Abstract

Hydrogen plays a central role in ensuring the fulfillment of the climate and energy goals established in the Paris Agreement. To implement sustainable and resilient hydrogen economies, it is essential to analyze the entire hydrogen value chain, following a Life Cycle Assessment (LCA) methodology. To determine the current methodologies, approaches, and research tendencies adopted when performing LCA of hydrogen energy systems, a systematic literature analysis is carried out in the present study. The choices regarding the “goal and scope definition”, “life cycle inventory analysis”, and “life cycle impact assessment” in 70 scientific papers were assessed. Based on the collected information, it was concluded that there are no similar LCA studies, since specificities introduced in the system boundaries, functional unit, production, storage, transportation, end-use technologies, geographical specifications, and LCA methodological approaches, among others, introduce differences among studies. This lack of harmonization triggers the need to define harmonization protocols that allow for a fair comparison between studies; otherwise, the decision-making process in the hydrogen energy sector may be influenced by methodological choices. Although initial efforts have been made, their adoption remains limited, and greater promotion is needed to encourage wider implementation.

1. Introduction

Climate change and environmental problems are among the biggest concerns of the 21st century. The first big step in fighting climate change was taken in 2015 with the Paris Agreement, where a commitment to limit the increase in the global average temperature to below 2 °C above pre-industrial levels, with the reference value of 1.5 °C above pre-industrial levels, by 2050 was established [1]. The Paris Agreement encouraged nations and organizations to develop strategies to reduce greenhouse gas (GHG) emissions.

In 2021, the International Renewable Energy Agency (IRENA) published the first edition of the World Energy Transition Outlook [2], where a pathway to reach the 1.5 °C mark was detailed. According to IRENA, six pathways are critical to sustain energy transition compatible with the 1.5 °C scenario goal, hydrogen being one of them. Hydrogen is expected to satisfy 12% of the final energy demand and support the reduction of 10% of the total carbon dioxide equivalent emissions [3,4].

According to the report released by the International Energy Agency (IEA) in October 2022, in 2021 hydrogen only accounted for 2.5% of the total final energy consumption [5], corresponding to 94 MtH2. This value is much lower than the target defined by IRENA. In addition, less than 2% of the hydrogen volume came from low-carbon sources in that year [5]. Currently, hydrogen is largely produced from fossil fuels, commonly referred to as gray hydrogen.

These two facts raise the need for a significant increase in hydrogen production to achieve the defined climate goals and, at the same time, to rethink the way hydrogen is currently produced so that its production does not generate significant GHG emissions that could compromise these goals. Thus, it is fundamental to look for a sustainable, resilient, and comprehensive hydrogen economy, aligned with energy and climate policy goals, that can overcome these challenges [6].

Building a fully green hydrogen economy requires developing new value chains, which brings the challenge of identifying the most effective pathways for designing cost-efficient green hydrogen systems [7]. Due to hydrogen’s versatility of production, storage, and distribution associated with local characteristics, such as weather and geographical conditions, existing infrastructures, demand sectors, and demand profile, it is not possible to define only one pathway as the most cost-effective option to design green hydrogen value chains, meaning that for each possible value chain specific assessments and investments need to be carried out [8,9,10]. In this sense, comprehensive analyses, such as Life Cycle Assessment (LCA), Life Cycle Costing (LCC), and Social Life Cycle Assessment (S-LCA), are required to evaluate the environmental, economic, and social benefits, respectively, of hydrogen energy systems.

Life Cycle Sustainability Assessment (LCSA), which results from the combination of LCA, LCC and S-LCA, is a comprehensive analytical methodology that considers the overall impacts of a product, process, or activity from the procurement and acquisition of raw materials to its disposal and waste management, encompassing its production and use while presenting an accurate picture of potential environmental trade-offs [11,12,13].

Owing to its methodological advantages, this approach has led to a notable growth in the number of LCA studies on hydrogen energy systems reported in the literature over the past decade. Nonetheless, despite the international standardization of the LCA methodology [8,11] and the existence of international reference guidelines [14], it is possible to identify a lack of consistency in the framework used to carry out both the individual and comparative Life Cycle Assessment of hydrogen energy systems. This inconsistency strongly affects the interpretation and comparison of the results of different studies.

The present work aims to characterize the current methodologies, approaches, and research tendencies adopted when performing LCA of hydrogen energy systems, while also defining the state of the art of the respective studies’ content and the inclusion of the economic and social perspective in the study. For that purpose, 70 articles were selected for in-depth analysis, comprising the most cited studies from the Scopus and Web of Science databases published between 1 January 2020 and 31 August 2023, as well as additional articles recommended by hydrogen field experts. The articles selected are presented in Table A1 of the Appendix A section.

Review studies can be found in the literature that focus on specific phases of the hydrogen value chain, such as article [15], which reviews the results of LCAs of hydrogen production technologies, or that concentrate on specific value chain configurations, such as article [16], which reviews LCA practices for fuel cell hydrogen systems. However, there is a lack of comprehensive studies that consider simultaneously all phases and configurations of the hydrogen value chain and provide a more holistic understanding that reflects the complexity and variability of real-world hydrogen systems. Furthermore, this work reviews the existing harmonized frameworks and protocols established to increase comparability among LCAs of hydrogen energy systems.

It is hoped that the results obtained in this work will contribute to the initial steps of defining a harmonized and consistent framework for performing LCA on hydrogen energy systems, and that the results will show the importance of expanding the current LCA studies to LCSA studies.

2. Systematic Literature Analysis Results

It is notable that, from 2020 onwards, the number of LCAs of hydrogen energy systems has sharply increased, as is represented in Figure 1. This significant increase coincides with the period when international institutions such as the IEA and the IRENA began to highlight hydrogen as one of the main pathways for achieving climate and energy goals.

Figure 1.

Evolution of the number of studies of LCA and LCSA on hydrogen energy systems published annually between January 2003 and December 2023 that are available on the Scopus database by searching for the word combination “Hydrogen” AND (“Life Cycle Assessment” OR “Life Cycle Sustainability Assessment”) in titles, abstracts, and authors’ keywords.

The LCA methodology is composed of four different phases [11,12,14]: (i) goal and scope definition, where the purpose of the study is defined, the unit of analysis is established, the study boundaries are set, and the main materials and energy flows are defined; (ii) Life Cycle Inventory Analysis–where the quantification of the inflows and outflows (material flow analysis) and the emissions and wastes is carried out; (iii) Life Cycle Impact Assessment, where the impacts of the Life Cycle Inventory flows are studied; and (iv) interpretation, where the results of the study are addressed and discussed with critical thinking, arriving at conclusions. The following sections explore the approaches adopted by studies in these phases.

2.1. Goal and Scope Definition

In the first phase of the LCA, the purpose of the study is defined, the unit of analysis is established, the study boundaries are set, and the main materials and energy flows are defined.

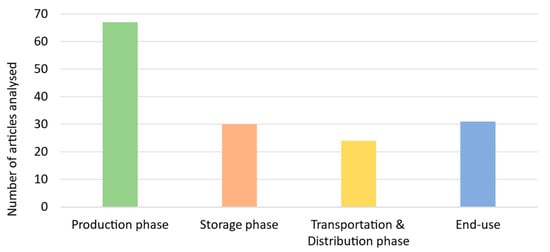

Most studies in the literature focus on studying production technologies. Among the 70 articles analyzed, 96% cover at least one hydrogen production technology, and 39% focus only on assessing the production phase of the hydrogen energy system, as shown in Figure 2. Storage, transportation, and distribution technologies are less often included in the LCA studies. The storage phase of the hydrogen value chain is considered in 43% of the studies analyzed, while the transportation and distribution phase is considered in 36% of the studies. The hydrogen end-use is considered in 44% of the studies analyzed.

Figure 2.

Representation of the total number of articles, among the 70 studies analyzed, that considered at least one technology of each of the hydrogen value chain phases.

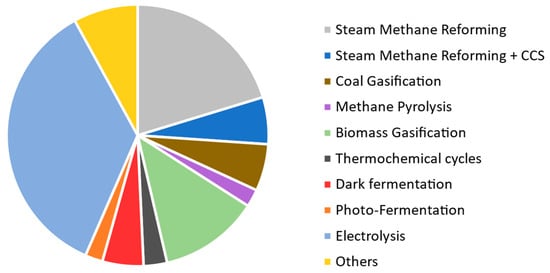

Among the production technologies analyzed in the LCA literature on hydrogen energy systems, technologies corresponding to thermochemical and electrolytic hydrogen production processes are the most studied (appearing in 61% and 70%, respectively, of the articles analyzed that study production technologies). Technologies corresponding to biological processes only appear in 16% of these articles.

Steam methane (or natural gas) reforming (SMR) is normally used as the reference technology to which the other technologies are compared to prove their beneficial environmental impacts (appearing in 40% of the articles analyzed that study production technologies). Coal Gasification (CG) is also sometimes considered the go-to technology to produce gray hydrogen (appearing in 11% of the articles analyzed). Water electrolysis, either polymer electrolyte membrane water electrolysis (PEMEL), alkaline water electrolysis (AEL), or solid oxide water electrolysis (SOEL), is normally referred to as the medium- to long-term option to produce low carbon hydrogen, being thus present in the majority of the existing studies (appearing in 70% of the articles analyzed that study production technologies), sometimes also accompanied by biomass gasification (appearing in 23% of these articles). SMR or CG with carbon capture and storage (CCS), methane pyrolysis, and thermochemical cycles are other hydrogen production technologies found in some studies [17,18,19]. Technologies with lower Technology Readiness Levels (TRLs), such as photo-fermentation, bio-photolysis, and photoelectrochemical water splitting, are only found in specific studies and are not included in strategic analyses to define hydrogen roadmaps. Figure 3 represents the distribution of the main hydrogen production technologies analyzed among the total number of technologies considered in the 70 studies assessed.

