost efficiency.

Table 3.

Comparison of traditional and AI-driven TVET outcomes.

4. Challenges and Limitations

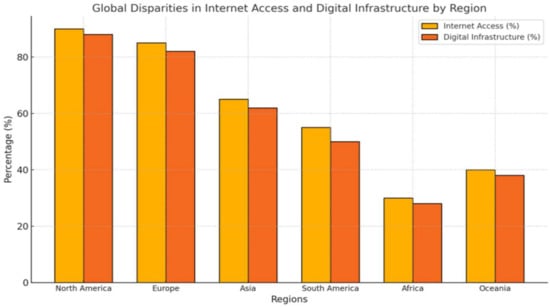

Despite the potential of AI and automation to revolutionize TVET, challenges and limitations hinder their effective implementation [10,11,12]. These issues are critical to address to ensure equitable and sustainable adoption. Limited access to digital tools and the Internet in rural and underdeveloped regions restricts the ability of students and institutions to adopt AI-driven solutions [13]. Inequalities in school hinder skill acquisition and job readiness, especially in low-income areas. Figure 6 shows global disparities in Internet access and digital infrastructure by region. Investments in the Internet and infrastructure are critical for equitable access to digital education tools globally. AI and automation systems require substantial upfront investment in hardware, software, and instructor training (Figure 6). Many TVET institutions, especially in developing countries, struggle to secure funding for implementation.

Figure 6.

Global disparities in internet access and digital infrastructure by region.

Many instructors lack the necessary skills and confidence to integrate AI and automation tools into their teaching practices, which slows down adoption and reduces the effectiveness of technology-driven training programs. Instructors and students might be resistant to adopting new technologies due to a lack of familiarity or fear of obsolescence. This leads to the underutilization of AI and automation tools. The use of AI in education raises questions about data privacy, algorithmic bias, and accountability. This undermines trust in AI-driven systems if not adequately addressed. Current AI systems are capable of handling structured tasks but struggle with complex, creative, or interdisciplinary problem-solving. This limits the ability to teach skillsets required in modern industries. AI-driven TVET programs often lack aligning their curricula with rapidly evolving industry demands, causing a mismatch between graduate skills and job market needs.

AI adoption in TVET is concentrated in high-income regions, exacerbating global skill gaps [9,14,15]. Programs with AI improve learning outcomes, but lack scalability. Governments and private entities must invest in digital infrastructure and subsidize AI tools for underserved regions [16]. Encourage partnerships with technology providers to reduce costs by using shared platforms and open-source AI tools. Therefore, it is necessary to launch nationwide training initiatives to upskill educators in AI and automation technologies [17].

5. Conclusions

The integration of AI and automation into TVET holds the potential for transformation in the preparation of workforces to meet the demands of Industry 4.0 and beyond. With AI-driven tools, virtual classrooms, and robotics labs, TVET institutions can offer personalized, scalable, and industry-relevant training [13]. However, such implementations face challenges including high costs, the digital divide, and the need for instructor upskilling [10]. AI-powered systems improve engagement and retention through personalized learning pathways and real-time feedback [5]. Virtual simulations and robotics labs provide possibilities for hands-on practice in safe and cost-effective environments. In addition, digital tools remove geographical barriers to education that characterize remote and underserved regions. Collaboration with industries ensures alignment of the curriculum with the latest workforce demands to equip students with future-ready skills.

High initial costs and inadequate infrastructure limit AI adoption, particularly in low-income countries. Many educators require significant upskilling to effectively use AI-driven tools. Resistance to change further slows adoption, and issues surrounding data security and algorithmic bias must be addressed to build trust in AI systems [13]. Strategic methods are necessary to realize the potential of AI and automation for TVET. Governments and organizations must invest to ensure access to AI tools in all regions. Partnerships with technology providers and open-source solutions reduce the cost of implementation for institutions. Training programs and professional development courses are vital in helping educators to effectively use AI. The clarity and transparency of AI policies are required to minimize bias and enhance information security. AI and its role in automation assist TVET in conceptualizing, providing, and evaluating vocational training [13]. The benefits outweigh the limitations, provided that governments, industries, and educational institutions cooperate to create an enabling ecosystem [10]. If these barriers are lowered, TVET plays a more important role in developing a resilient, skilled, and future-ready global workforce.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that supports the findings of this study are available upon request.

