Abstract

Fibre Bragg grating (FBG) grid sensors are an underexplored technology with potential to benefit nuclear thermal hydraulics experiments. This paper presents a new FBG grid sensor consisting of 38 FBGs across 8 flow-crossing chords. Using this sensor, experiments determined for the first time that an FBG grid can detect large air bubbles rising in standing liquids—demonstrated in both columns of water and 20W50 automotive oil. The instrument’s sensitivity was quantified by comparing its measurements to high-speed camera recordings. Analysis of Bragg wavelength shift timings on each chord enabled the surface of a bubble to be reconstructed using the air–oil data. Finally, the increase in Bragg wavelength when bubbles interact with the FBG grid suggests a variant sensing principle different from that reported in the literature for FBG grids in flowing liquids.

1. Introduction

Since the 1970s, pressurised water reactors (PWRs) and boiling water reactors (BWRs) have become the two most common types of nuclear reactor in operation across the globe [1]. While the exact implementation of these operating principles varies between reactors designs, all PWRs and BWRs are both cooled and moderated by light water. Therefore, understanding the thermal hydraulic behavior of water, along with related phenomenon and coupled neutronics, is essential to the design and safe operation of nuclear power stations.

Resultantly, to better understand the thermal hydraulics of water under reactor conditions, many multiphase flow imaging instruments have been developed since the start of the nuclear industry. Examples of these established flow imaging techniques include particle image velocimetry (PIV) [2], ultrasonic imaging [3], wire mesh sensors (WMS) [4], gamma ray densitometry [5], arrays of hot-wire anemometers [6] and needle probe sensors [7]—as well as other technologies. However, each of these flow imaging techniques has limitations that restricts the experimental scenarios where they can be practically applied, especially for reactor prototypic experimental conditions. This necessitates further research to developed new and robust flow imaging instrumentation that expands flow imaging capabilities beyond what is possible with existing technology.

Of particular interest for the study of multiphase flows are grids of fibre Bragg gratings (FBG). This under-researched instrumentation technique shows great potential for further development to support the study of multiphase flows. Primarily, because of the high temperature, pressure, and corrosion-resistant properties of FBGs. The use of FBG grids to measure void fraction [8], and reconstruct the profiles of large bubbles [9], has already been demonstrated in the literature. However, it has yet to be demonstrated if FBG grids can detect bubbles rising in a standing liquid. This remains an open question because the sensing principle used to detect bubbles in a flowing liquid relies on the reduction in force exerted on the grid when a bubble passes through the sensor. This relative decrease in force would not be present if the liquid phase is stagnant. This leaves open the question of whether an FBG grid would be able to detect a bubble engulfing the sensor, without an initial flow-strained condition to compare against it. The research presented in this paper endeavours to answer this question, with the ambition to demonstrate, as a proof-of-concept, a new scenario where FBG grids sensors can be utilised.

Currently, there is no published example of an FBG grid being used to study rising bubbles in any scenario. Therefore, this paper’s contribution to the literature is to present and evaluate if FBG grids can detect and dimension bubbles in these conditions. Identifying new potential capabilities and limitations of this instrumentation technique, such as for use in pool boiling studies.

2. Background Theory

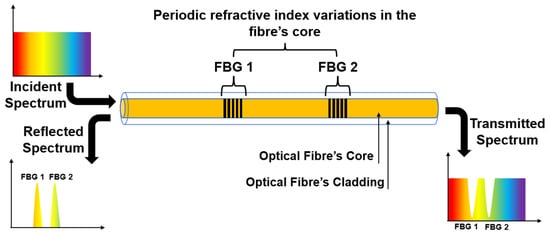

FBG grid sensors are instruments constructed from arrays of FBGs, created on optical fibres, that are concertinaed into a grid structure [10,11]. An FBG, which is a type of distributed Bragg reflector, consists of a region of periodic refractive index variation in the core of an optical fibre [12,13]. When an electromagnetic wave, typically visible or infrared light, passes through the optical fibre and interacts with an FBG, parts of the incident spectrum will be selectively transmitted or reflected, with the peak wavelength of the reflected spectra centred on the Bragg wavelength of the FBG [12,14]—as shown in Figure 1.

Figure 1.

Impact of two wavelength-division multiplexed FBGs on a spectrum in optical fibre.

An FBG’s Bragg wavelength is determined by both the FBG’s effective refractive index and its grating period; this being the distance between the periodic refractive index variations along the fibre, as shown in Equation (1) [12].

where is the Bragg wavelength (m), is the effective refractive index of the Bragg grating (dimensionless), and is the grating pitch (m).

If the temperature or strain on an FBG increases, its properties change, shifting the Bragg wavelength of the FBG. By measuring this shift in Bragg wavelength, as the temperature or strain imposed on an FBG is varied, FBG based temperature [15,16] and strain [17] sensors can be produced. Because FBGs are sensitive to both temperature and strain, the challenge of cross-sensitivity must be addressed to deconvolute changes in Bragg wavelength from thermal processes, from those from strain processes. Nevertheless, several techniques have been developed to successfully mitigate cross-sensitivity effects, including comparison to a reference FBG [18], machine learning algorithms [19], and fibre coatings to vary thermo-optic or photo-elastic coefficients [20,21].

Furthermore, FBGs have been widely utilised to develop instruments to measure properties other than temperature and strain, including pressure [22], flow rate [23,24], speed of sound [25], chemical concentration [26], and void fraction [8]. For invasive void fraction measurement, consider an FBG inserted perpendicularly to a two-phase flow. Each phase will impart a different hydrodynamic force on the fibre depending on the flow velocity and density of the phase, with the denser liquid phases inducing larger shifts than the gas phase. By analysing these shifts over time, the time-averaged void fraction can be estimated [8].

By applying the sensing principle demonstrated for void fraction measurement using a single fibre, to a grid of FBGs on multiple flow-crossing chords, a spatial dimension can be added to the data, enabling the determination of what parts of a given fluid cross-section are liquid and which are gas. By analysing this two dimensional cross-section over time, it is possible to create 3D plots (with one temporal and two spatial dimensions) of phase structures, i.e., bubbles, as they pass through an FBG grid. However, only Zamarreño et al. [9,10,27] have explored this functionality of FBG grid sensors. Therefore, given the proven high-temperature, pressure, and corrosion resistance of FBG-based devices [28,29,30], FBG grid sensors are ripe for future development, with potential to benefit thermal hydraulics research.

3. Experimental

3.1. Sensor Design

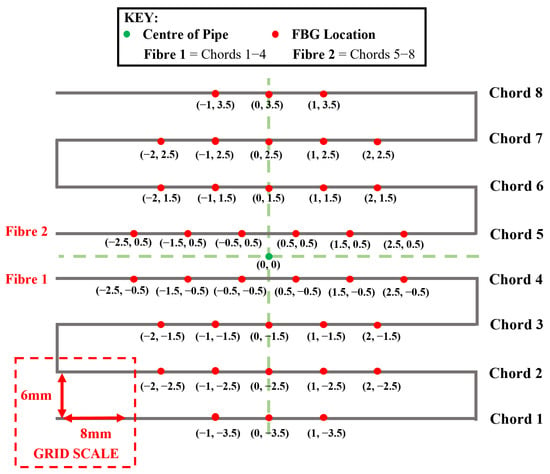

An FBG grid sensor has been designed that consists of two polymide-coated FBG arrays, each with 19 FBGs multiplexed upon them, with Bragg wavelengths ranging from 1527 nm to 1563 nm in 2 nm steps. An aluminium mounting gasket was manufactured, with the help of engineering staff and students at Coleg Menai, to secure the two FBG arrays into a concertinaed grid structure that can be mounted between DN50 flanges (Georg Fischer Piping Systems Ltd, Schaffhausen, Switzerland). Throughout this paper, the parts of the FBG grid’s optical fibres that pass through the fluid domain will be referred to as a chord. The nominal position of each FBG on the grid is shown in Figure 2, with each FBG along a chord being spaced apart by 8 mm, and each chord separated by 6 mm. The outer-most chords of the sensor are located equidistant from the edges of the mounting gasket so that the sensor is centred in the middle of the pipe.