Figure 3.

Distribution of the main hydrogen production technologies analyzed among the total number of technologies considered in the 70 assessed studies.

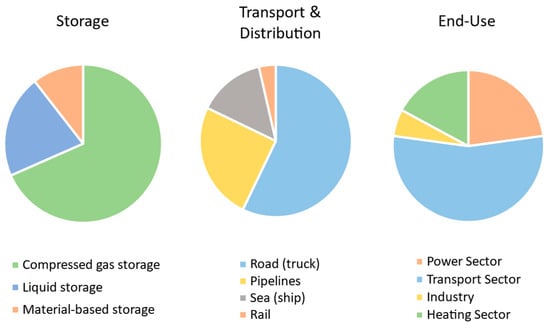

The storage phase, which follows the production phase in the hydrogen value chain, is not typically studied in the articles analyzed. Although it is addressed in 43% of the articles assessed, as mentioned earlier, in 77% of those only one technology is considered, and no comparison is made between different options. Compressed gas hydrogen storage stands out as the storage option most mentioned in the articles analyzed (appearing in 87% of the articles analyzed that study storage technologies). Liquid hydrogen storage is the second option most considered (appearing in 27% of these articles). Material-based storage options, such as adsorption, chemical hydrogen, and metal hydrides, are rarely discussed in the literature [20,21], appearing in only 13% of these articles.

Among the three main transportation and distribution options, by road, by pipelines, and by sea, the first one is the most frequently studied option (appearing in 64% of the articles analyzed that study transport and distribution options). Transport and distribution by pipelines and by sea are considered in 28% and 16% of the articles analyzed, respectively, and rail transportation was considered in one article.

Mobility is the end-use with a more frequent presence in the studies analyzed. Among the studies that consider the hydrogen use phase, 61% of the studies consider hydrogen value chains of the power-to-mobility or power-to-syngas type. Hydrogen value chains of the power-to-power and power-to-gas configurations are analyzed in 26% and 19%, respectively, of these studies. Some studies explore the potential of using hydrogen as a storage option in remote microgrids [22,23]. The hydrogen value chain configuration of power-to-industry is only assessed in 6% of the studies that consider the hydrogen use phase, meaning that the potential of using hydrogen as an option to decarbonize the industry sector has not been widely studied.

Figure 4 represents the distribution of the main hydrogen storage technologies, transport and distribution options, and hydrogen end-uses considered among the total number of studies assessed.

Figure 4.

Distribution of the main hydrogen storage technologies (left), transport and distribution options (center), and hydrogen end-uses (right) considered among the total number of studies assessed.

When looking at the system boundary, among the studies assessed, cradle-to-gate is the most used system boundary. Even in studies that carry out a complete analysis of the value chain and adopt an energy carrier cradle-to-grave system boundary, the end of life, and sometimes the construction of the equipment and infrastructure that support the value chain, is disregarded.

The scope of the studies previously analyzed is closely linked to the purpose of the analysis carried out in each article. Among the studies analyzed, 70% are comparative studies. In general, it is possible to group the articles available in the literature into three types of study purposes: (i) studies that aim to demonstrate the benefits of producing blue and green hydrogen as a replacement for the gray hydrogen currently produced; (ii) experimental studies that aim to determine the main advantages of investing in technologies with a low TRL; and (iii) studies that focus on characterizing the advantages of using hydrogen as a decarbonization pathway in different end-use sectors.

Typically, the articles that fall into the first group carry out comparative studies between different hydrogen production technologies (usually more than three) and do not focus on the next phases of the value chain [24,25,26]. These studies allow a direct comparison of the environmental, economic, and/or social impacts of the production of green, blue, and gray hydrogen, assuming that the other stages of the value chain are independent of the type of hydrogen produced, and therefore so are their respective impacts. The studies that fall into the second group focus on individually studying technologies that have a low TRL value (usually between 1 and 5) [27,28,29,30,31]. Typically, these studies are based on experimental setups [32,33] or on the collection of experimental data to support the analysis. In some cases, these studies also compare results with other studies where higher TRL technologies have been evaluated. The studies that fall into the third group focus mainly on the use phase of hydrogen [34], but do not explore different production, storage, transportation, and distribution options and their respective technical and geographical limitations [35,36]. In addition, there are also studies, although scarcer, which focus on comparing different hydrogen transportation and distribution options or different storage technologies [21,37,38,39].

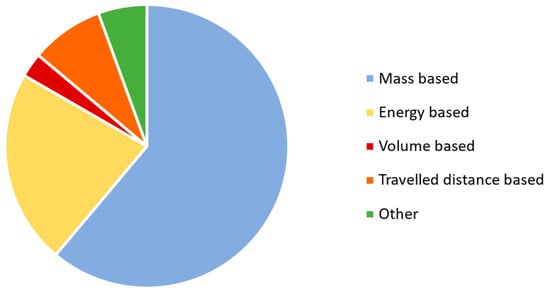

Different options can be taken regarding the definition of the functional unit, such as defining the unit of analysis based on a mass, volume, energy, traveled distance, passenger distance, or an economic nature approach. Overall, most studies select a mass approach (61% of the articles analyzed). In studies where the focus is on the end-use phase, it is possible to find functional units defined based on the distance traveled, usually when the end-use is mobility, and on energy, usually where the end-use is power, as presented in Figure 5.

Figure 5.

Distribution of the different options adopted to define the functional unit.

Typically, in studies where the mass approach is selected, the temperature, the pressure, and/or the hydrogen purity level are not considered in the functional unit definition. These undefined conditions affect the ability to establish comparisons between studies [40]. Among the articles analyzed that considered a mass-based functional unit, only 23% provided information regarding one of the three previous properties, and only 7% provided information on all three.

2.2. Life Cycle Inventory Analysis

In the second phase of the LCA methodology, Life Cycle Inventory Analysis (LCI), the quantification of the inflows and outflows and the emissions and wastes of all the intermediary processes is carried out.

Data source and data quality have a strong effect on the reliability of the studies performed. Typically, in the articles available in the literature, data quality ratings are disregarded by the authors. As such, the present analysis will focus on the data sources used to qualify the foreground and background processes.

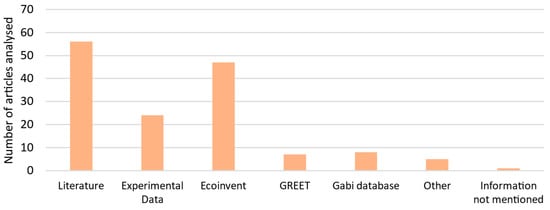

Currently, the availability of data related to hydrogen production, storage, and transportation in real-life applications is still scarce, since a hydrogen economy has not been implemented yet. In most studies, the scientific literature is the go-to option for quantifying foreground processes. The use of information available in the literature was used by 80% of the studies analyzed in the present analysis. Whenever experimental case studies are carried out or simulations are performed, the data acquired by the authors are used as a replacement for the previous information. Due to the need to prepare experimental setups and the difficulty in estimating the respective performance on a larger scale, such as the one necessary for the implementation of a hydrogen economy, this approach is only taken in 34% of the studies analyzed. LCA databases are also commonly used as data sources, mostly to quantify the background processes. Of the different databases available, the Ecoinvent database stands out as the one that is most used throughout the literature, used in 67% of the studies analyzed. Figure 6 represents the number of articles, out of the 70 analyzed, that used each type of data source to collect data to quantify either the foreground or background processes.

Figure 6.

Representation of different data sources used in the Life Cycle Inventory of the 70 studies analyzed.

2.3. Life Cycle Impact Assessment

In the third phase of the LCA methodology, the Life Cycle Impact Assessment, the impacts of the LCI flows are quantified.

The lifetime impacts of each hydrogen production, storage, transport, and distribution technology, as well as the respective end-use, can be evaluated in three different dimensions: (i) the environmental dimension, (ii) the economic dimension, and (iii) the social dimension, the three pillars of sustainability. To complement the evaluation of the first dimension, carried out by the Life Cycle Assessment, a Life Cycle Costing (LCC) and Social Life Cycle Assessment (SLCA) can be performed to measure the impact of the second and third dimensions, respectively.

Regarding the literature available on LCAs of hydrogen energy systems, it is concluded that, as expected, 100% of the studied articles consider environmental impacts. These studies consider either a midpoint approach or an endpoint approach. The first approach is considered in 97% of the articles analyzed, while the second one is considered in 7%, showing a clear preference for adopting a midpoint approach that presents a higher level of certainty, since direct and robust modeling problem–effect relations are considered [41]. On the other hand, the endpoint approach may present a higher level of relevance since fewer factors are considered, and those factors are directly linked to society’s concerns [41]. A total of 4% of the studies adopted both approaches, presenting simultaneously the midpoint and endpoint impacts.

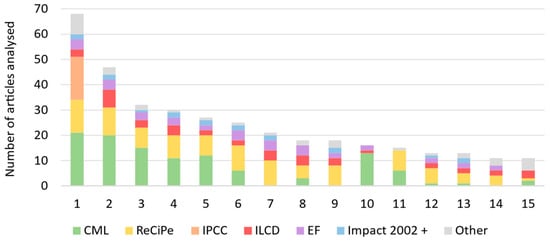

In terms of the LCIA method used by the studies analyzed, three families of methods stand out as the most selected: Centrum voor Milieukunde Leiden (CML), ReCiPe, and Intergovernmental Panel on Climate Change (IPCC). The first is used in around 50% of the studies analyzed, and the second and third are used in around 25%. IPCC methods are exclusively used to characterize GHG emissions. Among the studies analyzed, IPCC characterization factors are typically used when the global warming potential is analyzed and no specific LCIA method is adopted. Further information on LCIA methods can be found in [42,43].