Acknowledgments

During the preparation of this manuscript/study, the author used ChatGPT 4o for the purposes of generating images. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- UNESCO. The Future of TVET in a Digital World: Preparing for Industry 4.0; United Nations Educational, Scientific and Cultural Organization: Paris, France, 2022. [Google Scholar]

- International Labour Organization. Skills for Digital Transformation; ILO Report; International Labour Organization: Geneva, Switzerland, 2022; Available online: https://www.ilo.org/skills-digital-transformation (accessed on 31 July 2025).

- Peterson, A.C.; Miller, M.L. Artificial intelligence in education: Current applications and potential benefits. IEEE Trans. Learn. Technol. 2022, 14, 180–194. [Google Scholar]

- Lin, M.P.C.; Liu, A.L.; Poitras, E.; Chang, M.; Chang, D.H. An Exploratory Study on the Efficacy and Inclusivity of AI Technologies in Diverse Learning Environments. Sustainability 2024, 16, 8992. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Lee, J.H. Virtual reality-based simulations for TVET: Enhancing skills acquisition in Industry 4.0. IEEE Access 2023, 11, 12520–12532. [Google Scholar]

- World Economic Forum. The Future of Jobs Report: Implications of Automation and AI for Workforce Development; World Economic Forum: Geneva, Switzerland, 2023; Available online: https://reports.weforum.org/docs/WEF_Future_of_Jobs_Report_2025.pdf (accessed on 31 July 2025).

- Zhou, T.; Lam, H.K.; Pillai, R.V.K. Integrating robotics into TVET programs: Case studies and recommendations. IEEE Robot. Autom. Mag. 2023, 29, 56–64. [Google Scholar]

- QuantumBlack By McKinsey, The State of AI in 2022—And a Half Decade in Review. December 2022. Available online: https://www.mckinsey.com/capabilities/quantumblack/our-insights/the-state-of-ai-in-2022-and-a-half-decade-in-review (accessed on 31 July 2025).

- Davar, N.F.; Dewan, M.A.A.; Zhang, X. AI Chatbots in Education: Challenges and Opportunities. Information 2025, 16, 235. [Google Scholar] [CrossRef]

- Leong, W.Y. Enhancing Academic Integrity in E-Exams Through AI-Driven Proctoring Technologies. In Proceedings of the 14th International Conference on Educational and Information Technology (ICEIT 2025), Guangzhou, China, 14–16 March 2025. [Google Scholar]

- Leong, W.Y.; Zhang, J.B. Revolution in University Ranking System. ASM Sci. J. 2024, 19, 1–9. [Google Scholar] [CrossRef]

- OECD. AI and the Future of Education: Ensuring Equity and Quality; Organization for Economic Co-Operation and Development: Paris, France, 2022; Available online: https://www.oecd.org/en/blogs/2025/04/ensuring-equitable-ai-the-role-of-education.html (accessed on 31 July 2025).

- Leong, W.Y. Fostering Creative Thinking Through Immersive Virtual Reality Environments in Education. Educ. Innov. Emerg. Technol. 2024, 4, 8–25. [Google Scholar]

- Gheyssens, E.; Consuegra, E.; Engels, N.; Struyven, K. Creating inclusive classrooms in primary and secondary schools: From noticing to differentiated practices. Teach. Teach. Educ. 2021, 100, 103210. [Google Scholar] [CrossRef]

- Ramdas, S.; Slootman, M.; van der Zee, K. Creating equitable learning environments by building on differences in higher education: Design and implementation of the MIXED model. Learn. Environ. Res. 2025, 1–16. [Google Scholar] [CrossRef]

- Pannullo, L.; Böttinger, T.; Winkelmann, J. Inclusive and Digital Science Education—A Theoretical Framework for Lesson Planning. Educ. Sci. 2025, 15, 148. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).