Figure 2.

The nominal layout of the FBG grid sensor investigated during these experiments.

When securing the FBG arrays into the aluminium mounting gasket, the optical fibres were pretensioned using a 10 g hanging mass attached to the end of the fibre with strong double sided tape. Whilst under tension, the fibres were then affixed in place using a cyanoacrylate superglue (Loctite 401, Henkel, Düsseldorf, Germany). This adhesive was chosen for its low volume change during curing, and strength retention up to 120 °C, ensuring the fibre is minimally compressed during curing, and that it will remain secured in future high temperature experiments. The successful use of this adhesive to mount polyimide-coated optical fibres has also been previously reported in the literature [31]. After the cyanoacrylate superglue had fully cured, the remaining space around the channel cut for the optical fibres in the mounting gasket was then sealed using a neutral-curing silicone sealant (Silirub HT°N, Soudal, Turnhout, Belgium). This sealant was selected for its neutral curing properties, and high temperature resistance (up to 280 °C), ensuring water-tight mounting of the optical fibres, and preventing potential fibre coating damage from the acetic acid that is produced during the curing of more standard silicone sealants.

Both FBG arrays were interrogated by separate I-MON 256 USB interrogators (Ibsen Photonics, Farum, Denmark) using DL-BP1-150A general-purpose light sources (DenseLight Semiconductors Pte. Ltd., Singapore). This light source is a broadband superluminescent diode (SLD) with a central wavelength of 1550 nm, and a spectral width of 70 nm.

Unlike the FBG grid sensor design investigated by C. R. Zamarreño et al. [9,10,27], the grid sensor design presented in this paper consists of a single plane of FBG arrays crossing the fluid domain. This design decision was made to investigate if the sensor design of C. R. Zamarreño et al. can be improved upon by creating an instrument that is less invasive into the fluid domain, yet is capable of producing higher resolution data of phase structures that interact with the sensor. This was hypothesised because in steam-water flows, there can be a significant temperature difference between the phases, which may enable an approach to phase determination by analysing the effect of temperature-induced Bragg wavelength shifts, thus achieving greater resolution through the utilisation of more FBGs within the fluid domain, despite a smaller number of penetrations. This hypothesis is not explored in this work, but is the focus of ongoing experimental research to practically validate this design under steam-water flow conditions using the same FBG grid presented in this paper.

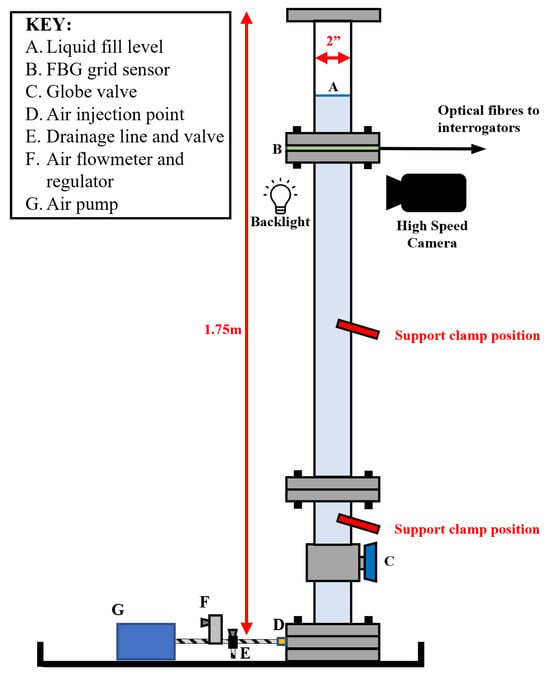

3.2. Liquid Column Instrumentation Rig

To characterise the response of this FBG grid sensor to bubbles rising in a stagnant liquid, the liquid column instrumentation rig (LCIR) was built. This rig consists of 2” diameter transparent test sections, assembled to a height of 1.75 m using flange connections, and filled with liquid to approximately 0.15 m below the maximum height of the column. The FBG grid sensor is then installed between the middle and upper sections of the LCIR, as shown in Figure 3. The lower section of the LCIR includes a globe valve which, when closed, prevents liquid drainage when re-configuring the air injection lines.

Figure 3.

Schematic of the liquid column instrumentation rig (LCIR) utilised in these experiments.

3.3. Methods

As shown in Figure 3, the FBG grid sensor was installed between the flange faces connecting the upper two transparent sections of the LCIR. The two optical fibres of the FBG grid sensor were then each connected to an SLD light source and an interrogator (optical analyser). Next, the LCIR was filled with deionised water until it was approximately 0.15 m below the top of the rig. After this, a Phantom 640 L (Vision Research Inc., Wayne, NJ, USA) high-speed camera with a Nikon (Nikon Corporation, Tokyo, Japan) 24–85 mm F/2.8-4D lens, was setup adjacent to the LCIR and aligned to record the propagation of bubbles immediately before the bubbles reached the FBG grid sensor. This allows for the data produced from the FBG grid to be compared to high resolution videos of the bubbles producing the responses from the sensor. Enabling a comparative assessment of the sensor’s ability to accurately and precisely detect or dimension air bubbles that pass through it. Behind the LCIR, a spotlight (Nanlite, Shantou, China) was setup to provide backlighting for the high-speed camera’s recordings to improve the clarity of the bubbles imaged, particularly for the air–oil experiments.

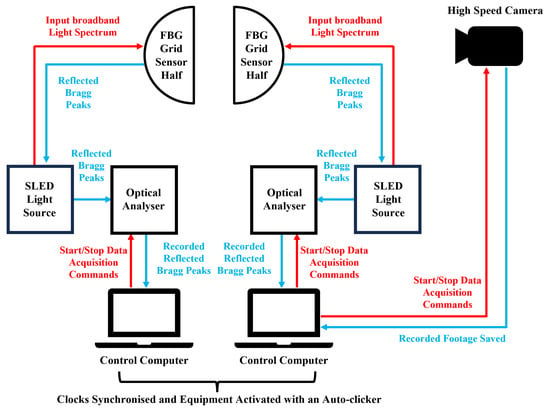

After this equipment had been setup and the LCIR filled with water, the SLD lights sources were turned on and the data acquisition software of both the Phantom high-speed camera and the Ibsen Photonics I-MON 256 USB interrogators was simultaneously triggered using a synchronised auto-clicker macro on both the control computers. The control and data transfer routes of this experimental setup are shown in Figure 4. The air injection pump was then turned on and air was injected into the LCIR at 2 ± 1 L/min through an air flow regulator. After 60 s had passed, all data acquisition was stopped and the produced data saved. For these experiments, both the high-speed camera and FBG interrogators were set to have a sample rate of 1000 Hz with a 500 s exposure. The experiment was then reset by waiting for all the bubbles remaining in the LCIR to rise and leave the liquid, before repeating this experiment two more times, producing three sets of high-speed camera images and synchronised FBG interrogation data. The LCIR was then drained and refilled with a 20W50 automotive oil (Halfords plc., Redditch, UK), and the above described experiment was then repeated three times for this new air–oil system.