When looking at the impact categories [42] considered in the studies under the present analysis, climate change stands out as the most widely employed category, being considered in 100% of the studies that assess midpoint impacts. Acidification, the depletion of abiotic resources/resource consumption, ozone depletion, human toxicity, and ecotoxicity are also other impact categories frequently considered, being present in 69%, 47%, 44%, 40%, and 37%, respectively, of the studies analyzed that consider midpoint indicators.

While the selection of the life cycle indicators is, in general, homogeneous across the articles analyzed, there is not a clearly predominant LCIA method to assess all, or even specific, impact categories, which may affect the cross-comparison between studies. Figure 7 represents the distribution of the impact categories among the total number of 70 studies assessed. The LCIA methods used for each category are also represented.

Figure 7.

Representation of the number of occurrences, among the studies analyzed, of each impact category (1: climate change; 2: acidification; 3: depletion of abiotic resources/resource consumption; 4: ozone depletion; 5: human toxicity; 6: ecotoxicity; 7: aquatic eutrophication; 8: ozone formation; 9: particulate matter emissions/respiratory inorganics; 10: terrestrial eutrophication; 11: photochemical oxidation potential; 12: ionizing radiation; 13: land use; 14: water use; 15: others) and respective distribution of the LCIA methods selected to quantify the impact.

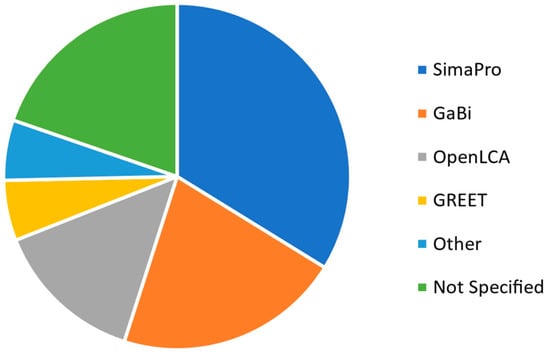

To carry out the LCA process and all calculations associated with it, software tools can be used. These tools enable the effective processing of a large amount of data and information. Among the studies analyzed, it is possible to identify a tendency to use one of these three LCA software tools: SimaPro, GaBi, and OpenLCA. The first one is used in 34% of the studies analyzed, the second in 21%, and the third in 14%, as shown in Figure 8. In total, 20% of these studies do not specify the tool used to carry out the analysis.

Figure 8.

Life Cycle Assessment software tools used in the studies analyzed.

When looking at the economic and social dimensions, it is concluded that, in the literature, a less meaningful role is assigned to both when compared to the environmental dimension, being considered in less than 25% and less than 10%, respectively, of the articles analyzed.

To assess the economic impact, the levelized cost of hydrogen (LCOH), which considers expenditures and the capital investment, is the most commonly used indicator [39,44,45]. Other existing indicators, though not so commonly used, are the net present value, payback period, and internal rate of return [46].

To assess the social impacts, indicators like local job creation, child labor, health expenditure, and knowledge and skills development, among others, have been used in a minor fraction of the studies analyzed [46,47,48,49].

2.4. Overview of the Main Results Obtained

Across the 70 articles analyzed, especially those that considered more than one phase of the hydrogen value chain, it was often impossible to clearly separate the emissions in each phase, as most authors focused on presenting the GHG emissions released in the production phase or in the entire value chain. In addition, as discussed in the next chapter, the difference between the methodological framework adopted in each case may influence the results obtained. So, in the present section, the main results of the articles studied will be presented without making any analytical comparison between studies.

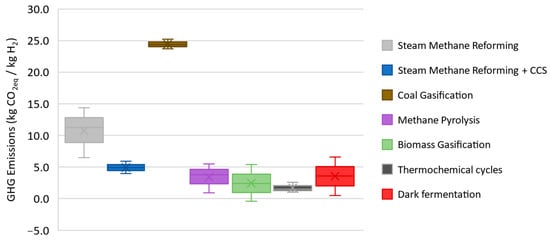

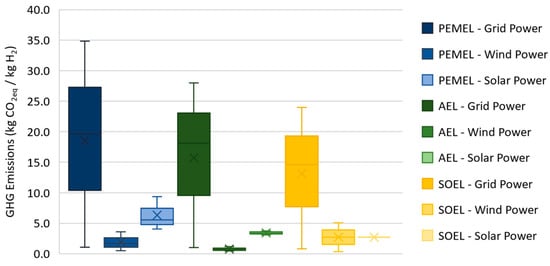

Figure 9 and Figure 10 present an overview of the GHG emissions of different production technologies by showing the minimum, maximum, and mean values of each technology. For the mean value, it was decided to exclude 10% of data points from the top and bottom tails of each data set to remove outliers.

Figure 9.

Box and whisker chart of GHG emissions of various hydrogen production technologies.

Figure 10.

Box and whisker chart of GHG emissions for the three types of electrolysis technologies, under different power sources.

As expected, GHG emissions (in CO2 equivalent) vary significantly among the technologies. SMR presented a mean value of 11.2 kg CO2eq /kg H2, which can be decreased to 4.9 kg CO2eq /kg H2 if carbon capture and storage is implemented. Lower SMR values occur when plant construction and resource transport are excluded from system boundaries, while higher values result from including hydrogen liquefaction as the last phase of the production process. Coal Gasification presents a value of 24.4 kg CO2eq /kg H2, biomass gasification of 2.4 kg CO2eq/kg H2, and methane pyrolysis of 3.8 kg CO2eq /kg H2. For biomass gasification, a negative value of GHG emissions was registered for a case where the off-gas of the Pressure Swing Adsorption was used in a combined cycle to generate electricity to supply the hydrogen compression phase and to supply the electric grid [25]. The minimum value registered for methane pyrolysis resulted from the use of low-carbon electricity. According to the authors, if renewable natural gas produced from the anaerobic digestion of food waste was used, a negative value of GHG would be obtained [18]. Thermochemical cycles present a mean value of 1.5 kg CO2eq /kg H2, and Dark fermentation of 3.6 kg CO2eq /kg H2.

Electrolysis shows the widest variation in GHG emissions, as the corresponding global warming potential lies in the source of energy used to power the system, as shown in Figure 10. In [50], the authors studied and compared hydrogen production via PEMEL, AEL, and SOEL in Belgium, Austria, and Iceland using different power sources. The authors proved the role of the energy mix and the geographical characteristics, due to the different capacity factors, on hydrogen production emissions.

Among the 70 articles analyzed, some studies considered the entire hydrogen value chain and presented the associated GHG emissions. In [51], the authors considered 11 production technologies and 4 storage and transportation options, considering COP26 and EU27 energy mixes, the first with a lower environmental burden. For transporting 1 ton of hydrogen over 100 km under the COP26 mix, emissions were 50, 83, 336, and 325 kg CO2eq for gaseous hydrogen by pipeline, gaseous hydrogen by road, liquid hydrogen by road, and liquid hydrogen by rail, respectively. When the EU27 mix was applied, emissions rose to 500, 665, 3332, and 3328 kg CO2eq, respectively.

In [37], the authors studied three hydrogen supply chain configurations under seven scenarios of demand and transportation distances, using wind powered electrolysis as the production technology, underground compressed gas hydrogen storage or chemical hydrogen storage as the storage options, and pipelines, Liquid Organic Hydrogen Carrier (LOHC) trucks, or compressed trucks, with a pressure level of 500 bar, as the transportation and distribution options. The emissions for hydrogen value chains with a pipeline configuration were 1.53 kg CO2eq/kg H2, 1.52 kg CO2eq/kg H2, and 1.71 kg CO2eq/kg H2 for a daily demand of 80, 40, and 10 tons, respectively. For the transportation through compressed hydrogen trucks, the emissions were 2.52 kg CO2eq/kg H2 and 4.33 kg CO2eq/kg H2 for transportation distances of 100 km and 400 km, respectively. For the same transportation distances, the emissions were 4.96 kg CO2eq/kg H2 and 5.84 kg CO2eq/kg H2 if the transportation was performed by LOHC trucks. LOHC trucks yield the highest level of GHG emissions due to the energy-intensive dehydrogenation process needed. The authors concluded that, when production relied on renewable power, transport dominated total emissions, with storage presenting a residual contribution.

In [52], a comparative LCA of the GHG emissions of hydrogen value chains and other energy carriers was carried out, considering SMR, SMR + CCS, PEMEL via wind power, and PEMEL via solar power as the production technologies, and long-distance (over 20,000 nautical miles) liquified hydrogen transportation by heavy fuel oil-fueled ocean tankers as the transportation option. The reported emissions were 14.39 kg CO2eq/kg H2, 5.90 kg CO2eq/kg H2, 3.60 kg CO2eq/kg H2, and around 5 kg CO2eq/kg H2 for each value chain configuration. The authors concluded that the production phase generated the most GHG emissions.

The authors in [20] compared seven different transportation pathways—(i) compressed hydrogen at 100 bar transported via pipeline, (ii) compressed hydrogen at 500 bar transported via truck, (iii) liquified hydrogen transported via truck, (iv) LOHC transported via truck with natural gas as a heating source, (v) liquid ammonia transported via truck, (vi) LOHC transported via trucks with hydrogen as a heating source, and (vii) liquid ammonia transported via truck with the direct utilization of ammonia as final energy—under three different scenarios. For a demand of 44 tons per day and a transportation distance of 100 km, the authors reported emissions of around 1.5, 1.7, 1.8, 3.5, 3.0, 2.3, and 1.5 kg CO2eq/kg H2, respectively (the values are presented in a graphical scheme and not in a numerical manner). The authors concluded that increasing the distance from 100 to 400 km raised the liquefied hydrogen transported via truck emissions by 45% and 75% for compressed hydrogen at 500 bar transported via truck.

Article [53] presents a comparative LCA of hydrogen supply chains with different hydrogen storage and transportation options. Hydrogen was produced via offshore wind-powered electrolysis, then compressed, liquefied, or converted to LOHC or ammonia and shipped, using marine diesel oil, to onshore storage. For a 100 km distance, and considering the use of grid energy for the post-processing process, the emissions were 1.15 kg CO2eq/kg H2 for compressed hydrogen, 1.33 kg CO2eq/kg H2 for liquid hydrogen, 10.11 kg CO2eq/kg H2 for LOHC, and around 4.8 kg CO2eq/kg H2 for ammonia. If wind power was considered for the post-processing process, the two last emissions values would decrease to 2.05 and 1,21 kg CO2eq/kg H2, respectively. The study found that, except for the transportation phase, the energy source influences more than 95% of the global warming potential. For transportation, the distance is the variable that most influences emissions. Increasing the transportation distance to 1000 km, the emissions of compressed hydrogen would increase to 3.52 kg CO2eq/kg H2, and of liquid hydrogen to 3.51 kg CO2eq/kg H2. If the transportation distance is increased to 10,000 km, the emissions of the LOHC supply chain would increase by 73%.

While only a subset of studies directly evaluates the economic performance of hydrogen, some report LCOH values compiled from the literature. Nevertheless, drawing definitive conclusions remains challenging. The reported LCOH values vary significantly across technologies, feedstocks, and geographical regions. For fossil-based production methods, SMR without CCS presents the lowest LCOH. A value of approximately 1.35 USD/kg was presented in [54], and of 1.87 USD/kg H2 in [48]. Incorporating CCS technologies in fossil-based production methods increases costs. SMR + CCS was reported at 2.01 USD/kg for certain configurations, while CG + CCS reached 2.32 USD/kg [54]. If the energy required for downstream processing, such as compression up to 300 bars for port logistics utilization, is considered, the LCOH rises. In these conditions, SMR was calculated at 8.73 USD/kg, and SMR + CCS ranged from 12.01 USD/kg to 13.33 USD/kg [45]. Electrolysis powered by renewable resources showed a competitive LCOH, such as Wind Electrolysis at USD5.61/kg and Nuclear Electrolysis at 4.95 USD/kg [54]. Emerging pathways also show varied economic performances; methane pyrolysis was estimated at 1.87 USD/kg and biomass gasification was reported at 2.40 USD/kg [54]. Finally, Life Cycle Costing studies found that hydrogen production from biowaste ranged from 0.39 to 2.37 USD/kg H2, while production from biomass ranged from 0.43 to 2.85 USD/kg H2 [55]. All values originally reported in euros have been converted to US dollars using a conversion rate of 0.86.

3. Discussion

3.1. Main Findings and Literature Gaps

In general, among the articles analyzed, it is possible to conclude that there are no two similar LCA studies, since specificities introduced in the system boundaries, functional unit, production, storage, transportation, end-use technologies, and LCA methodological approaches, among others, introduce variances between studies.

Regarding the scope and purpose of the studies analyzed, few studies provide a comprehensive analysis of all phases of the hydrogen value chain, such as the one performed in [56]. This presents a limitation on the existing information. Since the goal of using hydrogen as an energy carrier is to implement a complete supply chain, from primary material extraction to hydrogen usage, future studies should address the entire value chain. When designing a hydrogen chain, it is essential to consider simultaneously the production capacity, the demand needs, the distance between the production and demand sites, the transport options, and the storage needs. If each of these variables is evaluated individually, the holistic view of the hydrogen energy system is lost, making it impossible to define strategic hydrogen roadmaps.

In terms of the end-use considered, value chains of the power-to-industry configuration are underrepresented. Despite hydrogen being mainly used in the refining and industry sectors [8], the existing studies focus on emerging areas of hydrogen application, such as mobility and storage, where the introduction of hydrogen is more recent. Future research should explore these emerging areas, but must also assess the direct benefits of replacing gray hydrogen with low-carbon hydrogen in sectors with a longer tradition of hydrogen use.

Furthermore, most LCA studies focus on comparing different hydrogen technologies among each other, primarily for production methods, while only very few compare hydrogen energy systems with alternative energy systems. To fully understand the environmental, economic, and social advantages of hydrogen over other energy systems, more studies like the one presented in [52] are needed. In this article, the authors compared the life cycle emissions of liquefied natural gas, dimethyl ether, methanol, liquid ammonia, and liquid hydrogen from production to the use as a fuel in road vehicles’ internal combustion engines, considering long-distance transportation by ship. It was concluded that liquified hydrogen produced from solar electrolysis presents the lowest level of emissions.

In general, current studies use today’s data to construct and assemble their Life Cycle Inventory Analysis. Since the main objective of hydrogen systems is to assess the feasibility and benefits of a future hydrogen economy, all developments and improvements in hydrogen technologies should be considered. If not, they do not provide a real picture of what hydrogen is expected to accomplish. Therefore, more prospective LCAs should be developed [25], as highlighted in [57,58].

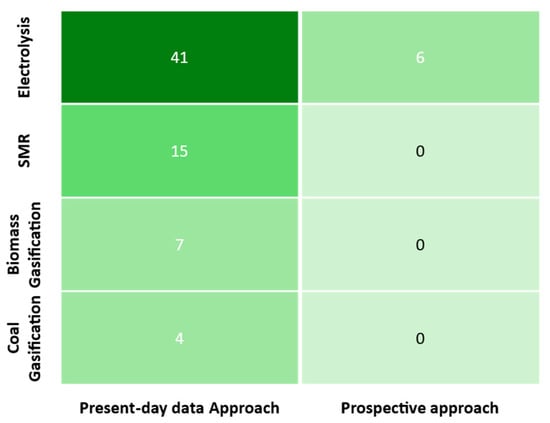

The correlation between production technologies and LCA approaches reveals a pattern. All studies adopting a prospective approach are focused on hydrogen produced by electrolysis, indicating the technology’s emerging status and the need to anticipate its future performance (Figure 11). In contrast, in studies considering established technologies such as SMR, biomass gasification, and Coal Gasification, where data and system configurations are well defined, only present-day data has been used to construct the Life Cycle Inventory. This particularity suggests that technology’s maturity strongly influences the choice of LCA approach: mature and commercially available systems are typically assessed retrospectively, whereas, for emerging or rapidly evolving technologies, there is a greater motivation to explore potential future scenarios.

Figure 11.

Meta-analysis of the studies considering a “prospective” approach vs. a “present-day data” approach.

Regarding environmental impact indicators, it is noticed that most of the articles focus on midpoint indicators. Among these, the climate change impact category is included in all studies. Endpoint indicators are not frequently mentioned, which does not constitute a research gap since midpoint indicators present a higher level of certainty, having a direct and robust modeling problem–effect relation. Some studies also consider the impacts of the hydrogen value chain in the economic and social dimensions, through Life Cycle Costing (LCC) and Social Life Cycle Assessment (S-LCA), respectively. According to [48], complete Life Cycle Sustainability Assessments, which consider simultaneously the environmental, economic, and social domains, are still rare in the available literature, which was also verified in the present work. In fact, only 17 documents with the word combination “Hydrogen” AND “Life Cycle Sustainability Assessment” in titles, abstracts, and authors’ keywords and published between January 2003 and December 2023 are indexed in the Scopus database. In contrast, the number of indexed documents when searching for the word combination “Hydrogen” AND (“Life Cycle Sustainability Assessment”) in the same conditions is 1.321.

As a result of these gaps, comparisons between studies are often unreliable, since differences in methodological approaches lead to inconsistent outcomes. Consequently, the decision-making process may be biased by methodological choices or constrained by discrepancies in the reported findings. This lack of methodological alignment undermines the development of robust conclusions about hydrogen’s sustainability and its role in future energy systems.

3.2. Comparison with Past Studies

The findings obtained in the present work can be compared to those obtained by Valente et al. [59] in 2016. The authors conducted a systematic literature review of 97 LCA studies of hydrogen energy systems, published until December 2015, to assess the methodological trends in the literature at the time.

Valente et al. [59] found that most studies adopted an attributional approach and were comparative analyses, which is similar to what was concluded in the present work. The mass approach for defining the functional unit was the most common in studies that focused on assessing hydrogen production technologies, and the end-of-life stage of hydrogen energy systems was underexplored. Life Cycle Inventories primarily relied on the scientific literature, followed by LCA databases. At that time, real, experimental, and simulation data were scarcely available, which resulted in a lower utilization of these data sources than what was verified in the present work. The selected LCIA method was generally homogeneous; CML was the most common family of methods and IPCC methods were the most common for quantifying greenhouse gas emissions. The most assessed indicators were, respectively, global warming, acidification, eutrophication, ozone layer depletion, photochemical oxidant formation, energy consumption, abiotic depletion, human toxicity, land use, and human health, with global warming being present in a greater number of studies, as verified in the present work. The present work has shown a similar trend in the selection of impact indicators; however, there is a lower use of CML as the LCA method. The authors of [59] have also concluded that only 15% of the analyzed articles included economic and/or social impacts, which is close to the value obtained in the present work (21%).