Figure 4.

Schematic of the experimental setup, showing control and data transfer routes.

Each frame from the high-speed camera is saved with a time stamp, and the sample times of the optical analyser are inferred from the sample rate, but with reference to a time stamp for the first data point, allowing the data produced from the FBG grid to be synchronised to the corresponding frames of the high-speed camera’s recording. This enables a detailed analysis of the causes of different Bragg wavelength shifts displayed in the FBG grid sensor’s data. To ensure the use of an auto-clicker provided accurate synchronisation between the optical analysers and the high-speed camera data, for each trial, the absolute time stamps at the start of each data recording were compared. This led to the identification of an approximately 0.5 s delay between the start of the optical analyser data capture, and the start of the high-speed camera recordings. Further investigation identified this discrepancy arose from a combination of a processing delay from the auto-clicker’s sequential execution of commands, and the time required by the high-speed camera to clear its internal memory. Therefore, to rectify this issue, the absolute time stamp from the high-speed camera recording’s first frame was used to align the two data sets. To prevent this in future work, a new trigger system will be developed to remove this delay.

4. Results and Discussion

4.1. General Analysis

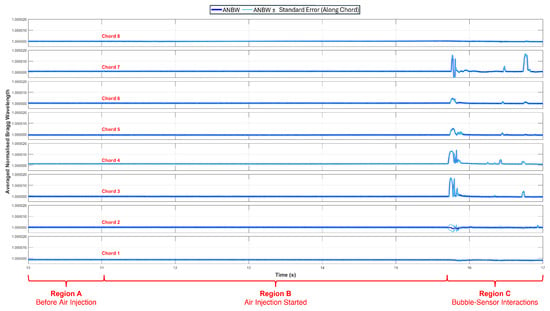

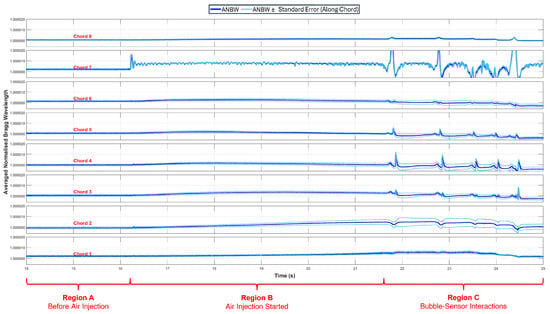

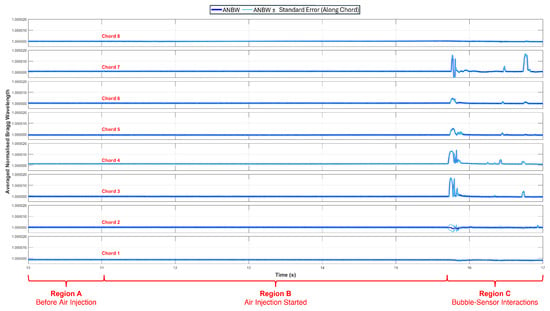

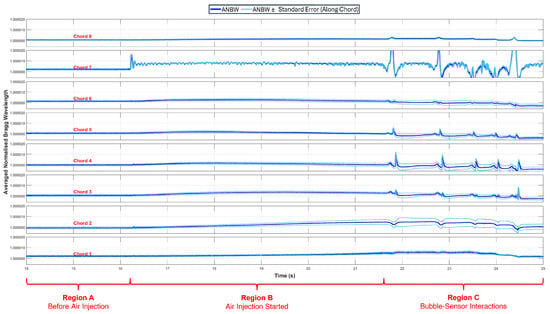

To reiterate, the parts of the FBG grid’s optical fibres that pass through the fluid domain will be referred to as a chord. Figure 5 and Figure 6 show the average normalised Bragg wavelength (ANBW) shifts for the water and oil experiments, respectively. These values are produced by calculating the mean average of all the normalised Bragg wavelength shifts of each FBG along a given chord, as shown in Equation (2).

where is the average normalised Bragg wavelength along a chord, is the normalised Bragg wavelength of the xth FBG on a chord, and N is the total number of FBG along a given chord.

The light blue lines, either side of the ANBW shift line, represent the spread of normalised Bragg wavelengths used to calculate the ANBW. This was achieved by calculating the standard deviation of the normalised Bragg wavelengths of each FBG along a chord (for each time step). With this value, the ANBW, plus/minus the standard error of the values used to calculate the ANBW, is plotted. Providing an indication of the precision with which the ANBW reflects the average Bragg wavelength shift along a chord. Figure 5 and Figure 6 show data from the first of the three repeated trials for the air–water and air–oil tests, respectively. The trends and features shown in these graphs are representative of the two subsequent repeated experiments that followed them. The x-axis of Figure 5 and Figure 6 has been limited to not show time from t = 0, as before air injection, there was no shift in the ANBW values.

Despite the different viscosity liquids through which the air bubbles travelled, Figure 5 and Figure 6 share many common features—indicated on these graphs by regions A, B, and C. Firstly, before the pump is activated, there are no additional forces being imposed on the FBG grid’s optical fibres in either experiments. This is represented in Figure 5 and Figure 6 by the region of no normalised Bragg wavelength change, corresponding to the time before the air injection pump was activated—shown in region A. During this time, the FBG grid is simply sat in the static liquid with no disturbance. Thus, starting from the first data point at t = 0 s, the unstrained reference values are produced that are used to normalise the Bragg wavelength values of each FBG along a chord. This reference value is the mean average Bragg wavelegnth, of each FBG, over the first 1000 data points.

Next, in region B, a difference is seen between the response of the FBG grid in oil (Figure 6) to its response in water (Figure 5). The air–oil experiments in region B show a gradual ANBW shift, across all optical fibre chords, implying a source of strain applied across the whole FBG grid. Through analysis of the synchronised high-speed video footage, it is seen that this region corresponds to the upwards flow of liquid beginning after the air injection is started, causing the liquid level in the column to rise as the liquid is displaced by the injected air. This upwards flow will impart a hydrodynamic force against each optical fibre chord, straining the FBGs, and increasing their Bragg wavelength until the maximum upwards flow rate is achieved. After this, the ANBW plateaus on a new flow-strained value. However, this gradual ANBW shift is not observed in Figure 5’s region B. This is likely because of the different viscosities of the liquid phases in the air–water and air–oil experiments. Because water (at 15 °C) is approximately fifteen times less viscous than the 20W50 automotive oil used in these experiments, when the air injection pump is activated, the water more easily flows around the FBG grid than than the oil, thus imparting less force against the optical fibres when the air is injected, and offering a possible explanation of why no meaningful additional strain is shown in Figure 5’s region B.

After region B, region C shows a series of peaks corresponding to the times when large air bubbles interact with and pass through the FBG grid. As 60 s of data for each trail has been recorded, for ease of presentation, Figure 5 and Figure 6 have been limited to only show the first five large air bubbles that reach the sensor. Through subsequent analysis of the width, timing, and shape of these peaks, it is possible to deduce dimensional properties of the bubbles passing through the FBG grid. In the following sections, this sensing principle, and how it can be used to measure the properties of air bubbles, will be discussed.

Next, an anomalous response shown in Figure 5 and Figure 6 is the larger and more variable ANBW shifts of chord 7 compared to what its position in the fluid cross-section would suggest. This behaviour is particularly present in the air–oil data where this behaviour is consistent across all three trials. Although no definitive explanation was identified, we speculate this behaviour is caused by uneven compression of the chord between the LCIR’s flanges. This is because a torque wrench was not used to tighten the FBG grid’s mounting bolts, and from possible non-uniform application of sealant around the fibre. This is significant because this chord was located near a flange bolt hole. Supporting this interpretation, subsequent experiments conducted after replacing sealant and using a torque wrench showed no abnormal behaviour, with chord 7 responding similarly to the other chords. This suggests the unexpected response was most likely due to the installation conditions, rather than from the fluid or a fabrication defect.

Figure 5.

Air–water experiments trial 1 results: variation of the average normalised Bragg wavelength along each chord of the FBG grid.

Figure 6.

Air–oil experiments trial 1 results: variation of the average normalised Bragg wavelength along each chord of the FBG grid.

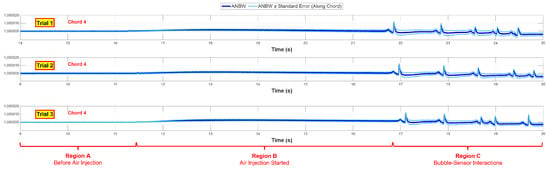

Finally, to demonstrate the cross-trial consistency of the results presented from trial 1, Figure 7 shows a comparison of the ANBW shift along chord 4 in trials 1–3 of the air–oil experiments. Just as with Figure 5 and Figure 6, Figure 7 is restricted to not show time from t = 0, but similarly shows the response of the FBG grid from just before air injection is started, until after the first five large air bubbles have passed through the sensor. Despite the difference in timings between the start of data capture and air injection between the trials, this example comparison shows the consistency of the FBG grid’s response between the repeated trails. As shown in Figure 7, each trial features the same three regions congruent with regions A, B, and C observed in Figure 5 and Figure 6. Furthermore, as will be discussed in Section 4.2, trials 1–3 show a multi-peak ANBW shift that occurs when bubbles pass through the FBG grid, supporting this later analysis of bubble–sensor interactions. This includes the multi-peak ANBW shifts being of similar magnitude, as expected from the consistent size of the bubbles produced in the air–oil experiments.

Figure 7.

Cross-trial comparison of the ANBW shift along chord 4 during trials 1–3 of the air–oil experiments.

4.2. Analysis of a Single Bubble

In the works of Zamarreño et al. [10], an FBG grid is used to study air–water multiphase flows. In these works, where both the liquid and gas phases are flowing through horizontal pipes, bubbles are detected by a decrease in the measured Bragg wavelength shift as the bubbles pass through the FBG grid. This is because, when Zamarreño et al.’s sensor is engulfed by a large air bubble, the hydrodynamic force acting against the FBG grid decreased, which also decreases the strain along each of the grid’s chords, reducing the Bragg wavelength shift. After passing through the sensor, the Bragg wavelength shift (and the strain along the grid’s chords) then returns to its initial flow-strained condition. However, in the experiments presented in this paper, clear increases in Bragg wavelength shift are observed when air bubbles interact with the FBG grid—in contrast to the results published by Zamarreño et al., implying a variant sensing principle and interaction process is present when the liquid phase is stagnant.

A common response seen in both Figure 5 and Figure 6, as well as shown in the cross-trial comparison in Figure 7, is a multi-peak ANBW shift when a large air bubble passes through the sensor. Insights into understanding the sensing principle and behaviour of an FBG grid can be gained through analysing this response. However, due to the design of the LCIR rig, and the requirement for the FBG grid sensor to be compatible with installation in other facilities in the future, it was not possible to position the high-speed camera to view the sensor as bubbles passed through it. Therefore, the following analysis of the ANBW shift is based on fluid and bubble dynamics theory, rather than direct observation. Future work will be aimed at rectifying this to attempt to corroborate this analysis.

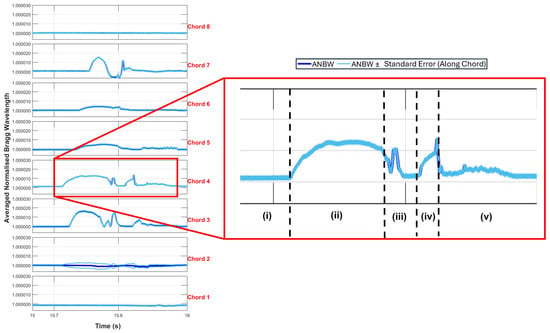

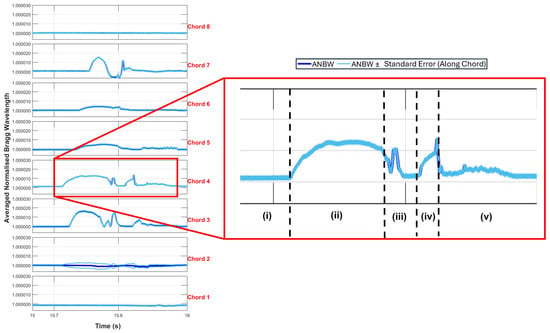

Figure 8 shows an isolated view of the ANBW shifts from Figure 5 that correspond to the first air bubble passing through the FBG grid. Given that each increase in ANBW implies an increase in strain along an FBG (see Equation (8)) the multi peak response suggests that when a bubble passes through an FBG grid, it imparts force on the optical fibres in several stages, rather than through a single action. In part (i) of Figure 8, before an air bubble reaches the FBG grid, the ANBW does not shift from its baseline or flow-strained value. Next, part (ii) occurs when the air bubble first begins to interact with the sensor, as estimated from the bubble’s velocity calculated from the high-speed camera footage. This region shows a gradually increasing ANBW shift, implying an increase in strain along the optical fibre chord. This is likely because as a large air bubble reaches the FBG grid, it will impart a force on the sensor through interactions with the bubble’s surface—and perhaps, as well, through the accelerated displaced liquid around the bubble.

Figure 8.

Magnified view of the ANBW response produced by the first air bubble from trial 1 of the air–water experiments.

After this, as the bubble continues to move upwards through the sensor, eventually its retaining surface tension effects will be overcome and it will either engulf the optical fibres, or the bubble will begin to fragment. This could explain the decrease in ANBW shown in Figure 8’s part (iii), because if there is no longer a defined surface acting against the FBG grid, then the force imparted on the sensor will be less, leading to a drop in strain along an optical fibre chord.

Following this, part (iv) shows a gradual increase in ANBW to a local maximum, before rapidly decreasing—potentially caused by the lower surface of the bubble reaching the FBG grid. This is because, after the sensor has become engulfed, the bubble will continue to rise through the FBG grid until its lower surface reaches the fibres. Here, it will begin to act against the FBG grid before passing through or fragmenting. This would impart force onto the sensor, straining the optical fibres, before quickly decreasing when the bubble has completely passed through the FBG grid.

Finally, behind the first large air bubble, there are smaller bubbles and turbulent liquid travelling upwards in its wake. These will, in turn, interact with the FBG grid as they flow through, likely causing small vibrations manifesting as fluctuating increases in strain. This can be seen in Figure 8’s part (v), where following the final large ANBW shift, for 0.6 s, the ANBW subtly oscillates before returning to a consistent baseline.