Valente et al. highlighted the need to define a harmonization protocol that allows a fair comparison between the life cycle impacts across hydrogen LCA studies. Seven years later, many of the issues raised by the authors have not been addressed yet, and methodological inconsistencies persist, which is increasingly important given the sharp increase in studies since 2021, as shown in Figure 1.

In [16], a systematic review of 100 LCA studies published from 2016 to 2020 focused on fuel cell hydrogen systems was performed to identify the current practices, gaps, and main factors that are responsible for the variability of the life cycle GHG emissions of hydrogen production systems. Although the authors found certain progress towards common methodological choices in LCAs of fuel cell hydrogen systems, mainly in the definition of the functional unit, it was also concluded that there is a lack of clearly defined technical parameters that increase the difficulty in comparing LCA outcomes of similar fuel cell and hydrogen systems.

Based on the information collected, there is a clear need to define protocols to harmonize the results obtained in the studies available in the literature and to define harmonized frameworks capable of ensuring the harmonization of new studies. If such steps are not taken, fair comparisons between studies cannot be made, and the decision-making process may be influenced by methodological choices.

3.3. Existing Harmonization Frameworks and Protocols

Initial efforts to establish harmonized frameworks for LCA have been undertaken. The FC-HyGuide project, carried out between October 2010 and September 2011 [60], developed guidelines for performing LCAs of hydrogen production systems and fuel cell technologies, in line with the International Reference Life Cycle Data System Handbook. More recently, the SH2E project [61] introduced a methodologically consistent multi-dimensional framework for LCSA and the prospective benchmarking of fuel cell hydrogen systems.

Other initiatives have proposed harmonization protocols, such as the IEA Hydrogen Task 36 [62], aimed at facilitating decision-making in the hydrogen energy sector through sustainability assessments of hydrogen energy systems. Building on this task, the authors of [63] proposed a protocol to harmonize the life cycle global warming impact of hydrogen production, which was based on the existing literature on LCAs of hydrogen energy systems, on LCA standards, and on the recommendations of the FC-Hy Guide guidance document. The protocol was applied to 71 case studies of hydrogen production through thermochemical, electrochemical, and biological processes and focused on harmonizing the attributional approach, functional unit, system boundaries, final hydrogen conditions, and multifunctionality approach of the respective studies. The authors later expanded to cumulative non-renewable energy demand and acidification [64,65], computed the harmonized energy and carbon footprints of 15 case studies involving hydrogen production through electrolysis, gasification, reforming, and the autocatalytic decomposition of fossil feedstock [66], and applied these indicators to evaluate the environmental performance of proton exchange membrane (PEM) fuel cell vehicles and nuclear-based hydrogen production [67,68].

Among the previously presented projects, only the SH2E project was completed after the period covered by the literature analyzed in this study. This suggests that earlier initiatives should have already influenced the literature; however, their widespread impact and adoption remain limited. These harmonized frameworks are voluntary, but the adoption of a stricter and uniformized approach to data collection, modeling, and stricter assumptions is required. Further efforts are necessary to promote the broader dissemination and implementation of these harmonized frameworks and protocols. These may include providing training and guiding resources to researchers and practitioners, developing open-source software tools with harmonized methodologies embedded, organizing knowledge sharing and dissemination events, and establishing specific standard certification schemes associated with the methodology adopted in the study. The elaboration of category rules for LCA elaboration and third-party verification can be beneficial.

4. Conclusions

The present work systematically analyzed 70 articles to answer the research question “What are the current methodologies, approaches, and research tendencies adopted when performing LCA of hydrogen energy systems?”. The results show that the approaches adopted are not harmonized, and that specificities introduced in the value chain scope, system boundaries, functional unit, Life Cycle Inventory databases, and Life Cycle Impact Assessment methods, among others, lead to inconsistencies between studies, making it impossible to compare their results.

Most studies focus on production technologies. Storage is sometimes studied, but critical analyses between different technologies are not carried out. In transportation and distribution options, the road is the most frequent option. Regarding the hydrogen end-use, the focus will have to be expanded to other sectors, such as industry.

The mass-based functional unit approach is the most frequently adopted option. The end-of-life impacts of the equipment and infrastructure are underexplored. Furthermore, most studies use today’s data to construct and assemble their Life Cycle Inventory Analysis, not considering prospective developments that could influence the performance of future hydrogen systems.

Although impact categories are relatively consistent, there is still no consensus on LCA methods, and few studies integrate environmental, economic, and social dimensions simultaneously.

These inconsistencies may undermine the development of robust conclusions on hydrogen’s sustainability and its role in future energy systems, introducing potential bias into the decision-making process.

To overcome this challenge, two complementary approaches can be taken: (i) define harmonized frameworks in lower scales, such as for each hydrogen value chain configuration, and (ii) define harmonization protocols to fairly compare existing studies. The first approach ensures that all new studies are carried out in a consistent manner, allowing for direct comparisons between studies evaluating the same hydrogen value chain. The second allows a comparison to be made between existing and future LCA studies on hydrogen energy systems. Initial efforts have been made to define harmonized frameworks and protocols; however, their widespread adoption still needs to be encouraged.

In future work, harmonized frameworks should be expanded to cover all possible configurations of the hydrogen value chain, rather than being limited to specific cases such as power-to-mobility. Furthermore, additional efforts are needed for the widespread adoption of harmonized frameworks, including improved knowledge sharing, the development of user-friendly tools with embedded methodologies, and the creation of standardized certification schemes.

Author Contributions

Conceptualization, M.S.C.; investigation, M.S.C.; writing—original draft Preparation, M.S.C.; writing—review and editing, P.J.C., A.F.F. and E.S.; visualization, M.S.C.; supervision, P.J.C. and A.F.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors acknowledge Fundação para a Ciência e a Tecnologia (FCT) for its financial support via the project LAETA Base Funding (DOI: 10.54499/UIDB/50022/2020). HyLab’s authors acknowledge the Base Funding Project of Collaborative Laboratory, managed by ANI Agência Nacional de Inovação and funded by the call RE-C05-i02—Missão Interface N.º 01/C05i02/2022 of the Portuguese Recovery and Resilience Plan (PRR), the Agenda H2 Green Valley (reference02/C05-i01.02/2022.PC645551860-00000064) project, and H2CZERO project funded by COMPETE2030-FEDER-00575800 program, SIID-I&D Empresarial-Operações em Copromoção-Outros Territorios, Cod. MPr-2023-7.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AEL | Alkaline Water Electrolysis |

| CCS | Carbon Capture and Storage |

| CG | Coal Gasification |

| CML | Centrum Voor Milieukunde Leiden |

| CO2 | Carbon Dioxide |

| COP | Conference of the Parties |

| GHG | Greenhouse Gas |

| IEA | International Energy Agency |

| IPCC | Intergovernmental Panel on Climate Change |

| IRENA | International Renewable Energy Agency |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LCIA | Life Cycle Impact Assessment |

| LCSA | Life Cycle Sustainability Assessment |

| LCOH | Levelized Cost of Hydrogen |

| LOHC | Liquid Organic Hydrogen Carrier |

| PEMEL | Polymer Electrolyte Membrane Water Electrolysis |

| PEM | Proton Exchange Membrane |

| S-LCA | Social Life Cycle Assessment |

| SMR | Steam Methane Reforming |

| SOEL | Solid Oxide Water Electrolysis |

| TRL | Technology Readiness Level |

Appendix A

Table A1.

List of articles analyzed in the present systematic literature analysis and the respective indication of study scope and impact dimensions considered.

Table A1.

List of articles analyzed in the present systematic literature analysis and the respective indication of study scope and impact dimensions considered.