This multistage ANBW response to a large air bubble, as presented in this analysis, can also be seen in the other central chords shown in Figure 8. Additionally, throughout Figure 6 (see chords 3–5) and Figure 7, multi-peak ANBW responses that approximately follow the outline of this single bubble analysis can also be identified. However, Figure 8’s chords 1 and 8 do not show this ANBW shift, and chords 5 and 6 show a much weaker response. As will be discussed in Section 4.5, from review of the high-speed camera data, chords 1 and 8 are situated outside the outer diameter of the air bubble interacting with the sensor at this time. Therefore, the lack of response from these FBGs can be explained by the bubble’s surface not acting against these fibre chords. Conversely, the weaker response from chords 5 and 6 remains more anomalous. Given the dimensions of the large air bubble, it should have interacted with these more central fibre chords, especially given that chord 7’s FBGs experienced larger magnitude ANBW shifts. A possible explanation for this could arise from errors in the fabrication process of the FBG grid, where these chords might have inadvertently become pretensioned differently to the other parts of the sensor. Leading to the FBGs on these chords having a weaker response to the bubble-imposed strain. Alternatively, upon reaching the sensor, the air bubble may have become deformed in a manner that unequally spread its surface; but given chord 6’s weaker response in all air–oil and air–water tests, this is less likely. In either case, future research is needed to study the effects of pretensioning on the response of an FBG grid, as well as fully transparent test section studies to observe the deforming and fragmenting effects of an FBG grid on bubbles in multiphase flow. From these future works, explanations of these anomalous results might be identified. In addition, when manufacturing future FBG grids, the optical fibres could be connected to an SLD and optical analyser whilst being pretensioned, enabling quality control to ensure that all fibre chords are pretensioned equally.

4.3. Measurement Precision

The ANBW shift lines on Figure 5 and Figure 6 (dark blue), are plotted alongside lines (light blue) showing the ABNW plus/minus the standard error. As each ANBW data point is the mean average of the normalised Bragg wavelength of every FBG along a given chord (at each time step) the standard error provides a statistical measure of the similarity of each FBG’s normalised Bragg wavelength, quantifying the precision of the plotted ANBW value. In these experiments, these values should be in close agreement given the absence of major temperature induced effects and the axial isotropy of strain. This is shown in both Figure 5 and Figure 6, where the bounding standard error lines closely follow and approximate the plotted ANBW value, showing that the ANBW is a high-precision representation of the overall shift in Bragg wavelength of each FBG along a chord. Moreover, the light blue lines do not represent an inter-trial average of each chord’s normalised Bragg wavelength shift. This is because in each trial, the time between the start of data collection, and the start of air injection, as well as the volume and frequency of each bubble produced, was different. This prevented a like-for-like comparison of each data point, disallowing an inter-trial averaging of results from being representative of the observations from any trial.

This high precision was also present in trials 2 and 3. In the air–water tests, the maximum standard error in the ANBW values recorded was never above ±3.23 × and ±2.96 × , respectively. Similarly, from the air–oil experiments’ trials 2 and 3, the maximum standard error of any ANBW measurement never increased above ±4.22 × and ±4.35 × , respectively. This supports the evaluation that the ANBW measurements produced using the developed FBG grid sensor are precise and reliable.

However, it is shown in chords 2–6 of Figure 6 that, following the activation of air injection, the ANBW’s error values begin to slightly increase. Additionally, in Figure 6’s region C, after the bubbles reach the FBG grid, the standard error lines (and thus also the standard deviation) also begin to diverge more from the average, but this increase in standard error gradually reduces before the next bubble reaches the sensor. This standard error line divergence and convergence process, about the ANBW, is not present in the air–water experiments typified by Figure 5. Therefore, this could be a result of the more viscous nature of oil acting on the fibre chords, or a thermo-optic effect from a possible greater difference in phase temperatures. This latter option would produce different Bragg wavelength shifts from different FBGs along a chord. However, given that the increase in standard error, that begins before the bubbles reach the FBG grid, only occurs in the air–oil test, and given the use of polyimide-coated optical fibres (with small thermal expansion coefficients [32,33,34]), it suggests that thermo-optic effects are less likely to be the cause, leaving this observation without satisfactory explanation.

The ability to have multiple sensing points along an optical fibre chord is a major advantage of FBG grid sensors. This is because, provided that cross-sensitivity effects are accounted for through experiment design or data analysis, each FBG along a given chord of an FBG grid should independently produce the same measurement in response to a strain along the chord, enabling reliable uncertainty quantification through comparison and statistical analysis of the distribution of these values. In these experiments, because of the use of polyimide-coated optical fibres to reduce thermo-optic effects, and the near uniform temperature through the measurement cross-section, this approach to uncertainty quantification was used, providing high-accuracy measurements of the bubble-induced strain along the sensor’s optical fibres.

4.4. Bubble Detection Sensitivity

To quantify the sensitivity of this FBG grid, an analysis is undertaken to compare the number of air bubbles that passed through the sensor, to the number ANBW peaks recorded. Table 1 and Table 2 display this information for trial 1 of both the air–water and air–oil experiments, alongside estimates of the diameter and length of the bubbles passing through the FBG grid (based on measurements from the high-speed camera data). These measurements were calculated using the external pipe diameter as a reference, and using image analysis software to measure the dimensions of the rising bubbles with this scale. For both the diameter and length, three measurements were made between different points on the bubbles’ perimeters that represented these dimensions—which were then averaged, providing estimates of the bubbles’ diameter and length when they pass through the FBG grid. The quoted uncertainties in Table 1 and Table 2 are the standard error of the three measurement values used to calculate each dimension. The predicted time it takes for each bubble to reach the FBG grid was calculated by measuring its upwards velocity from the high-speed camera data, with the time of ANBW shift values being taken from the data shown in Figure 5 and Figure 6.

Table 1.

Air–water experiments (trial 1 data): approximate bubble dimensions and interaction times with the FBG grid. Bubbles highlighted in yellow have a maximum observed width greater than a third of the diameter of the pipe, qualifying as a “large bubble” for this paper’s analysis.

Table 2.

Air–oil experiments (trial 1 data): approximate bubble dimensions and interaction times with the FBG grid. Every bubble in this table meets this paper’s definition of a “large bubble”, having an observed width greater than a third of the diameter of the test section.

For the purposes of this analysis, a large air bubble or air slug is defined as a bubble with a maximum observed width greater than a third of the diameter of the test section. Comparing Figure 5 and Table 1 shows that only some bubbles that passed through the FBG grid sensor produced an ANBW shift. In this period, as well as the first five large air slugs (highlighted in yellow in Table 1), nine other smaller bubbles passed through the sensor.

To understand the relationship between a bubble’s size and the observed shifts in ANBW, the factors effecting the net force of a rising bubble must be considered. The net force of a rising bubble is given by its buoyant force, minus the total effects of gravity, viscous resistance, the additional mass force, and the Basset force. This is shown in in Equation (3), where is the buoyant force (N), is force from gravity (N), is the viscous resistance (N), is the added mass force (N), and is the Basset force (N) [35].

For a bubble to rise in a liquid column, its buoyant force must be greater than the summation of all the forces opposing its motion. Therefore, as a bubble’s buoyant force is directly proportional to its volume, the greater a bubble’s volume, the greater the force it will impose on an FBG, eliciting a larger shift in the ANBW. When the first, and largest, air slug is predicted to reach the sensor (at 15.73 ± 0.01 s into data acquisition period), Figure 5 shows a clear, multi-chord response beginning at 15.72 ± 0.01 s, across chords 3 to 7. As this first bubble has the biggest volume observed in this experiment, it was hypothesised that it would produce the greatest magnitude ANBW shift across the largest number of fibre chords. From this analysis, this effect is clearly shown in Figure 5, where the first ANBW shift is larger than all other observed ANBW responses, supporting this interpretation of the interaction. Similarly, in the air–oil experiments, the first air bubble produced also has the greatest volume, and likewise produced the largest magnitude ANBW shift of the experiment. This effect is seen across the repeated trials 2 and 3 for both the air–water and air–oil experiments.

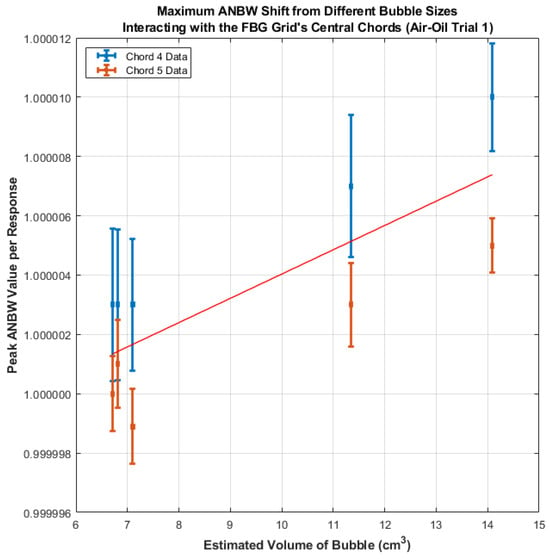

Furthermore, in the air–oil experiments, the size of the air bubbles was much more consistent, as shown in Table 2, with no small trailing bubbles produced between the first five large air bubbles. All of these bubbles were similar in geometry, and rose in the centre of the test section. Additionally, Table 2 also shows that the last three air bubbles had smaller volumes than the first two. Therefore, applying the previous logic, these bubbles would impart a smaller force on the FBG grid than the first two bubbles, meaning the magnitude of the associated ANBW shifts would be smaller. Chords 3–5 (and partially 2 and 6) of Figure 6 display this pattern, with the maximum ANBW shift value corresponding to the first two bubbles being greater than the maximum ANBW shift associated with the last three bubbles. Figure 9 further highlights this trend in the air–oil data, showing that the ANBW shift along the FBG grid’s central chords increases the larger the bubble volume interacting with the sensor. This reinforces the interpretation that it is the net force of a rising bubble that, upon interacting with an FBG grid in a standing liquid, imparts a measurable strain along the optical fibres that is proportional to the bubble’s volume. Given that the predicted times that the rising bubbles reach the FBG grid closely matches the start of each ANBW peak (no greater than a 0.02 s difference), combined with the more viscous oil minimising turbulence-induced strain, it can be deduced that the bubbles passing through the FBG grid are causing the ANBW peaks.

Figure 9.

Comparison of bubble volume against the maximum ANBW shift value produced by the bubble passing through the FBG grid (air–oil trial 1). The red line on this figure provides a trend line for the data.

However, unlike the air–oil experiments, in the air–water trials, not every bubble passing through the FBG grid has corresponding ANBW peaks. This includes some of the large air bubbles highlighted in yellow. This has two possible explanations: firstly, for the smallest air bubbles with a diameter less than 6 mm, which is the inter-chord distance, it is likely that these bubbles can pass through, or be deflected by, the FBG grid without interacting with any optical fibres, meaning that they will not produce strain along the FBGs, leading to no measured ANBW shift. Secondly, as the magnitude of the ANBW should be proportional to the volume of the bubble, then even if a bubble does interact with an optical fibre, its volume could be insufficient to produce a net force that measurably strains the FBGs, leading to these bubbles also being undetected. This latter explanation can even extended to some of the larger bubbles observed in these trails, because after the first large air slug had been produced, the subsequent bubbles with a diameter sufficient to meet the chosen definition or a “large bubble” still have volumes less than their air–oil experiment counterparts. Therefore, it can be posited that ANBW shift is proportional to bubble volume. Future works, with apparatus capable of more control over bubble volume, should endeavour to further quantify the minimum bubble size that can be detected by an FBG grid. Yet, from these experiments, no bubble with a volume less than 2.140 ± 0.001 produced an ANBW peak.

Finally, in general, it should be noted that the predicted times that bubbles are expected to reach the FBG grid do not all exactly match (outside statistical uncertainty) the measured times of the ANBW shifts. It should be reiterated that these are estimates based on the measured velocity of each bubble from the high-speed camera data. Thus, in the unobserved 41.08 mm distance between bottom of the flange and the FBG grid, interactions may occur between bubbles, turbulence, and from the FBG grid itself that can change the velocity, and geometry, of a rising bubble, explaining the small discrepancies between expected interaction time and the measured times of ANBW shifts.

4.5. Bubble Dimensioning

In a 2015 paper by C. R. Zamarreño et al. [10], it was reported that an 8 × 8 FBG grid could reproduce key dimensional properties of large air bubbles, including their general shape and size. This was achieved by analysing when FBGs on different fibre chords detected ANBW shifts and using the known spacing between chords to map the bubble surface. Using this approach, an attempt was made to analyse the data from the experiments in this work to infer the dimensions of the observed bubbles.

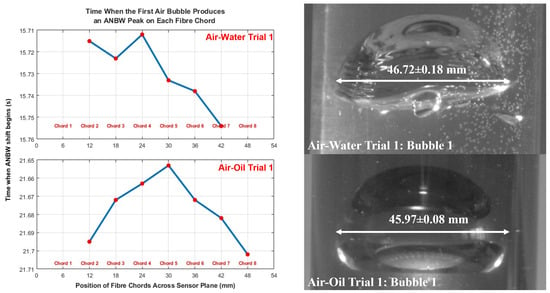

Consider again the first, and largest, air bubbles that pass through the FBG grid in both the air–water and air–oil experiments, these being bubble number 1 in both Table 1 and Table 2. To determine if the profile of the top of these bubbles can be reproduced, the time when each chord’s first ANBW peak began to increase is plotted against the chord’s positions in the sensing plane—as shown in Figure 10. From this graph, it can be seen that, for the air–oil experiment, a parabolic profile, centred in the middle of the FBG grid, exists between the timings of the first ANBW responses across the sensor’s chords. This observation is in agreement with the shape of the leading edge of the bubble, as recorded in the high-speed camera data, and also conforms to the anticipated response expected from the results published by C. R. Zamarreño et al. [9,10,27]. However, no such parabolic relationship is present in the response timings from the air–water experiment’s first bubble. Instead, a more sloped profile is seen, with chords 5–7 responding first, before chords 4, 3, and 2 sequentially. A possible explanation for this difference in response time profile could arise from the behaviour of bubbles in different viscosity liquids. In the air–oil experiments, the motion of the rising bubbles is much more regular and less erratic than the air–water tests. Therefore, in the region between the base of the flange and the sensor, when the bubble is unobserved by the high-speed camera, the bubble’s motion or shape could become perturbed, or be uncentred, leading to the slanted shape of the response time profile. Regrettably, validation of this proposed explanation is not possible without direct observation of the FBG grid as bubbles pass through it. This could not be achieved with the configuration of the LCIR; hence, further experiments will need to be conducted to analyse this proposed explanation.