| Article | Value Chain Phases Considered | Impacts Dimensions Considered | |||

|---|---|---|---|---|---|

| Production | Storage | Transportation | End-Use | ||

| [24] | X | Environmental | |||

| [37] | X | X | X | X | Environmental |

| [69] | X | Environmental | |||

| [70] | X | X | X | X | Environmental/Economic |

| [71] | X | Environmental | |||

| [72] | X | X | Environmental | ||

| [73] | X | Environmental/Economic | |||

| [74] | X | X | Environmental | ||

| [75] | X | X | X | Environmental | |

| [19] | X | Environmental | |||

| [76] | X | Environmental | |||

| [25] | X | Environmental | |||

| [35] | X | Environmental | |||

| [77] | X | X | Environmental | ||

| [78] | X | X | X | Environmental | |

| [17] | X | Environmental | |||

| [79] | X | X | Environmental | ||

| [47] | X | X | X | Environmental/Economic/Social | |

| [54] | X | Environmental/Economic | |||

| [80] | X | Environmental | |||

| [81] | X | Environmental/Economic | |||

| [82] | X | X | X | X | Environmental |

| [52] | X | X | X | X | Environmental |

| [83] | X | Environmental | |||

| [48] | X | Environmental | |||

| [84] | X | Environmental | |||

| [34] | X | X | X | Environmental | |

| [32] | X | X | X | X | Environmental |

| [26] | X | Environmental | |||

| [27] | X | X | Environmental | ||

| [85] | X | Environmental | |||

| [23] | X | X | X | Environmental/Economic | |

| [44] | X | X | X | X | Environmental/Economic |

| [20] | X | X | X | Environmental | |

| [86] | X | Environmental/Economic | |||

| [56] | X | X | X | X | Environmental |

| [87] | X | Environmental | |||

| [88] | X | X | Environmental/Economic | ||

| [89] | X | X | Environmental | ||

| [46] | X | X | X | X | Environmental/Economic/Social |

| [90] | X | Environmental | |||

| [91] | X | X | X | X | Environmental |

| [92] | X | Environmental | |||

| [18] | X | Environmental | |||

| [28] | X | X | Environmental | ||

| [93] | X | X | X | X | Environmental |

| [29] | X | Environmental | |||

| [21] | X | X | Environmental/Economic | ||

| [22] | X | X | X | Environmental | |

| [94] | X | X | X | X | Environmental |

| [95] | X | X | X | Environmental | |

| [96] | X | X | X | X | Environmental |

| [97] | X | X | X | Environmental | |

| [33] | X | Environmental | |||

| [49] | X | X | Environmental/Economic/Social | ||

| [36] | X | X | Environmental | ||

| [38] | X | X | Environmental | ||

| [98] | X | X | X | Environmental | |

| [99] | X | X | X | X | Environmental |

| [53] | X | X | X | Environmental | |

| [57] | X | Environmental | |||

| [100] | X | X | Environmental | ||

| [51] | X | X | X | Environmental | |

| [101] | X | X | X | X | Environmental |

| [30] | X | Environmental | |||

| [45] | X | X | X | X | Environmental/Economic |

| [31] | X | Environmental | |||

| [55] | X | Environmental/Economic | |||

| [50] | X | X | X | Environmental | |

| [39] | X | X | X | Environmental/Economic | |

References

- United Nations. Paris Agreement to the United Nations Framework Convention on Climate Change; T.I.A.S. No. 16-1104; United Nations: Paris, France, 2015. [Google Scholar]

- International Renewable Energy Agency. World Energy Transitions Outlook: 1.5 °C Pathway; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2021; pp. 1–54. ISBN 978-92-9260-334-2. [Google Scholar]

- International Renewable Energy Agency (IRENA). Global Hydrogen Trade to Meet the 1.5 °C Climate Goal: Part II—Technology Review of Hydrogen Carriers; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2022; ISBN 978-92-9260-431-8. [Google Scholar]

- International Renewable Energy Agency (IRENA). World Energy Transitions Outlook 2022; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2022; pp. 1–54. ISBN 978-92-9260-429-5. [Google Scholar]

- International Energy Agency (IEA). Global Hydrogen Review 2022; International Energy Agency (IEA): Paris, France, 2022. [Google Scholar] [CrossRef]

- Elegbeleye, I.; Oguntona, O.; Elegbeleye, F. Green Hydrogen: Pathway to Net Zero Greenhouse Gas Emission and Global Climate Change. Clean Energy 2025, 6, 29. [Google Scholar] [CrossRef]

- Zun, M.T.; McLellan, B.C. Cost Projection of Global Green Hydrogen Production Scenarios. Hydrogen 2023, 4, 932–960. [Google Scholar] [CrossRef]

- Coelho, M.S.; Gaspar, G.; Surra, E.; Coelho, P.J.; Ferreira, A.F. Systematic Analysis of the Hydrogen Value Chain from Production to Utilization. Appl. Sci. 2025, 15, 8242. [Google Scholar] [CrossRef]

- Uzoagba, C.E.J.; Ikpeka, P.M.; Nnabuife, S.G.; Onwualu, P.A.; Ngasoh, F.O.; Kuang, B. Development of the Hydrogen Market and Local Green Hydrogen Offtake in Africa. Hydrogen 2025, 6, 43. [Google Scholar] [CrossRef]

- Shanmugasundaram, S.; Thangaraja, J.; Rajkumar, S.; Denis Ashok, S.; Sivaramakrishna, A.; Shamim, T. A Review on Green Hydrogen Production Pathways and Optimization Techniques. Process Saf. Environ. Prot. 2025, 197, 107070. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Martín-Gamboa, M.; Campos-Carriedo, F.; Iribarren, D.; Dufour, J.; Wulf, C.; Schreiber, A.; Springer, S.; Ishimoto, Y.; Mizuno, Y.; Hamed, A.; et al. D5.1 SH2E Guidebook for Life Cycle Sustainability Assessment; SH2E: Brussels, Belgium, 2023; Available online: https://www.researchgate.net/publication/380896818_D51_SH2E_guidebook_for_Life_Cycle_Sustainability_Assessment (accessed on 1 March 2025).

- European Commission—Joint Research Centre (EC-JRC). ILCD Handbook: General Guide on LCA—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Longo, S.; Cellura, M.; Miccichè, G.; Ferraro, M. Critical Review of Life Cycle Assessment of Hydrogen Production Pathways. Environments 2024, 11, 108. [Google Scholar] [CrossRef]

- Puig-Samper, G.; Bargiacchi, E.; Iribarren, D.; Dufour, J. Life-Cycle Assessment of Hydrogen Systems: A Systematic Review and Meta-Regression Analysis. J. Clean. Prod. 2024, 470, 143330. [Google Scholar] [CrossRef]

- Antonini, C.; Treyer, K.; Streb, A.; van der Spek, M.; Bauer, C.; Mazzotti, M. Hydrogen Production from Natural Gas and Biomethane with Carbon Capture and Storage—A Techno-Environmental Analysis. Sustain. Energy Fuels 2020, 4, 2967–2986. [Google Scholar] [CrossRef]

- Diab, J.; Fulcheri, L.; Hessel, V.; Rohani, V.; Frenklach, M. Why Turquoise Hydrogen Will Be a Game Changer for the Energy Transition. Int. J. Hydrogen Energy 2022, 47, 25831–25848. [Google Scholar] [CrossRef]

- Karaca, A.E.; Dincer, I.; Gu, J. Life Cycle Assessment Study on Nuclear-Based Sustainable Hydrogen Production Options. Int. J. Hydrogen Energy 2020, 45, 22148–22159. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Dickson, R.; Liu, J.J. Life Cycle Assessment of Inland Green Hydrogen Supply Chain Networks with Current Challenges and Future Prospects. ACS Sustain. Chem. Eng. 2021, 9, 17152–17163. [Google Scholar] [CrossRef]

- Costamagna, M.; Barale, J.; Carbone, C.; Luetto, C.; Agostini, A.; Baricco, M.; Rizzi, P. Environmental and Economic Assessment of Hydrogen Compression with the Metal Hydride Technology. Int. J. Hydrogen Energy 2022, 47, 10122–10136. [Google Scholar] [CrossRef]

- Gandiglio, M.; Marocco, P.; Bianco, I.; Lovera, D.; Blengini, G.A.; Santarelli, M. Life Cycle Assessment of a Renewable Energy System with Hydrogen-Battery Storage for a Remote Off-Grid Community. Int. J. Hydrogen Energy 2022, 47, 32822–32834. [Google Scholar] [CrossRef]

- Mori, M.; Gutiérrez, M.; Casero, P. Micro-Grid Design and Life-Cycle Assessment of a Mountain Hut’s Stand-Alone Energy System with Hydrogen Used for Seasonal Storage. Int. J. Hydrogen Energy 2021, 46, 29706–29723. [Google Scholar] [CrossRef]

- Mehmeti, A.; Angelis-Dimakis, A.; Arampatzis, G.; McPhail, S.J.; Ulgiati, S. Life Cycle Assessment and Water Footprint of Hydrogen Production Methods: From Conventional to Emerging Technologies. Environments 2018, 5, 24. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Prospective Carbon Footprint Comparison of Hydrogen Options. Sci. Total Environ. 2020, 728, 138212. [Google Scholar] [CrossRef]

- Amaya-Santos, G.; Chari, S.; Sebastiani, A.; Grimaldi, F.; Lettieri, P.; Materazzi, M. Biohydrogen: A Life Cycle Assessment and Comparison with Alternative Low-Carbon Production Routes in UK. J. Clean. Prod. 2021, 319, 128886. [Google Scholar] [CrossRef]

- Sanchez, N.; Ruiz, R.; Rödl, A.; Cobo, M. Technical and Environmental Analysis on the Power Production from Residual Biomass Using Hydrogen as Energy Vector. Renew. Energy 2021, 175, 825–839. [Google Scholar] [CrossRef]

- Fernández-Ríos, A.; Santos, G.; Pinedo, J.; Santos, E.; Ruiz-Salmón, I.; Laso, J.; Lyne, A.; Ortiz, A.; Ortiz, I.; Irabien, Á.; et al. Environmental Sustainability of Alternative Marine Propulsion Technologies Powered by Hydrogen—A Life Cycle Assessment Approach. Sci. Total Environ. 2022, 820, 153189. [Google Scholar] [CrossRef]

- Rumayor, M.; Corredor, J.; Rivero, M.J.; Ortiz, I. Prospective Life Cycle Assessment of Hydrogen Production by Waste Photoreforming. J. Clean. Prod. 2022, 336, 130430. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, Z.; Lv, W.; Ye, H.; Dong, H. The Upper Thermal Efficiency and Life-Cycle Environmental Assessment of Nuclear-Based Hydrogen Production via Splitting H2S and CO2. Int. J. Hydrogen Energy 2023, 48, 9185–9197. [Google Scholar] [CrossRef]

- Karaca, A.E.; Dincer, I. Development of a New Photoelectrochemical System for Clean Hydrogen Production and a Comparative Environmental Impact Assessment with Other Production Methods. Chemosphere 2023, 337, 139367. [Google Scholar] [CrossRef]

- Peppas, A.; Kollias, K.; Politis, A.; Karalis, L.; Taxiarchou, M.; Paspaliaris, I. Performance Evaluation and Life Cycle Analysis of RES-Hydrogen Hybrid Energy System for Office Building. Int. J. Hydrogen Energy 2021, 46, 6286–6298. [Google Scholar] [CrossRef]

- Barghash, H.; AlRashdi, Z.; Okedu, K.E.; Desmond, P. Life-Cycle Assessment Study for Bio-Hydrogen Gas Production from Sewage Treatment Plants Using Solar PVs. Energies 2022, 15, 8056. [Google Scholar] [CrossRef]

- Di Lullo, G.; Oni, A.O.; Kumar, A. Blending Blue Hydrogen with Natural Gas for Direct Consumption: Examining the Effect of Hydrogen Concentration on Transportation and Well-to-Combustion Greenhouse Gas Emissions. Int. J. Hydrogen Energy 2021, 46, 19202–19216. [Google Scholar] [CrossRef]

- Ozturk, M.; Dincer, I. Life Cycle Assessment of Hydrogen-Based Electricity Generation in Place of Conventional Fuels for Residential Buildings. Int. J. Hydrogen Energy 2020, 45, 26536–26544. [Google Scholar] [CrossRef]

- Suer, J.; Traverso, M.; Jäger, N. Carbon Footprint Assessment of Hydrogen and Steel. Energies 2022, 15, 9468. [Google Scholar] [CrossRef]

- Wulf, C.; Reuß, M.; Grube, T.; Zapp, P.; Robinius, M.; Hake, J.; Stolten, D. Life Cycle Assessment of Hydrogen Transport and Distribution Options. J. Clean. Prod. 2018, 199, 431–443. [Google Scholar] [CrossRef]

- Tsiklios, C.; Hermesmann, M.; Müller, T.E. Hydrogen Transport in Large-Scale Transmission Pipeline Networks: Thermodynamic and Environmental Assessment of Repurposed and New Pipeline Configurations. Appl. Energy 2022, 327, 120097. [Google Scholar] [CrossRef]

- Kim, C.; Lee, Y.; Lee, H.; Lee, U.; Kim, K. Economic and Environmental Potential of Green Hydrogen Carriers (GHCs) Produced via Reduction of Amine-Captured CO2. Energy Convers. Manag. 2023, 291, 117302. [Google Scholar] [CrossRef]

- Elhaus, N.; Sharma, A.; Weitzer, M.; Herkendell, K.; Karl, J. Life Cycle Greenhouse Gas Emissions of Imported Renewable Hydrogen and Hydrogen Carriers—A Comparative Review. Renew. Sustain. Energy Rev. 2026, 226, 116275. [Google Scholar] [CrossRef]

- European Commission—Joint Research Centre (EC-JRC). ILCD Handbook: Framework and Requirements for LCIA Models and Indicators, 1st ed.; Publications Office of the European Union: Luxembourg, 2010; p. 102. [Google Scholar] [CrossRef]

- European Commission—Joint Research Centre (EC-JRC). International Reference Life Cycle Data System (ILCD) Handbook: Analysing of Existing Environmental Impact Assessment Methodologies for Use in Life Cycle Assessment; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar] [CrossRef]

- Wu, Y.; Su, D. Review of Life Cycle Impact Assessment (LCIA) Methods and Inventory Databases. In Sustainable Production and Development; Springer Nature: Berlin/Heidelberg, Germany, 2020; pp. 39–55. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Dickson, R.; Niaz, H.; Hwang, D.W.; Liu, J.J. Comparative Sustainability Assessment of a Hydrogen Supply Network for Hydrogen Refueling Stations in Korea—A Techno-Economic and Lifecycle Assessment Perspective. Green Chem. 2021, 23, 9625–9639. [Google Scholar] [CrossRef]

- Mio, A.; Barbera, E.; Pavan, A.M.; Danielis, R.; Bertucco, A.; Fermeglia, M. Analysis of the Energetic, Economic, and Environmental Performance of Hydrogen Utilization for Port Logistic Activities. Appl. Energy 2023, 347, 121431. [Google Scholar] [CrossRef]

- Masilela, P.; Pradhan, A. A Life Cycle Sustainability Assessment of Biomethane versus Biohydrogen—For Application in Electricity or Vehicle Fuel? Case Studies for African Context. J. Clean. Prod. 2021, 328, 129567. [Google Scholar] [CrossRef]

- Hoque, N.; Biswas, W.; Mazhar, I.; Howard, I. Life Cycle Sustainability Assessment of Alternative Energy Sources for the Western Australian Transport Sector. Sustainability 2020, 12, 5565. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Comparative Life Cycle Sustainability Assessment of Renewable and Conventional Hydrogen. Sci. Total Environ. 2021, 756, 144132. [Google Scholar] [CrossRef]

- Wijayasekera, S.C.; Hewage, K.; Hettiaratchi, P.; Siddiqui, O.; Razi, F.; Pokhrel, D.; Sadiq, R. Sustainability of Waste-to-Hydrogen Conversion Pathways: A Life Cycle Thinking-Based Assessment. Energy Convers. Manag. 2022, 270, 116218. [Google Scholar] [CrossRef]

- Vilbergsson, K.V.; Dillman, K.; Emami, N.; Ásbjörnsson, E.J.; Heinonen, J.; Finger, D.C. Can Remote Green Hydrogen Production Play a Key Role in Decarbonizing Europe in the Future? A Cradle-to-Gate LCA of Hydrogen Production in Austria, Belgium, and Iceland. Int. J. Hydrogen Energy 2023, 48, 17711–17728. [Google Scholar] [CrossRef]

- Hren, R.; Vujanović, A.; Van Fan, Y.; Klemeš, J.J.; Krajnc, D.; Čuček, L. Hydrogen Production, Storage and Transport for Renewable Energy and Chemicals: An Environmental Footprint Assessment. Renew. Sustain. Energy Rev. 2023, 173, 113113. [Google Scholar] [CrossRef]

- Al-Breiki, M.; Bicer, Y. Comparative Life Cycle Assessment of Sustainable Energy Carriers Including Production, Storage, Overseas Transport and Utilization. J. Clean. Prod. 2021, 279, 123481. [Google Scholar] [CrossRef]

- Noh, H.; Kang, K.; Seo, Y. Environmental and Energy Efficiency Assessments of Offshore Hydrogen Supply Chains Utilizing Compressed Gaseous Hydrogen, Liquefied Hydrogen, Liquid Organic Hydrogen Carriers and Ammonia. Int. J. Hydrogen Energy 2023, 48, 7515–7532. [Google Scholar] [CrossRef]

- Al-Qahtani, A.; Parkinson, B.; Hellgardt, K.; Shah, N.; Guillen-Gosalbez, G. Uncovering the True Cost of Hydrogen Production Routes Using Life Cycle Monetisation. Appl. Energy 2021, 281, 115958. [Google Scholar] [CrossRef]

- Arfan, M.; Eriksson, O.; Wang, Z.; Soam, S. Life Cycle Assessment and Life Cycle Costing of Hydrogen Production from Biowaste and Biomass in Sweden. Energy Convers. Manag. 2023, 291, 117262. [Google Scholar] [CrossRef]

- Booto, G.K.; Aamodt Espegren, K.; Hancke, R. Comparative Life Cycle Assessment of Heavy-Duty Drivetrains: A Norwegian Study Case. Transp. Res. Part D Transp. Environ. 2021, 95, 102836. [Google Scholar] [CrossRef]

- Weidner, T.; Tulus, V.; Guillén-Gosálbez, G. Environmental Sustainability Assessment of Large-Scale Hydrogen Production Using Prospective Life Cycle Analysis. Int. J. Hydrogen Energy 2023, 48, 8310–8327. [Google Scholar] [CrossRef]

- Martinez, G.E.; Degens, R.; Espadas-Aldana, G.; Costa, D.; Cardellini, G. Prospective Life Cycle Assessment of Hydrogen: A Systematic Review of Methodological Choices. Energies 2024, 17, 4297. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Life Cycle Assessment of Hydrogen Energy Systems: A Review of Methodological Choices. Int. J. Life Cycle Assess. 2017, 22, 346–363. [Google Scholar] [CrossRef]

- Fuel Ceslls and Hydrogen Joint Undertaking. FC-HyGuide Manual: Guidance Document for Performing LCAs on Fuel Cell Technologies and Hydrogen Technologies; Project No. 256850, FC-Hy Guide. 2011. Available online: https://fc-hyguide.eu/ (accessed on 25 October 2025).