Figure 10.

Timings when the first bubble creates an ANBW peak in the air–water and air–oil experiments’ trial 1. The connecting blue line provides a representation of the bubble’s surface as attempted to be reconstructed using the FBG grid sensor’s data.

Next, as only optical fibre chords that the bubbles interact with should experience an increase in strain, to measure the diameter of the bubbles passing through the sensor, the distance between the chords with FBGs that produced an ANBW peak is measured. This will only provide a coarse estimate of a bubble’s diameter, as this approach has a minimum resolution of 6mm. The results of this analysis technique are shown in Table 1 and Table 2 under the heading “Diameter from FBGs (mm)”. Despite accounting for the coarseness of measurement, comparing these values to the diameter measurements from the high-speed camera data reveals mixed results. In the air–water experiments, of the three air-bubbles that produced clear, multi-chord, ANBW peaks (bubbles 1, 8, and 12), the diameter measurements from the FBG grid only agrees with the camera diameter measurements for the last two large air bubbles. For these bubbles, their diameter was estimated to be 21.14 ± 0.50 mm and 23.85 ± 0.83 mm, respectively, using the high-speed camera data. Compared to 18.00 ± 3.00 mm and 24.00 ± 3.00 mm, respectively, from the FBG grid. Given the larger uncertainty range of the FBG grid measurements, it can be seen that both diameter measurement techniques produced values in statistical agreement. The same is also true for bubbles 4 and 5 in the air–oil trial, see Table 2. However, for the first bubble in the air–water experiment, and the first three bubbles in the air–oil experiments, the FBG grid produced statistically meaningful underestimates of the bubble diameters. These underestimates are approximately 8-16mm less than the values estimated from the high-speed camera data. A possible explanation for this inaccuracy is that the outer edges of these bubbles deformed when the top of the bubbles reached the FBG grid, changing it dimensions from when it was observed. Regardless of its cause, the absence of visual access to the FBG grid prevents confirmation of either explanation, and therefore will be explored in future work.

In summary, despite occasional success in these experiments, this approach to estimating bubble dimensions is unreliable, with limited accuracy achieved in measuring the diameter of the observed bubbles. Hence, in a standing liquid, unlike the results reported by C. R. Zamarreño et al. in flowing liquids [9,10], the FBG grid investigated cannot reproduce accurate 3D models of large air bubbles. Nonetheless, in the air–oil tests, some dimensional properties where inferred, such as the hemispherical shape of the top of a bubble, using the timings of strain increase on each chord. This is in contrast with previous techniques that relay on strain decreases in two-phase flow.

5. Conclusions

These experiments demonstrate, for the first time, several sensing capabilities of FBG grid sensors for studying bubbles risings in initially stagnant liquids. Previous experiments, by other authors, have only studied the use of FBG grids to detect bubbles in flowing liquid loops, identifying bubbles by drops in hydrodynamic force against an FBG grid as they pass through the sensor. In contrast, our experiments show increases in Bragg wavelength shift when bubbles interact with an FBG grid. These experiments have demonstrated the following:

- The detection of air bubbles rising through an FBG grid sensor in an initially stagnant liquid column. This was achieved by observing increases in Bragg wavelength shift associated with large air bubbles passing through the sensor. Comparing the timings of Bragg wavelength shifts to the expected interaction times calculated from high-speed camera recordings established a casual relationship.

- The partial quantification of the new FBG grid’s sensitivity by comparing high-speed camera estimates of bubble diameter and volume, to measurements produced from the FBG grid. From this, it was determined that no bubble with a diameter and volume less than approximately 21.14 ± 0.17 mm and 2.140 ± 0.001 , respectively, produced a clear ANBW shift across multiple chords. However, the course resolution of the FBG grid also limited the accuracy of diameter measurements produced using this sensor, but some dimensioning success was achieved in the air–oil experiments.

Finally, despite using the best equipment available to the researchers, flaws in the experimental setup were identified—limiting the analysis of the results. This primarily arose from a lack of visual access to the FBG grid. Therefore, to validate the analysis of the process of how a large air bubble produces strain across an FBG grid, further research with a fully transparent experimental setup is essential. Nevertheless, these experiments provide a proof-of-concept that an FBG grid can still detect large bubbles passing through the sensor, even if the FBG grid is placed in an initially stagnant liquid.

Author Contributions

Conceptualization, H.O.P. and M.M.; methodology, H.O.P.; software, H.O.P.; formal analysis, H.O.P.; investigation, H.O.P.; resources, M.M.; data curation, H.O.P.; writing—original draft preparation, H.O.P.; writing—review and editing, H.O.P. and M.M.; visualization, H.O.P.; supervision, M.M.; project administration, M.M.; funding acquisition, M.M. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded through the Sêr Cymru II programme by the Welsh European Funding Office (WEFO) under the European Development Fund (ERDF). Harvey Plows’ PhD project is funded by both the Worshipful Company of Drapers and the EPSRC Nuclear Energy Futures Centre for Doctoral Training.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to thank Coleg Menai for manufacturing the aluminium mounting gasket used to create the FBG grid used and studied in these experiments. We would also like to thank Horst-Michael Prasser for discussions and advice that assisted the analysis of the data presented in this paper, providing much appreciated guidance.

Conflicts of Interest

The authors declare that this study received funding from Worshipful Company of Drapers, as well as EPSRC’s Nuclear Energy Futures Centre for Doctoral Training. The funders were not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- Murakami, T. A historical review and analysis on the selection of nuclear reactor types and implications to development programs for advanced reactors; A Japanese study. Energy Rep. 2021, 7, 3428–3436. [Google Scholar] [CrossRef]

- Abdulwahab, M.R.; Ali, Y.H.; Habeeb, F.J.; Borhana, A.A.; Abdelrhman, A.M.; Al-Obaidi, S.M.A. A review in particle image velocimetry techniques (developments and applications). J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 65, 213–229. [Google Scholar]

- Xu, L.J.; Xu, L.A. Ultrasound tomography system used for monitoring bubbly gas/liquid two-phase flow. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 67–76. [Google Scholar]

- Tompkins, C.; Prasser, H.M.; Corradini, M. Wire-mesh sensors: A review of methods and uncertainty in multiphase flows relative to other measurement techniques. Nucl. Eng. Des. 2018, 337, 205–220. [Google Scholar] [CrossRef]

- Zhao, Y.; Bi, Q.; Yuan, Y.; Lv, H. Void fraction measurement in steam–water two-phase flow using the gamma ray attenuation under high pressure and high temperature evaporating conditions. Flow Meas. Instrum. 2016, 49, 18–30. [Google Scholar] [CrossRef]

- Francois, F.; Djeridi, H.; Barre, S.; Kledy, M. Measurements of void fraction, liquid temperature and velocity under boiling two-phase flows using thermal-anemometry. Nucl. Eng. Des. 2021, 381, 111359. [Google Scholar] [CrossRef]

- Teyssedou, A.; Tapucu, A.; Lortie, M. Impedance probe to measure local void fraction profiles. Rev. Sci. Instrum. 1988, 59, 631–638. [Google Scholar] [CrossRef]