- Sustainability Assessment of Harmonised Hydrogen Energy Systems (SH2E). Guidelines for Life Cycle Sustainability Assessment and Prospective Benchmarking; European Commission, Horizon 2020 Project SH2E, Grant Agreement No. 101007163; Fuel Cells and Hydrogen Joint Undertaking (FCH JU): Brussels, Belgium, 2023. [Google Scholar] [CrossRef]

- Iribarren, D.; Valente, A.; Dufour, J. IEA HIA Task 36 Final Report—Life Cycle Sustainability Assessment of Hydrogen Energy Systems; International Energy Agency: Paris, France, 2019; ISBN 978-1-945951-09-1. [Google Scholar]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonised life-cycle global warming impact of renewable hydrogen. J. Clean. Prod. 2017, 149, 762–772. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonising the cumulative energy demand of renewable hydrogen for robust comparative life-cycle studies. J. Clean. Prod. 2018, 175, 384–393. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonising methodological choices in life cycle assessment of hydrogen: A focus on acidification and renewable hydrogen. Int. J. Hydrogen Energy 2019, 44, 19426–19433. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonised carbon and energy footprints of fossil hydrogen. Int. J. Hydrogen Energy 2021, 46, 17587–17594. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Candelaresi, D.; Spazzafumo, G.; Dufour, J. Using harmonised life-cycle indicators to explore the role of hydrogen in the environmental performance of fuel cell electric vehicles. Int. J. Hydrogen Energy 2020, 45, 25758–25765. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonised life-cycle indicators of nuclear-based hydrogen. Int. J. Hydrogen Energy 2021, 46, 29724–29731. [Google Scholar] [CrossRef]

- Siddiqui, O.; Dincer, I. A well to pump life cycle environmental impact assessment of some hydrogen production routes. Int. J. Hydrogen Energy 2019, 44, 5773–5786. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Life-cycle cost assessment of alternative marine fuels to reduce the carbon footprint in short-sea shipping: A case study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- Sadeghi, S.; Ghandehariun, S.; Rosen, M.A. Comparative economic and life cycle assessment of solar-based hydrogen production for oil and gas industries. Energy 2020, 208, 118347. [Google Scholar] [CrossRef]

- Li, G.; Cui, P.; Wang, Y.; Liu, Z.; Zhu, Z.; Yang, S. Life cycle energy consumption and GHG emissions of biomass-to-hydrogen process in comparison with coal-to-hydrogen process. Energy 2020, 191, 116588. [Google Scholar] [CrossRef]

- Li, G.; Cui, P.; Wang, Y.; Liu, Z.; Zhu, Z.; Yang, S. Life cycle assessment and techno-economic analysis of biomass-to-hydrogen production with methane tri-reforming. Energy 2020, 199, 117488. [Google Scholar] [CrossRef]

- Bicer, Y.; Khalid, F. Life cycle environmental impact comparison of solid oxide fuel cells fueled by natural gas, hydrogen, ammonia and methanol for combined heat and power generation. Int. J. Hydrogen Energy 2020, 45, 3670–3685. [Google Scholar] [CrossRef]

- Eggemann, L.; Escobar, N.; Peters, R.; Burauel, P.; Stolten, D. Life cycle assessment of a small-scale methanol production system: A power-to-fuel strategy for biogas plants. J. Clean. Prod. 2020, 271, 122476. [Google Scholar] [CrossRef]

- Zhao, G.; Kraglund, M.R.; Frandsen, H.L.; Wulff, A.C.; Jensen, S.H.; Chen, M.; Graves, C.R. Life cycle assessment of H2O electrolysis technologies. Int. J. Hydrogen Energy 2020, 45, 23765–23781. [Google Scholar] [CrossRef]

- Partidário, P.; Aguiar, R.; Martins, P.; Rangel, C.M.; Cabrita, I. The hydrogen roadmap in the Portuguese energy system—Developing the P2G case. Int. J. Hydrogen Energy 2020, 45, 25646–25657. [Google Scholar] [CrossRef]

- Shimizu, T.; Hasegawa, K.; Ihara, M.; Kikuchi, Y. A region-specific environmental analysis of technology implementation of hydrogen energy in Japan based on life cycle assessment. J. Ind. Ecol. 2020, 24, 217–233. [Google Scholar] [CrossRef]

- Chisalita, D.A.; Petrescu, L.; Cormos, C.C. Environmental evaluation of European ammonia production considering various hydrogen supply chains. Renew. Sustain. Energy Rev. 2020, 130, 109964. [Google Scholar] [CrossRef]

- Sarkar, O.; Katakojwala, R.; Venkata Mohan, S. Low carbon hydrogen production from a waste-based biorefinery system and environmental sustainability assessment. Green Chem. 2021, 23, 561–574. [Google Scholar] [CrossRef]

- Gholkar, P.; Shastri, Y.; Tanksale, A. Renewable hydrogen and methane production from microalgae: A techno-economic and life cycle assessment study. J. Clean. Prod. 2021, 279, 123726. [Google Scholar] [CrossRef]

- Candelaresi, D.; Valente, A.; Iribarren, D.; Dufour, J.; Spazzafumo, G. Comparative life cycle assessment of hydrogen-fuelled passenger cars. Int. J. Hydrogen Energy 2021, 46, 35961–35973. [Google Scholar] [CrossRef]

- Lotrič, A.; Sekavčnik, M.; Kuštrin, I.; Mori, M. Life-cycle assessment of hydrogen technologies with the focus on EU critical raw materials and end-of-life strategies. Int. J. Hydrogen Energy 2021, 46, 10143–10160. [Google Scholar] [CrossRef]

- Delpierre, M.; Quist, J.; Mertens, J.; Prieur-Vernat, A.; Cucurachi, S. Assessing the environmental impacts of wind-based hydrogen production in the Netherlands using ex-ante LCA and scenarios analysis. J. Clean. Prod. 2021, 299, 126866. [Google Scholar] [CrossRef]

- Gerloff, N. Comparative Life-Cycle-Assessment analysis of three major water electrolysis technologies while applying various energy scenarios for a greener hydrogen production. J. Energy Storage 2021, 43, 102759. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, X.; Li, G.; Qiu, X.; Yao, D.; Zhu, Z.; Wang, Y.; Gao, J.; Cui, P. Energy consumption, environmental performance, and techno-economic feasibility analysis of the biomass-to-hydrogen process with and without carbon capture and storage. J. Environ. Chem. Eng. 2021, 9, 106752. [Google Scholar] [CrossRef]

- Loy, A.C.M.; Alhazmi, H.; Lock, S.S.M.; Yin, C.L.; Cheah, K.W.; Chin, B.L.F.; How, B.S.; Yusup, S. Life-cycle assessment of hydrogen production via catalytic gasification of wheat straw in the presence of straw derived biochar catalyst. Bioresour. Technol. 2021, 341, 125796. [Google Scholar] [CrossRef] [PubMed]

- Palmer, G.; Roberts, A.; Hoadley, A.; Dargaville, R.; Honnery, D. Life-cycle greenhouse gas emissions and net energy assessment of large-scale hydrogen production via electrolysis and solar PV. Energy Environ. Sci. 2021, 14, 5113–5131. [Google Scholar] [CrossRef]

- Bargiacchi, E.; Candelaresi, D.; Valente, A.; Spazzafumo, G.; Frigo, S. Life Cycle Assessment of Substitute Natural Gas production from biomass and electrolytic hydrogen. Int. J. Hydrogen Energy 2021, 46, 35974–35984. [Google Scholar] [CrossRef]

- Hermesmann, M.; Müller, T.E. Green, Turquoise, Blue, or Grey? Environmentally Friendly Hydrogen Production in Transforming Energy Systems. Prog. Energy Combust. Sci. 2022, 90, 100996. [Google Scholar] [CrossRef]

- Aydin, M.I.; Dincer, I. An Assessment Study on Various Clean Hydrogen Production Methods. Energy 2022, 245, 123090. [Google Scholar] [CrossRef]

- Zhang, J.; Ling, B.; He, Y.; Zhu, Y.; Wang, Z. Life Cycle Assessment of Three Types of Hydrogen Production Methods Using Solar Energy. Int. J. Hydrogen Energy 2022, 47, 14158–14168. [Google Scholar] [CrossRef]

- Rüdisüli, M.; Bach, C.; Bauer, C.; Beloin-Saint-Pierre, D.; Elber, U.; Georges, G.; Limpach, R.; Pareschi, G.; Kannan, R.; Teske, S.L. Prospective Life-Cycle Assessment of Greenhouse Gas Emissions of Electricity-Based Mobility Options. Appl. Energy 2022, 306, 118065. [Google Scholar] [CrossRef]

- Aydin, M.I.; Dincer, I. A Life Cycle Impact Analysis of Various Hydrogen Production Methods for Public Transportation Sector. Int. J. Hydrogen Energy 2022, 47, 39666–39677. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, Z.; He, Y.; Zhu, Y.; Cen, K. LCA Comparison Analysis for Two Types of H2 Carriers: Methanol and Ammonia. Int. J. Energy Res. 2022, 46, 11818–11833. [Google Scholar] [CrossRef]

- Li, L.; Feng, L.; Manier, H.; Manier, M.A. Life Cycle Optimization for Hydrogen Supply Chain Network Design. Int. J. Hydrogen Energy 2022, 52, 491–520. [Google Scholar] [CrossRef]

- Kolb, S.; Müller, J.; Luna-Jaspe, N.; Karl, J. Renewable Hydrogen Imports for the German Energy Transition—A Comparative Life Cycle Assessment. J. Clean. Prod. 2022, 373, 133289. [Google Scholar] [CrossRef]

- Ahmadi, P.; Khoshnevisan, A. Dynamic Simulation and Lifecycle Assessment of Hydrogen Fuel Cell Electric Vehicles Considering Various Hydrogen Production Methods. Int. J. Hydrogen Energy 2022, 47, 26758–26769. [Google Scholar] [CrossRef]

- Lui, J.; Sloan, W.; Paul, M.C.; Flynn, D.; You, S. Life Cycle Assessment of Waste-to-Hydrogen Systems for Fuel Cell Electric Buses in Glasgow, Scotland. Bioresour. Technol. 2022, 359, 127464. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Y.; Månsson, D. Greenhouse Gas Emissions from Hybrid Energy Storage Systems in Future 100% Renewable Power Systems—A Swedish Case Based on Consequential Life Cycle Assessment. J. Energy Storage 2023, 57, 106167. [Google Scholar] [CrossRef]

- Burchart, D.; Gazda-Grzywacz, M.; Grzywacz, P.; Burmistrz, P.; Zarębska, K. Life Cycle Assessment of Hydrogen Production from Coal Gasification as an Alternative Transport Fuel. Energies 2023, 16, 383. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).