- Baroncini, V.H.V.; Martelli, C.; Patyk, R.L.; dos Santos, E.N.; da Silva, M.J.; Morales, R.E.; do Amaral, C.E. Multiphase flow characterization using optical fiber Bragg gratings. In Proceedings of the OFS2012 22nd International Conference on Optical Fiber Sensors, Beijing, China, 15–19 October 2012; SPIE: Bellingham, WA, USA, 2012; Volume 8421, pp. 269–272. [Google Scholar]

- Zamarreño, C.; Martelli, C.; Baroncini, V.; Dos Santos, E.; Da Silva, M.; Morales, R.; Matias, I.; Arregui, F. Two-Phase Flow Imaging by means of an 8x8 Optical Fiber Bragg Grating Grid. In Proceedings of the Bragg Gratings, Photosensitivity, and Poling in Glass Waveguides, Virtual, 27–31 July 2014; Optica Publishing Group: Washington, DC, USA, 2014; p. BM3D.3. [Google Scholar]

- Zamarreño, C.R.; Martelli, C.; Baroncini, V.H.; dos Santos, E.N.; da Silva, M.J.; Morales, R.E.; Zubiate, P.; Arregui, F.J.; Matias, I.R. Single and multiphase flow characterization by means of an optical fiber Bragg grating grid. J. Light. Technol. 2015, 33, 1857–1862. [Google Scholar] [CrossRef]

- Plows, H.O.; Li, J.; Dahlfors, M.; Margulis, M. Flow Characterisation Using Fibre Bragg Gratings and Their Potential Use in Nuclear Thermal Hydraulics Experiments. J. Nucl. Eng. 2023, 4, 668–690. [Google Scholar] [CrossRef]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Light. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Lai, Y.; Martinez, A.; Khrushchev, I.; Bennion, I. Distributed Bragg reflector fiber laser fabricated by femtosecond laser inscription. Opt. Lett. 2006, 31, 1672–1674. [Google Scholar] [CrossRef]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber grating sensors. J. Light. Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Hirayama, N.; Sano, Y. Fiber Bragg grating temperature sensor for practical use. ISA Trans. 2000, 39, 169–173. [Google Scholar] [CrossRef] [PubMed]

- Kumar, J.; Singh, G.; Saxena, M.K.; Prakash, O.; Dixit, S.K.; Nakhe, S.V. Development and studies on FBG temperature sensor for applications in nuclear fuel cycle facilities. IEEE Sens. J. 2020, 21, 7613–7619. [Google Scholar] [CrossRef]

- Campanella, C.E.; Cuccovillo, A.; Campanella, C.; Yurt, A.; Passaro, V.M. Fibre Bragg grating based strain sensors: Review of technology and applications. Sensors 2018, 18, 3115. [Google Scholar] [CrossRef] [PubMed]

- Silveira, M.L.; Rocha, H.R.; Antunes, P.F.; André, P.S.; Segatto, M.E.; Frizera, A.; Díaz, C.A. An Optimized Self-Compensated Solution for Temperature and Strain Cross-Sensitivity in FBG Interrogators Based on Edge Filter. Sensors 2021, 21, 5828. [Google Scholar] [CrossRef]

- Sarkar, S.; Inupakutika, D.; Banerjee, M.; Tarhani, M.; Shadaram, M. Machine learning methods for discriminating strain and temperature effects on FBG-based sensors. IEEE Photonics Technol. Lett. 2021, 33, 876–879. [Google Scholar] [CrossRef]

- Lu, P.; Men, L.; Chen, Q. Resolving cross sensitivity of fiber Bragg gratings with different polymeric coatings. Appl. Phys. Lett. 2008, 92, 171112. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, Z.; Zhang, Y.; Chiang, K.S.; Dong, X. Simultaneous pressure and temperature measurement with polymer-coated fibre Bragg grating. Electron. Lett. 2000, 36, 1. [Google Scholar] [CrossRef]

- Xu, S.; Li, X.; Wang, T.; Wang, X.; Liu, H. Fiber Bragg grating pressure sensors: A review. Opt. Eng. 2023, 62, 010902. [Google Scholar] [CrossRef]

- Allil, A.S.; da Silva Dutra, F.; Dante, A.; Carvalho, C.C.; Allil, R.C.d.S.B.; Werneck, M.M. FBG-based sensor applied to flow rate measurements. IEEE Trans. Instrum. Meas. 2020, 70, 7000608. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, K.; Yang, J. Novel target type flowmeter based on a differential fiber Bragg grating sensor. Measurement 2005, 38, 230–235. [Google Scholar] [CrossRef]

- Ünalmis, Ö.; Johansen, E.S.; Perry, L. Evolution in optical downhole multiphase flow measurement: Experience translates into enhanced design. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Utrecht, The Netherlands, 23–25 March 2010; SPE: Bellingham, WA, USA, 2010; p. SPE-126741. [Google Scholar]

- Alemohammad, H.; Toyserkani, E.; Pinkerton, A. Femtosecond laser micromachining of fibre Bragg gratings for simultaneous measurement of temperature and concentration of liquids. J. Phys. D Appl. Phys. 2008, 41, 185101. [Google Scholar] [CrossRef]

- Zamarreño, C.R.; Martelli, C.; Baroncini, V.H.; dos Santos, E.N.; da Silva, M.J.; Morales, R.E.; Matias, I.; Arregui, F. Optical fiber Bragg grating mesh for multiphase flow sensing. In Proceedings of the 23rd International Conference on Optical Fibre Sensors, Santander, Spain, 2–6 June 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9157, pp. 1261–1264. [Google Scholar]

- Zhang, B.; Kahrizi, M. High-temperature resistance fiber Bragg grating temperature sensor fabrication. IEEE Sens. J. 2007, 7, 586–591. [Google Scholar] [CrossRef]

- Zhou, H.; Qiao, X.; Wang, H.; Feng, D.; Wang, W. Study of a high-temperature and high-pressure FBG sensor with Al2O3 thin-wall tube substrate. Optoelectron. Lett. 2008, 4, 260–263. [Google Scholar] [CrossRef]

- da Silva Marques, R.; Prado, A.R.; da Costa Antunes, P.F.; de Brito André, P.S.; Ribeiro, M.R.; Frizera-Neto, A.; Pontes, M.J. Corrosion resistant FBG-based quasi-distributed sensor for crude oil tank dynamic temperature profile monitoring. Sensors 2015, 15, 30693–30703. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, J.; Wang, Y.; Zhang, Q.; Duan, J.; Zhang, Z.; Huang, X.; You, Z. Principles and application of polyimide fiber Bragg gratings for surface strain measurement. Appl. Sci. 2017, 7, 995. [Google Scholar] [CrossRef]

- Jou, J.H.; Huang, P.T.; Chen, H.C.; Liao, C.N. Coating thickness effect on the orientation and thermal expansion coefficient of polyimide films. Polymer 1992, 33, 967–974. [Google Scholar] [CrossRef]

- Sezer Hicyilmaz, A.; Celik Bedeloglu, A. Applications of polyimide coatings: A review. SN Appl. Sci. 2021, 3, 363. [Google Scholar] [CrossRef]

- Sun, Q.; Feng, Y.; Guo, J.; Wang, C. Achieving both low thermal expansion and low birefringence for polyimides by regulating chain structures. Eur. Polym. J. 2023, 189, 111986. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Zhang, H. Multi-element coupling model of rising bubble in water. J. Phys. Conf. Ser. 2019, 1168, 052044. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).